Method for preparing high-quality fuel oil and/or chemical raw materials from biomass pyrolysis liquid

A technology for biomass pyrolysis and chemical raw materials, which is applied in the field of biomass pyrolysis liquid to prepare high-quality fuel oil and/or chemical raw materials, can solve problems such as catalyst deactivation, and achieve the effect of preventing deactivation and avoiding polymerization and coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

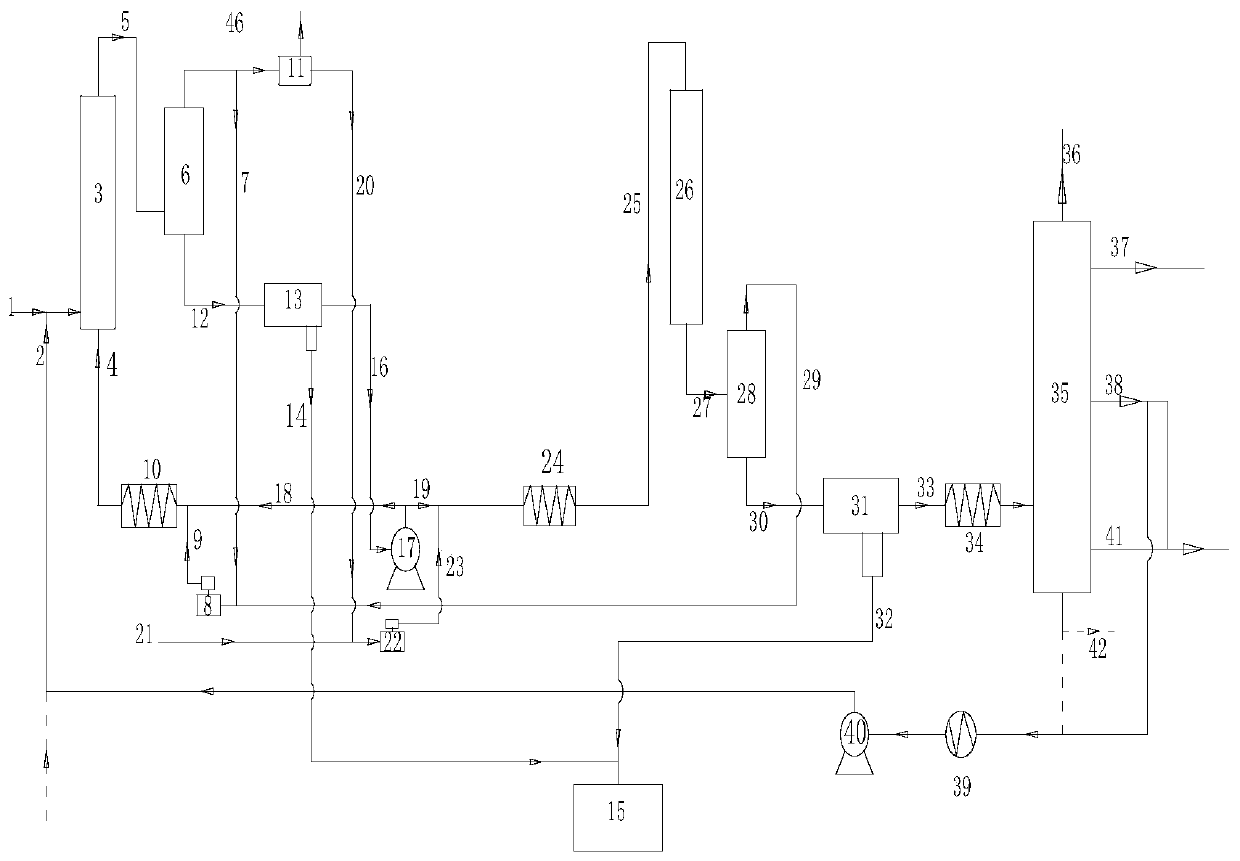

[0061] as attached figure 1 As shown, the biomass pyrolysis solution 1 directly enters the reaction bed area of the single-stage ebullating bed hydrodeoxygenation reactor 3 under the protection and protection of the hydrogen donor 2 at room temperature, and the biomass pyrolysis solution and the hydrogen donor The mass ratio is 1:0.5. The hydrogen donating agent is a petroleum hydrocarbon substance with a boiling point of 200-240°C. The mixed gas 9 formed after circulating hydrogen 7 and the gaseous substance 29 of the hydrocracking reaction is pressurized by the circulating hydrogen compressor 8 is mixed with the circulating oil 18 and heated by the heating furnace 10 to form a gas-liquid mixture 4 from the fluidized bed hydrodeoxygenation reaction The bottom of vessel 3 enters and provides fluidized kinetic energy for the hydrodeoxygenation reaction, and the temperature of the hydrodeoxygenation reaction is controlled at 280° C. by adjusting the temperature of the gas-liq...

Embodiment 2

[0100] In this embodiment, two-stage hydrodeoxygenation reactors in series and two-stage hydrocracking reactors in series are adopted. The hydrogen donor is a high-quality fuel product with a boiling point range of 180-240°C obtained in the present invention. In the first-stage hydrodeoxygenation reaction, the same catalyst Pd / C as in Example 1 is used, and in the second-stage hydrodeoxygenation reaction, the catalyst is NiMo / Al 2 o 3 , the temperature of the first-stage hydrodeoxygenation reaction is controlled at 280°C, and the temperature of the second-stage hydrodeoxygenation reaction is controlled at 330°C. Different catalysts are used in the fixed bed reaction, and the catalyst used in the first stage refining cracking reaction is CoMo / Al 2 o 3 , the reaction temperature is controlled at 180°C, and the liquid hourly volume space velocity is 4.0h -1 ; The catalyst for the second stage hydrocracking reaction is NiW / Al 2 o 3 The dimensions, specifications, catalyst lo...

Embodiment 3

[0116] In this example, a single-stage hydrodeoxygenation reactor is used, the biomass pyrolysis solution is a liquid product obtained by rapid pyrolysis of wheat straw, the hydrogen donor is light diesel oil, and the catalyst used in the hydrodeoxygenation reaction is Ru / C (Carbon-based material loaded with ruthenium), other operating conditions are the same as in Example 1. The hydrocracking reaction adopts a three-stage fixed-bed series connection method. The catalyst used in the first-stage and second-stage hydrocracking reactions is the same as that in Example 2, and other operating conditions are the same as in Example 2. The operating temperature of the third-stage hydrocracking reaction is The temperature is 380°C. The catalyst and other operating conditions of the third stage hydrocracking reaction are the same as those of the second stage hydrocracking reaction.

[0117] After 2000 hours of continuous operation, the properties of the high-quality fuel oil obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com