Efficient biomass conversion method

A biomass and high-efficiency technology, applied in the fields of biofuels, waste fuels, chemical recycling, etc., can solve the problems of waste of resources and insufficient utilization of heat, save energy, prevent waste of resources, and ensure the effect of reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

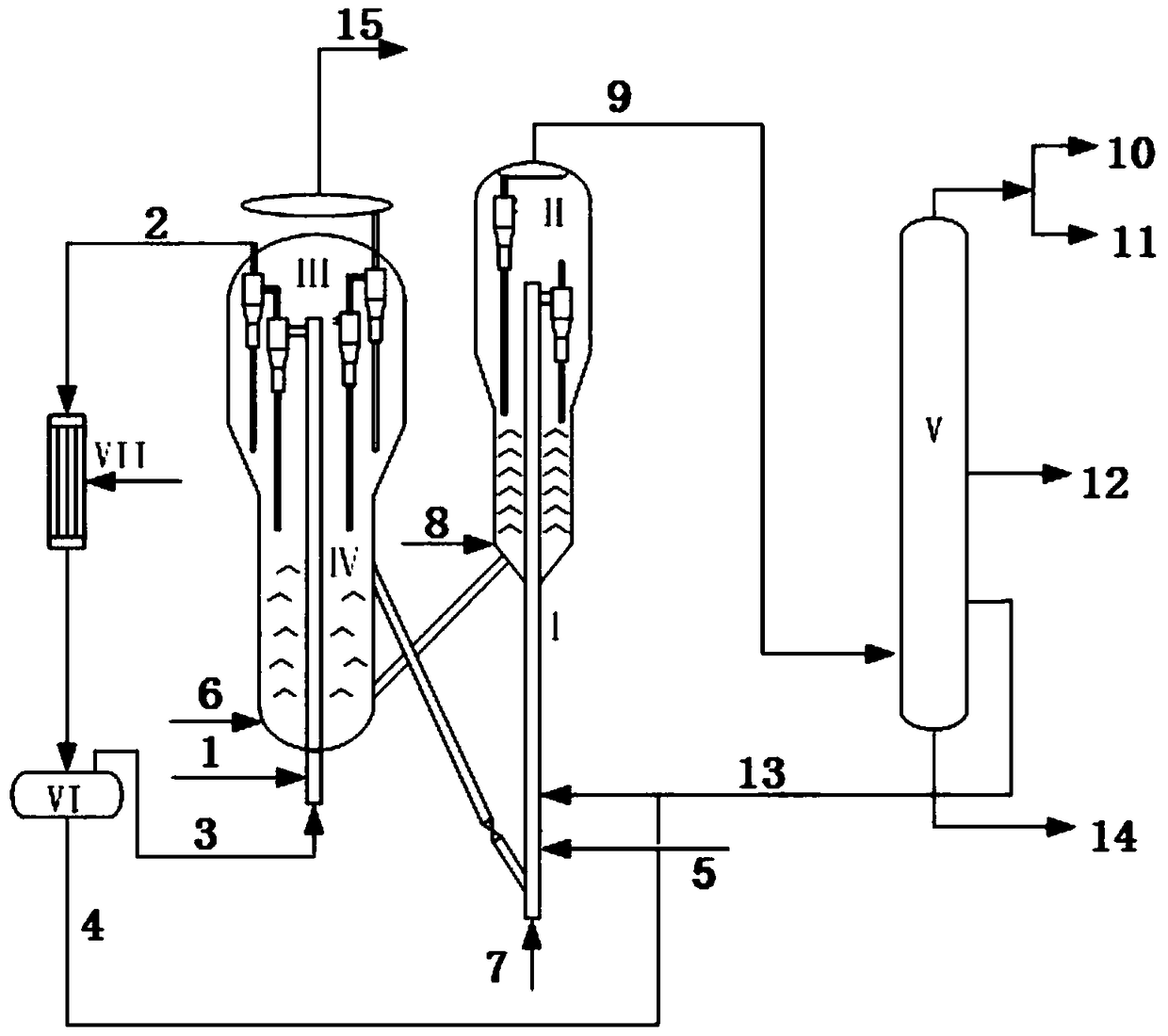

[0039] as attached figure 1 As shown, the equipment used in the present invention includes a riser reactor I, a settler II, a regenerator III, a pyrolysis reactor IV, a fractionation tower V, an oil-gas separation tank VI, and a condenser VII. When used specifically, the embodiment is as follows figure 1 As shown in the process flow: the dried and pulverized biomass raw material 1 enters the bottom of the pyrolysis reactor IV, and the non-condensable gas 3 passed through the bottom of the pyrolysis reactor IV is fluidized and lifted into the interior of the pyrolysis reactor IV. Under the heating of the high-temperature regenerated catalyst and flue gas in III, the pyrolysis reaction is carried out to generate pyrolysis oil gas 2 and biochar. After the pyrolysis oil gas 2 and biochar are separated by the cyclone separator, the biochar enters the regenerator III for combustion to release heat, and the pyrolysis oil gas 2 enters the oil-gas separation tank VII after being conden...

Embodiment 2

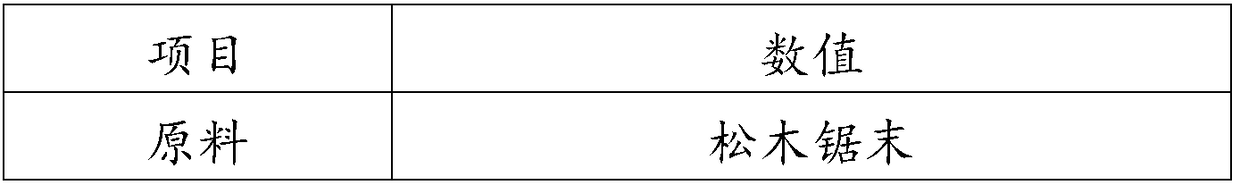

[0048] Adopt the equipment of embodiment 1, take pine wood sawdust as biomass raw material, nitrogen as fluidizing gas and carry out experiment in fixed fluidized bed type pyrolysis reactor:

[0049] (1) After being dried and crushed, the pine wood sawdust is continuously sent to the bottom of the pyrolysis reactor from non-condensable gasification to lift into the pyrolysis reactor for pyrolysis, and the reaction time is 0.5-20s. The outlet temperature of the pyrolysis reactor is 500-650°C , the reaction pressure is 0.1-0.4Mpa, generating pyrolysis gas and pine charcoal;

[0050] (2) The pyrolysis gas generated in step (1) is separated from the pine charcoal, the pine charcoal falls into the regenerator, the pyrolysis gas enters the oil-gas separation tank after being condensed by the condenser, and is separated into pyrolysis oil and non-condensable gas;

[0051] (3) The non-condensable gas generated in step (2) enters the bottom of the pyrolysis reactor together with nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com