A method and device for maximizing the preparation of phenol-containing oil and diesel oil from coal tar

A technology for coal tar and diesel oil, which is applied in heating/cooling refining, tar processing by distillation, petroleum industry, etc., can solve the problems of inability to handle pulverized coal tar, low yield of phenolic oil, etc., so as to improve comprehensive utilization rate, yield realization, and the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

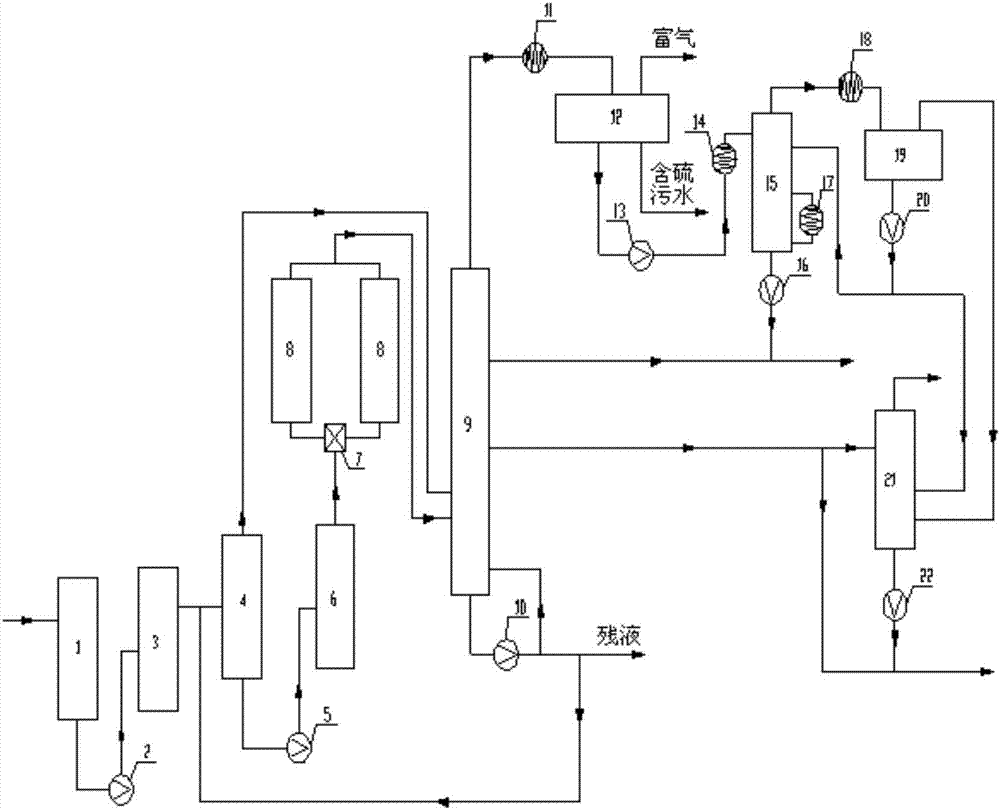

Method used

Image

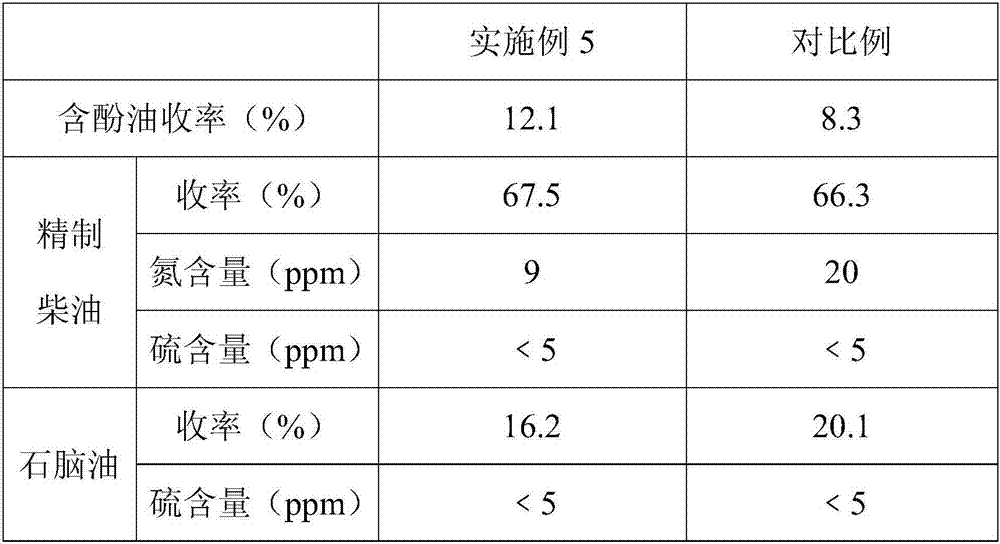

Examples

Embodiment 1

[0054] The method of utilizing coal tar to maximize the preparation of phenol-containing oil and diesel oil described in this embodiment includes:

[0055] (1) The medium-temperature coal tar is sent into the flash tower 4, and the coal tar is flashed under the conditions of 0.22MPa and 290° C., and the flash steam is collected at the top of the tower, and the liquid in the tower is the flash oil;

[0056] (2) The flash oil enters the coke tower 8, and carries out delayed coking under the conditions of 480°C, 0.2MPa, and a circulation ratio of 0.3, where cracking and condensation reactions occur to generate oil gas and pitch coke, and the pitch coke is decoked by hydraulic force Exit the coke tower;

[0057] (3) The flash gas of step (1) and the oil and gas of step (2) all enter the fractionation tower 9 and carry out fractionation treatment under the condition that the tower top pressure is 0.16MPa and the tower top temperature is 130°C, and the fractionation tower is from to...

Embodiment 2

[0061] The method of utilizing coal tar to maximize the preparation of phenol-containing oil and diesel oil described in this embodiment includes:

[0062] (1) Transport the pulverized coal tar to the preheating furnace 3 for preheating to 300° C. and then mix and exchange heat with part of the tail oil from the fractionation tower 9 to form a mixed oil, and then send the mixed oil to the flash tower 4. Under the conditions of MPa and 320°C, the mixed oil is flashed, and the flash steam is collected at the top of the tower, and the liquid in the tower is the flash oil;

[0063] Wherein the dust content in the pulverized coal-containing tar is 10wt%, the dust is coke powder and / or coal powder, and the particle size of the dust is less than 100 μm.

[0064] (2) The flash oil enters the coke tower 8 after being heated to 480°C by the heating furnace 6, and carries out delayed coking under the conditions of 480°C, 0.1MPa, and a circulation ratio of 0.55, and cracks and condenses t...

Embodiment 3

[0070] The method of utilizing coal tar to maximize the preparation of phenol-containing oil and diesel oil described in this embodiment includes:

[0071] (1) Transport the pulverized coal tar through the buffer tank 1 to the preheating furnace 3 for preheating to 320°C, then mix and exchange heat with part of the tail oil from the fractionating tower 9 to form a mixed oil, and then send the mixed oil to the flash tower 4. Under the conditions of 0.32MPa and 335°C, the mixed oil is flashed, and the flash steam is collected at the top of the tower, and the liquid in the tower is the flash oil;

[0072] Wherein the dust content in the tar containing pulverized coal is 5.5wt%, the dust is coke powder and / or coal powder, and the particle size of the dust is less than 100 μm.

[0073] (2) The flash oil enters the coke tower 8 after being heated up to 420°C by the heating furnace 6, and carries out delayed coking under the conditions of 420°C, 0.3MPa, and a circulation ratio of 0.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com