Patents

Literature

36results about How to "Improve carbon storage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

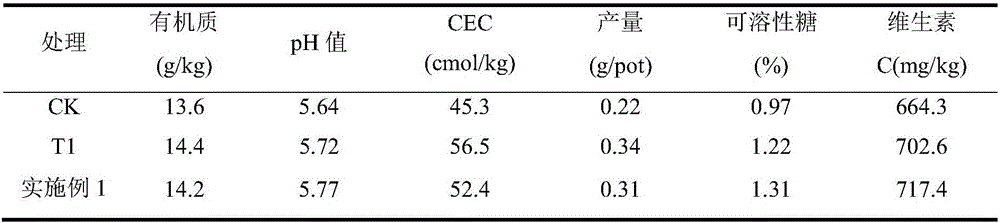

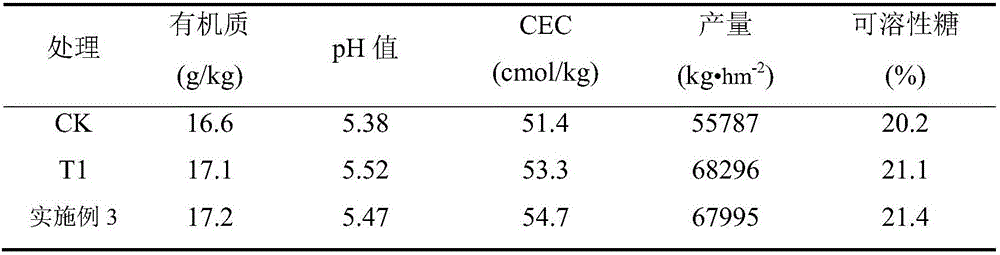

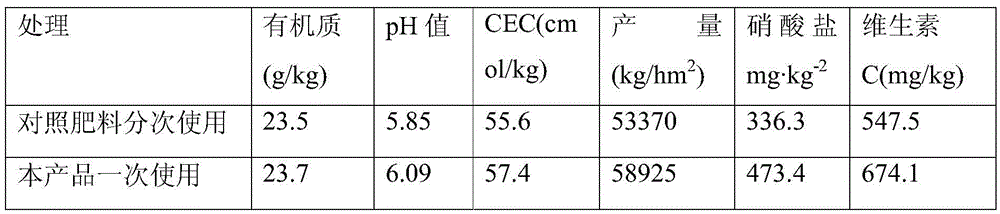

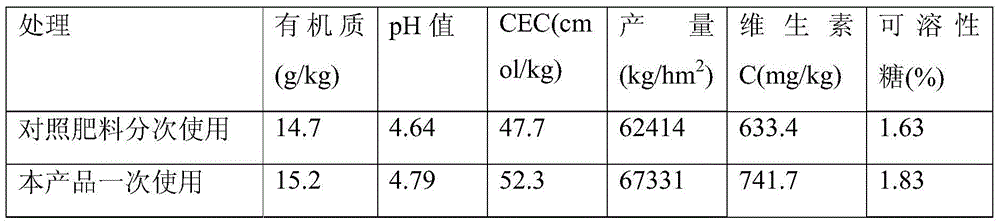

Special biochar-based organic and inorganic composite fertilizer for acidic soil and preparation method thereof

ActiveCN104211545AGood sustained release effectRaise the pHFertilizer mixturesFertilizerSodium silicate

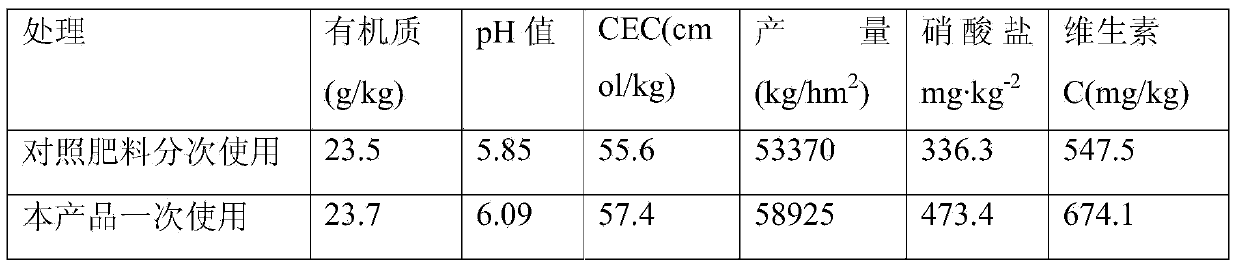

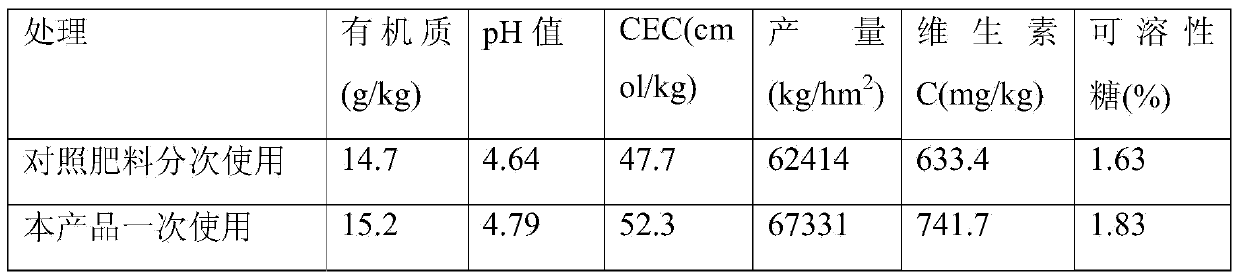

The invention relates to the field of fertilizers for acidic soil and particularly relates to a special biochar-based organic and inorganic composite fertilizer for acidic soil and a preparation method thereof. The special biochar-based organic and inorganic composite fertilizer for the acidic soil is prepared from the following raw materials: biochar, an acidity regulating substance, a nitrogen-containing substance, a phosphorus-containing substance, a potassium-containing substance, mineral powder and a granulation binder, wherein the granulation binder comprises attapulgite powder and sodium silicate. The composite fertilizer is prepared by mixing the biochar as a controlled-release material and an adsorption material with other components according to a certain proportion, the matching of the components is reasonable, and the nutritional requirements of growth of crops can be well met; the sustained-release effect is good, and the composite fertilizer only needs to be applied once; the composite fertilizer has the effects of improving the pH value of the soil, improving the content of a carbon pool in soil, improving the aggregate structure and the porosity of the soil and reducing toxicity of heavy metals and organic pollutants and can achieve the effects of saving labor, saving the fertilizer and improving the yield and the quality of agricultural products. The invention further provides the preparation method of the composite fertilizer. The preparation method is simple and feasible.

Owner:SOUTH CHINA AGRI UNIV +1

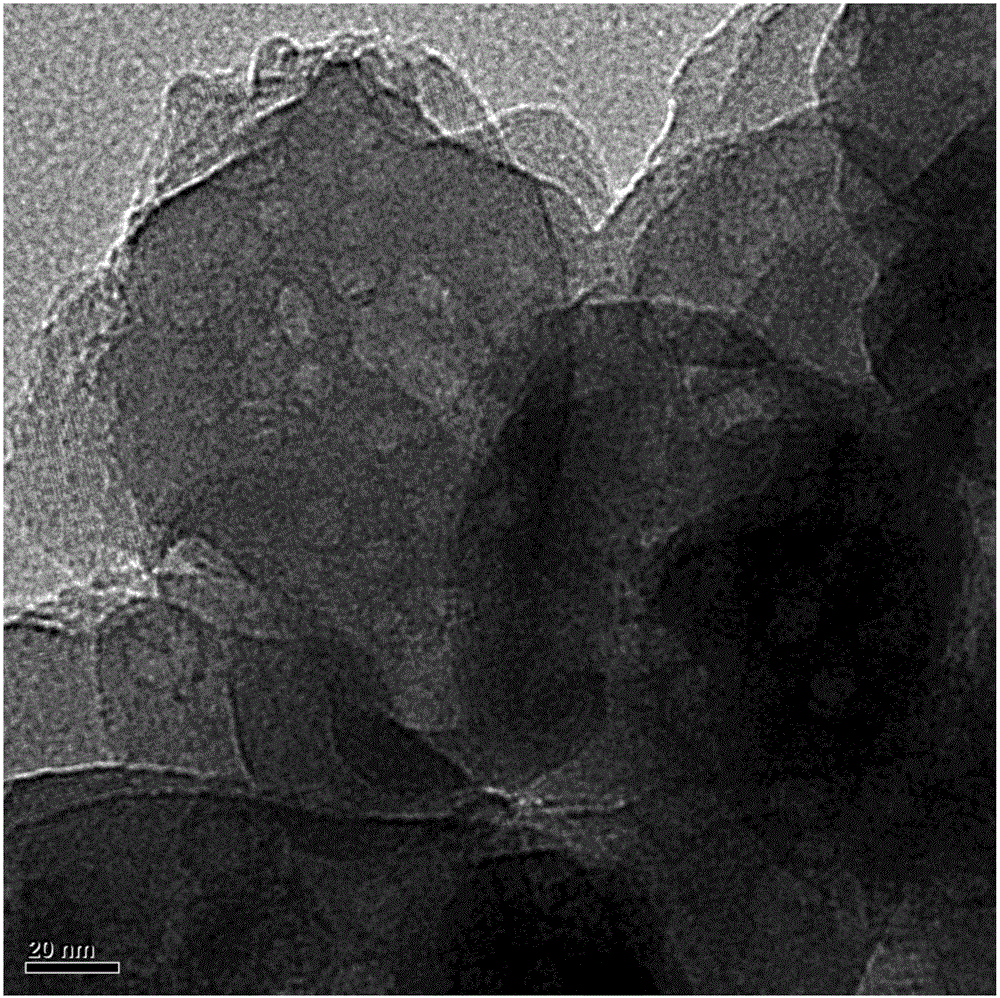

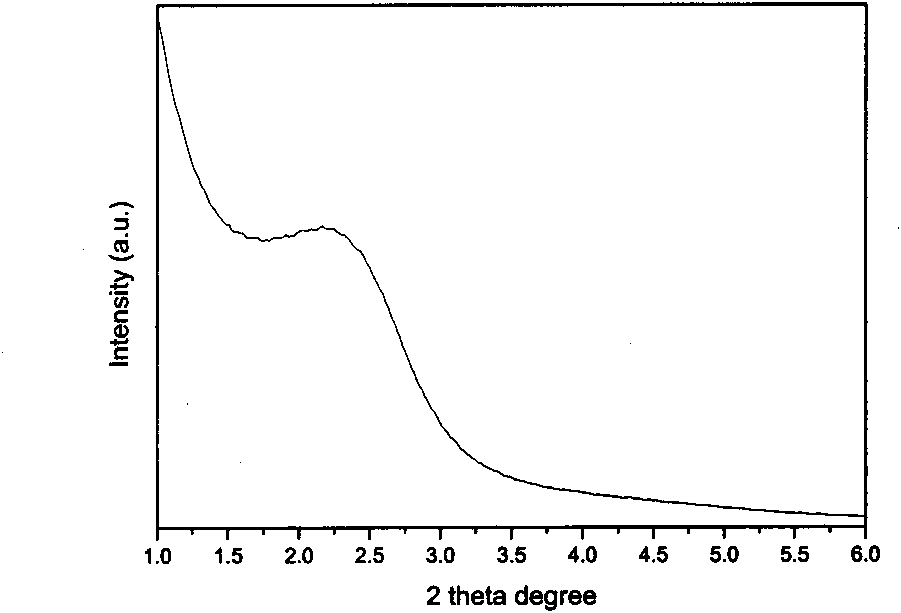

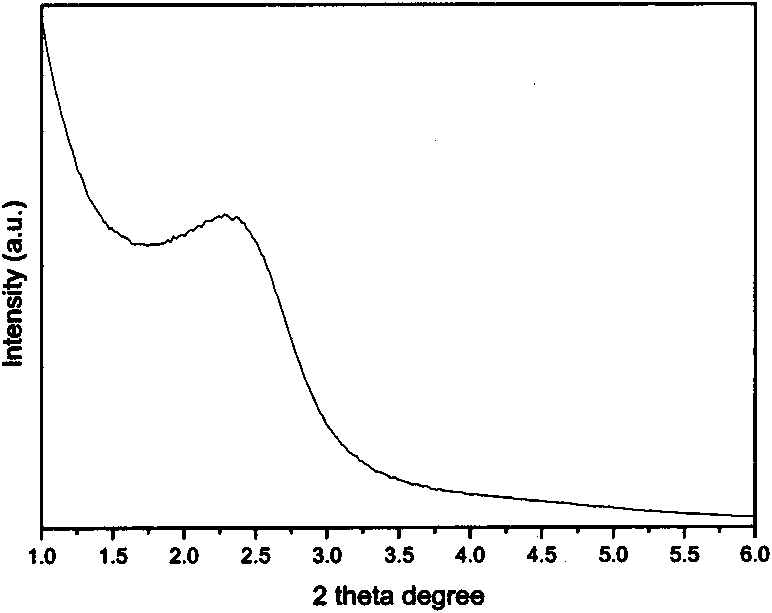

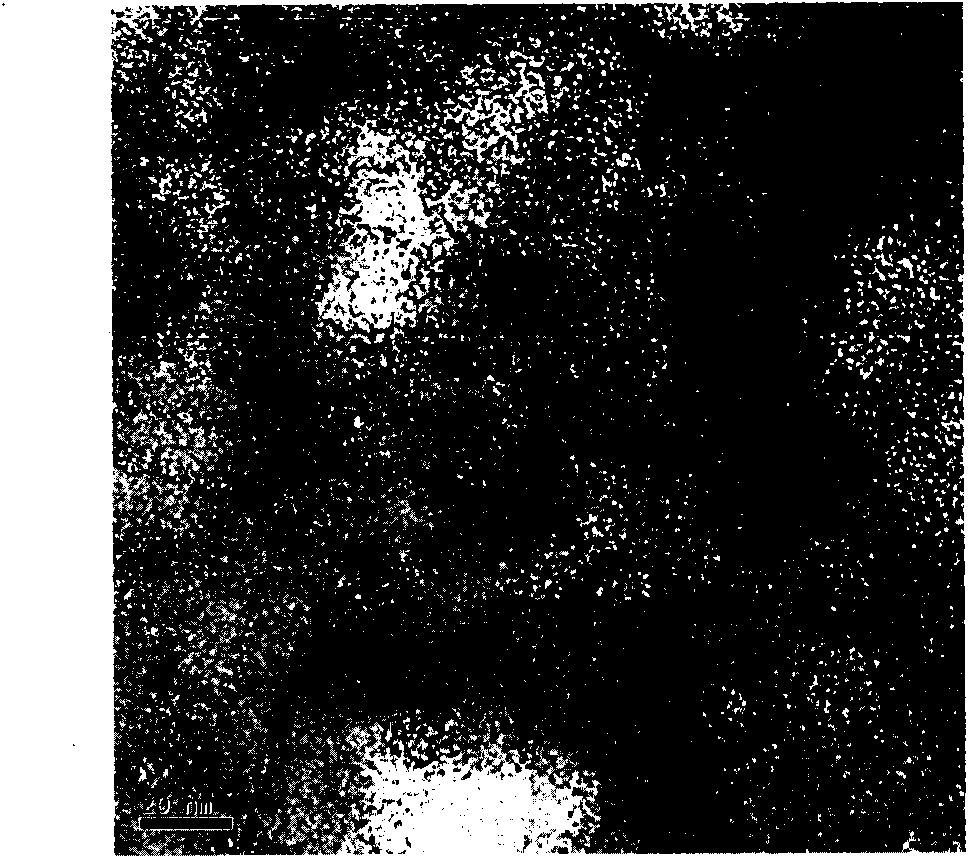

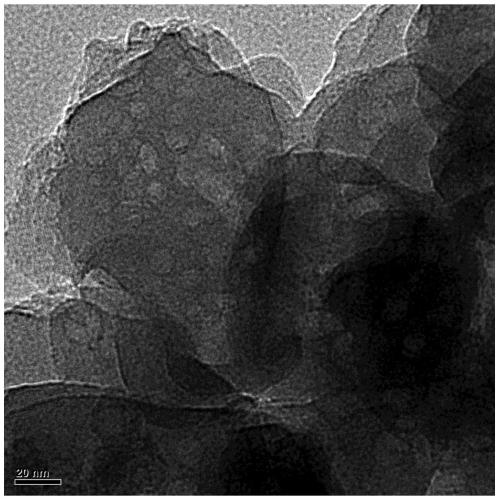

Ultrafine molecular sieve structured catalytic material based on porous silicon carbide carrier and preparation thereof

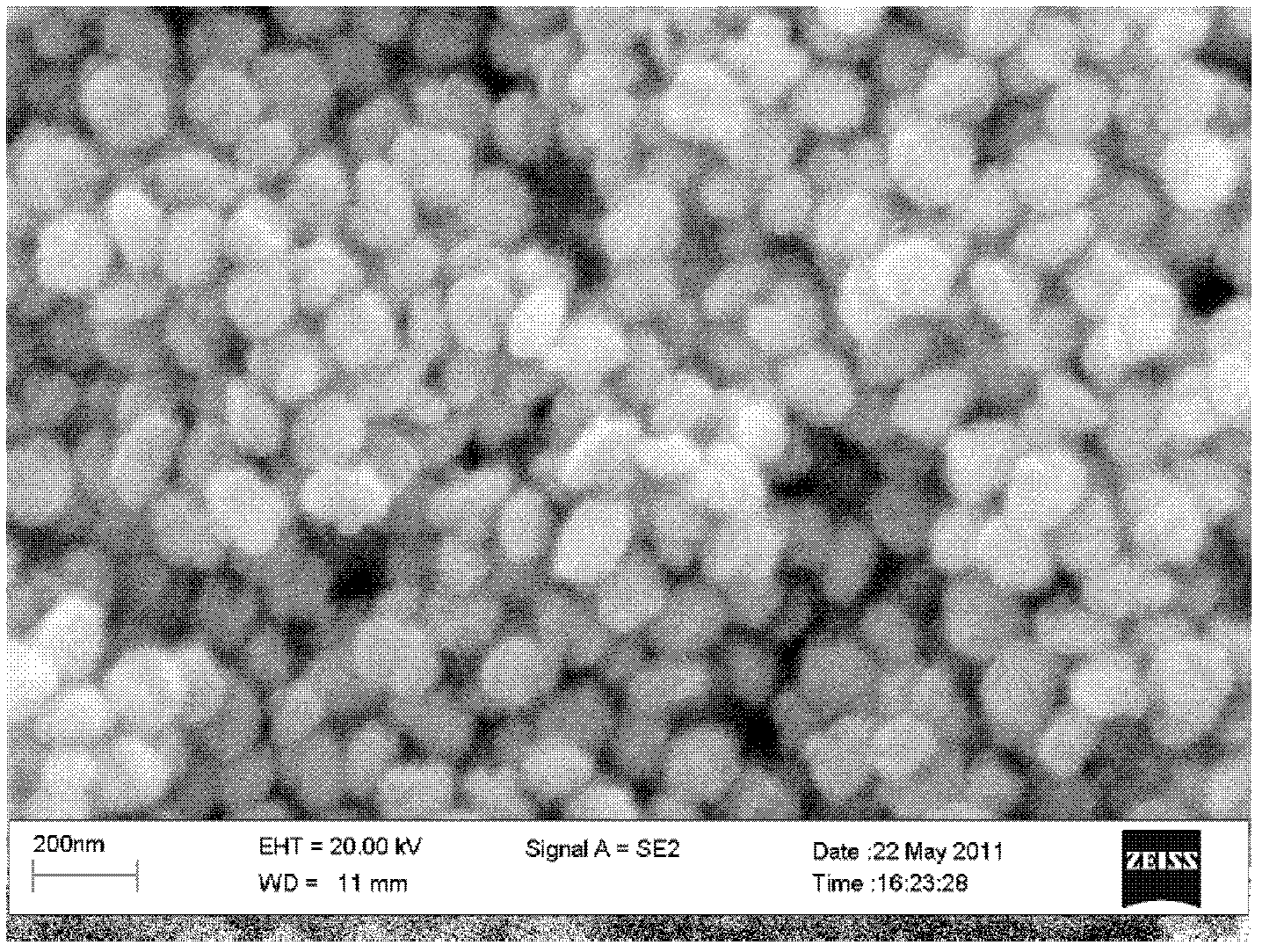

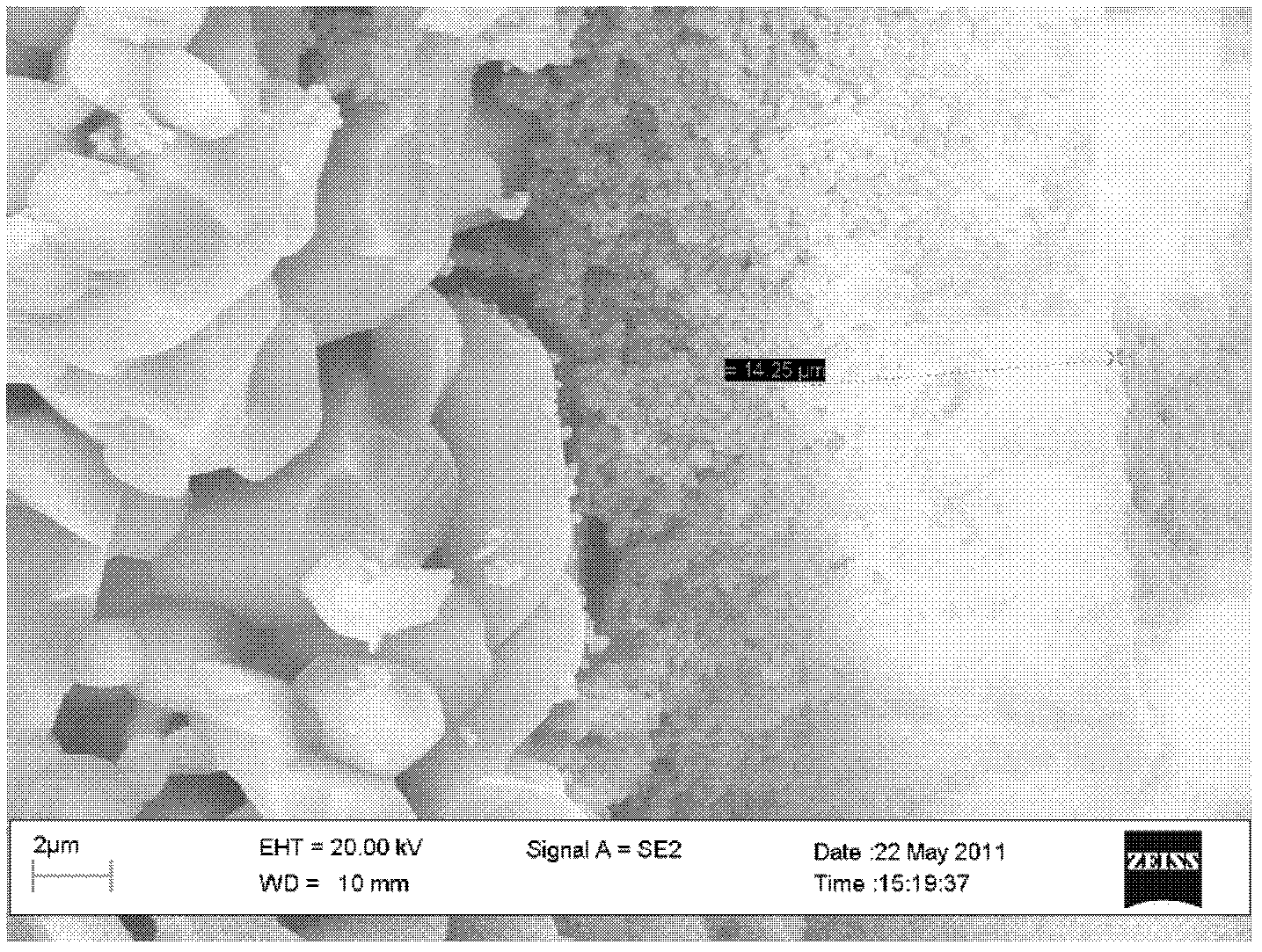

ActiveCN102716762ACrystal size can be controlledImprove bindingMolecular sieve catalystsMolecular sieveHigh activity

The invention, belonging to the technical field of catalyst and its application, particularly relates to an ultrafine molecular sieve structured catalytic material based on a porous silicon carbide carrier and a preparation method thereof. The material comprises ultrafine molecular sieve crystals as active elements and has a hierarchically porous structure, and the whole ultrafine molecular sieve coating has catalytic activity. The method is characterized by coating a colloidal molecular sieve precursor on the surface of a modified foam silicon carbide carrier, converting the molecular sieve precursor into ultrafine molecular sieve crystals by vapor phase treatment to realize the firm combination between the coating and the carrier. According to the invention, by controlling the synthesis conditions of the colloidal molecular sieve precursor and the method of adding a pore forming agent, the size of the molecular sieve crystals, silica-alumina ratio and intercrystalline porosity can be controlled; a pore structure and the type of the molecular sieve can be designed according to the geometrical structure of a target product; and the capacity of accommodating carbon is raised, the mass transfer capability of the catalyst is reinforced, and the life of catalyst is prolonged while keeping the high activity of the ultrafine molecular sieve and high target product selectivity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

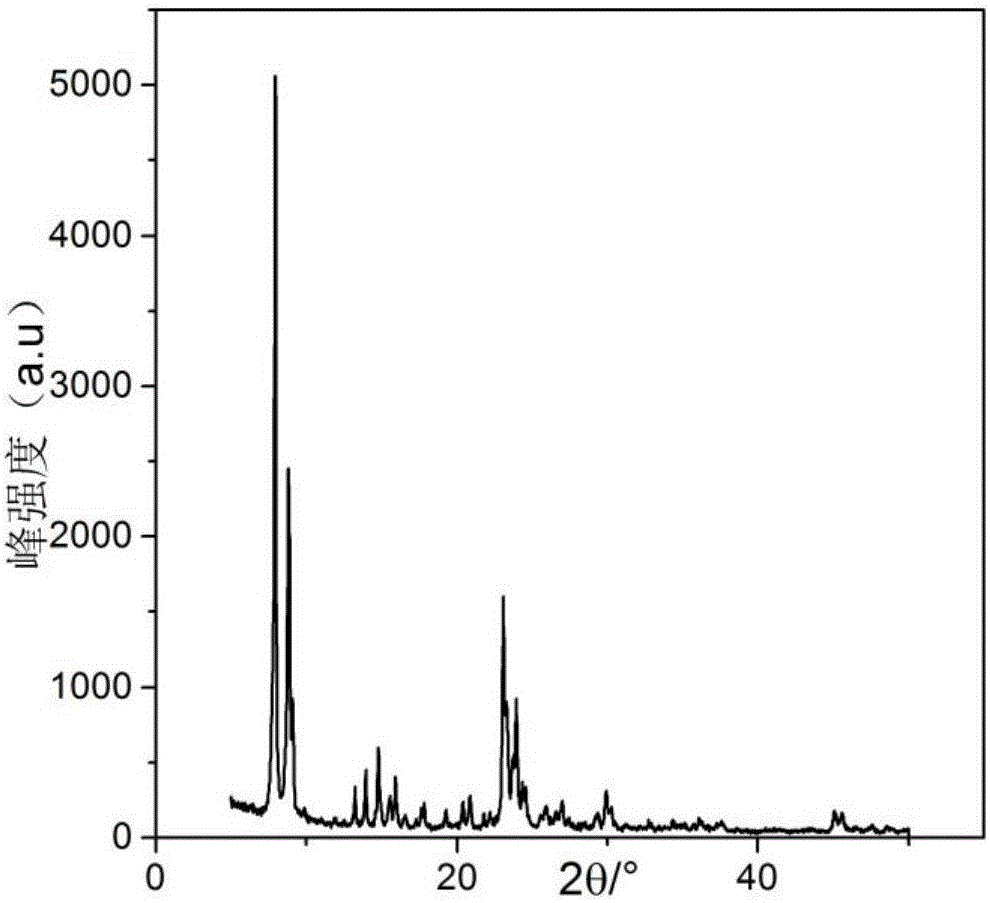

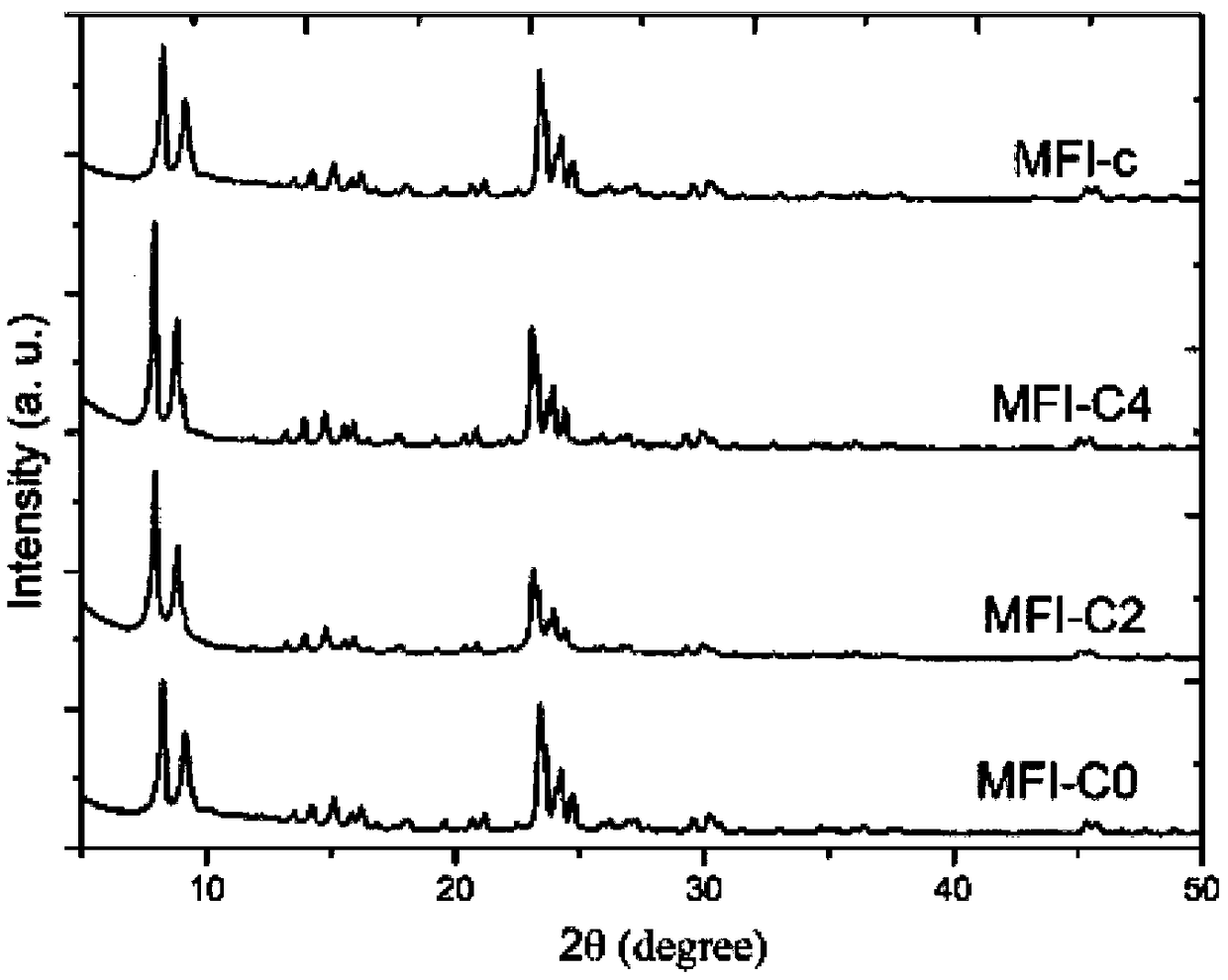

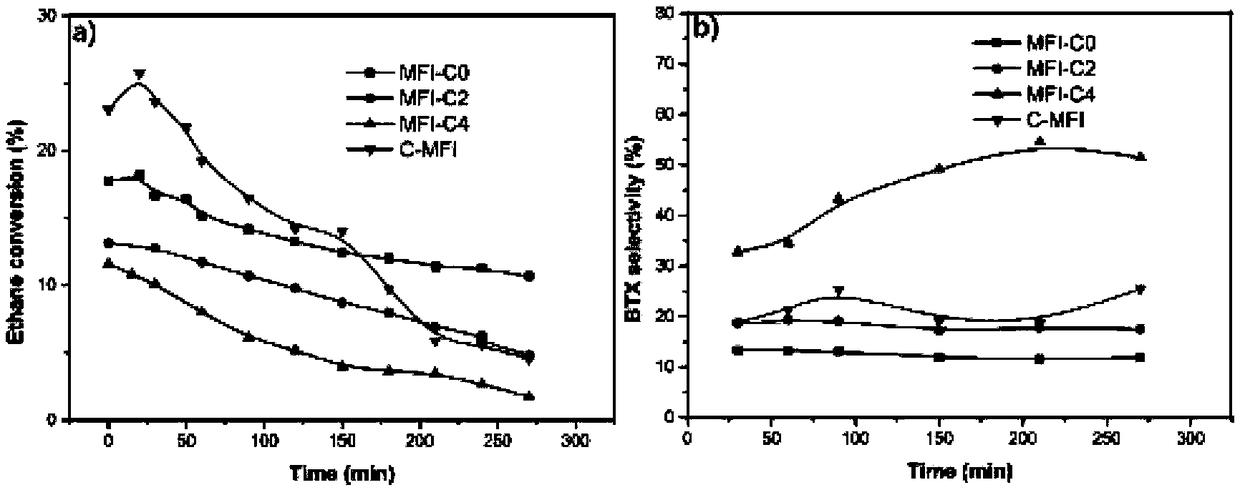

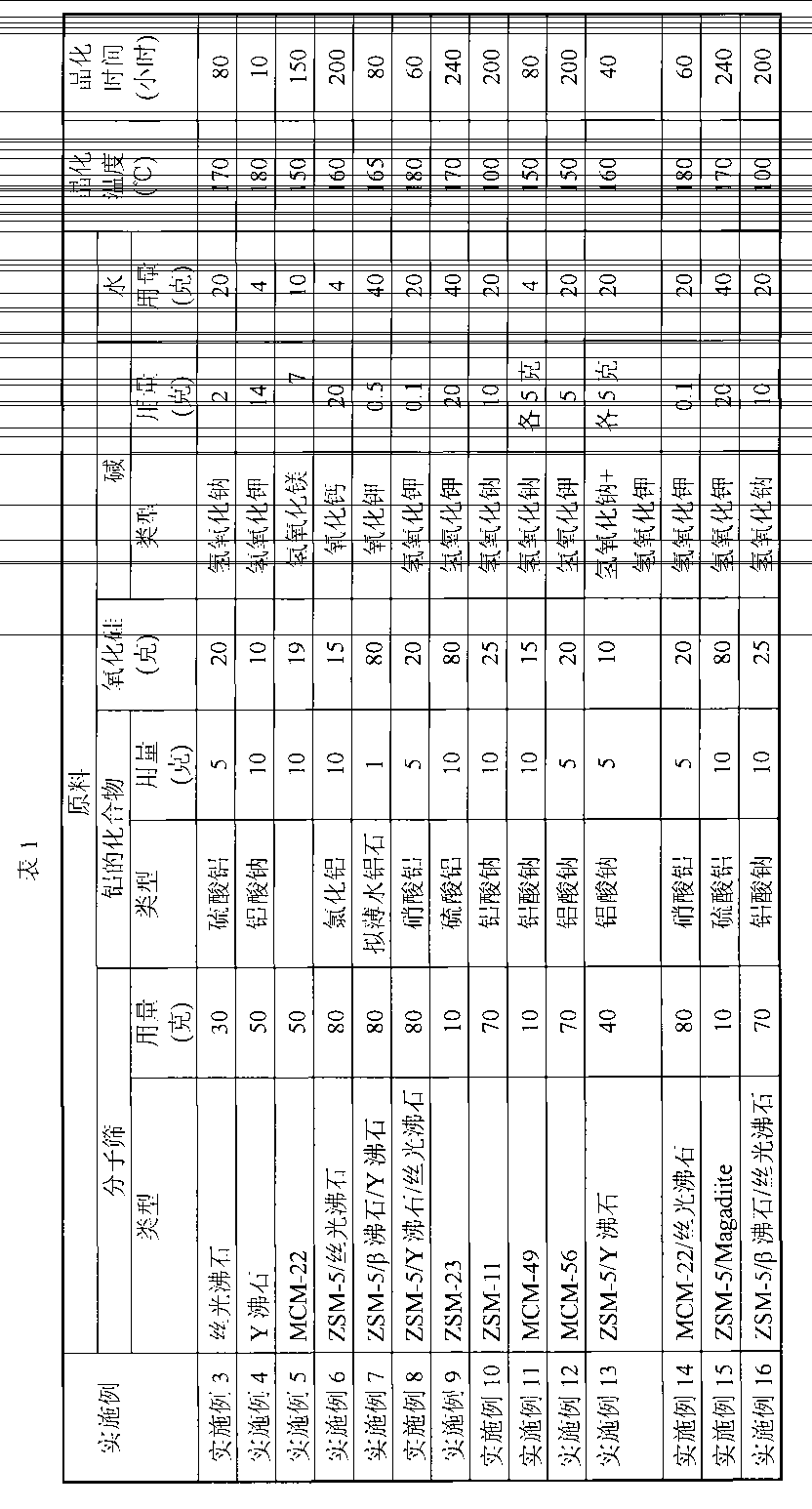

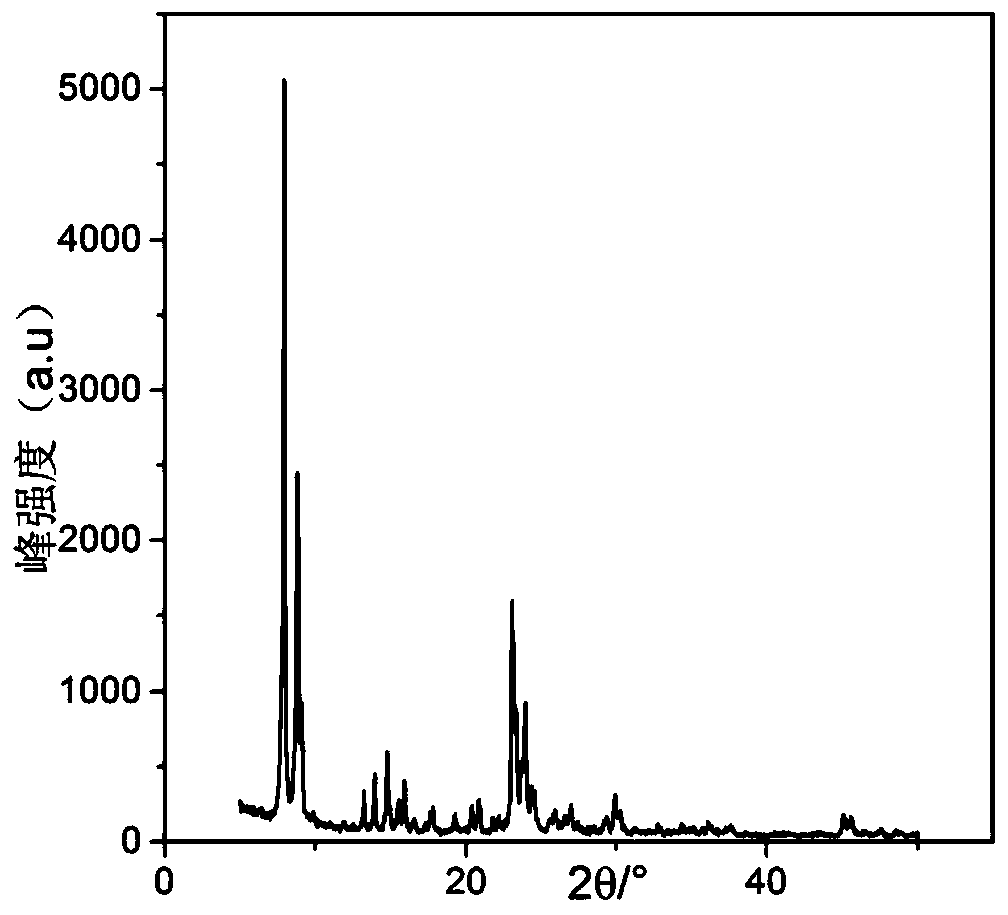

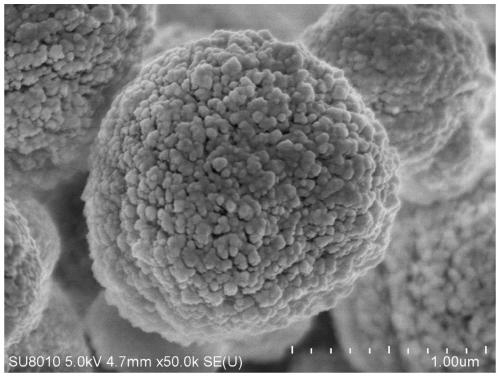

Multilevel structure ZSM-5 zeolite molecular sieve, as well as synthetic method and application thereof

ActiveCN106673008AImprove diffusion abilityHigh catalytic activityMolecular sieve catalystsOrganic compound preparationMolecular sieveSide reaction

The invention relates to a synthesized multilevel structure ZSM-5 zeolite molecular sieve with intracrystalline meso pores and intercrystalline meso pores, as well as a synthetic method and an application thereof. Except micropores of the zeolite structure, the multilevel structure ZSM-5 zeolite molecular sieve comprises the intracrystalline mesoporous and intercrystalline mesoporous structure, wherein primary nanometer crystal grain size is 40-500nm, and secondary accumulated particle size is 500nm-5[mu]m. The structure greatly improves diffusion performance and the catalyst activity of the molecular sieve, reduces possibility of generation of side reaction and carbon deposit, improves carbon accommodating capability of the molecular sieve catalyst, and prolongs life of the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

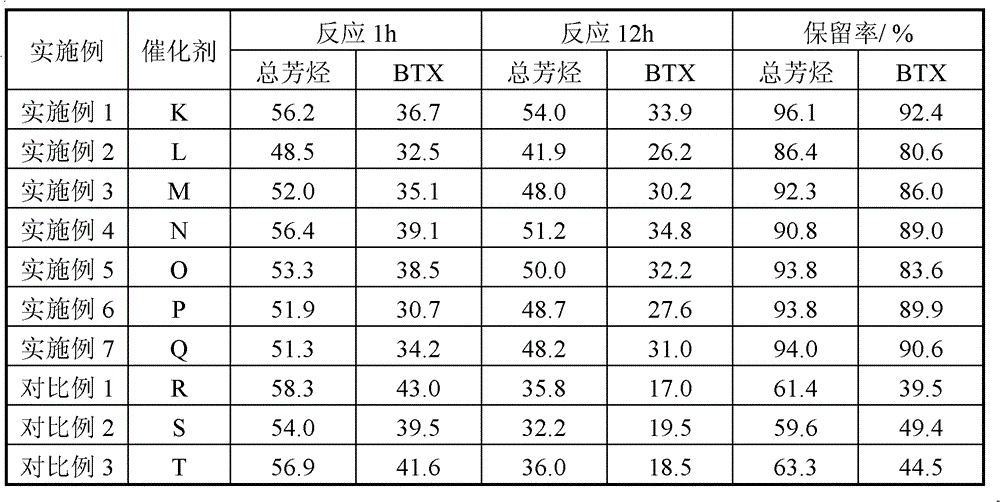

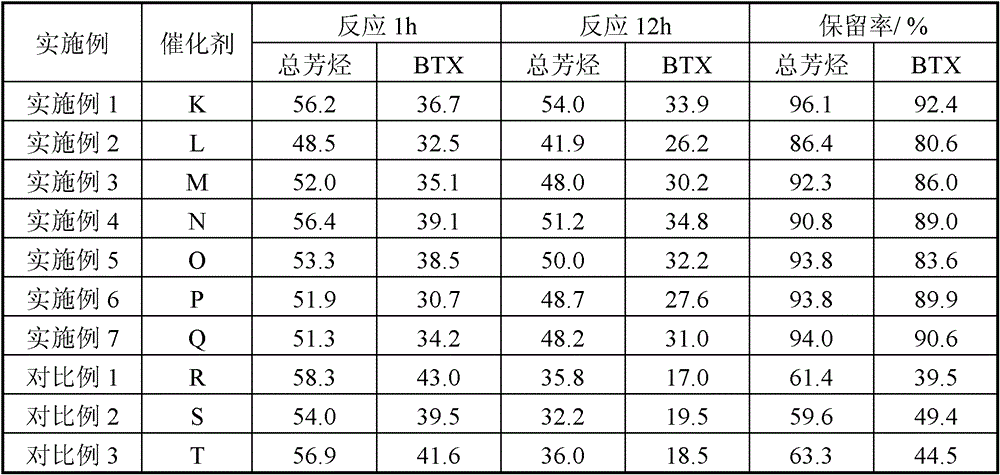

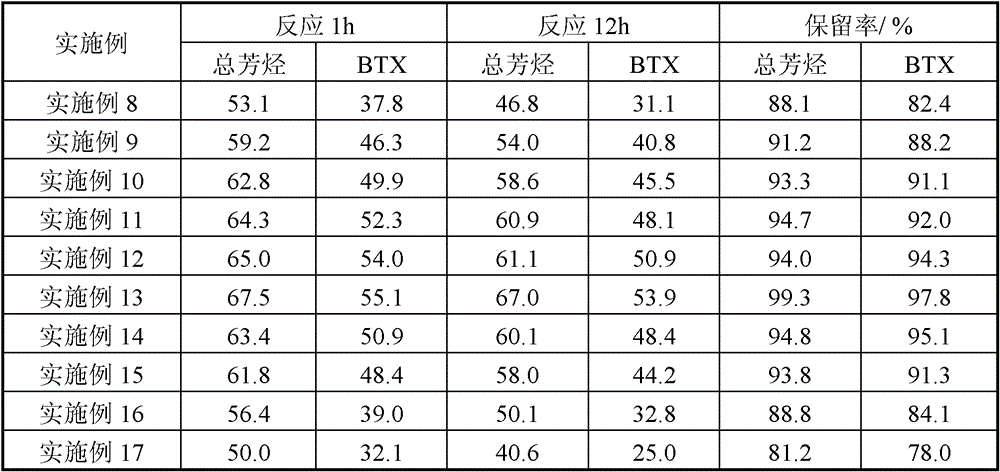

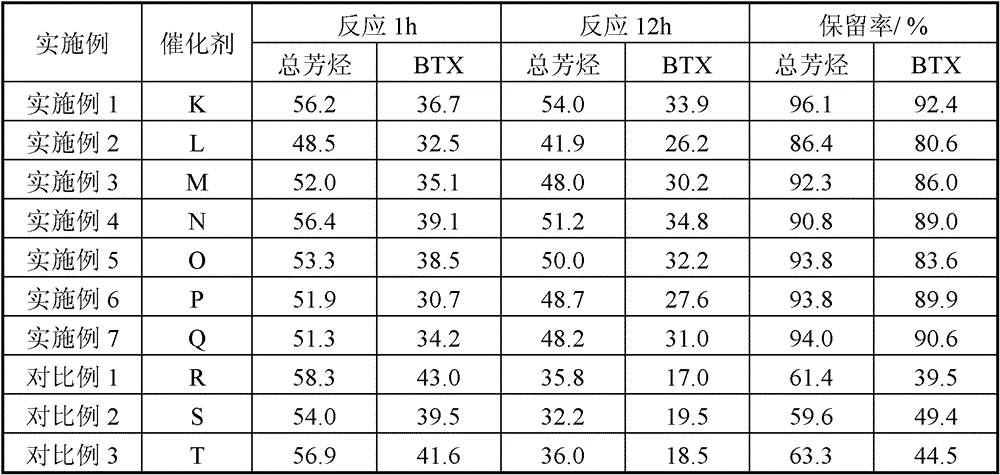

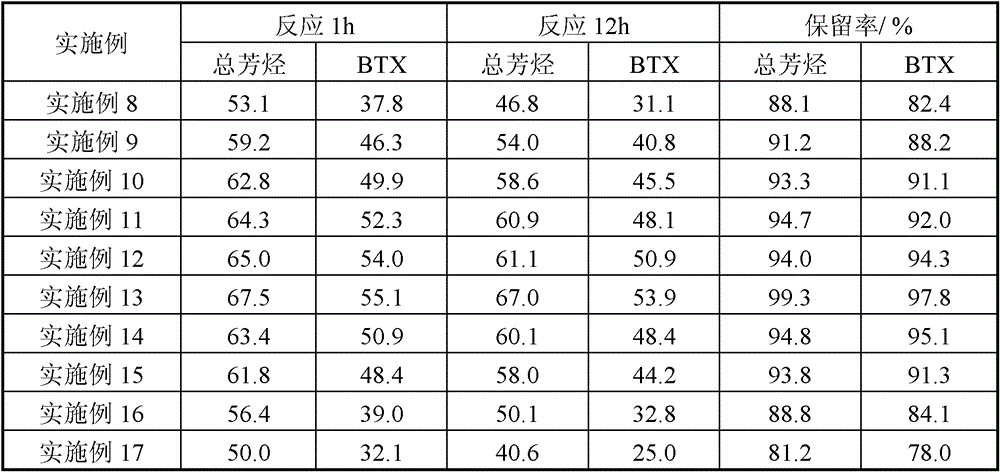

Catalyst for preparing arene via direct methanol conversion and preparation method thereof

InactiveCN103055928AImprove carbon storage capacityImprove stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAqueous sodium hydroxidePotassium hydroxide

The invention relates to a catalyst for preparing arene via direct methanol conversion and a preparation method thereof, and mainly solves the problems that the existing catalyst is fast in carbon deposition and low in stability during a reaction process. The catalyst provided by the invention comprises the following components according to parts by weight: a) 20 to 75 parts of binding agent; b) 20 to 75 parts of ZSM-5 molecular sieve; and c) 0.5 to 10 parts of zinc or oxides thereof, wherein the ratio of SiO2 to Al2O3 in the ZSM-5 molecular sieve is 20 to 200; the molecular sieve is firstly treated by using a base solution with the concentration of 0.1 to 2 mol / L before the catalyst is prepared; and the base solution is one of potassium hydroxide aqueous solution or sodium hydroxide aqueous solution. Therefore, according to the technical scheme of the catalyst and the preparation method thereof, the problems are solved well. As a result, the catalyst provided by the invention can be applied to the industrial production of arene via direct methanol conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hierarchical-hole molecular sieve catalyst for preparation of ethylene through dehydration of low-concentration ethanol, and preparation method and application thereof

InactiveCN106540736AUnobstructed pore size distributionImprove featuresMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveHigh activity

The invention relates to a hierarchical-hole HZSM-5 catalyst suitable for a reaction for preparation of ethylene through dehydration of low-concentration ethanol, and is used for mainly solving the problems of low catalyst activity, poor catalyst stability, easy loss of active metals and the like existing in the prior art. The invention also relates to preparation of the modified catalyst and an application of the modified catalyst in the reaction for preparation of ethylene through dehydration of low-concentration ethanol. The molecular sieve catalyst can convert ethanol into ethylene with high conversion rate and high selectivity, and has the advantages of high activity at low temperature, good stability, high selectivity of ethylene, long catalytic life and the like.

Owner:TAIYUAN UNIV OF TECH

Method for preparing low-carbon olefin through methanol dehydration

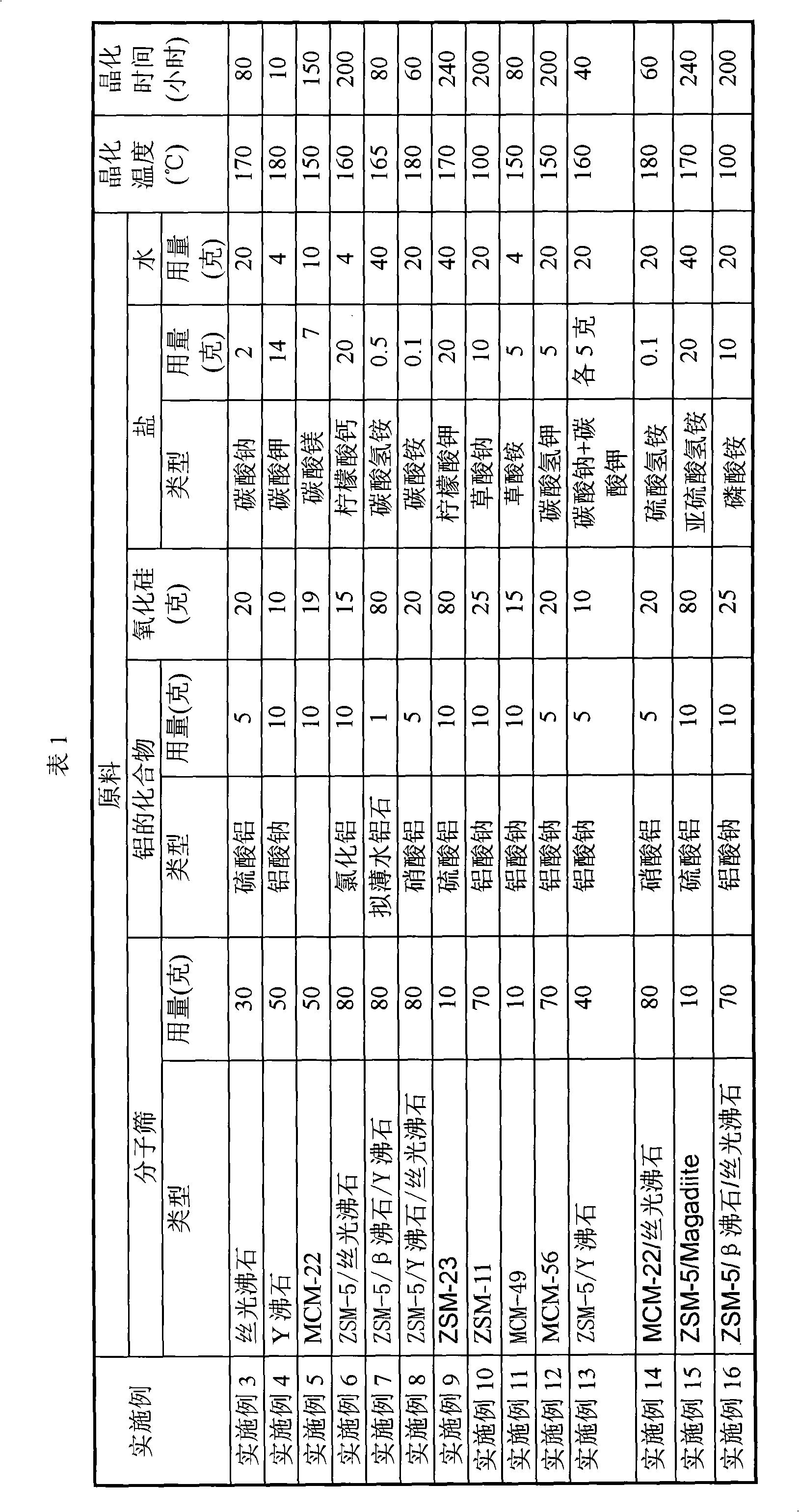

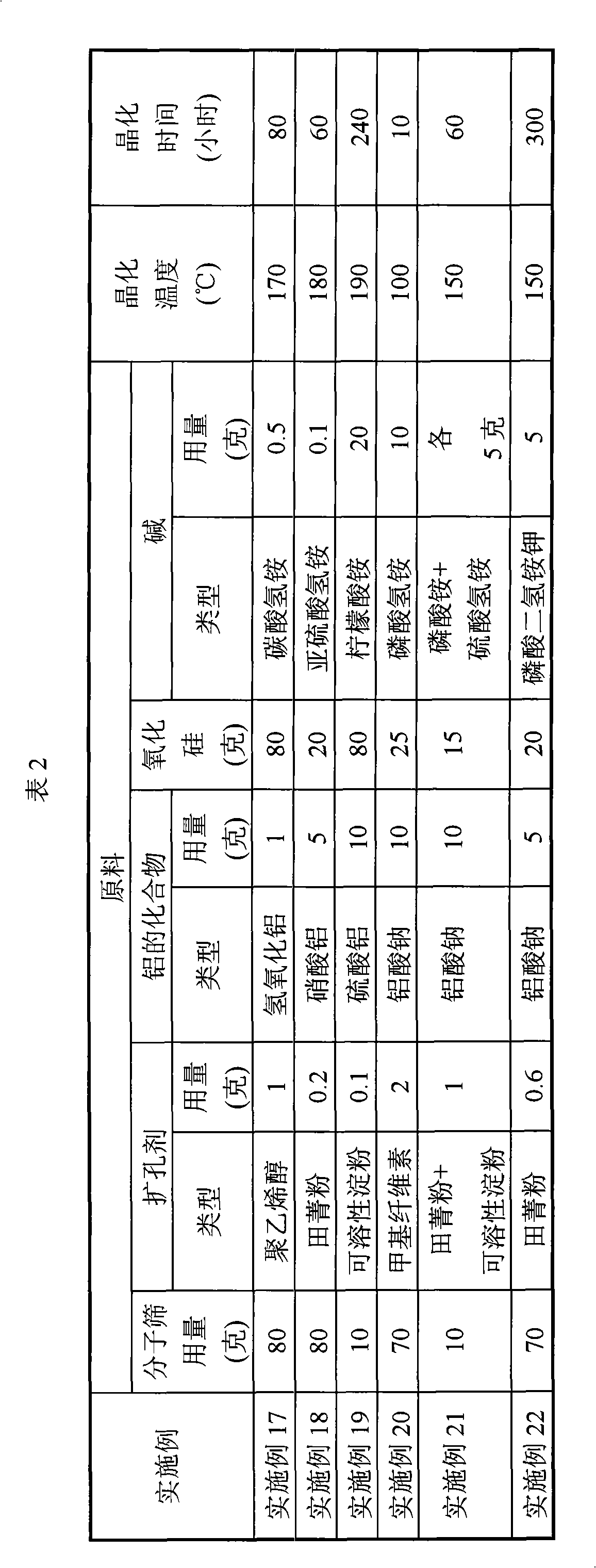

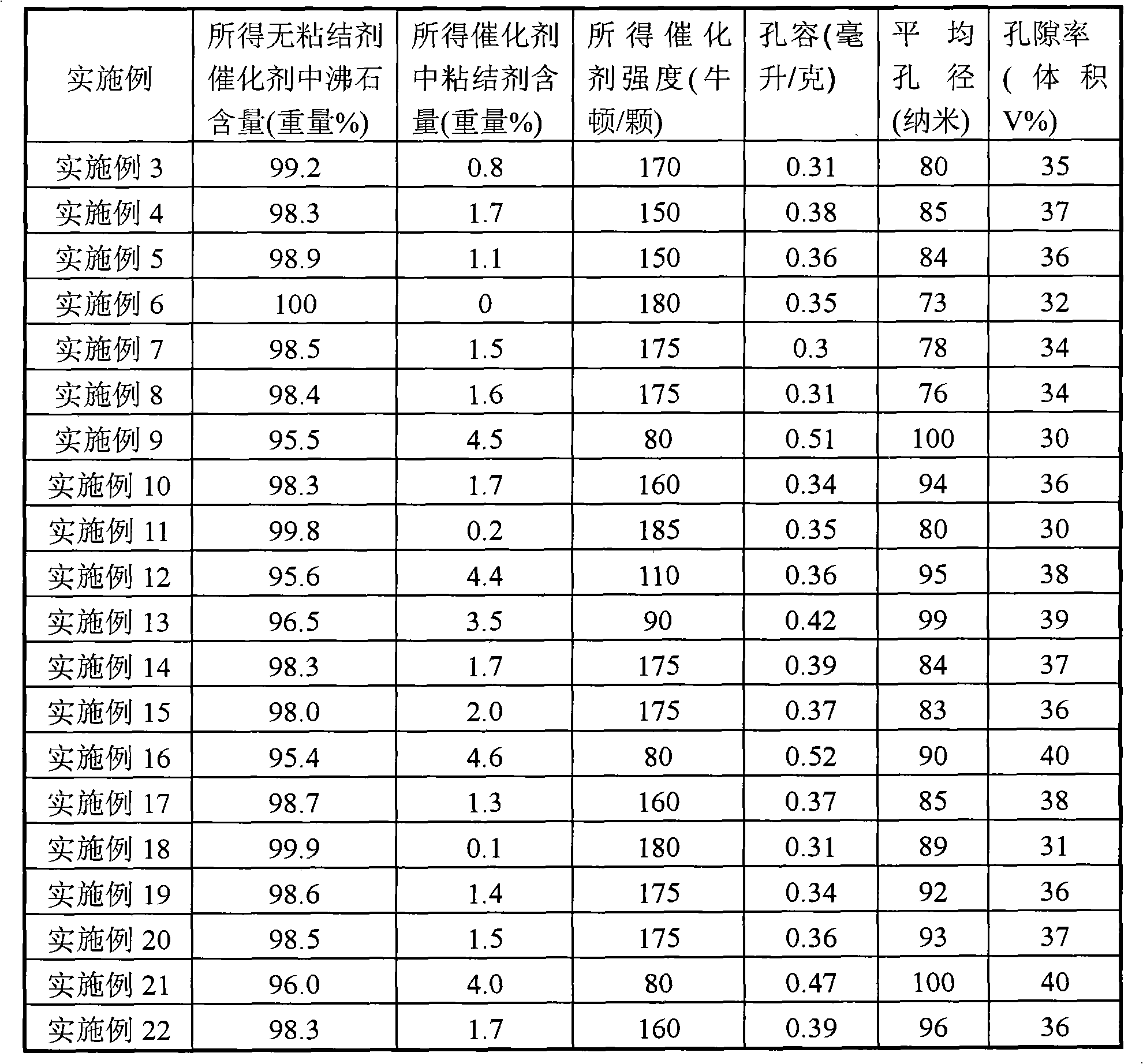

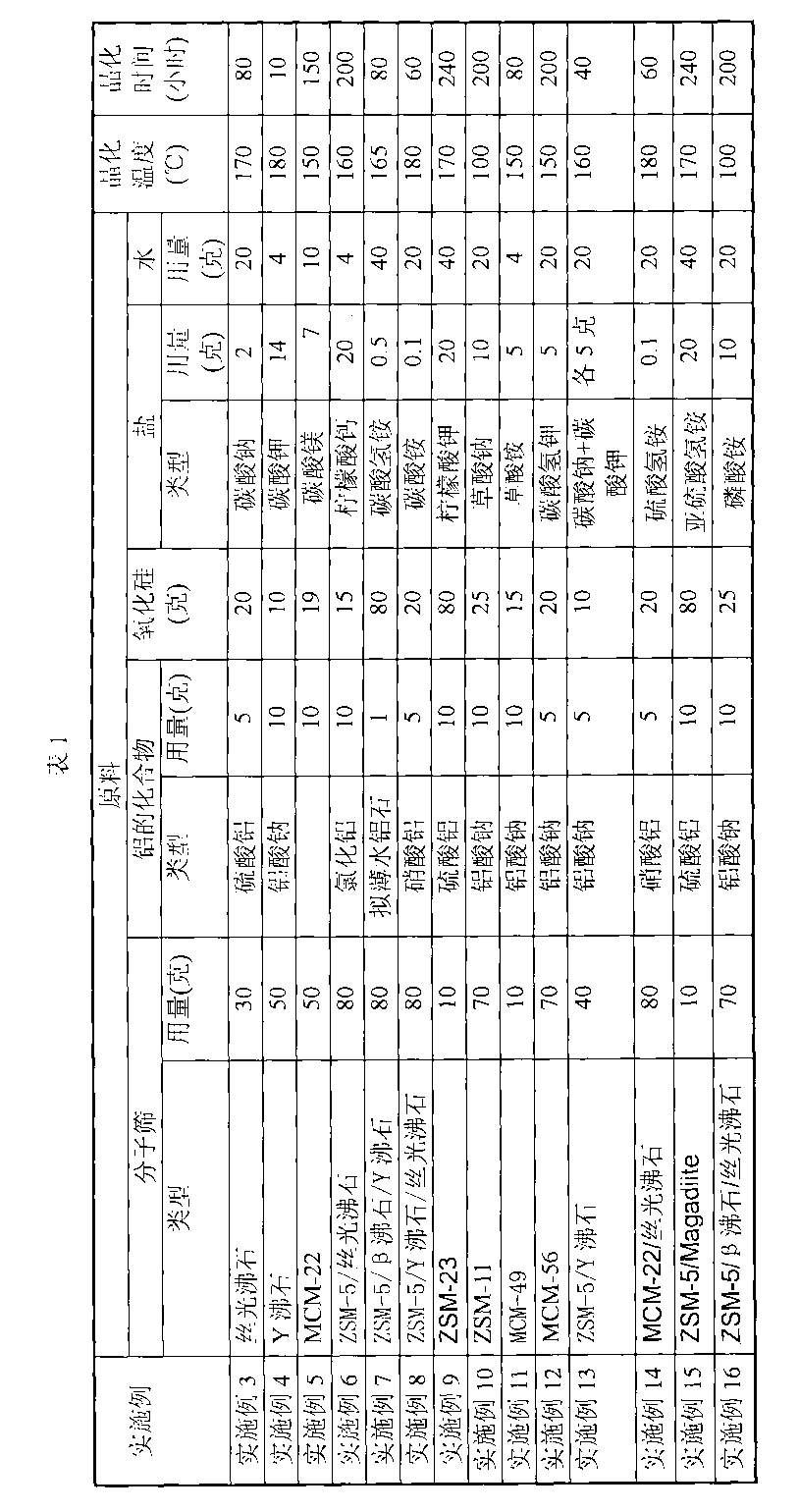

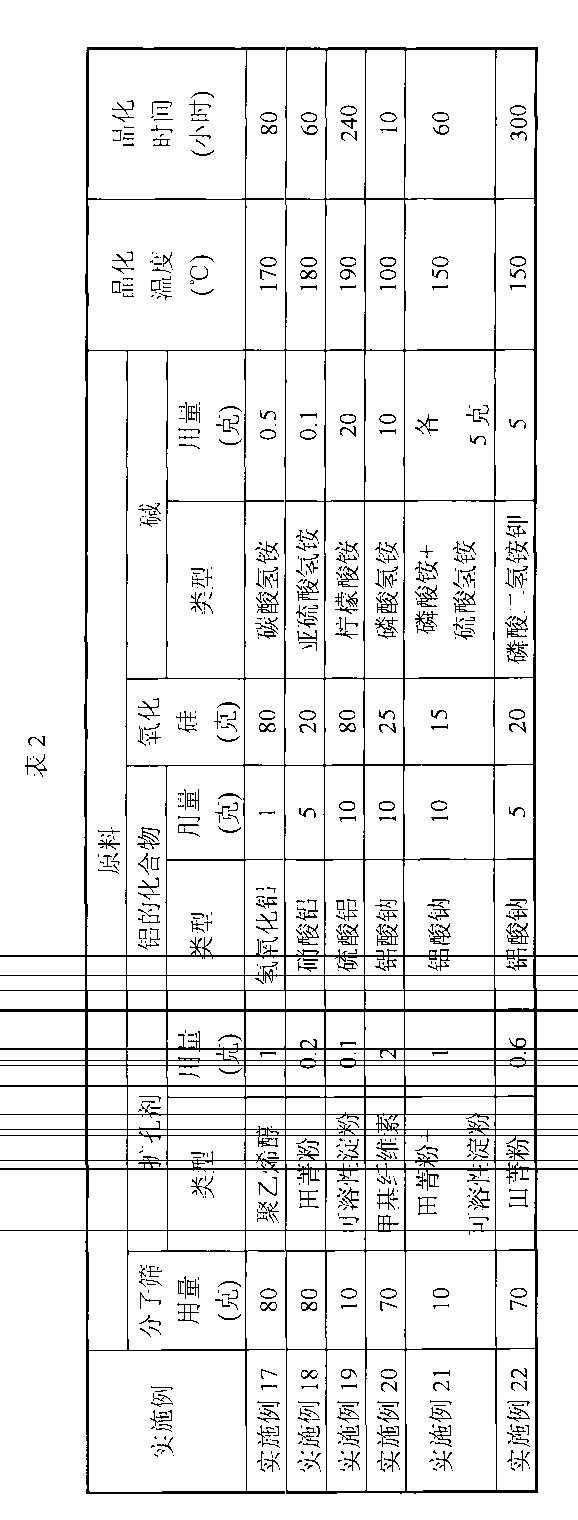

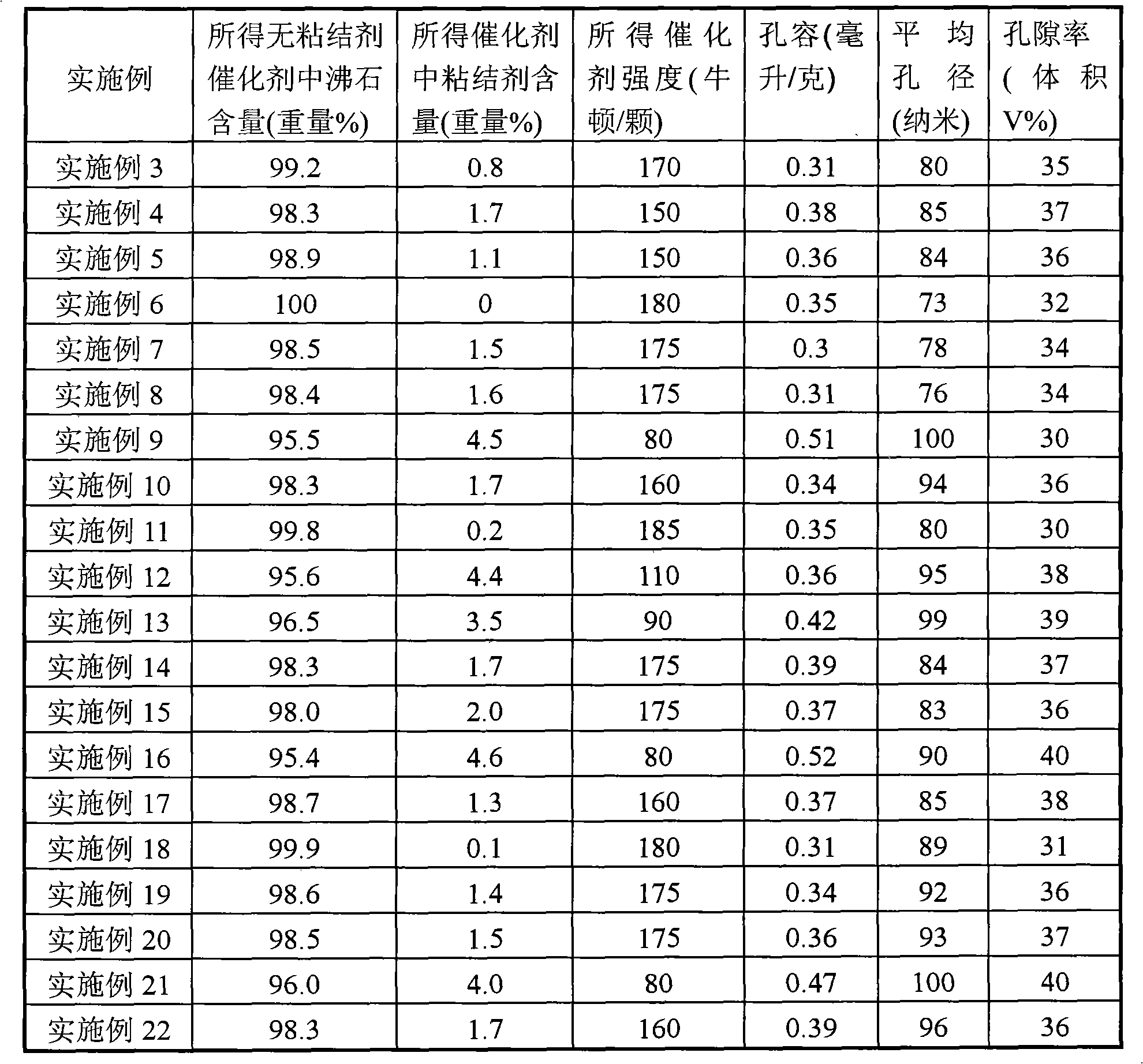

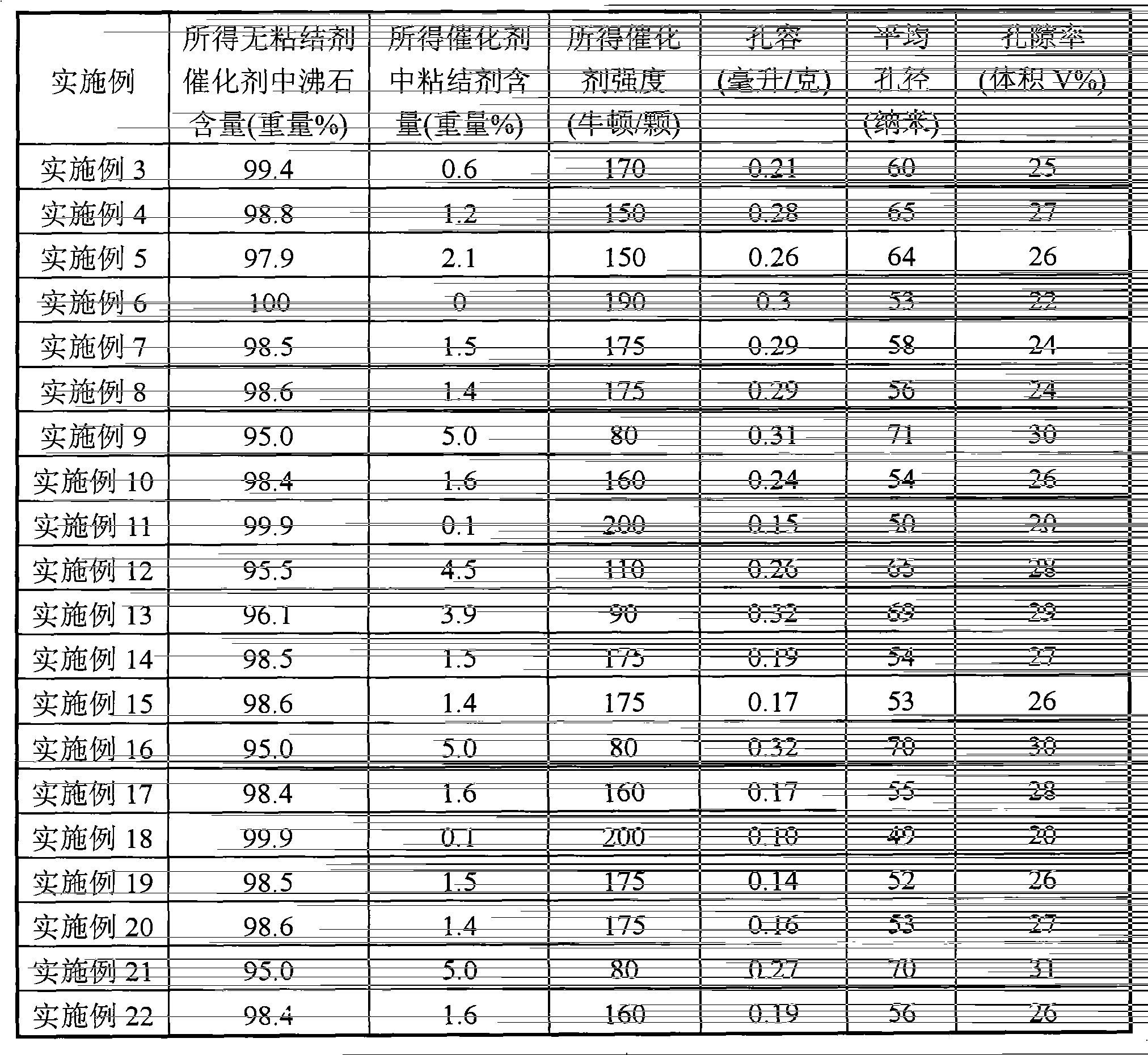

ActiveCN102372548AHigh strengthLarge hole volumeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveCatalytic pyrolysis

The invention relates to a method for preparing low-carbon olefin through methanol dehydration, and mainly solves the problems that the activity of a catalyst and the yield of the low-carbon olefin are low in the conventional technology for preparing the low-carbon olefin through catalytic pyrolysis. In the invention, methanol which is taken as a raw material is contacted with an adhesive-free molecular sieve catalyst through a catalyst bed to generate the low-carbon olefin under the conditions that the reaction temperature is 400 to 600 DEG C, the gauge pressure of the reaction is 0.001 to 0.5MPa, the weight space velocity of the reaction is 0.1 to 4h<-1> and the weight ratio of water to methanol is (0.1-3):1, wherein the pore volume, the average aperture and porosity of the adhesive-free molecular sieve catalyst are tested by mercury porosimetry, the pore volume is 0.31 to 0.5ml / g, the average aperture is 71 to 100nm, and the porosity is 31 to 40 percent. Through the technical scheme, the problems are better solved. The method can be used for the industrial production of the low-carbon olefin through methanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

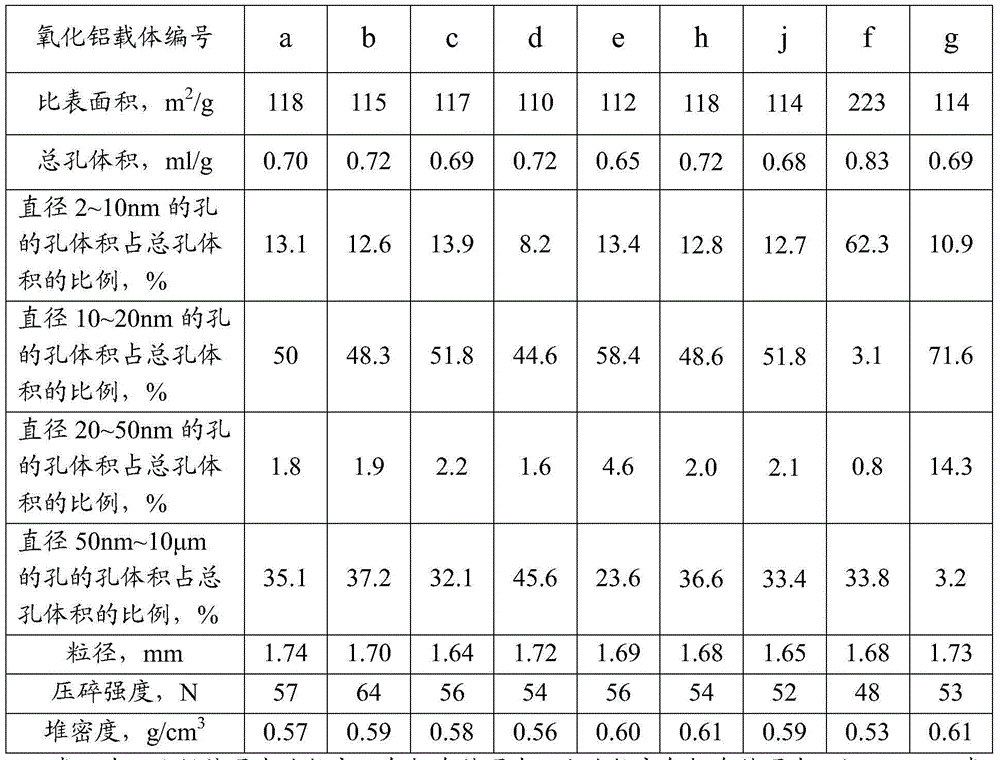

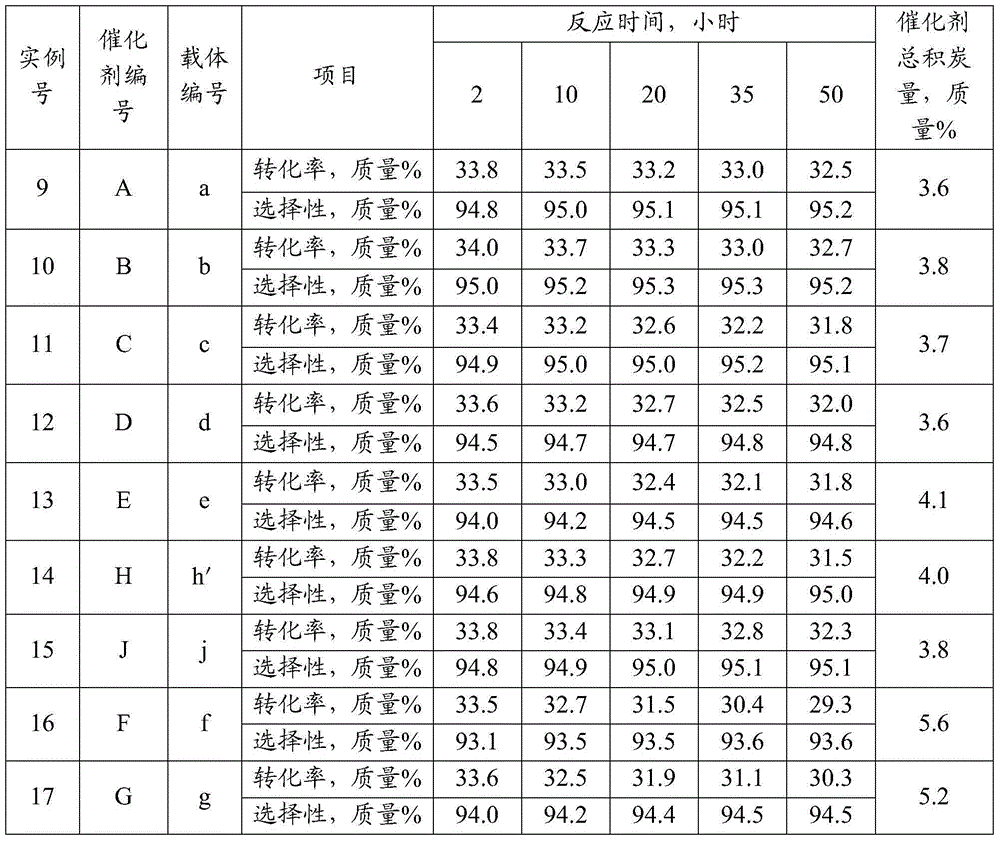

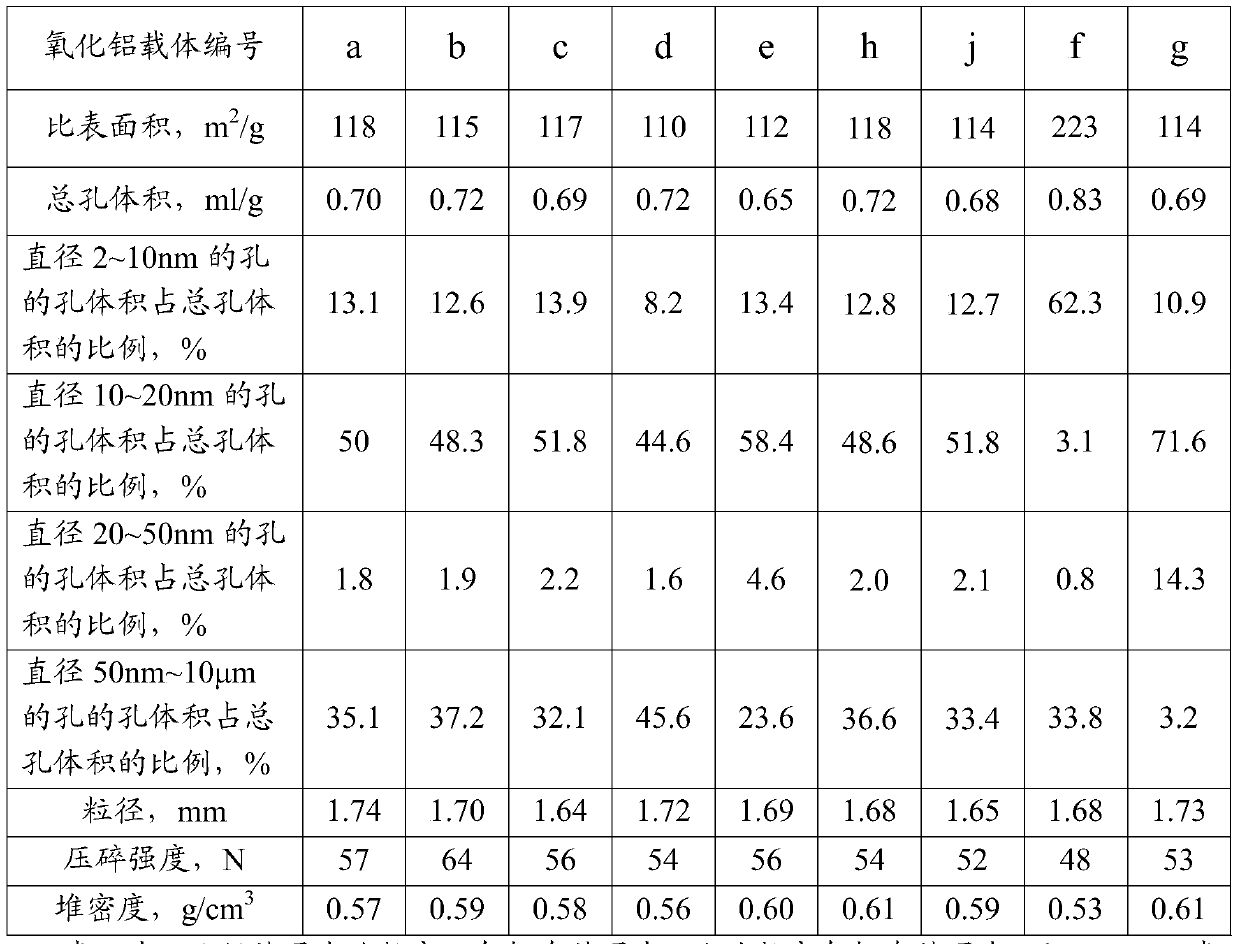

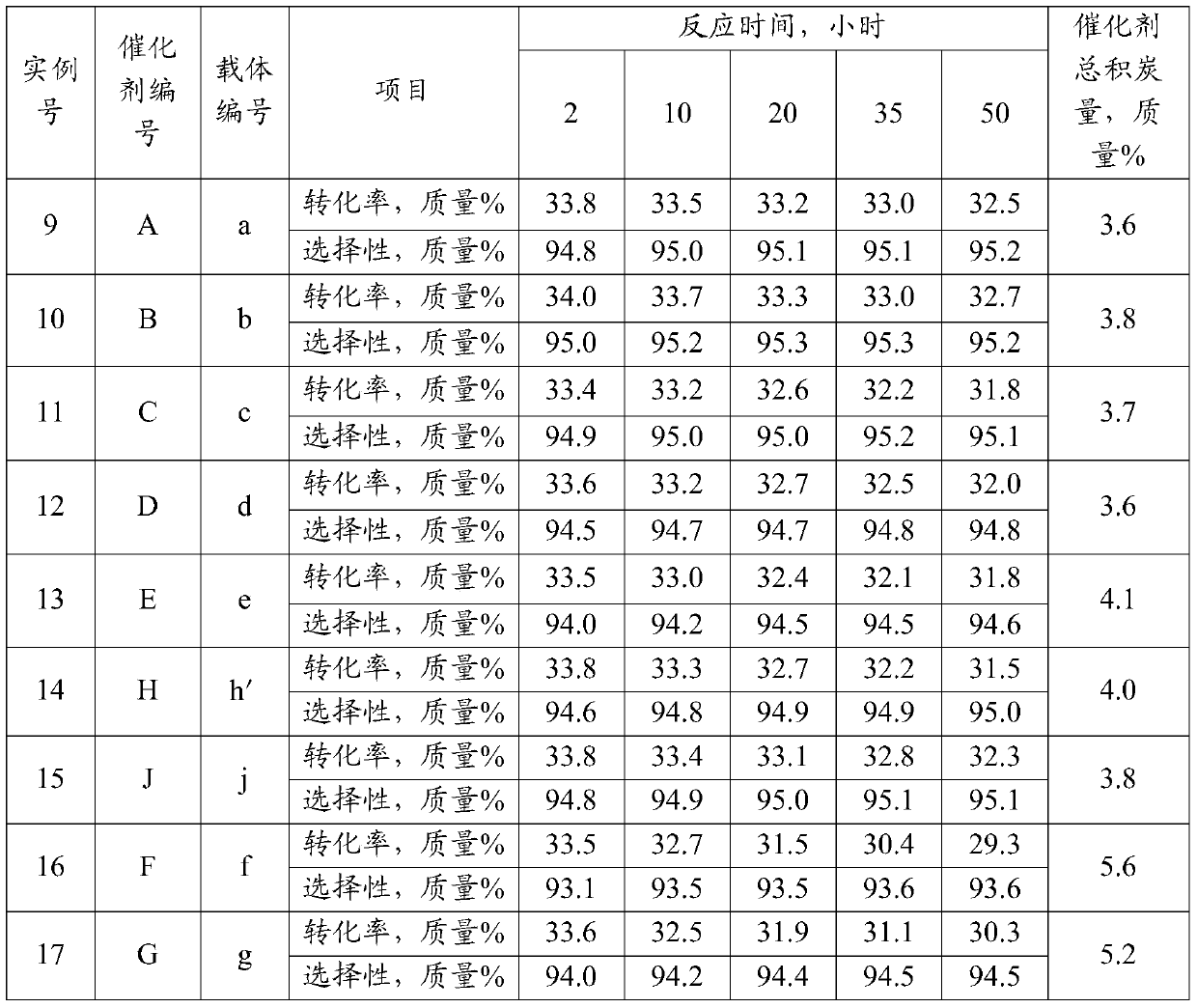

Alumina carrier and preparation method thereof

ActiveCN105312091AThe proportion of macropores increasesImprove carbon storage capacityCatalyst carriersHydrocarbonsAlkaneActive component

The invention relates to an alumina carrier, which has a specific surface area of 50-130 m<2> / g and a total pore volume of 0.5-1.0 ml / g, wherein the pore volume of the pore having a diameter of 2-10 nm in the carrier accounts for 4-15% of the total pore volume, the pore volume of the pore having a diameter of 10-20 nm in the carrier accounts for 40-60% of the total pore volume, the pore volume of the pore having a diameter of 20-50 nm in the carrier accounts for 1.0-5.0% of the total pore volume, and the pore volume of the large pore having a diameter of more than 50 nm and not more than 10 [mu]m in the carrier accounts for 20-50% of the total pore volume. According to the present invention, the catalyst obtained by loading the active component on the carrier has the good reaction performance when the catalyst is used for the olefin preparation reaction through low carbon alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing arene by utilizing methanol

ActiveCN103058807AImprove carbon storage capacityImprove stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsOxideMethanol

The invention relates to a method for producing arene by utilizing methanol, and mainly solves the problems of the existing method that a catalyst is rapid in carbon deposition and low in stability during a methanol producing process. The method comprises the following steps: based on methanol as a raw material, carrying out a contact reaction between methanol and the catalyst on a continuous fixing bed at the reaction temperature of 370 to 480 DEG C and the reaction weight space velocity of 0.5 to 4.0 h<-1>, thereby producing arene, wherein the catalyst comprises the following components according to parts by weight: a) 20 to 75 parts of binding agent; b) 20 to 75 parts of ZSM-5 molecular sieve; and c) 0.5 to 10 parts of zinc or oxides thereof; and the problems are solved well by adopting the technical scheme that the ratio of SiO2 to Al2O3 in the ZSM-5 molecular sieve is 20 to 200. Therefore, the method provided by the invention can be applied to the industrial production of arene by utilizing methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

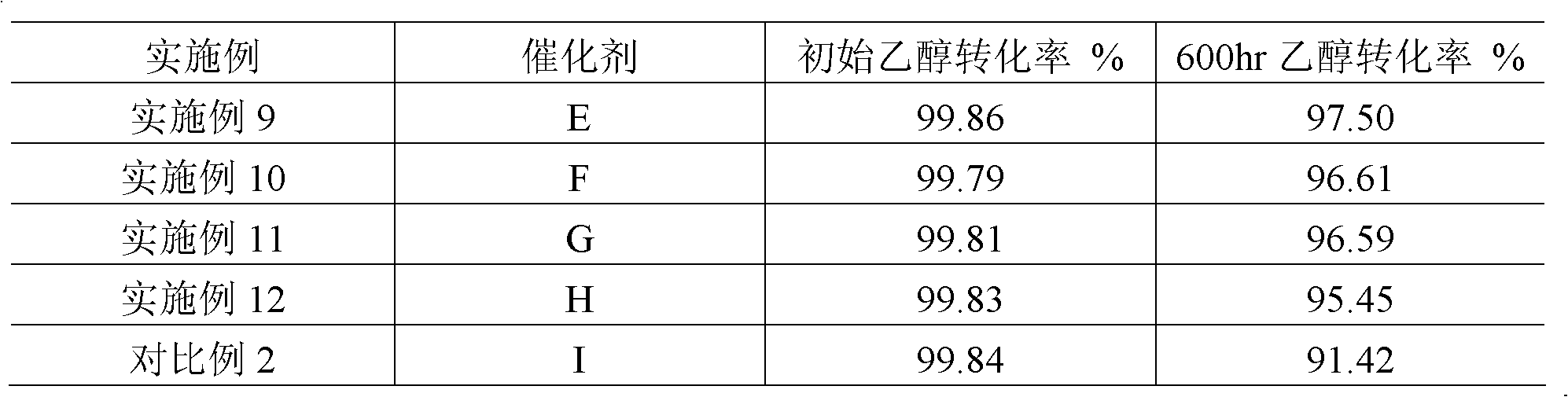

Modified molecular sieve catalyst for ethanol dehydration to produce ethylene, and application thereof

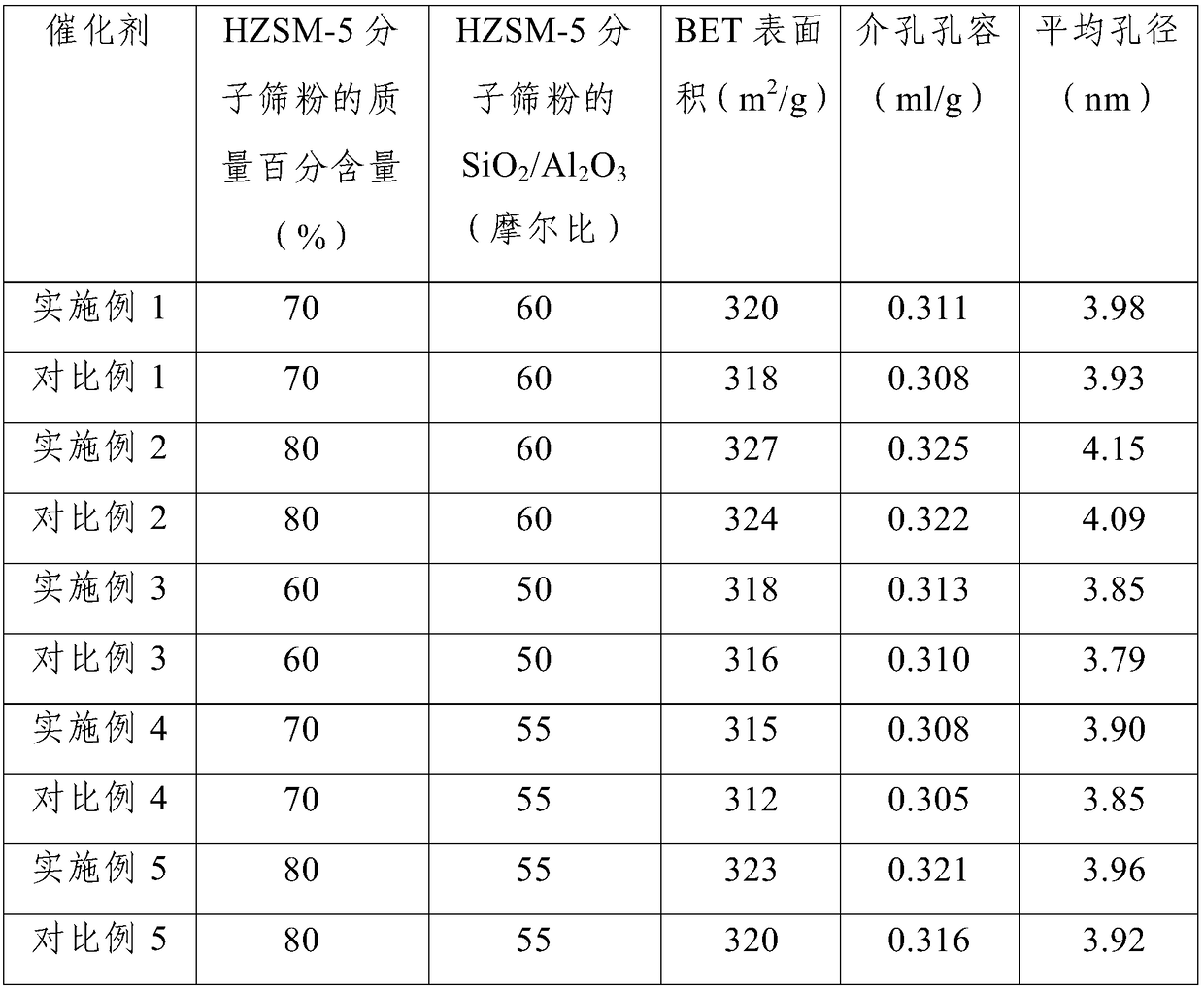

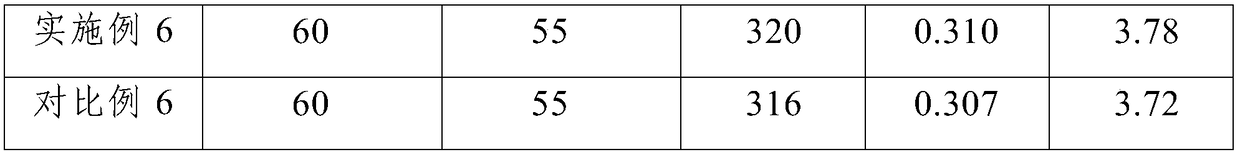

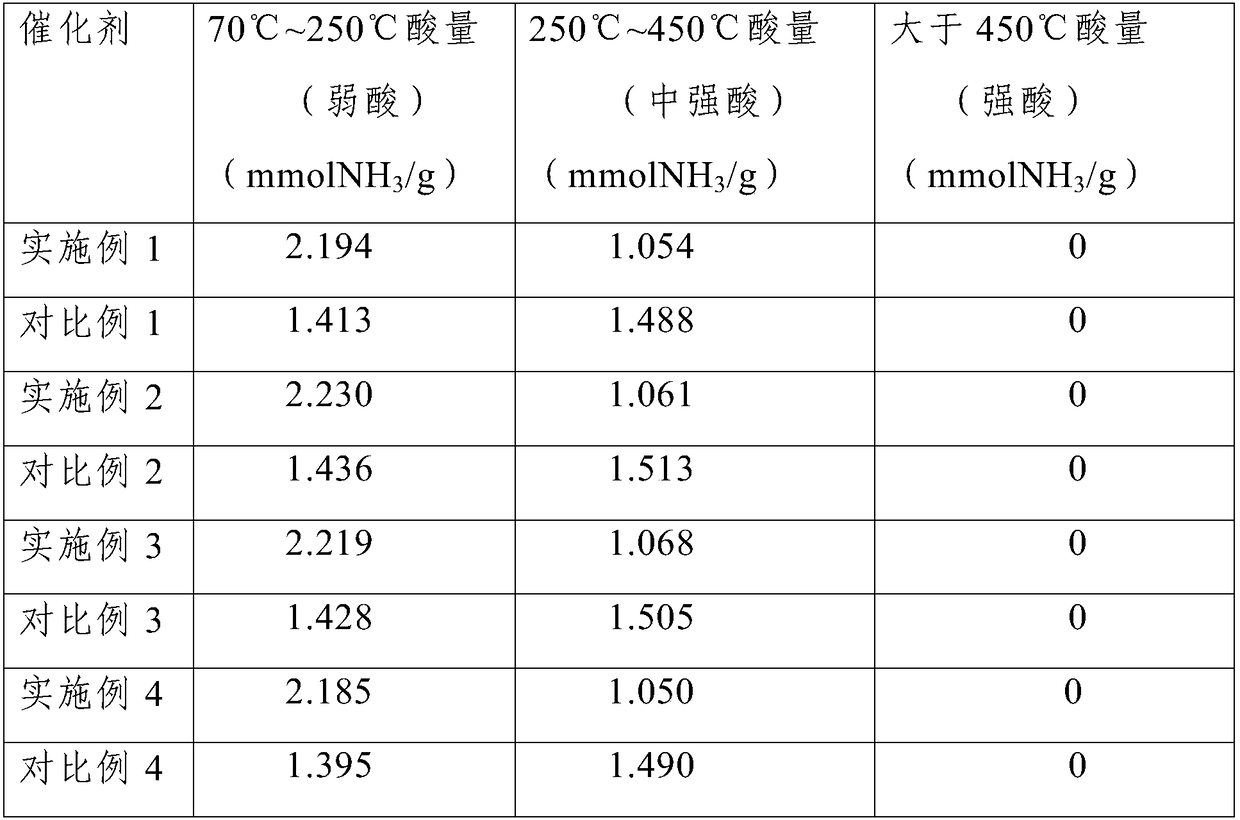

ActiveCN109174169AImprove carbon storage capacityImprove stabilityMolecular sieve catalystsCatalyst activation/preparationCooking & bakingMolecular sieve

The invention discloses a modified molecular sieve catalyst for ethanol dehydration to produce ethylene. The catalyst is prepared through the following steps: preparing an unmodified bar-shaped molecular sieve catalyst from HZSM-5 molecular sieve powder and macro-porous pseudo-boehmite powder, sequentially carrying out alkali modification and acid modification by using an aqueous Na2CO3 solution and an aqueous citric acid solution, and baking and calcining the modified bar-shaped molecular sieve catalyst. The invention also discloses an application of the modified molecular sieve catalyst forethanol dehydration to produce ethylene. The preparation modification process of the catalyst does not require a stirring process, so the preparation process is simplified, the weak acid amount of thesurface of the catalyst is greatly increased, and the medium and strong acid amount is reduced, thereby the catalysis effect of the modified molecular sieve catalyst on an ethanol dehydration reaction for producing ethylene is improved, the conversion rate of the raw material ethanol and the selectivity of the product ethylene are increased, and the service life of the modified molecular sieve catalyst is prolonged; and the modified molecular sieve catalyst has a simple application in the dehydration of ethylene to produce ethylene, and is suitable for being promoted.

Owner:XIAN ORIGIN CHEM TECH

Lamellar ZSM-5 catalyst, and preparation method and application thereof

InactiveCN108097294AImprove aromatics selectivityImprove catalytic stabilityMolecular sieve catalystsCatalyst activation/preparationLayer thicknessAromatic hydrocarbon

The invention provides a preparation method of a lamellar ZSM-5 catalyst. Under the action of double template agents, a lamellar ZSM-5 molecular sieve is controllably synthesized by utilizing a function of each template agent. The two template agents have the respective functions: the template agent A is used for synthesizing a lamellar ultrathin molecular sieve, and the template agent B is used for growing the conventional ZSM-5 molecular sieve on the basis of the lamellar molecular sieve. The molecular sieve is characterized by being capable of adjusting and controlling the layer thickness and the Si / Al molar ratio of the lamella ZSM-5 catalyst through controlling the compositional ratio of various raw materials in a precursor solution; the synthesized molecular catalyst has high aromatic hydrocarbon selectivity and carbon deposition resistance on a B acid site, and has high catalytic stability.

Owner:GUANGDONG UNIV OF TECH

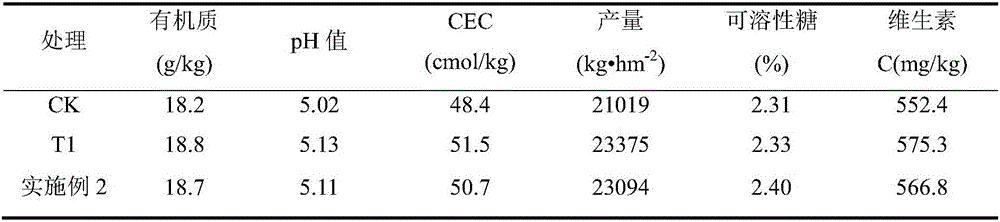

Bioorganic fertilizer of magnesium process desulphurization slag, and preparation method thereof

ActiveCN106699464AAdjust pHImprove carbon storage capacityExcrement fertilisersBioloigcal waste fertilisersSodium BentoniteSlag

The invention discloses a bioorganic fertilizer containing magnesium process desulphurization slag, and a preparation method thereof. The bioorganic fertilizer containing magnesium process desulphurization slag adopts animal manure, germ bran and rice bran as an organic matter source with stable quality; the magnesium process desulphurization slag can regulate the pH value of soil, improve the carbon storage capacity and the middle and trace element content of the soil, improve the granule structure of the soil and increase the output and the quality of crops; charcoal has good hydroscopicity, also has a part of functional hydrophobic groups, and can prevent hardening while adsorbing free water in the desulphurization slag; bentonite has great hydroscopicity, can adsorb the free water in the desulphurization slag, and modifies the desulphurization slag through ion displacement; humic acid can chelate metal ions in the soil and fertilizers, and facilitates transmission of nutrients to crops; and the bioorganic fertilizer also has the advantages of good ion exchange and buffer property, improvement of the structure of the soil, specific ratio of the raw materials, environmental protection, and improvement of the quality of the soil.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI +1

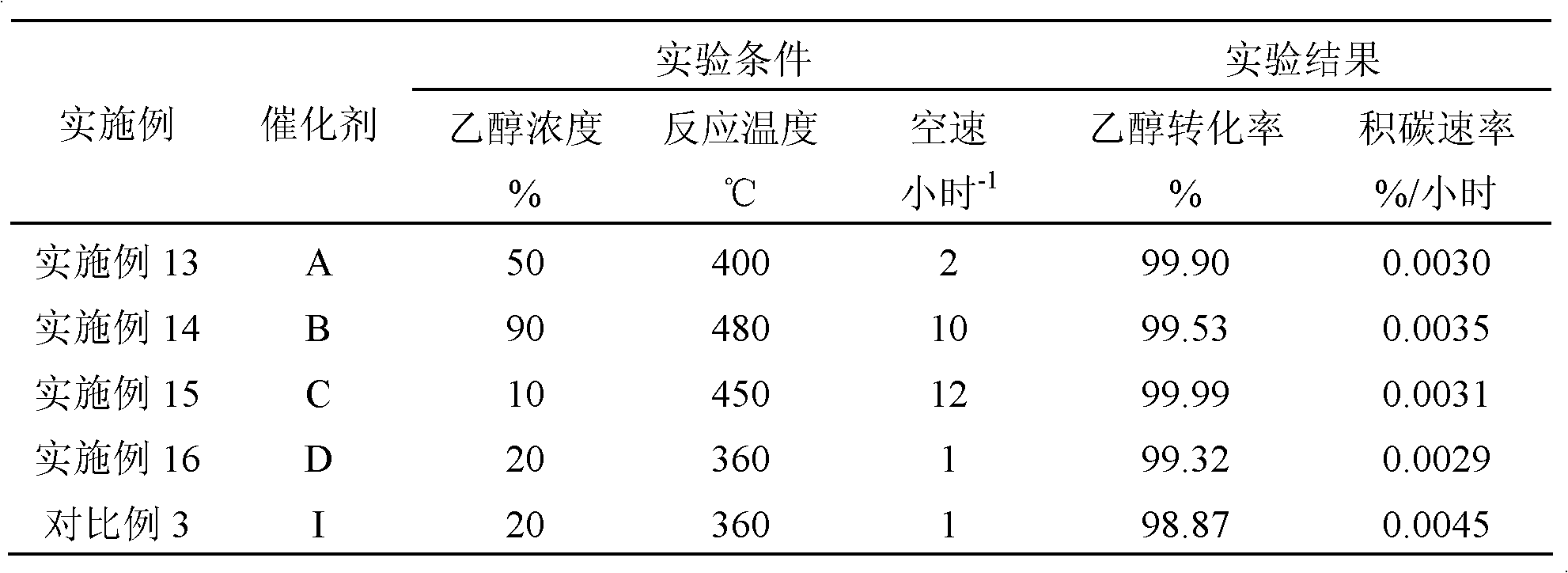

Method for dehydrating ethanol

ActiveCN101941878AImprove carbon storage capacityHigh activityHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureAqueous solution

The invention relates to a method for dehydrating ethanol, which mainly solves the problems of high reaction temperature and low catalyst activity or poor stability in the prior art. The method adopts the following technical scheme that: 5 to 100 weight percent ethanol aqueous solution is adopted as a raw material, and under the condition that the reaction temperature is between 200 and 450 DEG Cand the volume space velocity relative to the ethanol is 0.1 to 15 per hour, the reaction raw material contacts a catalyst to generate ethylene, wherein the catalyst is WO3 / ZrO2-SiO2 or MoO3 / ZrO2-SiO2, the molar ratio of W / Mo to Zr to Si is 0.05-0.3:1:5-50. The technical scheme of the invention well solves the problems, and the method can be used in the industrial production of preparing the ethylene by dehydrating the ethanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for dehydrogenation catalyst

ActiveCN108786831AHigh activityExtend one-way operation cycleHeterogenous catalyst chemical elementsHydrocarbonsDehydrogenationHigh activity

The invention discloses a preparation method for a dehydrogenation catalyst. The method comprises the following steps: (1) enabling soluble salt of Cr and soluble salt of La to be dissolved in benzoicacid solution, to obtain impregnation liquid containing Cr and La; and (2) dipping a carrier by using the impregnation liquid obtained in the step (1), drying, roasting, to obtain the dehydrogenationcatalyst. In the catalyst prepared by the method, the substance Cr stably exists on the surface of the aluminum oxide carrier, after the catalyst is recycled and regenerated for many times, the catalyst still has the higher dehydrogenation activity. The substance Cr largely exists in pore canals with larger pore diameters, and the substance Cr still has the higher activity under a higher carbon deposition quantity. A one-way running period of the catalyst is prolonged, and the operating cost of the device is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of alumina carrier and preparation method thereof

ActiveCN105312091BThe proportion of macropores increasesImprove carbon storage capacityCatalyst carriersHydrocarbonsAlkaneActive component

An alumina support has a specific surface area of 50-130m2 / g and a total pore volume of 0.5-1.0ml / g, and the pore volume of pores with a diameter of 2-10 nanometers in the support accounts for 4-15% of the total pore volume. The pore volume of pores with a diameter of 10-20 nm accounts for 40-60% of the total pore volume, the pore volume of pores with a diameter of 20-50 nm accounts for 1.0-5.0% of the total pore volume, and the diameter is greater than 50 nm but not greater than 10 The pore volume of micron macropores accounts for 20-50% of the total pore volume. The catalyst obtained after the carrier supports the active components is used for the reaction of producing olefins from the dehydrogenation of low-carbon alkanes, and has good reaction performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low-carbon olefin through methanol dehydration

ActiveCN102372548BHigh strengthLarge hole volumeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveCatalytic pyrolysis

Owner:CHINA PETROLEUM & CHEM CORP +1

Chitosan sustained release microsphere fertilizer loading 6-benzylaminopurine for tomatoes and preparation method thereof

InactiveCN106810350ALow costSimple processCalcareous fertilisersBio-organic fraction processingPhosphateMicrosphere

The invention relates to a chitosan sustained release microsphere fertilizer loading 6-benzylaminopurine for tomatoes. The fertilizer is characterized by being prepared from the following raw materials: chitin, sodium hydroxide, 6-benzylaminopurine, ethylene glycol, acetic acid, sodium stearyl lactate, cyclohexane, triphosadenine, glutaraldehyde, absolute ethyl alcohol, petroleum ether, isopropanol, rice straws, soybean straws, mercaptoacetic acid, saccharomycetes, lime powder, brown coal powder, borax, monopotassium phosphate, monoammonium phosphate and a proper amount of water. The fertilizer prepared by the invention integrates production increase, high efficiency and long effect, improvement of the quality and improvement of soil, and has the advantages of being low in cost, simple in process, free of residues, pollution-free, labor-saving and time-saving during construction and the like.

Owner:凤台县余跃蔬菜专业合作社

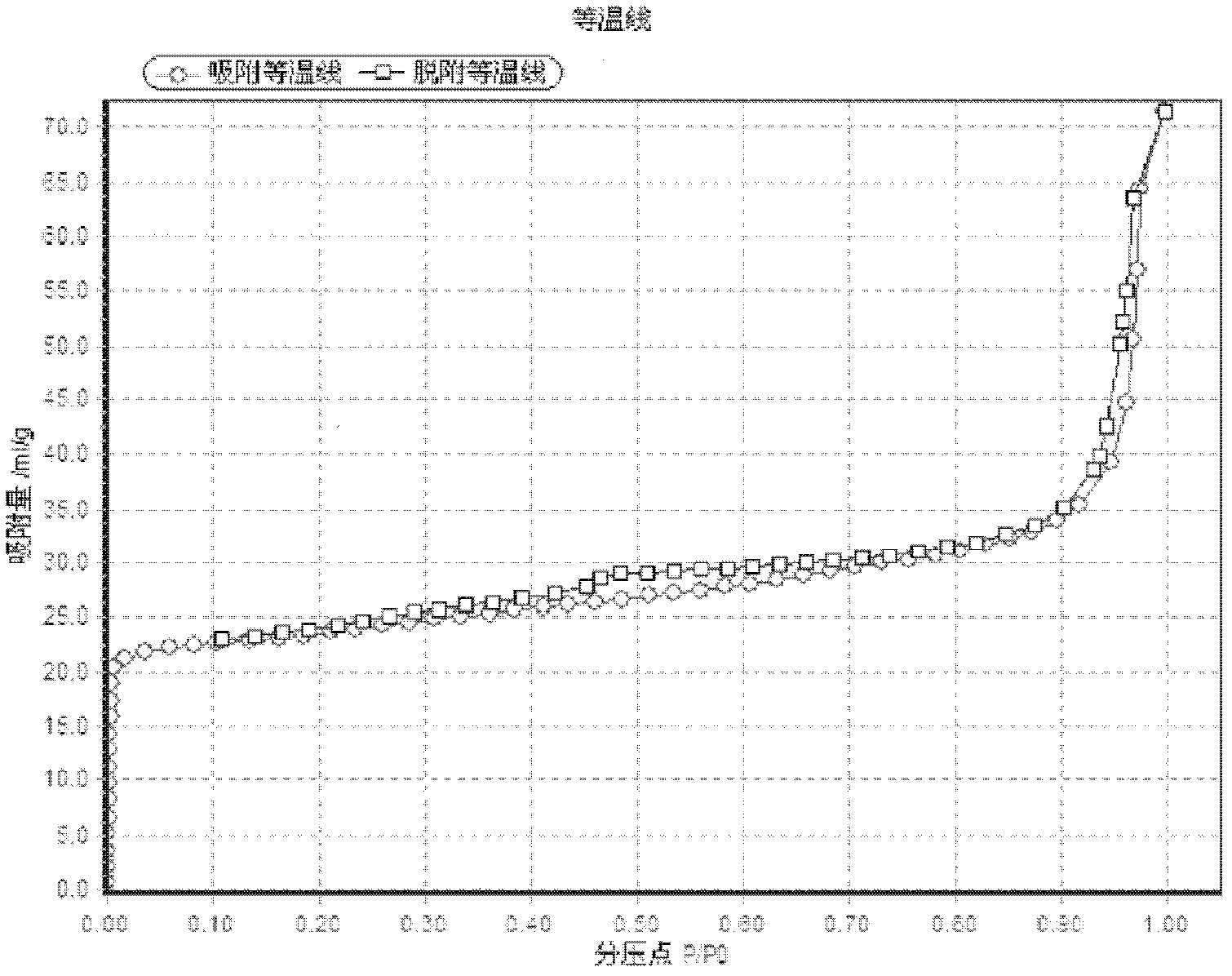

Zeolite molecular sieve with multi-stage pore structure and preparation method and application of zeolite molecular sieve

InactiveCN111977663ARich pore structureEnhance carbon storage capacityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveZeolite

The present invention discloses a zeolite molecular sieve with a multi-stage pore structure and a preparation method and an application of the zeolite molecular sieve. The zeolite molecular sieve withthe multi-stage pore structure is prepared by adding a small amount of a cationic polymer structure directing agent in a one-step manner. Compared with conventional molecular sieves, the zeolite molecular sieve has a relatively high specific surface area and pore volume, and a rich pore structure, solves problems of cumbersome post-processing operations or use of expensive organic templates whenthe conventional preparation of the molecular sieve with the multi-stage pore structure is conducted. At the same time, after active metal components are loaded, carbon holding capacity of a catalystis enhanced, reaction stability of the molecular sieve is effectively improved, and the molecular sieve shows good reaction performance when applied in anaerobic aromatization reaction of methane.

Owner:NORTHWEST UNIV

Slow-release fertilizer used for pear tree and capable of preventing and treating root rot disease, and preparation method thereof

InactiveCN106883048APromote deep root and leafy growth of plantsIncrease chlorophyll contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCorn starchPotassium permanganate

The invention relates to a slow-release fertilizer used for a pear tree and capable of preventing and treating a root rot disease. The slow-release fertilizer is characterized by being prepared from the following raw materials in parts by weight: 50 parts of soybean straws, 40-50 parts of rice straws, 30-40 parts of bentonite, 20-30 parts of potassium permanganate, 40-50 parts of urea, 30-40 parts of ammonium dihydrogen phosphate, 20-30 parts of potassium sulfate, 20-25 parts of corn starch, 10-12 parts of trichloroacetic acid, 18-20 parts of 1,2-ethylidene dithiocarbamate, 20-25 parts of dichlorotetraamine complex copper, 6-8 parts of sodium stearate, 70-80 parts of methacrylic acid, 20-30 parts of sodium hydroxide, 60-70 parts of acrylamide, 20-25 parts of a potassium persulphate solution, 30-40 parts of 1,2-dicarboxylate cyclohexane and a proper amount of deionized water. The slow-release fertilizer used for the pear tree and capable of preventing and treating the root rot disease has the advantages of being safe, low-toxic, efficient, stable, labor and time-saving during application, and the like.

Owner:叶集区华农种植专业合作社

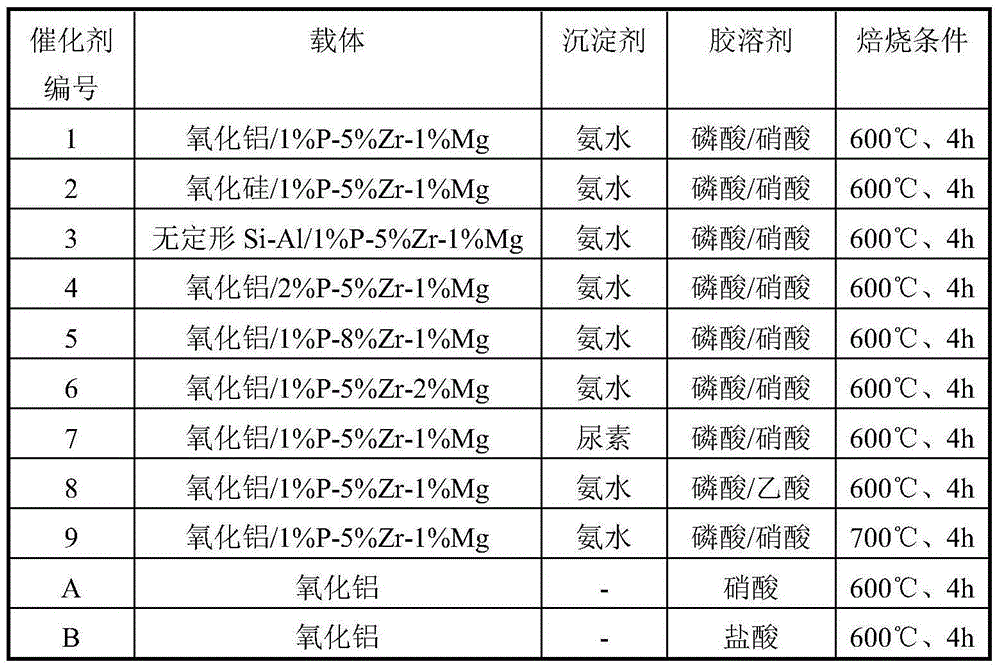

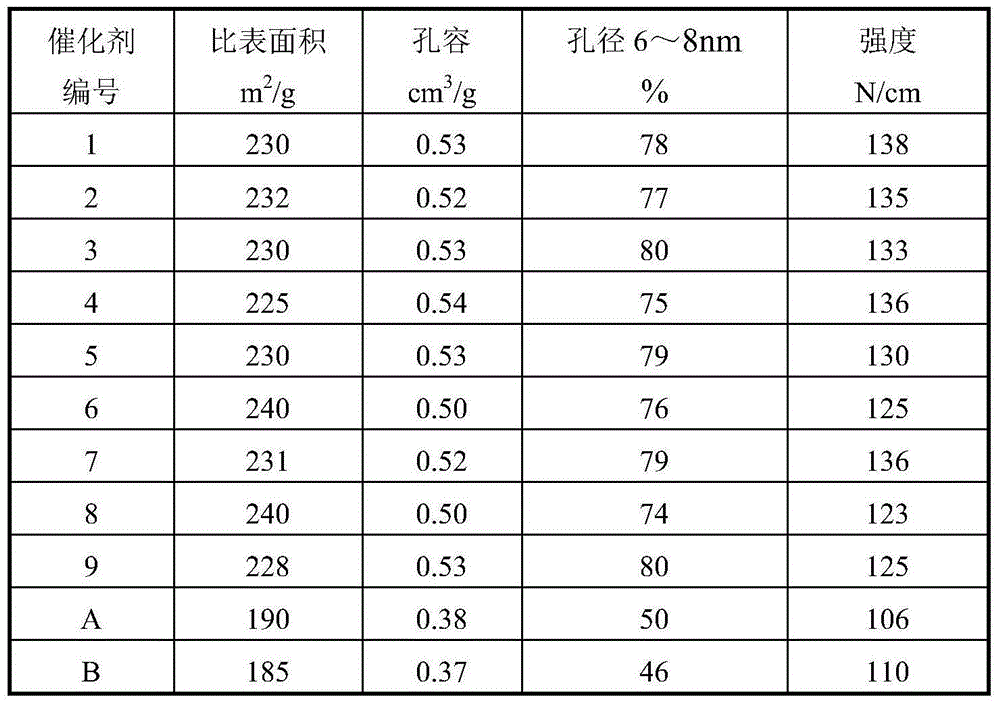

Distillate oil hydrofining catalyst carrier and preparation method thereof

ActiveCN106582732AEvenly distributedSuitable for acidityCatalyst carriersRefining to eliminate hetero atomsDistillationAmorphous silicon

The invention relates to a distillate oil hydrofining catalyst carrier and a preparation method thereof and mainly solves the problems that traditional hydrofining catalysts have non-centralized pore diameter distribution and poorer coking resistance and stability. The technical scheme is as follows: hydrofining catalyst carrier is prepared from, in percentage by weight, 68%-69.5% of at least one of aluminum oxide, silicon oxide and amorphous silicon-aluminum, 10%-20% of small-pore aluminum oxide, 0.5%-2% of P, 1%-8% of Zr and 0.5%-2% of Mg, so that the problems are better solved. According to the carrier preparation method, metal is added in the carrier preparation process, and the carrier has the characteristics of high strength, medium acidity and centralized pore diameter distribution and can be applied to the distillation oil refining field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene by dehydrating ethanol

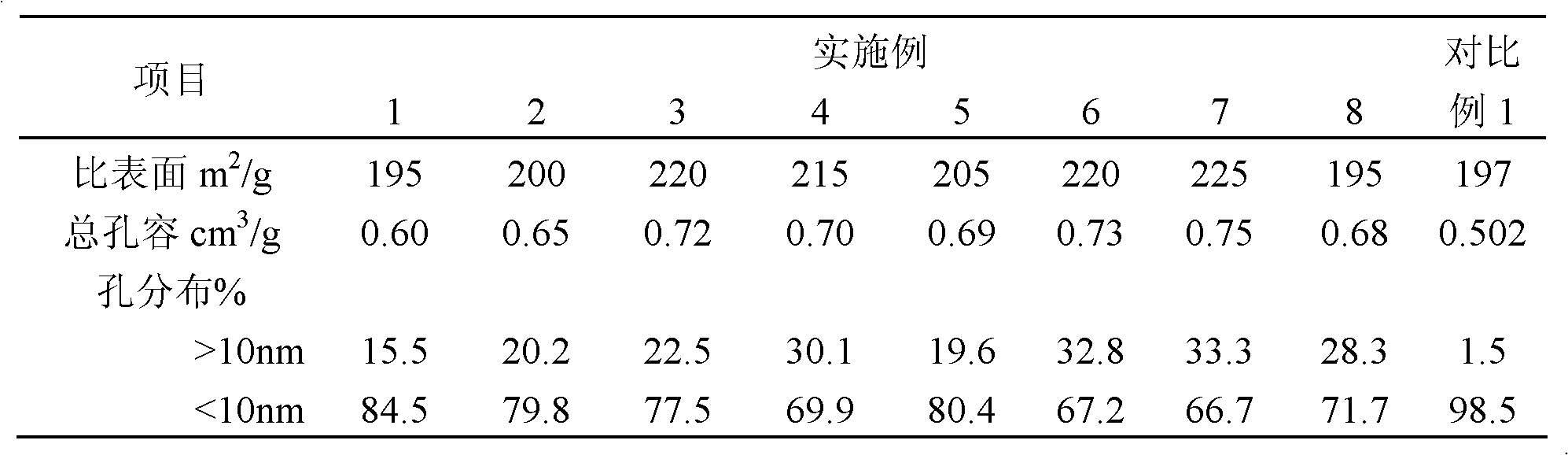

ActiveCN103121900AImprove carbon storage capacityExtend your lifePhysical/chemical process catalystsHydrocarbon from oxygen organic compoundsReaction temperaturePore diameter

The invention relates to a method for preparing ethylene by dehydrating ethanol and mainly solves the problem of low catalyst stability in the prior art. The problem is solved by adopting the technical scheme that ethanol which is used as a reaction raw material and a catalyst contact under the conditions that the reaction temperature is 300 to 550 DEG C, and the hourly space velocity relative to ethanol is 0.1 to 25 hours<-1> to react so as to generate ethylene, wherein the used catalyst is alumina of which the specific surface area is 150 to 250 m<2> / g and the total pore volumes are 0.5 to 1.0 cm<3> / g, and the pore volumes of pore diameters of less than 10 nanometers is 50 to 90 percent of the total pore volumes, and the pore volumes of pore diameters of more than 10 nanometers is 10 to 50 percent of the total pore volumes. The method can be used for industrial production of preparing the ethylene by dehydrating ethanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chitosan sustained releasing microsphere fertilizer for effective prevention and treatment of tomato fruit cracking and preparing method thereof

InactiveCN106518565ASimple processExtended service lifeCalcareous fertilisersAlkali orthophosphate fertiliserPhosphateMicrosphere

Disclosed is a chitosan sustained releasing microsphere fertilizer for effective prevention and treatment of tomato fruit cracking. The chitosan sustained releasing microsphere fertilizer is characterized by being prepared from raw materials of chitin, sodium hydroxide, calcium chloride, zinc sulfate, copper phosphate, acetic acid, glycerin monostearate, cyclohexan, folic acid, glutaraldehyde, petroleum ether, isopropanol, soybean straw, maize straw, livestock faeces, river sludge, urea, monopotassium phosphate, sodium dihydrogen phosphate, and an appropriate amount of water. The prepared chitosan sustained releasing microsphere fertilizer has the integrated characteristics of improving yield, being efficient, having long-acting effects, improving fruit quality and improving soil; meanwhile, the chitosan sustained releasing microsphere fertilizer has the advantages of being low in cost, simple in technology, having no residue and no pollution, saving labor and time during construction and the like.

Owner:凤台县余跃蔬菜专业合作社

Biochar-based organic-inorganic compound fertilizer special for acidic soil and preparation method thereof

The invention relates to the field of fertilizers for acidic soil and particularly relates to a special biochar-based organic and inorganic composite fertilizer for acidic soil and a preparation method thereof. The special biochar-based organic and inorganic composite fertilizer for the acidic soil is prepared from the following raw materials: biochar, an acidity regulating substance, a nitrogen-containing substance, a phosphorus-containing substance, a potassium-containing substance, mineral powder and a granulation binder, wherein the granulation binder comprises attapulgite powder and sodium silicate. The composite fertilizer is prepared by mixing the biochar as a controlled-release material and an adsorption material with other components according to a certain proportion, the matching of the components is reasonable, and the nutritional requirements of growth of crops can be well met; the sustained-release effect is good, and the composite fertilizer only needs to be applied once; the composite fertilizer has the effects of improving the pH value of the soil, improving the content of a carbon pool in soil, improving the aggregate structure and the porosity of the soil and reducing toxicity of heavy metals and organic pollutants and can achieve the effects of saving labor, saving the fertilizer and improving the yield and the quality of agricultural products. The invention further provides the preparation method of the composite fertilizer. The preparation method is simple and feasible.

Owner:SOUTH CHINA AGRI UNIV +1

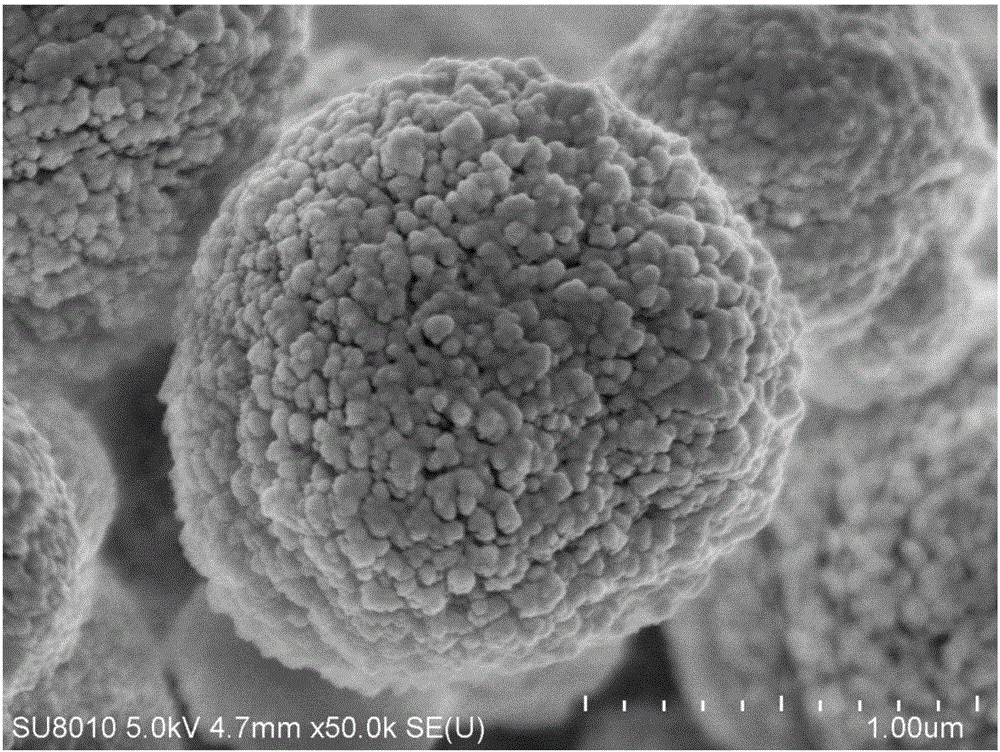

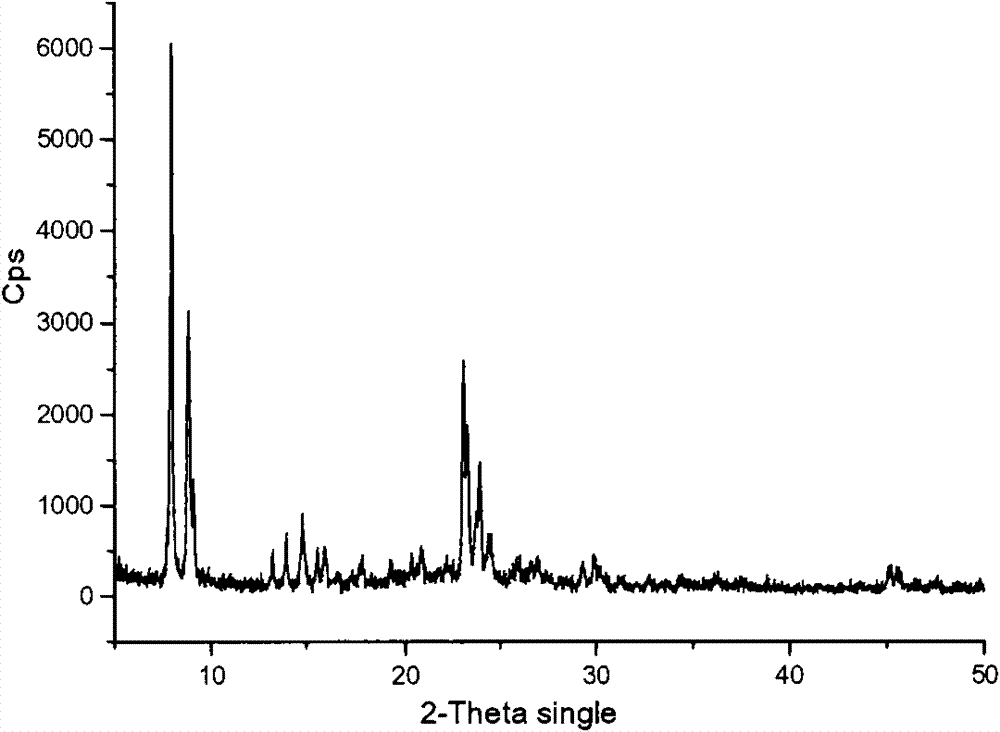

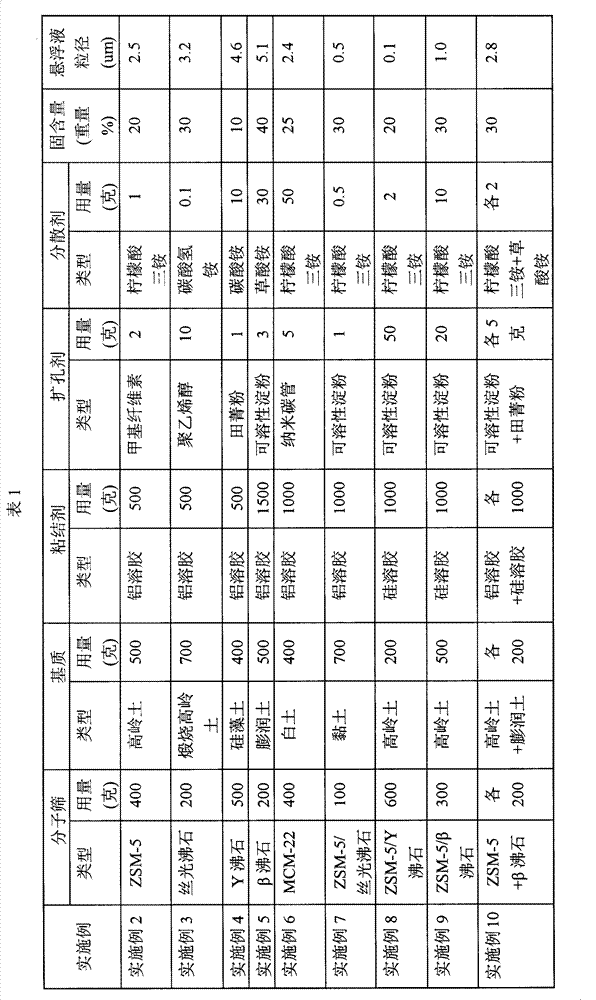

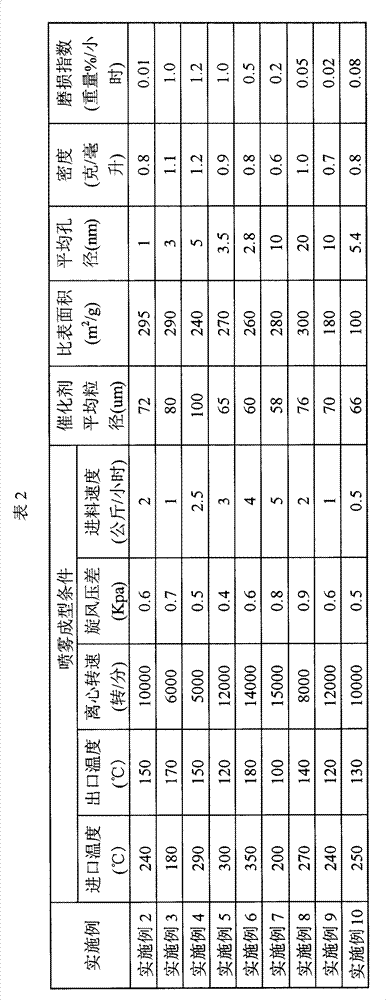

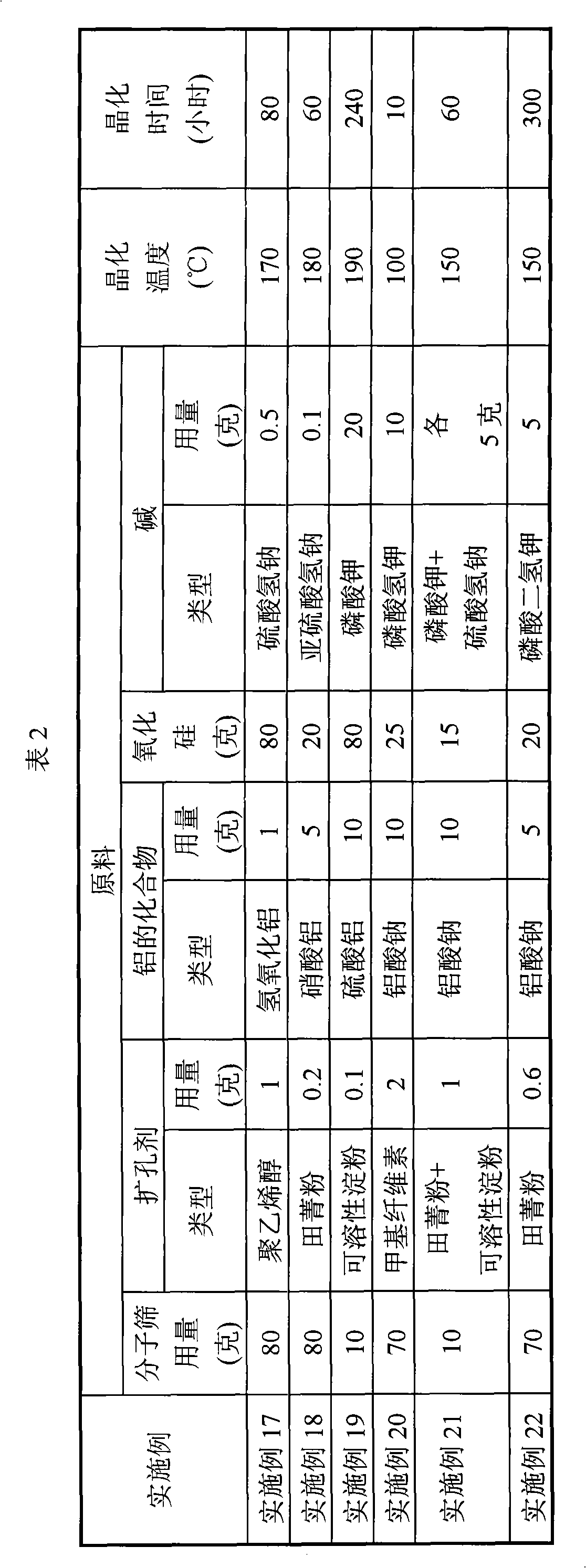

Preparation method for adhesive-free fluidized bed catalyst

ActiveCN102371183BFlat surfaceHigh sphericityCatalyst activation/preparationBulk chemical productionCatalytic pyrolysisLow activity

The invention relates to a preparation method for an adhesive-free fluidized bed catalyst. The problem of low activity of the fluidized bed catalyst in the prior art is mainly solved. The problem is well solved by adopting the technical scheme that the preparation method for the fluidized bed catalyst comprises the following steps of: (a) uniformly mixing molecular sieve, adhesive, a matrix material, a pore expanding agent, dispersant and a liquid medium to form suspension; (b) performing high-speed shearing and dispersion, and controlling the granularity of the materials in the suspension tobe between 0.1 and 5 microns; (c) performing spray drying on the suspension to form a micro-spherical catalyst precursor I; (d) roasting the micro-spherical catalyst precursor I at the temperature ofbetween 300 and 700 DEG C for 1 to 10 hours to obtain a catalyst precursor II; (e) putting the catalyst precursor II into template steam, and crystallizing at the temperature of between 100 and 200 DEG C for 10 to 200 hours to obtain a catalyst precursor III; and (f) roasting the micro-spherical catalyst precursor III at the temperature of between 400 and 700 DEG C for 1 to 10 hours to obtain a catalyst finished product. The catalyst can be applied to the reaction process of preparing low-carbon olefin by catalytic pyrolysis of light oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

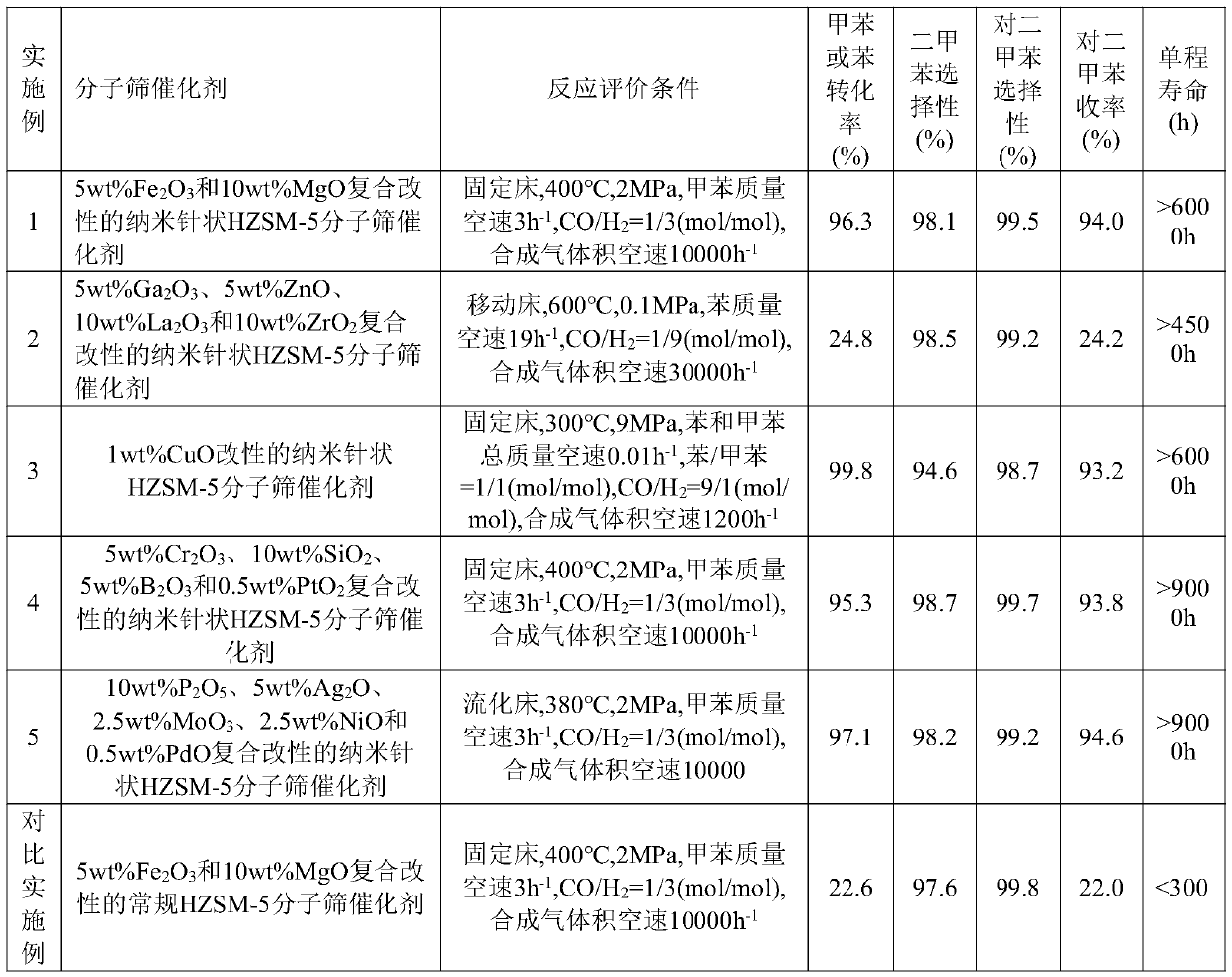

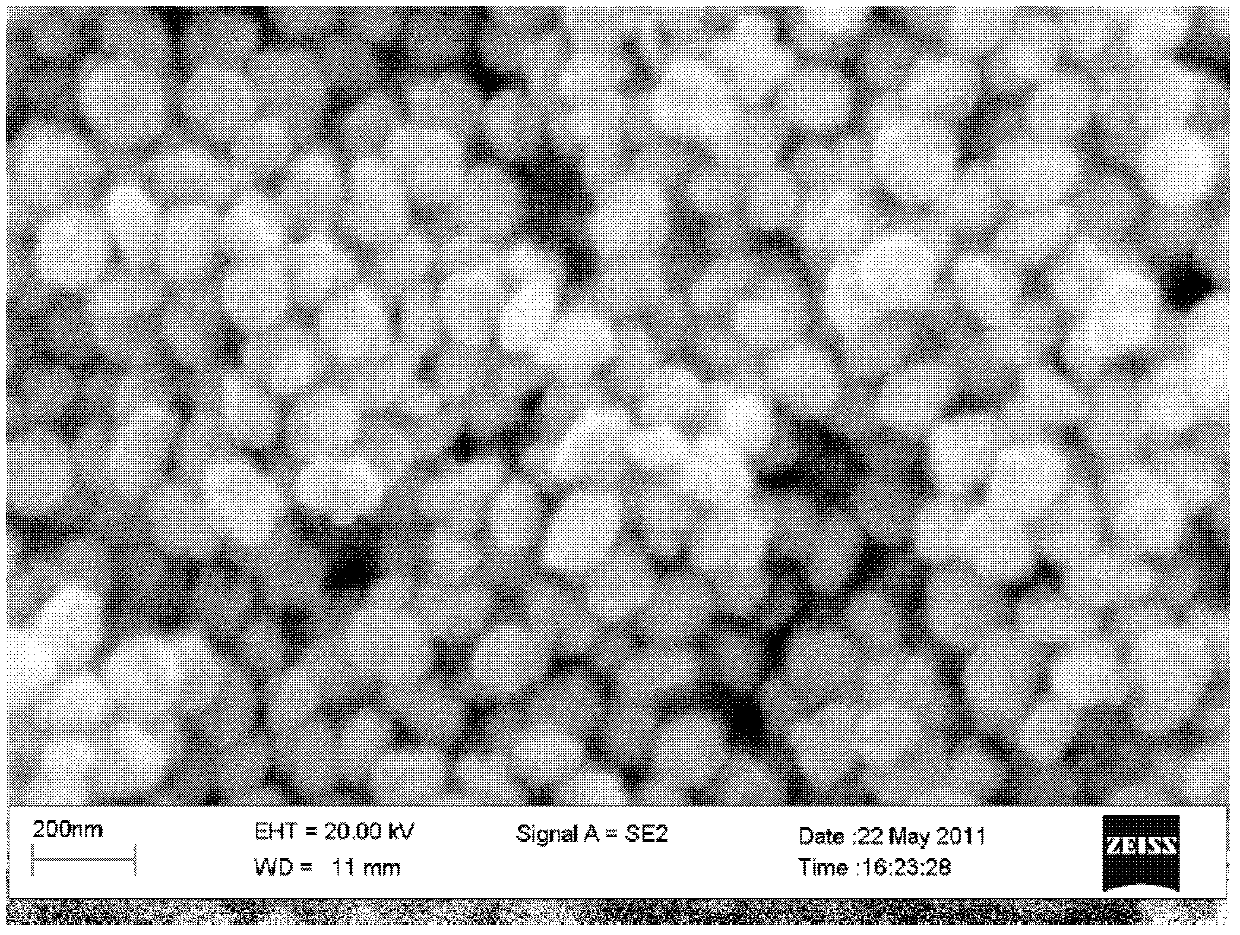

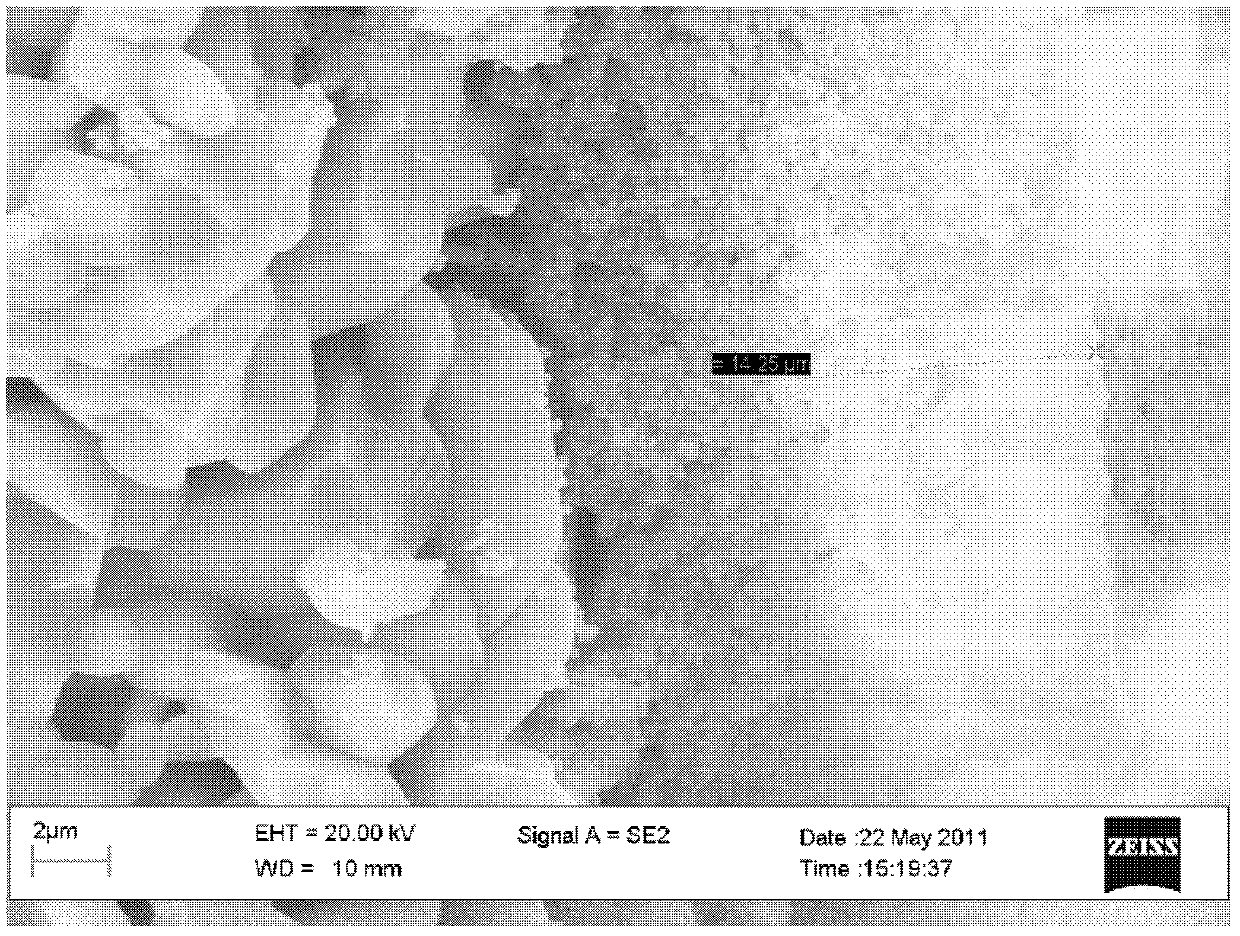

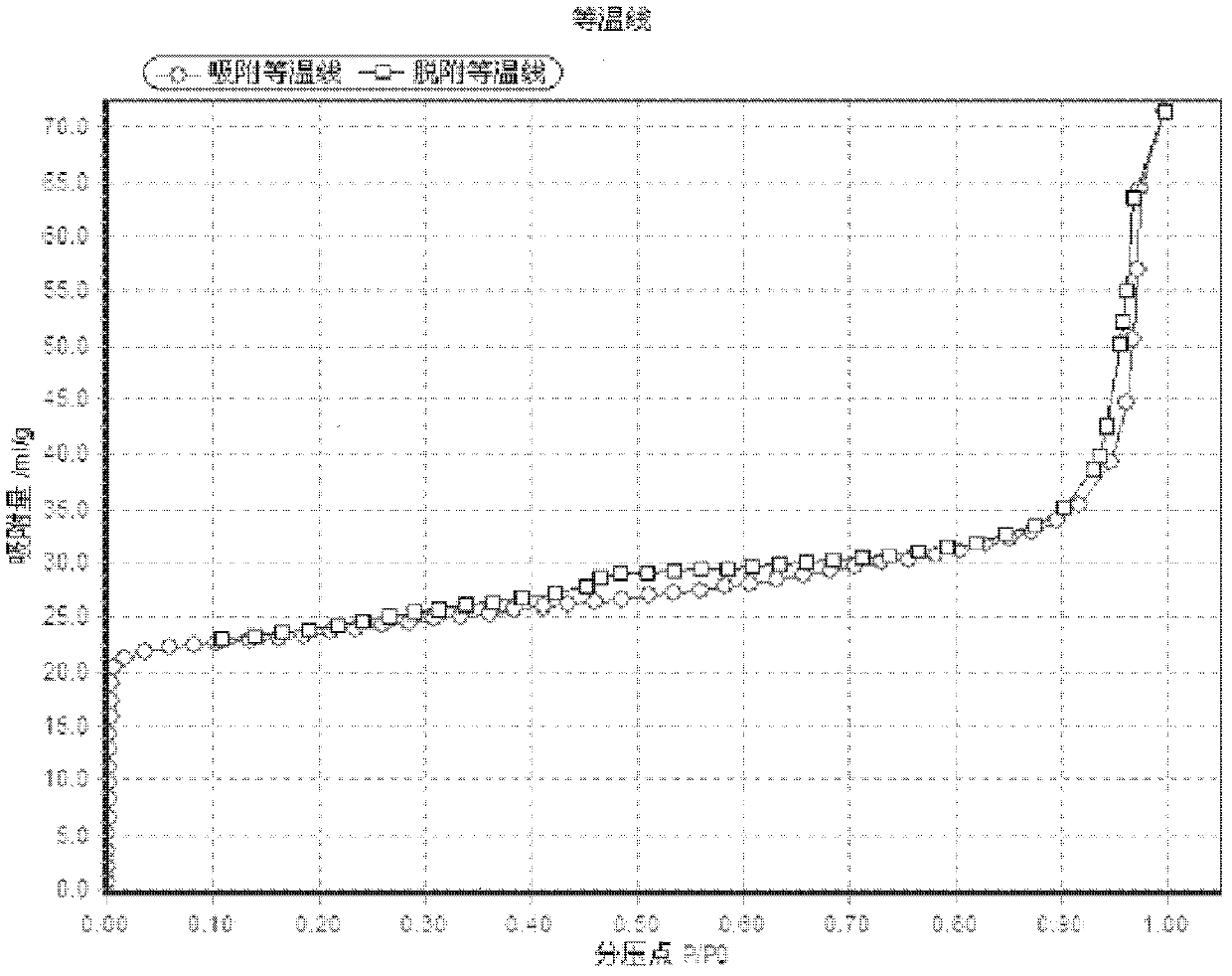

Shape-selective catalyst for efficiently preparing p-xylene from synthesis gas and light aromatic hydrocarbon

InactiveCN110694674AImprove conversion efficiencyHigh yieldMolecular sieve catalystsMolecular sieve catalystXylyleneMolecular sieve

The invention discloses a shape-selective catalyst for efficiently preparing p-xylene from synthesis gas and light aromatic hydrocarbon, and an application method of the shape-selective catalyst, wherein the shape-selective catalyst comprises 60-95 wt% of a hydrogen type nanometer needle-like short-pore ZSM-5 molecular sieve, 5-40 wt% of a binder and a modification aid, and the content of the modification aid is 10-30 wt% of the total weight of the molecular sieve and the binder. Compared with the catalyst in the prior art, the catalyst of the invention has the following characteristics that with the application of the catalyst in to a reaction for preparing p-xylene from synthesis gas and light aromatic hydrocarbon, the catalyst is a short-pore shape-selective catalyst, especially has high p-xylene selectivity, high light aromatic hydrocarbon conversion efficiency and long service life, and can effectively improve the p-xylene yield and reduce the catalyst regeneration and replacementfrequency so as to significantly improve the technical economy of the synthesis route.

Owner:XIANGTAN UNIV

Ultrafine molecular sieve structured catalytic material based on porous silicon carbide carrier and preparation thereof

ActiveCN102716762BHigh activityImprove carbon storage capacityMolecular sieve catalystsMolecular sieveHigh activity

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing light olefin by dehydrating oxygen compound

ActiveCN102372547BHigh strengthLarge hole volumeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPorosityCatalytic pyrolysis

The invention relates to a method for preparing light olefin by dehydrating oxygen compound, mainly solving the problems that activity of a catalyst is low and yield of the light olefin is low in the traditional technology for preparing the light olefin through catalytic pyrolysis. In the invention, a method for preparing the light olefin by dehydrating the oxygen compound is adopted, a binder-free molecular sieve is taken as a catalyst, methanol or dimethyl ether is taken as raw material, the raw material is contacted with the catalyst by virtue of a catalyst bed and reaction is carried out to generate the light olefin under the conditions that reaction temperature is 400-600 DEG C, reaction gauge pressure is 0.001-0.5MPa, reaction weight airspeed is 0.1-4 / hour and weight ratio of water to methanol is (0.1-3): 1, wherein pore volume of the binder-free molecular sieve catalyst is 0.1-0.3ml / g, average pore size is 50-70nm, porosity factor is 20-30%, and content of the binder is 0-5%; and strength of the catalyst after moulding and sintering is 60-200N. By adopting the technical scheme, the problems are solved, and the method provided by the invention can be applied to industrial production of the light olefin prepared by dehydrating the oxygen compound.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of multi-level structure zsm-5 zeolite molecular sieve and its synthesis method and application

ActiveCN106673008BHigh activityReduce inactivationMolecular sieve catalystsOrganic compound preparationMolecular sieveSynthesis methods

The invention relates to a method for synthesizing a multi-level structure ZSM-5 zeolite molecular sieve with intracrystalline mesopores and intercrystalline mesopores and its synthesis method and application. In addition to the micropores of the zeolite structure, the multi-level structure ZSM-5 zeolite molecular sieve also has inter-crystalline mesopores and intra-crystalline mesopore structures, in which the primary nanocrystal particle size is 40-500nm and the secondary accumulation particle size is 500nm-5μm. This structure greatly improves the diffusion performance and catalyst activity of the molecular sieve, reduces the possibility of side reactions and carbon deposition, increases the carbon holding capacity of the molecular sieve catalyst, and extends the catalyst life.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for producing arene by utilizing methanol

ActiveCN103058807BImprove carbon storage capacityImprove stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureZinc

The invention relates to a method for producing arene by utilizing methanol, and mainly solves the problems of the existing method that a catalyst is rapid in carbon deposition and low in stability during a methanol producing process. The method comprises the following steps: based on methanol as a raw material, carrying out a contact reaction between methanol and the catalyst on a continuous fixing bed at the reaction temperature of 370 to 480 DEG C and the reaction weight space velocity of 0.5 to 4.0 h<-1>, thereby producing arene, wherein the catalyst comprises the following components according to parts by weight: a) 20 to 75 parts of binding agent; b) 20 to 75 parts of ZSM-5 molecular sieve; and c) 0.5 to 10 parts of zinc or oxides thereof; and the problems are solved well by adopting the technical scheme that the ratio of SiO2 to Al2O3 in the ZSM-5 molecular sieve is 20 to 200. Therefore, the method provided by the invention can be applied to the industrial production of arene by utilizing methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shape-selective catalyst for efficient alkylation of light aromatic hydrocarbon and methanol

InactiveCN110721737AHigh shape selectivityHigh Methanol Alkylation EfficiencyMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention discloses a shape-selective catalyst for efficient alkylation of light aromatic hydrocarbon and methanol, and an application method thereof. The shape-selective catalyst comprises a hydrogen-type short-pore mixed crystal molecular sieve with a special morphology, a binder and a modifying aid, wherein the weight percentage of the hydrogen-type short-pore mixed crystal molecular sievewith the special morphology is 60-95 wt%, and the weight percentage of the binder is 5-40 wt%; and the content of the modifying aid is 10-40% of the total weight of the molecular sieve and the binder.The catalyst is used for the alkylation reaction of the light aromatic hydrocarbon and methanol to generate p-xylene. Compared with catalysts in the prior art, the catalyst of the invention, which isthe short-pore shape-selective catalyst, has the advantages of high selectivity to p-xylene, high methanol alkylation efficiency, long service life, effectiveness in improvement of the light aromatichydrocarbon conversion rate, the methanol utilization rate and the p-xylene yield, reduction of the catalyst regeneration and replacement frequency, and substantial improvement of the technical economical property of the synthesis route.

Owner:XIANGTAN UNIV

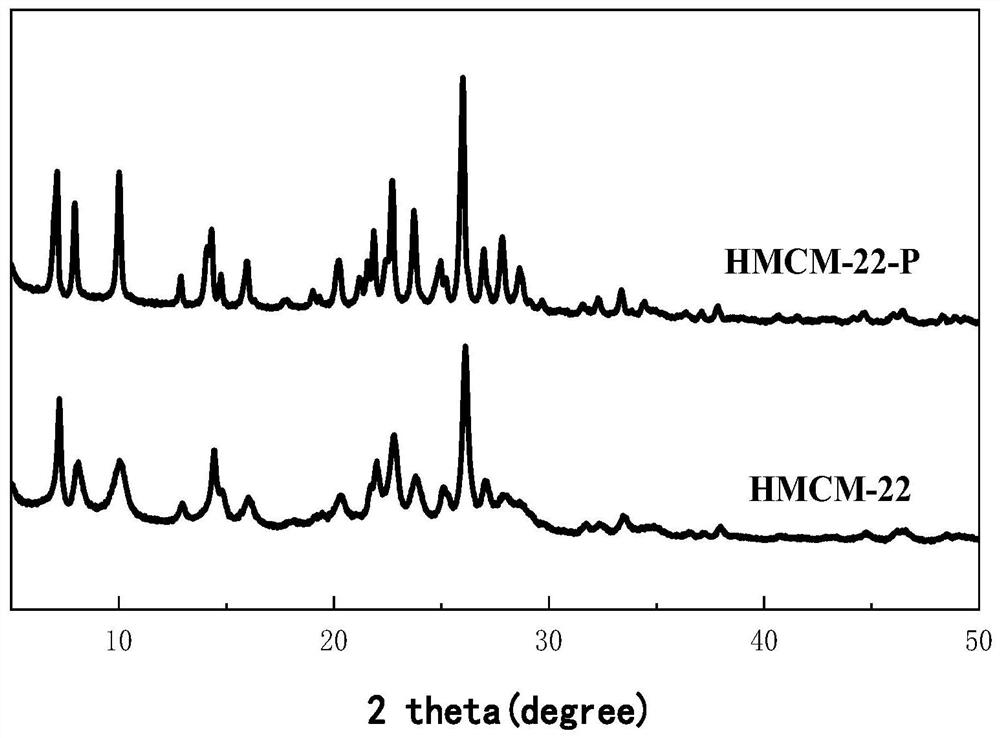

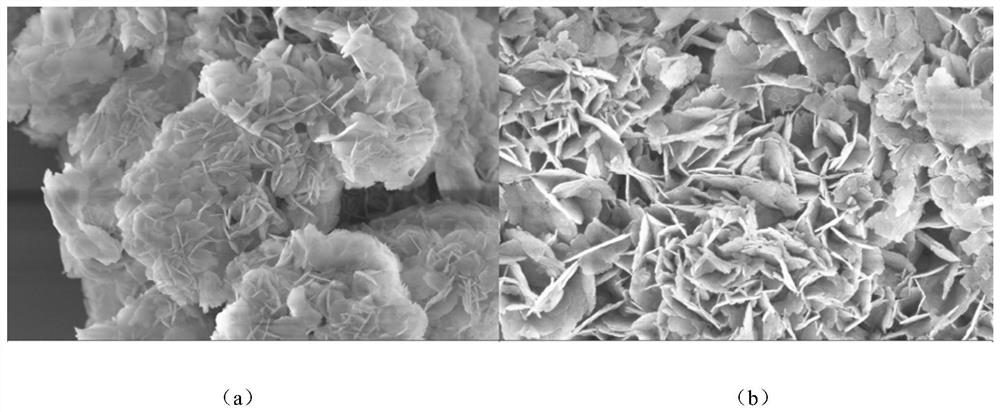

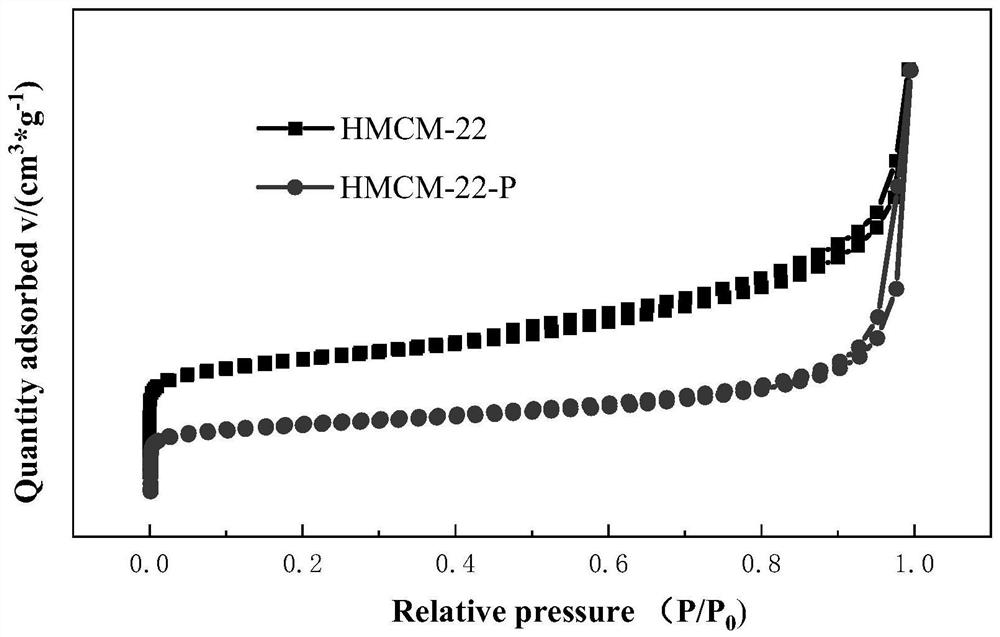

A composite hierarchical porous molecular sieve catalyst for producing aromatics from low-carbon alkanes and its preparation method

ActiveCN113198527BImprove stabilityImprove diffusion abilityMolecular sieve catalystsLiquid hydrocarbon mixtures productionMolecular sieveAlkane

The invention belongs to the field of catalysts and their preparation, and relates to a composite hierarchical porous molecular sieve catalyst for producing aromatics from low-carbon alkanes and a preparation method thereof. The catalyst component includes: a multi-level porous HZSM-5 molecular sieve synthesized by a hard template method, a HMCM-22 molecular sieve, a main active component, a noble metal / non-precious metal modifier and a small amount of binder. The catalyst of the invention has excellent low-carbon alkane aromatization performance, simple preparation process, controllable cost and good industrial application prospect.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com