Catalyst for preparing arene via direct methanol conversion and preparation method thereof

A catalyst and direct technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low stability and fast carbon deposition of catalysts, and achieve the effect of improving stability and enhancing carbon capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

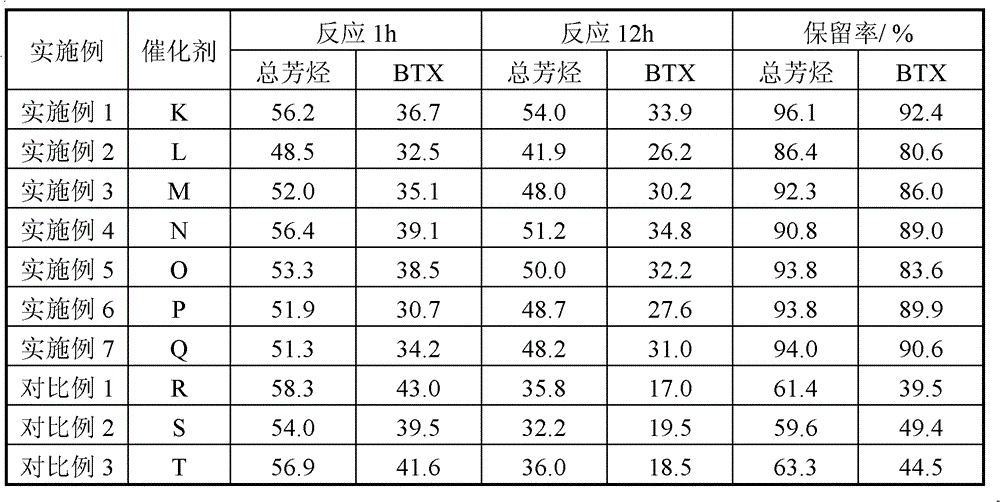

Examples

Embodiment 1

[0019] a) Take 100g silicon aluminum ratio SiO 2 / Al 2 o 3 Add 20 ZSM-5 molecular sieve raw powder to 600g of 1.5mol / L sodium hydroxide solution, stir at 30°C for 30min, filter and wash with water, and then dry the filter cake at 100°C for 8h.

[0020] b) Take 80 g of molecular sieves dried in step a), mix them with 400 g of 5% ammonium nitrate solution, heat at 80°C for 2h, filter and wash with water, then dry the filter cake at 100°C for 8h, and roast at 500°C for 4h to obtain type H ZSM-5 molecular sieve.

[0021] c) Take 20g of the HZSM-5 molecular sieve prepared in the step b), and mix it with 58g of pseudo-boehmite and 2.0g of turmeric powder. Dilute nitric acid was added to the mixture, kneaded evenly, extruded, dried at 110°C for 12 hours, and calcined at 600°C for 6 hours to prepare a catalyst carrier.

[0022] d) Dissolve 2.7g of zinc nitrate in 15g of water, add 20g of the catalyst carrier prepared in step c), dry at 110°C for 12h, and roast at 600°C for 4h to p...

Embodiment 2

[0024] a) Take 100g silicon aluminum ratio SiO 2 / Al 2 o 3 Add 200 ZSM-5 molecular sieve raw powder to 600 g of 0.1 mol / L potassium hydroxide solution, stir at 80 °C for 240 min, filter and wash with water, and then dry the filter cake at 100 °C for 10 h.

[0025] b) Take 80 g of molecular sieves dried in step a), mix them with 400 g of 5% ammonium nitrate solution, heat at 80°C for 2h, filter and wash with water, then dry the filter cake at 120°C for 8h, and roast at 550°C for 4h to obtain type H ZSM-5 molecular sieve.

[0026] c) Take 20g of HZSM-5 molecular sieve prepared in step b), 30g of pseudo-boehmite, and 1.0g of starch and mix them evenly. Dilute nitric acid was added to the mixture, kneaded evenly, extruded, dried at 100°C for 12 hours, and calcined at 580°C for 5 hours to prepare a catalyst carrier.

[0027] d) Dissolve 1.0 g of zinc sulfate in 28 g of water, add 40 g of the catalyst carrier prepared in step c), dry at 120°C for 8 hours, and roast at 600°C for ...

Embodiment 3

[0029] a) Take 100g silicon aluminum ratio SiO 2 / Al 2 o 3 Add 100 ZSM-5 molecular sieve raw powder to 500 g of potassium hydroxide solution with a concentration of 0.5 mol / L, stir at 80 °C for 120 min, filter and wash with water, and then dry the filter cake at 120 °C for 2 h.

[0030] b) Take 80 g of molecular sieves dried in step a), mix them with 400 g of 5% ammonium nitrate solution, heat at 80°C for 2h, filter and wash with water, then dry the filter cake at 100°C for 16h, and roast at 580°C for 3h to obtain type H ZSM-5 molecular sieve.

[0031] c) Take 38g of the HZSM-5 molecular sieve prepared in step b), 10g of pseudo-boehmite, and 1.5g of celadon powder and mix them evenly. Dilute nitric acid was added to the mixture, kneaded evenly, extruded, dried at 100°C for 12 hours, and calcined at 550°C for 5 hours to prepare a catalyst carrier.

[0032] d) Dissolve 3.3g of zinc chloride in 20g of water, add 20g of the catalyst carrier prepared in step c), dry at 110°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com