Patents

Literature

195results about How to "Avoid selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

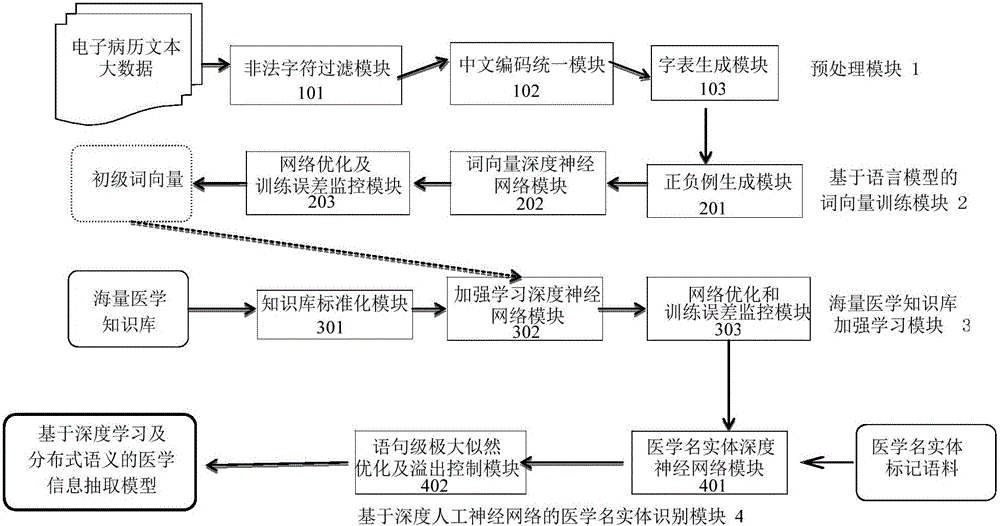

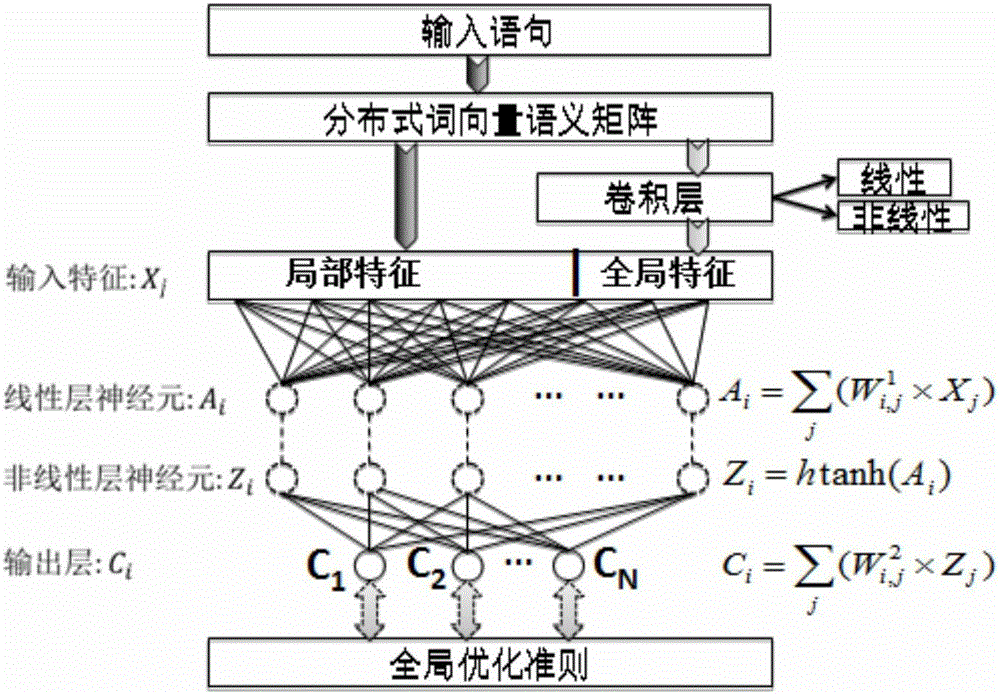

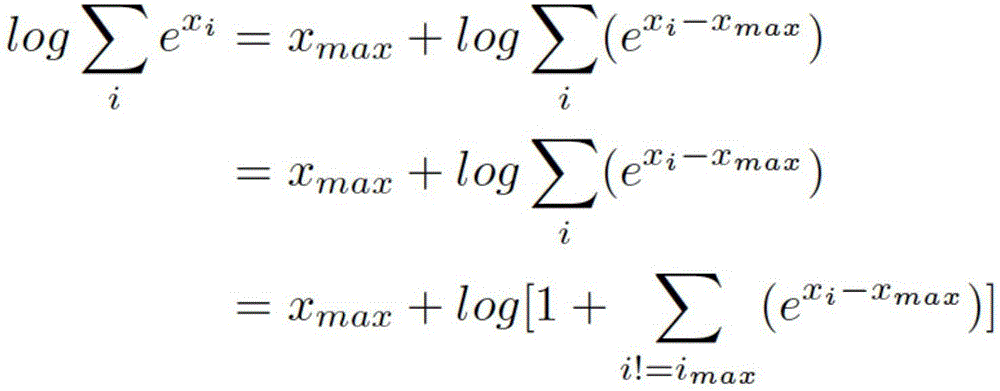

Medical information extraction system and method based on depth learning and distributed semantic features

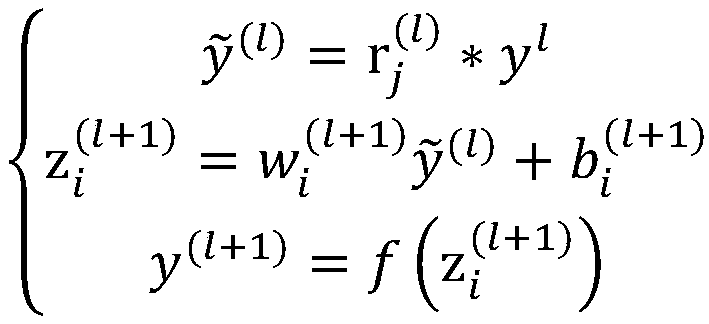

ActiveCN105894088AAvoid floating point overflow problemsHigh precisionNeural learning methodsNerve networkStudy methods

he invention discloses a medical information extraction system and method based on depth learning and distributed semantic features. The system is composed of a pretreatment module, a linguistic-model-based word vector training module, a massive medical knowledge base reinforced learning module, and a depth-artificial-neural-network-based medical term entity identification module. With a depth learning method, generation of the probability of a linguistic model is used as an optimization objective; and a primary word vector is trained by using medical text big data; on the basis of the massive medical knowledge base, a second depth artificial neural network is trained, and the massive knowledge base is combined to the feature leaning process of depth learning based on depth reinforced learning, so that distributed semantic features for the medical field are obtained; and then Chinese medical term entity identification is carried out by using the depth learning method based on the optimized statement-level maximum likelihood probability. Therefore, the word vector is generated by using lots of unmarked linguistic data, so that the tedious feature selection and optimization adjustment process during medical natural language process can be avoided.

Owner:神州医疗科技股份有限公司 +1

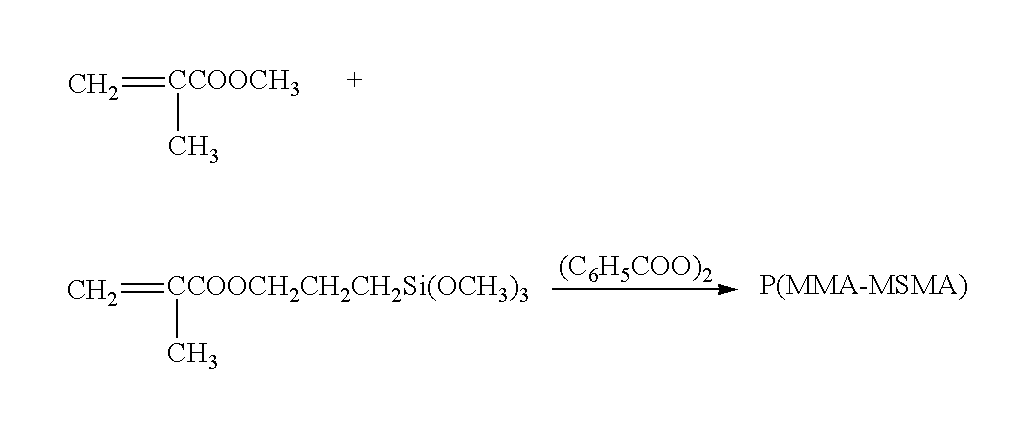

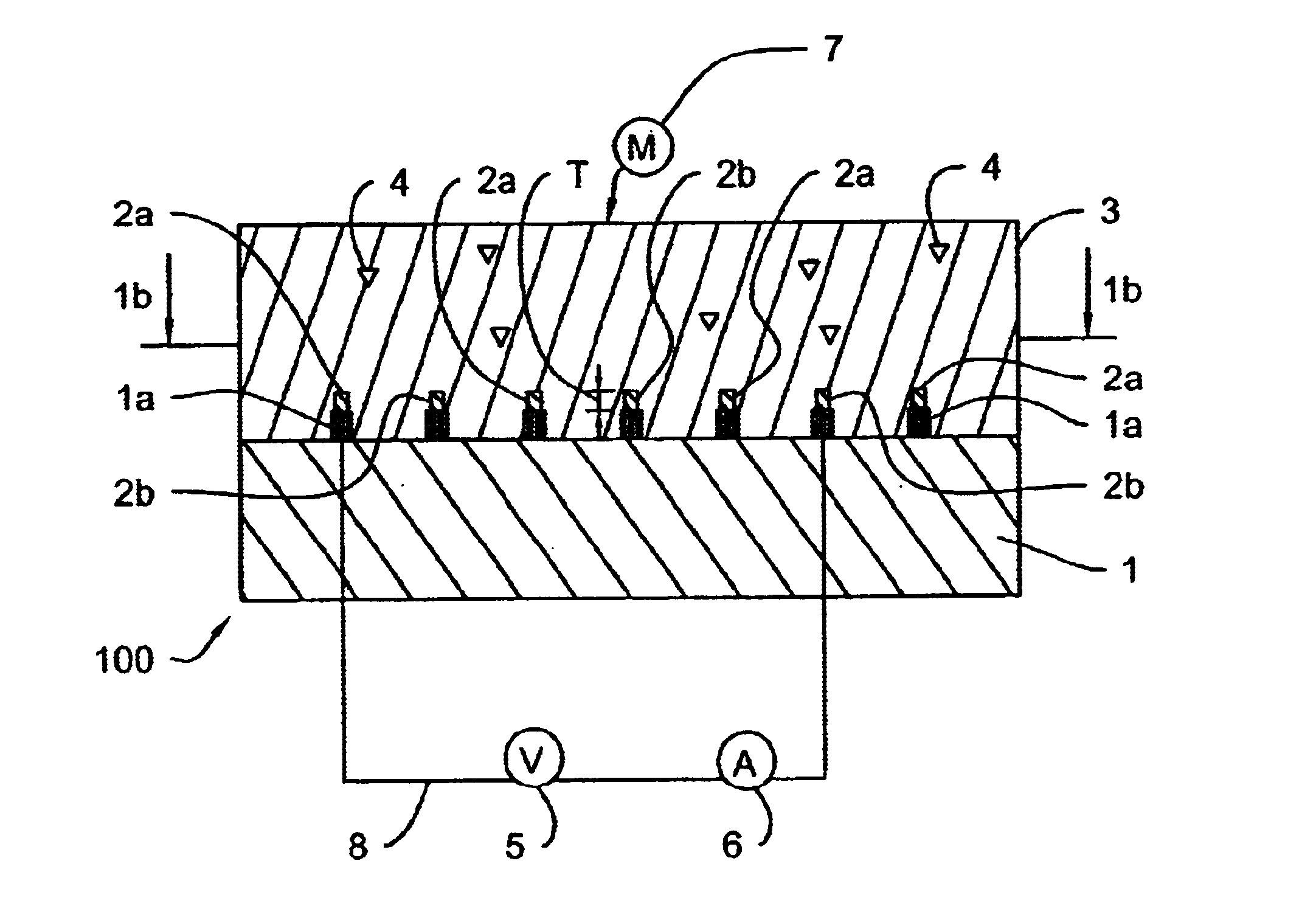

Sensor for chemical and biological materials

InactiveUS6730212B1Good choiceSolve the high false alarm rateImmobilised enzymesBioreactor/fermenter combinationsEngineeringChemical agent

A sensor and method for detecting biological and chemical agents comprising metal interdigitized electrodes coated with hybrid polymer-based conducting film and an instrument for applying electrical voltage to the electrodes and registering the change in voltage. The hybrid film also comprises indicator biomolecules encapsulated within the film or attached to it. When these indicator biomolecules come in a contact with a biological and chemical agent, morphological changes occur in the film and electrical current flowing through the electrodes is modulated. The change in current indicates the presence of a biological and chemical agent and is registered.

Owner:HRL LAB

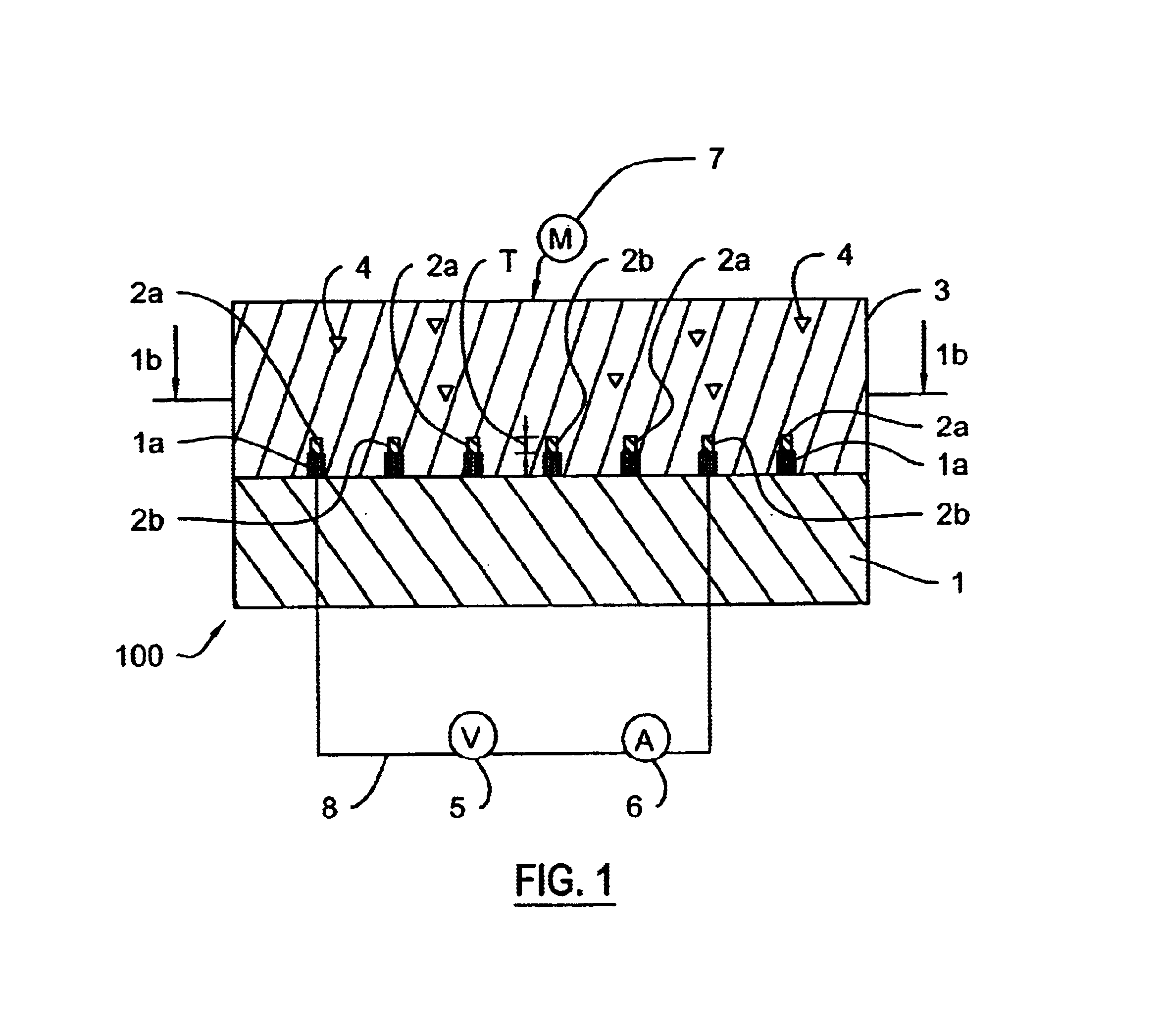

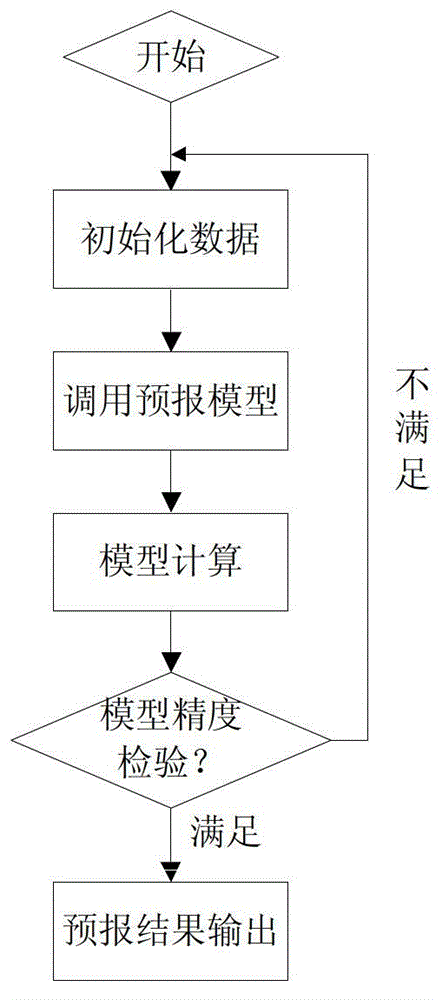

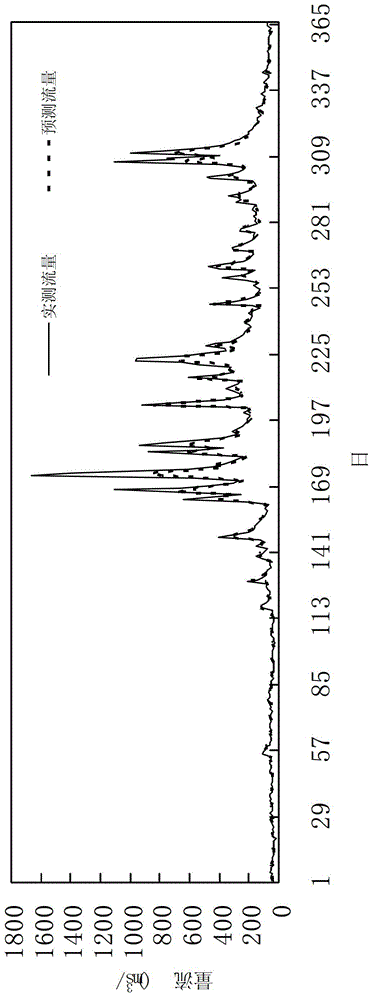

Method and system for predicting short-term running water

InactiveCN102867106AAvoid selectivityHigh precisionSpecial data processing applicationsHydrometryEnvironmental engineering

The invention discloses a method and system for predicting short-term running water. The method comprises the steps of: S1, analyzing a running water law in a river basin and initializing data, wherein the analysis of the running water law in the river basin comprises analysis on relevance and characteristics of the river basin, analysis on running water sequence period and trend of the river basin, hydrologic year division, staging of reservoir regulation and selection of step-shaped typical year of the river basin; S2, establishing and calling a short-term running water prediction model; and S3, solving the short-term running water prediction model, verifying if the precision of the model is optimal, and outputting a short-term running water prediction result. According to the method and system for predicting the short-term running water, disclosed by the invention, the precision of prediction of the short-term running water can be improved.

Owner:GUIZHOU WUJIANG HYDROPOWER DEV

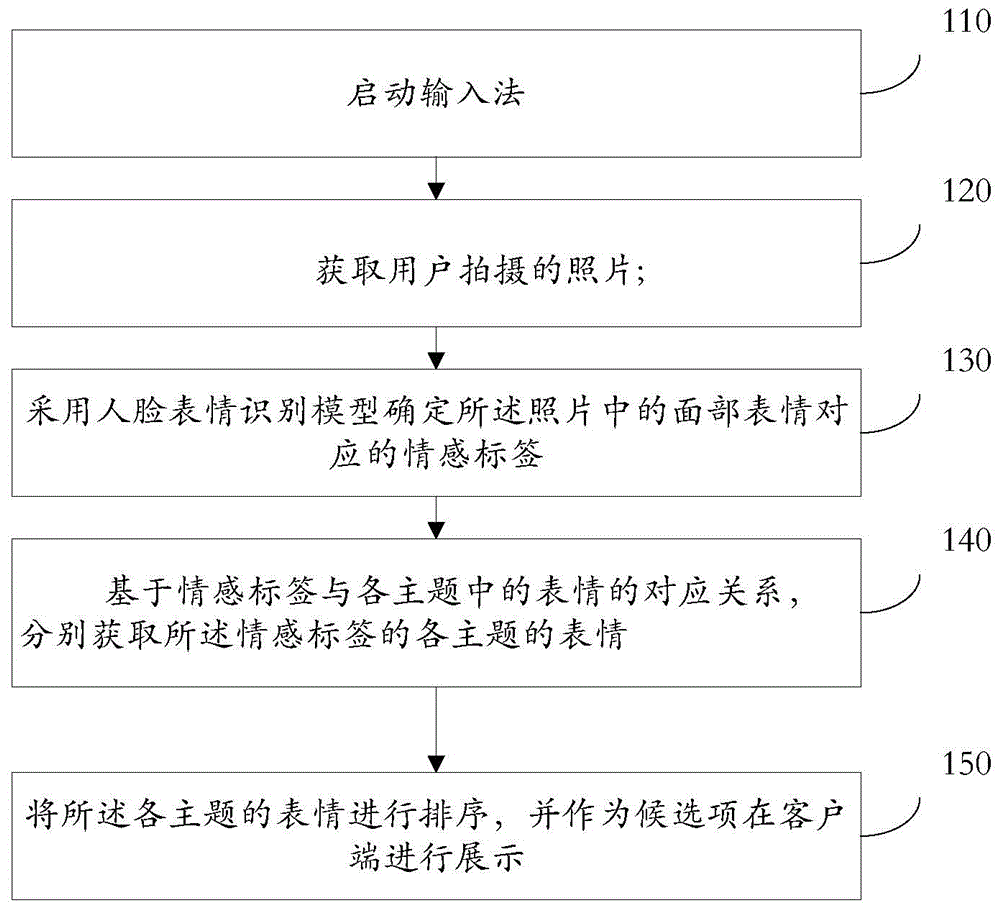

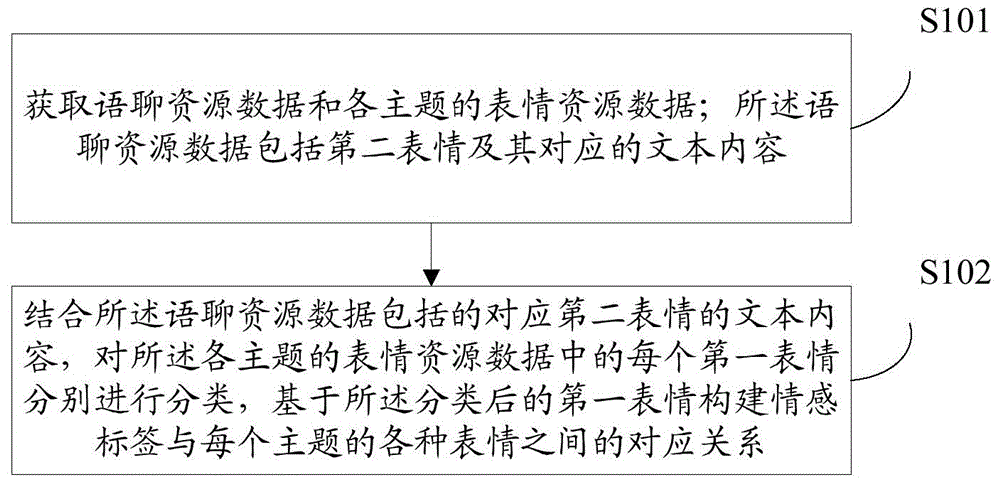

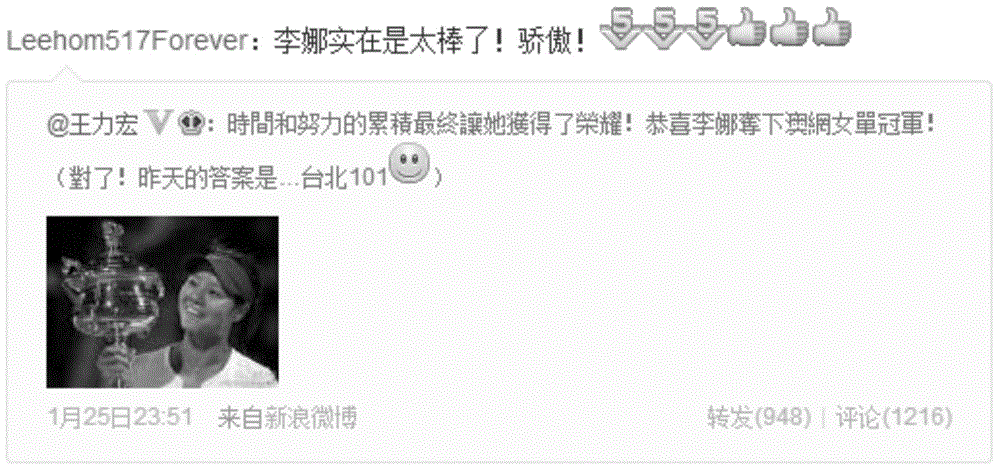

Expression input method and device based on face identification

ActiveCN104063683AAvoid selectivityAvoid the situationCharacter and pattern recognitionSpecial data processing applicationsComputer visionSubject specific

The invention discloses an expression input method and device based on face identification, and relates to the technical field of input methods. The method comprises the steps of starting an input method, acquiring a shot picture of a user, determining emotion labels corresponding to the facial expression in the picture by a face expression identification model, acquiring the expressions of all themes of the emotion labels respectively based on the corresponding relation of the emotion labels and the expressions in all the themes, the expressions of all the themes are ordered and used as candidate items to be displayed in a client end. According to the expression input method and device, the labels can be directly identified and matched according to the currently-shot picture of the user, the user can input the expression conveniently, the expression accuracy is high, and rich and wide-range expression resources are provided for the user.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

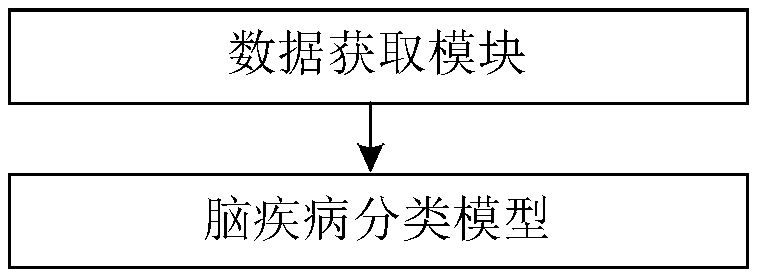

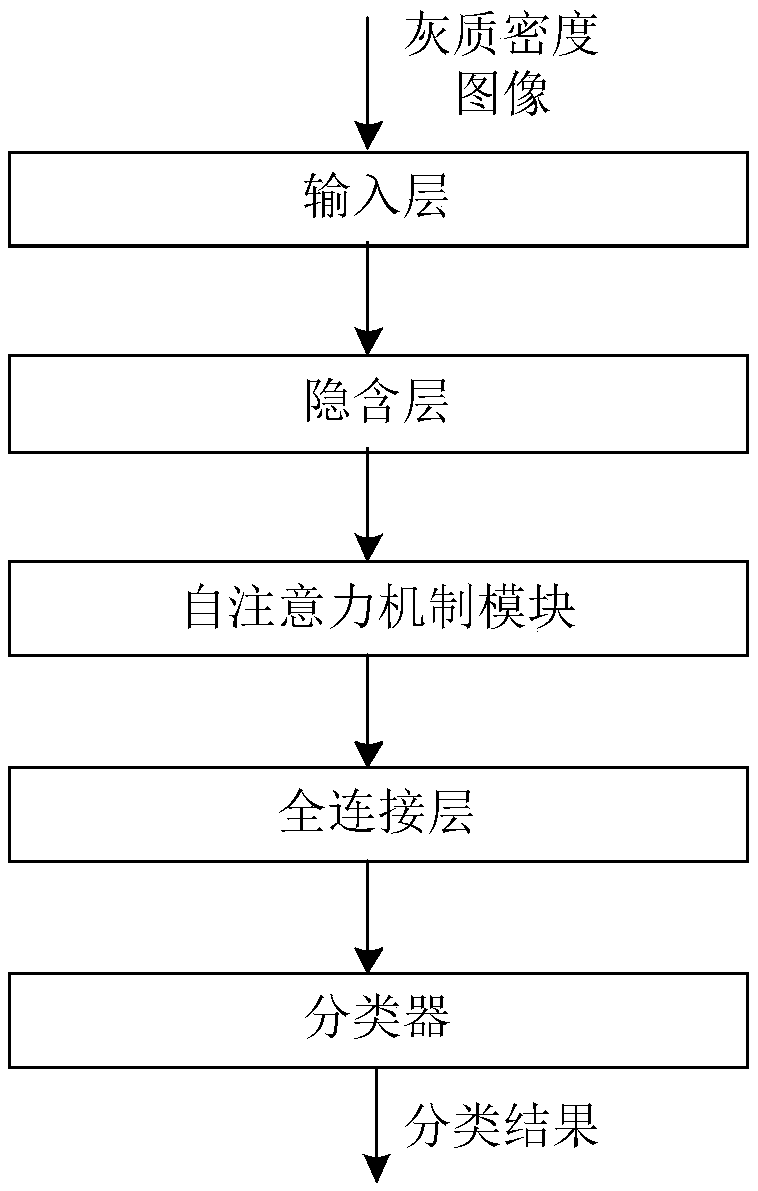

Brain disease classification system based on self-attention mechanism

ActiveCN109165667AImprove classification performanceIncrease weightMedical automated diagnosisCharacter and pattern recognitionDiseaseNerve network

The invention relates to the technical field of image processing, and proposes a brain disease classification system based on a self-attention mechanism, aiming at solving the technical problems of low classification accuracy caused by the complicated process of preprocessing, feature extraction and feature selection of magnetic resonance images required in the classification and diagnosis of brain diseases. For this purpose, the brain disease classification system based on the self-attention mechanism in the invention comprises the following steps: pre-processing the acquired human brain magnetic resonance images of the brain disease patients to obtain the gray matter density map of the human brain; using a pre-constructed brain disease classification model to classify the gray matter density map to obtain a brain disease category of the brain disease patient, wherein The pre-constructed brain disease classification model is a three-dimensional convolutional neural network model basedon the self-attention mechanism. The system shown in the embodiment of the invention can quickly and accurately classify the categories of brain diseases.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

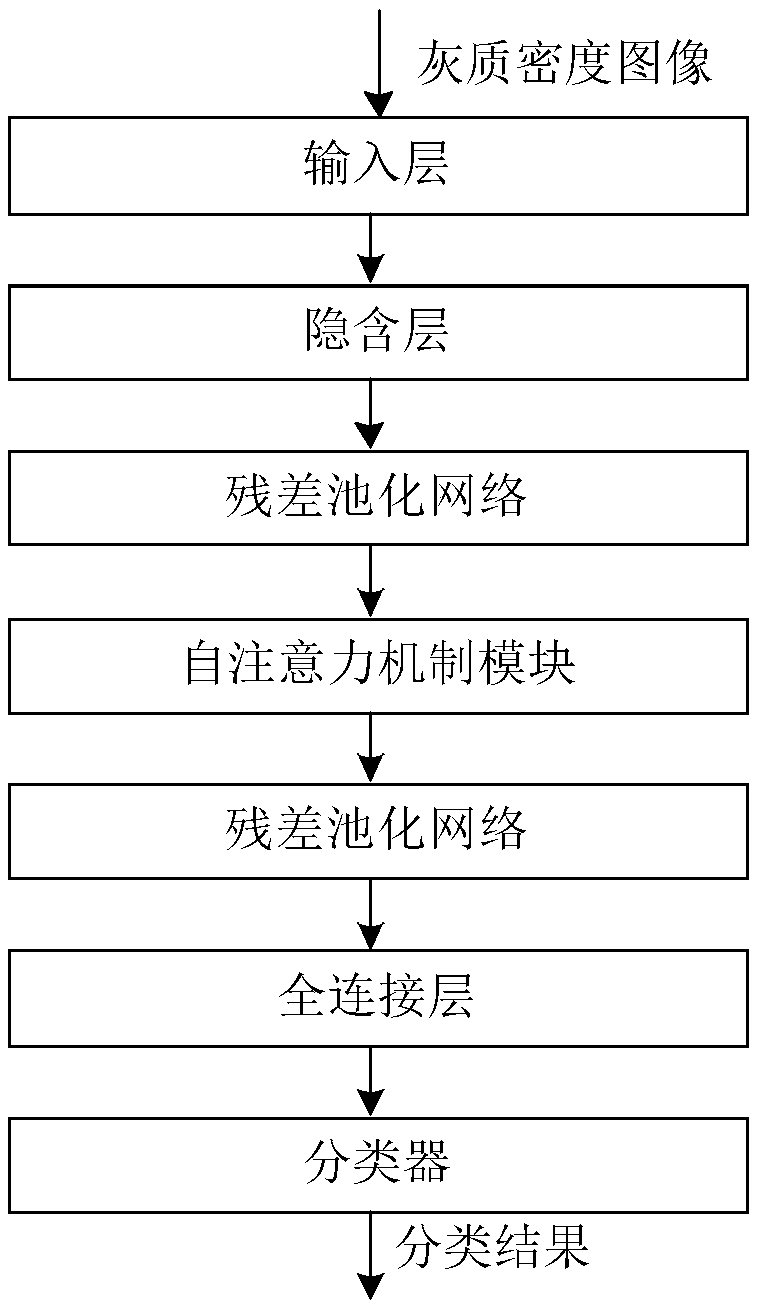

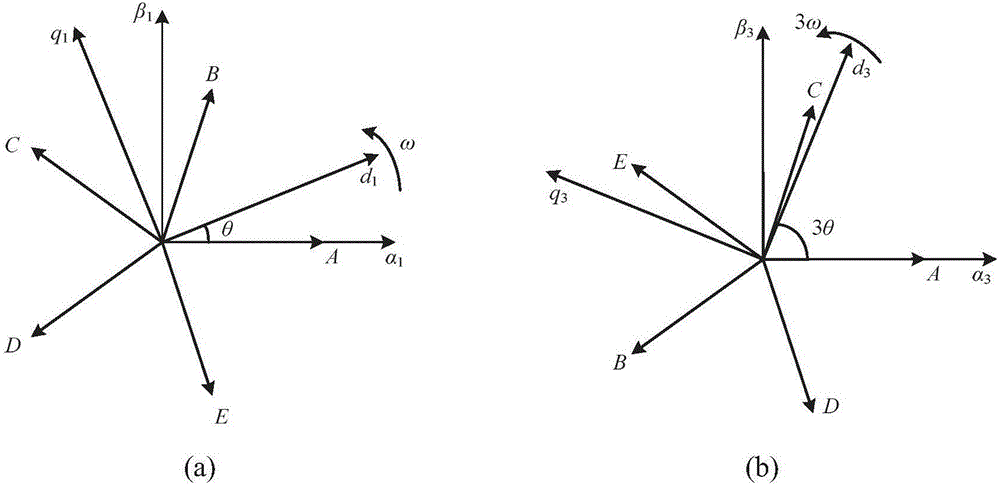

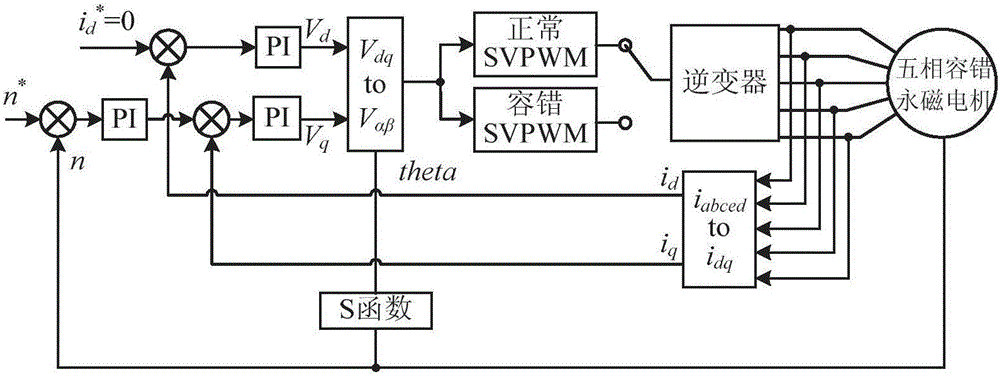

Full-vector control method of five-phase fault-tolerant permanent magnet motor

ActiveCN105119547AAvoid software and hardware changesAvoid selectivityElectronic commutation motor controlVector control systemsCurrent meterControl vector

The invention discloses a full-vector control method of a five-phase fault-tolerant permanent magnet motor. According to the method, a five-phase SVPWM method is adopted when the motor operates normally; after a one-phase open-circuit fault occurs on the motor, the traditional SVPWM method and a current hysteresis control method are combined together to re-construct a post-fault coordinate system; re-distribution and sector reconstruction of space vectors are performed on the reconstructed coordinate system; target vectors are synthetized through re-selection of the space vectors; and therefore, full-vector control on the five-phase fault-tolerant permanent magnet motor can be realized. With the full-vector control method adopted, problems such as hardware variation and loop width selection brought about by the switching of normal five-phase SVPWM to current hysteresis control existing on most current methods can be solved, and tracking performance can be ensured, and torque ripples after open-circuit faults can be effectively restrained.

Owner:东台城东科技创业园管理有限公司

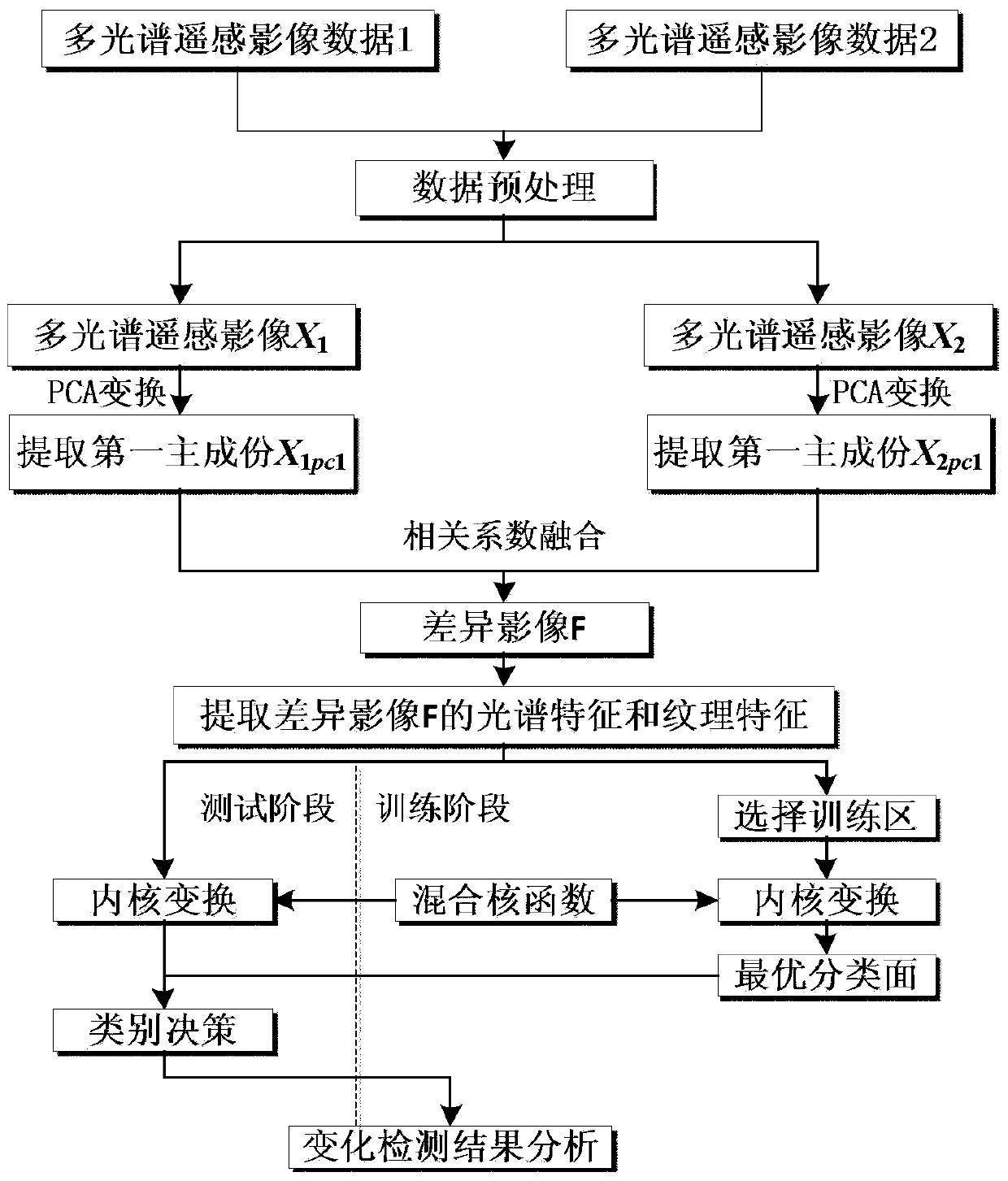

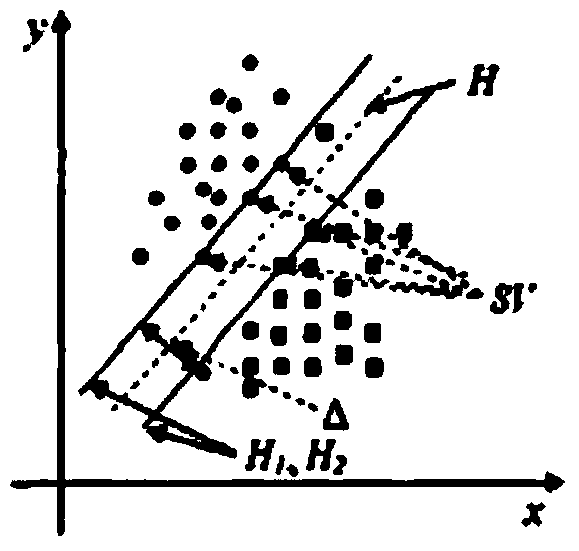

Multi-spectrum remote sensing image change detection method

InactiveCN103500450AEliminate dependenciesReduce distractionsImage analysisSupport vector machineCorrelation coefficient

The invention discloses a multi-spectrum remote sensing image change detection method. The traditional remote sensing image change detection method comprises the following steps of forming a difference image on the two remote sensing images different in time phases through an algebraic method, then modeling the difference image, determining the change threshold value, and detecting the change of the image. However, the process has the problems that the difference image may not meet the designated model and the change threshold value is difficultly determined, so the remote sensing image change detection method based on an SVM (support vector machine) mixed kernel function is put forward for solving the problems. The implementation process comprises the following steps of firstly, constructing the difference image in a way of combining PCA (primary component analysis) conversion and a correlation coefficient integrating method; then, extracting the gray feature and texture feature of the difference image, and carrying out normalization and formatting; selecting a training area, and constructing the SVM mixed kernel function to train; finally, enabling an SVM mixed kernel classifier to classify the difference image, so the change detection result of the target image is obtained.

Owner:HOHAI UNIV +1

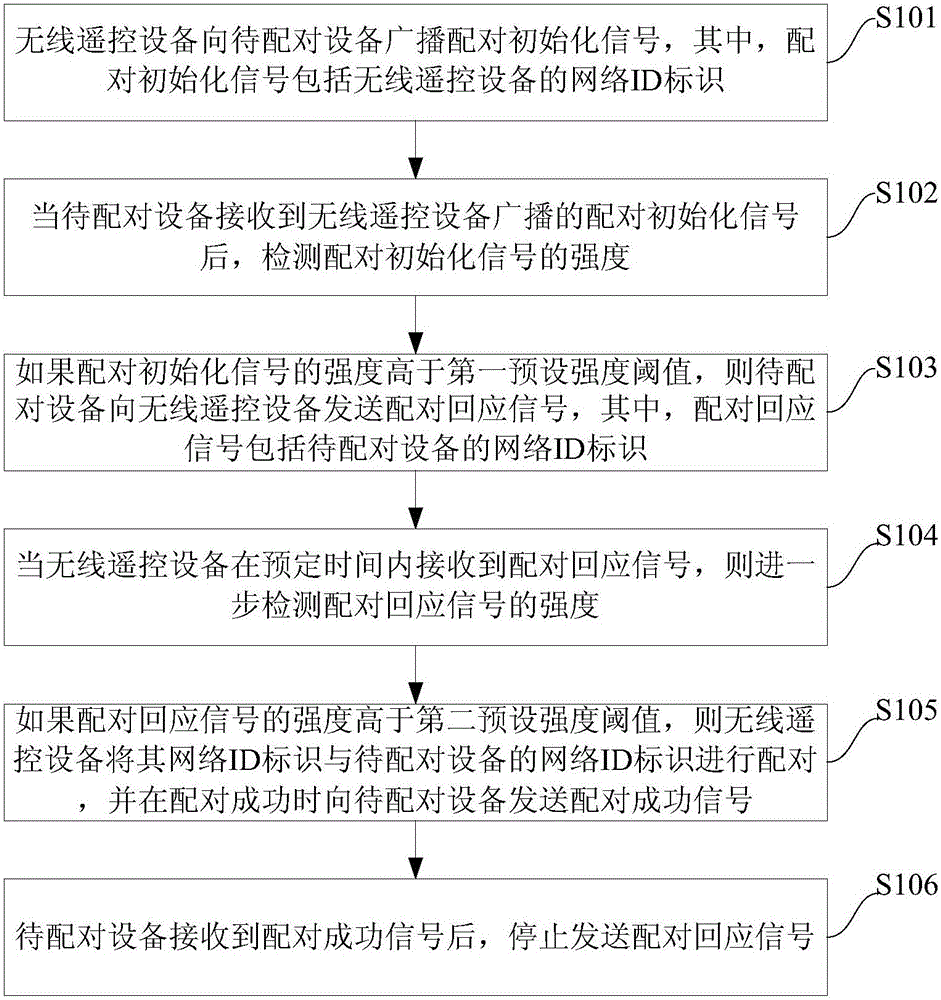

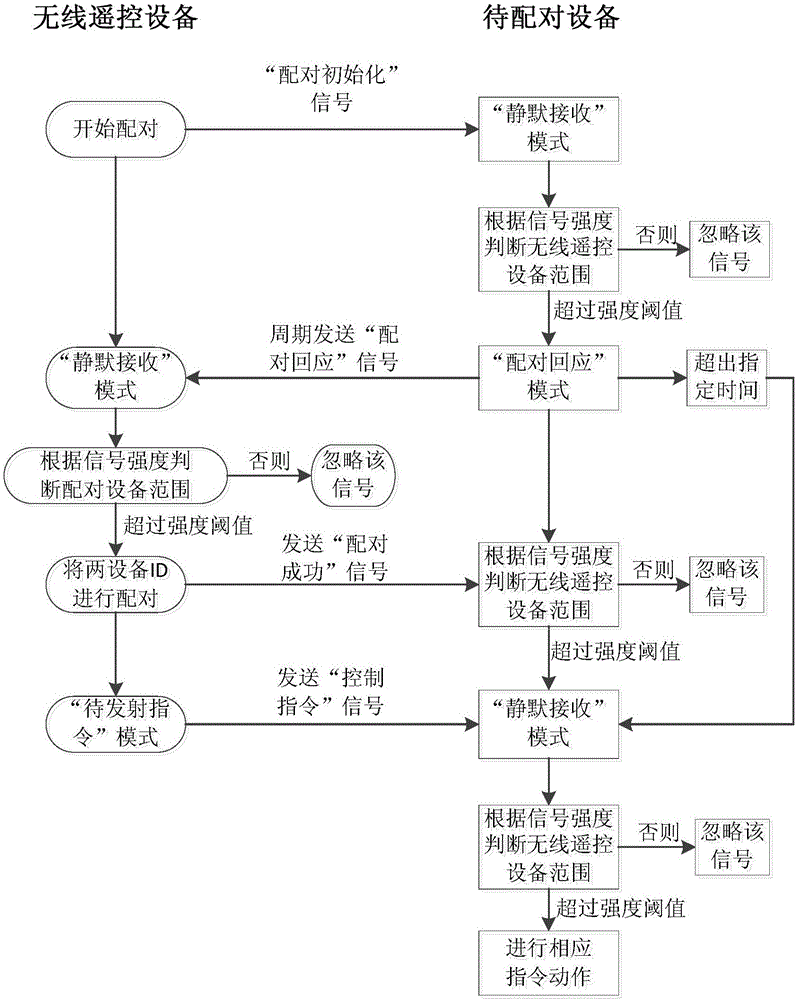

Automatic equipment pairing method based on wireless signal intensity

InactiveCN105101467AAvoid tedious and complicated pairing processEasy to implementConnection managementRemote controlCommunications security

The invention provides an automatic equipment pairing method based on wireless signal intensity. The automatic equipment pairing method comprises: wireless remote control equipment broadcasts a pairing initialization signal to equipment to be paired; after the equipment to be paired receives the pairing initialization signal, detecting the intensity of the signal; if the intensity of the signal is higher than a first preset intensity threshold, sending a pairing response signal to the wireless remote control equipment; when the wireless remote control equipment receives the pairing response signal within a preset time, detecting the intensity of the pairing response signal; if the intensity is higher than a second preset intensity threshold, the wireless remote control equipment pairs the network ID identifier thereof with the network ID identifier of the equipment to be paired, and sends a pairing success signal to the equipment to be paired in the case of pairing success; and the equipment to be paired stops sending the pairing response signal after receiving the pairing success signal. The method provided by the invention can be used for automatically completing equipment pairing and ensuring the pairing and communication security of the equipment, moreover, the method is easy to achieve, and the user experience is improved.

Owner:TSINGHUA UNIV

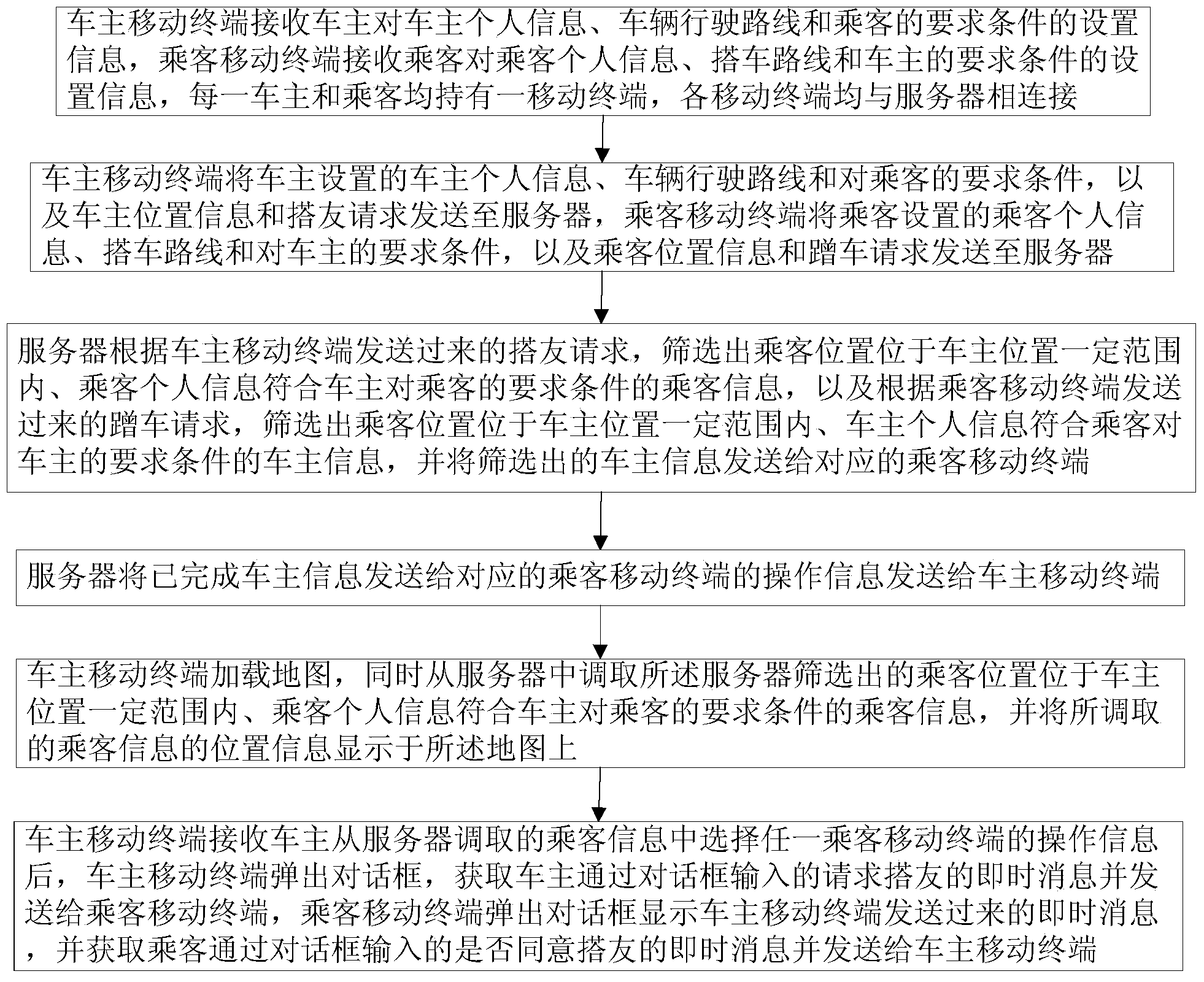

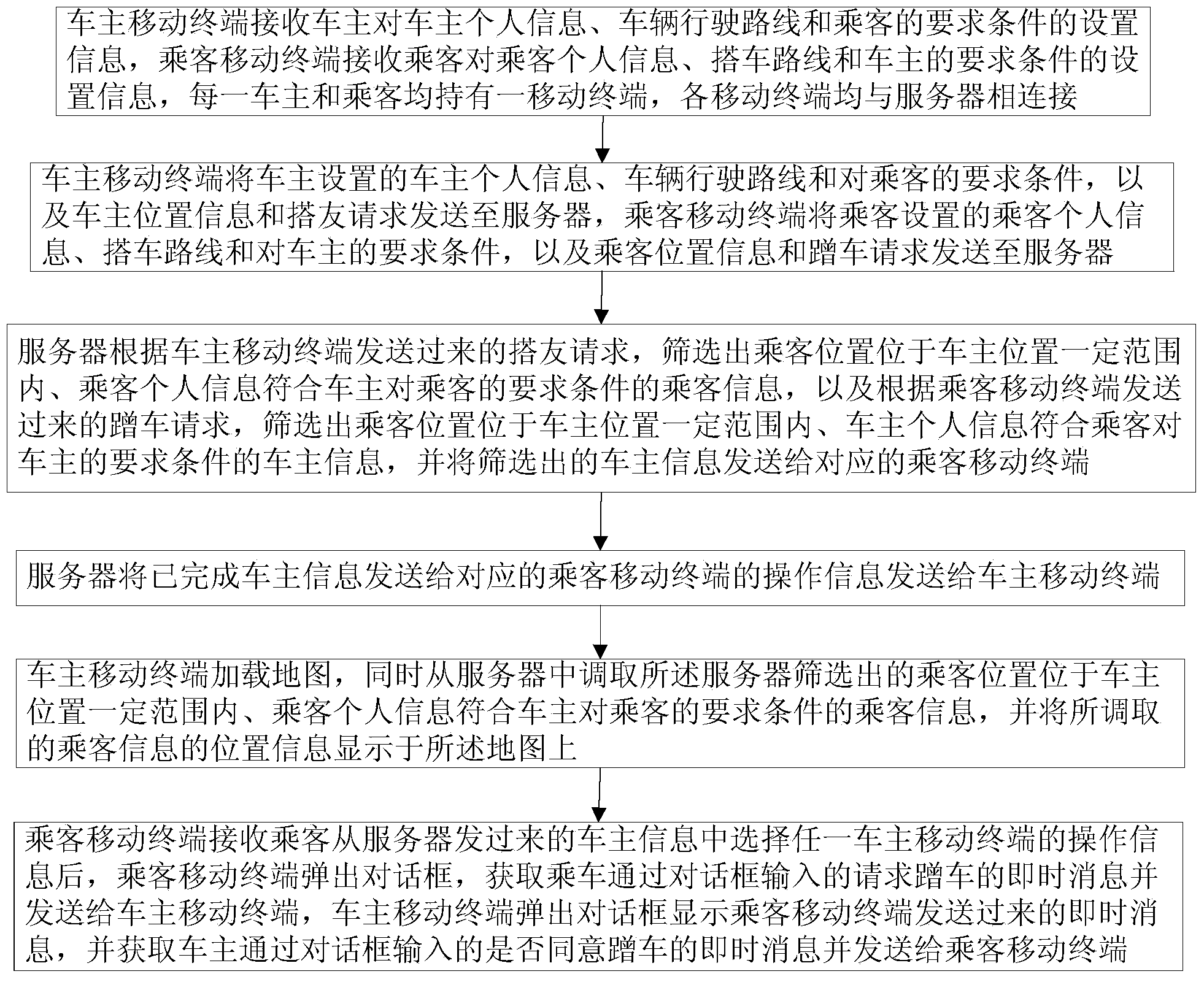

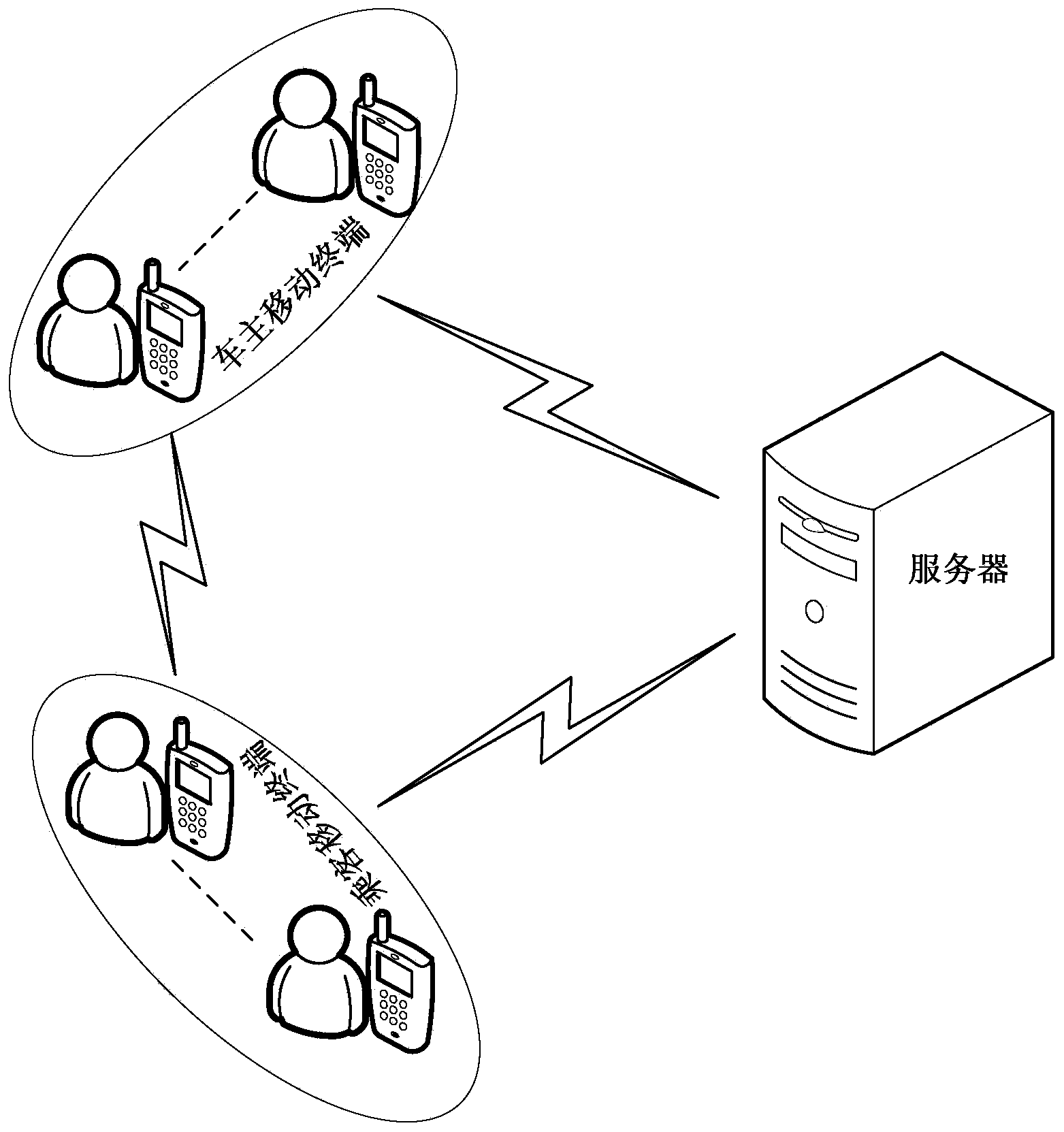

Car-taking method and system based on mobile terminals

InactiveCN103632539AReduce usageRealize rational utilizationRoad vehicles traffic controlLocation information based serviceComputer terminalComputer science

The invention discloses a car-taking method and system based on mobile terminals. The method comprises the following steps: a car owner moving terminal receives car owner personal information, a car running route and setting information about the demand condition of a passenger; a passenger moving terminal receives passenger personal information, a car-taking route and setting information about the demand condition of a car owner; a server screens out the passenger information meeting the requirements that the passenger position is in a certain range of the car owner position and the passenger personal information accords with the demand condition of the car owner on the passenger, and screens out the car owner information meeting the requirements that the passenger position is in a certain range of the car owner information and the car owner personal information accords with the demand condition of the passenger on the car owner; the car owner moving terminal loads a map, so that the position information of retrieved passenger information shows on the map; the car owner moving terminal obtains the instant message of a car-taking request inputted by the car owner, and the passenger moving terminal obtains instant message whether to agree the car-taking request inputted by the passenger. By adopting the car-taking method and system based on the mobile terminals, reasonable use of free spaces of private cars can be achieved.

Owner:赵书扬

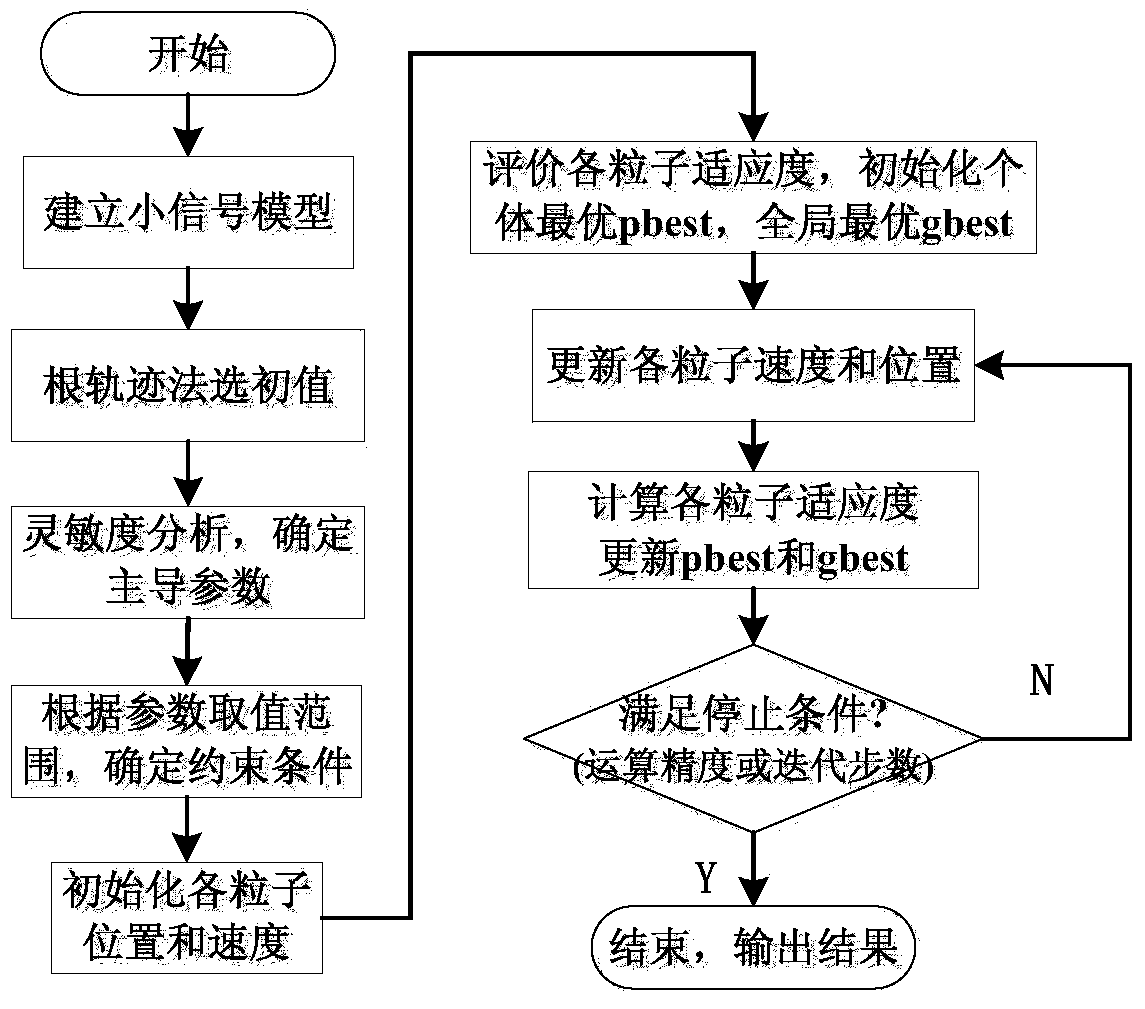

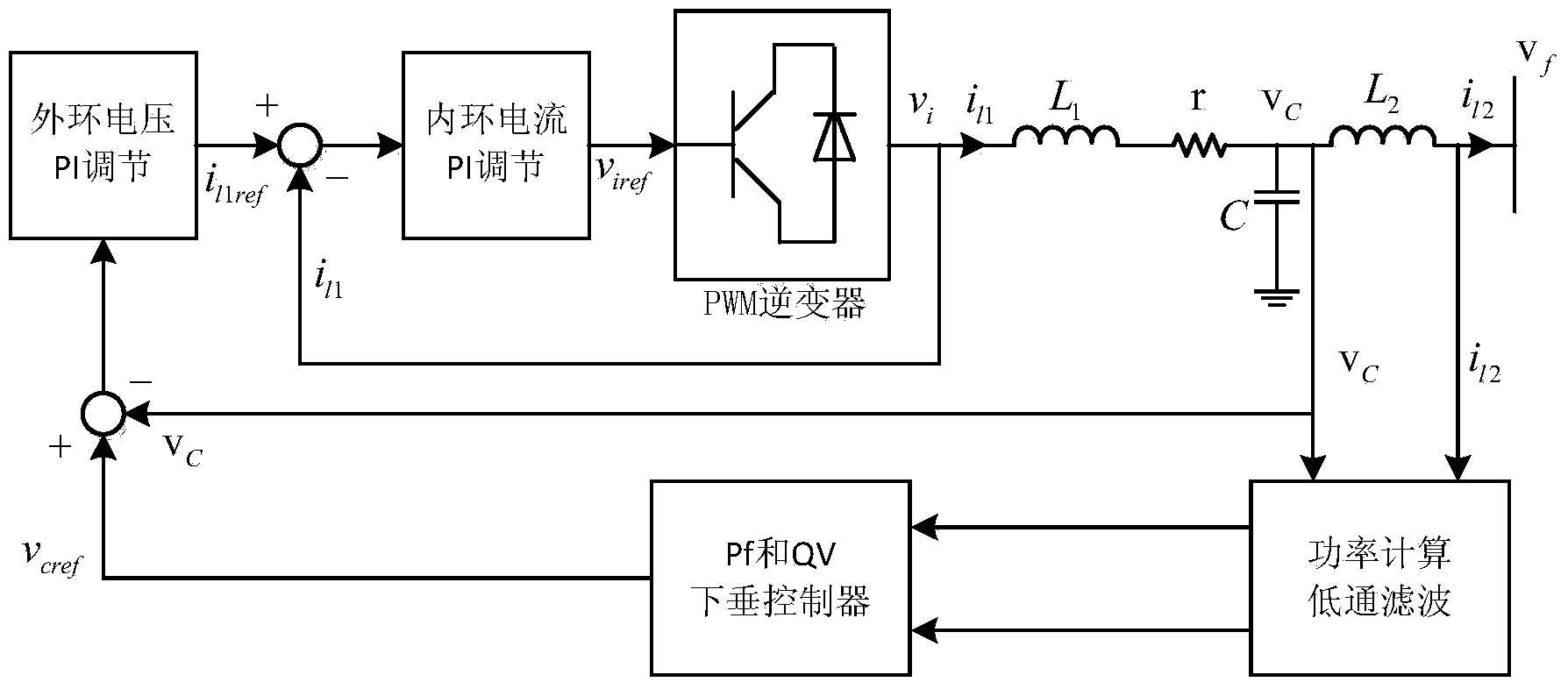

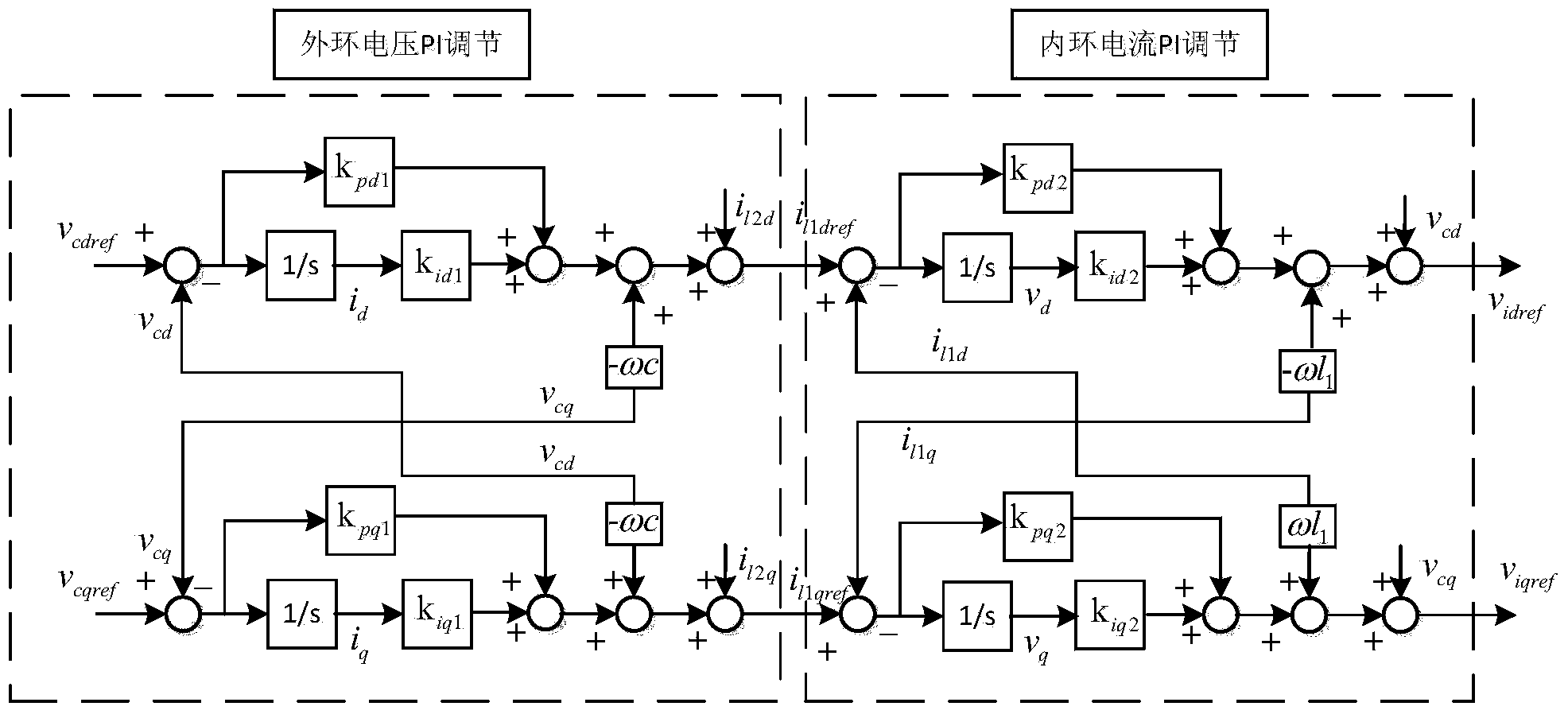

Micro-grid small signal stability analyzing and parameter coordinated setting method

The invention discloses a micro-grid small signal stability analyzing and parameter coordinated setting method, and belongs to the technical field of power system micro-grid operation and control. The micro-grid small signal stability analyzing and parameter coordinated setting method comprises the steps of establishing micro-grid mathematical models which comprise a network and load small signal model and an inverter small signal model and are in need of parameterized design, determining each parameter of the micro-grid according to the root-locus method and using the parameters as initial values of the particle swarm algorithm, conducting sensitivity analyzing through a characteristic value, determining a leading parameter, determining the value range of all the parameters or the mathematical relationships among all the parameters, solving the constraint conditions in the process by the utilization of the particle swarm algorithm, determining the initial values, the parameters in need of optimization and the constraint conditions, and conducting parameter optimization and coordinated setting by the utilization of the particle swarm algorithm. By means of the micro-grid small signal stability analyzing and parameter coordinated setting method, determining of each parameter can be realized quickly and accurately in a coordinated mode, the complexity of setting the parameters one by one is avoided, and the system is made to be more stable on the basis of small signal stability; target functions and boundary conditions are flexibly adjusted, the working time is greatly shortened and the efficiency is improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +2

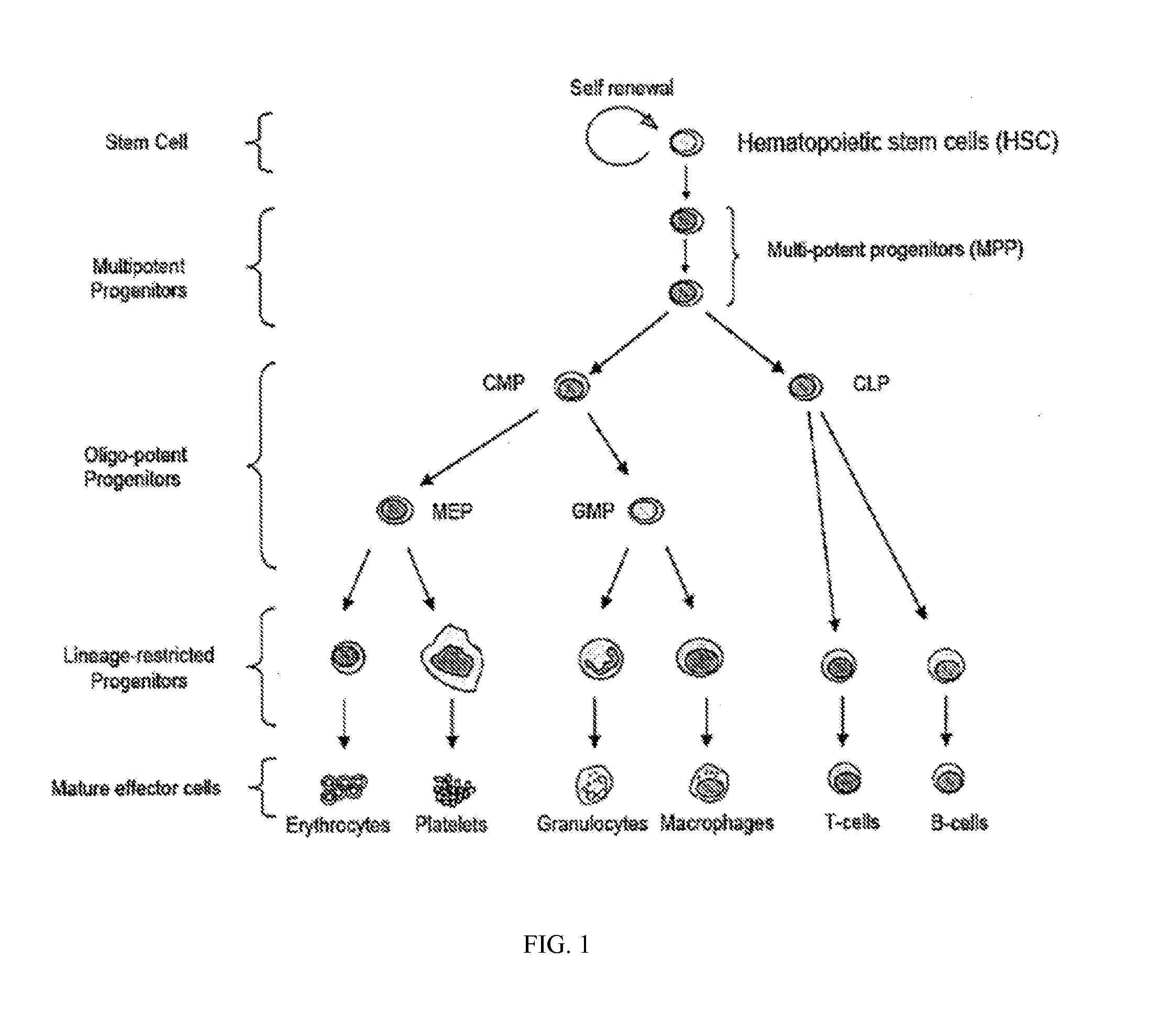

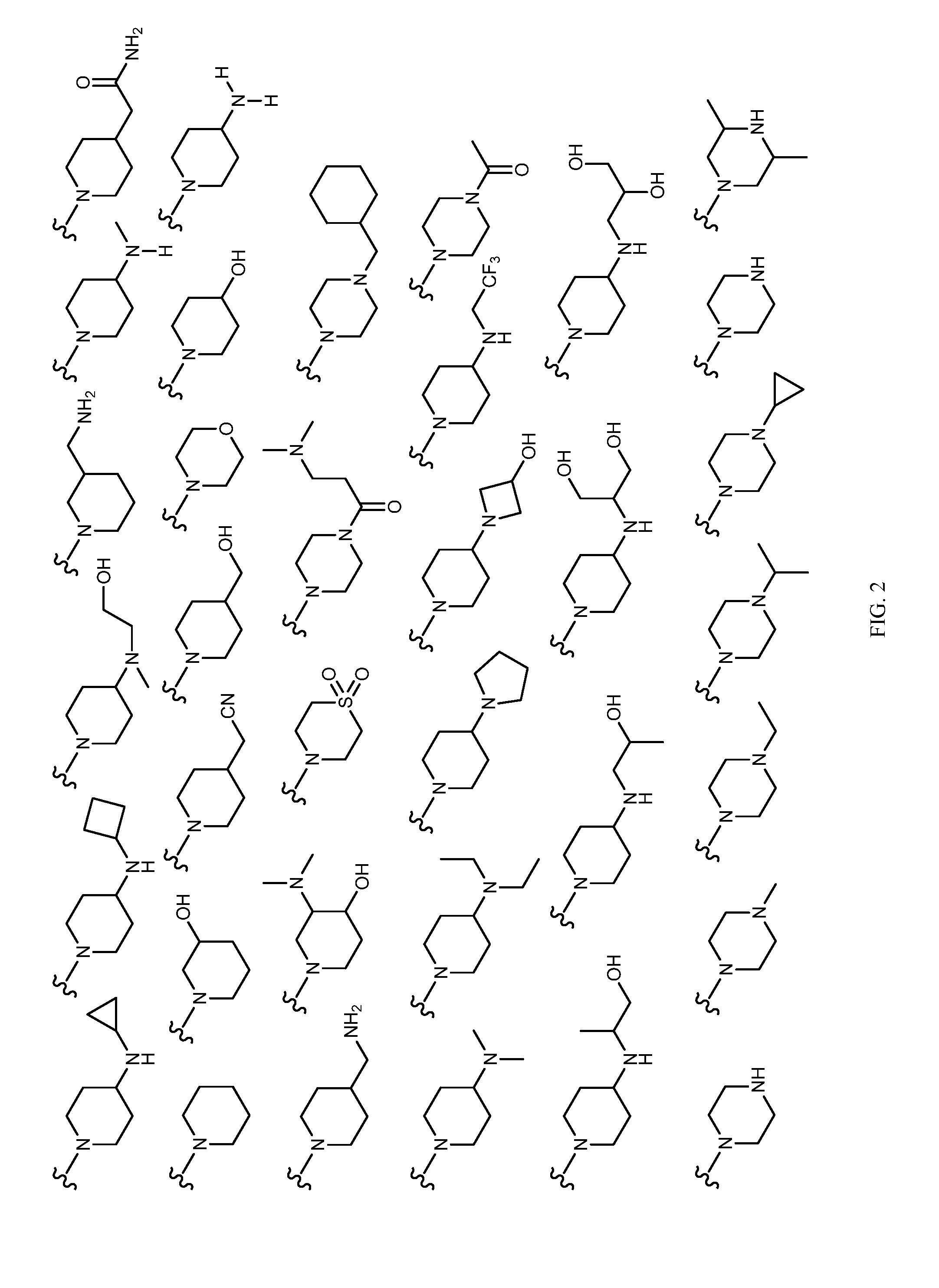

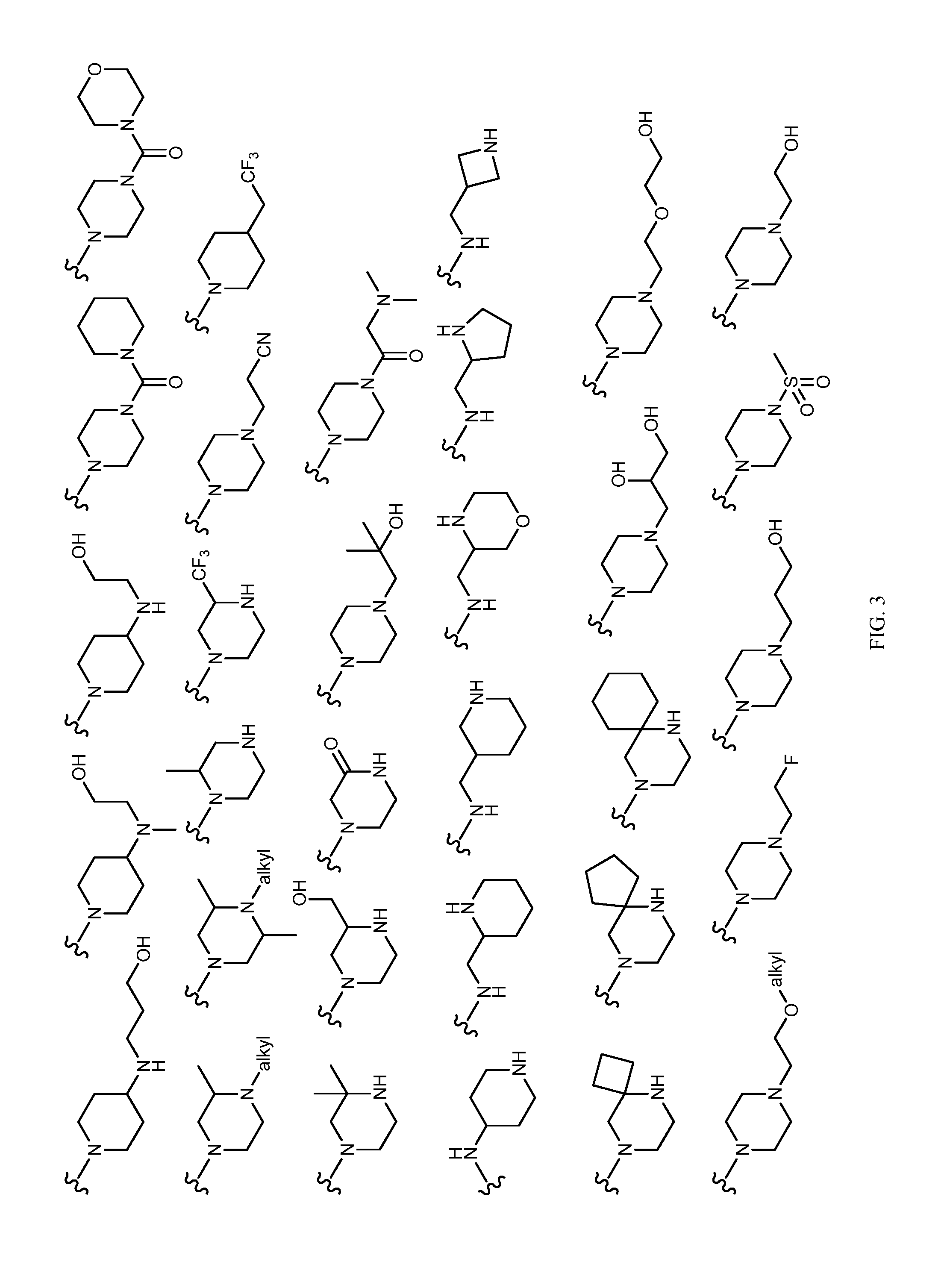

Tricyclic Lactams for Use in the Protection of Normal Cells During Chemotherapy

InactiveUS20150297607A1Minimize impactAvoid selectivityOrganic active ingredientsOrganic chemistryProgenitorRegimen

This invention is in the area of tricyclic lactam compounds, compositions and methods of protecting healthy cells, and in particular hematopoietic stem and progenitor cells (HSPC) as well as renal cells, from damage associated with DNA damaging chemotherapeutic agents. In one aspect, protection of healthy cells is disclosed using compounds that act as cyclin-dependent kinase 4 / 6 (CDK 4 / 6) inhibitors when administered to subjects undergoing DNA damaging chemotherapeutic regimens for the treatment of proliferative disorders.

Owner:G1 THERAPEUTICS INC

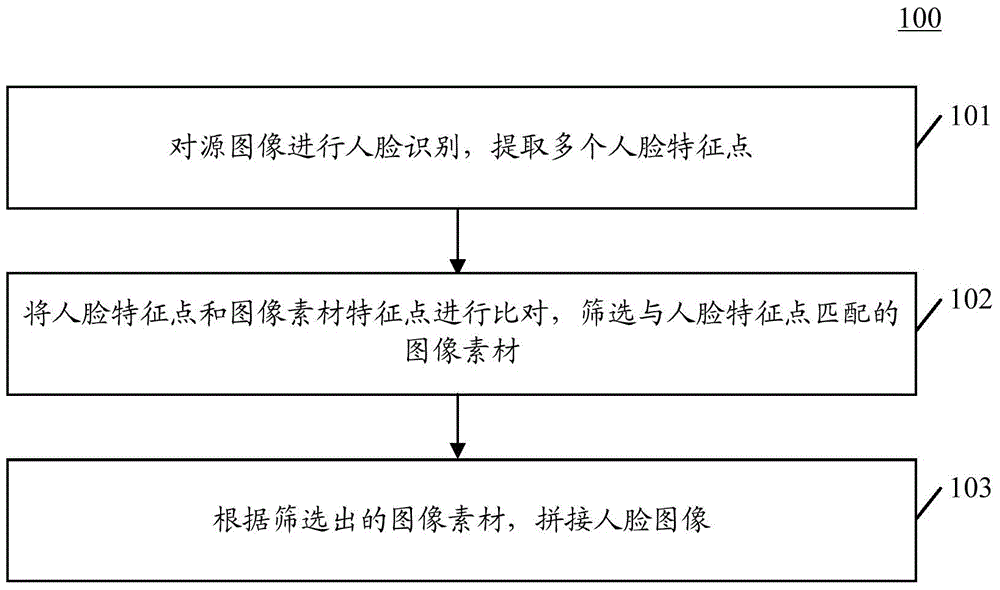

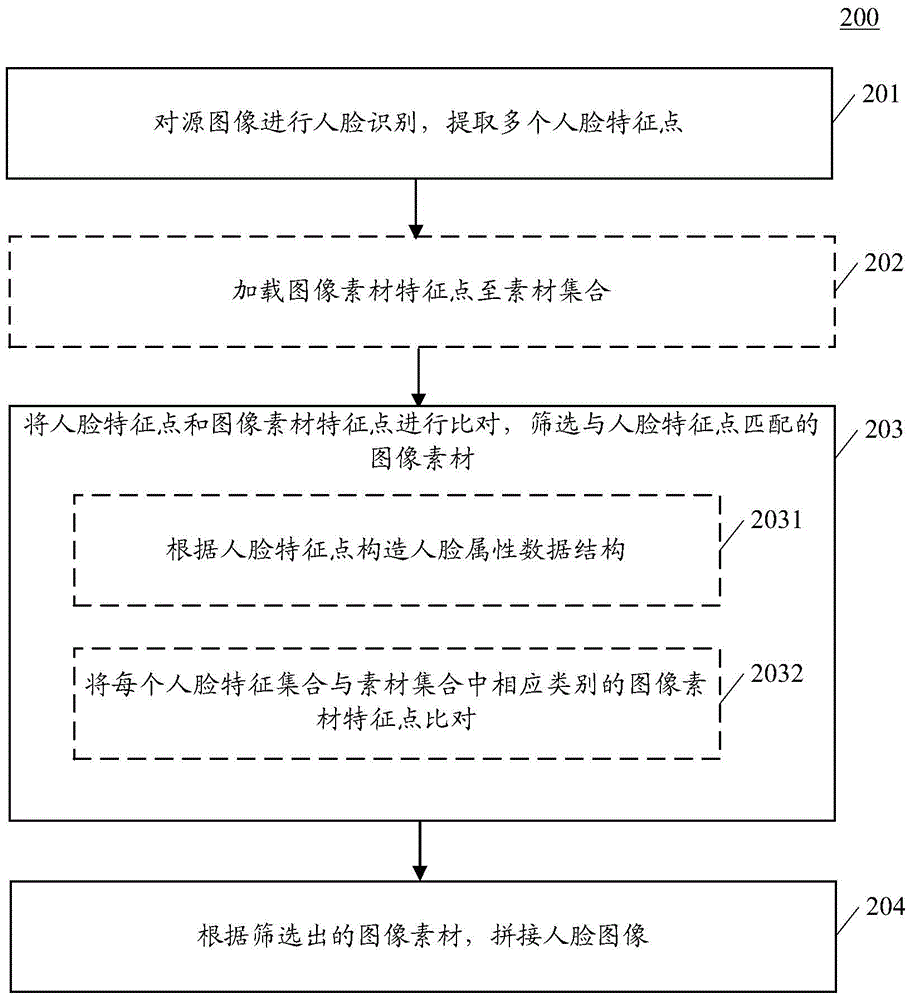

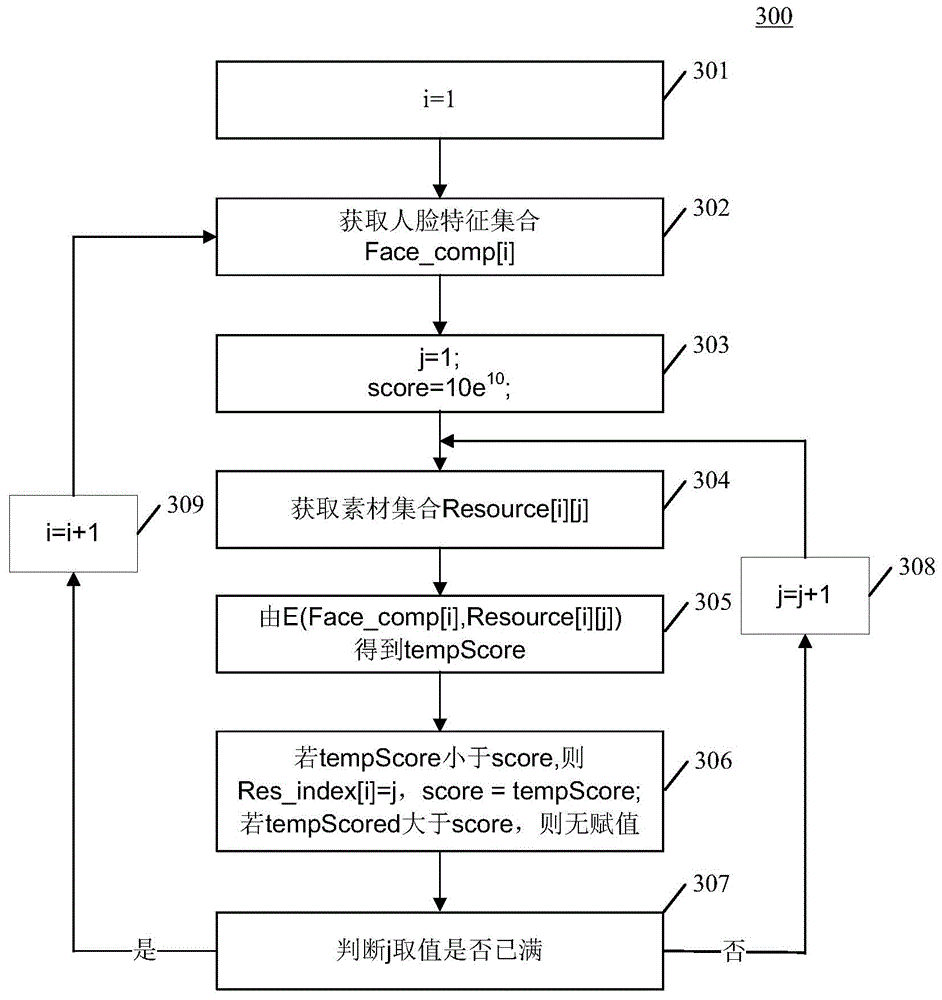

Image generation method based on face recognition technology and apparatus

ActiveCN104915634AReduce the number of processesShorten the timeCharacter and pattern recognitionSource imageFeature point matching

The invention discloses an image generation method based on a face recognition technology and an apparatus. A specific embodiment of the method comprises the following steps: carrying out face identification on a source image and extracting a plurality of face characteristic points; comparing the face characteristic points to image material characteristic points and screening an image material which matches with the face characteristic points, wherein the image material characteristic points are extracted from the image material; according to the screened image material, splicing a face image. By using the method and the apparatus, browsing and operation processes of a user can be reduced and conversion from a real face image to a cartoon image is completed.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

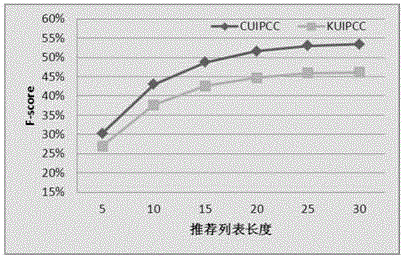

Hadoop cloud platform-based Web resource personalized recommendation system and method

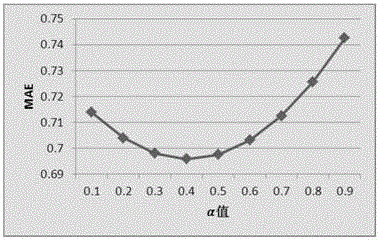

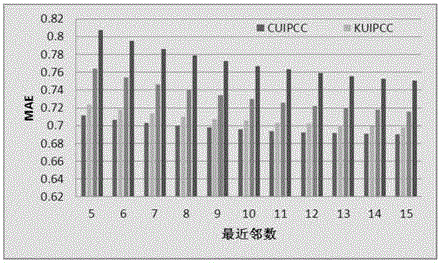

InactiveCN106503140AGuaranteed pertinenceGuaranteed reliabilitySpecial data processing applicationsPersonalizationNear neighbor

The invention discloses a Hadoop cloud platform-based Web resource personalized recommendation system and method. The system comprises a user model module which collects browsing behavior information of a user on a Web resource page, endows different weights to different behavior types of the user according to the browsing behavior information of the user on the Web resource page, and calculates the degree of interest of the user in the Web resource page according to the different weights, a recommendation algorithm module which carries out clustering processing on the collected browsing behavior information of the user on the Web resource page by using a recommendation algorithm according to the degree of interest calculated by the user model module, then constructs a matrix according to a clustering result, carries out nearest neighbor analysis on a target resource through the constructed matrix to obtain a nearest neighbor result of the target resource, and forecasts and fuses the degree of interest of the user according to the nearest neighbor result to obtain a recommendation scheme, and a parallel processing module which carries out off-line distributed calculation on the recommendation algorithm under a Hadoop cloud platform, and saving a calculation result.

Owner:ANHUI UNIVERSITY

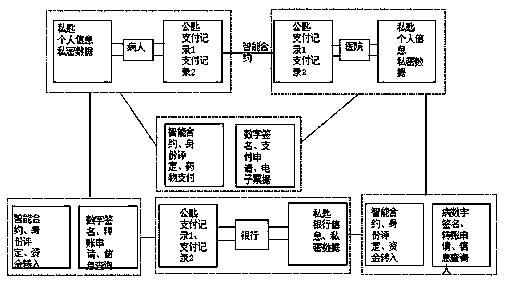

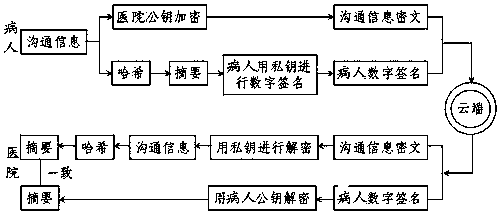

A medical block chain-based payment system

The invention discloses a medical block chain-based payment system and method. In the blockchain payment system, a patient party, a hospital party and a bank party are respectively a node on the blockchain; Information flow, the capital flow and the medicine flow between three parties form an electronic payment system closed loop; a decentralized block chain public chain is set; nodes participating in the system are freely accessed according to the system specification; in a Data layer, a Data block, a Chain type structure, a Hash algorithm, a Merkel tree and a timestamp mechanism are used for storing each piece of payment transaction data and ensuring the safety of data transaction information by using an asymmetric encryption technology; In the network layer, a peer-to-peer network isadopted to organize nodes to dispersedly participate in verification and accounting of transaction data of each time of payment, in the consensus layer, a POS consensus mechanism is adopted, 1% of transaction amount is adopted as a reward to give accounting nodes in the incentive layer, and in the contract layer, intelligent contracts are packaged in the contract layer, so that the advantages of safe, efficient and convenient payment are achieved.

Owner:陕西医链区块链集团有限公司

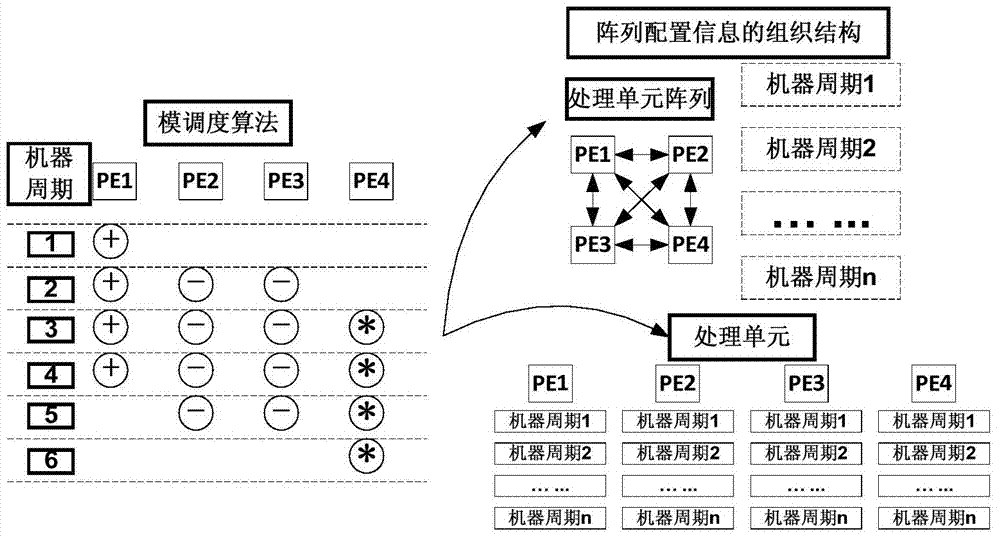

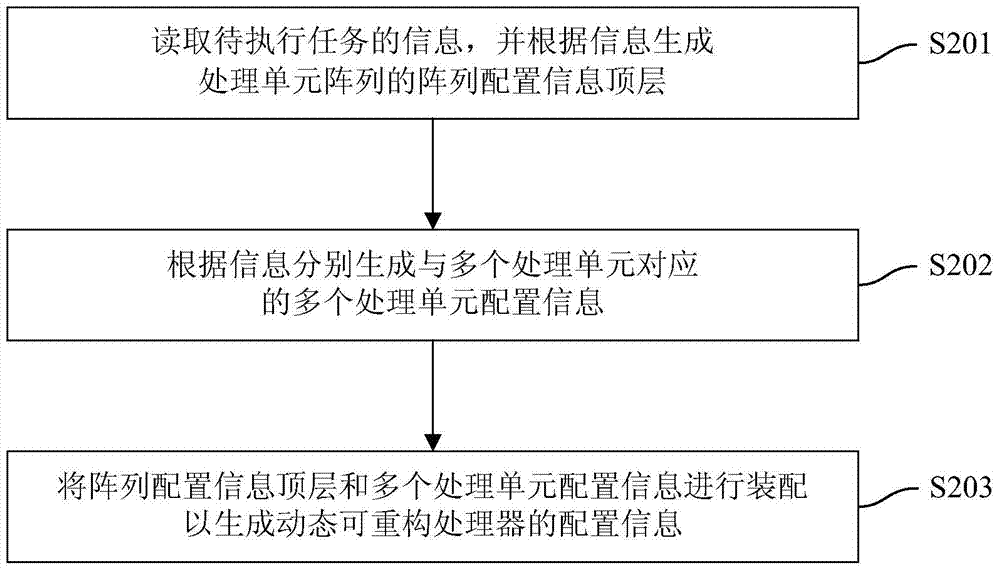

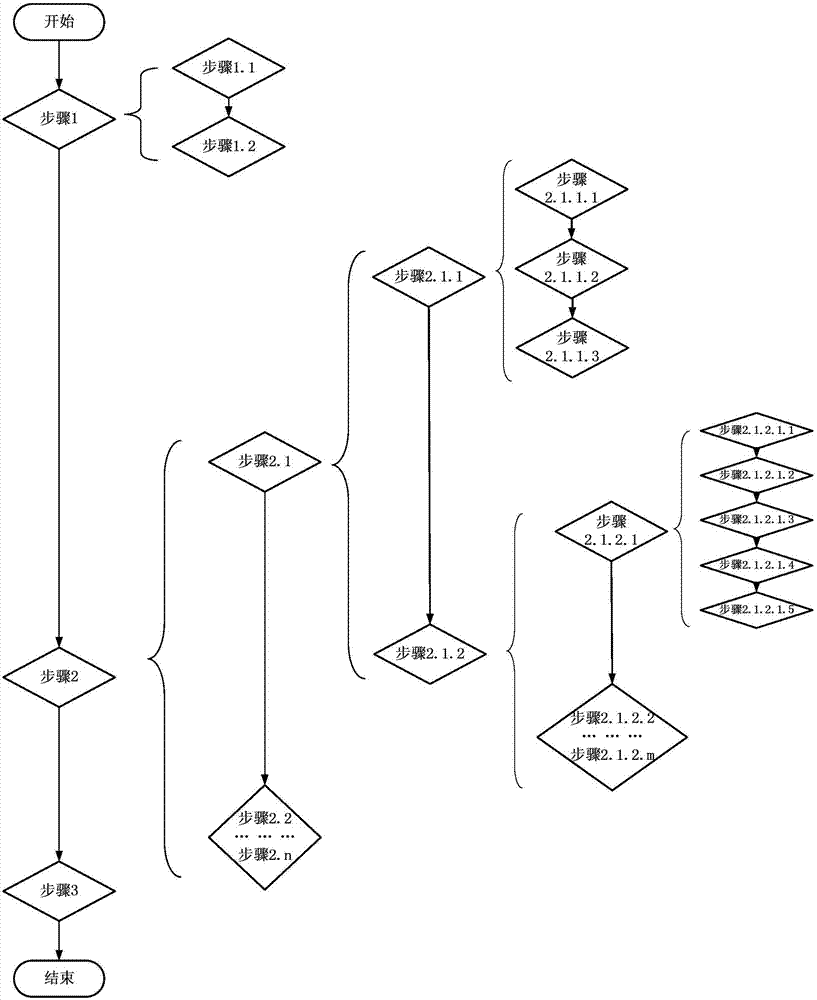

Method and device for generating configuration information of dynamic reconfigurable processor

ActiveCN103942181AAvoid duplicate configurationImplement partial configuration and selective configurationProgram initiation/switchingDigital computer detailsComputer hardware

The invention discloses a method and device for generating configuration information of a dynamic reconfigurable processor, and a processor configuring device. The dynamic reconfigurable processor is composed of processing unit arrays, and each processing unit array comprises a plurality of processing units. The method includes the steps of reading information of a task to be executed, generating a top layer of array configuration information of the processing unit arrays according to the information, generating multiple pieces of processing unit configuration information corresponding to the multiple processing units, and assembling the top layer of the array configuration information and the multiple pieces of processing unit configuration information to generate configuration information of the dynamic reconfigurable processor. According to the method, each processing unit has its own independent configuration information, only the processing units where configuration switching is needed are configured when the arrays are configured, the other processing units keep unchanged in the configuration, and therefore the processing units are prevented from being repeatedly configured, partial configuration and selective configuration are achieved, and flexibility of configuration is improved.

Owner:TSINGHUA UNIV

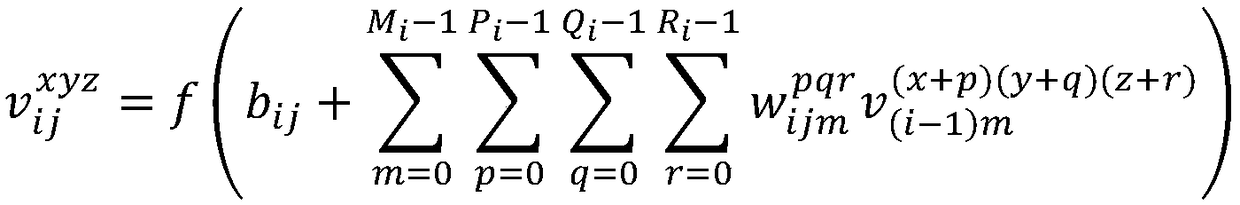

A hyperspectral remote sensing data classification method based on depth neural network

InactiveCN109344891AImprove generalization abilityImplement classificationCharacter and pattern recognitionNeural architecturesSensing dataHyperspectral data classification

A hyperspectral remote sensing data classification method based on depth neural network comprises the following steps: (1) reading hyperspectral data; (2) determining the number of categories and selecting training samples and test samples; (3) performing Spatial and spectral feature joint extraction based on three-dimensional convolution and space pyramid pooling; (4) Establishing the hyperspectral data classification model based on depth neural network; (5) optimizing the model by transfer learning strategy and avoiding over-fitting; (6) inputting All the sample points to be classified intothe model for classification, and the classification result map is obtained. The classifier model in this method migrates the features from the source domain data to the target domain data by optimizing the training of migration learning strategy. Therefore, this method can obtain higher classification accuracy when the number of training samples is small.

Owner:BEIHANG UNIV

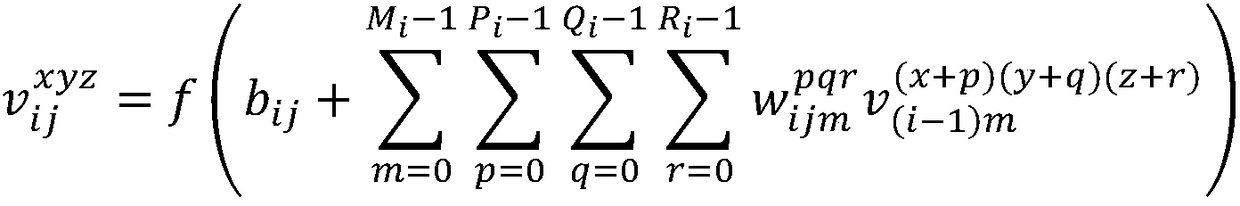

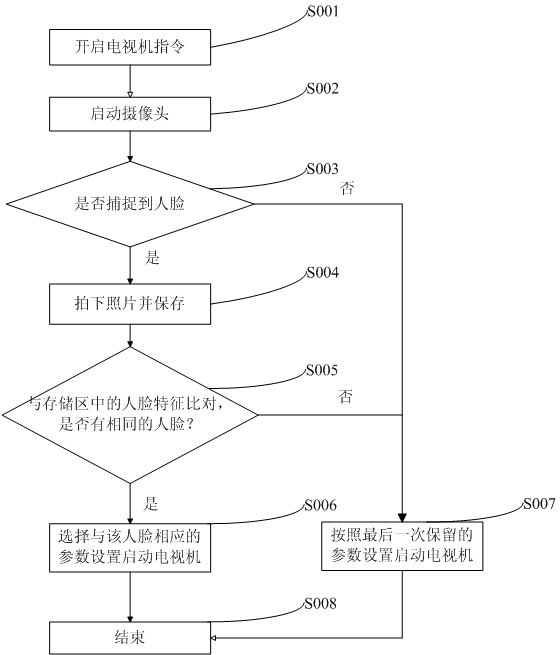

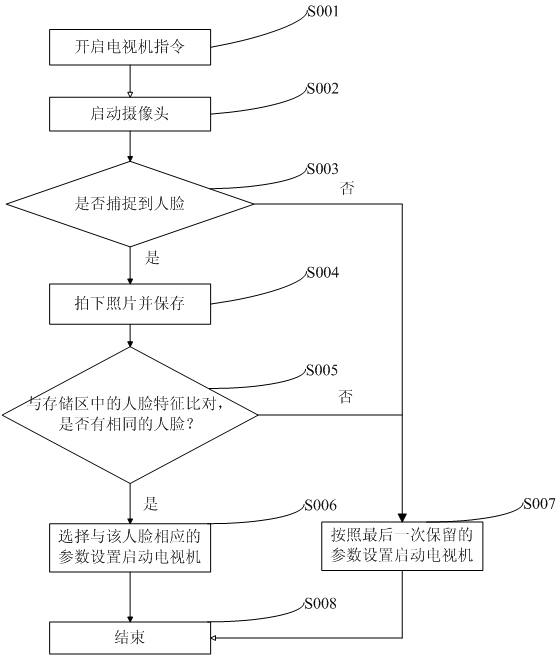

Face recognition technology-based television set parameter setting method and television set

InactiveCN102595078AAvoid selectivityFully automatedTelevision system detailsCharacter and pattern recognitionPersonalizationUser needs

The invention discloses a face recognition technology-based television set parameter setting method and a television set. The method comprises the following steps of: A, receiving a television set start instruction; B, starting a photographic device, obtaining face information by the photographic device; C, if the face is captured, executing next step; if the face is not captured, directly executing a step G; D, automatically shooting a photo, and storing the photo; E, performing face sign comparison between the shot photo and the photo stored in a storage region, if the face with the same characteristics is found, executing the next step; if the face with the same characteristics is not found, directly executing the step G; F, selecting parameter settings corresponding to the face to start the television set; and G, starting the television set according to the parameter settings retained at the last time. The method avoids the trouble that users need to regulate the parameters when starting the television set each time, realizes the automatic and personalized settings of the television set parameters, and is convenient for the users of different types to watch television.

Owner:KONKA GROUP

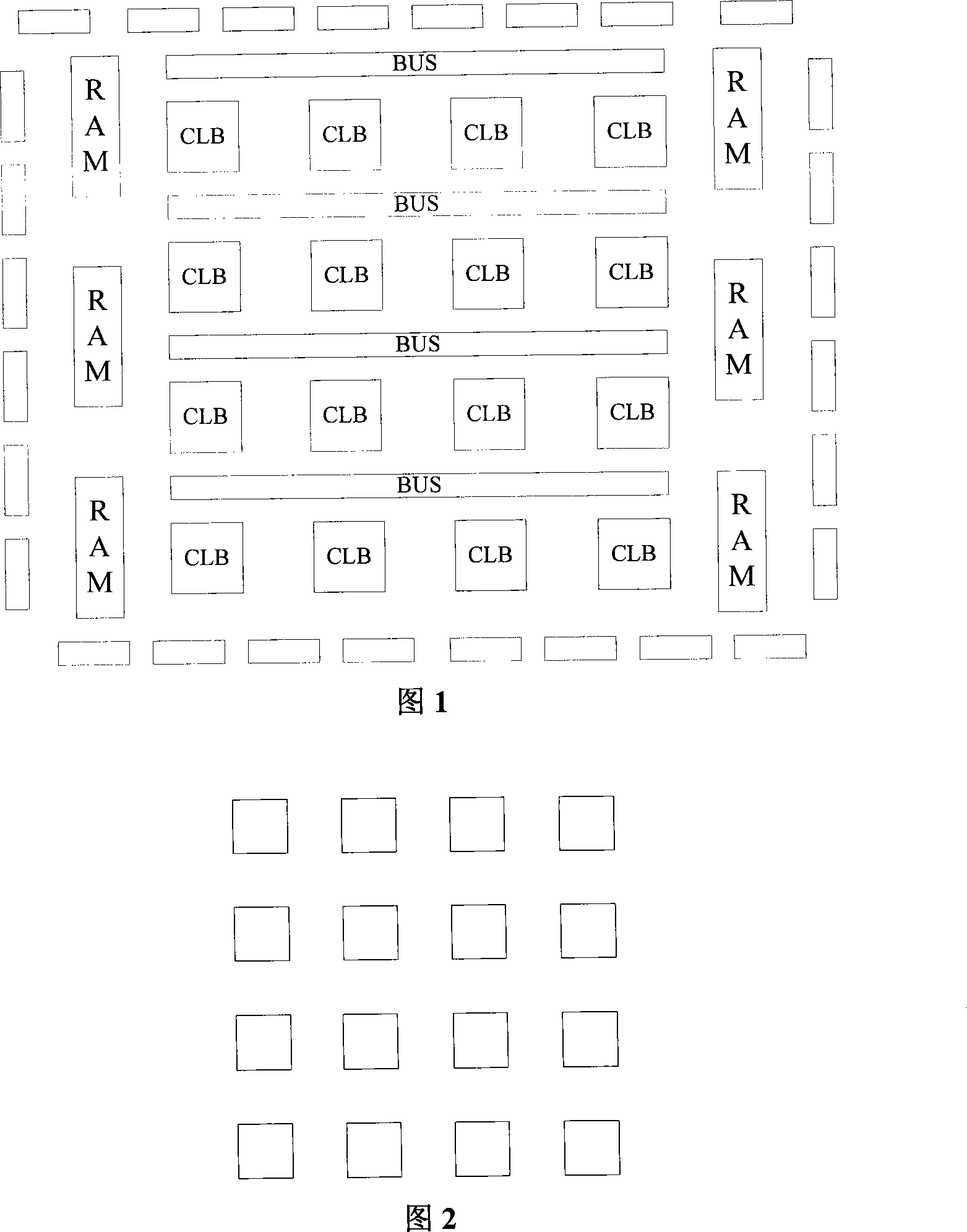

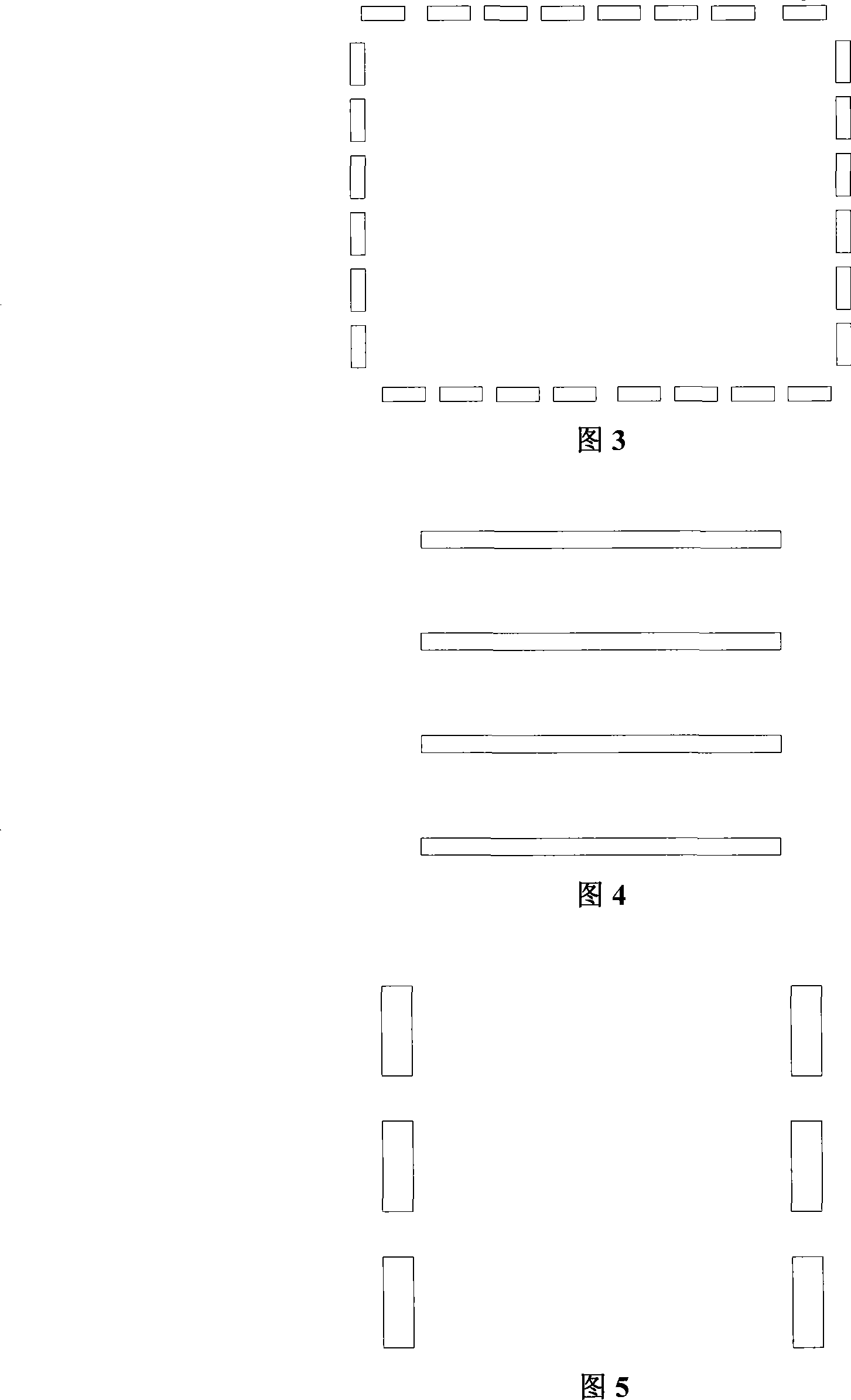

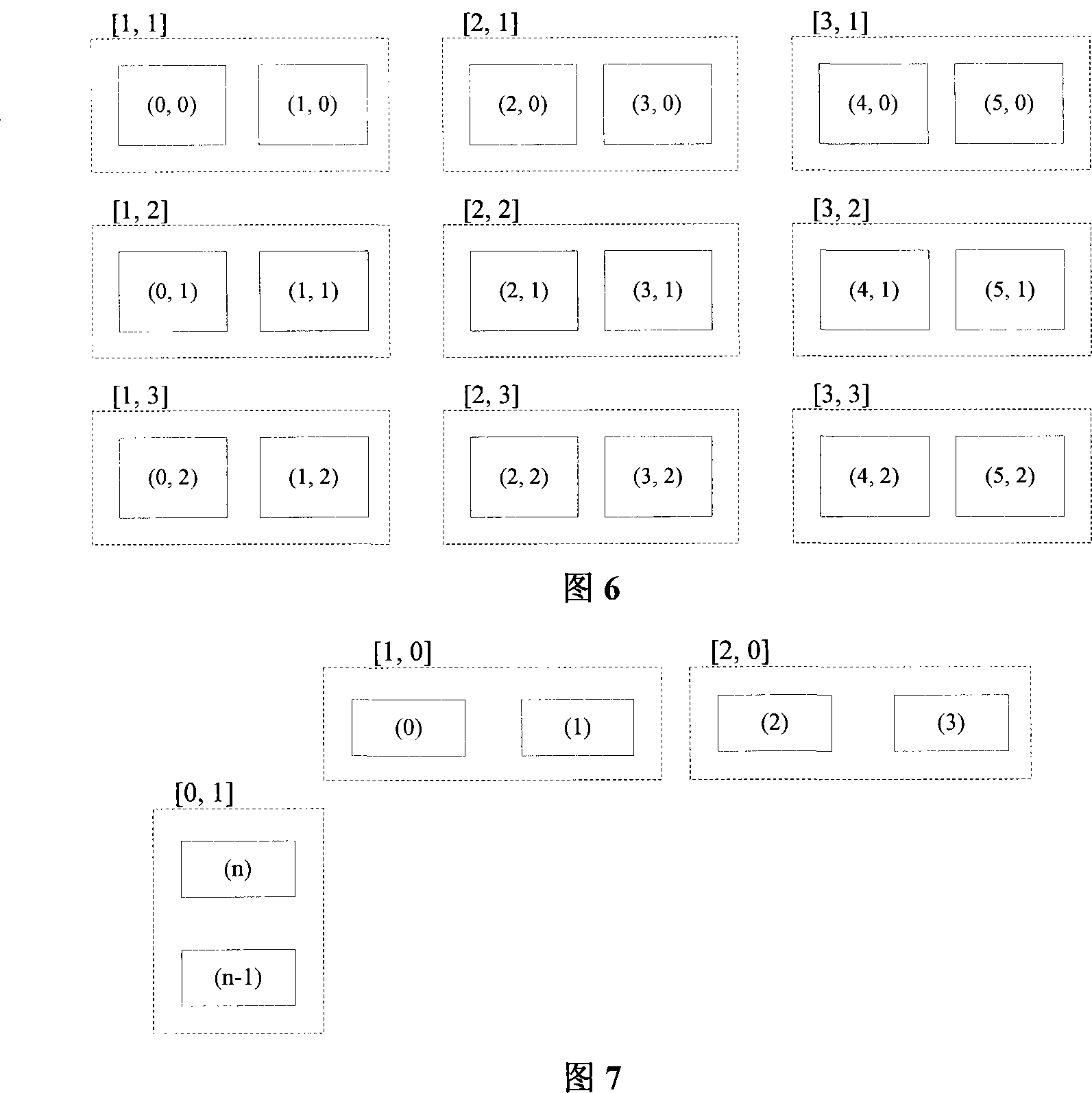

Layering placement modeling method for modern programmable logic device software system

InactiveCN101231674AImprove operational efficiencyImprove acceleration performanceSpecial data processing applicationsHardware structureSoftware system

The invention belongs to the electronic technology field, in particular to a hierarchical layout design modeling method of a modern FPGA software system. The invention is a layout software modeling method aiming at a modern FPGA hardware structure, and has the details that the FPGA structure is logically divided into a plurality of logic unit layers according to the types of the logic unit, such as a programmable logic block layer, a programmable input-output block layer, a block random memory layer, a bus layer and a global clock layer, etc.; then models are respectively established on each logic unit layer according to a specific geometric structure, and the layout scheme is adjusted according to the practical situation. The invention can greatly improve the running efficiency and the algorithm expansibility of the FPGA layout software in the whole FPGA CAD process through respectively carrying out the layout on each logic unit layer.

Owner:FUDAN UNIV

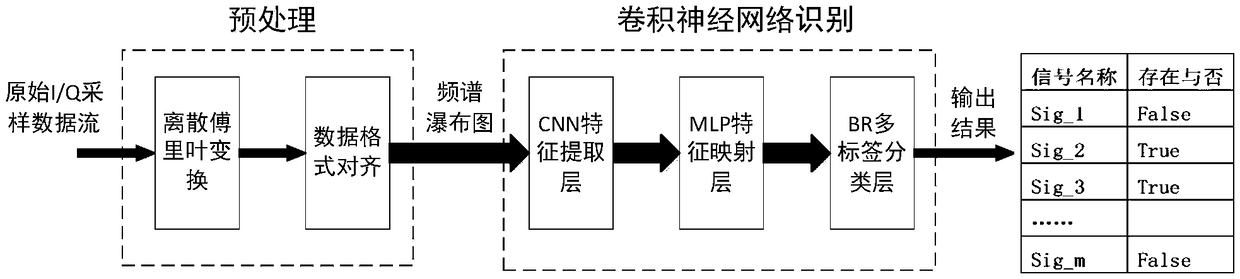

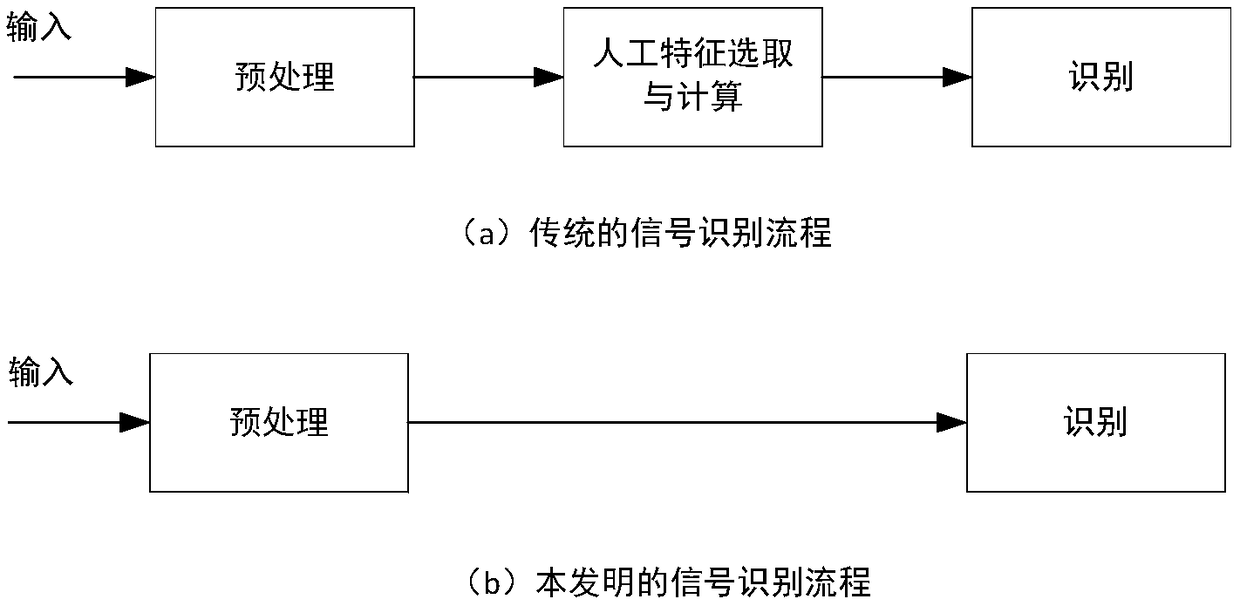

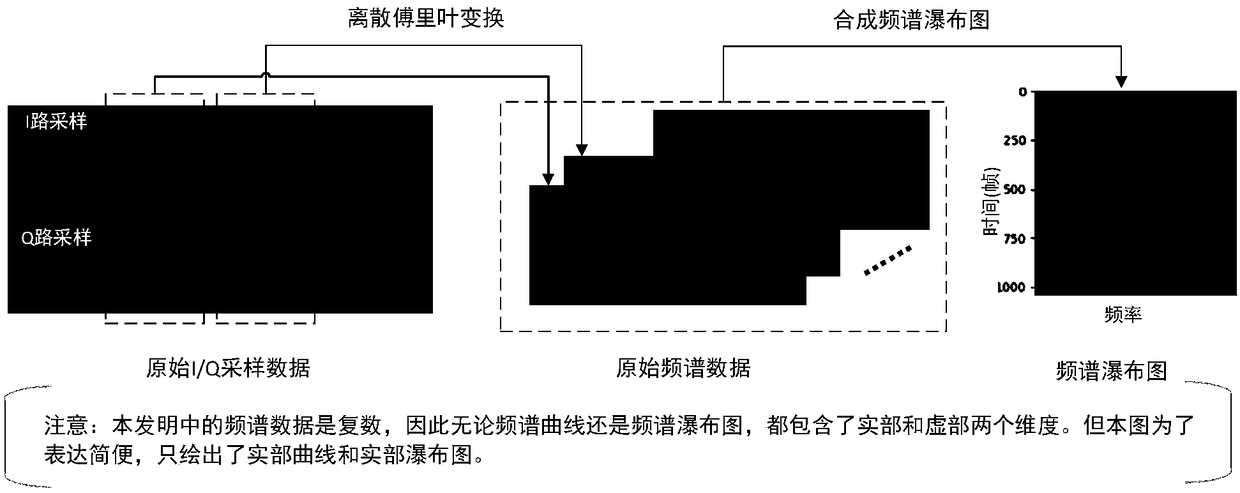

Radio signal identification method based on end-to-end convolutional neural network

InactiveCN108764013AImprove accuracyImprove robustnessCharacter and pattern recognitionNeural architecturesFrequency spectrumFeature extraction

The present invention relates to a radio signal identification method based on an end-to-end convolutional neural network. The method is characterized in that: an original I / Q sampling data of an observation window is subjected to execution of preprocessing and identification through a convolutional neural network in order. The preprocessing step is that: the original I / Q sampling data of the observation window is taken as input, and a frequency spectrum waterfall plot is output after discrete Fourier transform and data format alignment processing; the step of identification through the convolutional neural network is that: the frequency spectrum waterfall plot obtained by preprocessing is taken as input, and a one-dimensional boolean vector configured to show whether all the signals to beidentified are existed or not is output after the input passes through a CNN feature extraction layer, an MLP feature mapping layer and a BR multi-tag classification layer. Compared with the mode offeature extraction and classification identification, the radio signal identification method employs the end-to-end technical solution thinking to avoid complex and low-efficient feature engineering,improve the signal identification accuracy, robustness and intelligence level, and has important meaning of radio monitoring of important areas and important activity scenes.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

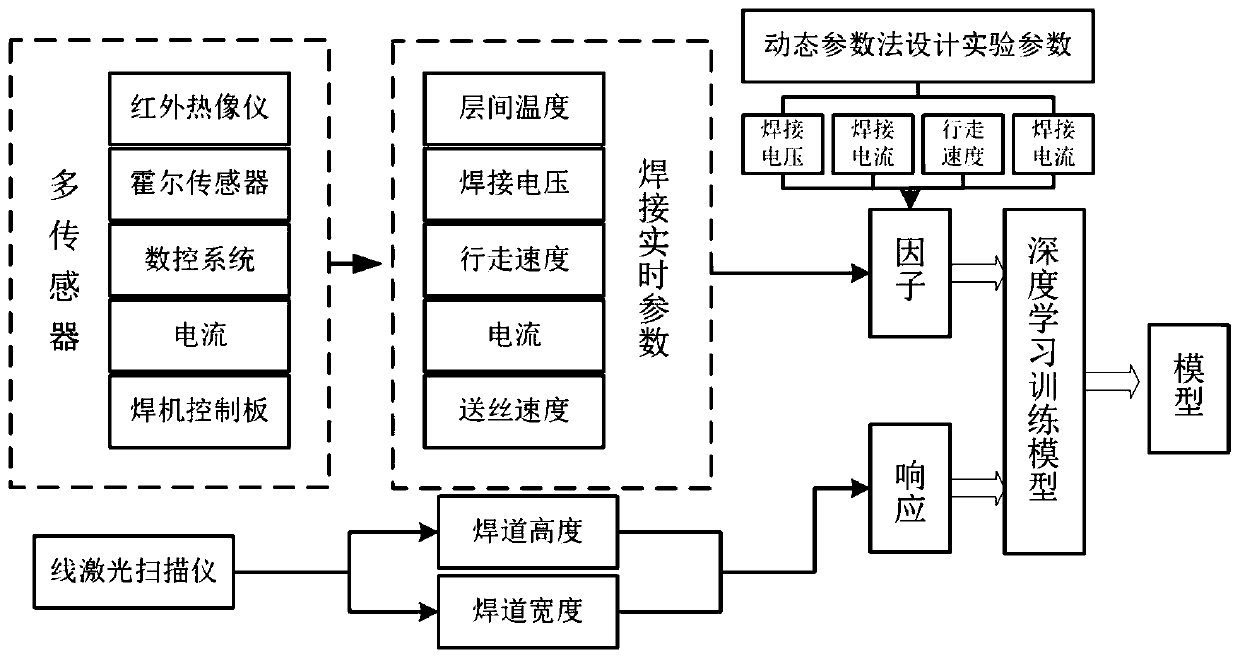

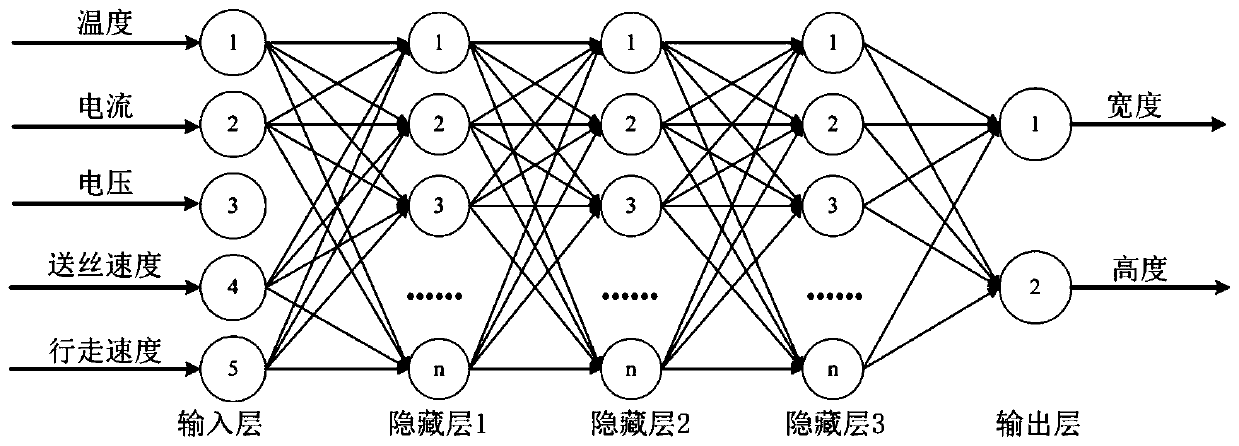

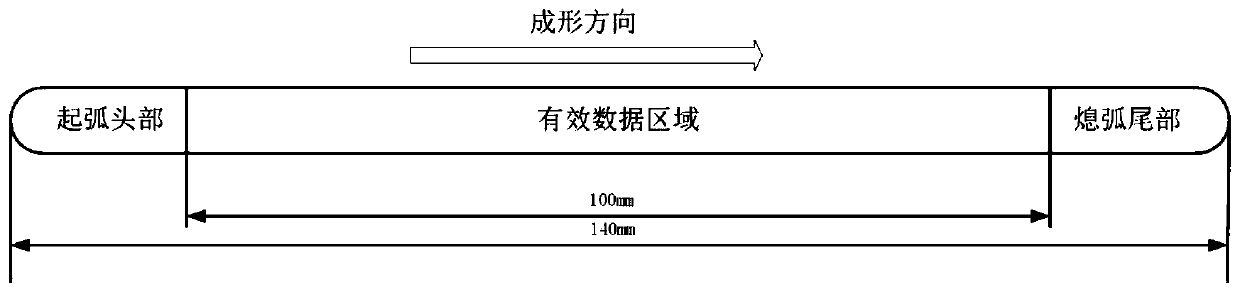

Weld bead modeling method, device and system for arc additive manufacturing

ActiveCN110883403AAvoid selectivityShorten the timeAdditive manufacturing apparatusWelding accessoriesLaser sensorMechanical engineering

The invention belongs to the field of manufacturing of arc wire feed additives, and discloses a weld bead modeling method, device and system for arc additive manufacturing. According to the method, adynamic parameter method is adopted, and different welding process parameters are adopted in the same welding bead in the one-time arc additive manufacturing process, so that a welding bead of which the shape is synchronously and dynamically changed according to the dynamic change of the welding process parameters; and a line laser sensor is used for scanning to obtain the processed weld bead segmented shapes, and each segment of weld bead shape is in one-to-one correspondence with the welding process parameter of the same segment and used as training data to train the neural network so that aweld bead modeling model of the corresponding weld bead shape can be obtained according to the input welding process parameters. According to the method, multiple sets of experimental data can be obtained through one-time processing experiment, sufficient training data are provided under the condition of reducing experiment times and experimental cost, and meanwhile, the technical problems that atraditional orthogonal experiment method and a corresponding curved surface method require complex regression equation selection and parameter optimization are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

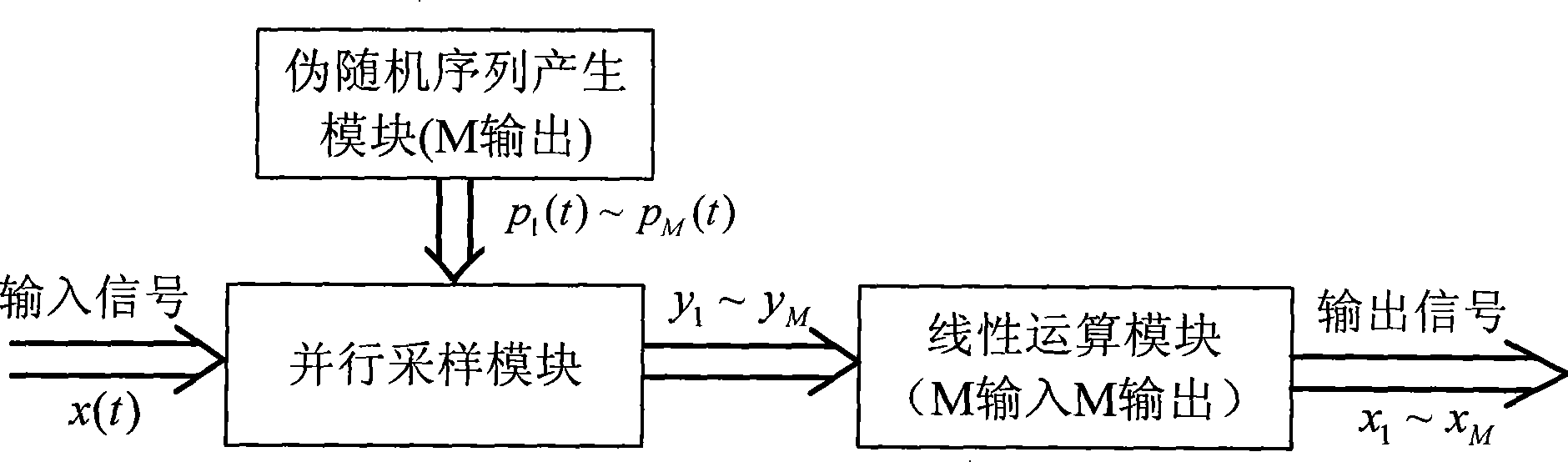

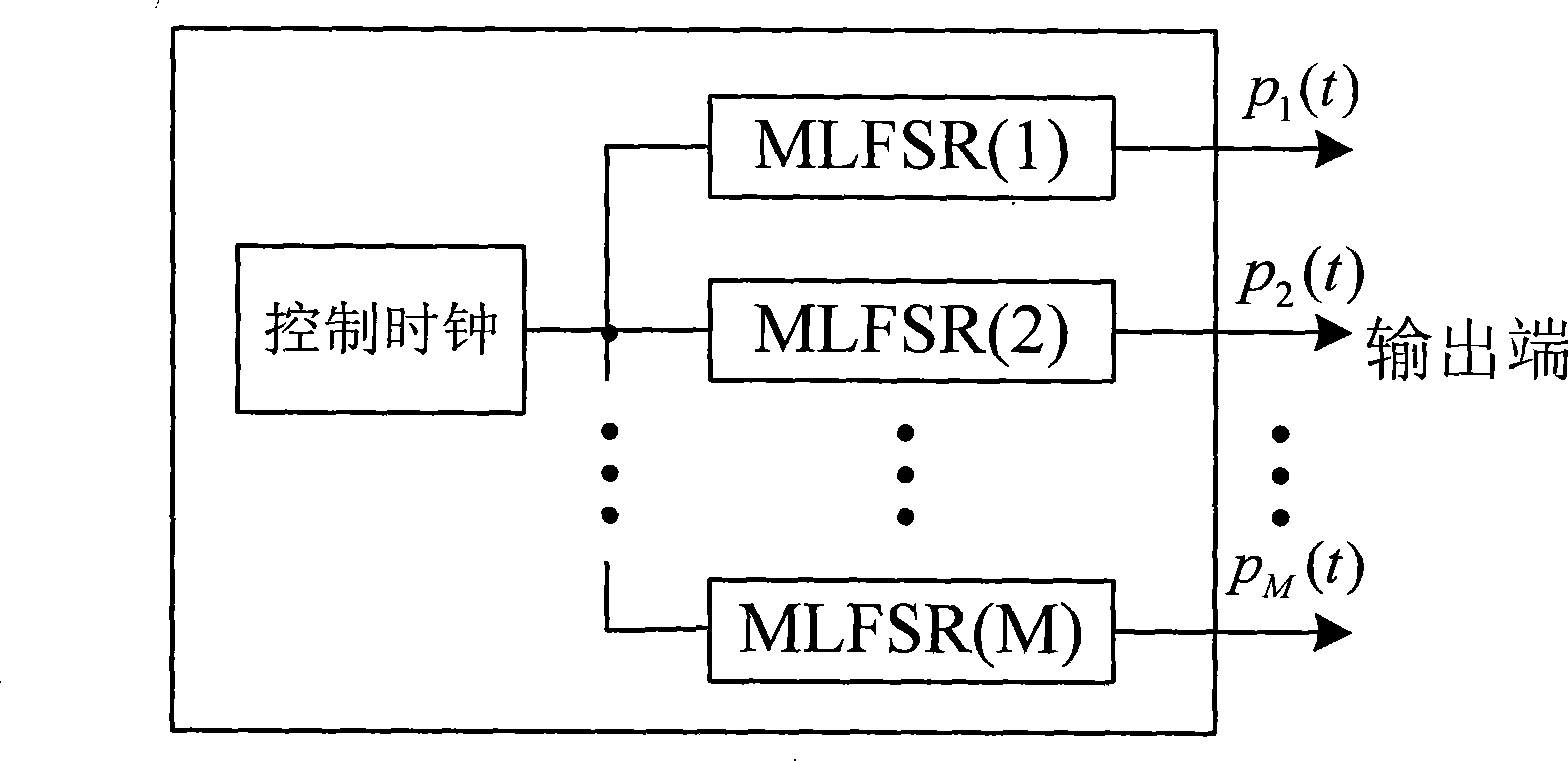

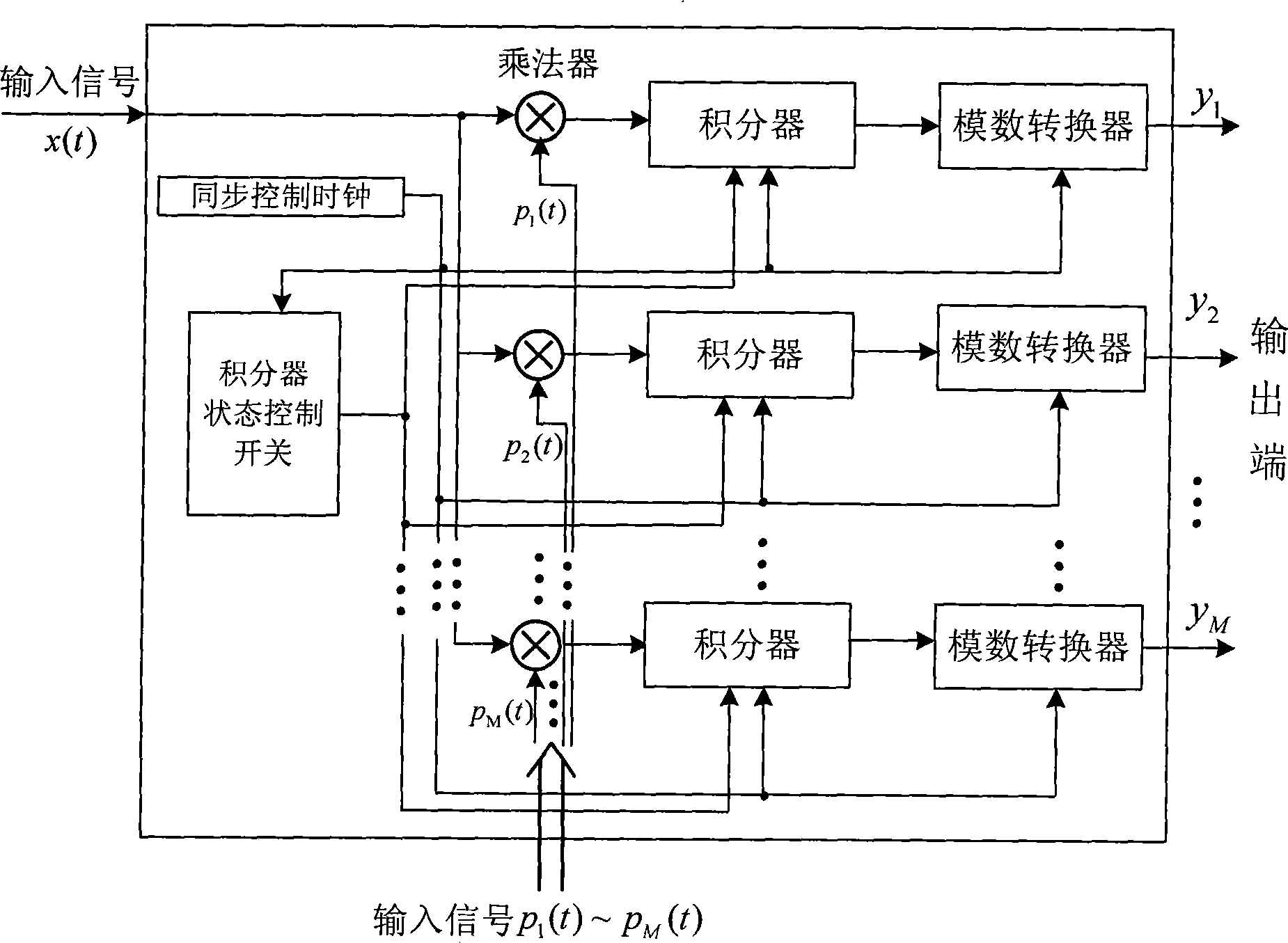

Ultra-broadband analogue signal parallel sampling system based on accidental projection

InactiveCN101247137AEasy to implementAchieving Process StabilityAnalogue-digital convertersTransmissionAnalog signalBroadband

The present invention discloses a parallel sampling system basing on the super-wideband which is projected randomly, and the invention mainly settles the problem of complex realization and no suitability for processing the common super-wide band in the homogeneous system. The system is mainly composed of a function generating module, a parallel sampling module and a linear operating module. In the system the function generating module adopts a pseudorandom sequence generating module for generating a group of pseudorandom sequence for inputting to the parallel sampling module. The parallel sampling module realizes the projection operation of the upper-wide band analog signal on the self-contained pseudorandom space and obtains the digital projection coefficient signal for inputting to the linear operating module. The linear operating module adopts the M-input and M-output linear structure and conveys the output projection coefficient signal of the parallel sampling module to the parallel digital sampling signal and then outputs. The invention has the advantages of low complexity in the circuit operation, being easily realized and broad applying sphere. The invention can be used for executing digitization sampling processing to the super-wideband signal.

Owner:XIDIAN UNIV

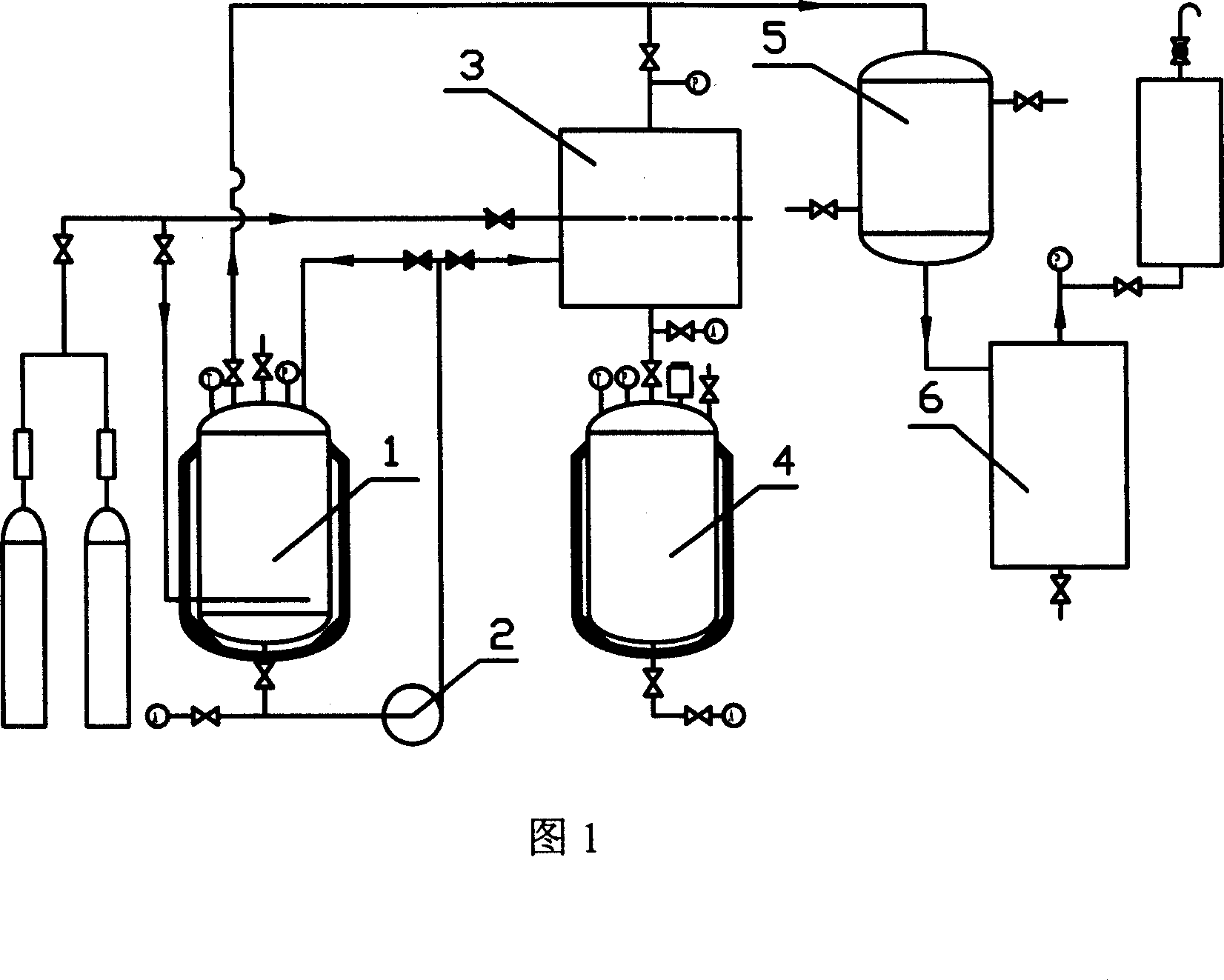

Production of anone by cyclohexane liquid-phase oxidation

InactiveCN1982273ASolve the problem of reduced selectivityGood choiceOrganic compound preparationCarbonyl compound preparationCyclohexanoneMixed oxide

Production of cyclohexanone by cyclohexane liquid-phase oxidation is carried out by oxidation inductive reacting, inducing oxy-gas and mixed oxide liquid with cyclohexanone, cyclohexanol and cyclohexyl-hydrogen peroxide into super-gravity reactor, continuous oxidation reacting for cyclohexanone and decomposing for cyclohexyl-hydrogen peroxide under cyclohyexanone oxidation. It's efficient, has better selectivity and no environmental pollution.

Owner:BEIJING UNIV OF CHEM TECH

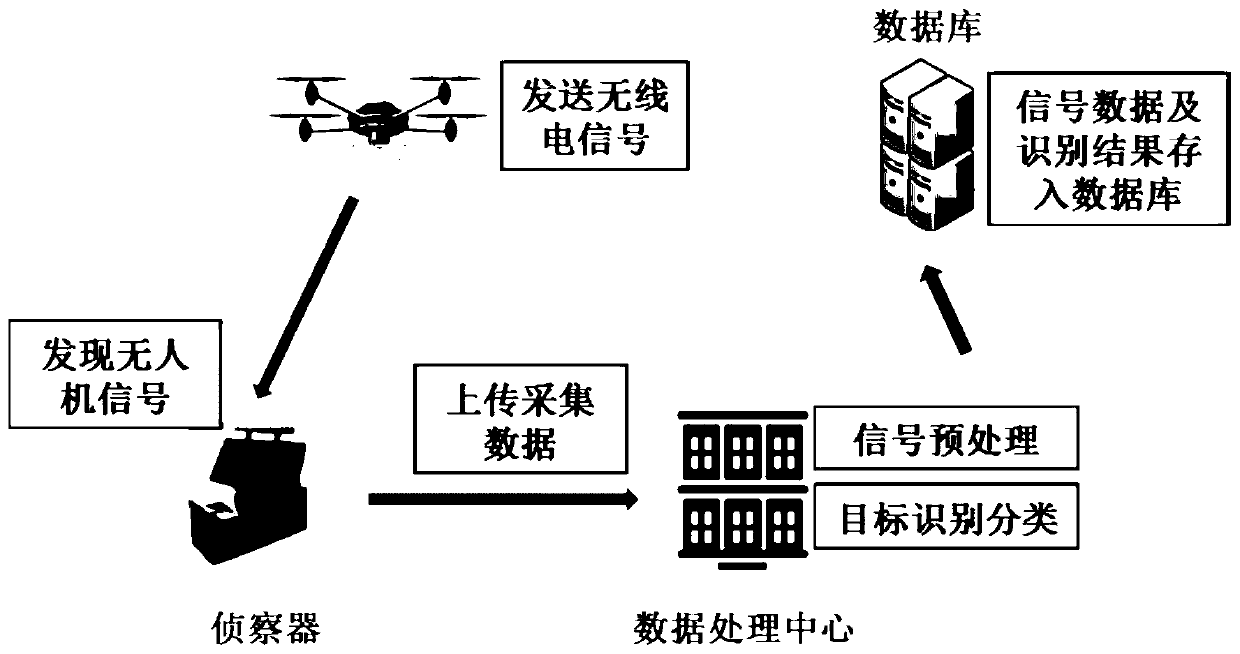

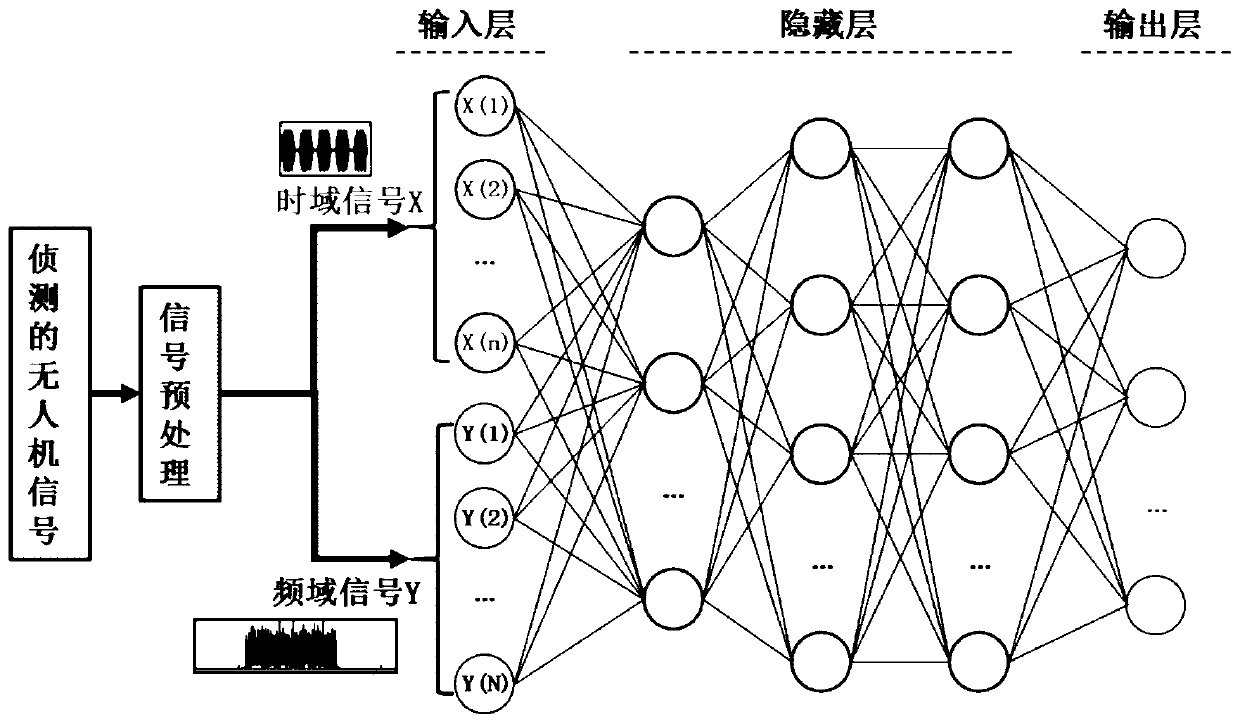

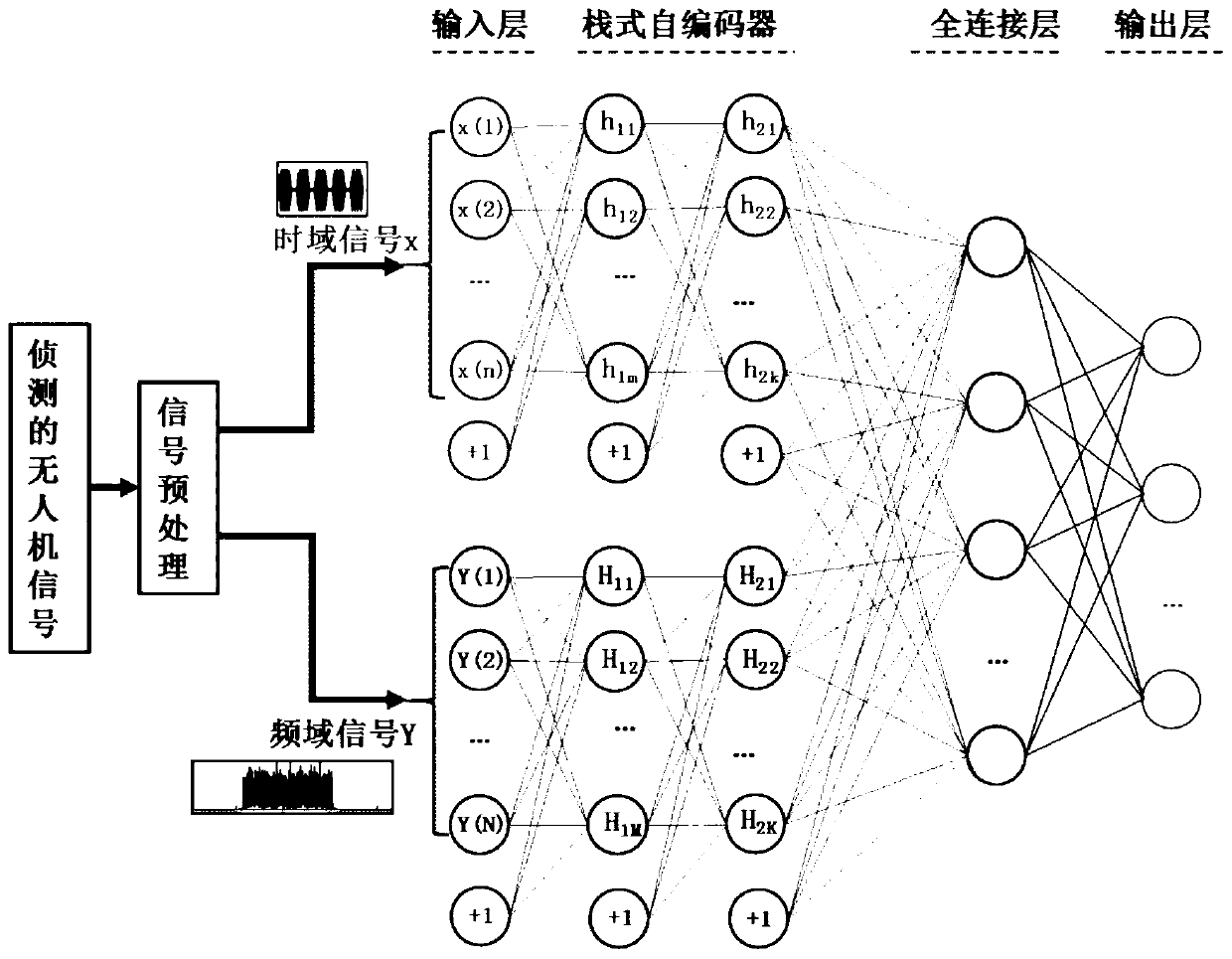

Unmanned aerial vehicle target recognition and classification method based on deep learning

ActiveCN110084094AImprove efficiencyImprove noise immunityCharacter and pattern recognitionNeural architecturesTime domainClassification methods

The invention discloses an unmanned aerial vehicle target recognition and classification method based on deep learning, and the method comprises the specific processing steps: (1), carrying out the collection through a radio monitoring means, and obtaining a link signal of a small civil unmanned aerial vehicle; (2) sending the link signal to a data processing center, and carrying out signal preprocessing to obtain a time domain characteristic and a frequency domain characteristic of the signal; (3) inputting the time domain characteristics and the frequency domain characteristics of the signalinto a deep learning network for calculation, and outputting to obtain a target identification classification result of the signal; and (4) storing the acquired signal data and the identification result in a database, and if the acquired signal data and the identification result are newly discovered target categories, adding the newly discovered target categories to a signal identification library after manual confirmation. According to the unmanned aerial vehicle target identification classification method provided by the invention, the deep learning algorithm is applied to the field of unmanned aerial vehicle radio signal monitoring, so that the application bottleneck of a traditional radio signal analysis method is broken through, and the unmanned aerial vehicle signal monitoring and identification problems in low-altitude safety protection are solved practically.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

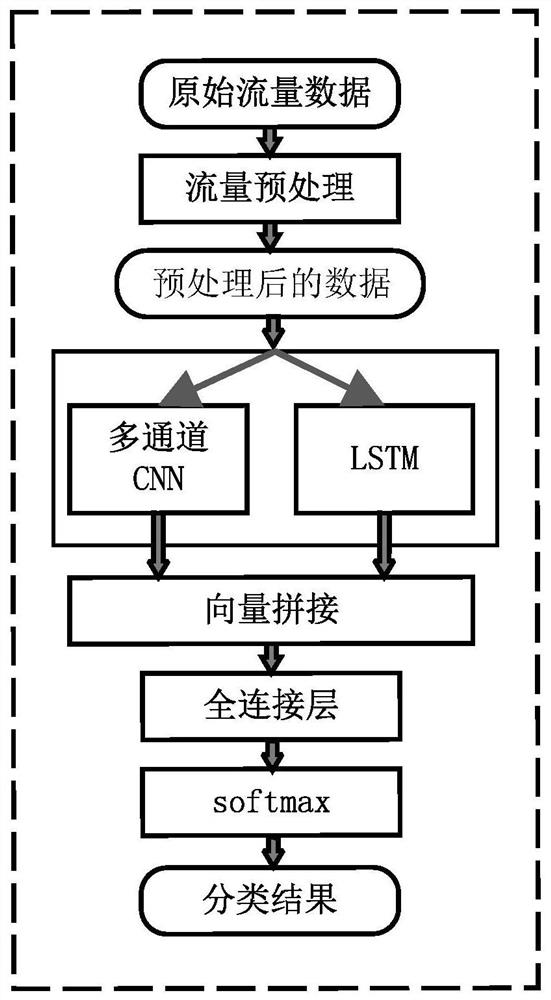

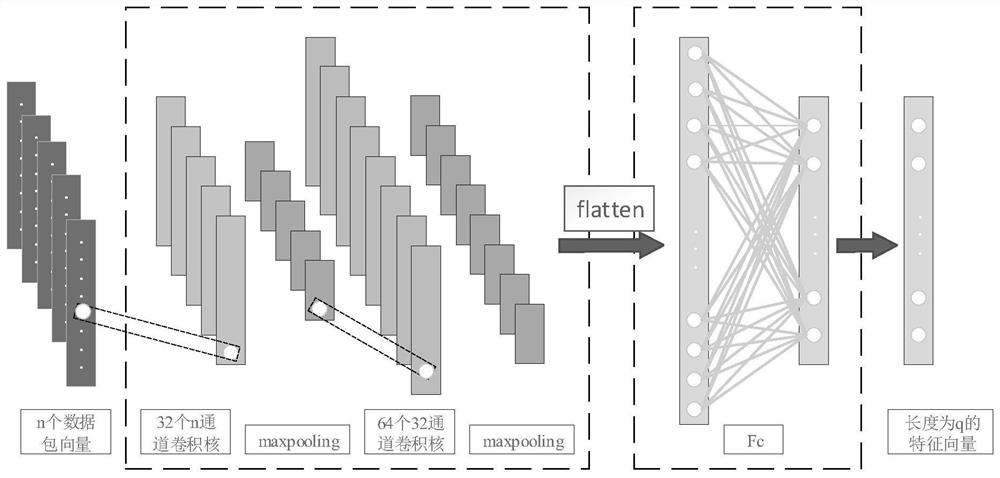

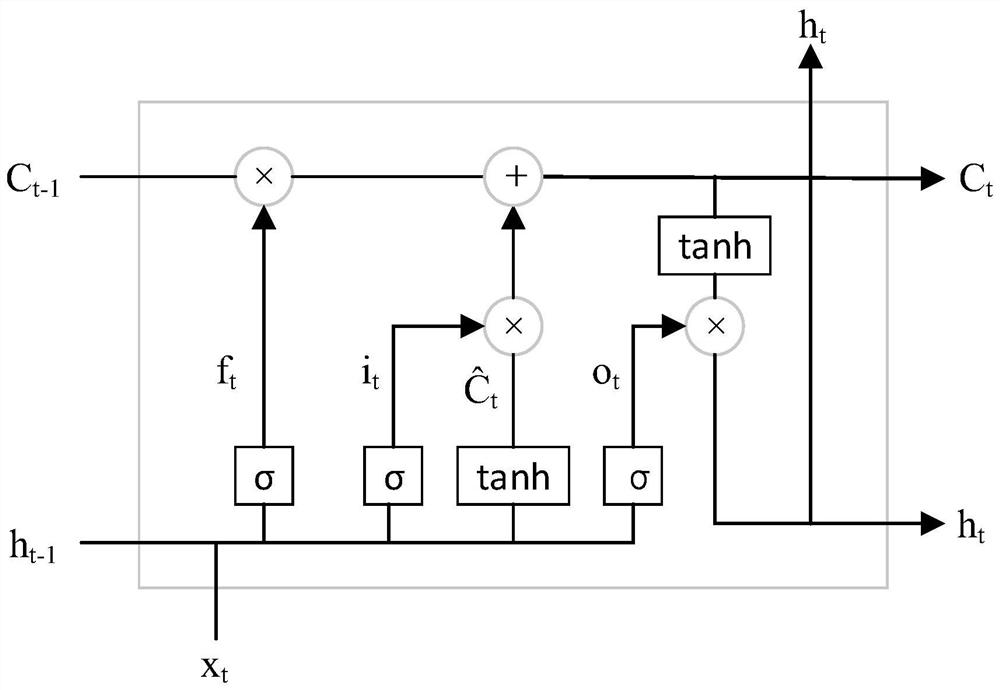

Network encryption traffic classification method and system based on multi-feature learning

ActiveCN113037730AImprove classification accuracyImprove classification recognition abilityNeural architecturesData switching networksData packData set

The invention belongs to the technical field of network security, and particularly relates to a network encryption traffic classification method and system based on multi-feature learning, and the method comprises the steps: carrying out the preprocessing of an original traffic data set, and obtaining a traffic data package vector used for the input of a deep learning model; respectively inputting the traffic data packet vectors into a trained multi-channel CNN model and a trained LSTM model for parallel learning, extracting the data packet space features through the multi-channel CNN model, and extracting traffic time sequence features through the LSTM model; carrying out vector splicing on the data packet space feature and the traffic time sequence feature to obtain an omnibearing traffic feature vector; and inputting the omni-directional traffic feature vector into a neural network full-connection layer, and obtaining an encrypted traffic classification type through a traffic type probability. According to the method, the traffic features can be comprehensively and automatically extracted and utilized from the angles of the spatial features and the time features, the classification capability of the encrypted traffic is improved, and the method has good application value.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU +1

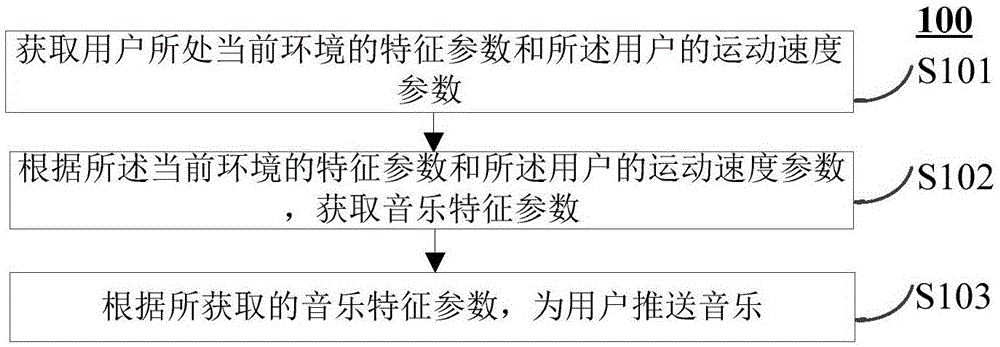

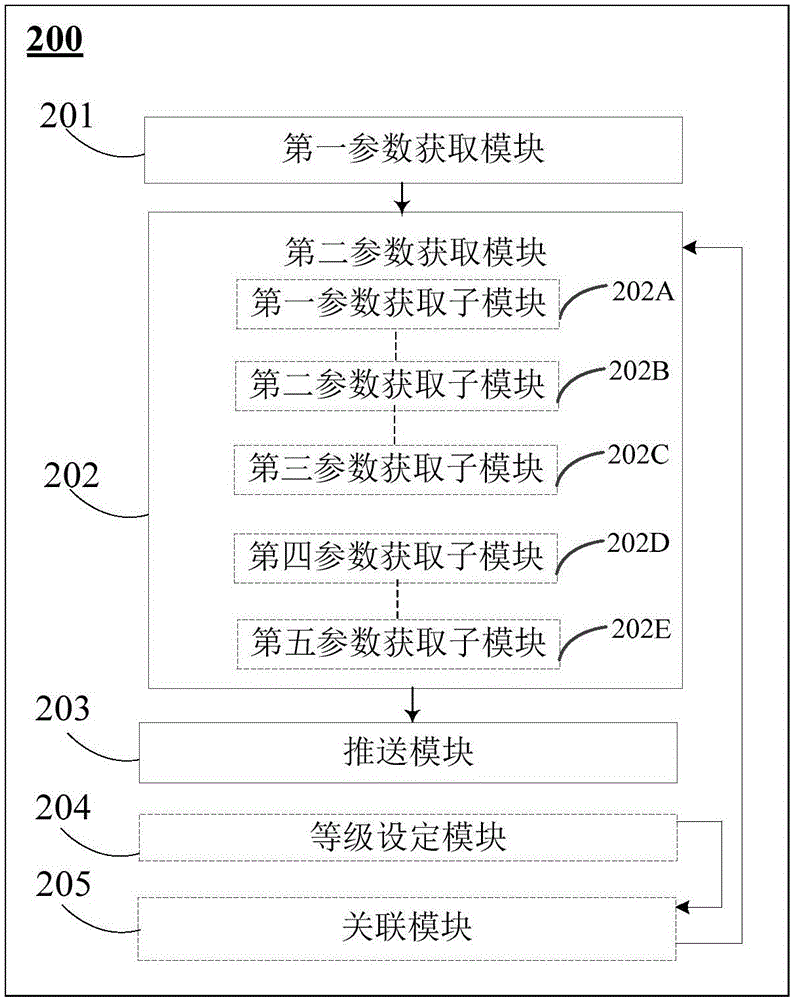

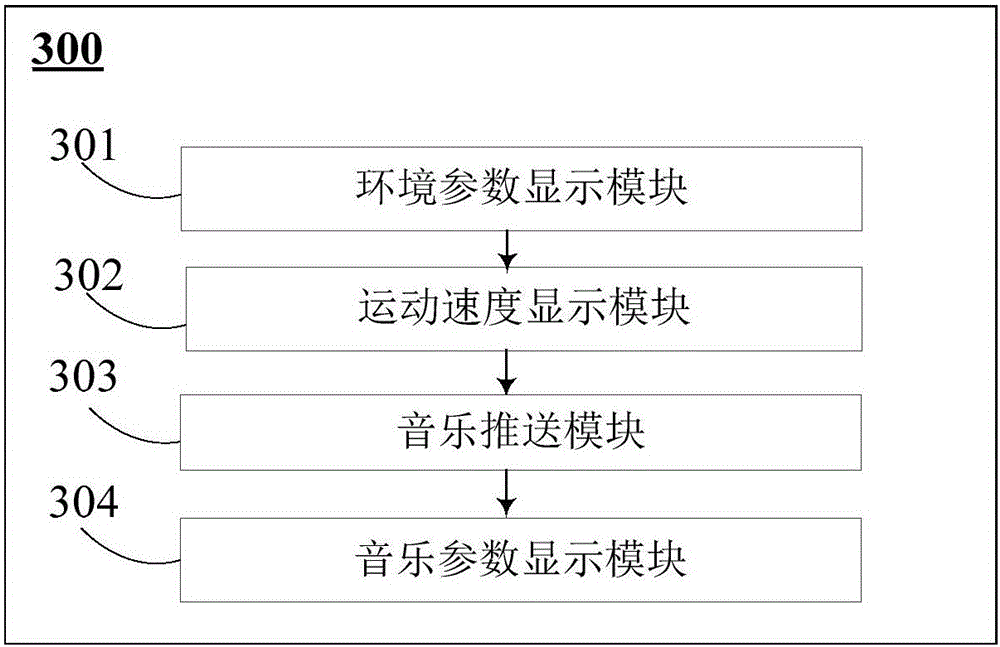

Method and device for pushing music for user

InactiveCN106254541ASimplify calculationImprove efficiencyTransmissionOperation timeSystems engineering

The mode of execution of the invention provides a method and device for pushing music for a user. The method comprises the following steps: acquiring a feature parameter of the current environment of the user and a movement speed parameter of the user; acquiring the music feature parameter according to the feature parameter of the current environment and the movement speed parameter of the user; and pushing the music for the user according to the acquired music feature parameter. Through the adoption of the mode provided by the invention, the playing and pushing of the music are more flexible and accurate, the manual regulation and selection of a rider are avoided, the riding security is enhanced, the operation time is saved, and the operation efficiency is improved.

Owner:HANGZHOU NETEASE CLOUD MUSIC TECH CO LTD

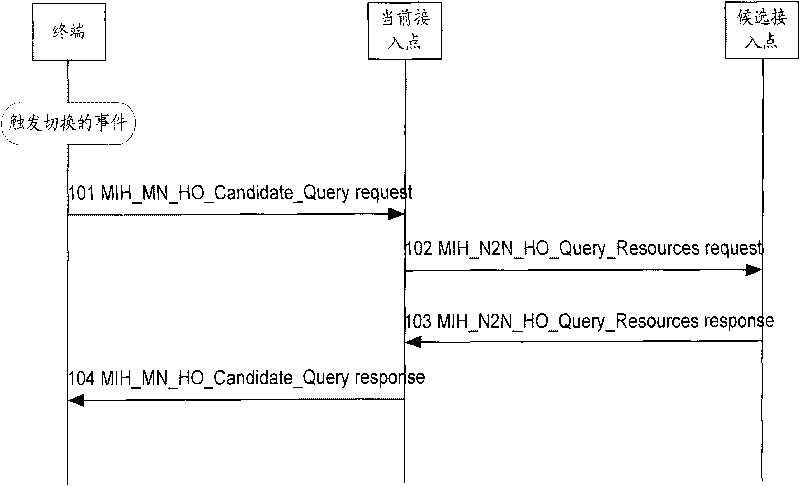

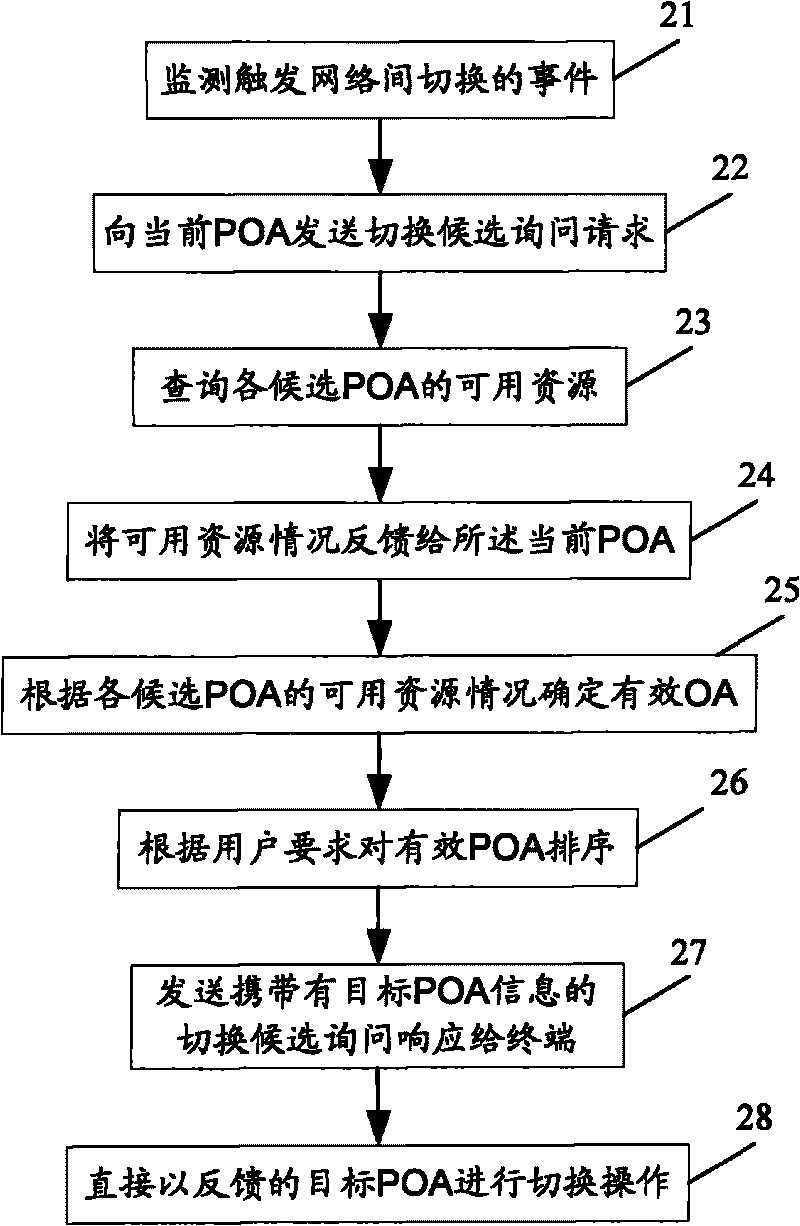

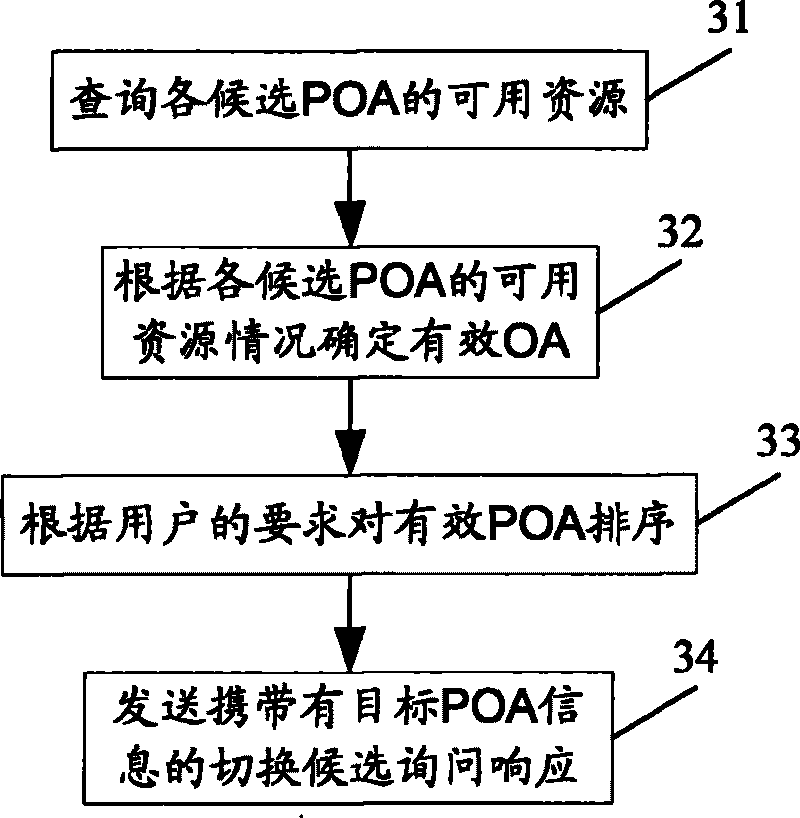

Method/system, access point equipment and terminal equipment for switching initialization between heterogeneous networks

InactiveCN101715220AReduce processing complexityReduce power consumptionAssess restrictionTerminal equipmentHeterogeneous network

The invention relates to a method for switching initialization between heterogeneous networks, which comprises the following steps: sending a switching candidate inquiry request carrying user requirements to the current access point by a terminal; inquiring available resources of each candidate access point and determining effective access points by the current access point; sorting the effectiveaccess points according to the user requirements by the current access point; using the first effective access point after sorting as a target access point by the current access point, and feeding the switching candidate inquiry response including the object access point back to the terminal; and directly carrying out switching operation by the terminal through the object access point fed back. By adopting the method, the network side can select the most appropriate object access point according to the user requirements to avoid the occurrence of the inconsistent condition of user selection and network selection, thereby bringing good switching feeling for users. The invention also provides a system, access point equipment and a terminal for switching the initialization between heterogeneous networks.

Owner:BEIJING NUFRONT MOBILE MULTIMEDIA TECH

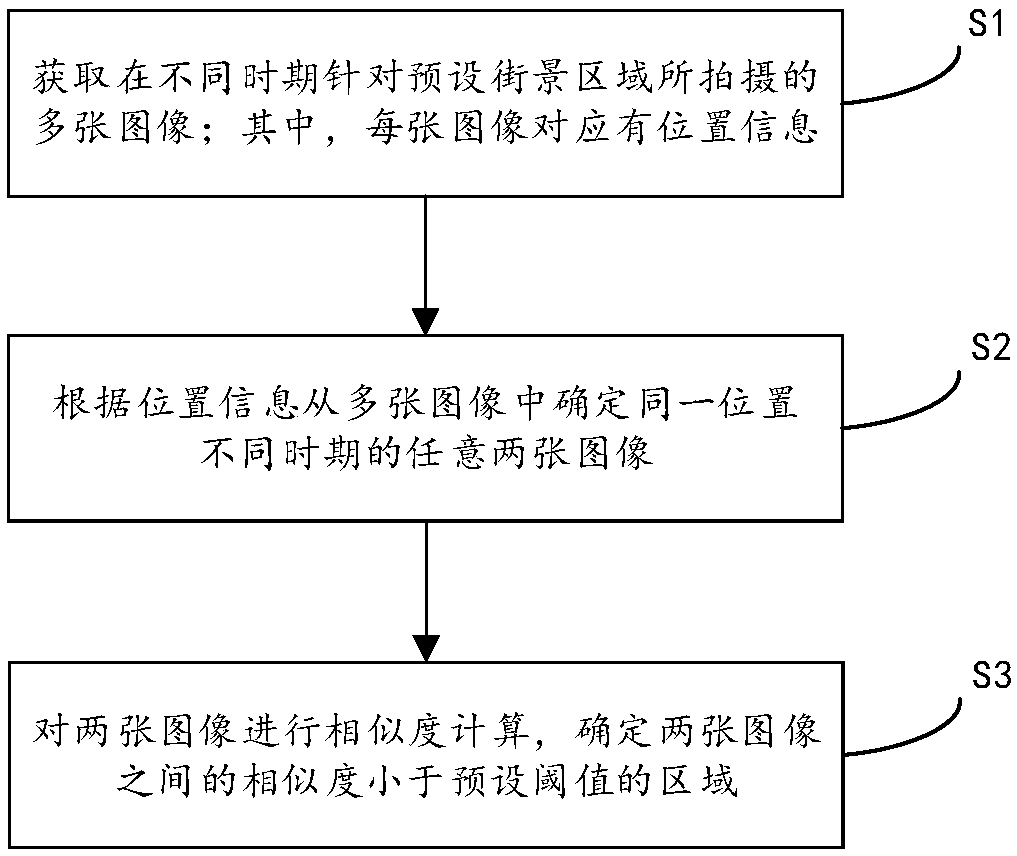

A street scene image difference comparison method and a device

InactiveCN109034185AEfficient automatic detection methodReduce labor intensityImage analysisCharacter and pattern recognitionUrban managementImage pair

The invention discloses a street scene image difference comparison method and a device. The method comprises the following steps: S1, acquiring a plurality of images taken for a preset street view area in different periods, where each image pair should have position information; S2: determining any two images at the same position from the plurality of images according to the position information;S3: calculating the similarity between the two images to determine an area in which the similarity between the two images is smaller than a preset threshold value. The invention provides an efficientautomatic detection method for searching for differences in street scene images taken in different periods, reduces labor intensity of professionals, improves detection efficiency, and can more effectively avoid wrong selection or omission caused by human subjectivity. Automatic identification of street scene differences in different periods can make up for the shortcomings of manual searching fordifferences time-consuming and labor-consuming subjectivity and incomplete difference searching and provide an efficient means for urban management.

Owner:汪俊

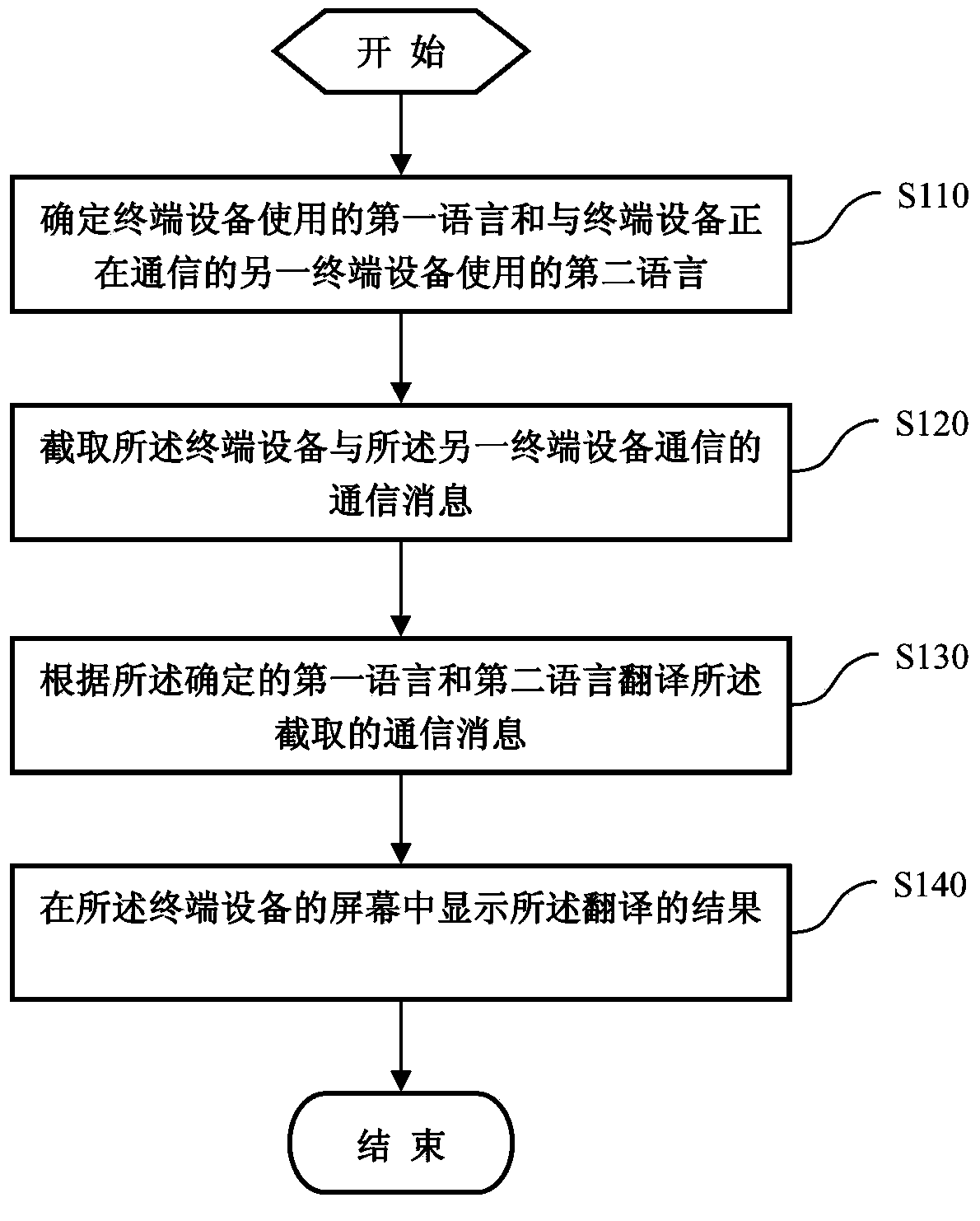

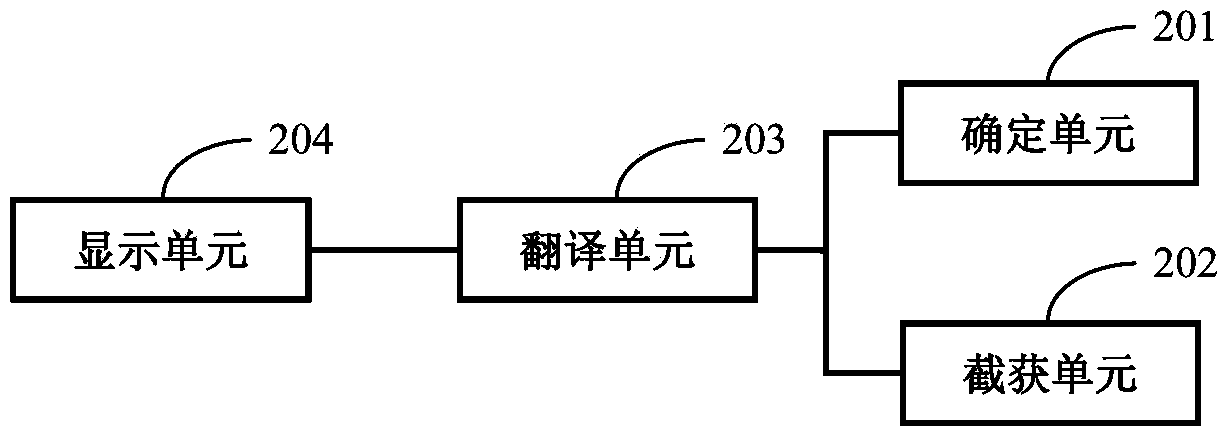

Method and device for translating messages

InactiveCN103530285AOvercome language barriersImprove experienceSpecial data processing applicationsTerminal equipmentComputer terminal

The invention provides a method and device for translating messages. The method for translating the messages in terminal equipment includes the steps that a first language used in the terminal equipment and a second language used in another terminal equipment in communication with the terminal equipment are determined; communication messages between the terminal equipment and the another terminal equipment in communication are intercepted; the intercepted communication messages are translated according to the determined first language and the second language; translated results are displayed in a screen of the terminal equipment. By the adoption of the method and device, not only can language communication disorders of the terminal equipment in the process of message communication be effectively overcome, but also user operation can be effectively reduced, and the whole translation and operation processes are more convenient and intelligent.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

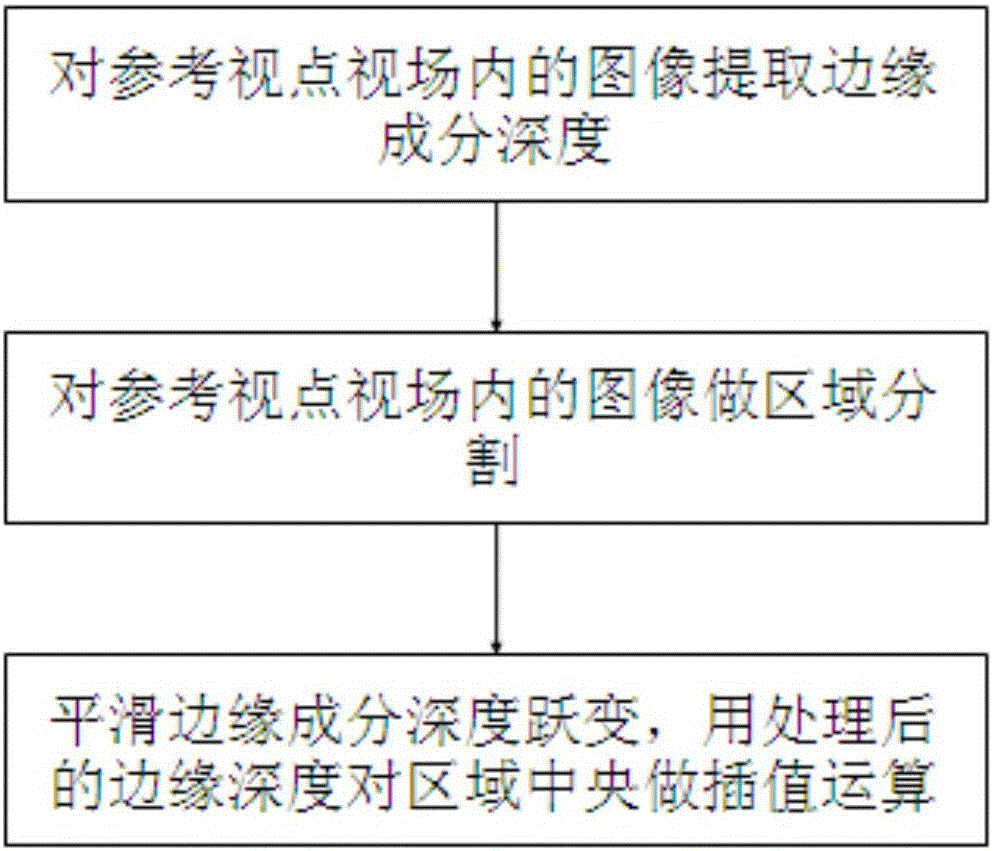

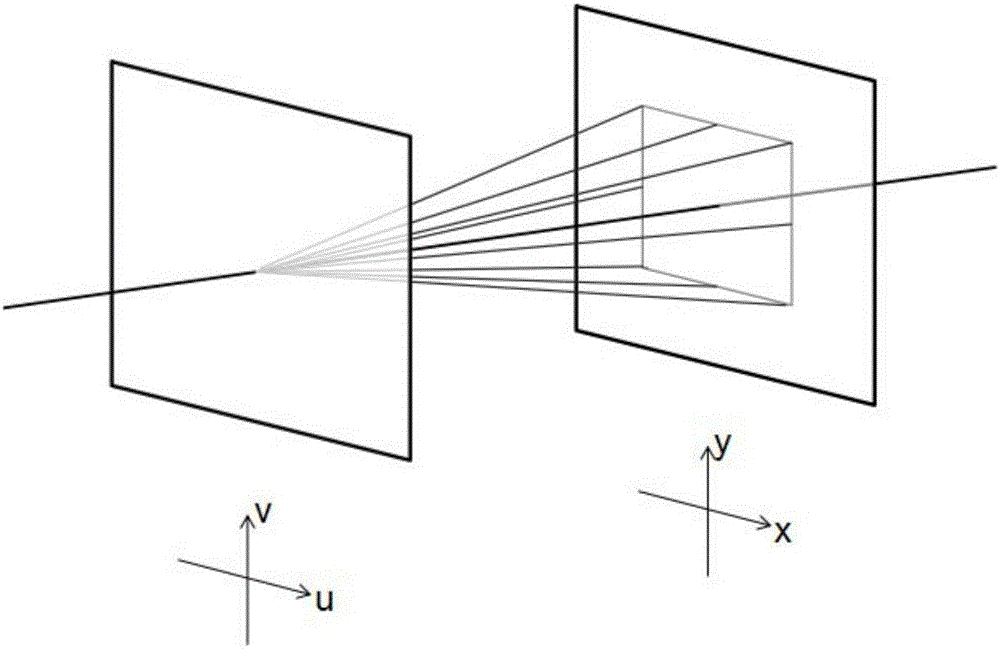

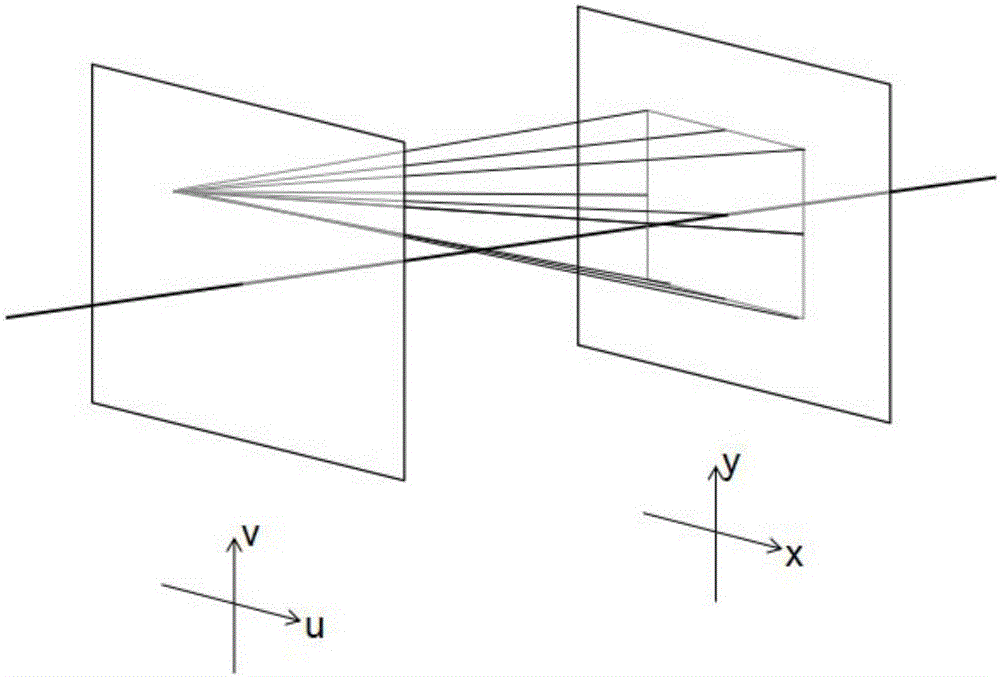

Spatial depth extraction method based on light field information

ActiveCN106257537AAvoid selectivityAvoid timeImage enhancementImage analysisFunction optimizationTabu search

The invention discloses a spatial depth extraction method based on light field information. The method comprises the following steps that step 1, a reference view point is selected in four-dimensional light field data, and the spatial depth of the image edge component of the reference view point is calculated; step 2, area segmentation operation is performed on the image of the reference view point, and the image is segmented into multiple areas according to the color or brightness uniformity; and step 3, the spatial depth of all the segmented area edges is corrected, and interpolation operation is performed on the spatial depth of the central part of the area according to the corrected spatial depth. The problems of difficult description function selection and uncertain operation time of a spatial depth description function optimization method can be avoided through the method of taboo search, area segmentation and depth interpolation, etc. so that rapid and accurate operation of spatial depth extraction can be realized.

Owner:ZHEJIANG UNIV

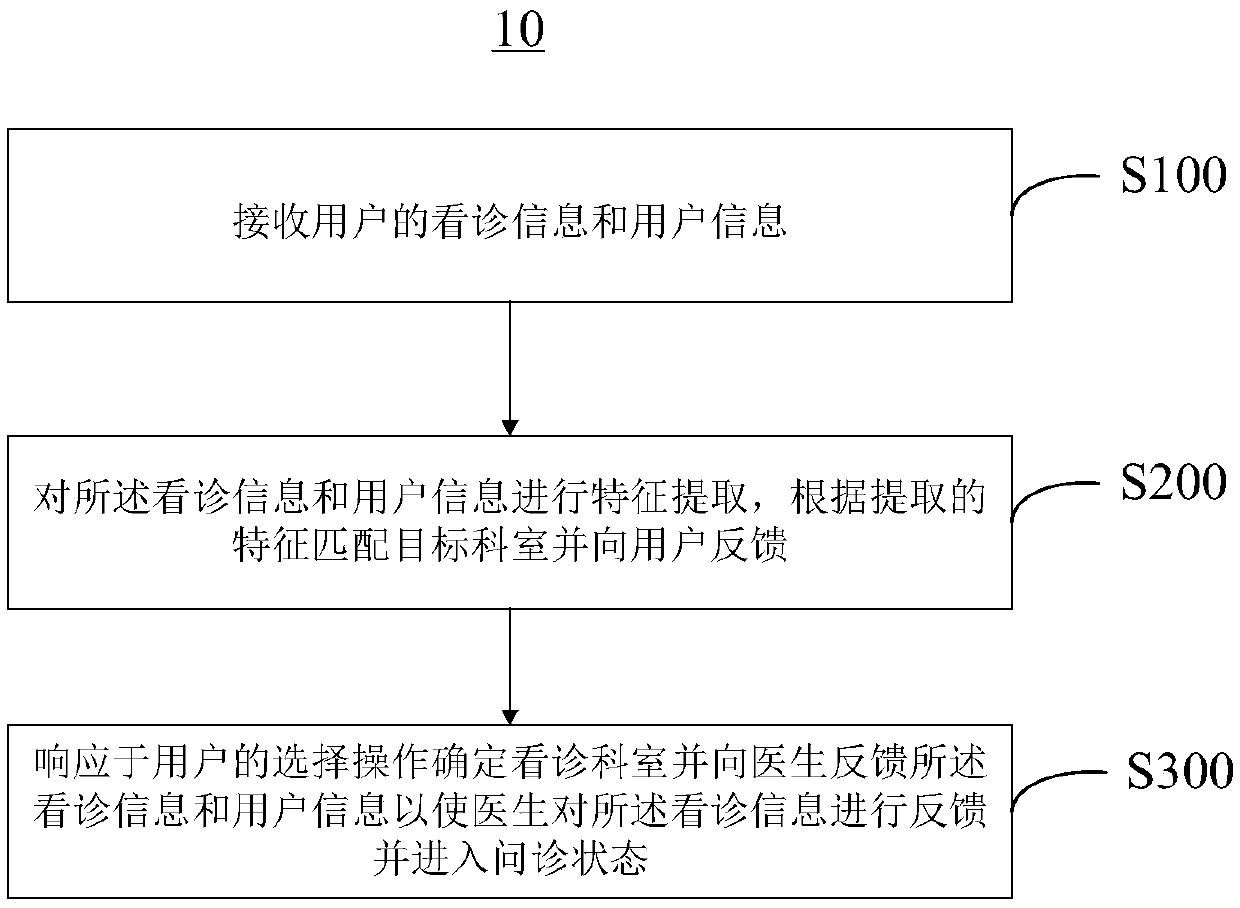

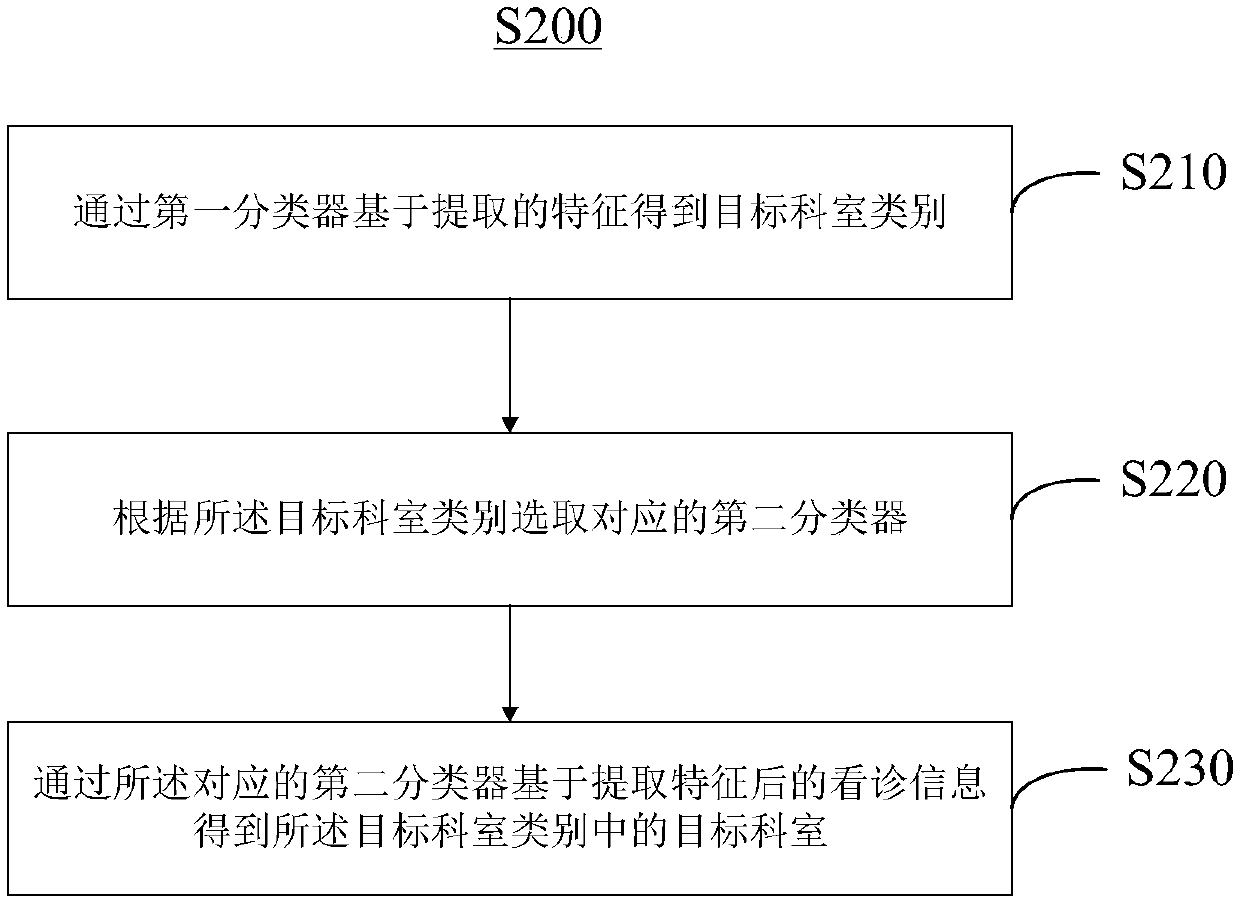

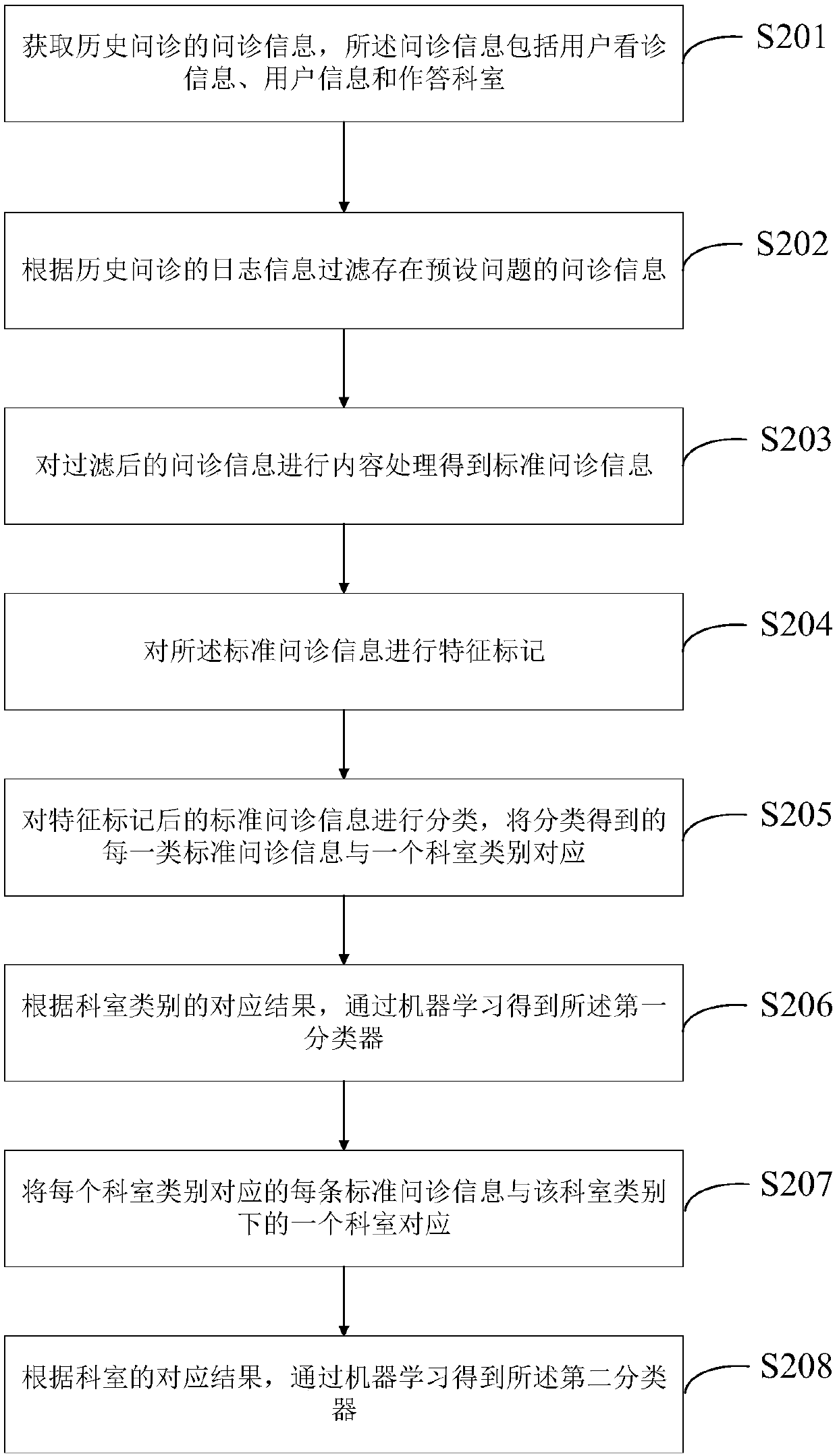

Triage method for online interrogation, sever, terminal, equipment and medium

ActiveCN109599187AAvoid selectivitySimple processMedical communicationInstrumentsTriageFeature extraction

The invention provides a triage method for online interrogation, a sever, a terminal, equipment and a medium. The method comprises the following steps: receiving triage information and user information of a user; extracting characteristics of the information and user information and matching a target department according to the extracted characteristics and feeding the information to the user; determining the triage department by responding to a selecting operation of the user and feeding the information and user information back to a doctor, wherein the doctor can feed the triage informationback and enters an interrogation state. According to the triage method, a proper triage department can be provided to the user accurately and efficiently, so that the online triage flow of the user isoptimized.

Owner:北京春雨天下软件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com