Solid-phase sintering synthetic method of nano lithium iron phosphate (LiFePO4)

A technology of solid phase sintering and synthesis method, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of high price, affecting the speed and cost of mass production, and the precursor is easy to be oxidized, so as to shorten the diffusion path, The effect of accelerating the solid phase reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

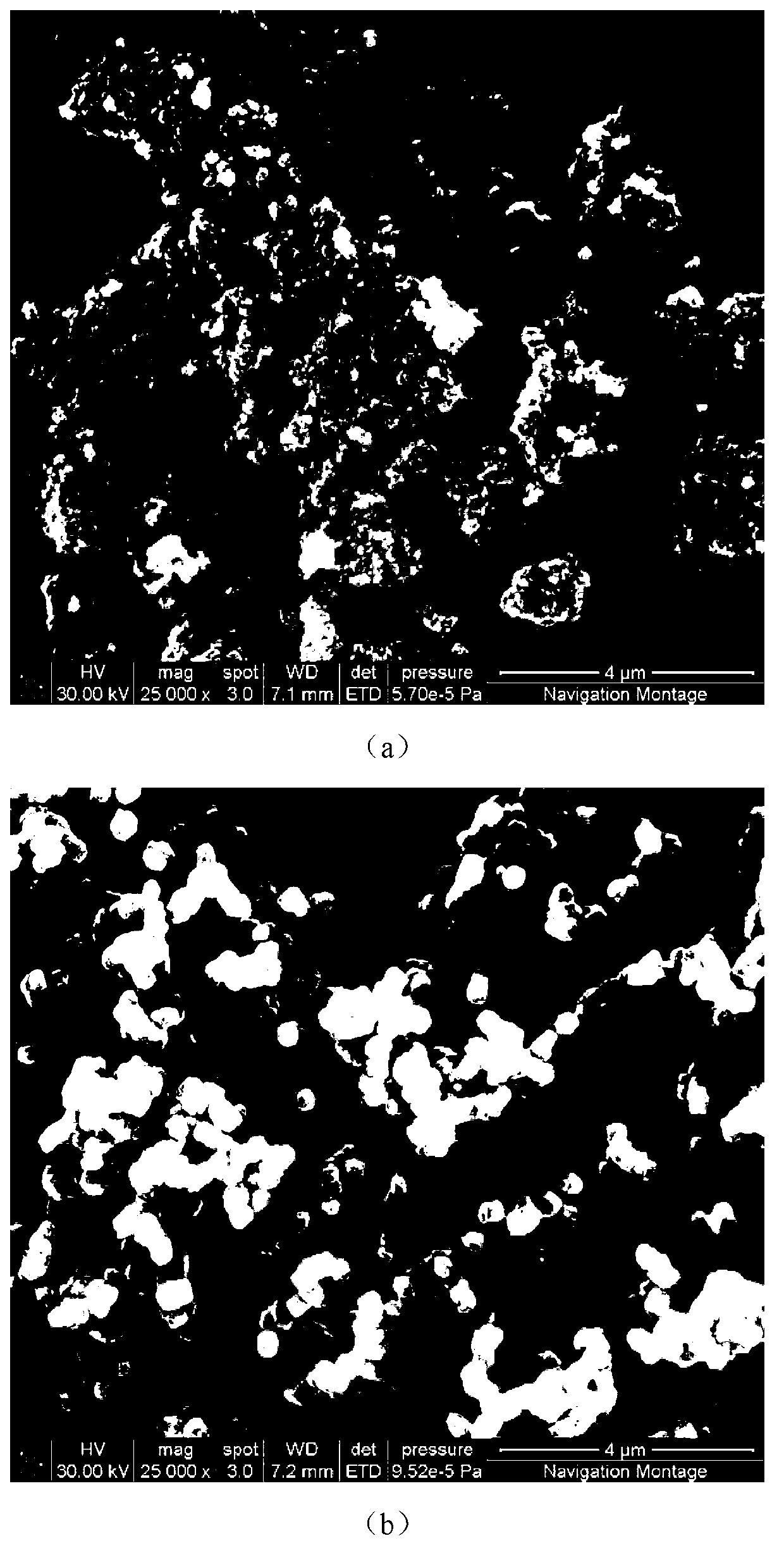

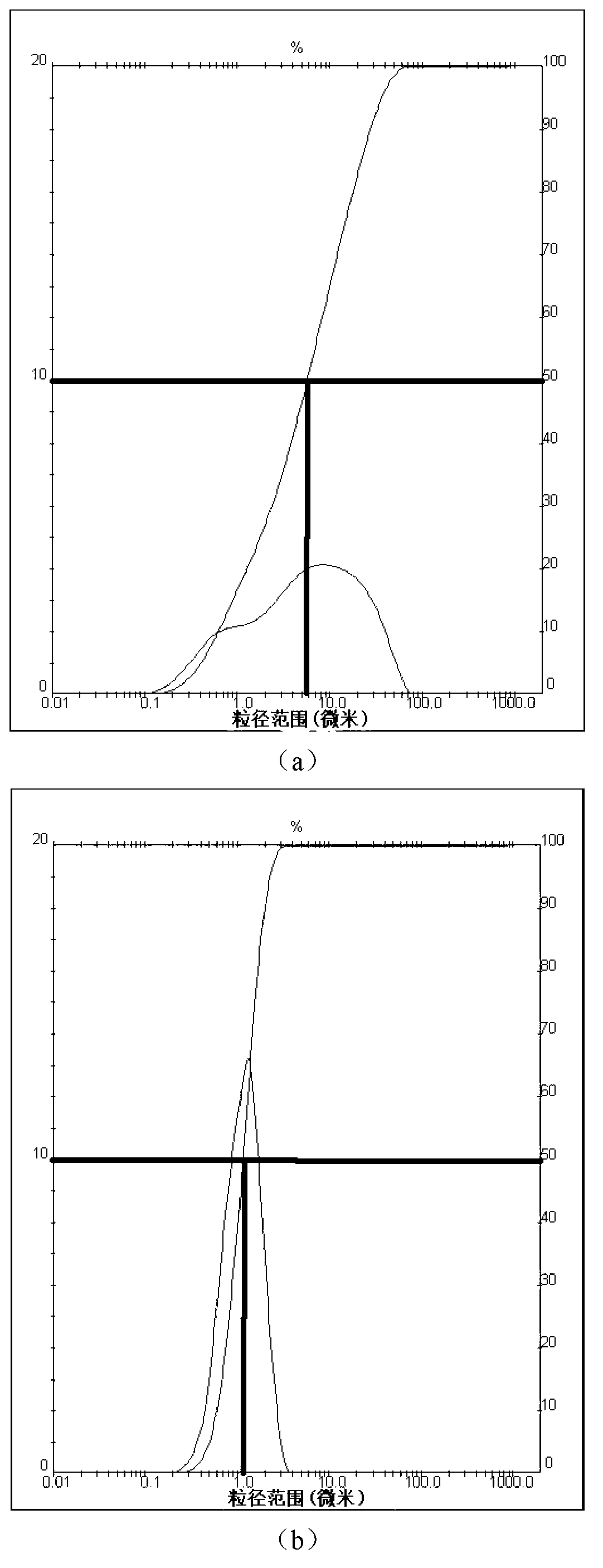

[0020] 1. Raw material weighing

[0021] Weigh 0.2626g of lithium salt, 3.0328g of ferric oxide, 3.6695g of phosphorus salt, 1.0749g of carbon source, 150g of grinding medium, and measure 50ml of acetone.

[0022] Wherein, the lithium salt is at least any one of lithium hydroxide, lithium acetate, lithium carbonate, lithium fluoride, lithium nitrate or lithium dihydrogen phosphate. Iron salt is Fe 3 o 4 , α-Fe 2 o 3 , γ-Fe 2 o 3 , Nano α-Fe 2 o 3 , Nano γ-Fe 2 o 3 At least any one of the . Phosphate salt is at least any one of phosphoric acid, ammonium dihydrogen phosphate, diammonium hydrogen phosphate, phosphorus pentoxide, ammonium phosphate or lithium dihydrogen phosphate. The carbon source is at least any one of sucrose, glucose, organic pyrolytic carbon, conductive carbon black, carbon nanotubes, and graphene; the material of the grinding medium can be alumina, agate, zirconia, or stainless steel, and the shape can be spherical , columnar or rod-shaped.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com