Method used for preparing sericite powder used for cosmetics

A technology of sericite powder and cosmetics, which is applied in the field of preparation of sericite powder for cosmetics, can solve problems such as easy peeling, achieve stable indicators, improve product purity, and reduce agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

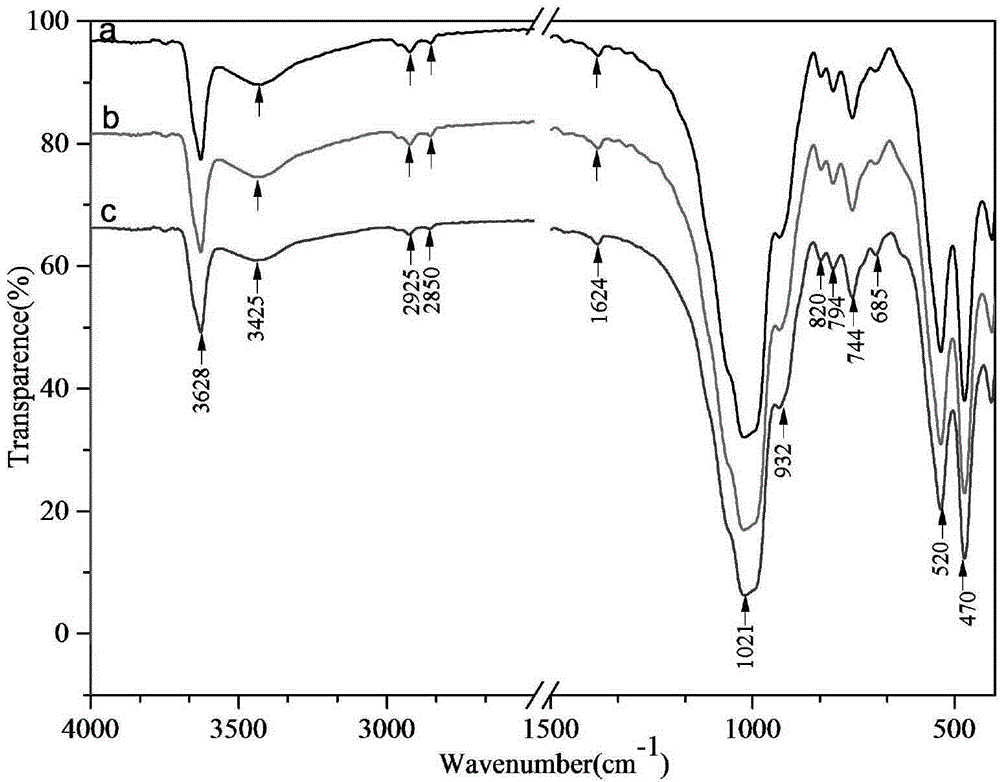

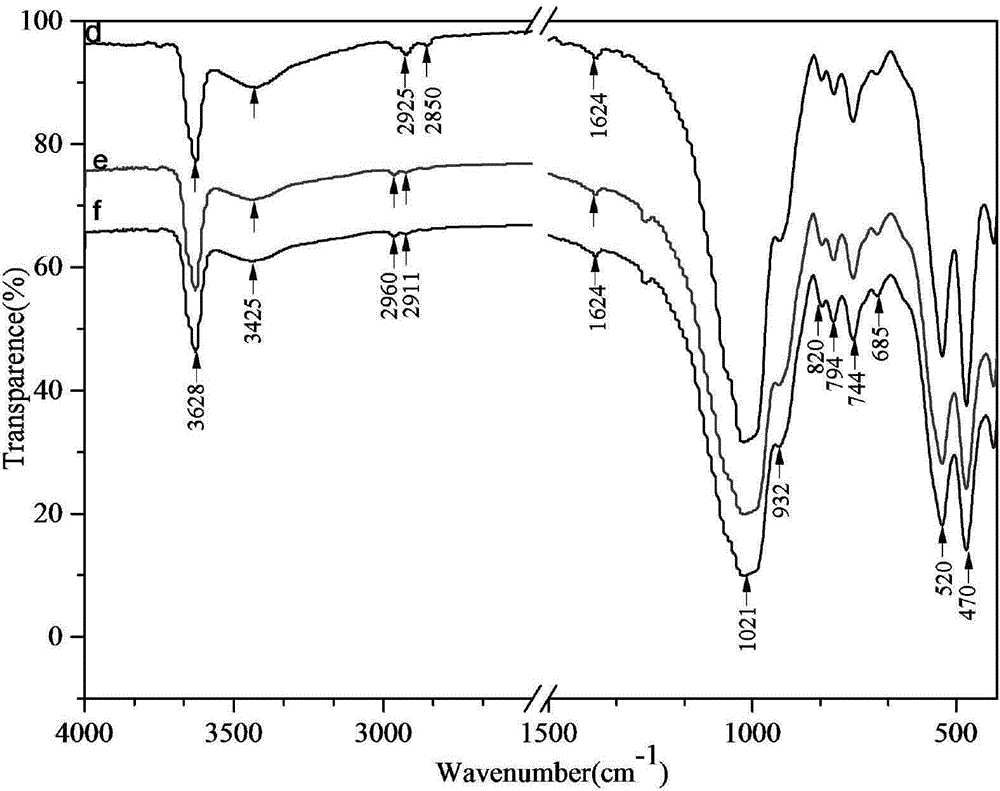

Image

Examples

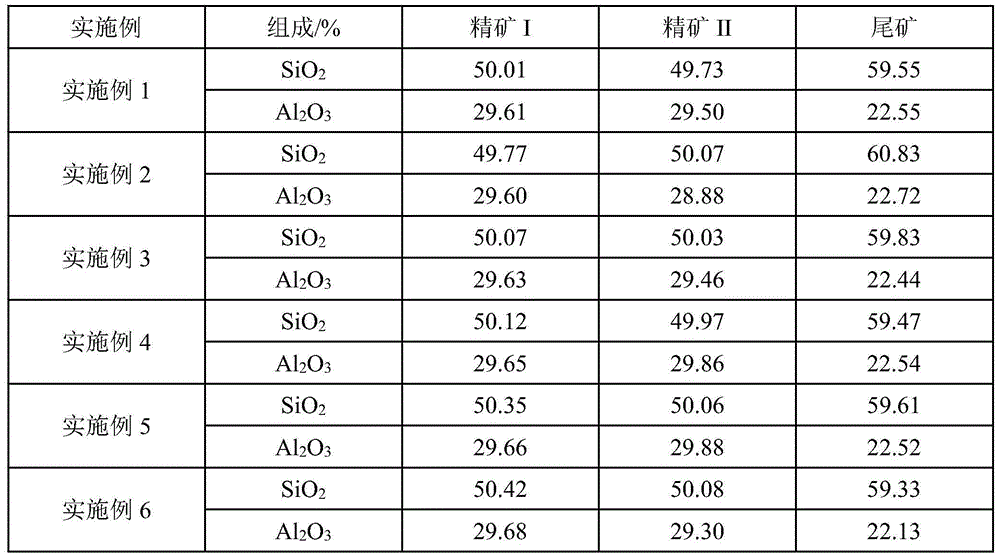

Embodiment 1

[0051] Shear flocculation of sericite quartz pulp: Sericite quartz powder is added to the stirring sand mill and dispersing multipurpose machine at a mass concentration of 10%, and after stirring and dispersing for 8 minutes at a rotating speed of 1200rpm, 1200g / t of acidic water glass with m=2.5 and pH=4 is sequentially added Stirring 8min, H 2 SO 4 Adjust the pH value of the slurry to 2-3 and stir for 8 minutes, then stir for 10 minutes with a surface treatment agent (polymethylhydrogensiloxane:isopropanol=100:100) with 2% by weight of sericite quartz powder, and stir for 300g / t cationic collector After 10 minutes, shear flocculated pulp was obtained.

[0052] Flotation purification: the sericite quartz pulp after shearing and flocculation is transferred to the flotation machine, the concentration of the pulp is adjusted to 5%, and the pH value of the pulp is kept at 2 to 3, and the concentrate I is obtained by micro-bubble flotation, and the cationic collection is continue...

Embodiment 2

[0057] Shear flocculation of sericite quartz pulp: Sericite quartz powder enters the stirring sand mill dispersing multi-purpose machine at a mass concentration of 50%, stirs and disperses at a speed of 1200rpm for 8 minutes, then adds 1600g / t of acidic water glass with m=2.5 and pH=4 in turn and stirs 8min, H 2 SO 4 Adjust the pH value of the slurry to 2-3 and stir for 8 minutes, then stir for 10 minutes with a surface treatment agent (polymethylhydrogensiloxane:isopropanol=100:200) with 2% by weight of sericite quartz powder, and stir for 10 minutes with 250g / t cationic collector After 10 minutes, a shear flocculated sericite slurry was obtained.

[0058] Flotation purification: the sericite quartz pulp after shearing and flocculation is transferred to the flotation machine, the concentration of the pulp is adjusted to 5%, and the pH value of the pulp is kept at 2 to 3, and the concentrate I is obtained by micro-bubble flotation, and the cationic collection is continued Ag...

Embodiment 3

[0063] Shear flocculation of sericite quartz slurry: Sericite quartz powder enters the stirring sand mill dispersing multi-purpose machine at a mass concentration of 50%, and after stirring and dispersing at 1500rpm for 8 minutes, add 800g / t of acidic water glass with m=2.5 and pH=4 in turn and stir 8min, H 2 SO 4 Adjust the pH value of the slurry to 2-3 and stir for 8 minutes, then stir for 10 minutes with a surface treatment agent (polymethylhydrogensiloxane:isopropanol=100:200) with a weight of 1.6% of sericite quartz powder, and stir for 350g / t cationic collector After 10 minutes, a shear flocculated sericite slurry was obtained.

[0064] Flotation purification: the sericite quartz pulp after shearing and flocculation is transferred to the flotation machine, the concentration of the pulp is adjusted to 5%, and the pH value of the pulp is kept at 2 to 3, and the concentrate I is obtained by micro-bubble flotation, and the cationic collection is continued Agent 150g / t, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com