A Production Batch Scheduling Control Method for Improving Operational Efficiency of Large Ethylene Cracking Furnace

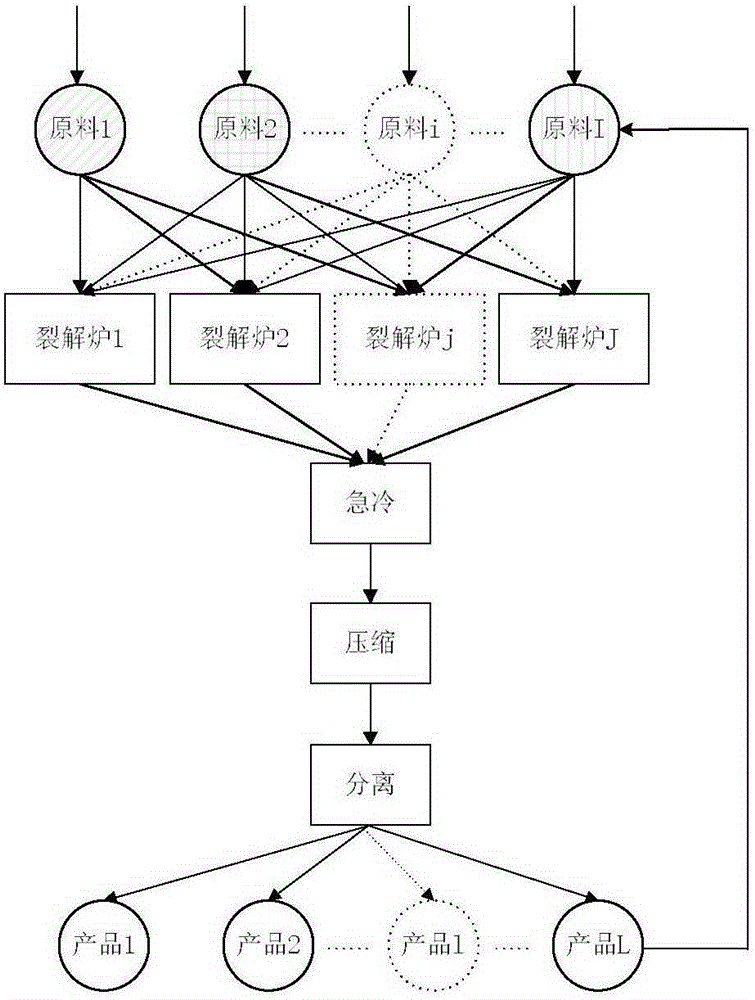

An ethylene cracking furnace and ethylene cracking technology, applied in the chemical process industry, can solve the problem of low energy consumption in cracking operations, and achieve the effects of optimizing the utilization of coke cleaning resources, controlling energy consumption indicators, and stabilizing material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

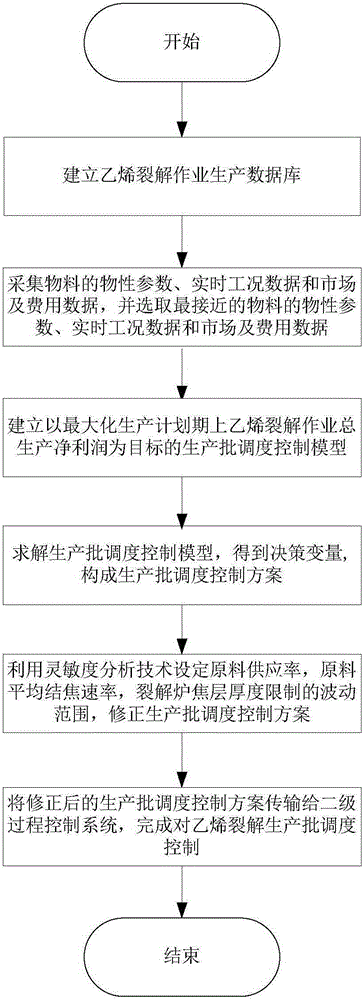

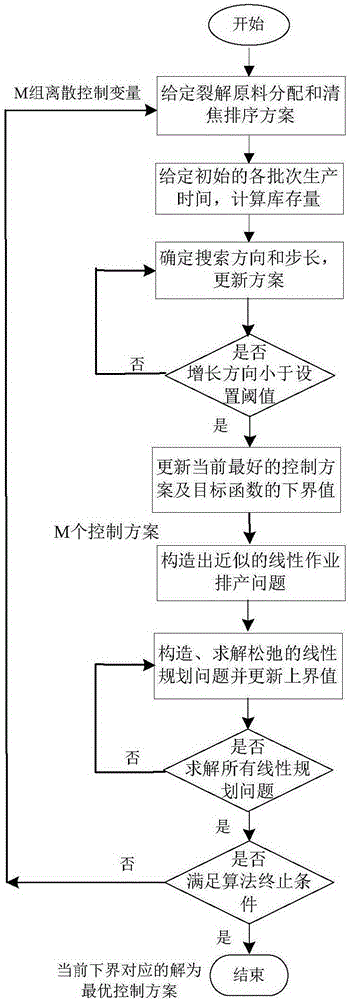

[0055] A production batch scheduling control method for improving the operating efficiency of large-scale ethylene cracking furnaces, such as figure 2 shown, including the following steps:

[0056] Step 1: Establish a production database for ethylene cracking operations. The data in the database include physical parameters, working condition data and coke cleaning equipment parameters of materials in ethylene cracking production;

[0057] The physical parameters of materials include coking rate data and the average yield of ethylene cracking products;

[0058] Working condition data include: the flow rate of raw materials in the cracking furnace, the product yield of each cracking furnace, the average coking rate of each cracking furnace, the upper and lower limits of the continuous cracking cycle of different cracking furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com