Graphene preparation method

A graphene and graphite technology, applied in the field of reducing graphene oxide aqueous solution to prepare graphene, can solve the problems of easy agglomeration of graphene, high toxicity of reducing agent, incomplete reduction, etc., and achieve sufficient reduction, less impurities and defects, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

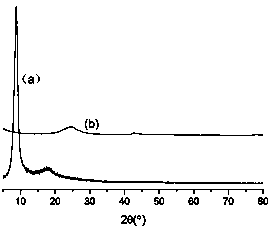

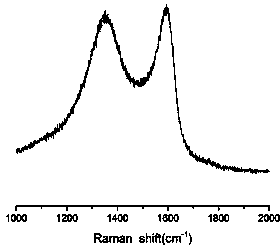

Method used

Image

Examples

Embodiment 1

[0027] (1) Under the conditions of a stirring rate of 200r / min and an ice-water bath, add 3g of graphite and 1.8g of sodium nitrate to 120mL of sulfuric acid with a mass concentration of 98%, continue stirring for 30min, and use a water bath to heat the mixture to a low temperature. At 10°C, add 18g of potassium permanganate and continue to stir for 2h; heat the water bath to 40°C and react for 3h; then add 120mL of deionized water, continue to stir for 30min, then add 300mL of warm water at 35°C and 72mL of mass concentration 30% hydrogen peroxide, continue stirring for 20 min; ultrasonically disperse the above solution for 30 min, then filter, then wash 5 times with 10% hydrochloric acid and deionized water, and dry the filtered product at 70°C to obtain 4.9 g of graphite.

[0028] (2) Weigh 500 mg of graphite oxide and dissolve it in 500 mL of deionized water, and apply ultrasonic waves for 2 hours to obtain a graphene oxide aqueous solution with a concentration of 1.0 mg / m...

Embodiment 2

[0034] (1) Under the conditions of a stirring rate of 150r / min and an ice-water bath, add 2g of graphite and 1g of sodium nitrate to 70mL of sulfuric acid with a mass concentration of 98%, continue stirring for 20min, and heat the mixture to no higher than At 10°C, add 10g of potassium permanganate and continue stirring for 1.5h; heat the water bath to 35°C and react for 2h; then add 50mL of deionized water, continue stirring for 20min, add 160mL of warm water at 33°C and 35mL with a mass concentration of 25% hydrogen peroxide, continue to stir for 15 minutes; ultrasonically disperse the above solution for 20 minutes and then filter, then wash with 8% hydrochloric acid and deionized water for 5 times, and dry the filtered product at 60°C to obtain 3.3g of graphite oxide .

[0035] (2) Weigh 300 mg of graphite oxide and dissolve it in 600 mL of deionized water, and apply ultrasonic waves for 1.5 h to obtain a graphene oxide aqueous solution with a concentration of 0.5 mg / mL.

...

Embodiment 3

[0041] (1) Under the conditions of a stirring rate of 100r / min and an ice-water bath, add 1g of graphite and 0.4g of sodium nitrate to 30mL of sulfuric acid with a mass concentration of 98%, continue stirring for 15min, and use a water bath to heat up the mixture to a low temperature. At 10°C, add 4g of potassium permanganate and continue to stir for 1h; heat the water bath to 30°C and react for 1h; then add 15mL of deionized water, continue to stir for 15min, add 60mL of warm water at 30°C and 12mL with a mass concentration of 20% hydrogen peroxide, continue to stir for 10 minutes; ultrasonically disperse the above solution for 15 minutes and then filter, then wash with 5% hydrochloric acid and deionized water for 3 times, and dry the filtered product at 50°C to obtain 1.7g of graphite oxide .

[0042] (2) Weigh 100 mg of graphite oxide and dissolve it in 1 L of deionized water, and apply ultrasonic waves for 1 hour to obtain a graphene oxide aqueous solution with a concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com