Dehydrogenation method for light alkanes

A technology for low-carbon alkanes and dehydrogenation, which is applied in the fields of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., and can solve problems such as the inability to control the depth of sulfidation as required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The dehydrogenation catalyst can be prepared by a conventional method, such as using an impregnation method to support the dehydrogenation active metal, and the auxiliary agent can be introduced during the preparation of the alumina or weakly acidic molecular sieve carrier and / or by an impregnation method.

[0014] The catalyst of the present invention uses alumina or weakly acidic molecular sieve as a carrier, and the dehydrogenation active metal component is generally selected from one or more of platinum, palladium, iridium, rhodium or osmium in the platinum group, and the amount used is calculated as a carrier 0.01%~2% of the weight. The content of Sn is 0.1%~10% of the weight of the carrier in terms of simple substance.

[0015] In the dehydrogenation catalyst based on alumina or weakly acidic molecular sieve of the present invention, the dehydrogenation active metal component can be evenly distributed in the catalyst, preferably the dehydrogenation active metal co...

example 1

[0030] Alumina is used as a carrier. The support was impregnated with 0.01M tin tetrachloride ethanol solution, dried, aged, and calcined at 650°C for 4 hours to obtain alumina pellets containing 0.3wt% Sn.

[0031] The alumina pellets containing 0.3wt% Sn were calcined at 800°C for 3h, the calcined carrier was immersed in an aqueous solution containing chloroplatinic acid for 6h at 70°C, dried at 120°C for 2h, and calcined at 500°C for 4h. Dechlorination in air containing 20v% water vapor at 450°C for 4h. Then at 70 °C with KNO 3 Soaked in aqueous solution for 2h, dried and roasted under the same conditions without reduction. The loading amount of each component in the catalyst is: Pt 0.5wt%, Sn 0.3wt%, K0.5wt%.

[0032] Restore conditions : High-purity hydrogen with a volumetric space velocity of 900h -1 , temperature 500 ° C, reduction time 1h.

[0033] Evaluation conditions : volumetric space velocity 2000 h -1 , the reaction temperature is 550°C, the raw materia...

example 2

[0041] A dehydrogenation catalyst was prepared in the same manner as in Example 1.

[0042] Restore conditions : High-purity hydrogen with a volumetric space velocity of 900 h -1 , temperature 500 ℃, reduction time 1h.

[0043] Evaluation conditions : volume airspeed 2000 h -1 , the reaction temperature is 550°C, the dehydrogenation raw material is a mixture of hydrogen: isobutane with a molar ratio of 1:1, and the content of methyl mercaptan in the dehydrogenation raw material is 5 μmol / mol.

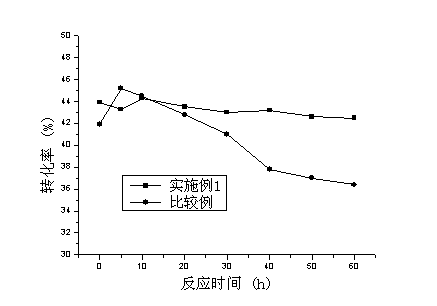

[0044] Evaluation results : The catalyst was continuously evaluated for 60 hours, the isobutane conversion rate was 42.8%, the isobutene selectivity was 97.1%, the conversion rate decreased by 1.8%, the selectivity was basically unchanged, and the carbon deposition amount was only 0.31%, showing good catalytic activity. and stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com