Method for hydrogenation conversion of naphthenic hydrocarbon

A technology for hydrotransformation and naphthenic hydrocarbons, which is applied in chemical instruments and methods, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of poor selectivity and low cyclohexane conversion activity, and achieves reduction of strong acid centers and cracking options. The effect of reducing carbon deposition reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] SiO 2 / Al 2 o 3 25 mordenite 195g with γ-Al 2 o 3 Mix 107.1g evenly, then add dilute nitric acid and safflower powder, knead evenly, extrude into strips, roast to make a carrier, cut into pellets and place in an impregnation container. The metal precursor iridium chloride was dissolved in water, mixed evenly, impregnated with the surface of the carrier, dried at 120°C for 4 hours, and calcined at 500°C for 3 hours to prepare the catalyst HC-5.

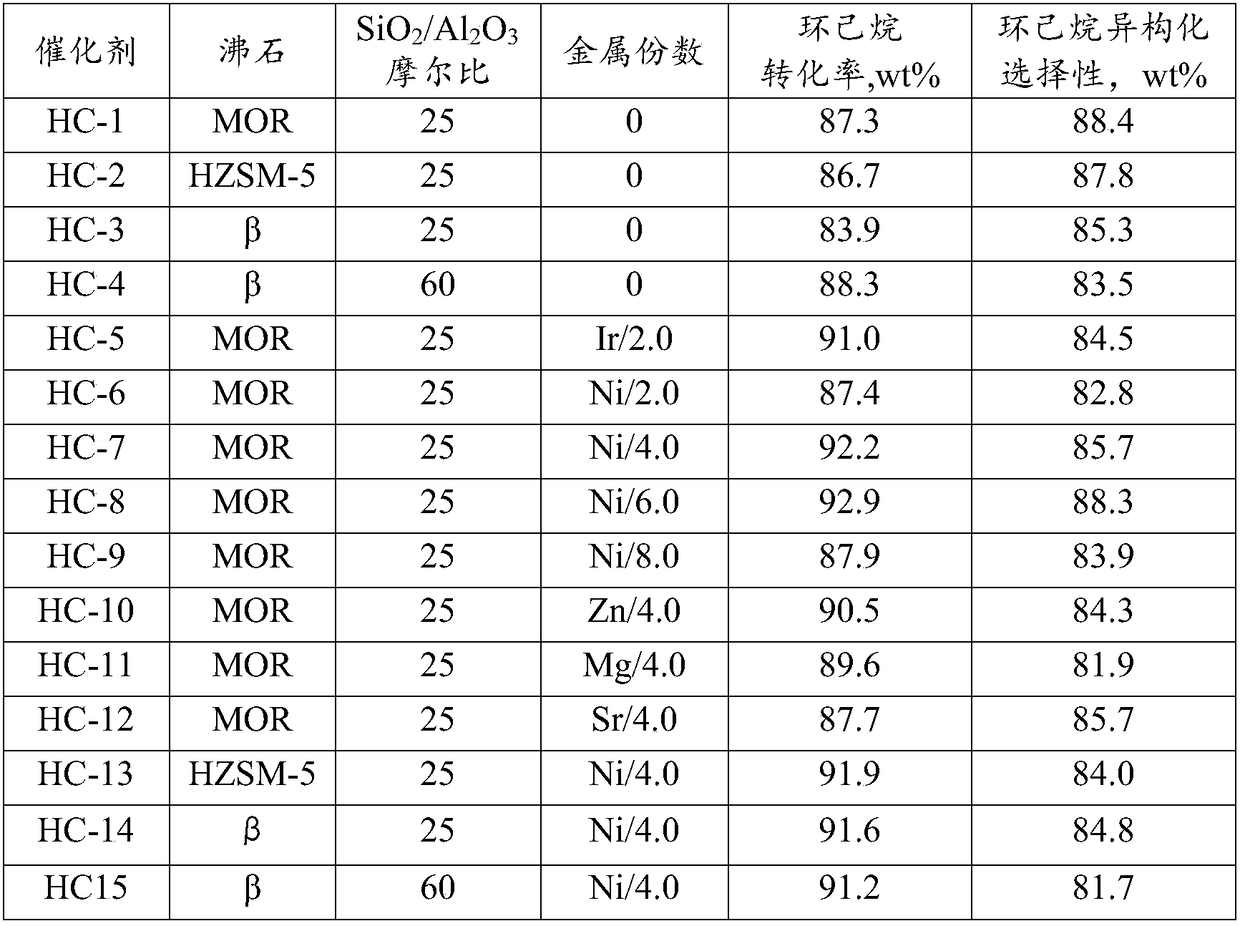

[0034] In a fixed-bed reactor, install 20 grams of catalyst HC-5, feed hydrogen, heat up to 400°C, purging for two hours for reduction activation, the reaction temperature is 400°C, the pressure is 3MPa, according to WHSV=2.5h -1 Working condition feed, hydrogen hydrocarbon molecular ratio 3.0. Raw material cyclohexane. The catalyst reaction performance results are shown in Table 1. The catalyst reaction remained stable for 300 hours.

Embodiment 2

[0036] SiO 2 / Al 2 o 3 25 mordenite 195g with γ-Al 2 o 3Mix 107.1g evenly, then add dilute nitric acid and safflower powder, knead evenly, extrude into strips, roast to make a carrier, cut into pellets and place in an impregnation container. The metal precursor nickel nitrate was dissolved in water, mixed evenly, impregnated with the surface of the carrier, dried at 120°C for 4 hours, and calcined at 500°C for 3 hours to prepare the catalyst HC-6.

[0037] In a fixed-bed reactor, install 20 grams of catalyst HC-6, feed hydrogen, heat up to 400°C, purging for two hours for reduction activation, the reaction temperature is 400°C, the pressure is 3MPa, according to WHSV=2.5h -1 Working condition feed, hydrogen hydrocarbon molecular ratio 3.0. Raw material cyclohexane. The catalyst reaction performance results are shown in Table 1. The catalyst reaction remained stable for 300 hours.

Embodiment 3

[0039] SiO 2 / Al 2 o 3 25 mordenite 195g with γ-Al 2 o 3 Mix 107.1g evenly, then add dilute nitric acid and safflower powder, knead evenly, extrude into strips, roast to make a carrier, cut into pellets and place in an impregnation container. The metal precursor nickel nitrate was dissolved in water, mixed evenly, impregnated with the surface of the carrier, dried at 120°C for 4 hours, and calcined at 500°C for 3 hours to prepare the catalyst HC-7.

[0040] In a fixed-bed reactor, install 20 grams of catalyst HC-7, feed hydrogen, heat up to 400°C, purging for two hours for reduction activation, the reaction temperature is 400°C, the pressure is 3MPa, according to WHSV=2.5h -1 Working condition feed, hydrogen hydrocarbon molecular ratio 3.0. Raw material cyclohexane. The catalyst reaction performance results are shown in Table 1. The catalyst reaction remained stable for 300 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com