Cobalt-based reforming catalyst and modifying preparation method thereof

A technology for reforming catalysts and catalysts, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., which can solve the problems of easy carbon deposition and deactivation of catalysts, and achieve the effect of avoiding rapid deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

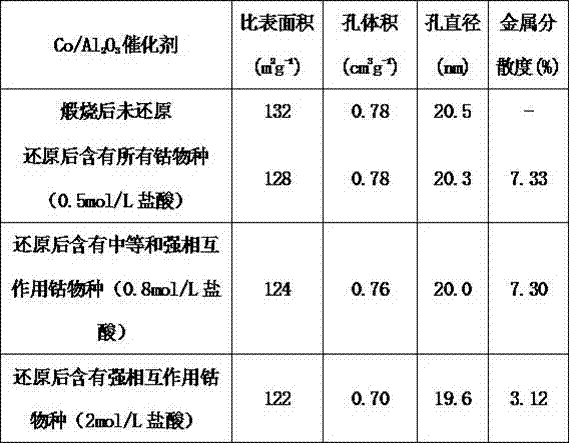

Embodiment 1

[0021] This embodiment provides a method for modifying and preparing a cobalt-based reforming catalyst. The method is carried out according to the following steps:

[0022] S101: Weigh 30g of alumina and stabilize it in air at 923K for 6 hours. The particle size of the weighed alumina is between 0.35 and 0.60mm, and the specific surface area is between 100 and 150m 2 / g between.

[0023] S102: Prepare the catalyst precursor: according to the mass percentage of metal cobalt loaded on the alumina carrier, add water to the prepared cobalt nitrate according to the equal impregnation method to form Co(NO 3 ) 2 •6H 2 O solution, and then the configured Co(NO 3 ) 2 •6H 2 The O solution was quickly poured into the alumina, so that the Co(NO 3 ) 2 •6H 2 O solution and alumina are fully impregnated to obtain a catalyst precursor; wherein, the weight percentage of metal cobalt on the alumina carrier is 10%.

[0024] 103: drying the catalyst precursor at a temperature of 385K for...

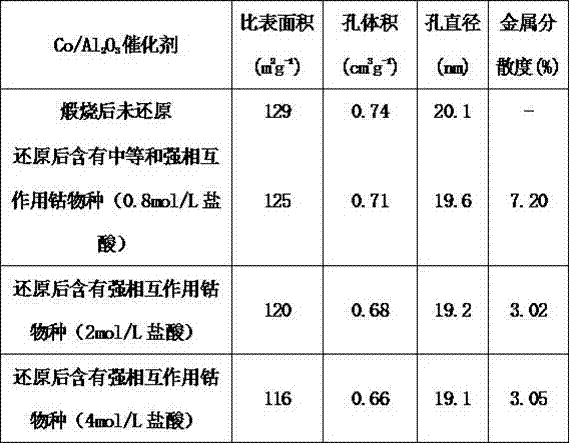

Embodiment 2

[0042] This embodiment provides a method for modifying and preparing a cobalt-based reforming catalyst. The method is carried out according to the following steps:

[0043] S101: Weigh 80g of alumina and stabilize it in air at 923K for 10 hours. The particle size of the weighed alumina is between 0.35 and 0.60mm, and the specific surface area is between 100 and 150m 2 / g between.

[0044] S102: Prepare the catalyst precursor: according to the mass percentage of metal cobalt loaded on the alumina carrier, add water to the prepared cobalt nitrate according to the equal impregnation method to form Co(NO 3 ) 2 •6H 2 O solution, and then the configured Co(NO 3 ) 2 •6H 2 The O solution was quickly poured into the alumina, so that the Co(NO 3 ) 2 •6H 2 O solution and alumina are fully impregnated to obtain a catalyst precursor; wherein, the weight percentage of metal cobalt on the alumina carrier is 25%.

[0045] S103: drying the catalyst precursor at a temperature of 400K f...

Embodiment 3

[0063] This embodiment provides a method for modifying and preparing a cobalt-based reforming catalyst. The method is carried out according to the following steps:

[0064] S101: Weigh 80g of alumina and stabilize it in air at 923K for 8 hours. The particle size of the weighed alumina is between 0.35 and 0.60mm, and the specific surface area is between 100 and 150m 2 / g between.

[0065] S102: Prepare the catalyst precursor: according to the mass percentage of metal cobalt loaded on the alumina carrier, add water to the prepared cobalt nitrate according to the equal impregnation method to form Co(NO 3 ) 2 •6H 2 O solution, and then the configured Co(NO 3 ) 2 •6H 2 The O solution was quickly poured into the alumina, so that the Co(NO 3 ) 2 •6H 2 O solution and alumina are fully impregnated to obtain a catalyst precursor; wherein, the weight percentage of metal cobalt loaded on the alumina carrier is 20%.

[0066] S103: drying the catalyst precursor at a temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com