Patents

Literature

48results about How to "Avoid rapid deactivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

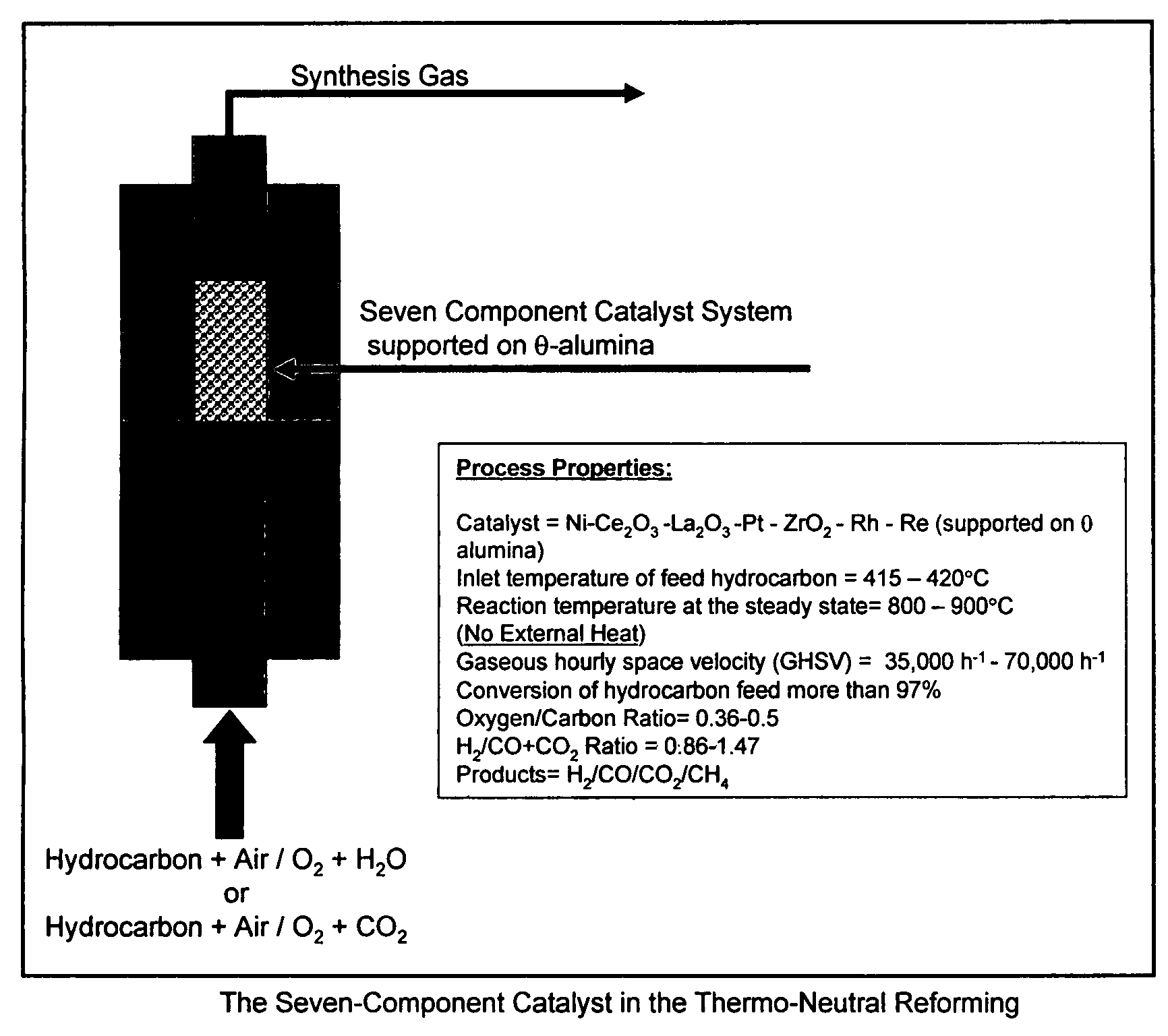

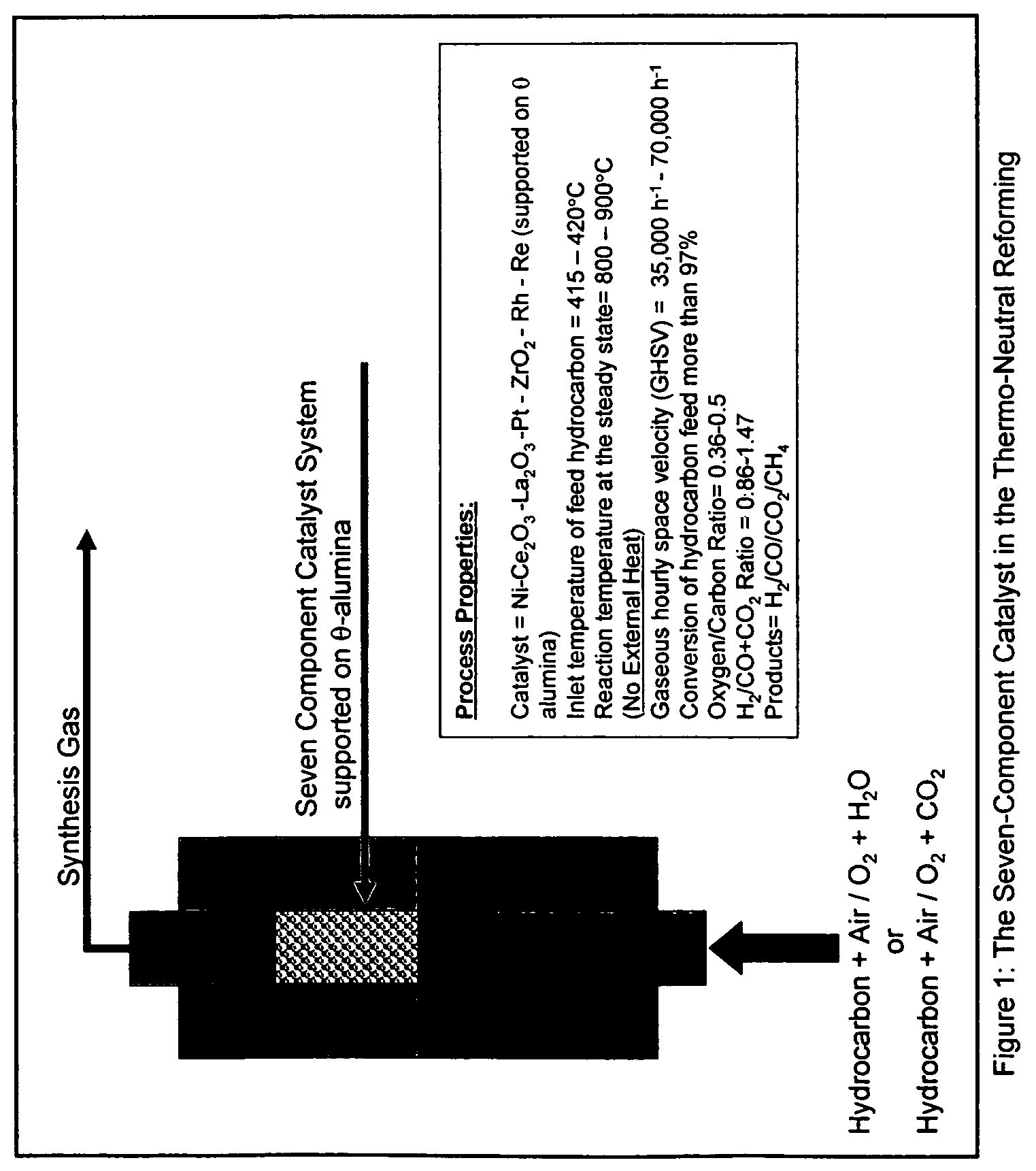

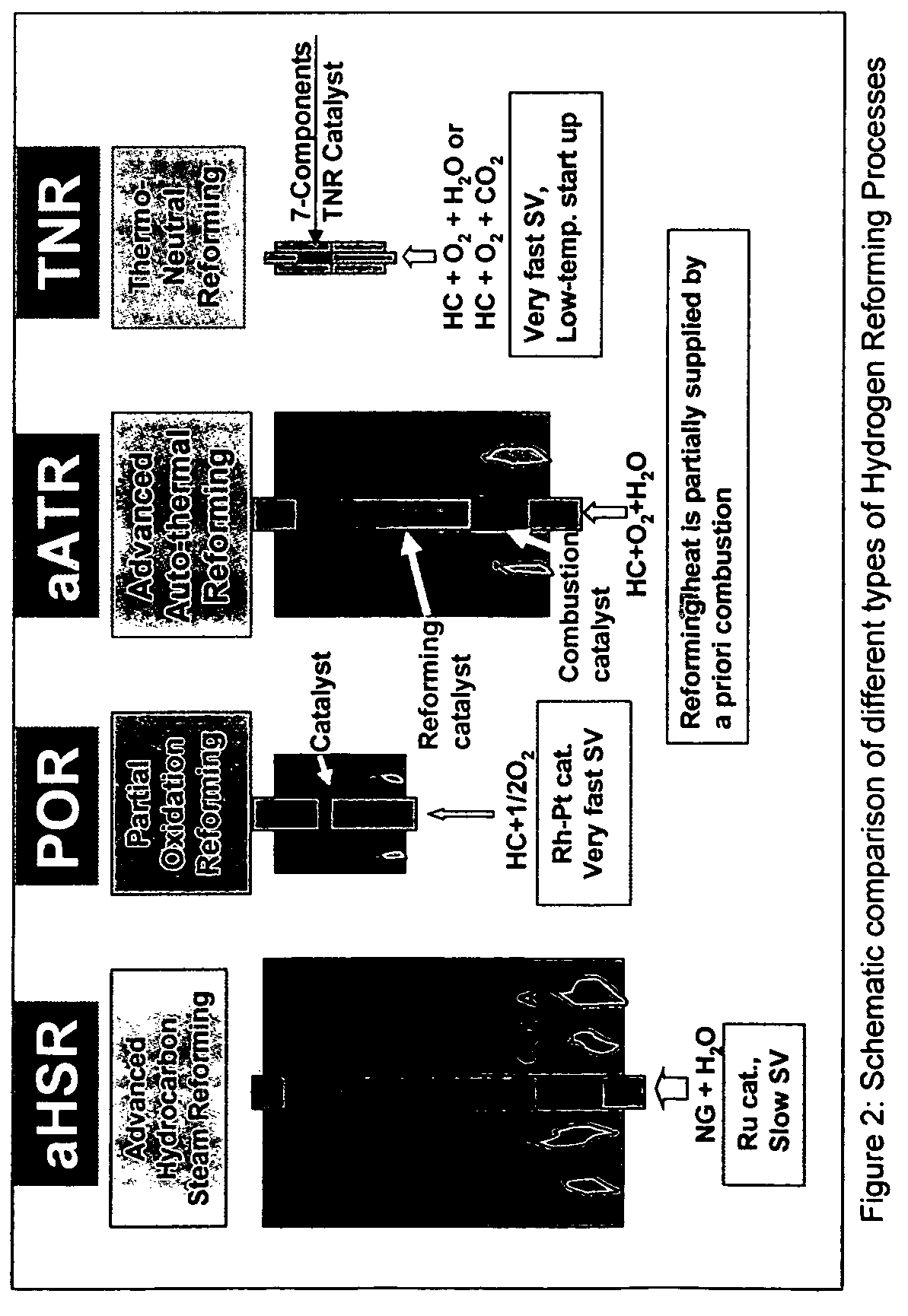

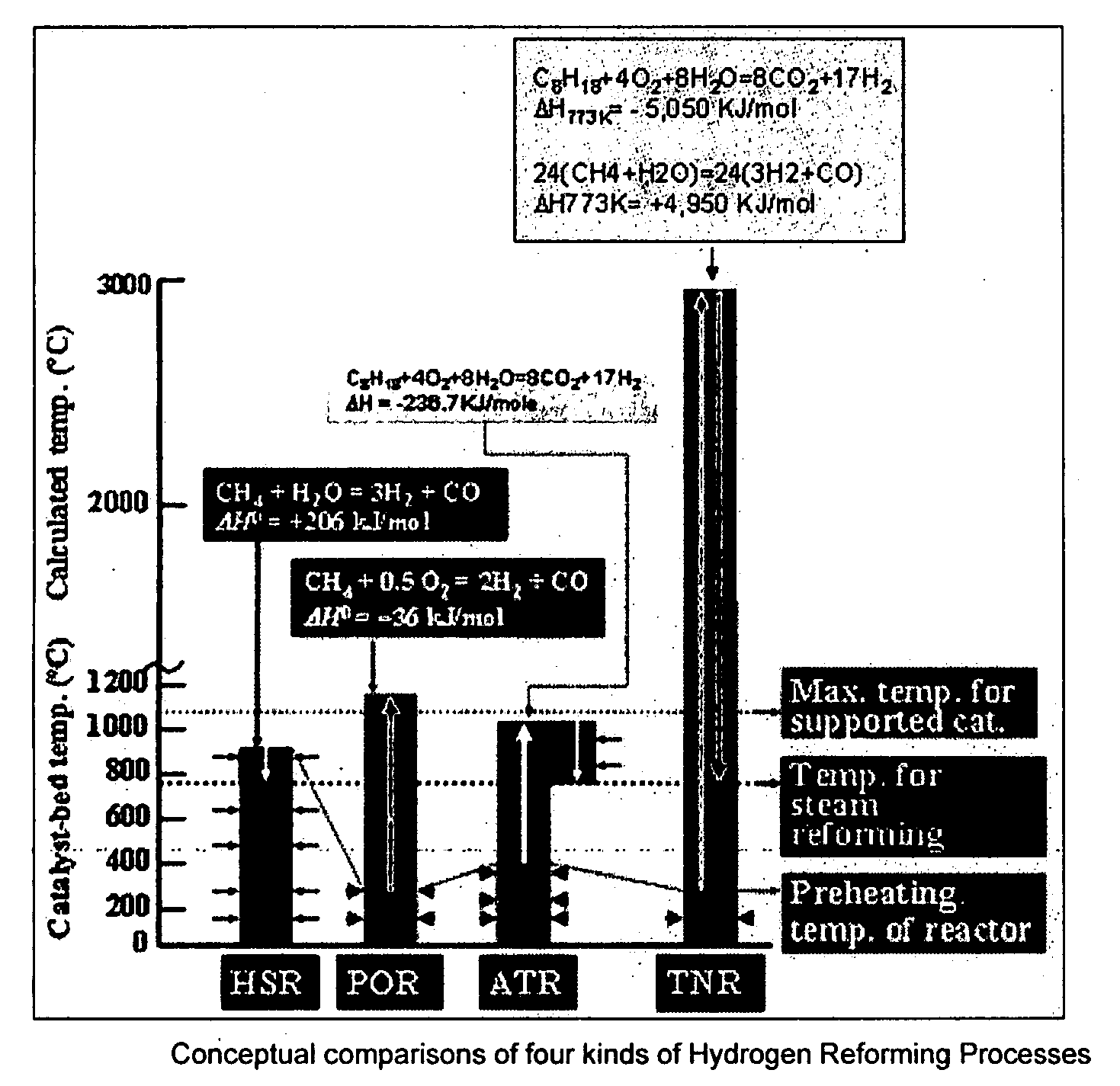

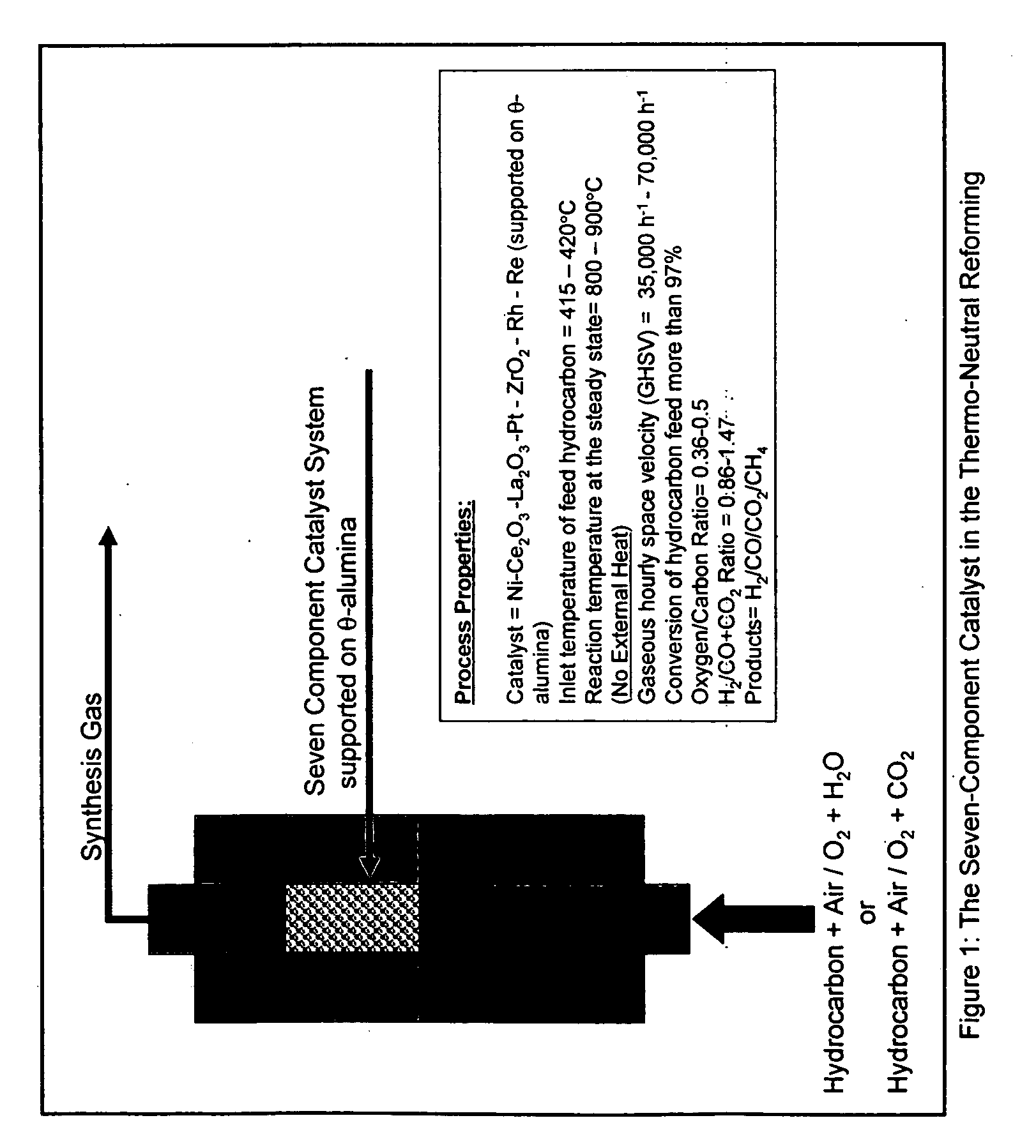

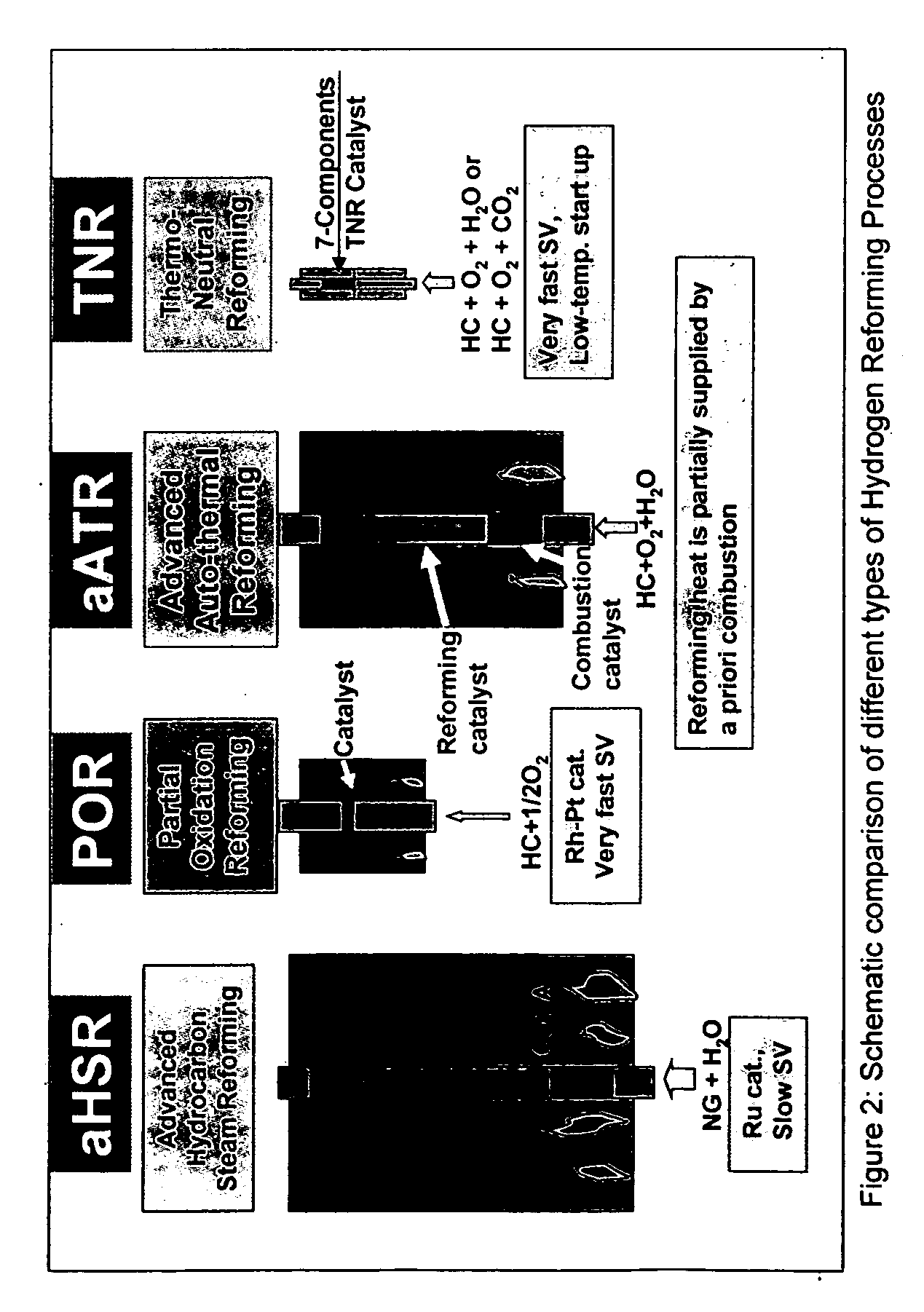

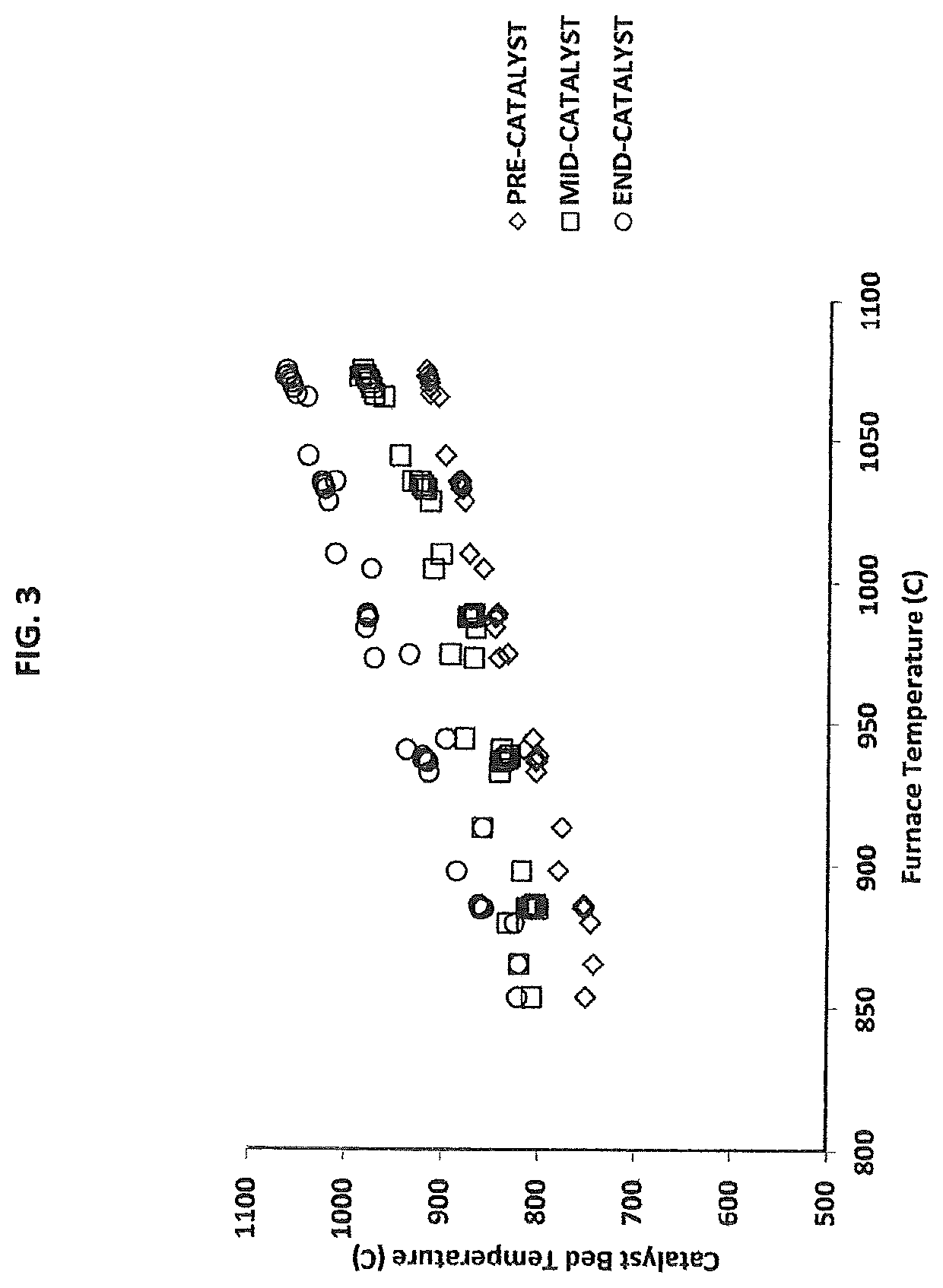

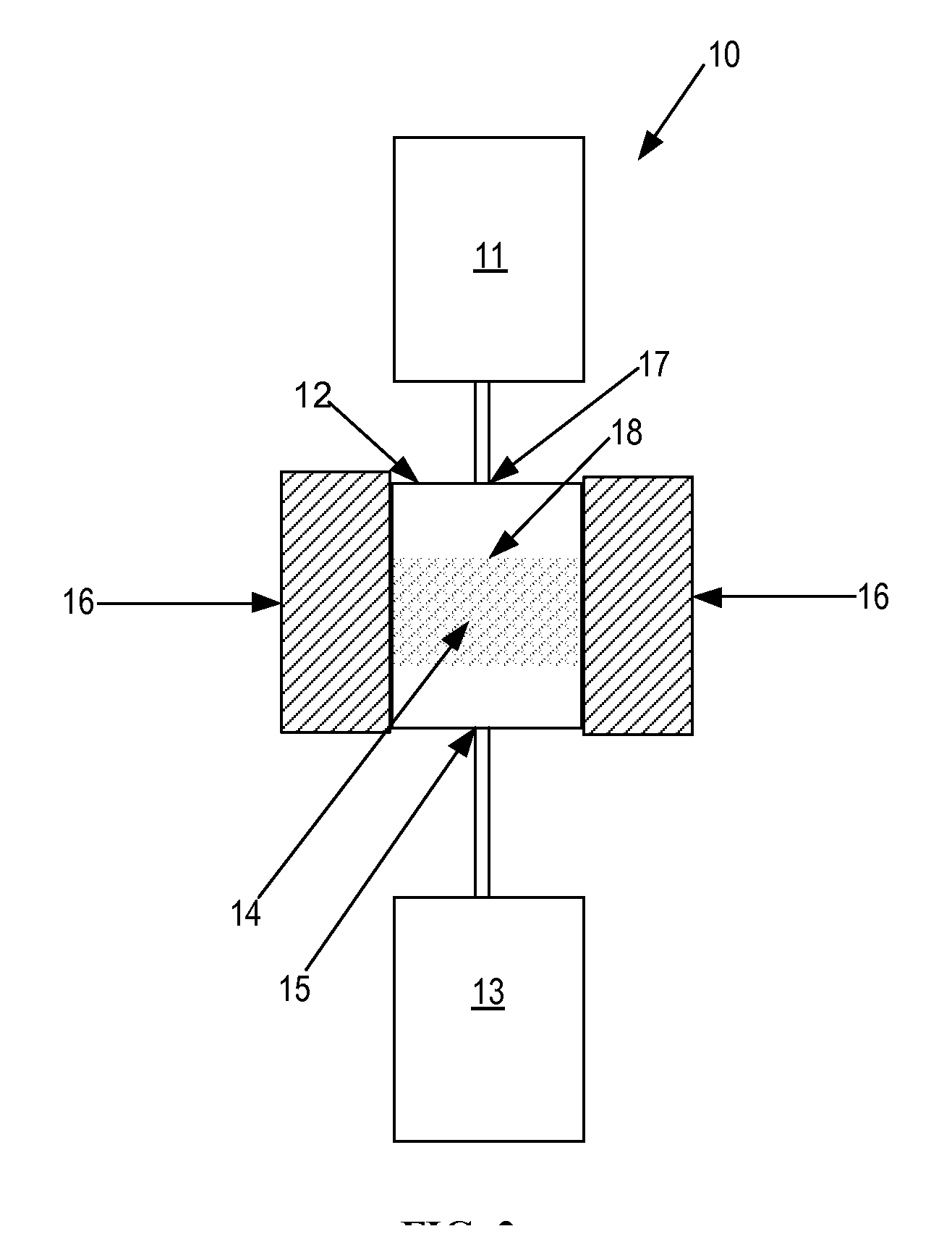

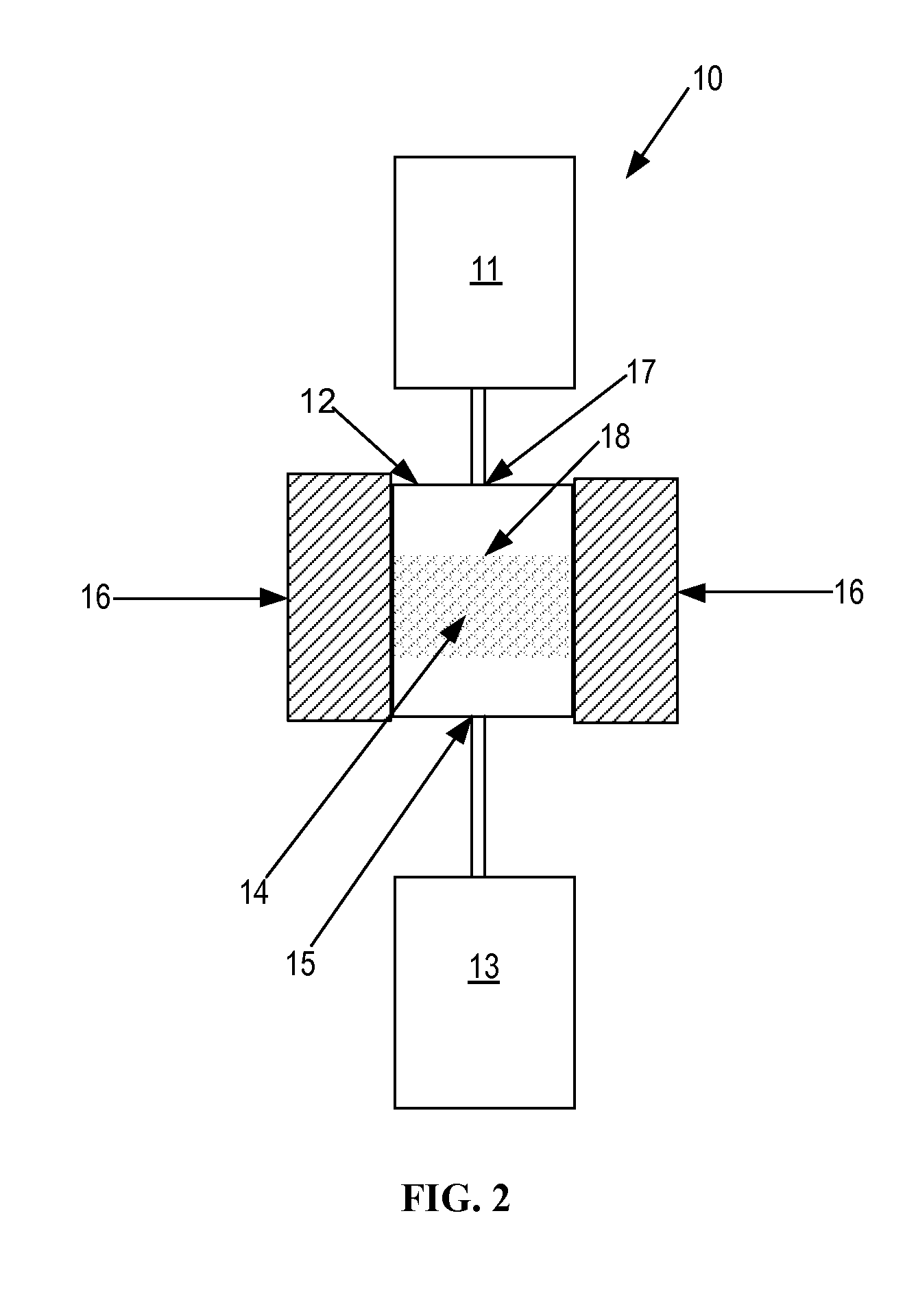

Oil-based thermo-neutral reforming with a multi-component catalyst

ActiveUS7700005B2Enhance the activity of the base metal-supported thermo-neutral reforming catalystProcesses liquid hydrocarbon fuels efficiently and reliablyHydrogenHydrocarbon from carbon oxidesSteam reformingCombustion

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

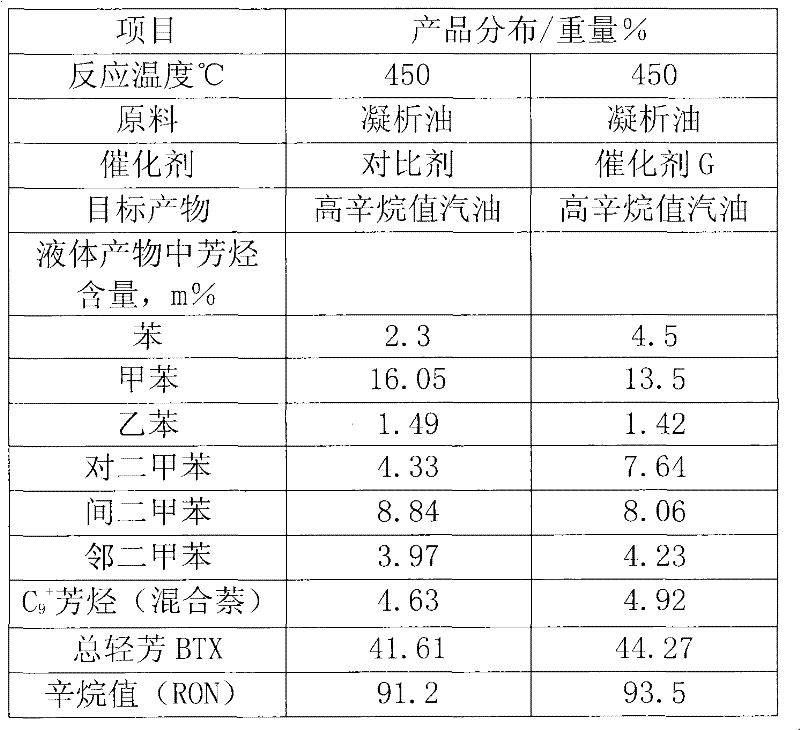

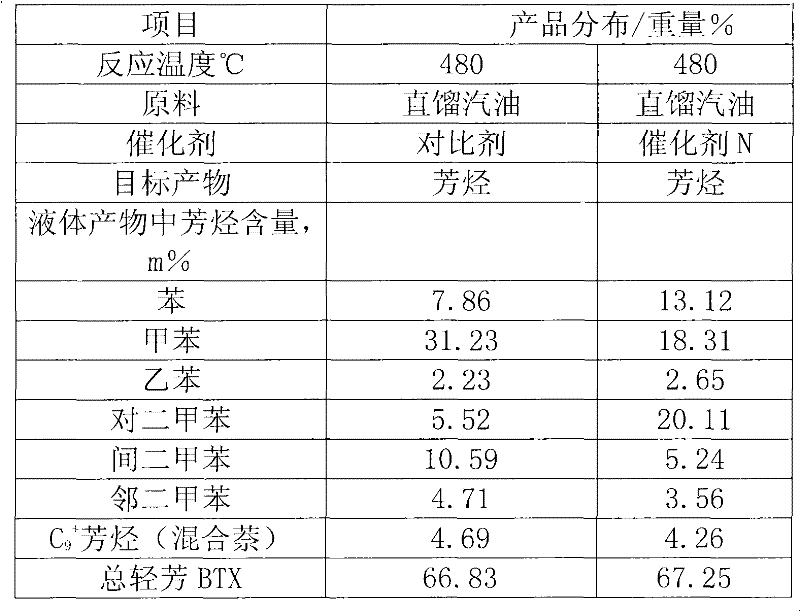

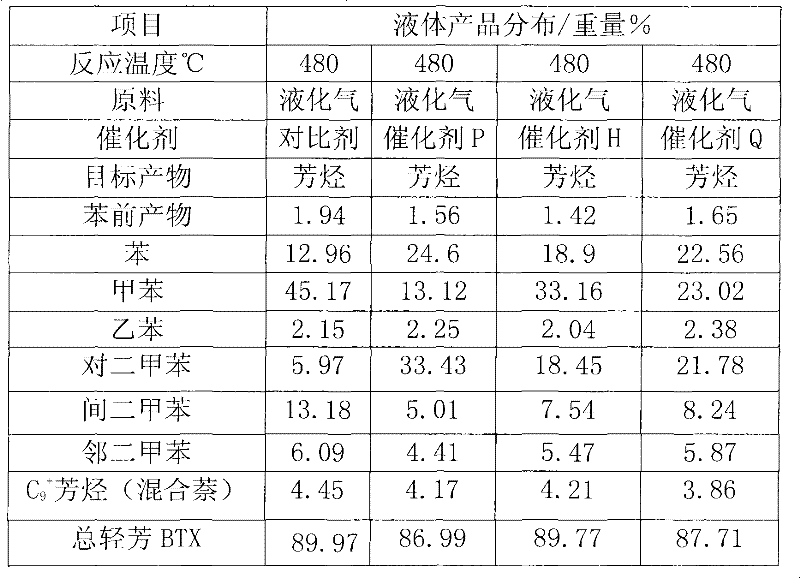

Aromatization catalyst and applications thereof

ActiveCN102218341AAdjust acid distributionIncrease total acidMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumAdhesive

The invention discloses an aromatization catalyst and applications thereof, and aims at solving the problems such as low yield of benzene and mixed xylene in the liquid outcomes and the like during the existing hydrocarbon aromatization reaction. The catalyst comprises the following components by weight percentage of 30-90wt% of molecular sieves, 0-60wt% of carriers and 10-20 wt% of adhesives, wherein the molecular sieves are mixtures of a molecular sieve I, a molecular sieve II, a molecular sieve III and a molecular sieve IV; the molecular sieve I is at least one modified HZSM-5 molecular sieve out of modified elements zinc, gallium and lanthanum; the molecular sieve II is at least one modified HZSM-5 molecular sieve out of modified elements bismuth, molybdenum, silver, copper, zirconiumand rhenium; the molecular sieve III is the HZSM-5 molecular sieve formed by modifying polysiloxane; and the molecular sieve IV is a modified hydrogenated mercerization type molecular sieve, a modified hydrogenated Beta-type molecular sieve, a hydrogenated ZSM-11 molecular sieve and a hydrogenated MCM-22 molecular or mixtures thereof.

Owner:CHINA PETROCHEMICAL CORP +1

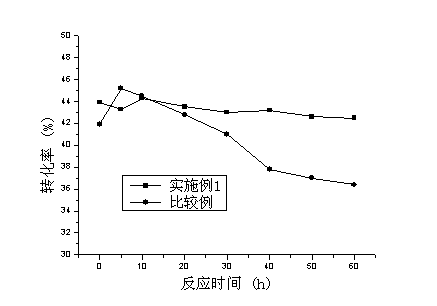

Process for preparing propylene from methanol

ActiveCN102211971AReduced service lifeAvoid rapid deactivationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveMethanol

The invention discloses a process for preparing propylene from methanol. In the process, the methanol is used as a raw material, water is used as a diluent, and a two-section type fixed bed is adopted for reaction, wherein a catalyst used in the process for preparing the propylene from the methanol is a manganese modified ZSM-5 molecular sieve catalyst. By using the process for preparing propylene from methanol, the selectivity of propylene and a P / E ratio are effectively improved, the conversion rate of raw material, namely methanol can maximally reach above 99%, and the one-path selectivity of propylene is larger than 47%.

Owner:SHANGHAI HUAYI GRP CO

Method for producing propylene by using cracking olefin of carbon four and higher

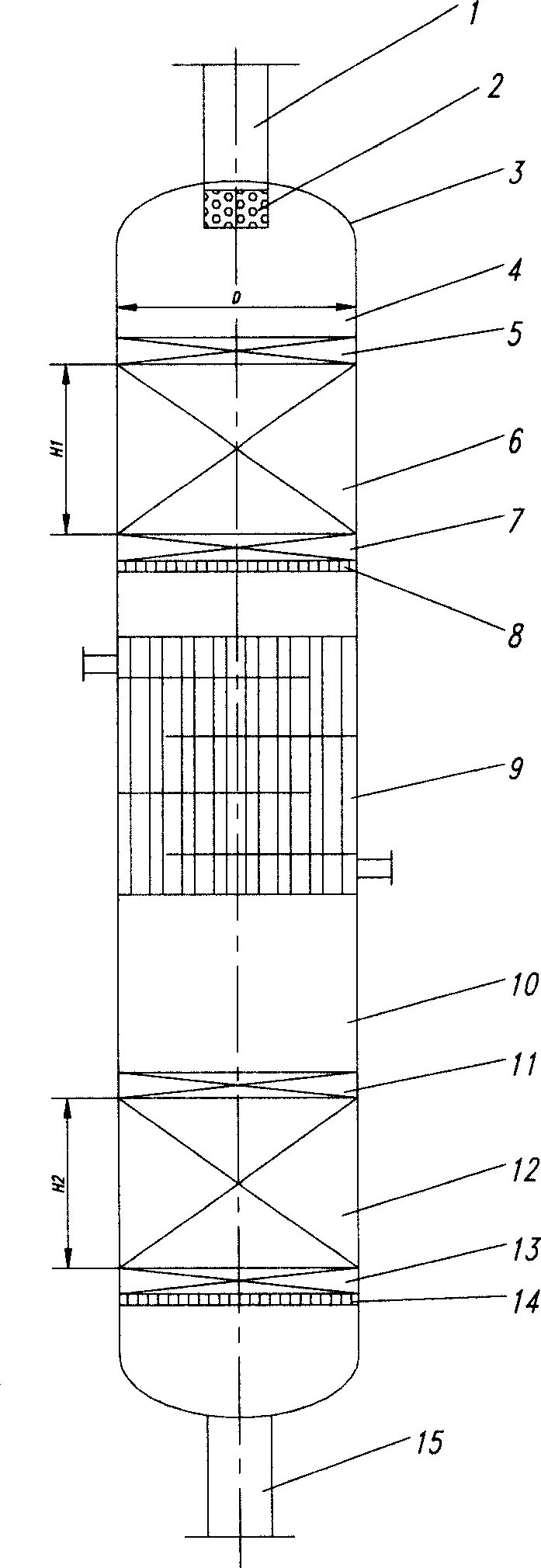

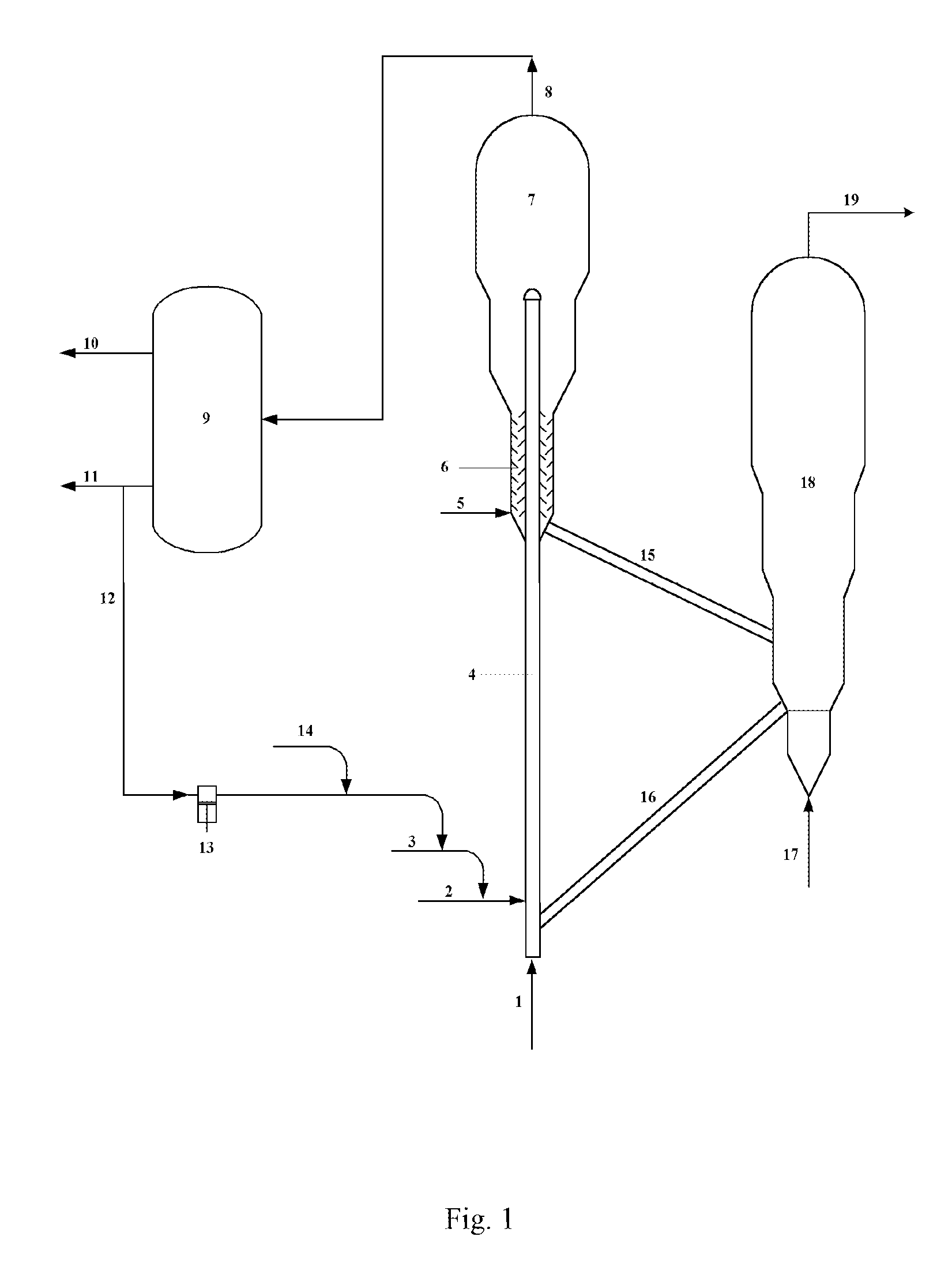

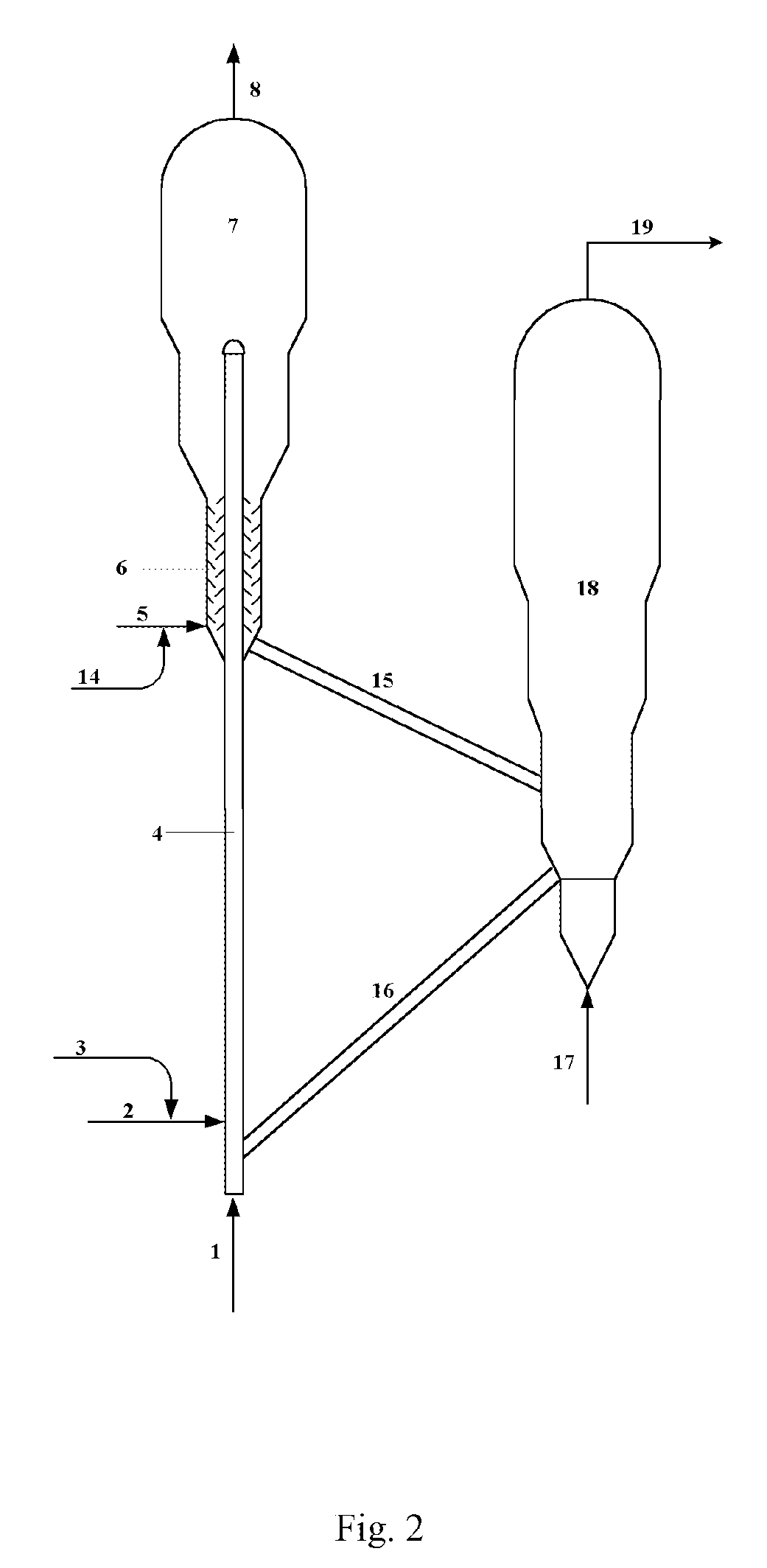

ActiveCN1915929AModerate polymerization exothermMaximize yieldChemical recyclingHydrocarbon by hydrocarbon crackingIntermediate heat exchangerDistributor

This invention relates to a method for manufacturing propylene by C4+ alkenes catalytic cracking. The method adopts a mixture containing ore or more C4+ alkenes as the raw material, and contacts the raw material with a crystalline aluminosilicate catalyst with SiO2 / Al2O3 mol ratio not lower than 10 in a two-stage catalyst bed layer to obtain an effluent containing propylene. The reactor comprises an inlet pipe, a gas-distributor, a first catalyst bed layer, an intermediate heat exchanger, a second catalyst bed layer and an outlet pipe. The method solves the problems of low propylene selectivity, low yield and short catalyst regeneration period, and can be used in propylene industrial manufacture by C4+ alkenes catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

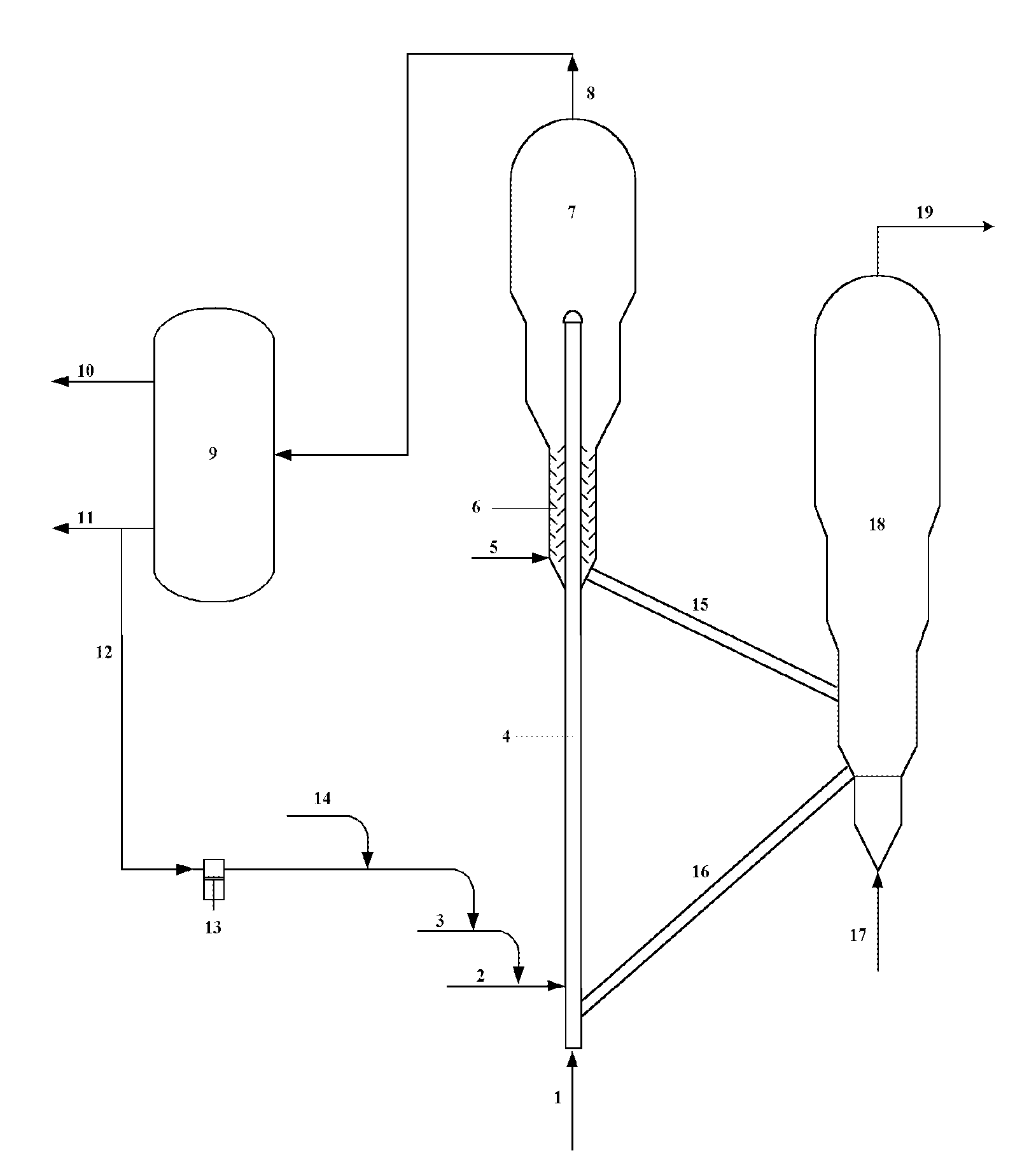

Catalytic Conversion Method Of Increasing The Yield Of Lower Olefin

ActiveUS20080314799A1Increase productionIncrease light olefin yieldCatalytic crackingMolecular sieve catalystsReaction zoneReagent

A catalytic conversion process for increasing the light olefin yields, which comprises bringing a hydrocarbon oil feedstock into contact with a catalytic conversion catalyst in a catalytic conversion reactor including one or more reaction zones to carry out the reaction, wherein the hydrocarbon oil feedstock is subjected to the catalytic conversion reaction in the presence of an inhibitor; and separating the reactant vapor optionally containing the inhibitor from the coke deposited catalyst, wherein a target product containing ethylene and propylene is obtained by separating the reactant vapor, and the coke deposited catalyst is stripped and regenerated for recycle use by being returned to the reactor. The process can weaken the further converting reaction of produced light olefins such as ethylene and propylene to 50-70% of the original level by injecting the inhibitor; thereby it can increase the yields of the target products. When vacuum gas oil is used as the feedstock, the yield of ethylene is as high as 8.73 wt % and that of propylene is as high as 29.30 wt %, increasing by 14.4% and 26.6% respectively comparing to those obtained without the inhibitor being injected.

Owner:RES INST OF PETROLEUM PROCESSING SINOPEC +1

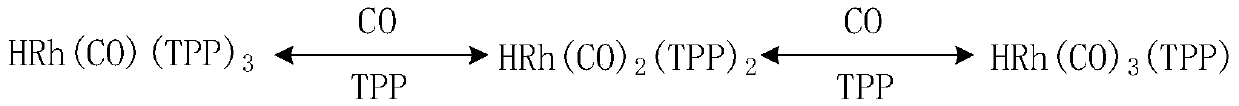

Catalyst composition for reducing normal-to-isomer ratio of hydroformylation products of olefin

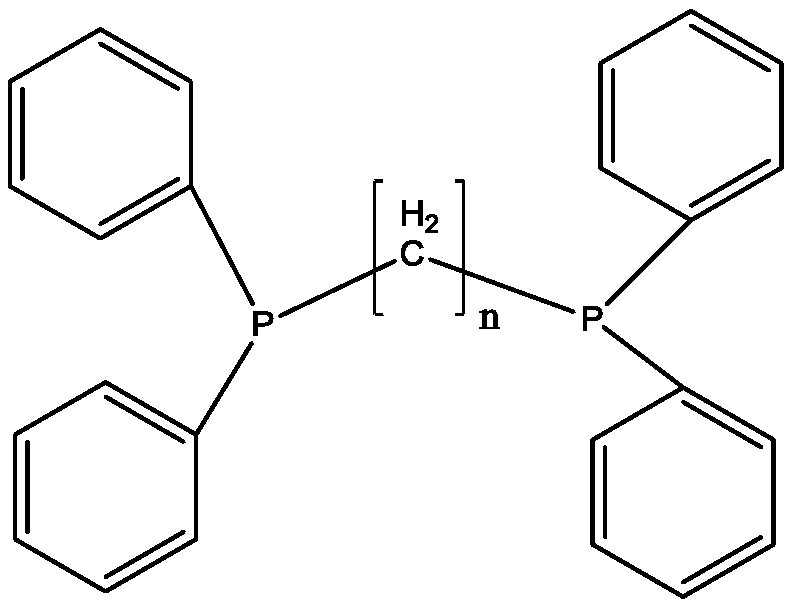

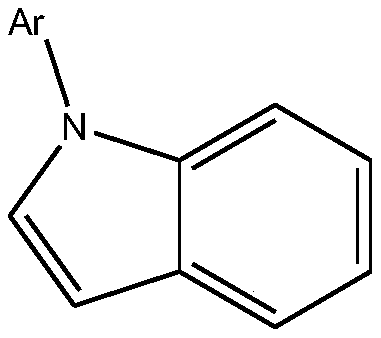

ActiveCN110252405AAvoid rapid deactivationAvoiding Tuning Rapid Deactivation ProblemsOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsBenzeneFormylation reaction

The invention discloses a catalyst composition for reducing the normal-to-isomer ratio of aldehyde products which are obtained through a hydroformylation reaction of olefin. The catalyst composition comprises a solvent, a catalyst active component, a cocatalyst, an assistant A and an assistant B, wherein the catalyst active component is a rhodium salt, the cocatalyst is triphenylphosphine, the assistant A is a phosphine-containing alkyl ligand, and the assistant B is indole structure-containing doped benzene. The catalyst composition is applied to hydroformylation of olefin, the normal-to-isomer ratio in the products can be reduced, and the selectivity and stability of a catalyst under the condition of a low normal-to-isomer ratio of less than 10 can be improved.

Owner:WANHUA CHEM GRP CO LTD

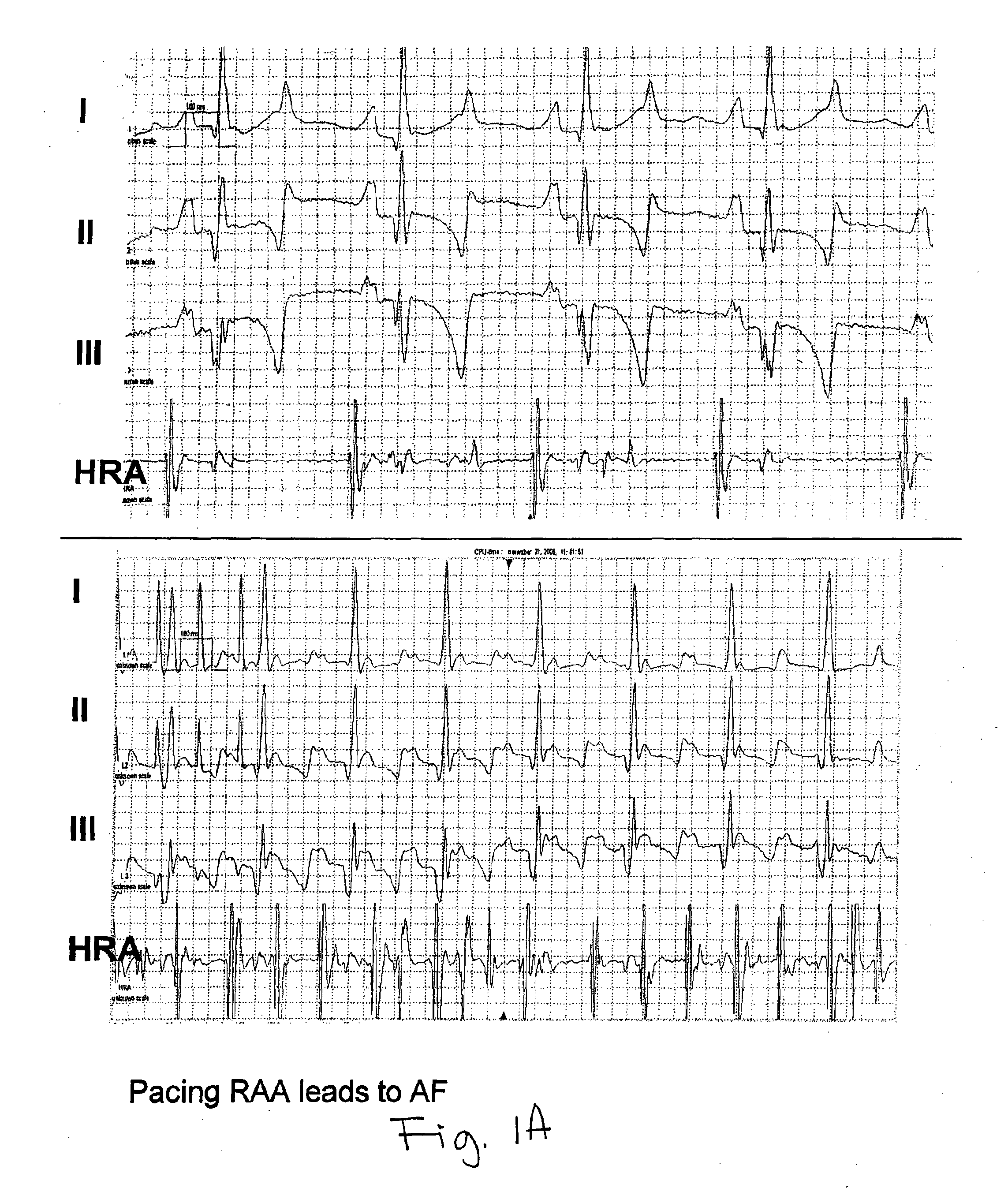

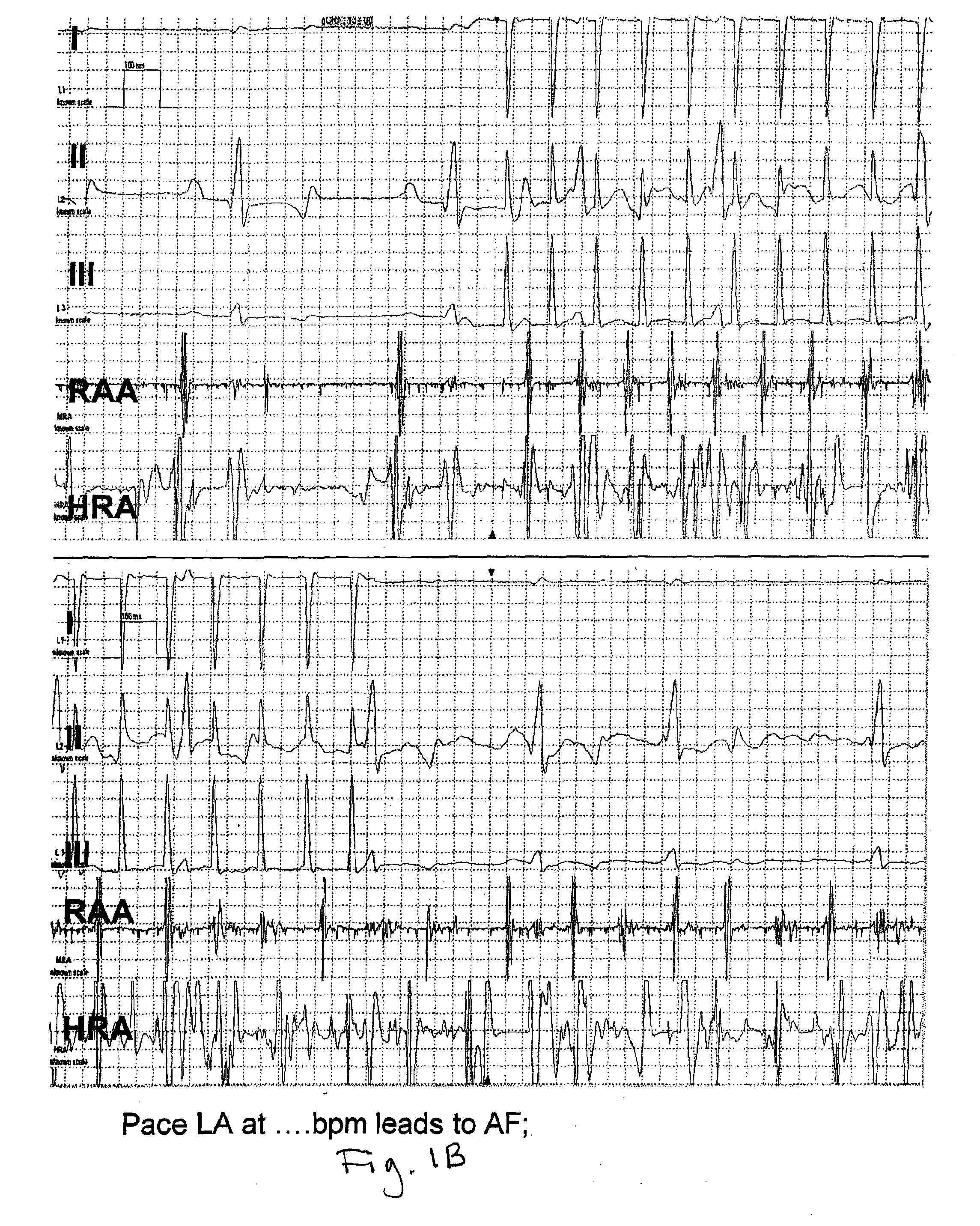

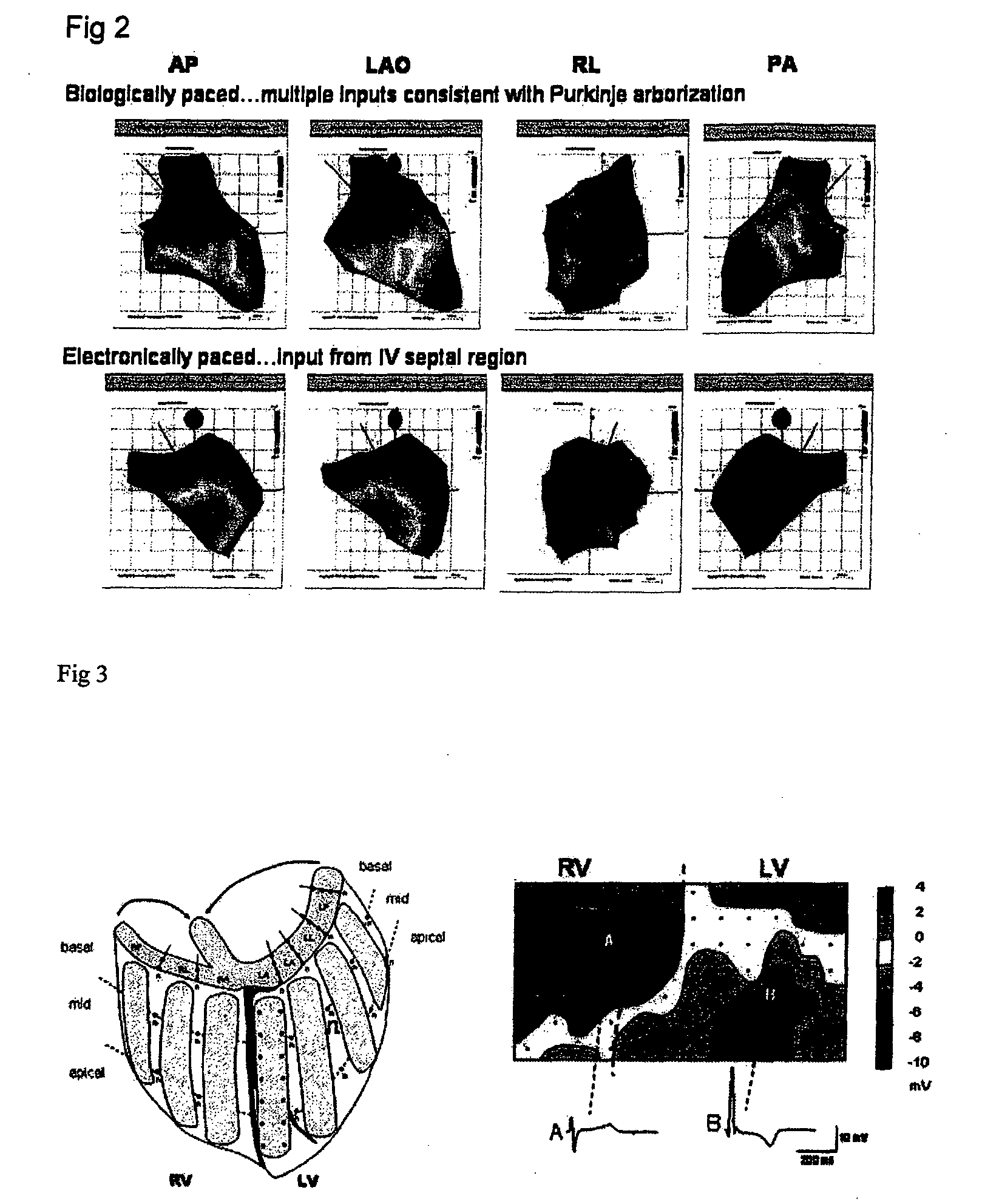

Methods and compositions to treat arrhythmias

InactiveUS20100189701A1Extended refractory periodAvoid rapid deactivationCompounds screening/testingOrganic active ingredientsVentricular tachycardiaFire resistance

The present invention provides compositions and methods of treatment for atrial fibrillation and ventricular tachycardia. The compositions are useful for modifying the conducting properties of heart tissues in which impulses are generating and / or are useful for altering refractoriness without prolonging repolarization.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +1

Method for preparing olefins by using dehydrogenation of light alkanes with sulfur-containing substances added in raw materials

ActiveCN102910997AAvoid rapid deactivationEasy to useHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkanePtru catalyst

The present invention discloses a method for preparing olefins by using dehydrogenation of light alkanes with sulfur-containing substances added in raw materials, comprising: the dehydrogenation catalyst, which is a platinum group metal-supported catalyst, is not subjected to a reduction and sulfurization before use; and a small amount of sulfur-containing materials are added in the dehydrogenation raw materials for a dehydrogenation reaction directly, wherein the concentration of the sulfur-containing materials in the dehydrogenation raw materials is 5-100 [mu]mol / mol. Compared with the prior art, the method of the present invention improves the stability of the dehydrogenation catalyst, and can effectively prolong the service life of the dehydrogenation catalyst and reduce the carbon deposition rate of the catalyst, thereby improving the economic benefits of preparing corresponding olefins by using light hydrocarbon dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

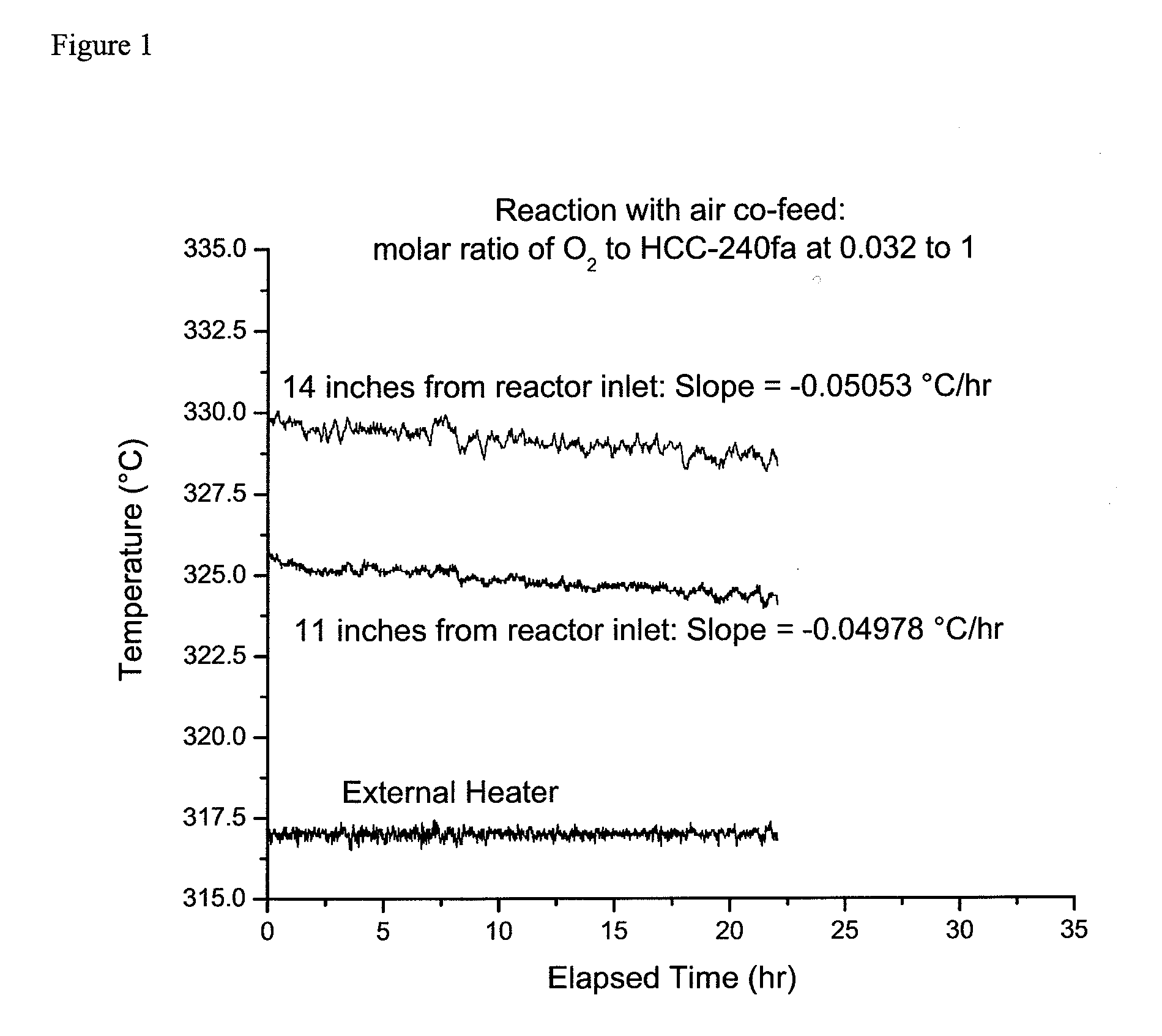

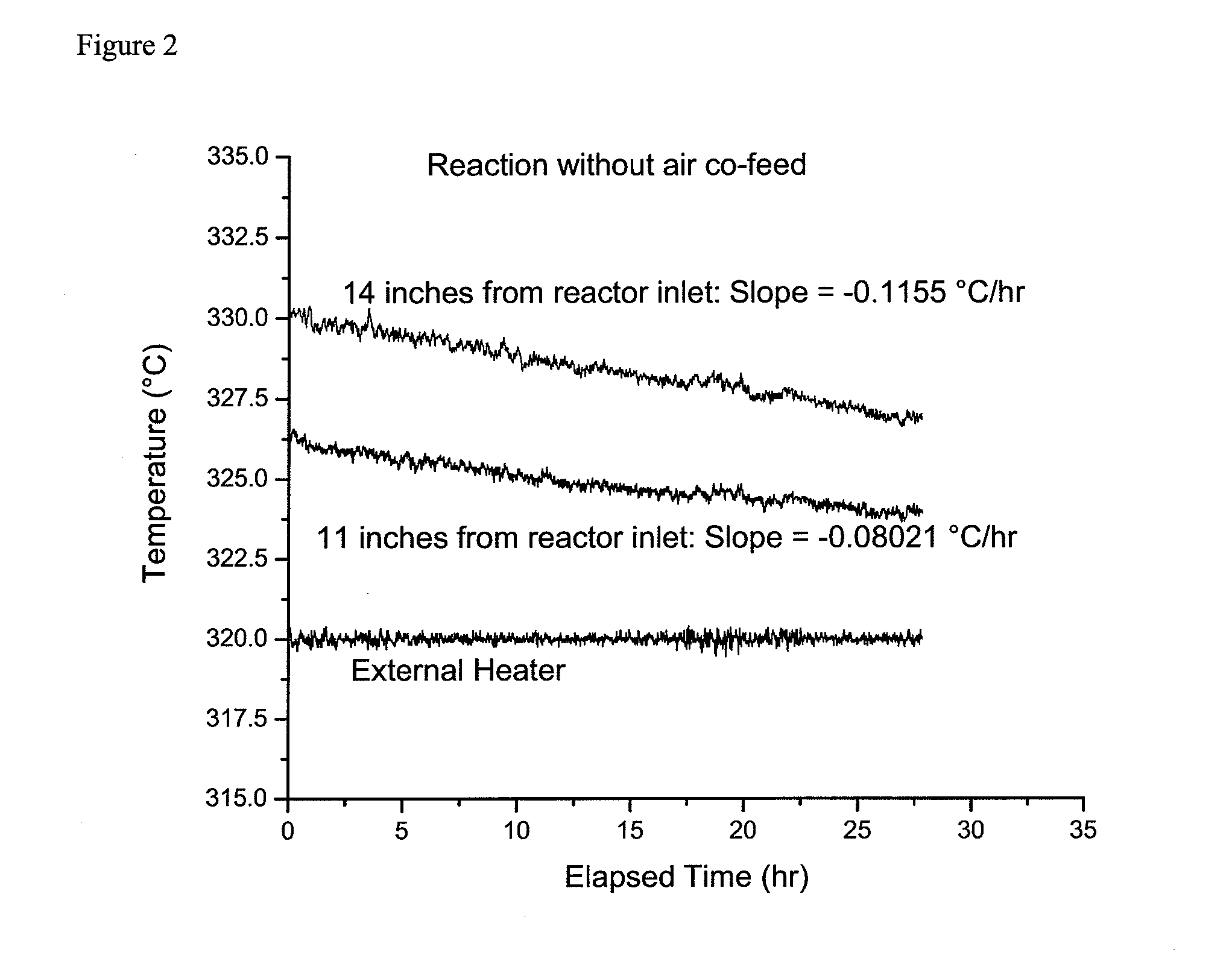

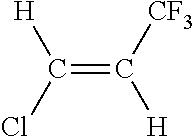

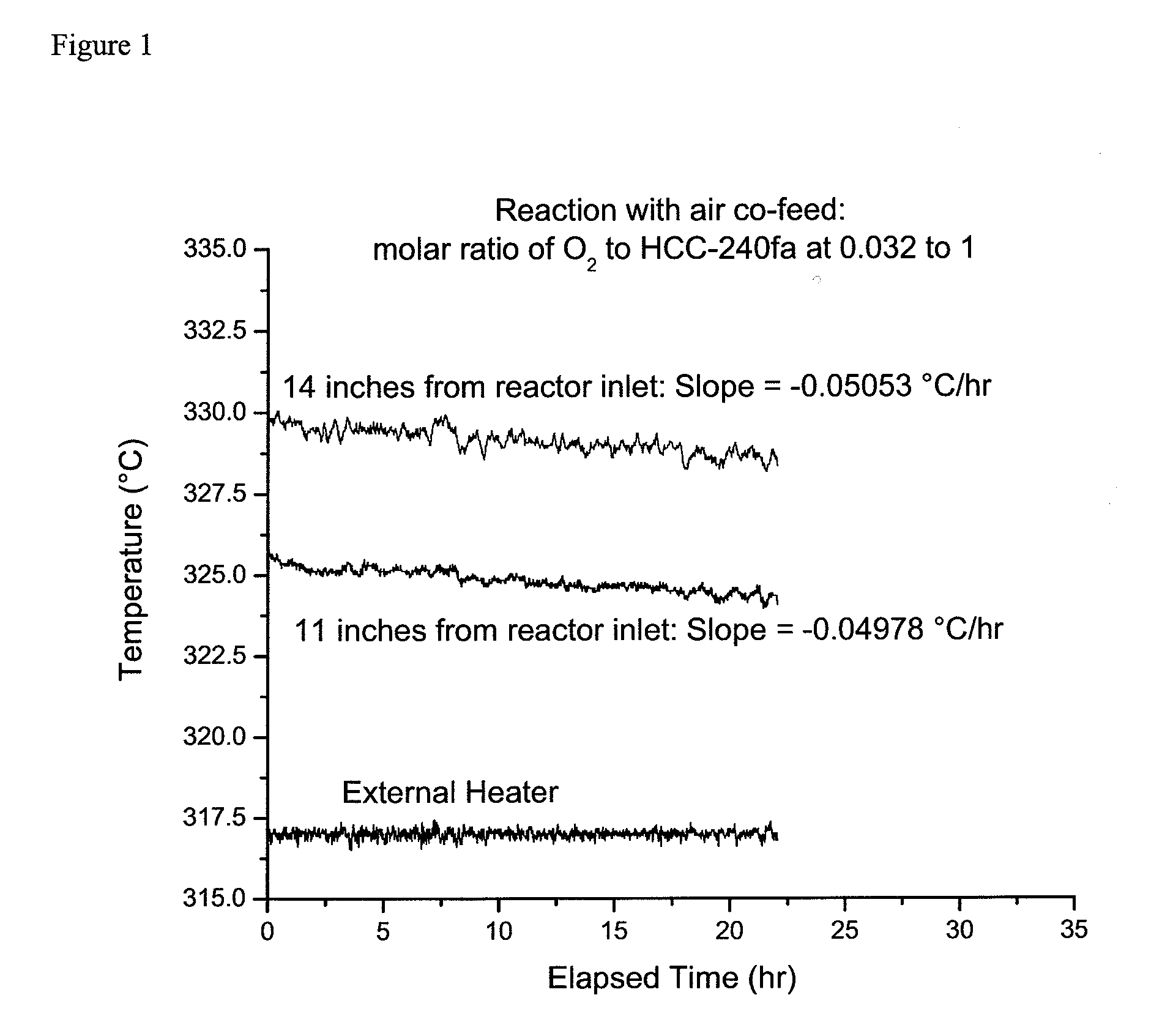

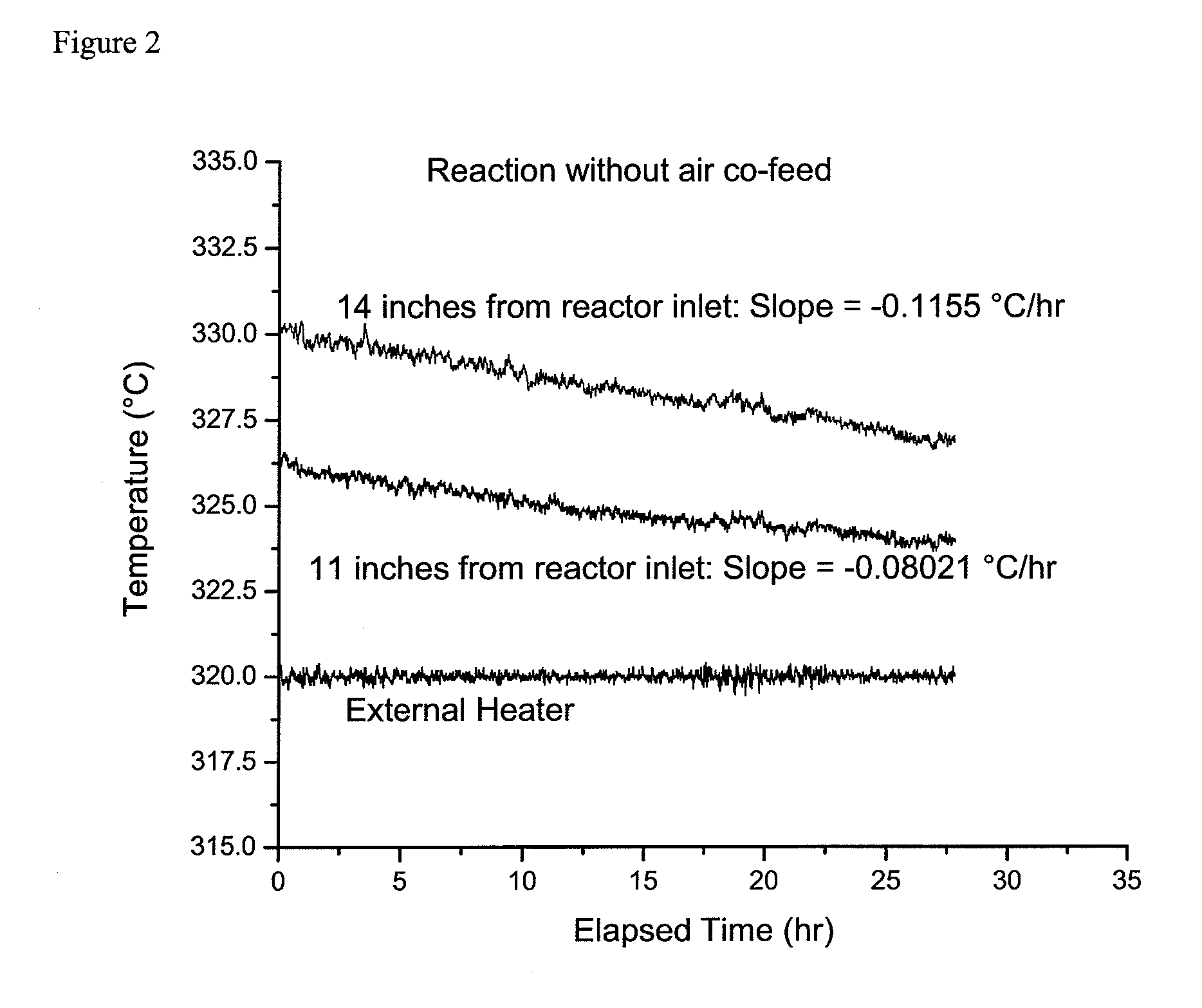

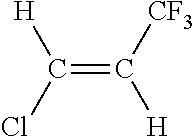

Catalyst Life Improvement for the Vapor Phase Manufacture of 1-Chloro-3,3,3-Trifluoropropene

ActiveUS20110224465A1Loss of production timeIncrease catalyst lifePreparation by hydrogen halide split-offCatalyst regeneration/reactivationVapor phaseHydrogen fluoride

This invention achieves a catalyst life improvement for the catalyzed vapor phase reaction of 1,1,1,3,3-pentachloropropane with hydrogen fluoride to form 1-chloro-3,3,3-trifluoropropene by introducing an oxygen co-feed into the fluorination reactor. By introduction of an oxygen co-feed to the reactor feed, the catalyst life was extended a minimum of two-fold (2×).

Owner:HONEYWELL INT INC

Dehydrogenation method for light alkanes

ActiveCN102911000AInhibition of initial cracking performanceAvoid rapid deactivationHydrocarbonsHydrocarbon preparationAlkanePtru catalyst

The present invention discloses a dehydrogenation method for light alkanes, and the method comprises: the dehydrogenation catalyst, which is a platinum group metal-supported catalyst, is reduced by using the low concentration hydrogen before use; and after the reduction, a small amount of a sulfur compound is added into dehydrogenation raw materials for the dehydrogenation reaction directly, wherein the concentration of the sulfur compound is 5-100[mu]mol / mol in the dehydrogenation raw materials. Compared with the prior art, the method of the present invention improves the stability of the dehydrogenation catalyst, and can effectively prolong the service life of the dehydrogenation catalyst and reduce the carbon deposition rate of the catalyst, thereby improving the economic benefits of preparing corresponding olefins by using light hydrocarbon dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

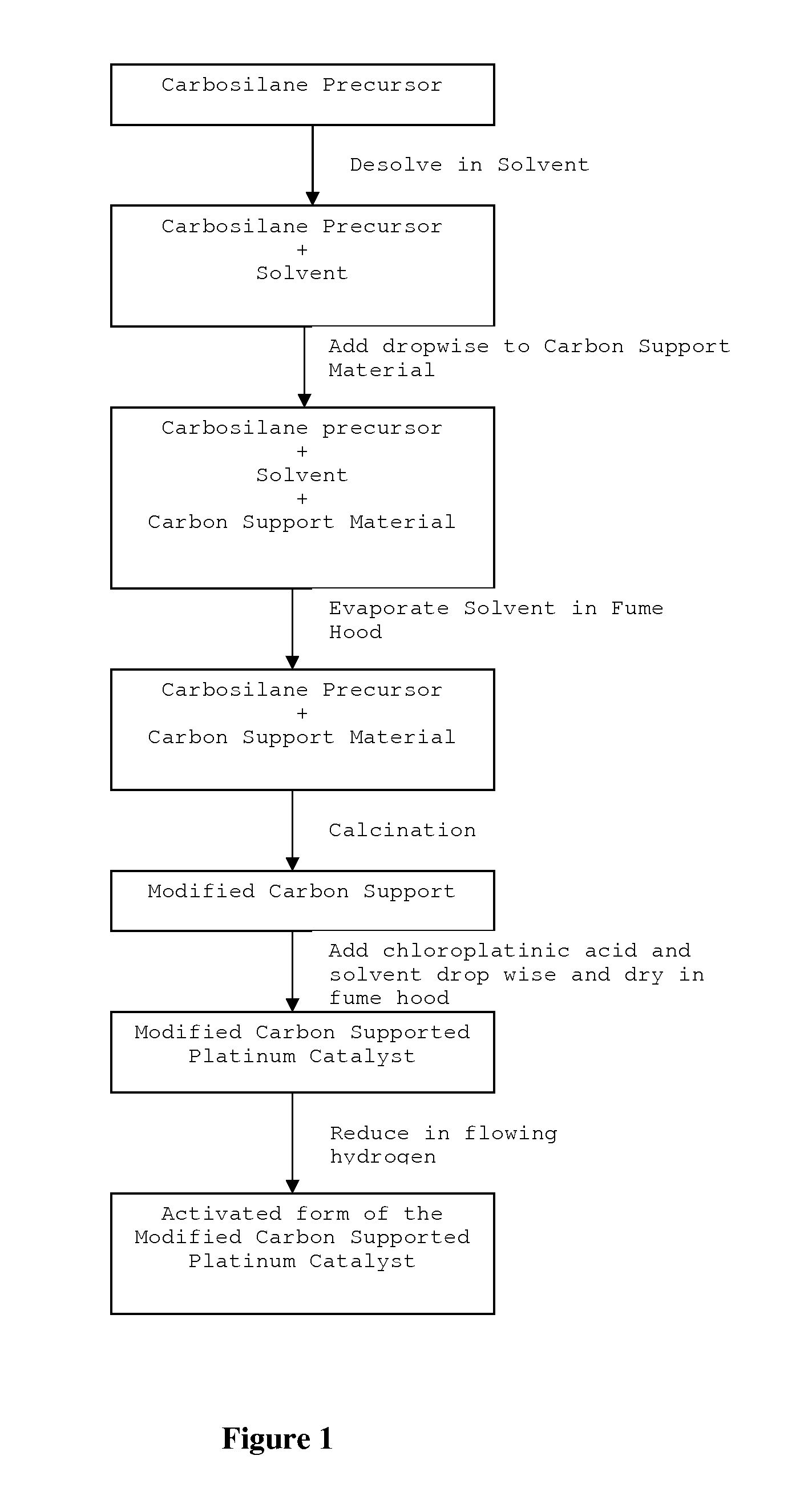

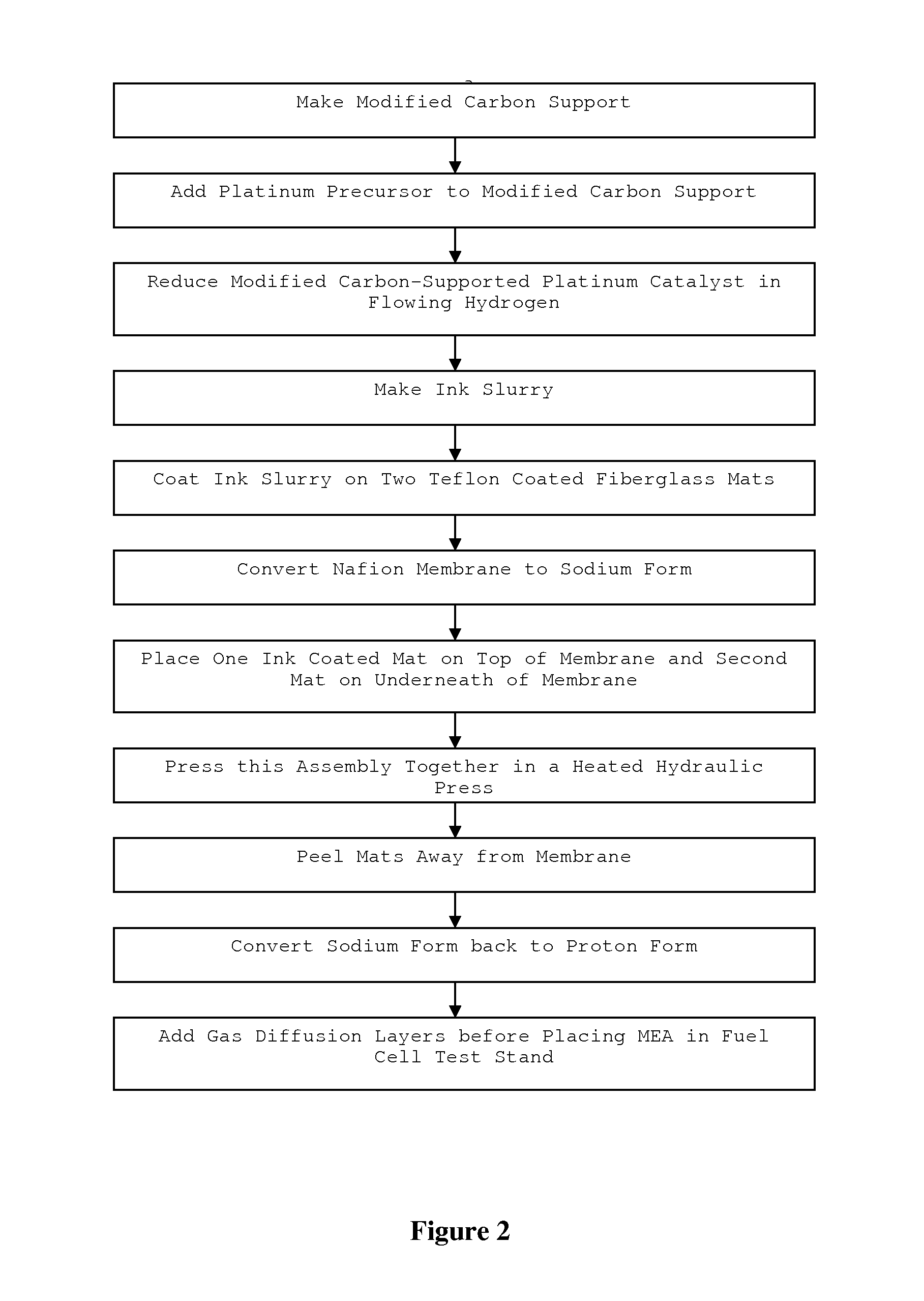

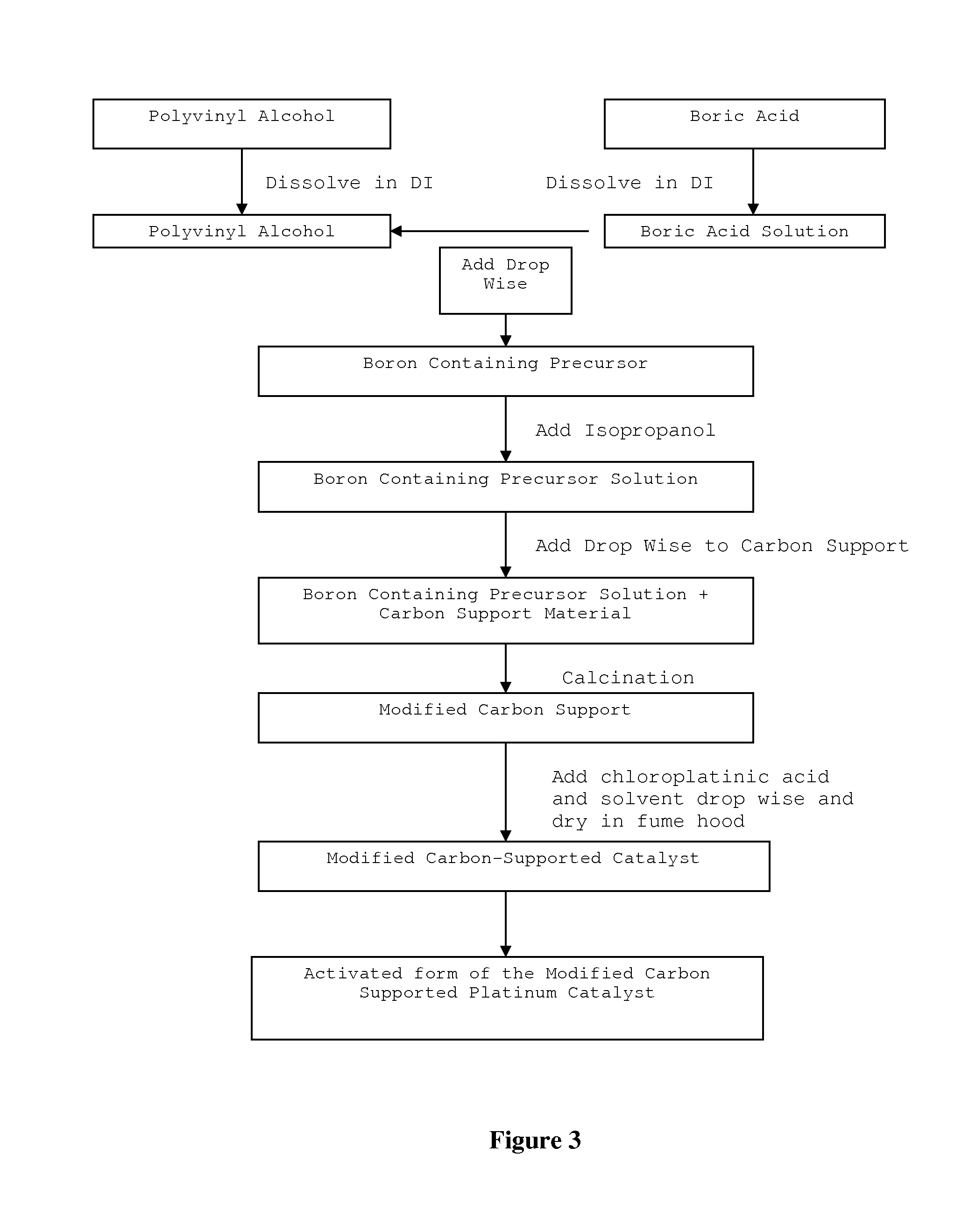

Fuel Cells with Improved Durability

InactiveUS20120237855A1Increased durabilityAvoid rapid deactivationOrganic-compounds/hydrides/coordination-complexes catalystsActive material electrodesFuel cellsMetal catalyst

A modified carbon-supported metal catalyst is disclosed which has durability and activity wherein the surface of the carbon support has been modified by the addition of silicon carbides or boron carbides made by calcination. This catalyst is used as a catalyzed electrode in fuel cells.

Owner:MICHIGAN MOLECULAR INST

Process for ammoximation of carbonyl compounds

ActiveUS7408080B2Shorten the timeDelayed recoveryOrganic compound preparationOrganic chemistry methodsDissolutionAmmonia

The present invention discloses a process for the ammoximation of carbonyl compounds, wherein a reaction in a liquid reaction system comprising a carbonyl compound, ammonia and hydrogen peroxide is carried out in the presence of a sillicon-containing catalyst, characterized in that a liquid silicon-containing assistant is added to the reaction system so that the silicon concentration in the system reaches a range of between 0.1 and 10000 ppm. In the process according to the present invention, the deactivation of catalyst due to dissolution of silicon in the catalyst can be reduced, thus lifetime of the catalyst extended and the stable operation time elongated.

Owner:CHINA PETROCHEMICAL CORP +1

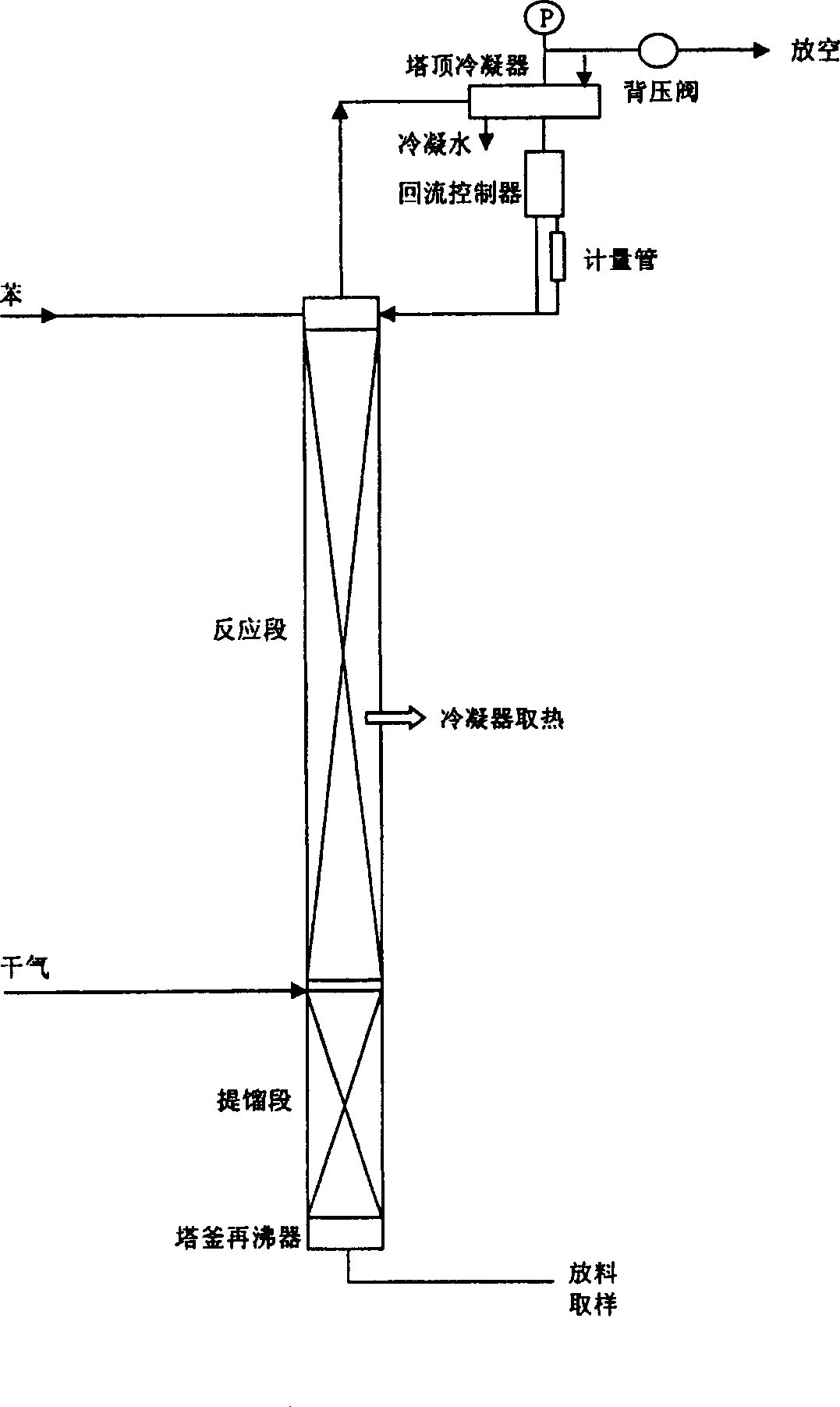

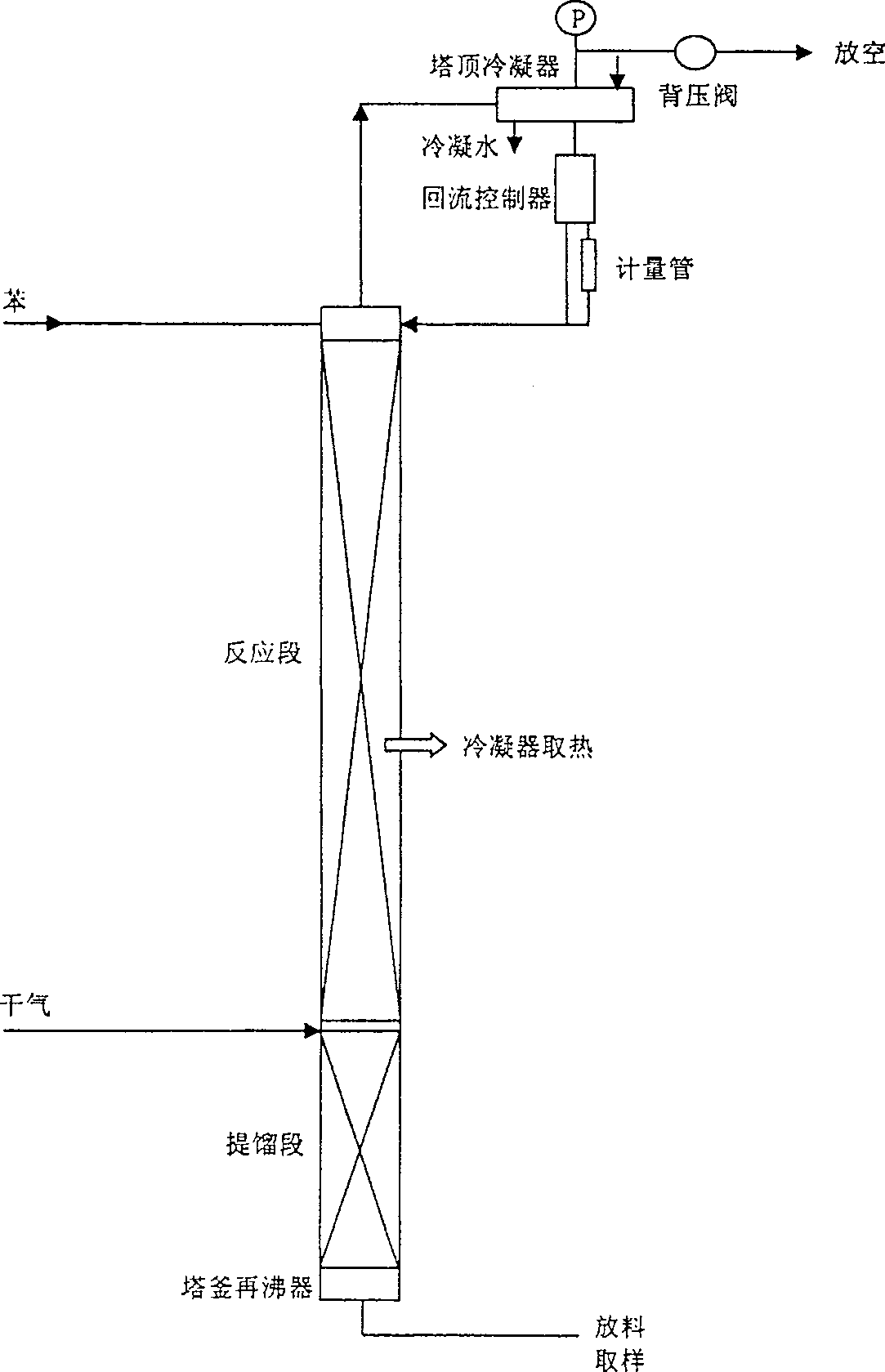

Method for producing ethyl benzene by catalysis, distillation and alkylation

InactiveCN1807373AAvoid rapid deactivationWater resistantHydrocarbonsBulk chemical productionAlkyl transferReboiler

The preparation method for ethylbenzene selects high-pure ethene or refinery dry gas as material for alkylation reaction in catalytic distillation tower. Wherein, the tower comprises a reboiler, a stripping section, a reaction section with one or more condensers to take up some heat and condense part benzene vapour to improve ethene conversion, and a condenser on tower top.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

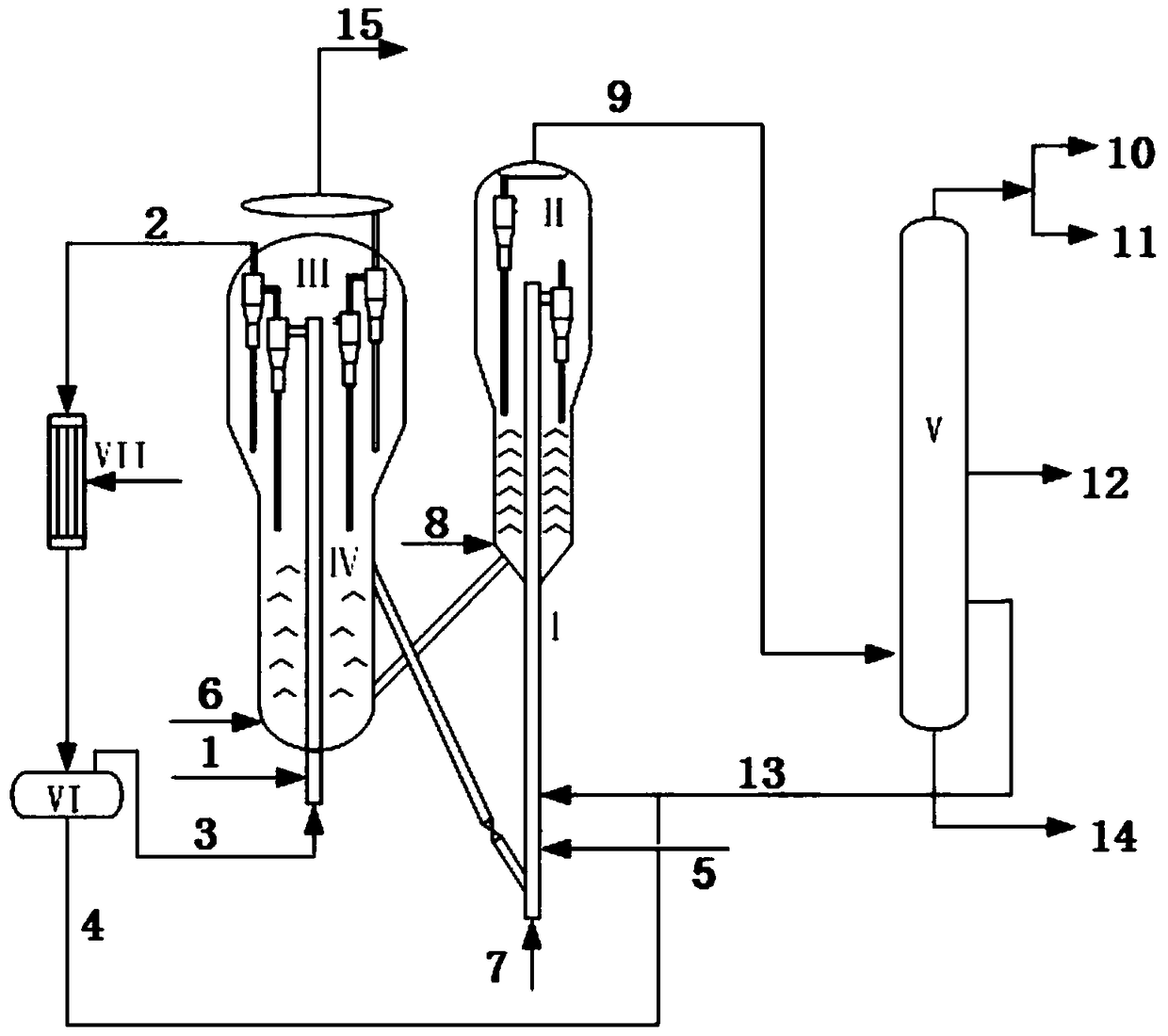

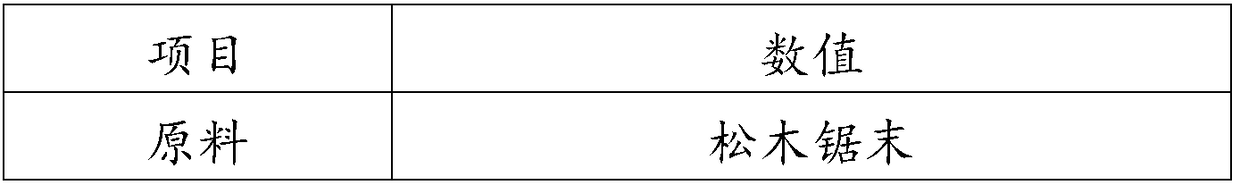

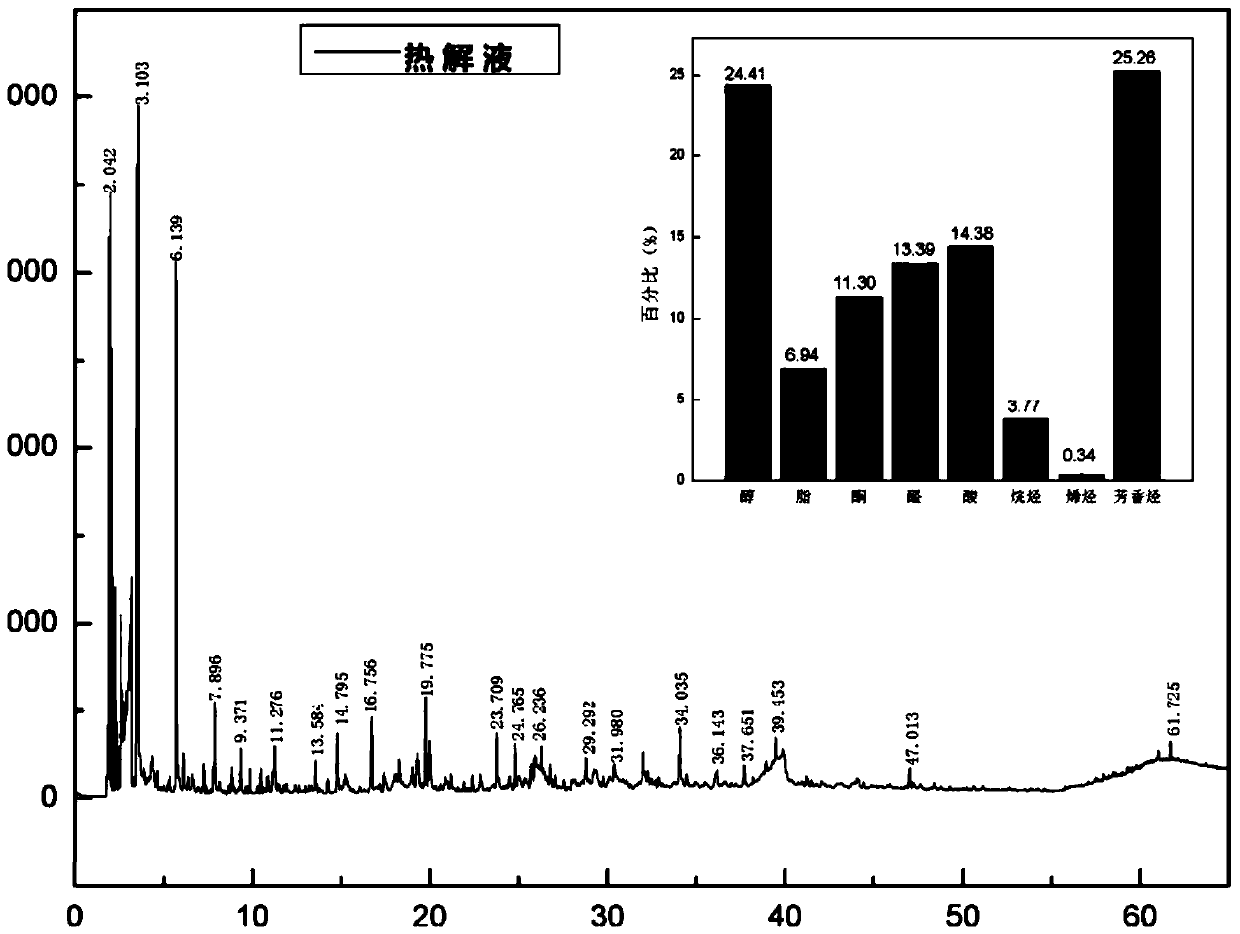

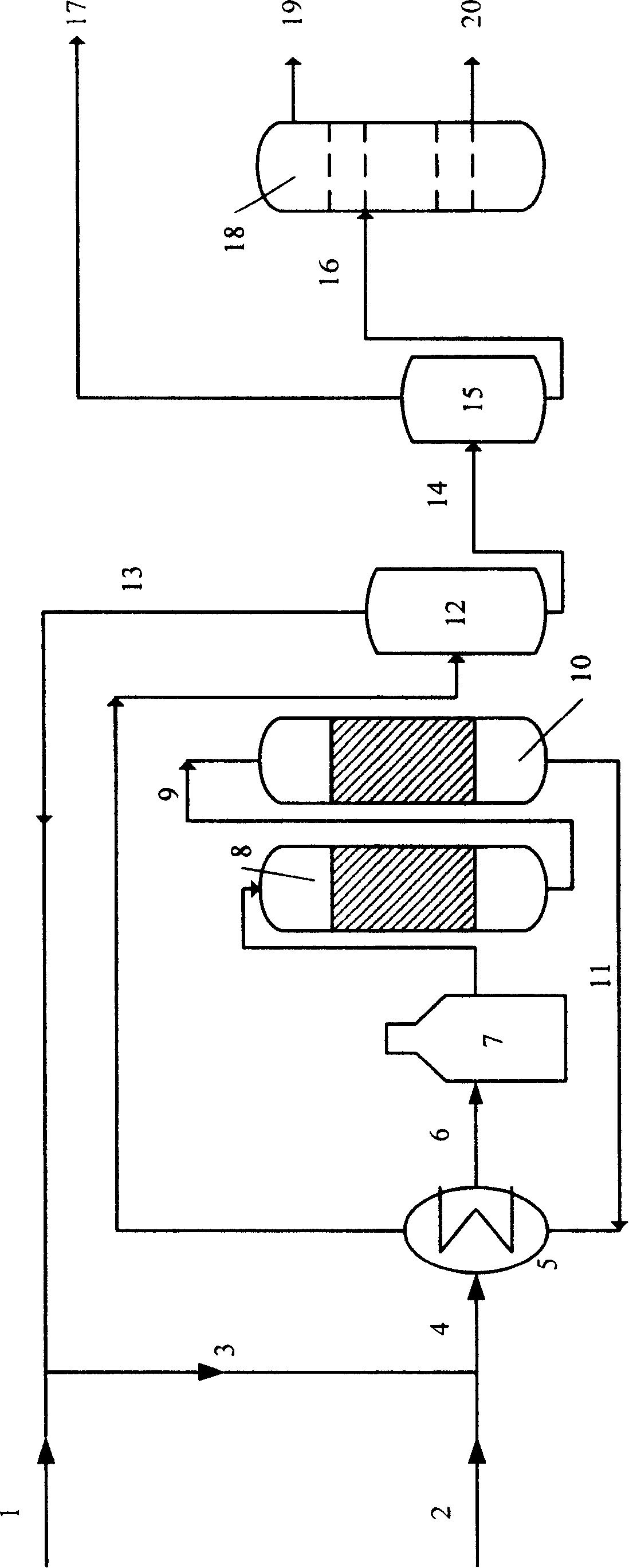

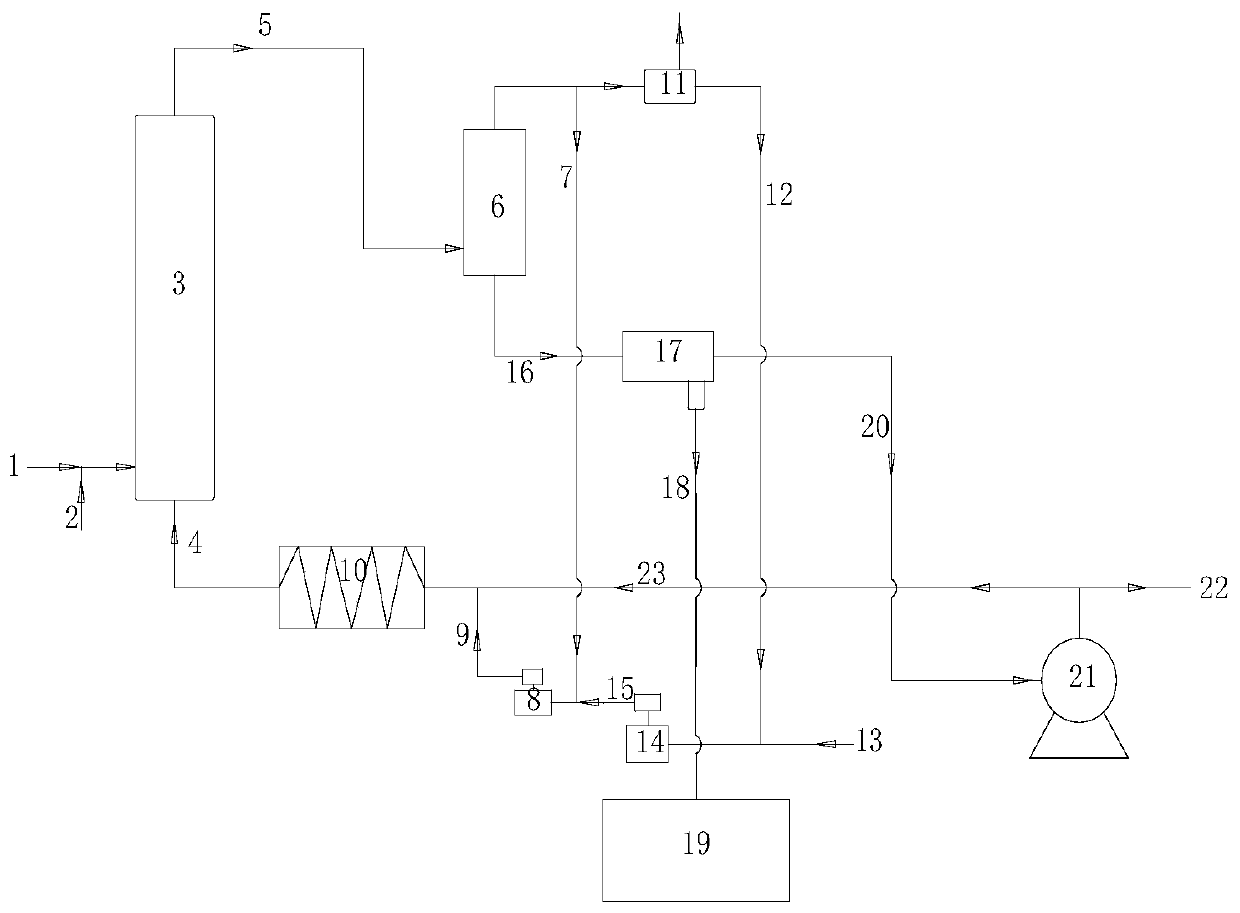

Efficient biomass conversion method

ActiveCN109054875AIncrease profitAvoid wastingBiofuelsWaste based fuelOil processingDistillates petroleum

The invention discloses a method for achieving efficient biomass conversion by adopting a catalytic cracking device in a petroleum processing process. Heat generated by burning coke generated in a catalytic cracking process is used for achieving heat self sufficiency of the whole process, meanwhile, through catalytic cracking, modification of biomass pyrolytic tar is achieved, a process of converting biomass into high-quality fuel oil directly is achieved, and the catalytic cracking device is used fully, so that there is no need to build a biomass pyrolysis device individually, the productioncost is reduced, and meanwhile, the problems that during individual biomass oil catalytic cracking modification, coking is prone to happen, and a catalyst is prone to bond and aggregate can be solved.A technology involves a pyrolysis reactor, a riser reactor, a reproducer, a settler, an oil-gas separation tank and a fractionating tower, wherein the pyrolysis reactor is placed in the reproducer, and is used for biomass pyrolysis and liquefaction; a catalytic cracking reactor is used for catalytic cracking of a petroleum fraction and the biomass pyrolytic oil, and a catalytic cracking product is separated into cracking gas, gasoline and diesel fractions through the fractionating tower.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

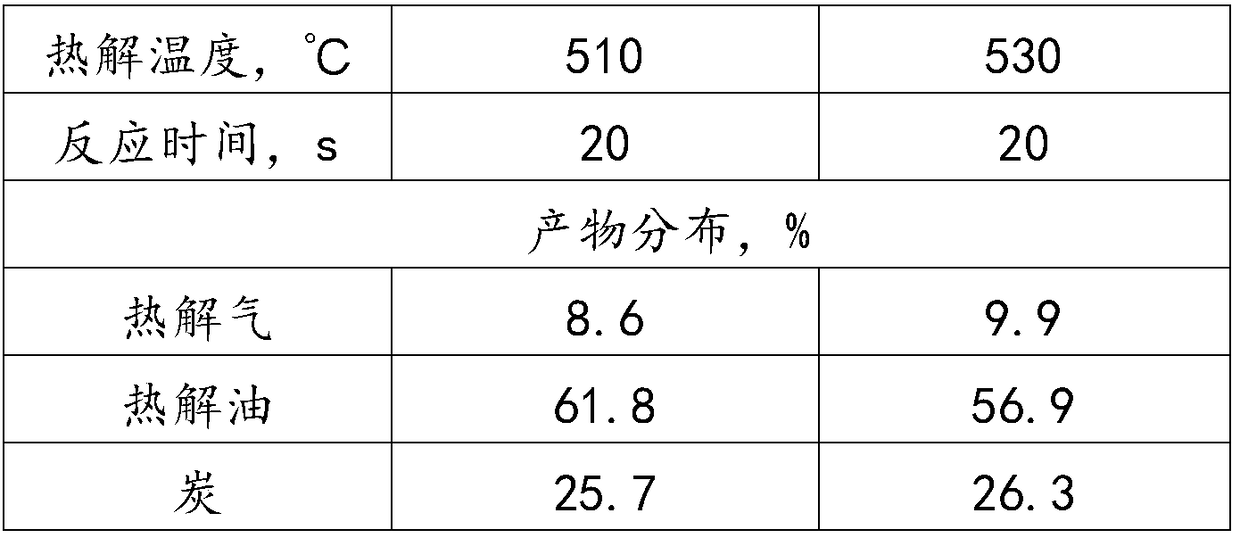

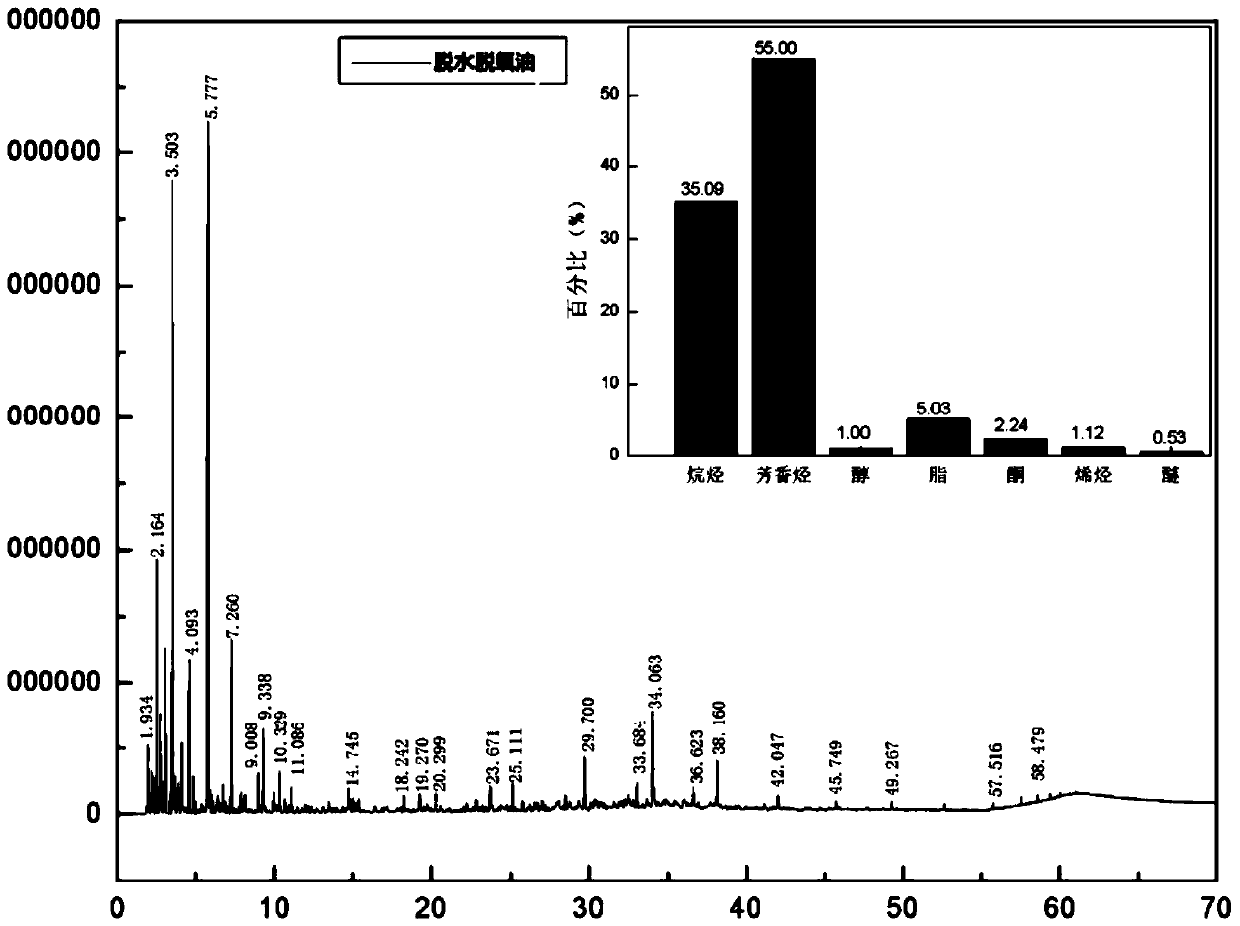

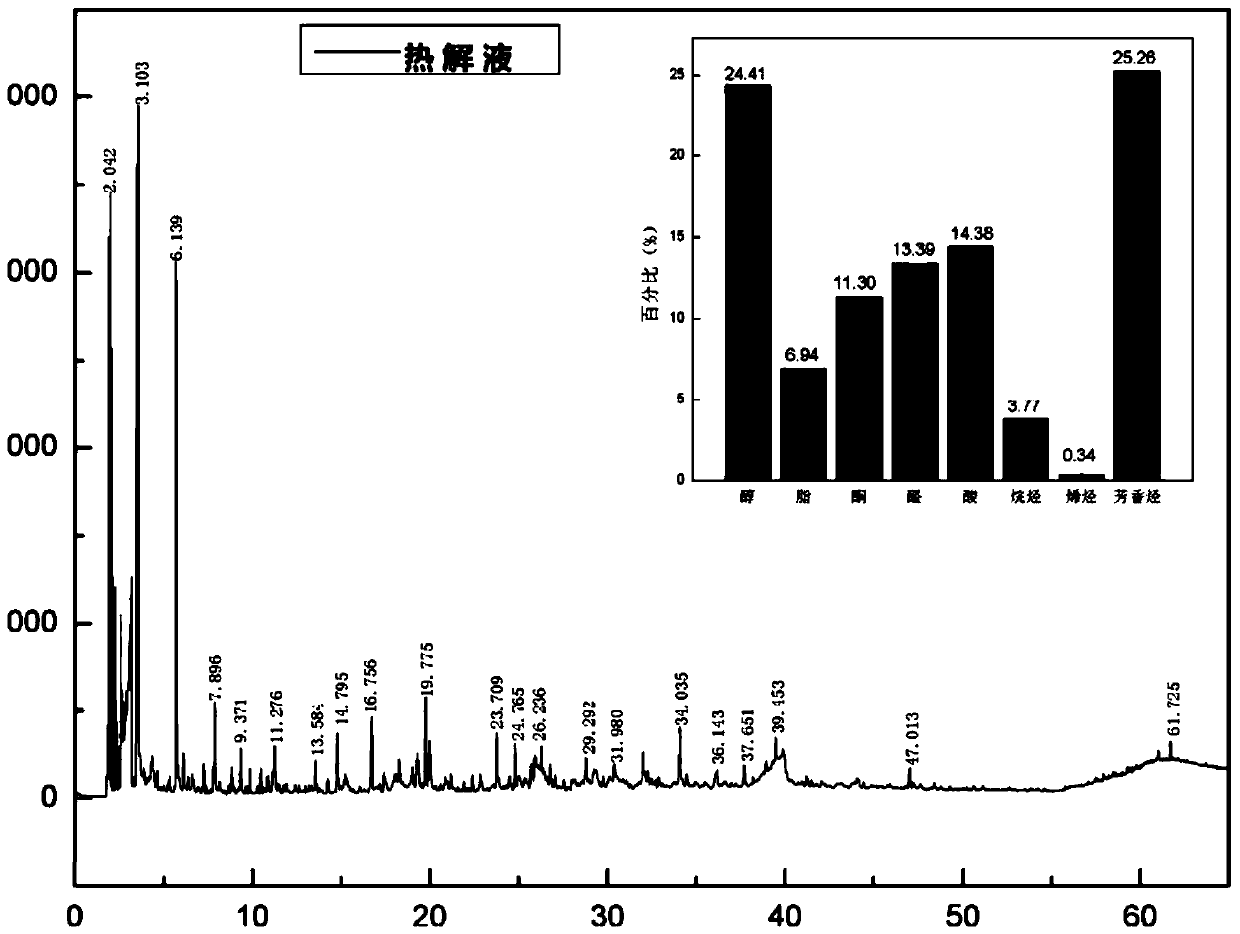

Method for preparing high-quality fuel oil and/or chemical raw materials from biomass pyrolysis liquid

ActiveCN110028985AAvoid aggregation and cokingAvoid inactivationHydrocarbon oils refiningBiofuelsBiomassChemistry

The invention discloses a method for preparing high-quality fuel oil and / or a chemical raw material from biomass pyrolysis liquid. The method comprises the following steps: carrying out hydrodeoxygenation reaction on biomass pyrolysis liquid in a catalyst full-mixed-flow circulating system in a fluidized bed reactor to obtain deoxidized oil, and carrying out hydrocracking reaction on the obtaineddeoxidized oil in a fixed bed reactor to obtain high-quality fuel oil and / or the chemical raw material. According to the method, condensation and coking of the biomass pyrolysis liquid can be prevented, the problem that a catalyst is fast to inactivate is solved, and the biomass pyrolysis liquid can be converted into high-quality fuel oil and chemical products which can be directly used by vehicles.

Owner:HENAN BUF BIOENERGY CO LTD +2

Production method of high-bioctyl-value diesel oil by coal liquification

ActiveCN100389169CAvoid rapid deactivationReduce processing difficultyLiquid hydrocarbon mixture productionNaphthaHydrogen

Production of high-cetane diesel oil from coal is carried out by filtering direct-liquefied diesel oil fraction of hydrogenated stabilized coal, mixing with hydrogen, contacting with hydrogenation refined catalyst and hydrogenation modified catalyst, separating out effluent from hydrogenation modified reactor to obtain naphtha fraction and diesel fraction, and returning hydrogen-enriched flow into diesel hydrogenation modified reactor. It is simple and fast, has better dearomatization and denitrification functions.

Owner:CHINA PETROLEUM & CHEM CORP

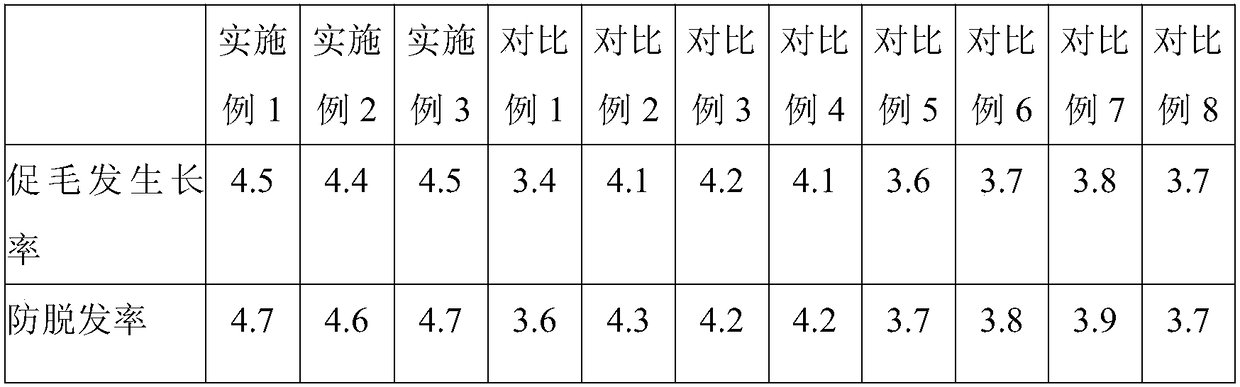

Composition for preventing hair loss and promoting hair growth and preparation method of composition

ActiveCN109157486AIncrease growth rateImprove anti-hair loss rateCosmetic preparationsHair cosmeticsPullulanCocamidopropyl betaine

The invention discloses a composition for preventing hair loss and promoting hair growth and a preparation method of the composition. The composition for preventing hair loss and promoting hair growthcomprises the following materials: ethanol extract of traditional Chinese medicine, pullulan, vitamin E, hydroxypropyl methylcellulose, camphor, cocamidopropyl betaine, propylene glycol, avocado oil,hydrolyzed wheat protein, methyl isothiazolinone, menthol, preservative, L-cystine, zinc gluconate, copalic acid, xylan, water-soluble pectin and deionized water, wherein the composition for preventing hair loss and hair growth is prepared by steps of mixing, stirring and the like. According to the invention, copalic acid, xylan and water-soluble pectin are used as a reinforcing system to improvea hair loss preventing rate and a hair growth promoting rate of the composition for preventing hair loss and promoting hair growth.

Owner:周健

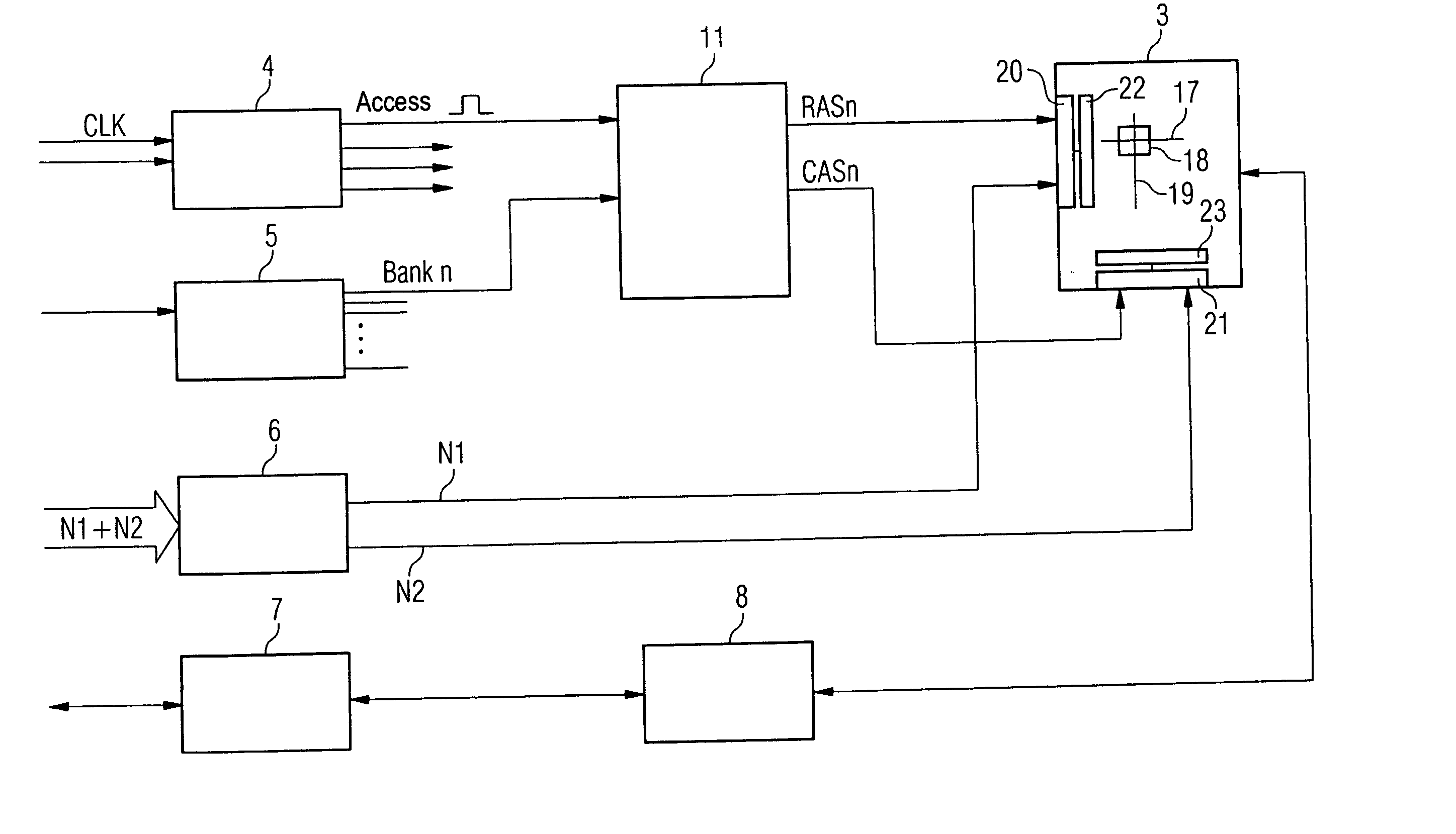

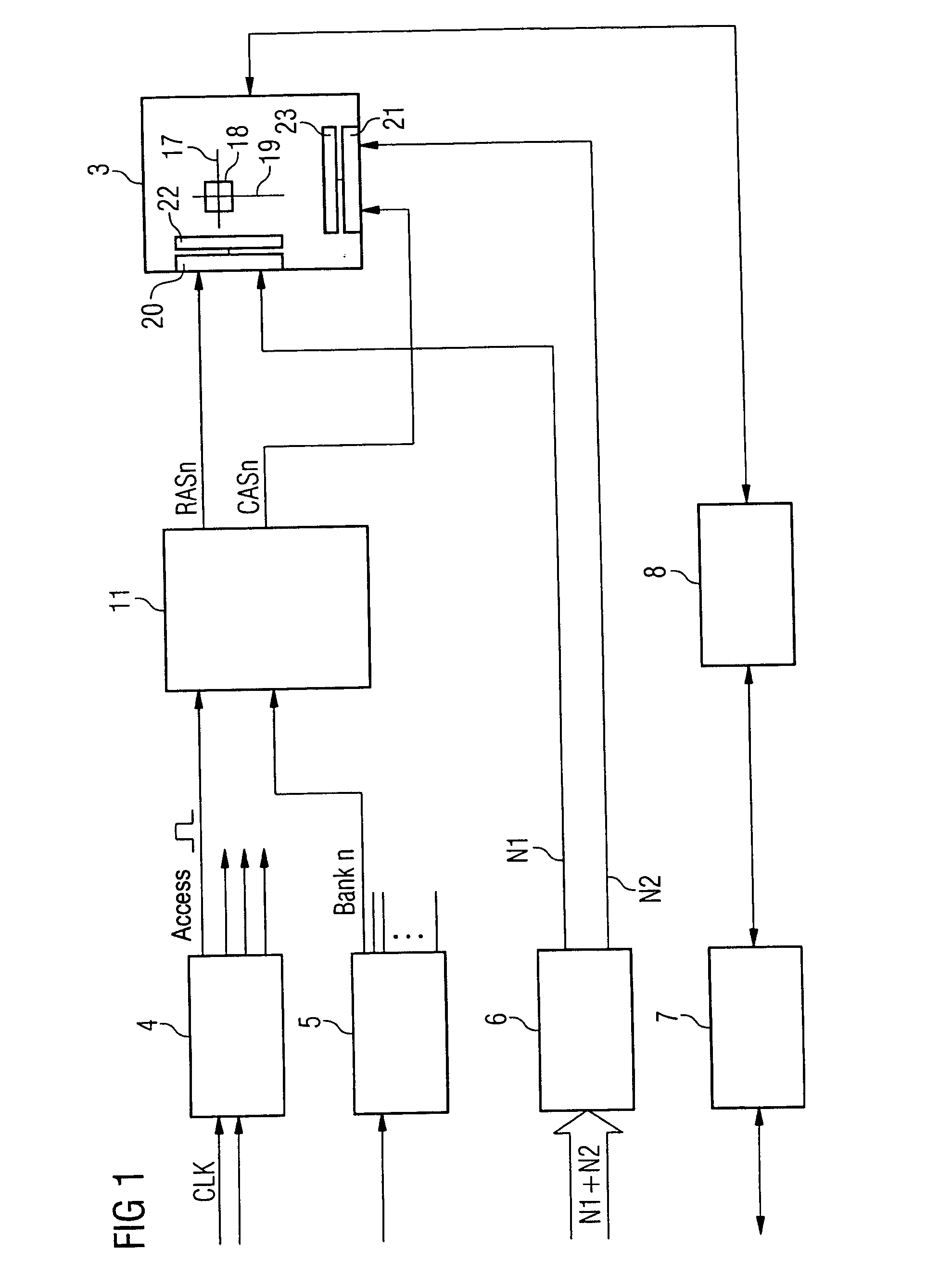

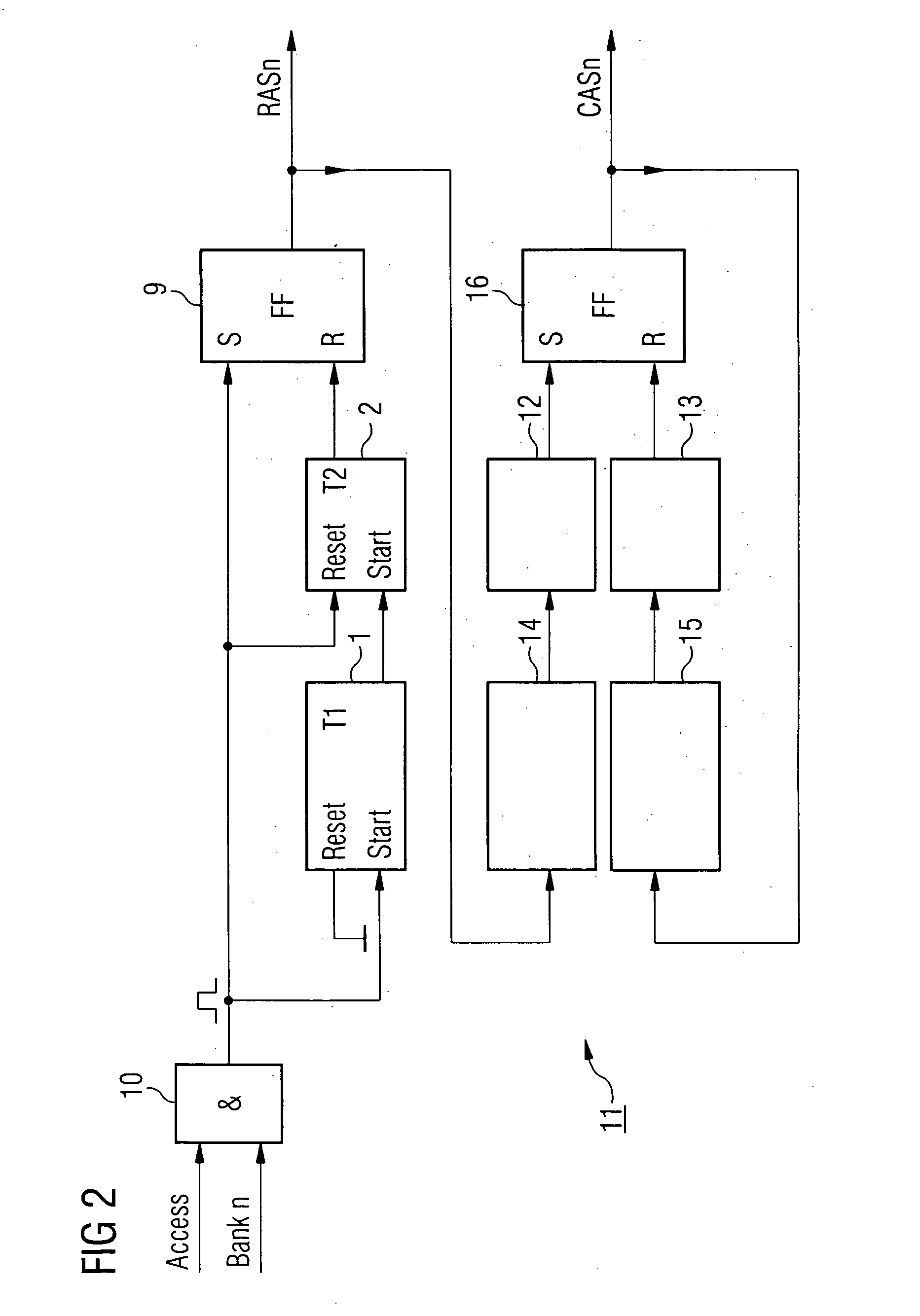

Apparatus for flexible deactivation of word lines of dynamic memory modules and method therefor

InactiveUS20050002220A1Expand accessAvoid rapid deactivationDigital storageComputer scienceMemory module

An apparatus and a method are proposed, which can be used to delay a deactivation of a row address in the event of repeated access to a bank of an RLDRAM memory module.

Owner:CONVERSANT INTPROP MANAGEMENT INC

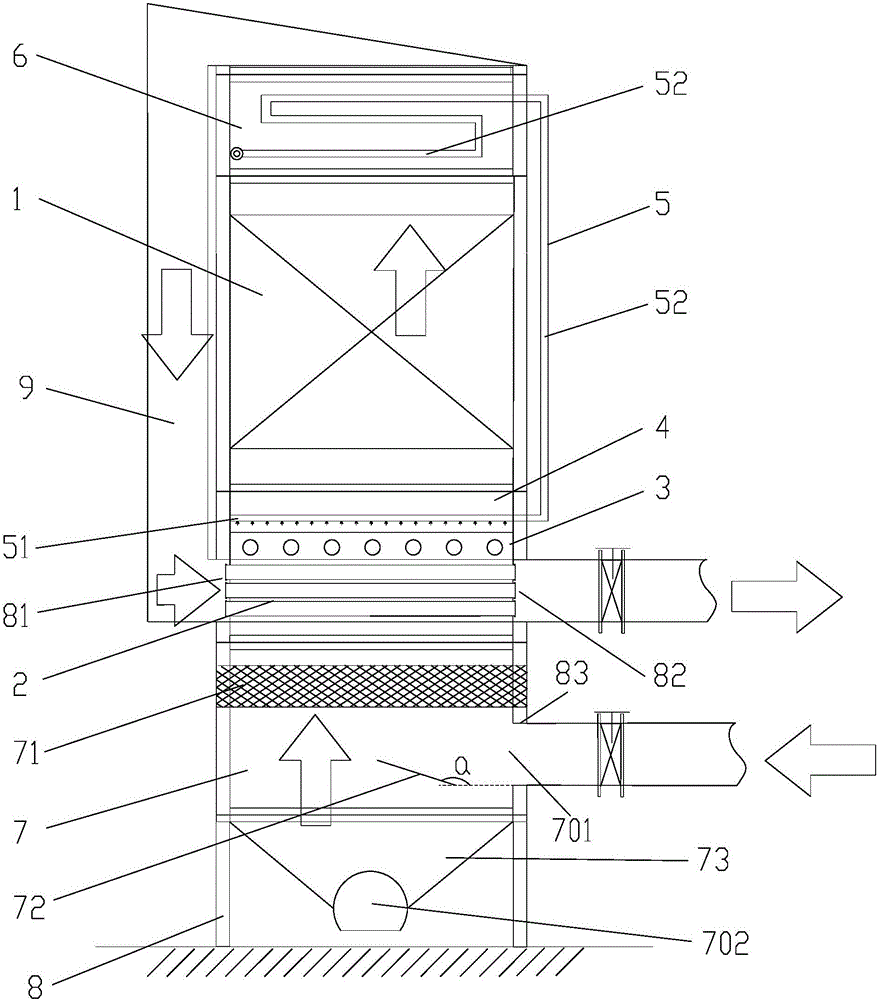

Integrated energy-saving SCR denitration device

ActiveCN105944565AIncrease profitLow running costLighting and heating apparatusDispersed particle separationPipeline transportHeat losses

The invention provides an integrated energy-saving SCR denitration device. The integrated energy-saving SCR denitration device comprises an SCR denitration reaction chamber and a heat exchange chamber. Smoke before reaction is fed through a cold fluid inlet of the heat exchange chamber, and a cold fluid outlet is connected with a smoke inlet of the SCR denitration reaction chamber; a hot fluid inlet of the heat exchange chamber is connected with a smoke outlet of the SCR denitration reaction chamber, and a hot fluid outlet is a smoke outlet. Reacted high-temperature smoke serves as hot fluid to heat the smoke before reaction, waste heat of the reacted high-temperature smoke is sufficiently used, the energy use rate is increased, and running cost is reduced. According to the integrated energy-saving SCR denitration device, a dust removing chamber, the heat exchange chamber, a gas mixing chamber, the SCR denitration reaction chamber and a reduction agent evaporation chamber are integrally arranged in a cylinder shell in an optimized mode, design is compact, the pipe conveying flow of smoke is effectively shortened, no pipe is required between every two adjacent chambers, heat losses of smoke in the pipe conveying process are reduced, and meanwhile the occupied area of the denitration device is saved.

Owner:北京方信立华科技有限公司

Multi-functional catalyst for reforming hydrogen production and preparation method and application of catalyst

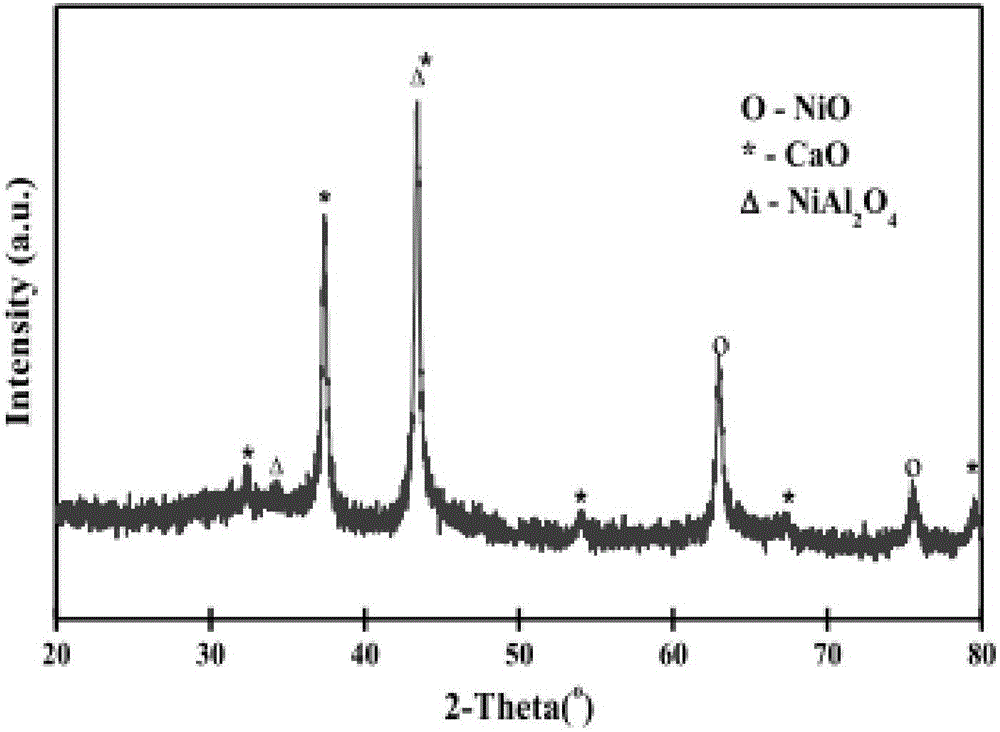

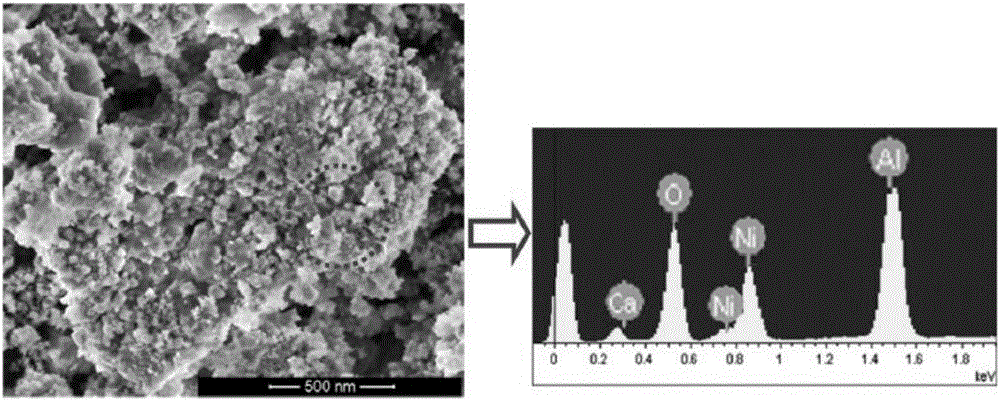

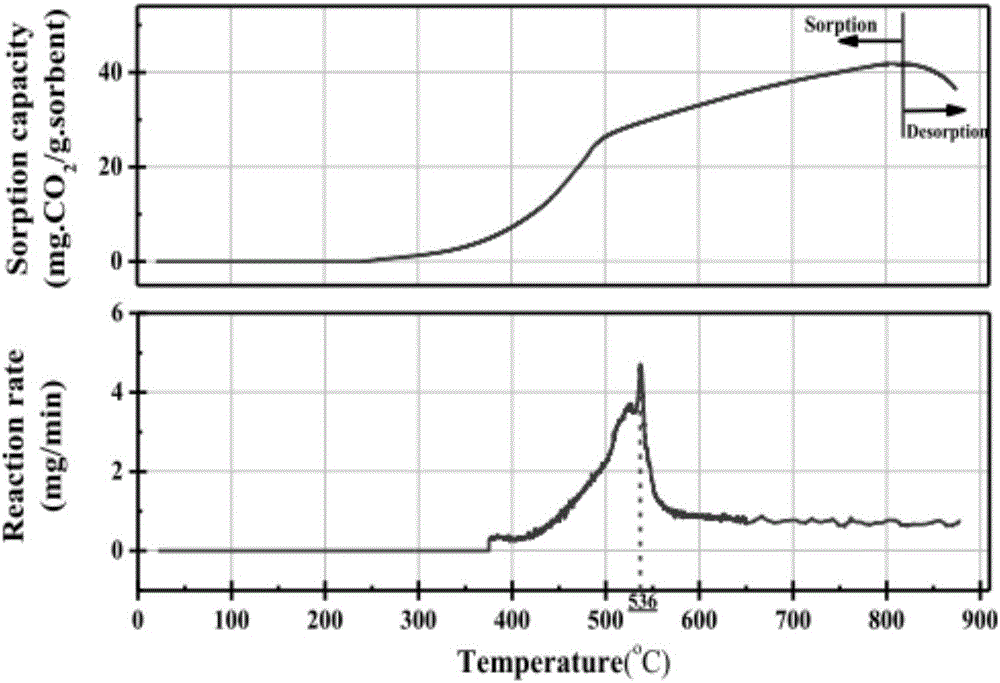

InactiveCN106111144AAvoid rapid deactivationImprove thermal stabilityProductsHydrogenComposite functionHydrogen production

The invention relates to the technical field of preparation of a catalyst, and discloses a multi-functional catalyst for reforming hydrogen production and a preparation method and application of the catalyst. The catalyst is excellent in catalytic hydrogen production performance and CO2 adsorption performance, simple in preparation process, low in cost and beneficial for popularization and application. The chemical formula of the catalyst is NiO-CaO-NiAl2O4 / Al2O3. Al2O3 is a carrier, and NiAl2O4 has a spinel structure. The catalyst comprises raw materials, by weight part, 23-42 parts of NiO, 25-35 parts of gamma-Al2O3 and 23-52 parts of Ca(NO3)2.6H2O. The invention further discloses a preparation method of the catalyst and an application of the catalyst to reforming hydrogen production from glycerin.

Owner:GUANGDONG UNIV OF TECH

Oil-based thermo-neutral reforming with a multi-component catalyst

ActiveUS20080152572A1Enhance the activity of the base metal-supported thermo-neutral reforming catalystProcesses liquid hydrocarbon fuels efficiently and reliablyHydrogenHydrocarbon from carbon oxidesSteam reformingCombustion

A method is provided for the thermo-neutral reforming of liquid hydrocarbon fuels which employs a Ni, Ce2O3, La2O3, Pt−ZrO2, Rh and Re catalyst having dual functionalities to achieve both combustion and steam reforming.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

A method for producing ethyl benzene by catalysis, distillation and alkylation

InactiveCN100465143CAvoid rapid deactivationWater resistantHydrocarbonsBulk chemical productionAlkyl transferReboiler

The preparation method for ethylbenzene selects high-pure ethene or refinery dry gas as material for alkylation reaction in catalytic distillation tower. Wherein, the tower comprises a reboiler, a stripping section, a reaction section with one or more condensers to take up some heat and condense part benzene vapour to improve ethene conversion, and a condenser on tower top.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

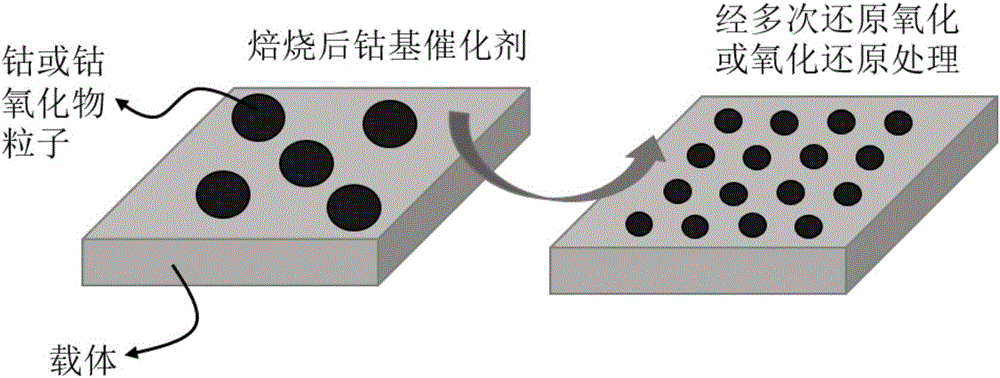

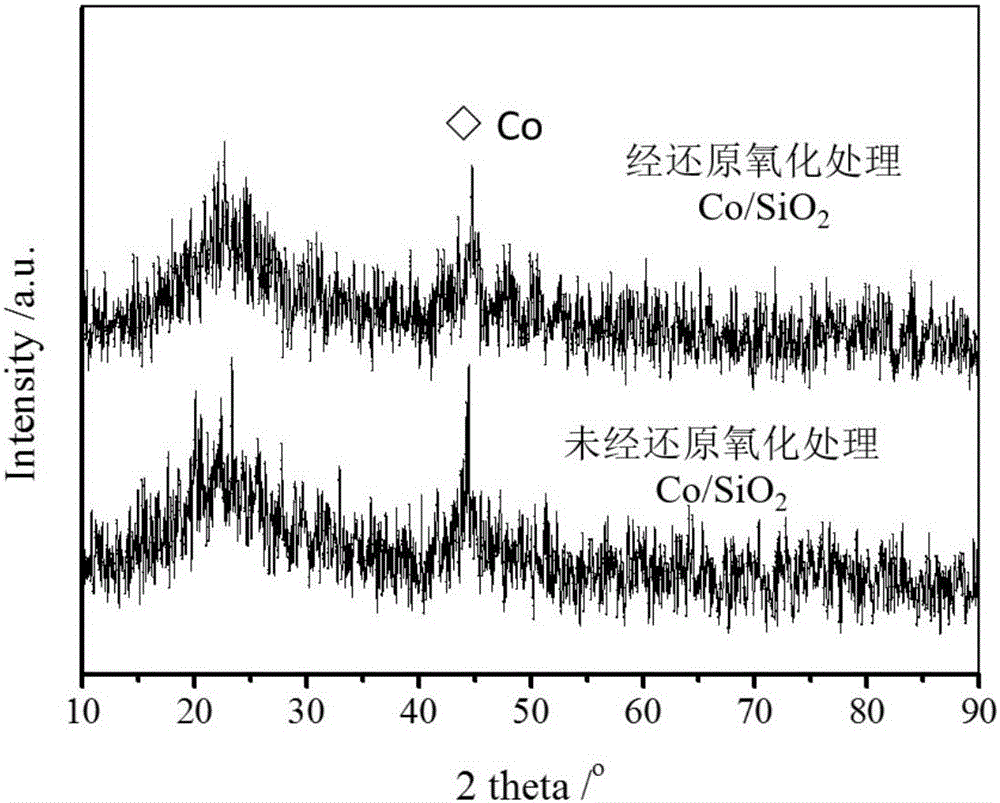

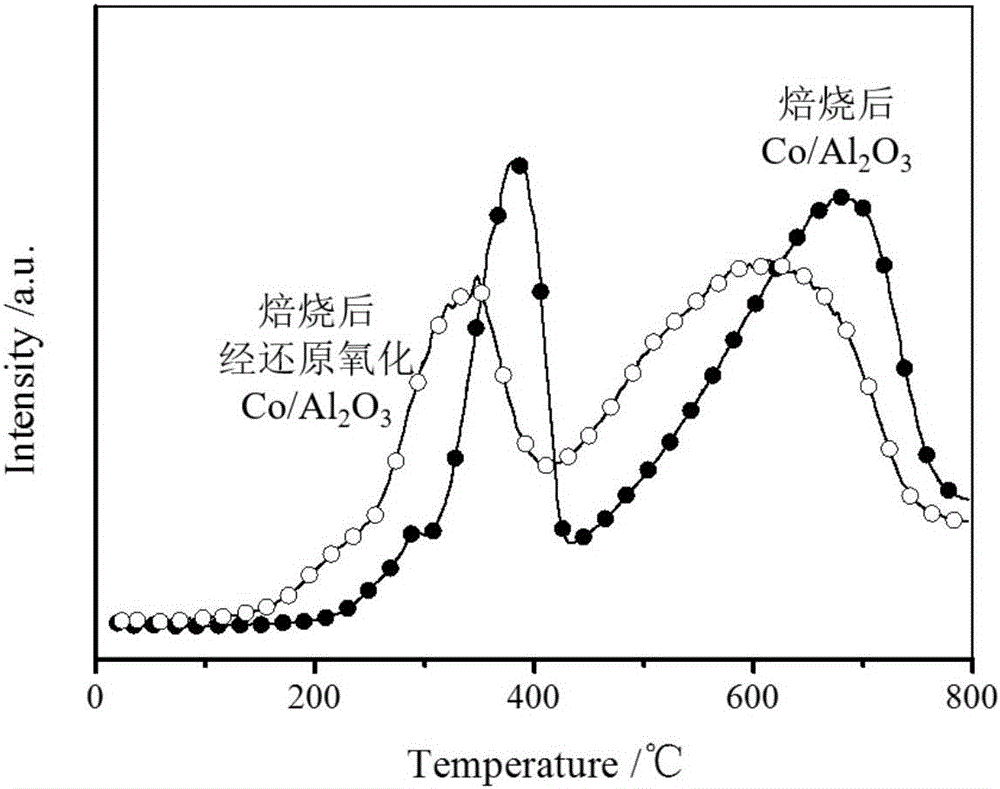

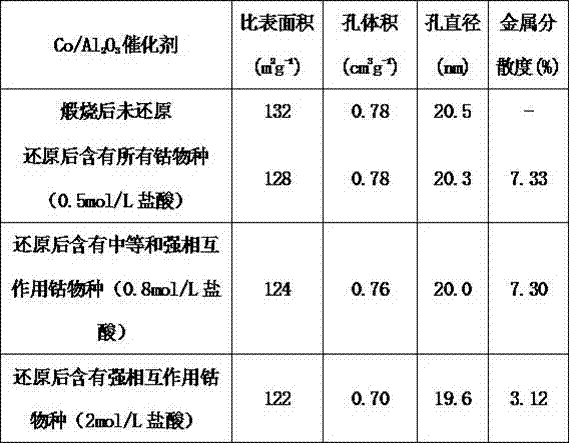

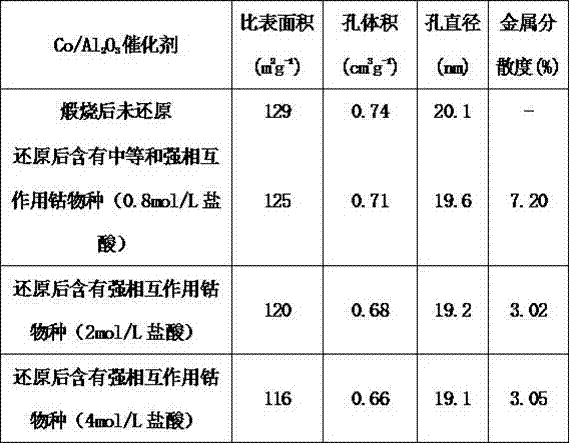

Treatment method for improving activity and dispersity of active components in cobalt-based catalyst for Fischer-Tropsch synthesis

ActiveCN105944727AExtend your lifeImprove conversion rateCatalyst activation/preparationLiquid hydrocarbon mixture productionDispersityHydrogen

The invention discloses a treatment method for improving activity and dispersity of active components in a cobalt-based catalyst for Fischer-Tropsch synthesis. By repeated reduction oxidation or oxidation reduction of calcined cobalt-based catalyst, dispersity of cobalt particles on the surface of a carrier can be improved. Reduction conditions in the method include: a reduction atmosphere is an atmosphere of hydrogen or mixture of hydrogen and other gases, a temperature is 200-750DEG C, a pressure is 0.1-4.0MPa, duration is 0.5-48h, and an air speed is 1000-30000mL / g / h. Oxidation conditions include: an oxidation atmosphere is an atmosphere of air or mixture of oxygen and other gases, a temperature is 200-750DEG C, a pressure is 0.1-3.0MPa, duration is 0.5-48h, and an air speed is 1000-30000mL / g / h. Compared with an untreated catalyst, the treated catalyst has advantages that CO conversion rate and higher hydrocarbon yield can be evidently increased, and catalyst stability can be improved.

Owner:JIANGNAN UNIV

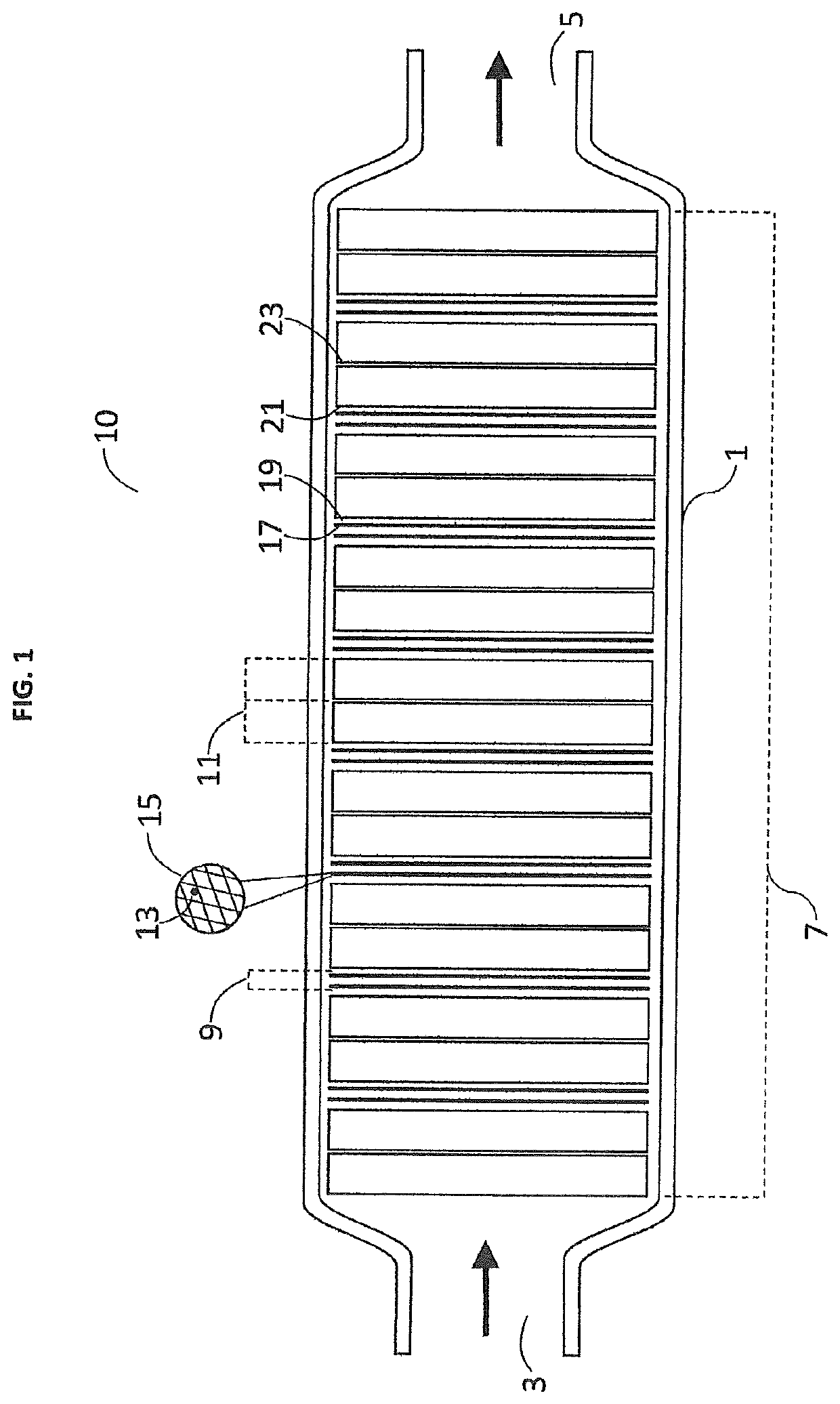

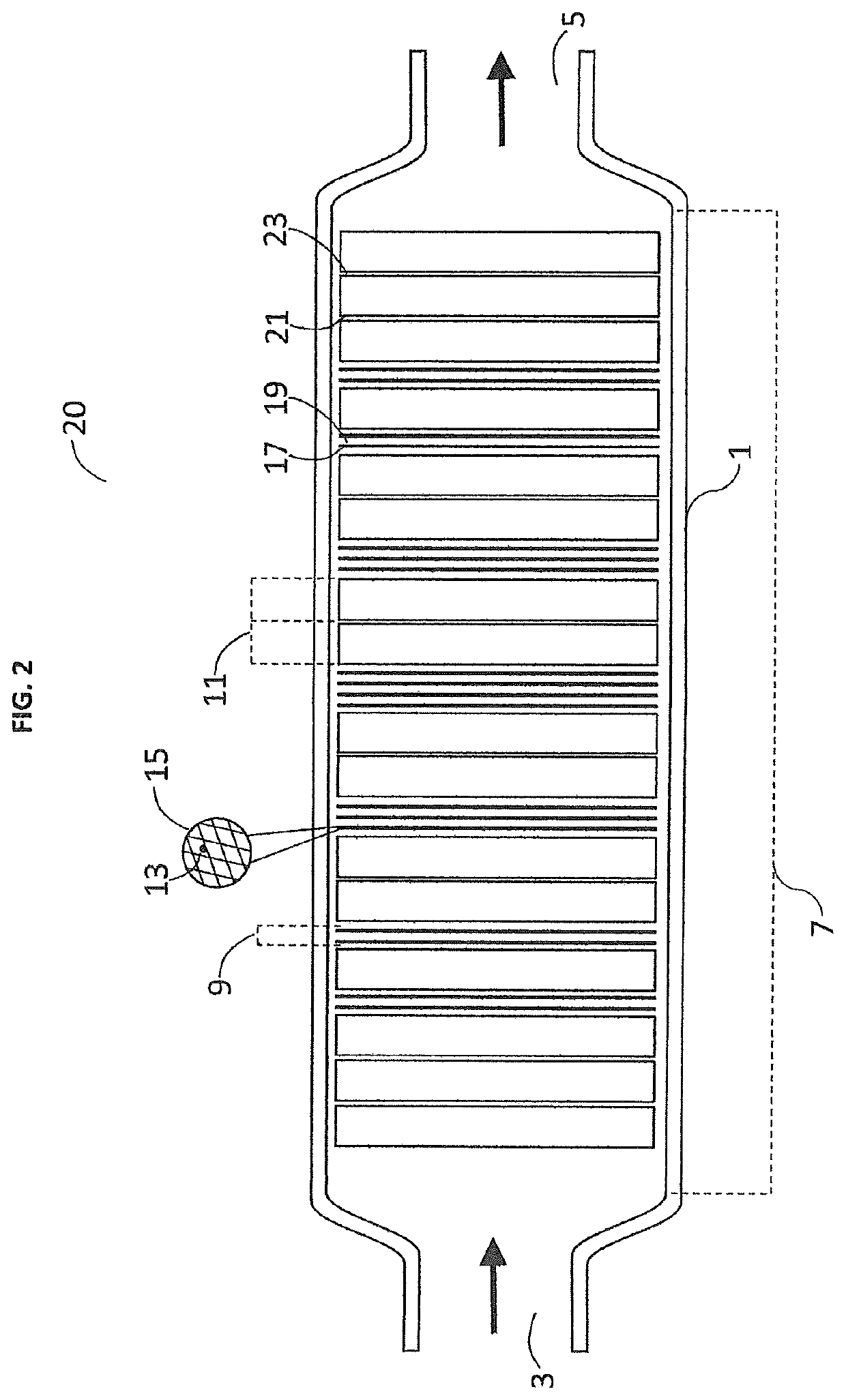

Catalytic reactor

ActiveUS11325070B1Improve catalytic performanceRetarding carbon formationGas treatmentDispersed particle separationPtru catalystChemical reaction

A catalytic reactor constructed of a thermally conductive housing defining a reaction zone having disposed therein: (a) a plurality of catalytic elements, each comprising a porous material having a catalyst supported thereon, and (b) a plurality of heat transfer elements, each comprising a porous, thermally conductive, and essentially catalytically inactive material; wherein the plurality of catalytic elements and the plurality of heat transfer elements are disposed in an alternating configuration within the reaction zone. The catalytic reactor is useful in chemical reactions where heat transfer is a rate limiting step.

Owner:PRECISION COMBUSTION

Stable conversion of alkyl halide to olefins

InactiveUS20160362349A1More catalytically stableAvoid rapid deactivationMolecular sieve catalystsMolecular sieve catalystAlkeneHalide

Disclosed are stable catalysts, and methods for their use, that are capable of producing an olefin from an alkyl halide. The catalysts include a phosphorus-treated silicoalummophosphate (SAPO) having a structure of X / SAPO or X / Z-SAPO, where X includes a non-framework phosphorus and Z is one or more elements from Groups 2A, 3A, IVB, VIB, VIIB, VIII, IB of the Periodic Table, or compounds thereof comprised in the SAPO framework.

Owner:SABIC GLOBAL TECH BV

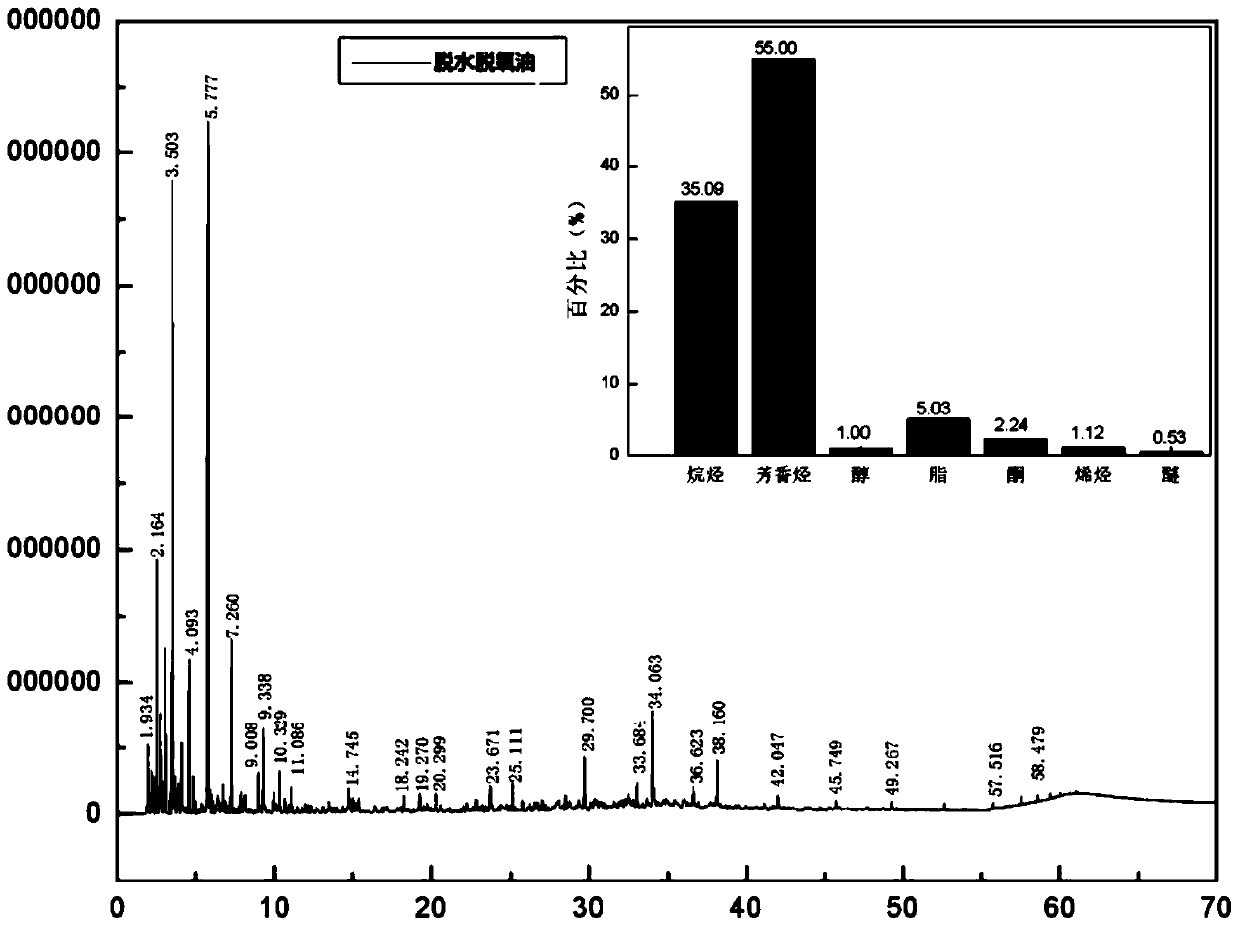

Method for preparing fuel oil from biomass pyrolysis liquid

The invention discloses a method for preparing fuel oil from biomass pyrolysis liquid. Unpretreated biomass pyrolysis liquid is added into a reaction area of a fluidized bed reactor under the protection of a hydrogen donor for hydrotreating. The biomass pyrolysis liquid is hydrogenated and converted into fuel oil in a catalyst full-mixed-flow circulating system fluidized bed reactor formed throughthe combined action of circulating oil, a catalyst, hydrogen and an inner component, one part of the fuel oil serves as circulating oil and returns to the fluidized bed reactor, and the other part ofthe fuel oil is discharged outwards to serve as a product. The obtained fuel oil can be mutually dissolved with fossil fuel oil in any proportion, the sulfur and nitrogen content is very low, and meanwhile, a certain proportion of oxygen is contained, so that complete combustion is facilitated, and the fuel oil is especially suitable for high-altitude areas. Meanwhile, the biomass pyrolysis liquid is prevented from being condensed and coked under heating action, the problem that a catalyst is fast inactivated is solved, coke is prevented from being formed, and the requirement for industrial long-period operation can be met.

Owner:HENAN BUF BIOENERGY CO LTD +2

Catalyst life improvement for the vapor phase manufacture of 1-chloro-3,3,3-trifluoropropene

ActiveUS8293954B2Long catalyst lifeAvoid rapid deactivationPreparation by hydrogen halide split-offCatalyst regeneration/reactivationHydrogen fluorideGas phase

This invention achieves a catalyst life improvement for the catalyzed vapor phase reaction of 1,1,1,3,3-pentachloropropane with hydrogen fluoride to form 1-chloro-3,3,3-trifluoropropene by introducing an oxygen co-feed into the fluorination reactor. By introduction of an oxygen co-feed to the reactor feed, the catalyst life was extended a minimum of two-fold (2×).

Owner:HONEYWELL INT INC

Cobalt-based reforming catalyst and modifying preparation method thereof

InactiveCN106955707AAvoid rapid deactivationRapid inactivationHydrogenCatalyst activation/preparationChemistryCorrosion

The invention provides a cobalt-based reforming catalyst and a modifying preparation method thereof. The modifying preparation method comprises the following steps: pouring Co(NO3)2-6H2O solution into aluminum oxide to soak, thereby obtaining a catalyst precursor; and roasting the obtained catalyst precursor, grinding the catalyst precursor into particles, and reducing the particles under H2 atmosphere, thereby obtaining the cobalt-based reforming catalyst. The obtained cobalt-based reforming catalyst is finally placed into hydrochloric acid solutions with different concentrations, through the selective corrosion of the hydrochloric acid, a cobalt species which are in intermediate mutual action with an aluminum oxide carrier and show relatively high activity in stream reforming reaction are kept, metal cobalt which enables the catalyst to be quickly inactivated as steam reforming reaction easily generates side reaction is inhibited, and the cobalt-based reforming catalyst is prevented from being quickly inactivated, so that stability of the catalyst is improved.

Owner:UNIV OF JINAN

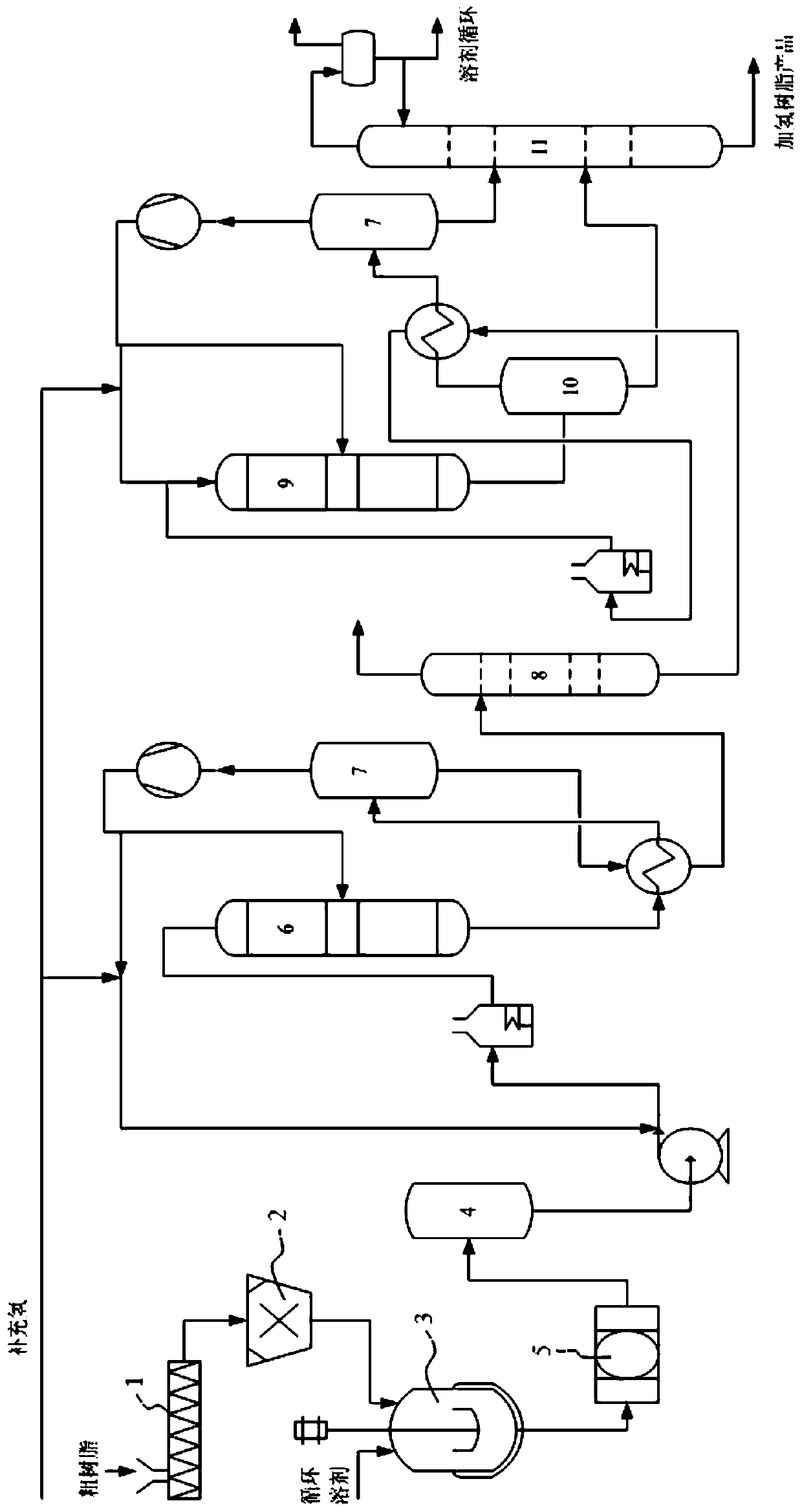

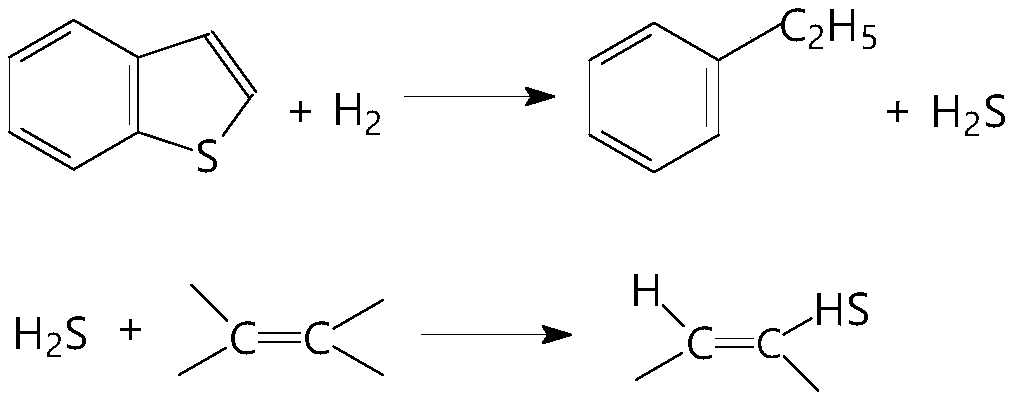

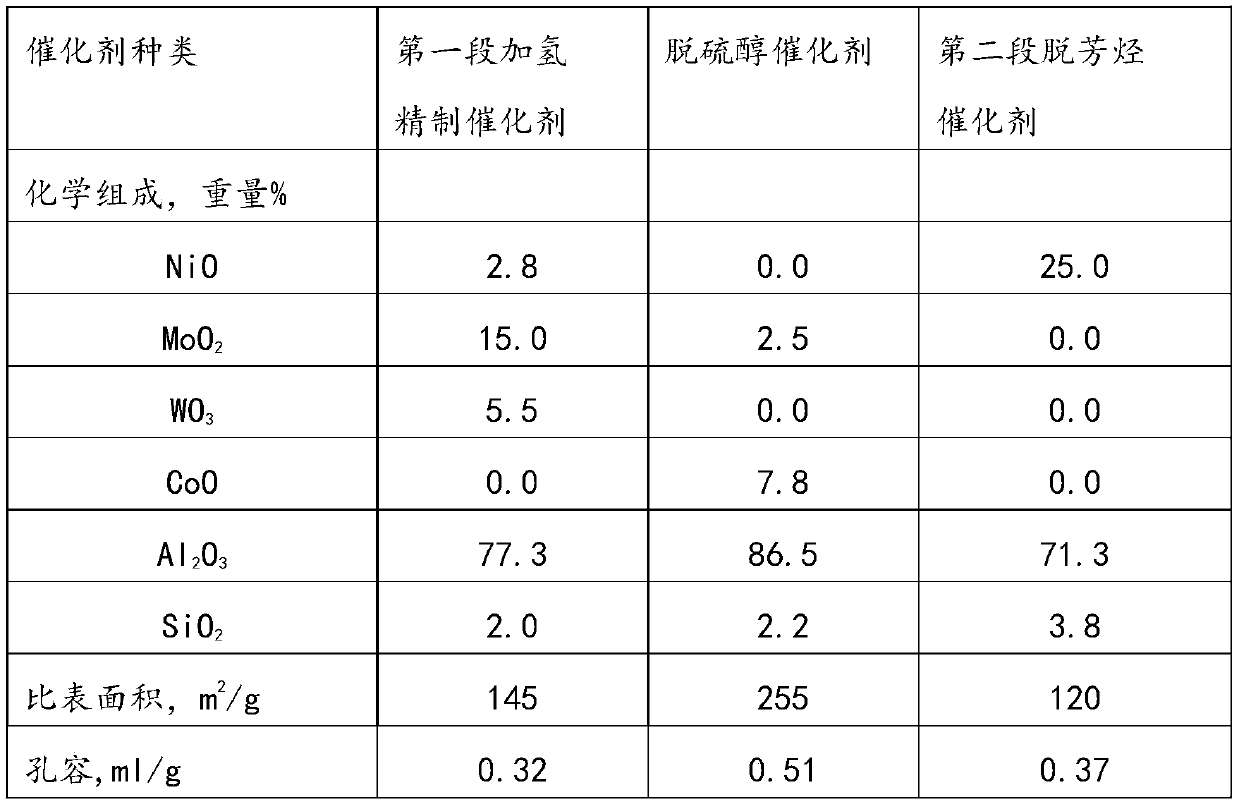

Petroleum resin hydrotreating method

ActiveCN106563461BReduce usageLow running costHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPetroleum productReaction temperature

Owner:BEIJING SIXINTONG SCI & TECH

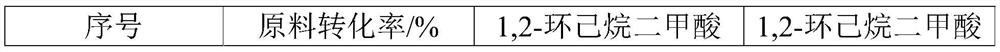

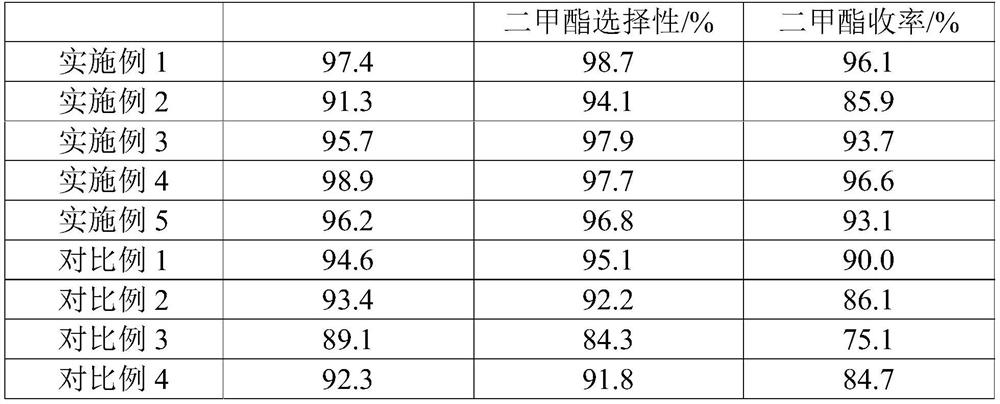

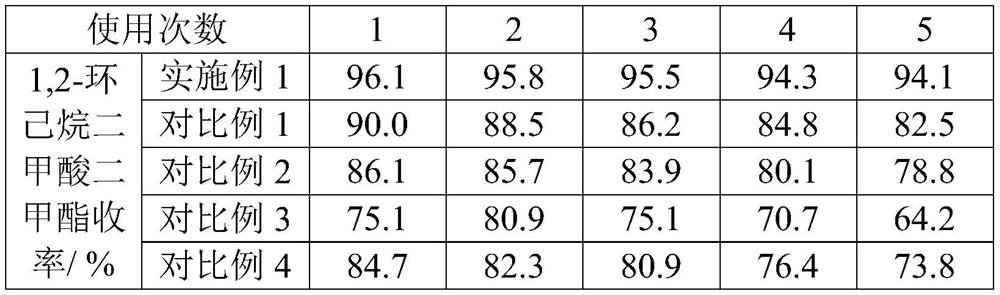

Preparation method and application of monatomic catalyst for synthesizing dimethyl 1,2-cyclohexanedicarboxylate from dimethyl phthalate

PendingCN113680370AStrong acid and alkali resistanceLarge specific surface areaCatalyst carriersMolecular sieve catalystsPtru catalystPhthalic acid

The invention belongs to the field of preparation of catalysts, and particularly relates to a preparation method and application of a monatomic catalyst for synthesizing dimethyl 1,2-cyclohexanedicarboxylate from dimethyl phthalate. Nitrogen-doped carbon nanotubes prepared by an improved chemical vapor deposition method are used as a carrier; and the M / nitrogen-doped carbon nanotube monatomic catalyst (M=Pd, Ni, Ru) is prepared by an impregnation method. The preparation method is simple, and the M / nitrogen-doped carbon nanotube monatomic catalyst has the advantages of large specific surface area, high mechanical strength, small mass transfer limit, more uniform dispersion of metal active components on the surface of the carrier and the like, has high atom utilization rate and longer service life, and is used for hydrogenation synthesis reaction of dimethyl 1,2-cyclohexanedicarboxylate from dimethyl phthalate, and the reaction activity of the catalyst and the selectivity of the dimethyl 1,2-cyclohexanedicarboxylate are obviously improved.

Owner:RUNTAI CHEM TAIXING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com