Treatment method for improving activity and dispersity of active components in cobalt-based catalyst for Fischer-Tropsch synthesis

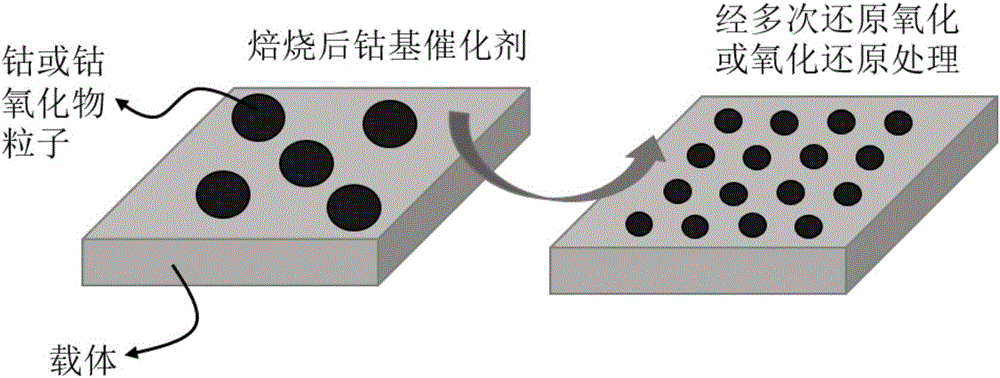

A technology of cobalt-based catalysts and active components, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as redispersion of cobalt particles that are rarely considered, to avoid rapid deactivation, The method is simple and easy, and the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

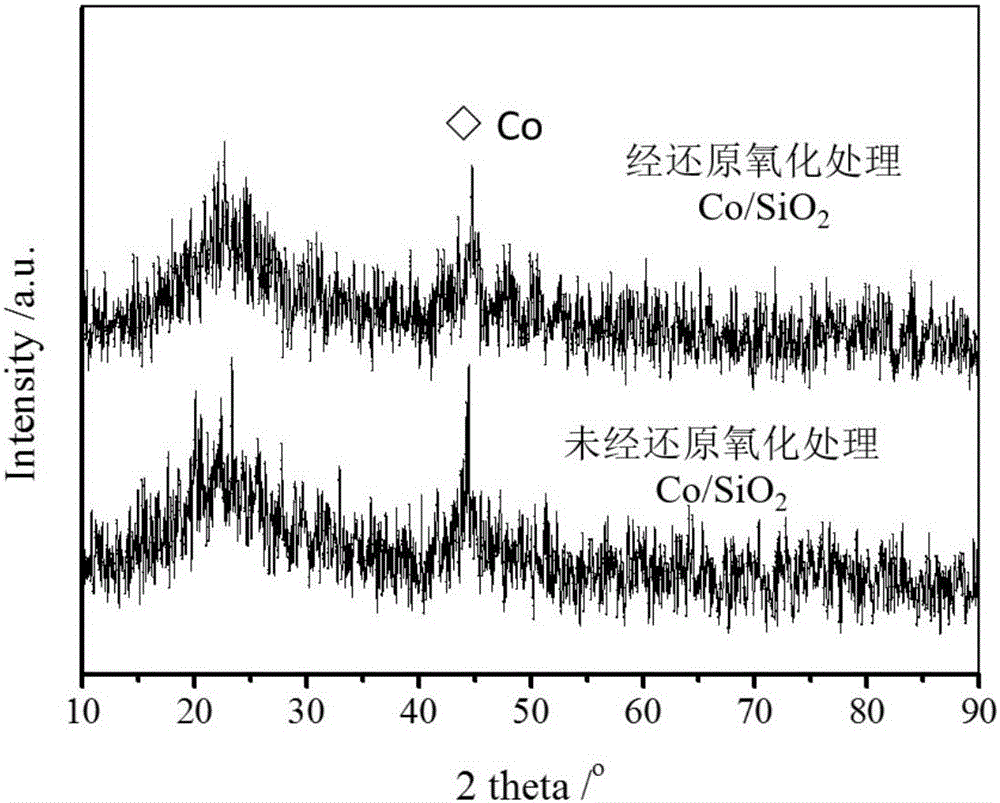

[0018] Take Co(NO 3 ) 2 20wt% Co / SiO prepared as cobalt precursor and prepared by equal volume method 2 Catalyst (calcined at 500°C in air for 5h, 40-60 mesh) 1g, mixed evenly with 2g of quartz sand, filled into a pressurized fixed-bed reactor, and reduced in hydrogen (30mL / min, 0.1MPa) at 500°C for 5h And then lower the temperature to 300°C in air (30mL / min, 0.1MPa) for 5h reduction oxidation cycle, and then reduce the treatment in hydrogen at 300°C for 5h, and finally lower the temperature to 230°C and introduce hydrogen to carbon monoxide with a molar ratio of 2 of synthesis gas, the pressure was adjusted to 1.0MPa, the space velocity was 4500mL / g / h, and the Fischer-Tropsch synthesis reaction was carried out. The reaction results are shown in Table 1. Co / SiO after firing 2 The XRD of the catalyst samples after and without reduction and oxidation treatment can be seen figure 2 .

Embodiment 2

[0020] Take Co(NO 3 ) 2 20wt% Co / SiO prepared as cobalt precursor and prepared by equal volume method 2 Catalyst (calcined at 500°C in air for 5h, 40-60 mesh) 1g, mixed evenly with 2g of quartz sand, filled into a pressurized fixed-bed reactor, and reduced in hydrogen (30mL / min, 0.1MPa) at 500°C for 5h And then lower the temperature to 300°C in air (30mL / min, 0.1MPa) for 5h reduction oxidation cycle twice, then reduce the treatment in hydrogen at 300°C for 5h, and finally lower the temperature to 230°C and introduce hydrogen to carbon monoxide with a molar ratio of 2 of synthesis gas, the pressure was adjusted to 1.0MPa, the space velocity was 4500mL / g / h, and the Fischer-Tropsch synthesis reaction was carried out. The reaction results are shown in Table 1.

Embodiment 3

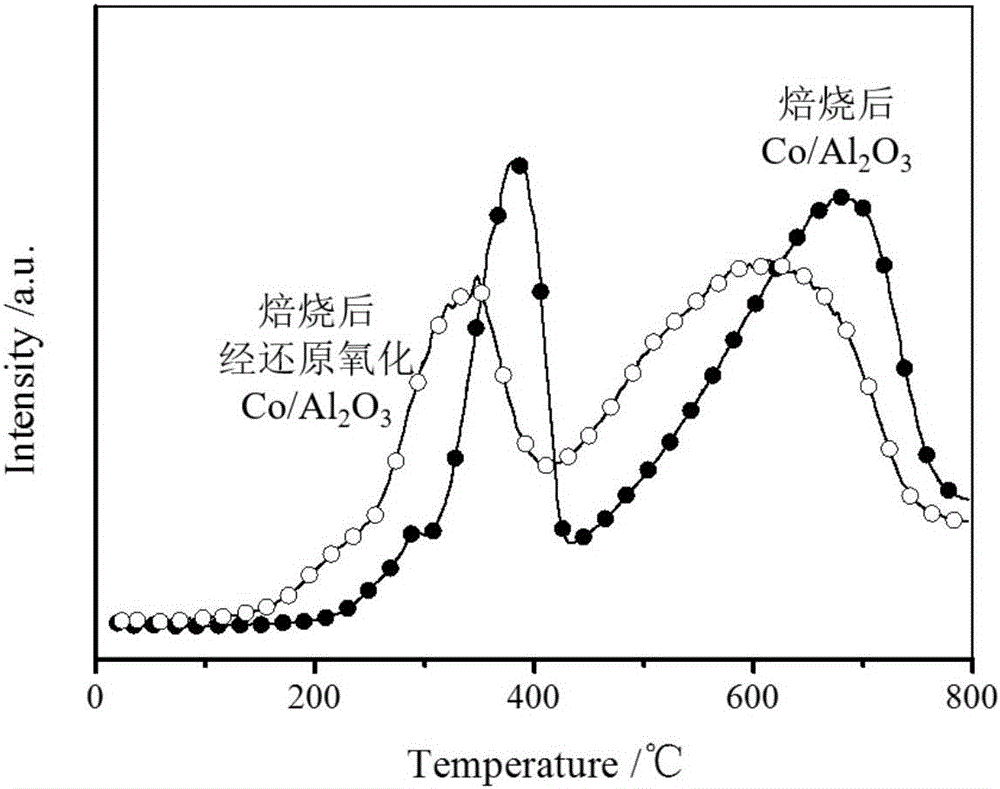

[0022] Take Co(NO 3 ) 2 20wt% Co / Al prepared by equal volume method as cobalt precursor 2 o 3 Catalyst (calcined at 500°C in air for 5h, 40-60 mesh) 1g, mixed evenly with 2g of quartz sand, filled into a pressurized fixed-bed reactor, and reduced in hydrogen (30mL / min, 0.1MPa) at 500°C for 5h And then lower the temperature to 300°C in air (30mL / min, 0.1MPa) for 5h reduction oxidation cycle, and then reduce the treatment in hydrogen at 300°C for 5h, and finally lower the temperature to 230°C and introduce hydrogen to carbon monoxide with a molar ratio of 2 of synthesis gas, the pressure was adjusted to 1.0MPa, the space velocity was 4500mL / g / h, and the Fischer-Tropsch synthesis reaction was carried out. The reaction results are shown in Table 1. Co / Al after firing 2 o 3 H 2 -TPR curve see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com