Composite mineralizing agent suitable for white sulphoaluminate cement clinker calcination and preparation method thereof

A technology for calcining sulfoaluminate cement and clinker, which is applied in the direction of cement production, etc., can solve the problems of white sulfoaluminate cement affecting the whiteness, great influence on the whiteness of cement, and inability to improve performance, and can reduce the calcination temperature , the reaction rate is accelerated, and the effect of improving the performance of clinker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

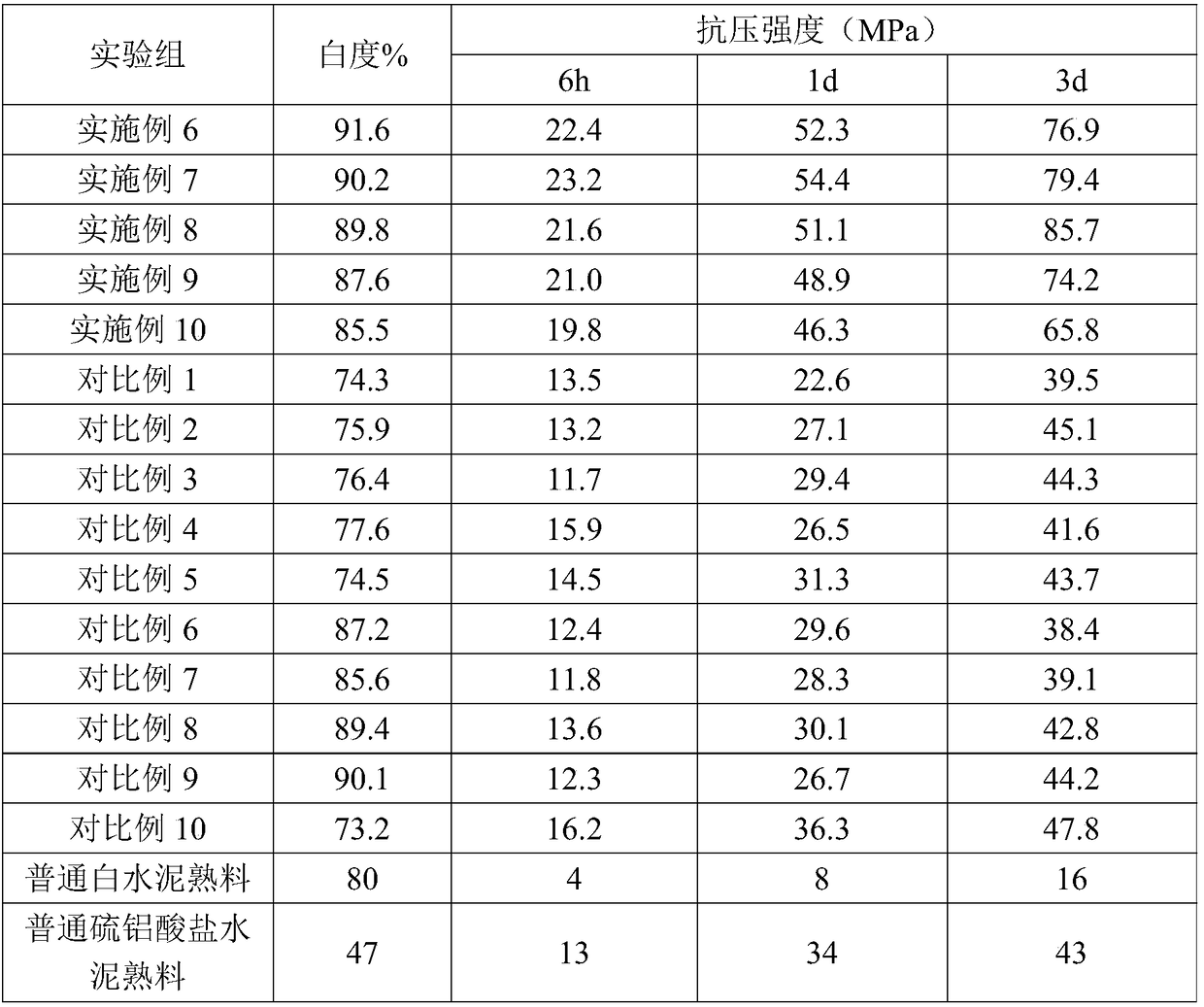

Examples

Embodiment 1

[0057] A preparation method for a composite mineralizer suitable for white sulphoaluminate cement, comprising the steps of:

[0058] (1) Choose fluorite, low-iron strontium slag, smithsonite, aluminum slag, and white slag as the raw materials for the compound mineralizer, and press CaF 2 0.4 part, 0.4 part of SrO, 0.35 part of ZnO, the proportioning of 0.35 part of MgO prepares composite mineralizer raw material, parts by weight;

[0059] (2) According to the formula of the compound mineralizer, each raw material in the step (1) is mixed evenly according to the proportion, and then dried until the moisture content is lower than 1%;

[0060] (2) Add the raw materials dried in step (2) into a KEQ-4L planetary ball mill, grind and mix evenly, pass through a 200-mesh sieve, and stop grinding when the sieve residue is less than 5 wt%, to obtain a composite mineralizer.

Embodiment 2

[0062] A preparation method of a composite mineralizer suitable for white sulphoaluminate cement, the same as in Example 1, the difference is that the ratio of the composite mineralizer is: CaF 2 0.65 parts, 0.1 parts of SrO, 0.1 parts of ZnO, 0.65 parts of MgO, parts by weight.

Embodiment 3

[0064] A preparation method of a composite mineralizer suitable for white sulphoaluminate cement, the same as in Example 1, the difference is that the ratio of the composite mineralizer is: CaF 2 0.3 parts, SrO 1.5 parts, ZnO 0.7 parts, MgO 1.0 parts, parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com