A method for promoting the conversion of butane to aromatics

A technology for butane and aromatics, applied in the field of promoting the conversion of butane to aromatics, can solve the problems of low utilization rate of butane, great difference in the development and utilization of production technology products, etc., and achieve the effect of improving the conversion rate of butane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 metal supported catalyst preparation

[0044] The HZSM-5, HZSM-11, and HZSM-22 (Si / Al=20-100) molecular sieve catalysts used in the experiment were purchased from Nankai University Catalyst Factory.

[0045] Weigh 100.00 g (dry basis) of the molecular sieve carrier, add a certain concentration of metal salt solution, and then add a certain amount of 25-28% ammonia water, and stir until it becomes a paste. Dry at 120°C for 6 hours, then increase the temperature at a rate of 5°C / min to 550°C and bake for 5 hours, cool to room temperature and grind to powder, bake at 350°C for 2 hours, after cooling, go through tableting, grinding, Sieve, and keep catalyst particles of 60 mesh to 80 mesh for future use.

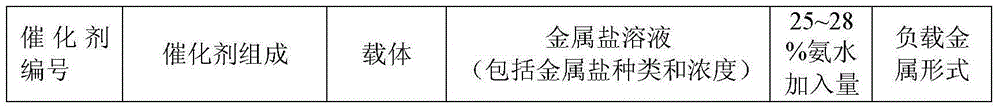

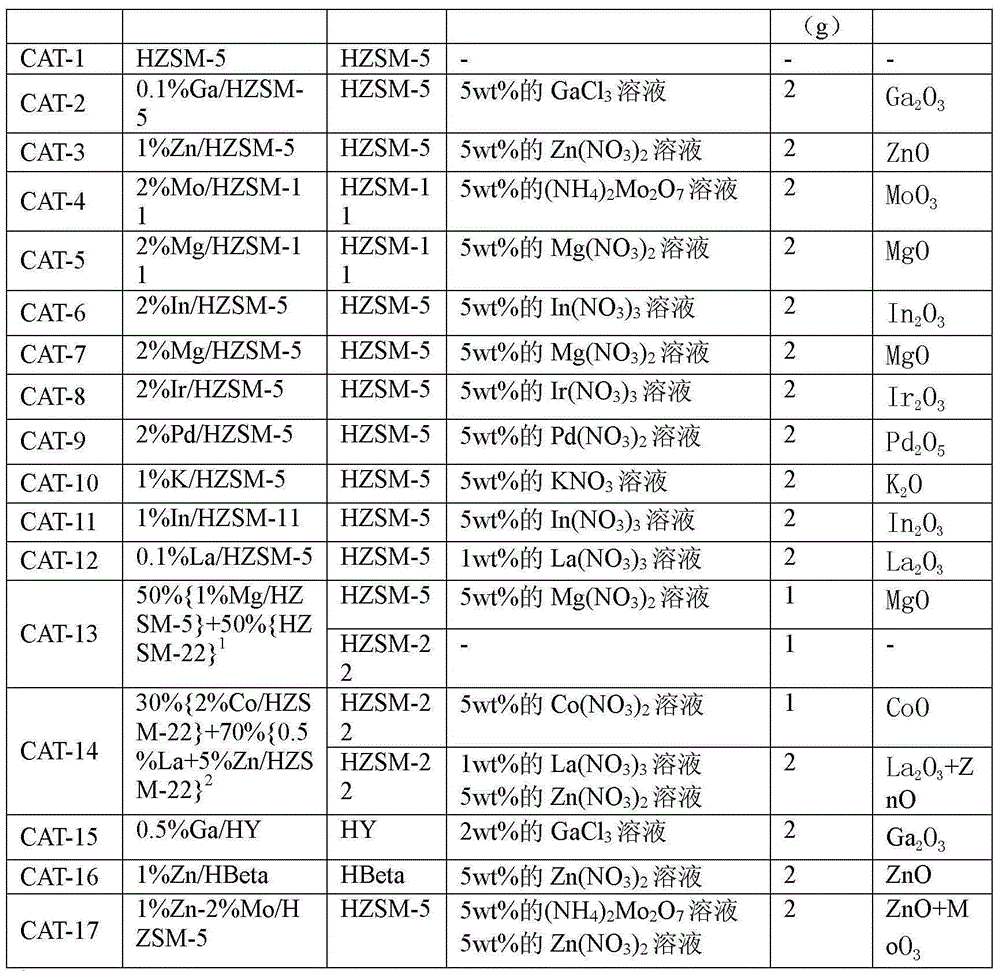

[0046] Table 1 shows the relationship between the number of the obtained catalyst sample and the molecular sieve carrier used, the metal salt solution, the amount of 25-28% ammonia water added, and the mass percentage of the metal supported on the catalyst. ...

Embodiment 2

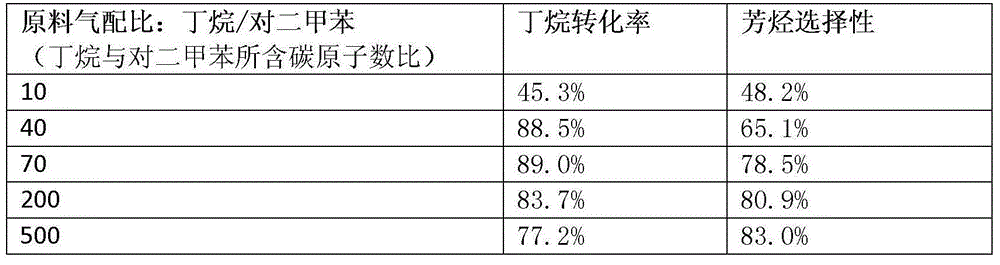

[0057] Methanol as a promoter mixed with butane on various catalysts for pulse reaction experiments

[0058] Load 32mg of catalyst into a quartz tube with an inner diameter of 3mm, heat to 550°C in the flow of activated gas (nitrogen, hydrogen, methane or a mixture of any of several) and maintain it for 30 minutes in this state, Complete the catalyst activation process. Then the raw material gas of 1ml under normal pressure is passed through catalyzer, and the contact time of raw material gas and catalyzer is 1s, and raw material gas proportioning is: butane / methanol=70 (the carbon number ratio that butane and promotor contain), its concrete The composition is: butane 52.5%, methanol (steam) 3%, helium 44.5%, and the above percentages are mole percentages. The product after reaction enters chromatographic analysis, and its analysis condition is as comparative example 1, and result is as shown in table 2 (aromatic hydrocarbon product comprises benzene, toluene, ethylbenzene, s...

Embodiment 3

[0062] Impulse reaction experiment of various accelerators mixed with butane on CAT-1

[0063] 32 mg of CAT-1 catalyst was loaded into a quartz tube with an inner diameter of 3 mm, heated to 550° C. in an activation gas (nitrogen) flow and kept there for 30 minutes to complete the catalyst activation process. Then the feed gas of 1ml under normal pressure is passed through catalyzer, and the contact time of feed gas and catalyzer is 1s, and feed gas proportioning is: butane / promotor=70 (butane and promotor contain carbon number ratio), above-mentioned The percentages are all mole percentages. The reacted product enters the chromatogram for analysis, and the analysis conditions are as in Comparative Example 1, and the results are shown in Table 3.

[0064] Table 3: Pulse reaction experiment of various accelerators mixed with butane on CAT-1

[0065] Accelerator

[0066] Iodomethane

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com