A kind of multistage nano-reactor catalyst for directly preparing aromatic compounds from syngas and its preparation and application

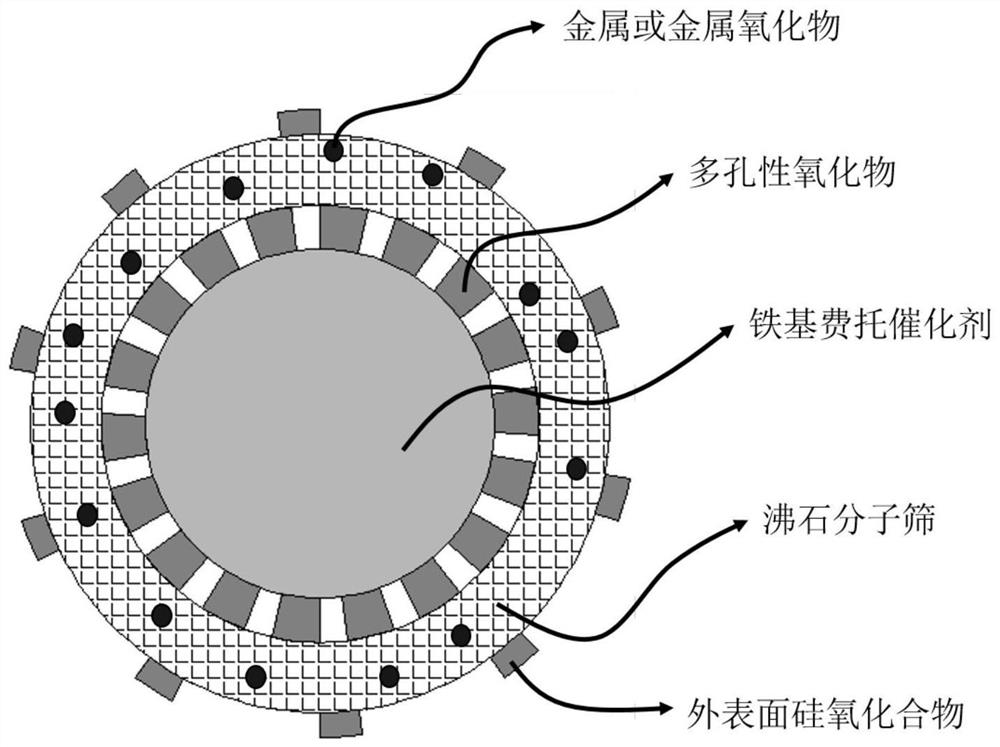

An aromatic compound, nano-reactor technology, applied in the direction of carbon compound catalyst, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the escape of intermediate products, uneven distribution, and final aromatics selection. To solve the problems of low methane selectivity and low yield, it can achieve the effect of low methane selectivity and high aromatics selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

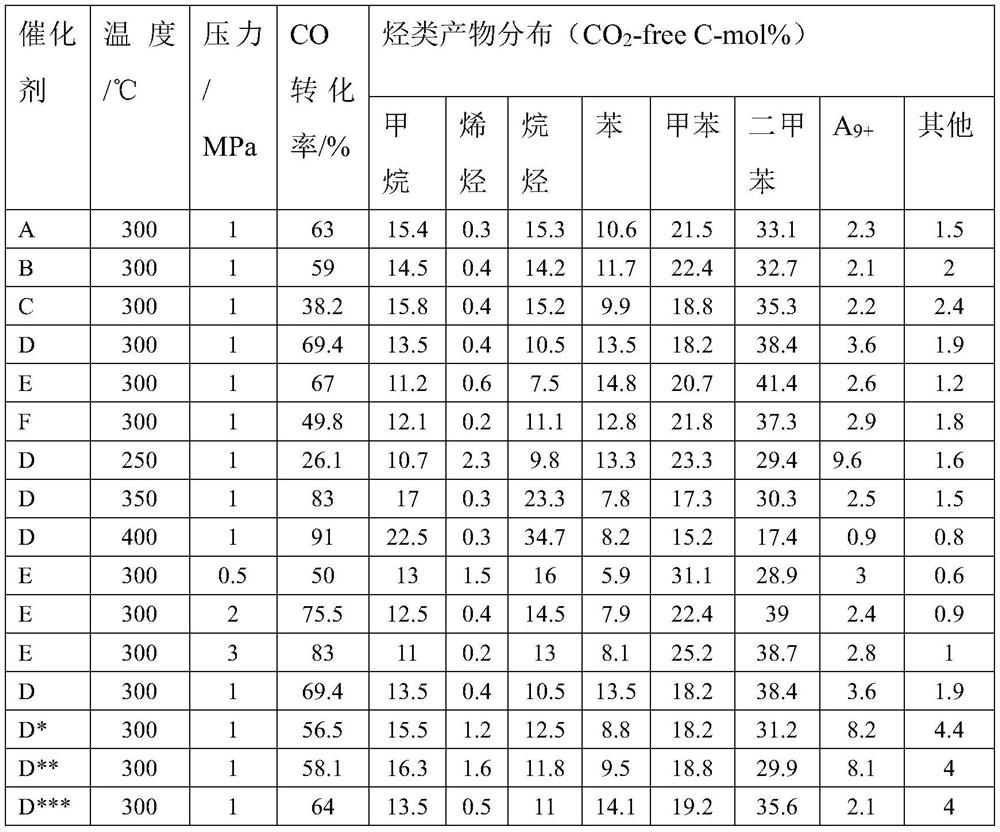

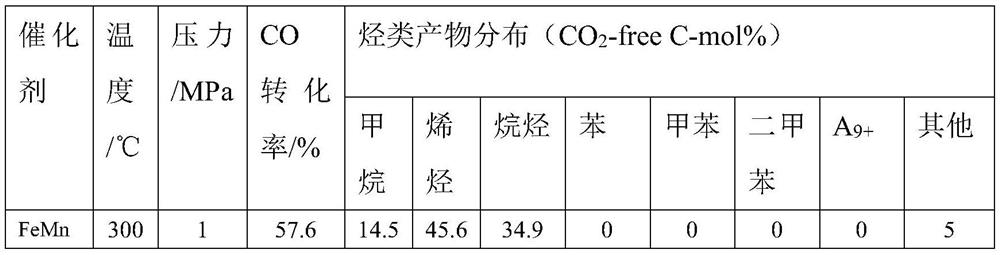

Embodiment 1

[0025] Dissolve a certain amount of ferric nitrate and manganese nitrate in deionized water, use ammonia water as a precipitant to precipitate at pH=8.0, age, filter, wash and dry at 120°C for 12 hours, and finally bake at 500°C for 5 hours A precipitated FeMn catalyst with an atomic ratio of iron to manganese of 96 to 4 was obtained. The prepared catalyst is impregnated in a certain amount of tetraethyl orthosilicate solution, and stirred continuously, and then the solvent is removed by rotary evaporation and dried and roasted to obtain SiO 2 Coated samples. Then impregnate the sample in a template containing tetrapropylammonium hydroxide, tetraethyl orthosilicate, Al 2 o 3 , NaOH, H 2 In the solution of O, among which tetrapropyl ammonium hydroxide, tetraethyl orthosilicate, Al 2 o 3 , NaOH, H 2 The ratio of O is 0.3:1.0:0.03:0.015:130, stirred for 4 hours, then put into a hydrothermal kettle, sealed, heated to 180°C, and hydrothermally crystallized for 48 hours. Afte...

Embodiment 2

[0027] Get the precipitation type FeMn catalyst that makes in the last example, place in a certain amount of aluminum isopropoxide trihydrate and keep stirring, then rotary evaporation removes solvent and dry roasting, obtain the 2 o 3 Coated samples. Then place the sample in a template containing tetrapropylammonium hydroxide template, tetraethyl orthosilicate, Al2 o 3 , NaOH, H 2 In the solution of O, among which tetrapropyl ammonium hydroxide, tetraethyl orthosilicate, Al 2 o 3 , NaOH, H 2 The ratio of O is 0.3:1.0:0.03:0.015:130, stirred for 4 hours, then put into a hydrothermal kettle, sealed, heated to 180°C, and hydrothermally crystallized for 48 hours. After the crystallization was completed and cooled, the solid product was filtered, washed until the pH of the washing solution was 8, then dried at 120°C for 12 hours, and then calcined at 500°C for 5 hours to obtain a core layer with a weight fraction of 64% and a transition layer with a weight fraction of 8%. Ca...

Embodiment 3

[0029] Preparation of 20wt%Fe1wt%K / SiO by Equal Volume Impregnation Method 2 Supported iron-based catalysts. Finally, the sample is placed in a certain amount of aluminum isopropoxide trihydrate and stirred continuously, and then the solvent is removed by rotary evaporation and dried and roasted to obtain a 2 o 3 Coated samples. Then place the sample in a template containing tetrapropylammonium hydroxide template, tetraethyl orthosilicate, Al 2 o 3 , NaOH, H 2 In the solution of O, among which tetrapropyl ammonium hydroxide, tetraethyl orthosilicate, Al 2 o 3 , NaOH, H 2 The ratio of O is 0.3:1.0:0.05:0.010:130, stirred for 4 hours, then put into a hydrothermal kettle, sealed, heated to 180°C, and hydrothermally crystallized for 48 hours. After the crystallization was completed and cooled, the solid product was filtered, washed until the pH of the washing solution was 8, then dried at 120°C for 12 hours, and then calcined at 500°C for 5 hours to obtain a core layer wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com