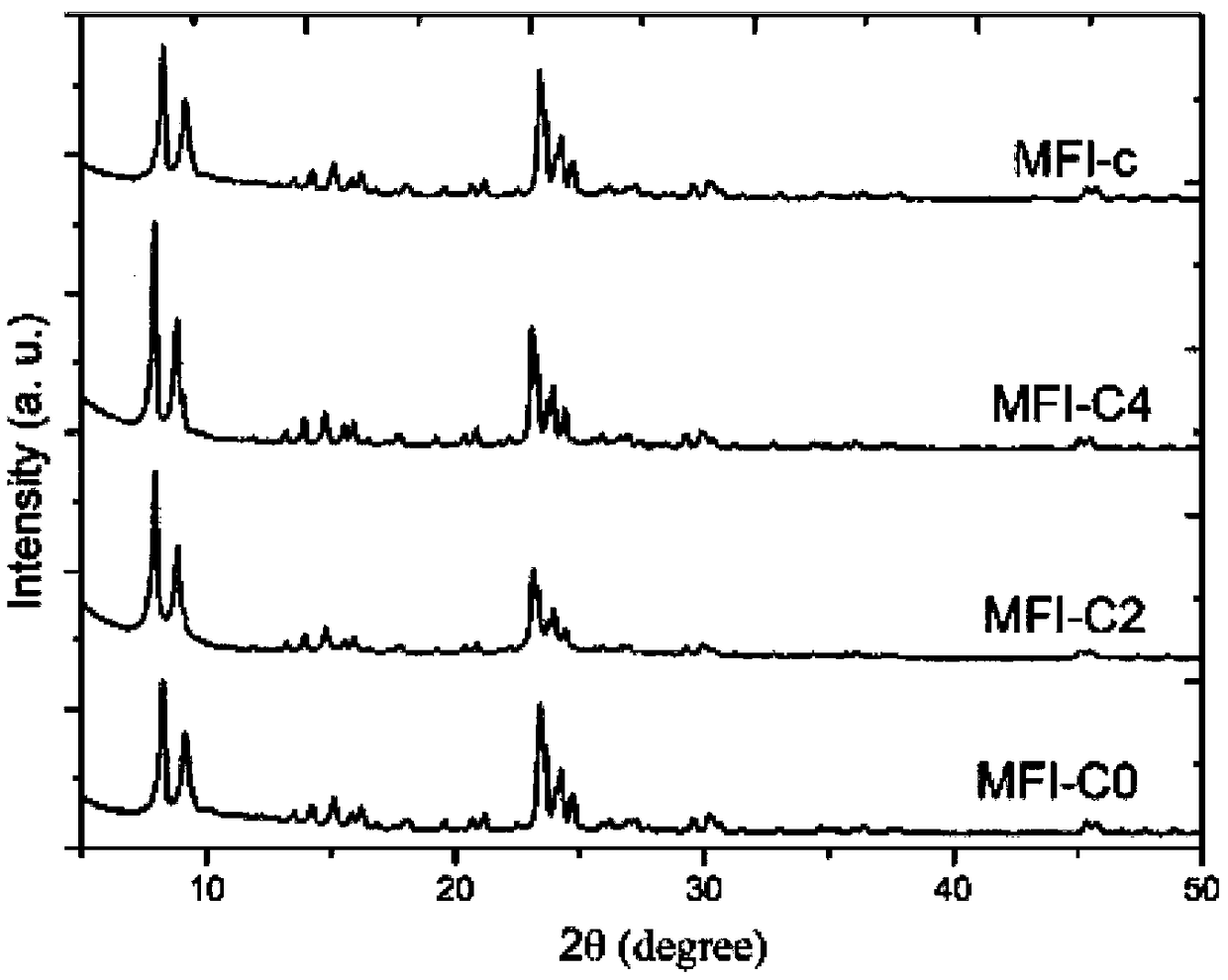

Lamellar ZSM-5 catalyst, and preparation method and application thereof

A technology of ZSM-5 and catalyst, which is applied in the field of layered ZSM-5 catalyst and its preparation, and can solve problems affecting BTX selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a kind of preparation method of layered ZSM-5 catalyst, comprises the following steps:

[0036] A) Silicon source compound, aluminum source compound, template A, template B, structure aid, alkali and water are (1-100): (1-100): (1-50): (1 ~50): (1 ~ 40): (1 ~ 10): (1 ~ 7000) After mixing, let stand to obtain the precursor aqueous solution;

[0037] Described templating agent A is selected from [C 22 h 45 –N + (CH 3 ) 2 –C 6 h 12 –N + (CH 3 ) 2 –C 6 h 13 ]Br 2 , [C 22 h 45 –N + (CH 3 ) 2 –C 4 h 8 –N + (CH 3 ) 2 –C 6 h 13 ]Br 2 , [C 22 h 45 –N + (CH 3 ) 2 –C 4 h 8 –N + (CH 3 ) 2 –C 4 h 9 ]Br 2 and [C 22 h 45 –N + (CH 3 ) 2 –C 6 h 12 –N + (CH 3 ) 2 –C 4 h 9 ]Br 2 one or more of

[0038] The template agent B is selected from one or more of TPAOH, TPABr, CTAB, triethylamine, ethylenediamine and pyrrolidone homologues;

[0039] The precursor aqueous solution is subjected to hydrothermal crystallizatio...

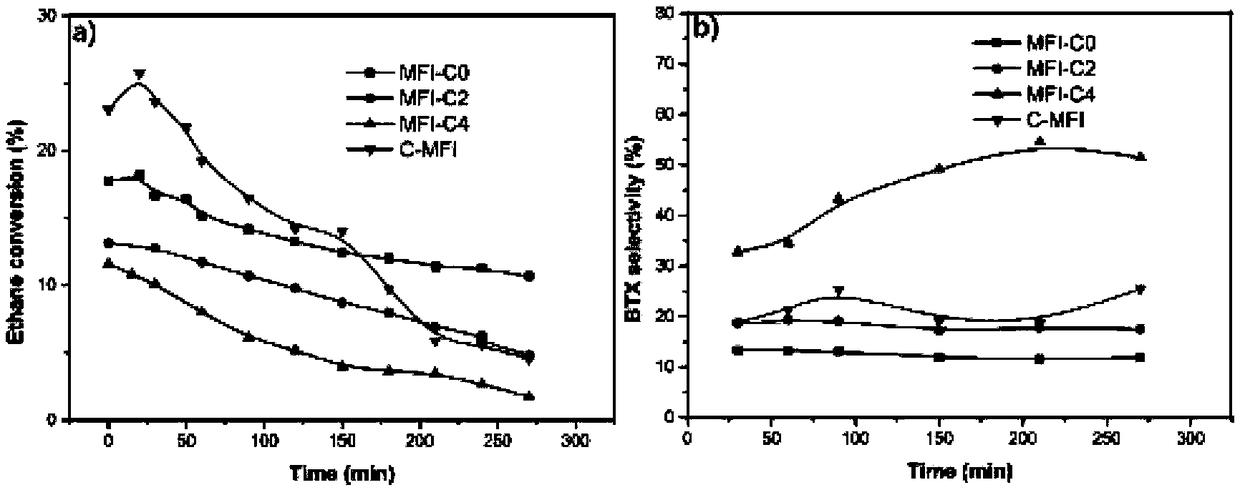

Embodiment 1

[0073] 12.0g ethyl orthosilicate, 4.1g [C 22 h 45 –N + (CH 3 ) 2 –C 4 h 8 –N + (CH 3 ) 2 –C 6 h 13 ]Br 2 , a certain amount of CTAB, 1.1g of aluminum sulfate, and 0.7g of NaOH were mixed together to form a precursor aqueous solution, and left to stand for 24 hours. After separating the solid and liquid from the reaction material, it was dried at 110°C for 10 hours, and then roasted at 600°C for 6 hours to obtain the initial product; The initial product was stirred in a 1mol / L ammonium nitrate solution for 8 hours, filtered, washed, and this step was repeated 5 times, dried at 110°C for 10 hours, and then calcined at 500°C for 2 hours to obtain a hydrogen-type ZSM-5 molecular sieve; Hydrogen type ZSM-5 molecular sieve was mixed with molybdenum precursor solution, the type of molybdenum was ammonium molybdate, accounting for 1% mass ratio of molecular sieve, placed at room temperature for 12h, and then calcined at 500°C for 2h to obtain ZSM-5 catalyst.

[0074] Where...

Embodiment 2

[0078] 12.0g ethyl orthosilicate, 4.1g [C 22 h 45 –N + (CH 3 ) 2 –C 4 h 8 –N + (CH 3 ) 2 –C 6 h 13 ]Br 2 , 4g of CTAB, a certain amount of aluminum sulfate, and 0.7g of NaOH were mixed and stirred to form a precursor aqueous solution, which was left to stand for 24 hours. After the solid-liquid separation of the reaction material, it was dried at 110°C for 10 hours, and then roasted at 600°C for 6 hours to obtain the initial product; The initial product was stirred in a 1mol / L ammonium nitrate solution for 8 hours, filtered and washed, and this step was repeated 5 times, dried at 110°C for 10 hours, and then roasted at 500°C for 2 hours to obtain a hydrogen-type ZSM-5 molecular sieve; the obtained hydrogen Type ZSM-5 molecular sieve was mixed with molybdenum precursor solution, the type of molybdenum was ammonium molybdate, accounting for 1% mass ratio of molecular sieve, placed at room temperature for 12h, and then calcined at 500°C for 2h to obtain ZSM-5 catalyst....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com