Aromatization catalyst and applications thereof

A catalyst and aromatization technology, applied in physical/chemical process catalysts, molecular sieve catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of low yield of mixed xylenes, benzene and mixed xylenes Low yield and other problems, to achieve the effect of low reaction temperature, increased yield, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

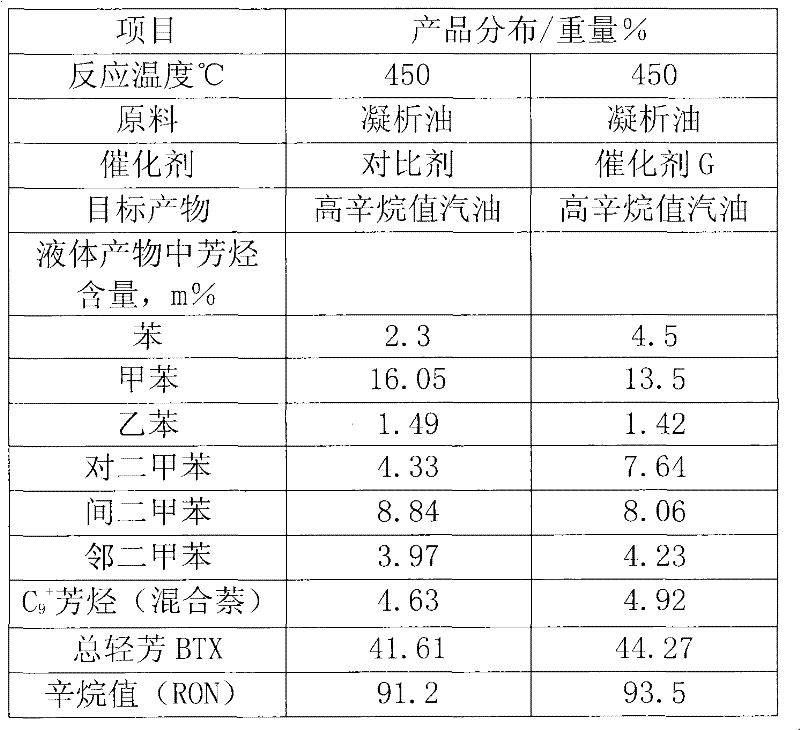

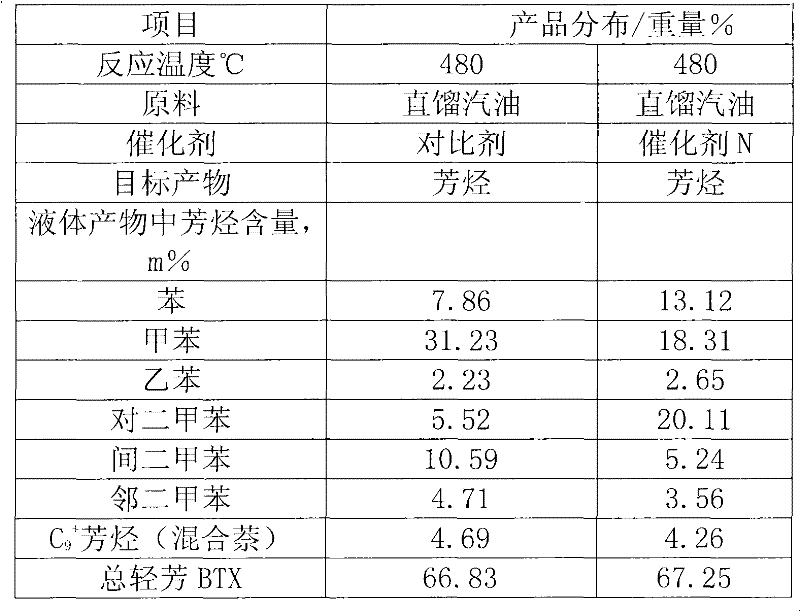

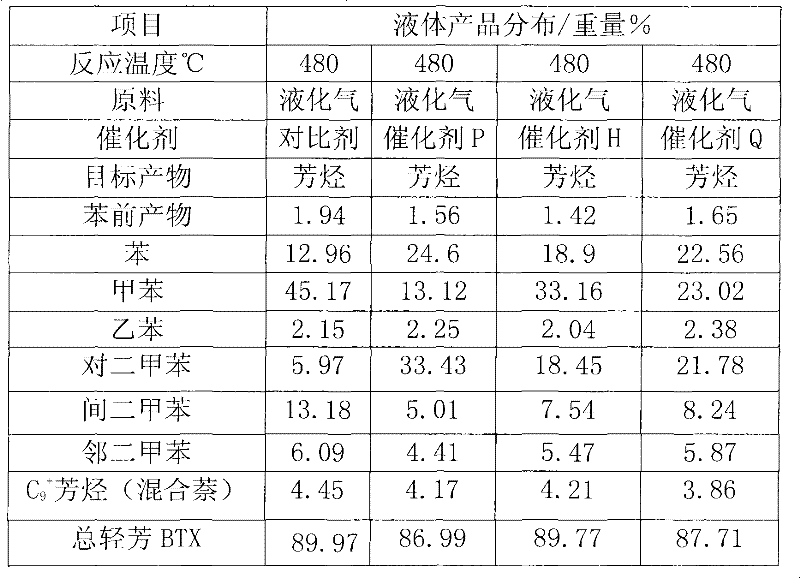

Examples

Embodiment 1

[0034] Take SiO 2 / Al 2 o 3 500 grams of HZSM-5 molecular sieve with a molar ratio of 38, gradually poured into 500 milliliters of zinc nitrate solution containing 15% zinc in batches, mixed and stirred for one hour, dried at 120 degrees for 4 hours, and roasted at 550 degrees for 6 hours , cooled and ground to obtain catalyst active component A1 for use.

Embodiment 2

[0036] Take SiO 2 / Al 2 o 3 500 grams of HZSM-5 molecular sieve with a molar ratio of 38, gradually poured into 500 milliliters of zinc nitrate solution containing 10% zinc in batches, mixed and stirred for one hour, dried at 120 degrees for 4 hours, and roasted at 550 degrees for 6 hours , cooled and ground to obtain catalyst active component A2 for use.

Embodiment 3

[0038] Take SiO 2 / Al 2 o 3 500 grams of HZSM-5 molecular sieve with a molar ratio of 38, gradually poured into 500 milliliters of zinc nitrate solution containing 5% zinc in batches, mixed and stirred for one hour, dried at 120 degrees for 4 hours, and roasted at 550 degrees for 6 hours , cooled and ground to obtain catalyst active component A3 for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com