Integrated energy-saving SCR denitration device

A denitration and thermal fluid technology, applied in chemical instruments and methods, dispersed particle separation, lighting and heating equipment, etc., can solve the problems of high reaction temperature, energy waste, high temperature flue gas evacuation, etc., to reduce dust content, reduce Operating cost, effect of reducing operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

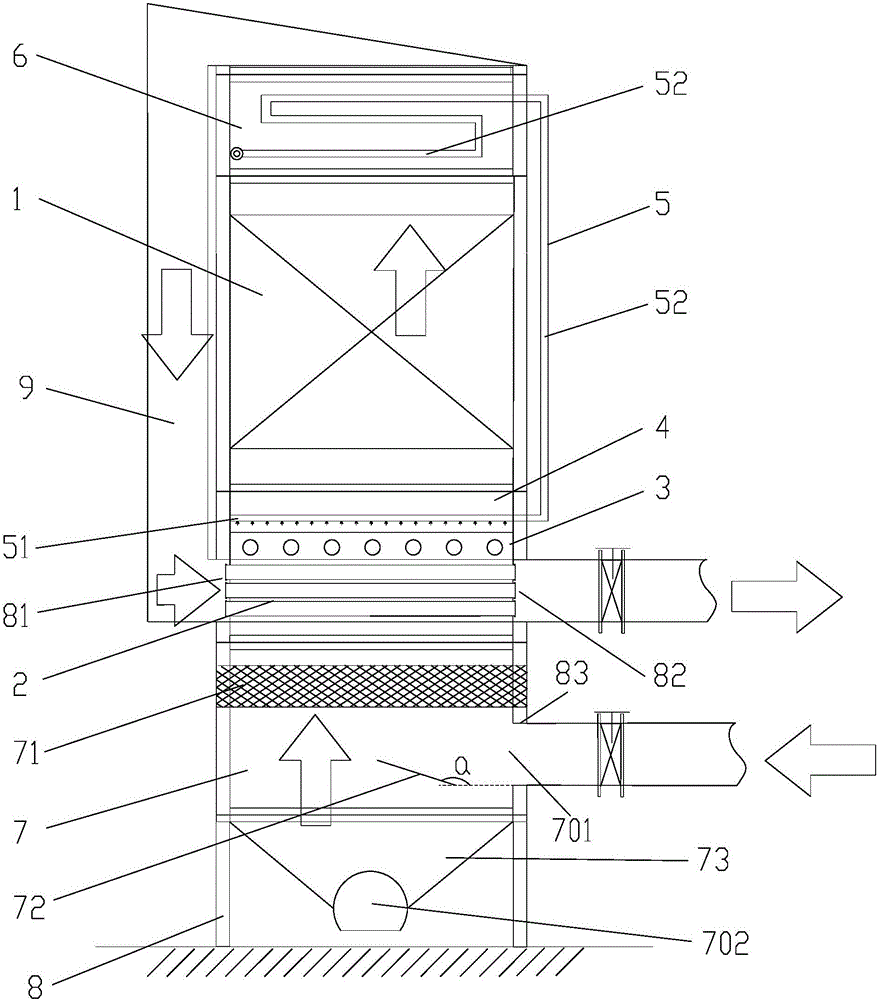

[0028] An integrated energy-saving SCR denitrification device, including an SCR denitrification reaction chamber 1 and a heat exchange chamber 2; port connection; the thermal fluid inlet of the heat exchange chamber 2 is connected to the smoke outlet of the SCR denitration reaction chamber 1, and the thermal fluid outlet is a smoke exhaust port. That is, the pre-reaction flue gas entering the SCR denitrification reaction chamber 1 is used as a cold fluid, and the post-reaction flue gas flowing out of the SCR denitrification reaction chamber 1 is used as a hot fluid, which respectively flows through the heat exchange chamber 2 to utilize the post-reaction flue gas. The residual heat of the flue gas increases the reaction temperature of the pre-reaction flue gas, and the pre-reaction flue gas passing through the heat exchange chamber 2 flows into the SCR denitration reaction chamber to realize the utilization of waste heat and improve resource utilization.

[0029] The heat exch...

Embodiment 2

[0031] The temperature of the pre-reaction flue gas after passing through the heat exchange chamber sometimes does not reach the reaction temperature required by the SCR denitration reaction chamber 1. Therefore, before the pre-reaction flue gas enters the SCR denitration reaction chamber 1, the flue gas temperature needs to be adjusted. .

[0032] Therefore, in the preferred technical solution of Embodiment 2 of the present invention, it also includes a flue gas temperature adjustment chamber 3 and a flue gas temperature control system (not shown in the figure), and a heater (not shown in the figure) is installed in the flue gas temperature adjustment chamber 3 ); the smoke inlet of the flue gas temperature adjustment chamber 3 is connected to the cold fluid outlet of the heat exchange chamber 2, and the smoke outlet is connected to the smoke inlet of the SCR denitration reaction chamber 1.

[0033]The flue gas temperature control system includes a controller and a temperatur...

Embodiment 3

[0036] In the existing SCR denitrification technology, it is necessary to use an appropriate reducing agent (eg, ammonia, urea, etc.) as a reducing agent for catalytic reactions under certain conditions to convert nitrogen oxides into harmless nitrogen and water vapor. Therefore, before the pre-reaction flue gas enters the SCR denitrification reaction chamber 1, it is necessary to add an appropriate amount of reducing agent to the pre-reaction flue gas to promote the catalytic reaction and effectively decompose the harmful substances in the flue gas.

[0037] The preferred technical solution of this embodiment 3 is to further include a gas mixing chamber 4 and a reducing agent supply unit 5; before flowing into the SCR denitration reaction chamber 1, the pre-reaction gas is connected to the gas mixing chamber 4, The flue gas before the reaction after mixing the reducing agent flows into the SCR denitration reaction chamber 1; the gas injection port 51 of the reducing agent supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com