Production method of high-bioctyl-value diesel oil by coal liquification

A technology for producing high cetane and coal direct liquefied oil, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, etc., can solve the problems affecting the start-up period and deactivation of hydrogenation upgrading catalysts, etc., so as to prolong the start-up period and prevent Rapid inactivation and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

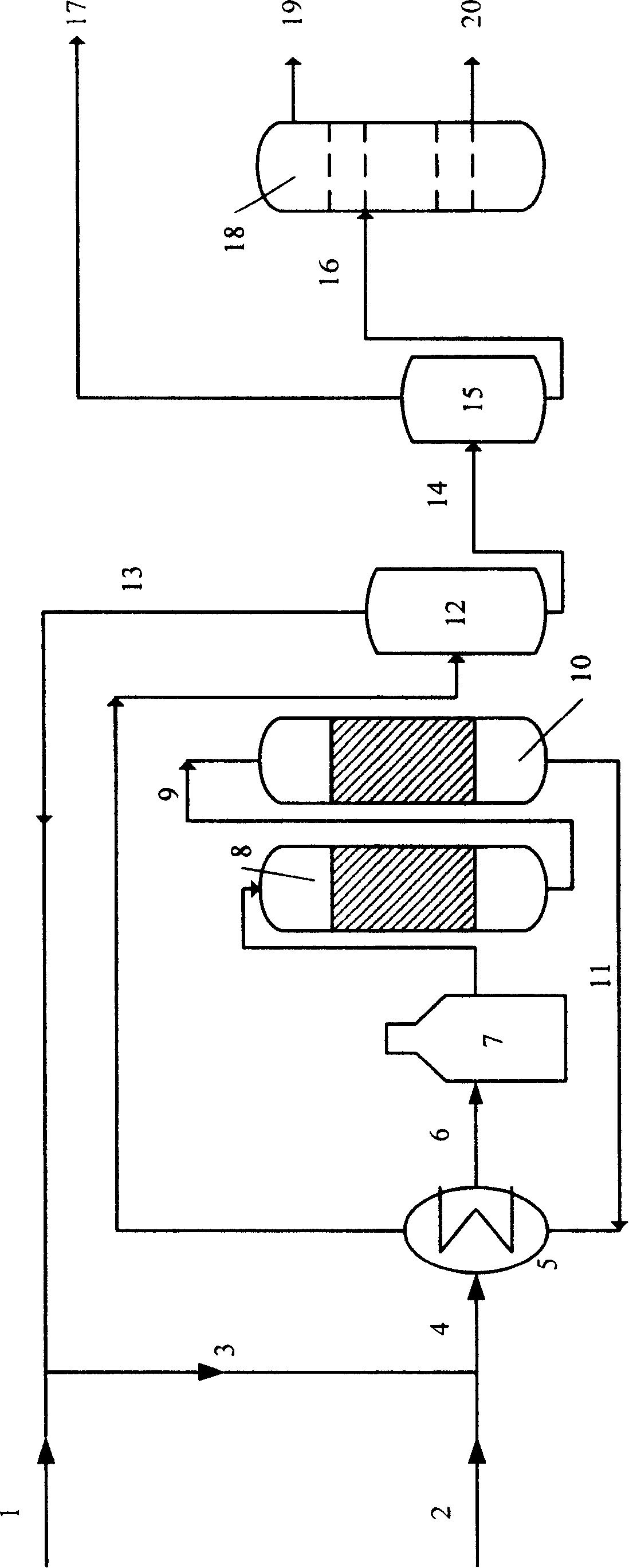

Image

Examples

Embodiment 1

[0030] The test raw material is diesel fraction A stabilized by direct coal liquefied oil hydrogenation. Hydrogen upgrading catalyst RIC-1 contact reaction. The process conditions and product diesel fraction properties of deep hydro-upgrading technology are listed in Table 2 and Table 3, respectively. It can be seen from the table that the density of hydrogenated stable coal direct liquefied oil diesel fraction is not too high, and the dry point is 342°C. The process conditions adopted by deep hydrogenation upgrading technology are relatively moderate, and the sulfur and nitrogen content of the product diesel fraction are very low. , the content of aromatics is low, and it has reached the index requirements of Class III diesel in the "World Fuel Specification", and its cetane number exceeds 45, which is a qualified diesel product. The hydrogenation upgrading catalyst is RIC-1 and the operation period is 36 months.

Embodiment 2

[0032] The test raw material is hydrogenated stabilized coal direct liquefied oil diesel fraction B, and the properties of the raw oil are listed in Table 1. The deep hydro-upgrading technology is a single-stage double-agent one-pass process, that is, the raw material oil and hydrogen are sequentially contacted and reacted with the hydrofining catalyst RN-10 and the hydro-upgrading catalyst RIC-1. The process conditions and diesel product properties of deep hydrogenation technology are listed in Table 2 and Table 3, respectively. It can be seen from the table that the diesel fraction of direct coal liquefaction oil has a high density and high impurity content, and the process conditions for deep hydrogenation and upgrading are relatively harsh. The content of sulfur and nitrogen in the product diesel fraction is very low, and the content of aromatics is low, reaching " According to the index requirements of Class III diesel oil in the World Fuel Specification, a cetane number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com