A modified molecular sieve catalyst for ethanol dehydration to ethylene and its application

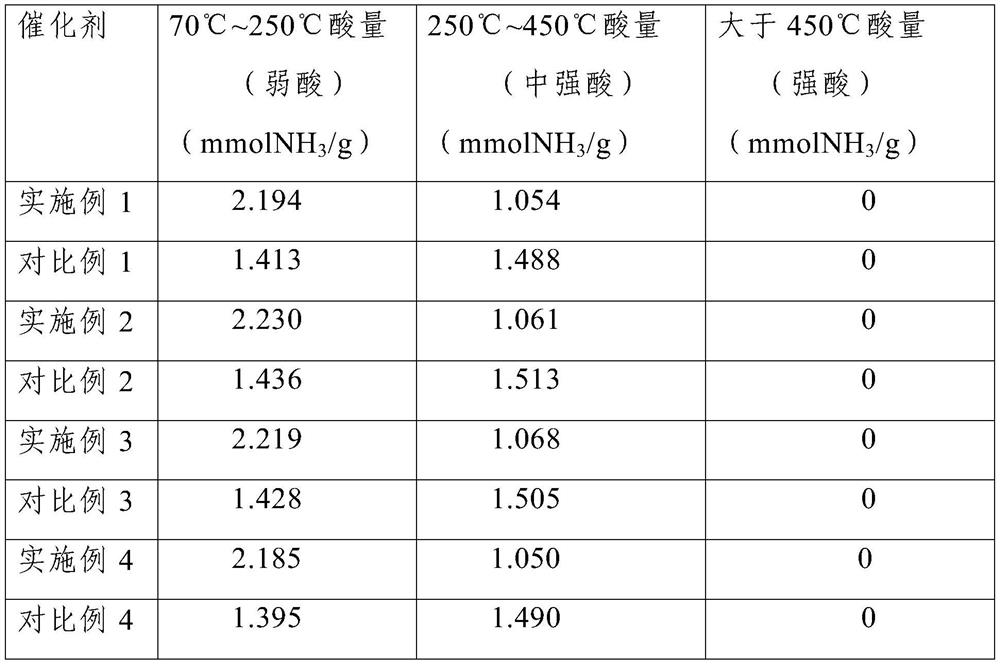

An ethanol dehydration and molecular sieve technology, which is applied in molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of high preparation cost, high energy consumption and complex modification process of modified catalysts, and avoid ethylene The effect of reducing selectivity, reducing the amount of medium and strong acids, and increasing the amount of weak acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The modified molecular sieve catalyst of the present embodiment is prepared by the following method:

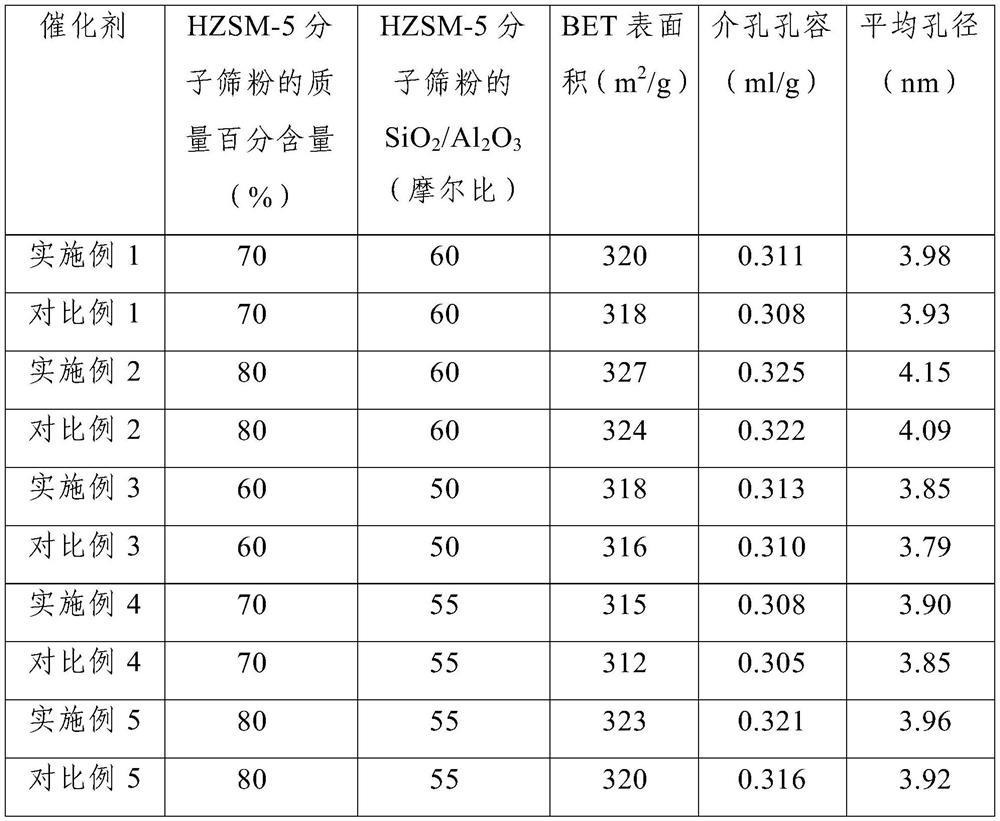

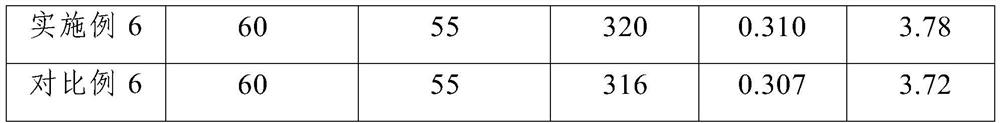

[0032] Step 1. Mix 70.0g HZSM-5 molecular sieve powder, 43.0g macroporous pseudo-boehmite powder and 3.5g scallop powder for 20 minutes to obtain a mixture, and then add 40.2mL of carboxylate with a mass concentration of 0.5% to the mixture. The sodium methylcellulose aqueous solution was mixed uniformly and rolled for 40 minutes, and then extruded into a cylindrical catalyst with a diameter of 2.0 mm on an extruder, and the cylindrical catalyst was placed in an oven and dried at a temperature of 110 ° C for 2 hours. , obtained unmodified bar-shaped molecular sieve catalyst after natural cooling; the average particle size of the HZSM-5 molecular sieve powder is 0.5 μm, the molar ratio of silicon to aluminum is 60, and the specific surface area is 210m 2 / g, the pore volume is 0.18mL / g, Na 2 The mass percentage of O is 0.05%; the specific surface area of the macropor...

Embodiment 2

[0040] The modified molecular sieve catalyst of the present embodiment is prepared by the following method:

[0041] Step 1. Mix 80.0g HZSM-5 molecular sieve powder, 28.6g macroporous pseudo-boehmite powder and 3.4g scallop powder for 20 minutes to obtain a mixture, and then add 39.8mL of carboxylate with a mass concentration of 0.5% to the mixture. The sodium methylcellulose aqueous solution was mixed uniformly and rolled for 40 minutes, and then extruded into a cylindrical catalyst with a diameter of 2.0 mm on an extruder, and the cylindrical catalyst was placed in an oven and dried at a temperature of 110 ° C for 2 hours , obtained unmodified bar-shaped molecular sieve catalyst after natural cooling; the average particle size of the HZSM-5 molecular sieve powder is 0.5 μm, the molar ratio of silicon to aluminum is 60, and the specific surface area is 210m 2 / g, the pore volume is 0.18mL / g, Na 2 The mass percentage of O is 0.05%; the specific surface area of the macroporo...

Embodiment 3

[0049] The modified molecular sieve catalyst of the present embodiment is prepared by the following method:

[0050] Step 1. Mix 60.0g of HZSM-5 molecular sieve powder, 57.1g of macroporous pseudoboehmite powder and 3.7g of turnip powder for 20 minutes to obtain a mixture, and then add 44.1mL of carboxylate with a mass concentration of 0.5% to the mixture. The sodium methylcellulose aqueous solution was mixed uniformly and rolled for 40 minutes, and then extruded into a cylindrical catalyst with a diameter of 2.0 mm on an extruder, and the cylindrical catalyst was placed in an oven and dried for 3 hours at a temperature of 100 ° C. , obtained unmodified bar-shaped molecular sieve catalyst after natural cooling; the average particle size of the HZSM-5 molecular sieve powder is 0.5 μm, the molar ratio of silicon to aluminum is 50, and the specific surface area is 210m 2 / g, the pore volume is 0.18mL / g, Na 2 The mass percentage of O is 0.05%; the specific surface area of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com