Catalyst composition for reducing normal-to-isomer ratio of hydroformylation products of olefin

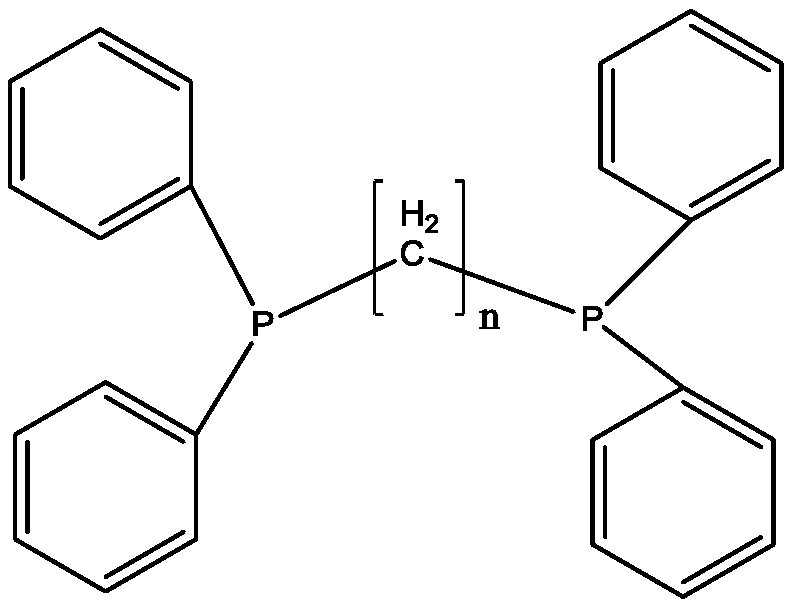

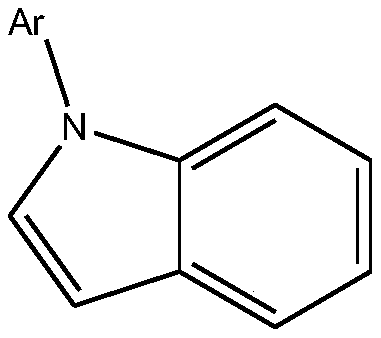

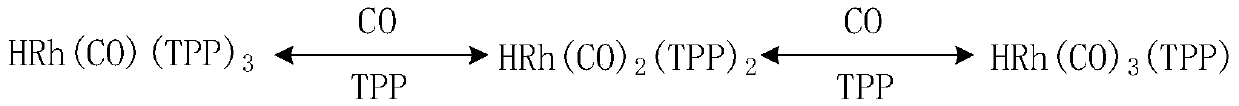

A catalyst and composition technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, catalytic reaction, etc., can solve the lack of catalyst stability and reaction activity, shortening catalyst life, key influence Factors are not clear and other problems, to achieve the effect of improving catalytic conversion rate and conversion rate, strong catalytic activity and stability, and strong π electron accepting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] With nitrogen, the catalyst preparation tank is replaced to an oxygen content lower than 0.1%, and in the preparation tank, 592.5 g of mixed butyraldehyde (normal isotropic ratio 5: 1) is added successively, rhodium Parker 0.63 g, co-catalyst triphenylphosphine 112.5 g, co-catalyst Add 37.5g of agent A (A1), 7.5g of auxiliary agent B, heat to 50°C, and stir for 120min.

[0054] Test rhodium content 168ppm, co-catalyst 15%, co-agent A (A1) 5%, co-agent B 1%.

[0055] Utilize propylene hydroformylation reaction to evaluate the catalytic system of the present embodiment:

[0056] The reaction was carried out in a tank reactor with a stirring paddle (the volume of the stirred tank was 0.5 L, and the stirring rate was 200 r / min), and 50 g of the prepared catalyst composition was added into the reactor in advance. Propylene (polymerization grade) and synthesis gas (the molar ratio of hydrogen to carbon monoxide is 1.05:1) are fed continuously from the bottom of the reactor i...

Embodiment 2

[0058] Use nitrogen to replace the catalyst preparation tank until the oxygen content is lower than 0.1%, add 652.5 g of mixed butyraldehyde (normal to isotropic ratio 5:1), 0.75 g of rhodium parka, 90 g of cocatalyst triphenylphosphine, and auxiliary agent A (A2) 3.75g, additive B 3.75g, heated to 50°C, and stirred for 120min.

[0059] Test rhodium content 200ppm, cocatalyst 12%, auxiliary agent A (A2) 0.5%, auxiliary agent B 0.5%.

[0060] Utilize propylene hydroformylation reaction to evaluate the catalytic system of the present embodiment:

[0061] The reaction was carried out in a tank reactor with a stirring paddle (the volume of the stirred tank was 0.5 L, and the stirring rate was 200 r / min), and 50 g of the prepared catalyst composition was added into the reactor in advance. Propylene (polymerization grade) and synthesis gas (the molar ratio of hydrogen to carbon monoxide is 1.05:1) are fed continuously from the bottom of the reactor in the gas phase, the reaction te...

Embodiment 3

[0063] Use nitrogen to replace the catalyst preparation tank until the oxygen content is lower than 0.1%, add 600 g of mixed butyraldehyde (normal to isotropic ratio 5:1), 0.91 g of rhodium parka, 75.12 g of cocatalyst triphenylphosphine, and additives in the preparation tank. A (A3) 60g, additive B 15g, heated to 50°C, stirred for 120min.

[0064] Test rhodium content 242ppm, co-catalyst 10%, co-agent A (A3) 8%, co-agent B 2%.

[0065] Utilize propylene hydroformylation reaction to evaluate the catalytic system of the present embodiment:

[0066] The reaction was carried out in a tank reactor with a stirring paddle (the volume of the stirred tank was 0.5 L, and the stirring rate was 200 r / min), and 50 g of the prepared catalyst composition was added into the reactor in advance. Propylene (polymerization grade) and synthesis gas (the molar ratio of hydrogen to carbon monoxide is 1.05:1) are fed continuously from the bottom of the reactor in the gas phase, the reaction tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com