Method for preparing fuel oil from biomass pyrolysis liquid

A biomass pyrolysis and biomass technology, which is applied in the field of renewable energy and biomass energy, can solve problems such as catalyst deactivation, achieve low operating costs, low hydrogen consumption, and avoid polymerization and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

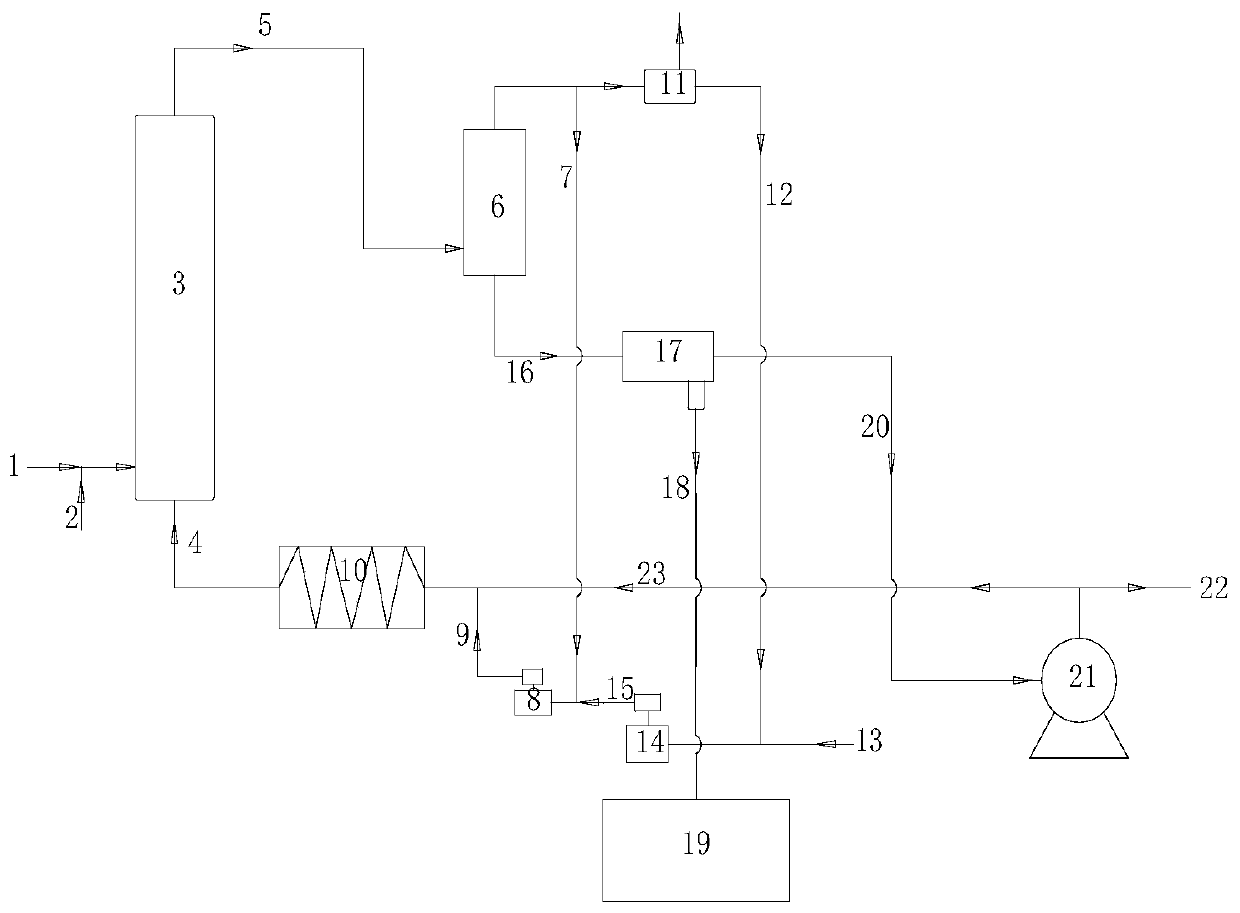

[0056] as attached figure 1 As shown, the biomass pyrolysis solution 1 directly enters the reaction bed area of the single-stage ebullating bed hydroprocessing reactor 3 under the protection of the hydrogen donor 2 at room temperature, and the mass ratio of the biomass pyrolysis solution to the hydrogen donor is It is 1:0.5. In this embodiment, the hydrogen donor is middle distillate oil with a boiling point range of 180-220°C. The mixed gas 9 formed after circulating hydrogen 7 and mixed new hydrogen 15 is pressurized by circulating hydrogen compressor 8 is mixed with circulating oil 23 and heated by heating furnace 10 to form a gas-liquid mixture 4 enters from the bottom of ebullating bed reactor 3 and is added The hydroprocessing reaction provides kinetic energy for fluidization, and the temperature of the hydroprocessing reaction is controlled at 280° C. by adjusting the temperature of the gas-liquid mixture 4 . The biomass pyrolysis liquid is rapidly heated, mixed an...

Embodiment 2

[0079] In this example, two-stage hydrotreating reactors are connected in series. For the process, see Figure 5 . The biomass pyrolysis solution is a liquid product obtained by slow pyrolysis of a mixture of poplar branches and bark, and the hydrogen donor is a substance with a boiling point range of 180-240°C obtained by hydrogenation of coal tar. It adopts the same catalyst Pd / C as in Example 1 in the first-stage hydroprocessing reaction, and the catalyst used in the second-stage hydroprocessing reaction is NiMo / Al 2 o 3 , the temperature of the first-stage hydroprocessing reaction is controlled at 280°C, and the temperature of the second-stage hydrotreating reaction is controlled at 330°C. Other operating conditions and process flow are the same as in Example 1, except that the heavy oil 24 is mixed with the first-stage ebullated-bed reaction product 25 and enters the second-stage ebullated-bed reactor 27 through a heating furnace 26 . The fuel properties obtained after...

Embodiment 3

[0086] In this embodiment, a single-stage ebullating bed hydrotreating reactor will be used. For the process, see figure 1 , the biomass pyrolysis solution is the liquid product obtained in the carbonization process of corn stalks, the catalyst is CoMo / C, the reaction temperature is 350°C, and the mass ratio of the biomass pyrolysis solution to the hydrogen donor is 1:2, 2 :1 and 4:1, other operating conditions are identical with embodiment one. The hydrogen-donating agent in this embodiment is a hydrocarbon substance obtained by further hydrocracking the deoxygenated fuel oil obtained in the present invention, and its boiling point range is 180-240°C. The fuel properties obtained after 2000 hours of continuous operation are shown in Table 6.

[0087] Table 6 Comparison of properties of fuel oil produced by hydrotreating under different ratios of biomass pyrolysis liquid and hydrogen donor

[0088]

[0089]

[0090] It can be seen from the results that as the concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com