Bioorganic fertilizer of magnesium process desulphurization slag, and preparation method thereof

A bio-organic fertilizer and magnesium desulfurization technology, applied in the field of bio-organic fertilizer and its preparation of magnesium desulfurization slag, can solve the problems of low soil microbial community, easy loss of nutrient elements, and secondary pollution of the environment, and achieve improved soil structure , Improve crop yield and quality, improve the effect of soil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of the present invention is as above-mentioned bio-organic fertilizer, and each raw material is mixed.

[0062] In the above preparation method, the method of mixing is not particularly limited. Can enumerate a kind of mixing mode, as it can specifically comprise the following steps:

[0063] Mixing the biochar, bentonite and humic acid to form the first component;

[0064] mixing the first component and the magnesium desulfurization slag to form a second component;

[0065] mixing the second component with livestock and poultry manure, rice bran, and fungus bran to form a third component;

[0066] mixing the three components and a sulfur-containing substance to obtain a fourth component;

[0067] And, mixing the fourth component and the compound microbial agent.

[0068] The above-mentioned third component may also include fermentation for 60-84h before being mixed with the sulfur-containing substance, such as fermentation for 60h, 62h, 65h, ...

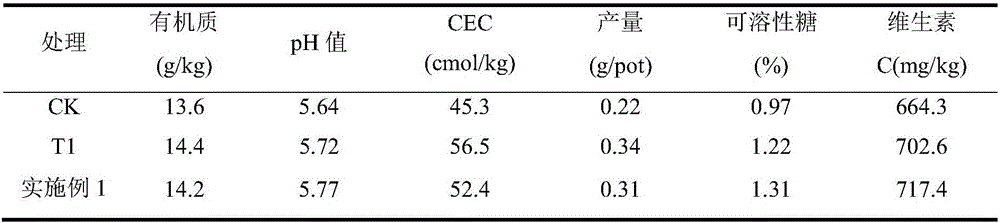

Embodiment 1

[0076] After crushing 2 parts of citrus sticks and corn stalks and anaerobically cracking them at 400°C for 2.5 hours, the biochar was crushed and passed through a 150-mesh sieve, 5 parts of calcium-based bentonite passed through a 200-mesh sieve and 4 parts of biochar with a pH of 4.0 humic acid is mixed to obtain the first mixture;

[0077] The first mixture was mixed with 5 parts of desulfurization magnesium slag whose free water was 13%, and stirred evenly to obtain the second mixture;

[0078] Mix 28 parts of chicken manure with 80% water content and 30 parts of cow manure with 70% water content, then mix with 9 parts of rice bran and 8.8 parts of fungus manure. The mixture is uniformly mixed with the second mixture, the water content is adjusted to 60%, and the mixture is transferred into an aerobic fermentation tank for aerobic fermentation, which is the third mixture.

[0079] After moving into the fermenter, maintain aeration for 8 minutes, stop for 22 minutes, add t...

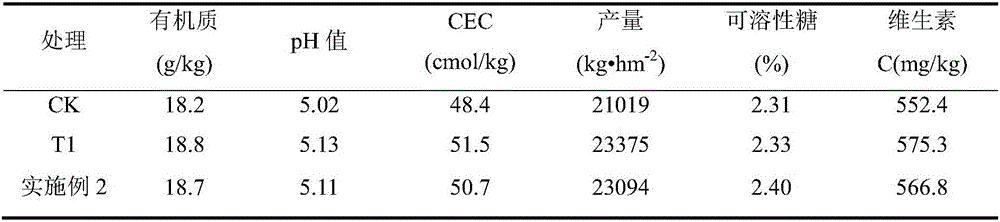

Embodiment 2

[0086] After crushing 2.3 parts of peanut shells and corn stalks and anaerobic pyrolysis at 400°C for 2 hours, the biochar was crushed and passed through a 150-mesh sieve, 4.5 parts of calcium-based bentonite passed through a 200-mesh sieve and 3 parts of humic acid with a pH of 4.5 Acids are mixed to obtain a first mixture;

[0087] The first mixture is mixed with 4 parts of desulfurization magnesium slag whose free water is 13%, and stirred evenly to obtain the second mixture;

[0088] Mix 32 parts of pig manure with 82% water content and 32 parts of cow manure with 73% water content, then mix with 5 parts of rice bran and 9 parts of fungus chaff. The mixture is uniformly mixed with the second mixture, the water content is adjusted to 60%, and the mixture is transferred into an aerobic fermentation tank for aerobic fermentation, which is the third mixture.

[0089] After moving into the fermentation tank, keep aeration for 10 minutes, stop for 20 minutes, add the 4 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com