Method for producing ethyl benzene by catalysis, distillation and alkylation

A technology of catalytic distillation and catalytic distillation column is applied in the field of catalytic distillation to produce ethylbenzene, and can solve the problems such as difficult to reach, low reaction speed, lowering of ethylene partial pressure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

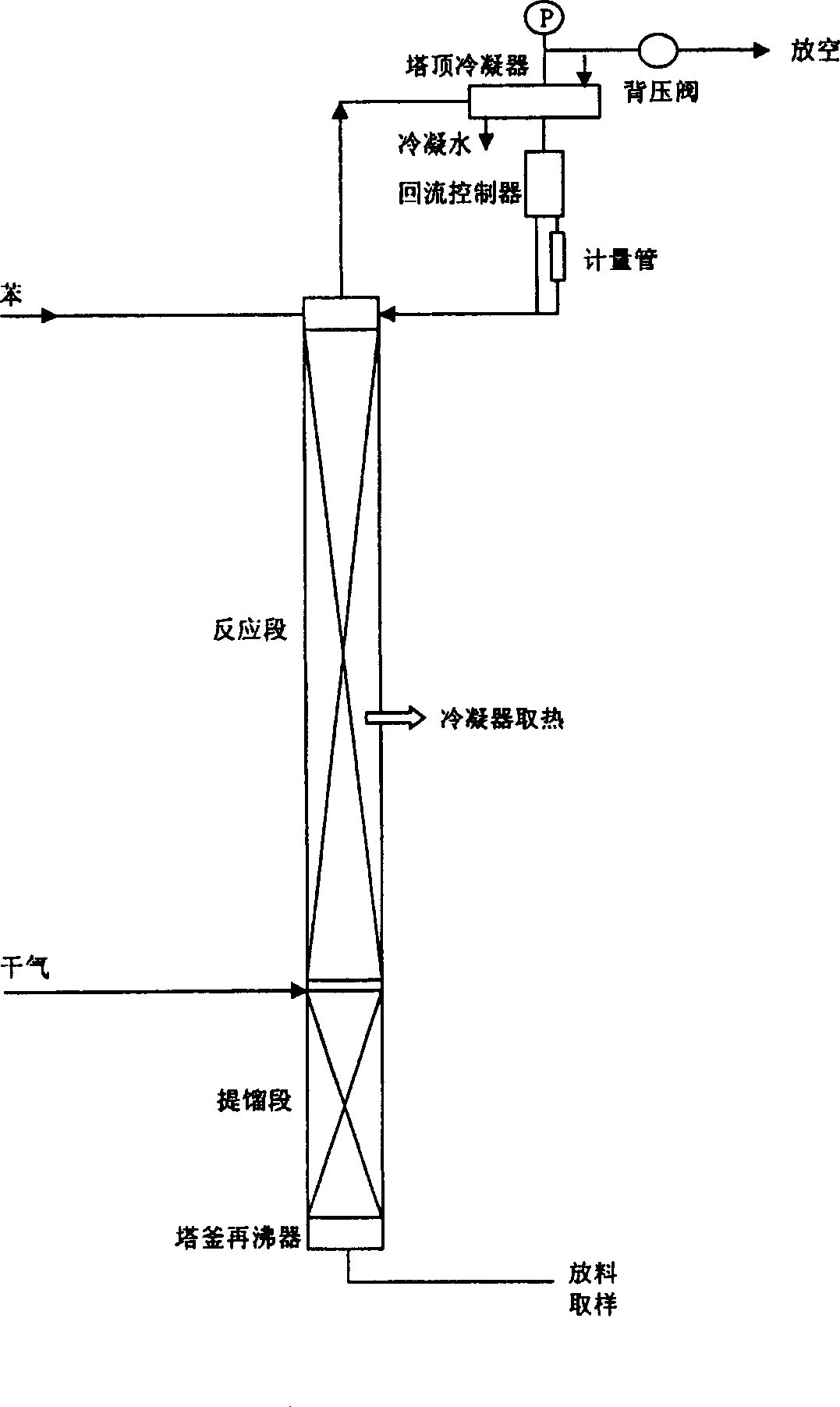

[0018] Embodiment 1 Catalytic distillation reaction process

[0019] The schematic diagram of the catalytic distillation column is shown in the attached figure 1 . The total height of the catalytic distillation column is 3.5m, including the overhead condenser, reaction section, stripping section and column bottom reboiler, without rectification section. The inner diameter of the reaction section and the stripping section is 25 mm, and the effective height of the reaction section is 1.5 meters. The catalyst strips (volume fraction 20%) of Φ1.6×4~6mm are mixed and filled with Φ4×4mm stainless steel rolling orifice rings; the stripping section is effective The height is 0.5 meters, and it is filled with Φ4×4mm stainless steel rolling ring. The total reflux operation is adopted. The condensate at the top of the column is measured by the reflux controller equipped with a metering tube and then all refluxed into the column. The reaction tail gas is measured and vented from the top...

Embodiment 2

[0021] Embodiment 2 adopts beta zeolite as catalyst

[0022] 100 grams of zeolite beta powder (SiO 2 / Al 2 O 3 For 27,600 ℃ roasting 3 hours weight loss 17%) and 47 grams of SB powder (a kind of pseudo-boehmite imported from Germany, 600 ℃ roasting 3 hours weight loss 25%), appropriate amount of succulent powder, add appropriate amount of nitric acid and Deionized water, extruded into strips, made into strips with a diameter of 1.6 mm, dried at 120 °C overnight, calcined in a muffle furnace at 540 °C for 3 hours, and then used 0.8M NH 4 NO 3 The aqueous solution was exchanged 3 times at 90°C, washed 3 times with deionized water, dried at 120°C for 4 hours, calcined at 530°C for 2 hours, and finally treated with water vapor at 350°C for 2 hours, and broken into catalysts with a length of 4-6 mm.

[0023] After 100 grams of the above catalyst was activated in high-purity nitrogen flow at 550°C for 1 hour, under the protection of high-purity nitrogen, it was mixed with 603 ml...

Embodiment 3

[0024] Embodiment 3 adopts Y zeolite as catalyst

[0025] 100 grams of HY zeolite raw powder (SiO 2 / Al 2 O 3For 10, 600 ℃ roasting 3 hours weight loss 19%) and 24 grams of SB powder (a kind of pseudo-boehmite imported from Germany, 600 ℃ roasting 3 hours weight loss 25%), an appropriate amount of saffron powder, add appropriate amount of nitric acid and Deionized water, extruded on an extruder to form a strip catalyst with a diameter of 1.6 mm, dried at 120 °C overnight, calcined in a muffle furnace at 500 °C for 2 hours, treated with water vapor at 400 °C for 2 hours, and broken into 4 pieces. ~6 mm long catalyst.

[0026] After 70 grams of the above-mentioned catalysts were activated at 550° C. for 1 hour in a high-purity nitrogen stream, mixed with 610 ml of stainless steel rolling pore rings of Φ4×4 mm under the protection of high-purity nitrogen, and then loaded into the reaction section of the catalytic distillation column according to Example 1. The same catalytic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com