Trichlorosilane vaporization device

A trichlorosilane and vaporization device technology, applied in the direction of silicon, etc., can solve the problems affecting product quality, fluctuations in proportion, uneven mixing, etc., and achieve the effect of good appearance quality of crystal grains, avoiding liquid foam entrainment, and stable proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

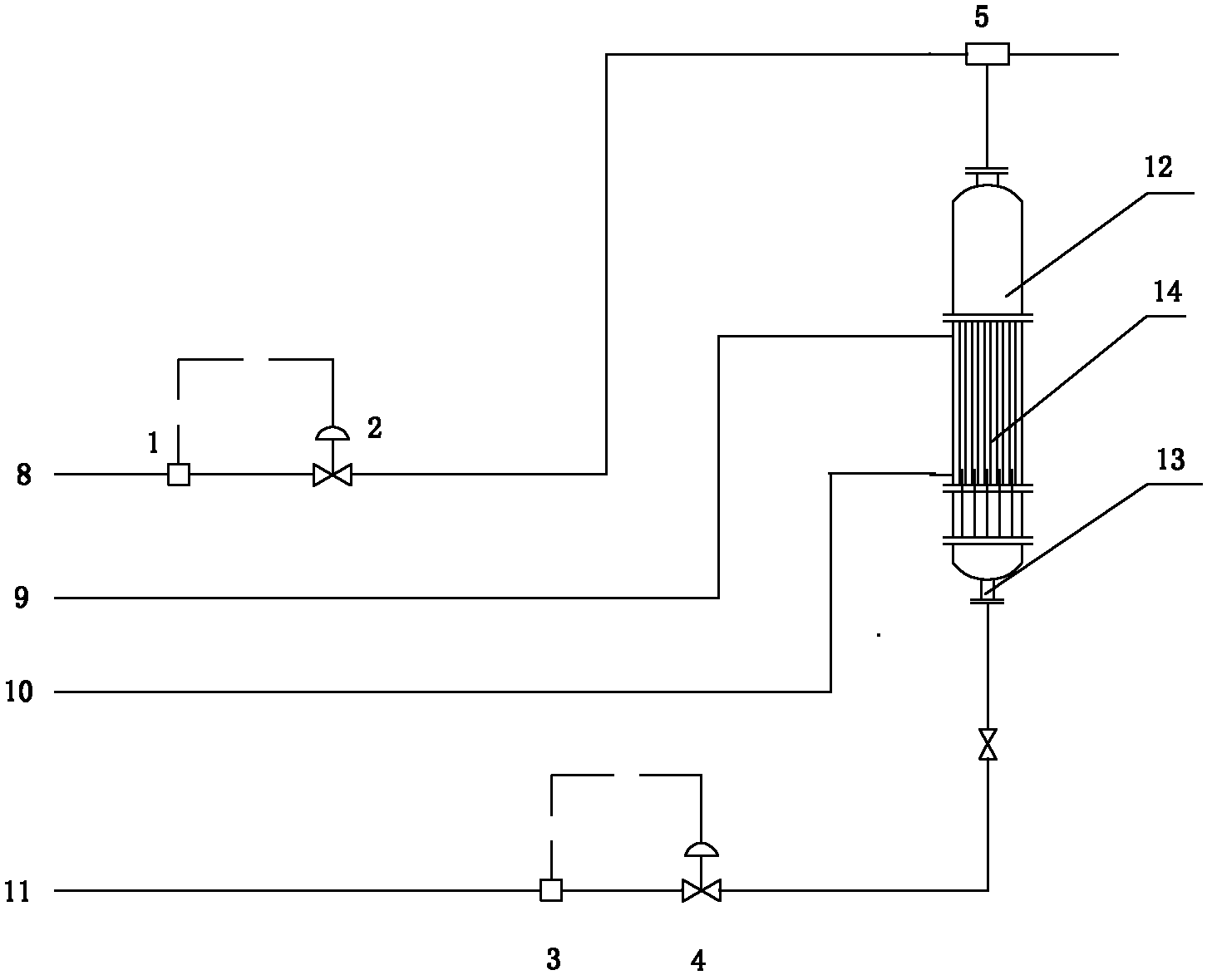

[0042] Such as figure 1 As shown, the trichlorosilane vaporization device listed in this embodiment includes an evaporator 12, a mixer 5, a trichlorosilane liquid delivery pipe, a trichlorosilane gas delivery pipe, and a mixed gas delivery pipe, and the evaporator 12 includes a tube array Type heat exchanger 14, the bottom of evaporator 12 is provided with trichlorosilane liquid inlet 13, and the top is provided with trichlorosilane gas outlet 16, and trichlorosilane liquid inlet 13 is connected with trichlorosilane liquid delivery pipe; The tube side of the type heat exchanger 14 communicates with the trichlorosilane liquid delivery pipe, and the shell side communicates with the pipeline for transporting external circulating water.

[0043] The mixer 5 communicates with the hydrogen delivery pipe, the trichlorosilane gas delivery pipe and the mixed gas delivery pipe respectively.

[0044] The trichlorosilane liquid delivery pipe is provided with a trichlorosilane mass flowm...

Embodiment 2

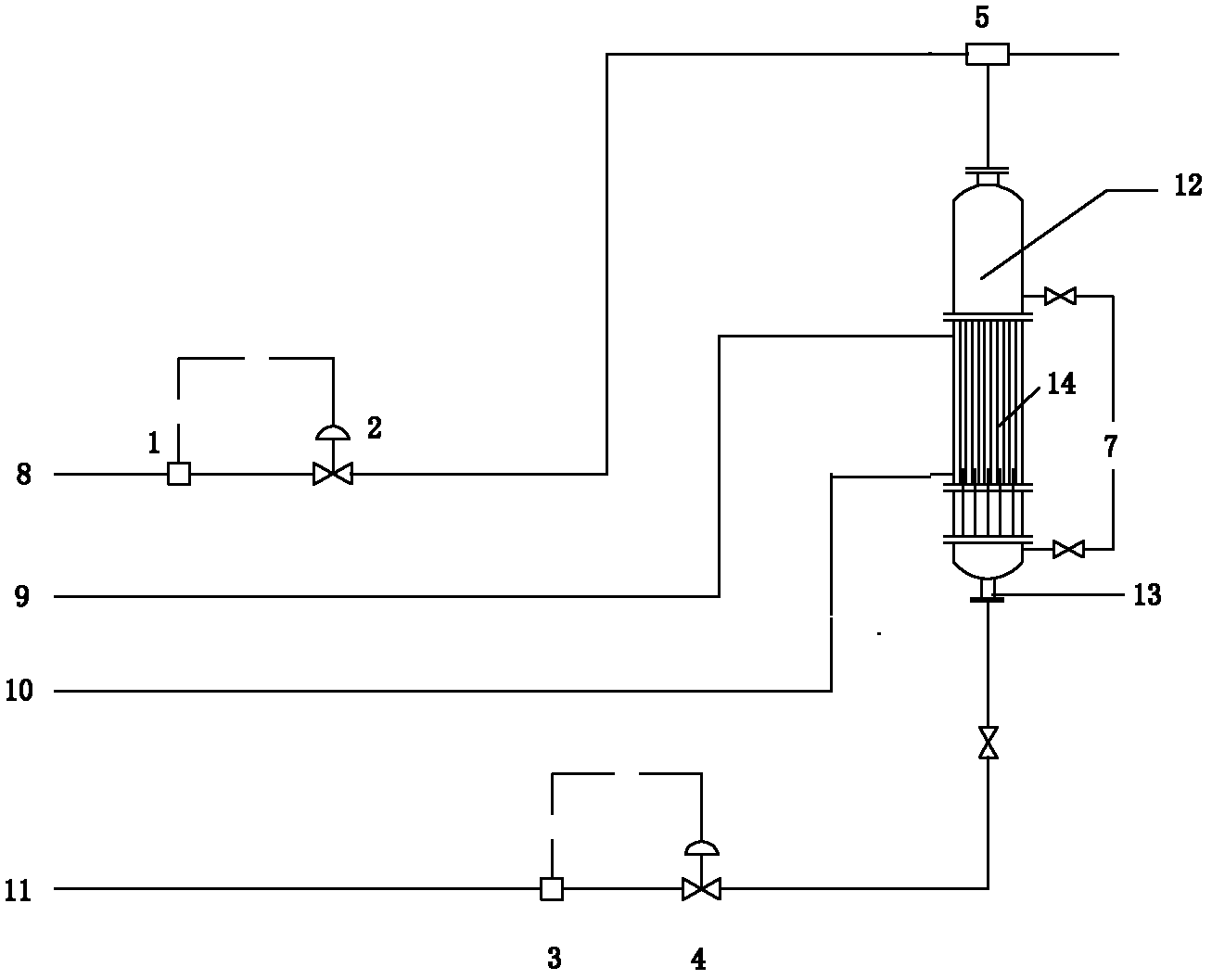

[0054] Such as figure 2 As shown, the trichlorosilane vaporization device listed in this embodiment includes an evaporator 12, a mixer 5, a trichlorosilane liquid delivery pipe, a trichlorosilane gas delivery pipe, and a mixed gas delivery pipe, and the evaporator 12 includes a tube array Type heat exchanger 14, the bottom of evaporator 12 is provided with trichlorosilane liquid inlet 13, the top is provided with trichlorosilane gas outlet 16, and trichlorosilane liquid inlet 13 is connected with trichlorosilane liquid delivery pipe; Evaporator 12 is also provided with a liquid level gauge 7, the liquid level gauge 7 is an internal floating magnetic liquid level gauge, the tube side of the tube-and-tube heat exchanger is connected with the trichlorosilane liquid delivery pipe, and the shell side is connected with the pipeline for transporting the external circulating water connected.

[0055] The mixer 5 communicates with the hydrogen delivery pipe, the trichlorosilane gas d...

Embodiment 3

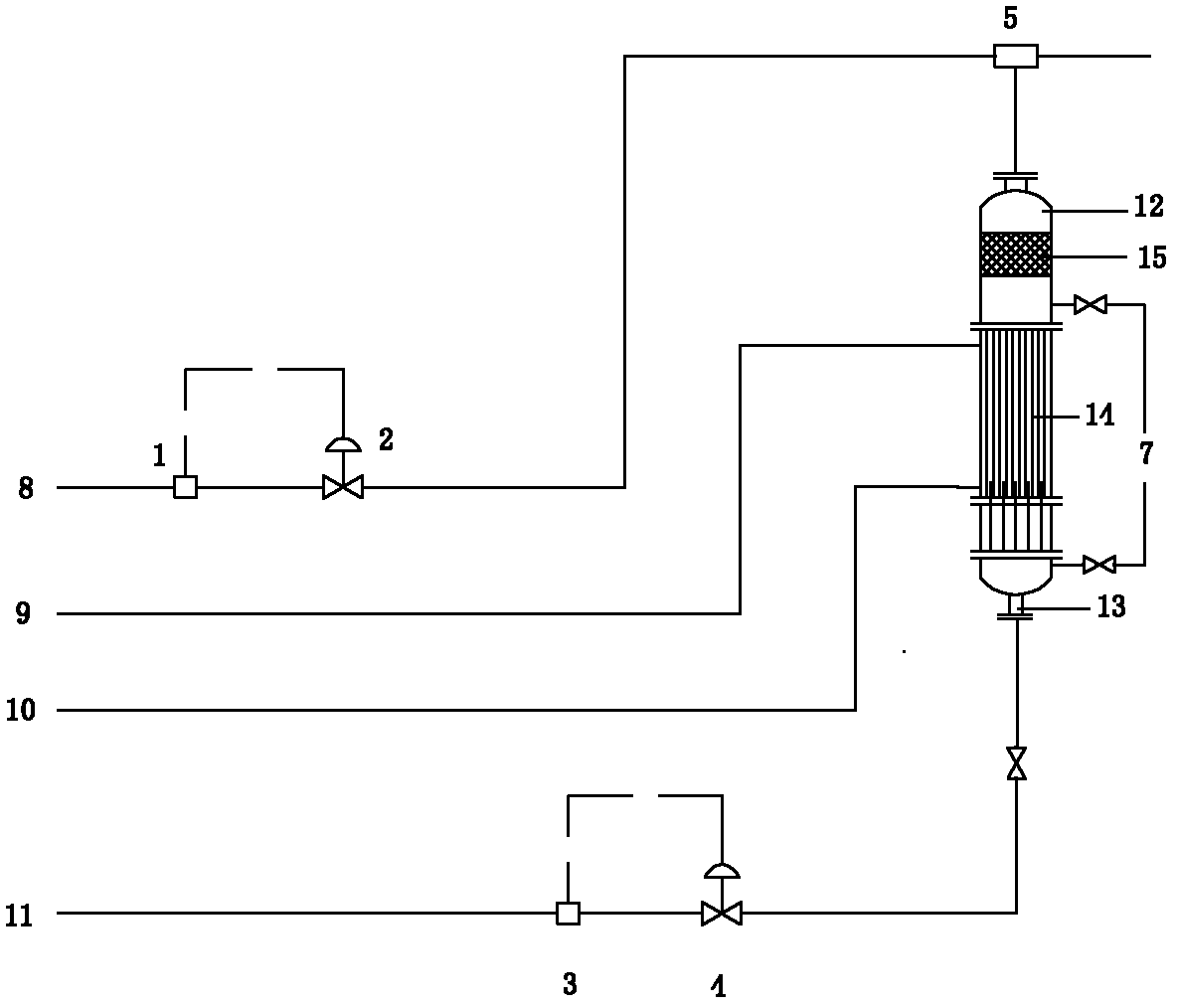

[0059] Such as image 3 As shown, the trichlorosilane vaporization device listed in this embodiment includes an evaporator 12, a mixer 5, a trichlorosilane liquid delivery pipe, a trichlorosilane gas delivery pipe, and a mixed gas delivery pipe, and the evaporator 12 includes a lower The shell and tube heat exchanger 14 and the demister 15 on the top, the bottom of the evaporator 12 is provided with a trichlorosilane liquid inlet 13, the top is provided with a trichlorosilane gas outlet 16, the trichlorosilane liquid inlet 13 is connected with trichlorohydrogen The silicon liquid delivery pipe is connected; the evaporator 12 is also provided with a liquid level gauge 7, the liquid level gauge 7 is an internal floating magnetic liquid level gauge, and the tube side of the tube-and-tube heat exchanger is connected with the trichlorosilane liquid delivery pipe, The shell side communicates with the pipeline for conveying the external circulating water.

[0060] The mixer 5 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com