Method for producing propylene by using cracking olefin of carbon four and higher

An olefin and propylene technology, which is applied in the field of adiabatic multi-stage composite fixed-bed reactor for propylene production, can solve the problems of low propylene selectivity, short catalyst regeneration period and low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

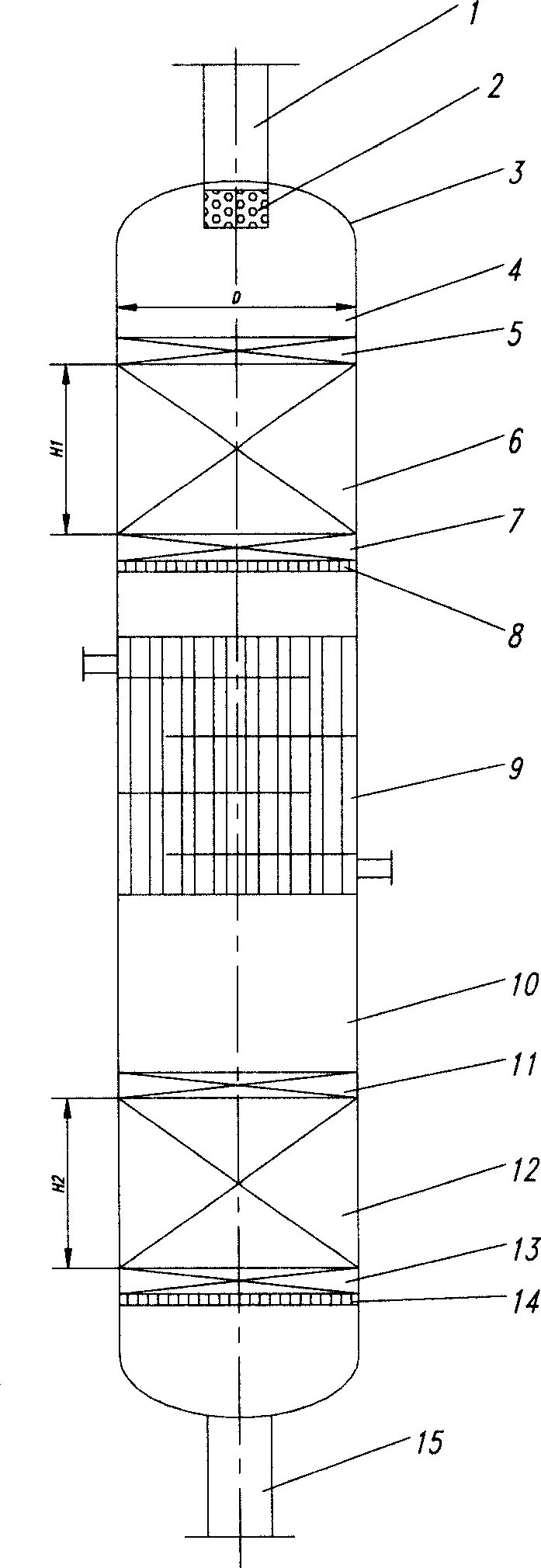

[0016] 100,000 tons / year C4 and above olefin cracking method to prepare propylene adopts such as figure 1 Shown is a two-stage composite fixed-bed reactor. Reactor diameter D = 1700 mm, tangent height 7400 mm, first stage catalyst bed height H 1 =980 mm, height H of catalyst bed in the second stage 2 =700 mm, the first stage reaction temperature is 470°C, and the space velocity is 8.6 hours -1 , the second reaction temperature is 550°C, and the space velocity is 12 hours -1 , total airspeed 5 hours -1 , using the silicon-aluminum molar ratio (SiO 2 / Al 2 o 3 ) is the ZSM-5 type molecular sieve catalyst of 200, and the reaction raw material is etherified carbon four in ethylene factory, and the yield of main purpose product propylene and the change of conversion rate are shown in Table 1, and conversion rate drops to 57.03% from 71.69% after 250 hours %, but the selectivity of propylene is improved, and the yield of propylene is stable at 21.0-23.0%, basically unchanged....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com