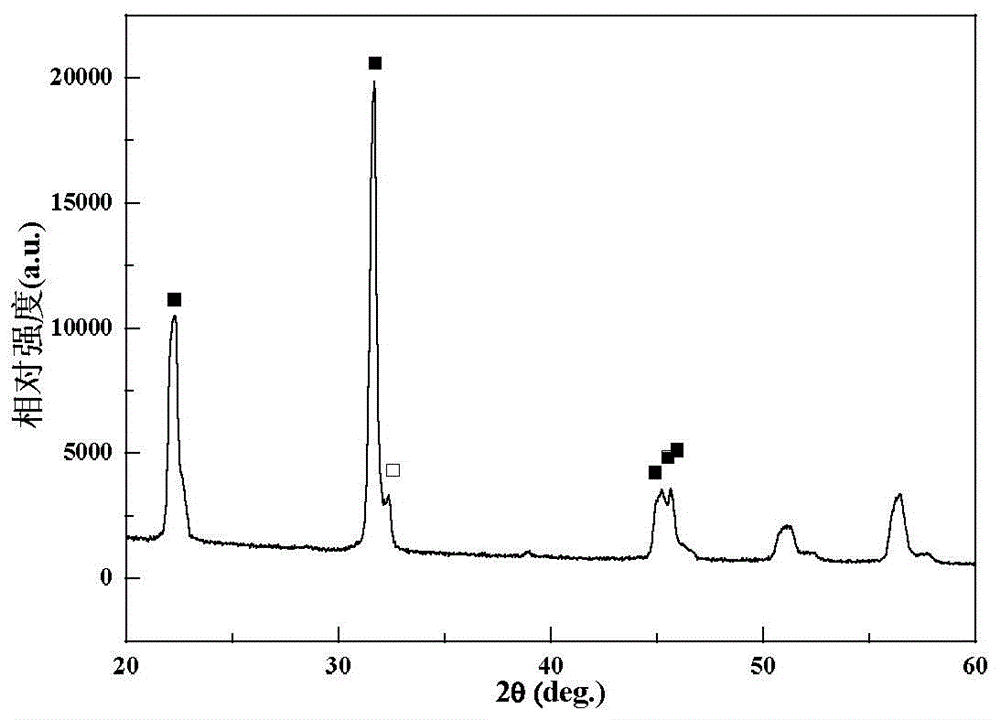

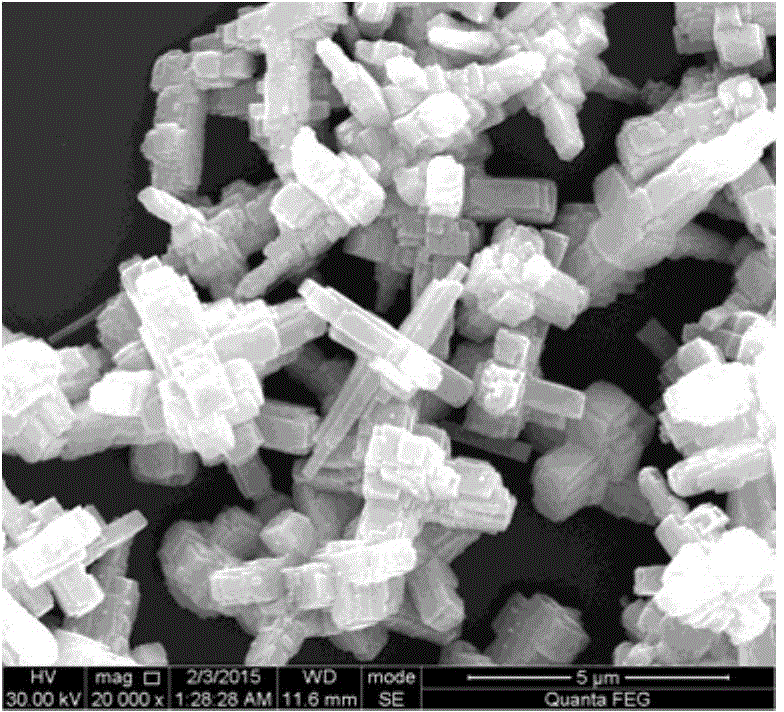

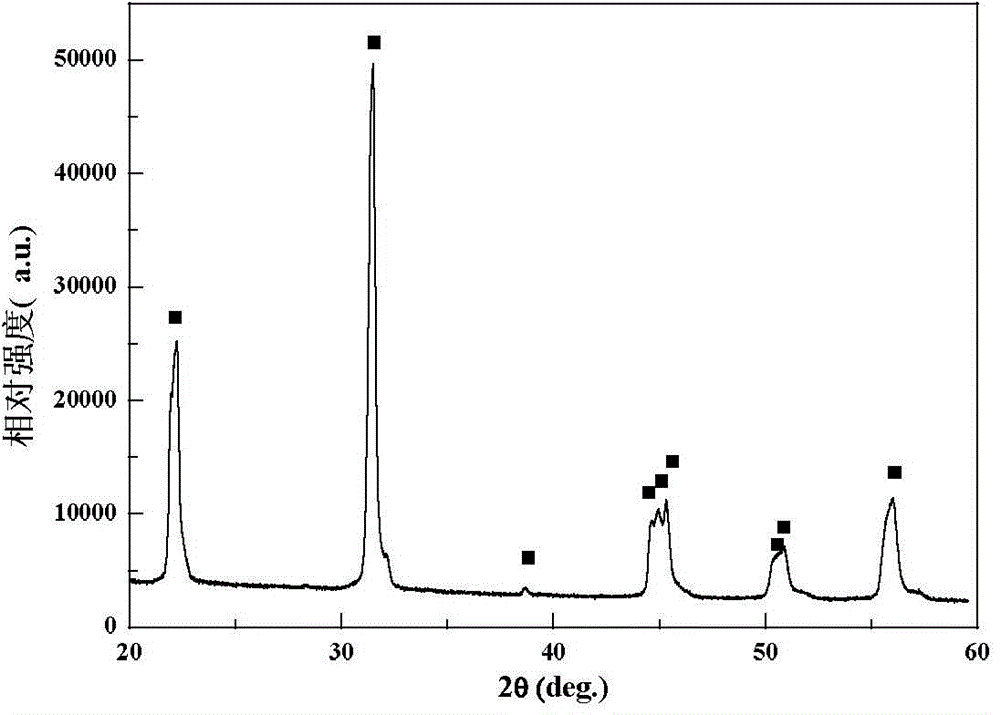

Synthetic method of sodium potassium columbate ferroelectric nano structure with monoclinic phase

A technology of sodium potassium niobate and a synthesis method, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as high cost, poor product consistency, and high lead toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: the synthetic method of sodium potassium niobate ferroelectric nanorod of the present embodiment is as follows:

[0016] 1. Add sodium acetate and potassium acetate to 20ml of ethylene glycol at a molar ratio of (7-12):28, and stir at room temperature until the mixture of sodium acetate and potassium acetate is completely dissolved to obtain solution A;

[0017] 2. In the state of stirring, add niobium ethanol solution dropwise to solution A, so that the molar ratio of the sum of sodium ions and potassium ions to niobium ions is 1:1, and then stir at room temperature for 6 hours to obtain niobic acid Sodium potassium sol;

[0018] 3. Dry the sodium potassium niobate sol at 50°C-80°C for 48h-168h until the sol is completely dry to obtain a dry gel precursor;

[0019] 4. In a 10ml polytetrafluoroethylene lining, mix sodium hydroxide and potassium hydroxide at a molar ratio of (7~12):28 to make 8ml of an aqueous solution containing sodium hydroxid...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, sodium acetate and potassium acetate are added to 20 ml of ethylene glycol at a molar ratio of 0.24:0.76. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the drying temperature in step 3 is 80°C. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com