Patents

Literature

57results about How to "Precisely control the ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic tea making machine

InactiveCN102987920AEasy to make teaPrecisely control the ratioBeverage vesselsControl systemProcess engineering

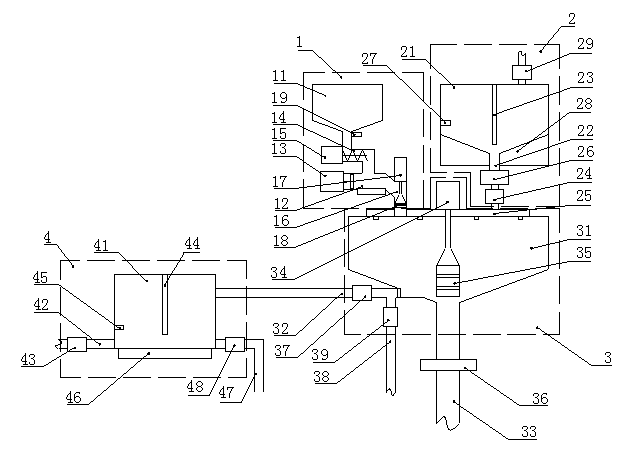

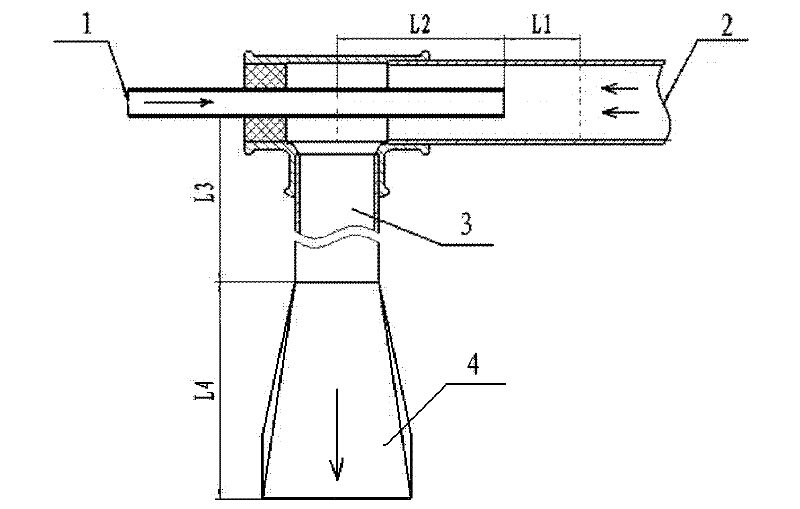

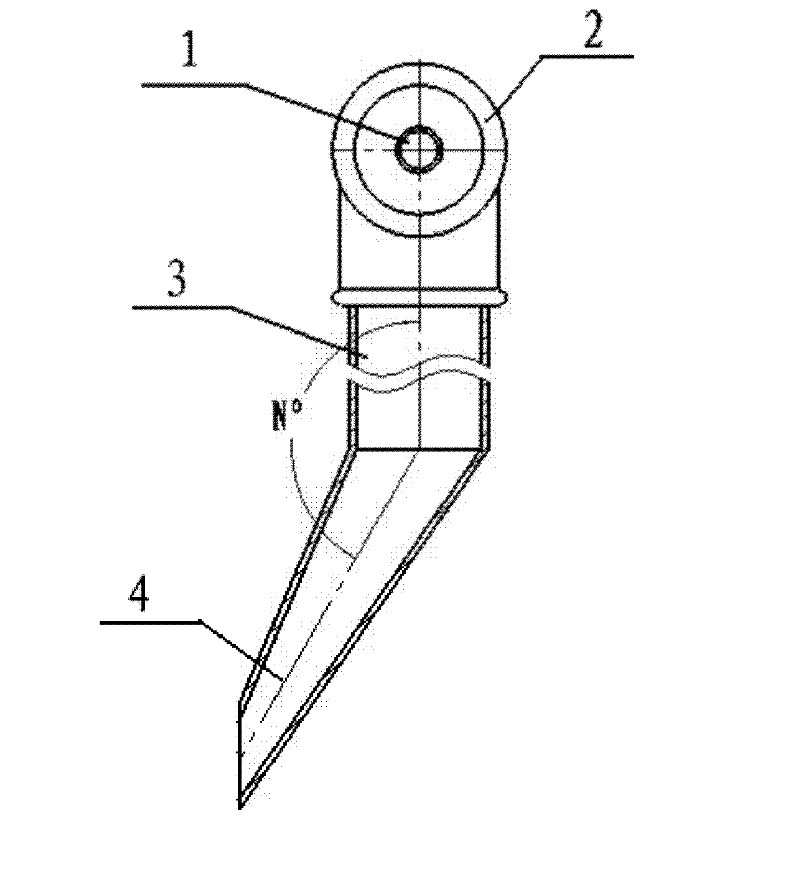

The invention discloses an automatic tea making machine. The automatic tea making machine comprises a control system, a tea supply system, a water supply system and a tea making system, wherein the tea supply system comprises a tea canister; the water supply system comprises a first water container; the tea making system comprises a second water container; the first water container is communicated with the second container through a water conveying pipeline; a tea conveying pipeline comprises a transverse weighing pipeline; a weighing device is arranged at the bottom of the weighing pipeline; a pushing device is arranged at one end of the weighing pipeline; tea leaves are conveyed into the second water container by the pushing device; a first liquid level sensor is arranged in the first water container; a water discharging electromagnetic valve is arranged on the water conveying pipeline and controls the opening and closing of the water conveying pipeline; and the control system controls the quantity of water which enters the second water container. The automatic tea making machine is simple in structure and can realize accurate ratio of the tea leaves to the water to the temperature so as to improve the taste and the quality of tea water.

Owner:朱楷

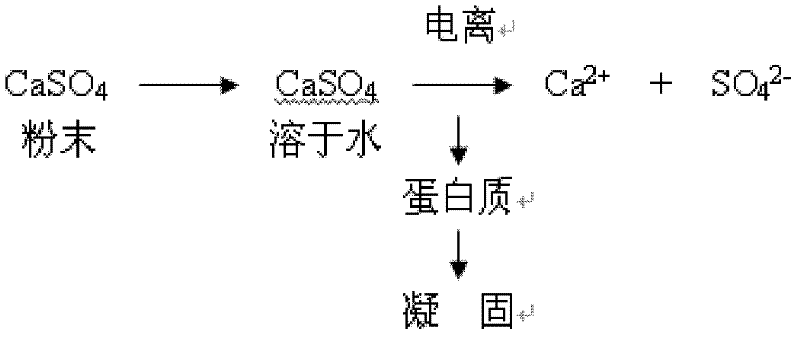

Production method for boxed bean curd and boxed bean curd

ActiveCN102550698AEnergy savingReduce energy consumptionCheese manufactureMilk substitutesChemistrySoybean oil

The invention discloses a production method for boxed bean curd and the boxed bean curd. The production method for the boxed bean curd comprises the following steps of: boiling soybean milk by taking soybeans as raw materials; controlling the temperature of the boiled soybean milk to be above 85 DEG C; mixing the boiled soybean milk with a coagulating agent; and filling the mixture into a packing container; keeping the temperature of mixed milk of the soybean milk and the coagulating agent in the packing container for 10 to 30 minutes; and solidifying to form the boxed bean curd. The production method has a scientific process and simple steps. According to the production method, defects in the prior art are overcome, a solidification process of the soybean milk can be more effectively controlled, industrialized production can be really realized, and the aims of reducing energy consumption to a great extent, simplifying equipment and diversifying varieties are fulfilled, and boxed lactone bean curd and boxed southern bean curd and northern bean curd which fit conventional taste can be prepared.

Owner:FOODSTUFF INST BEIJING

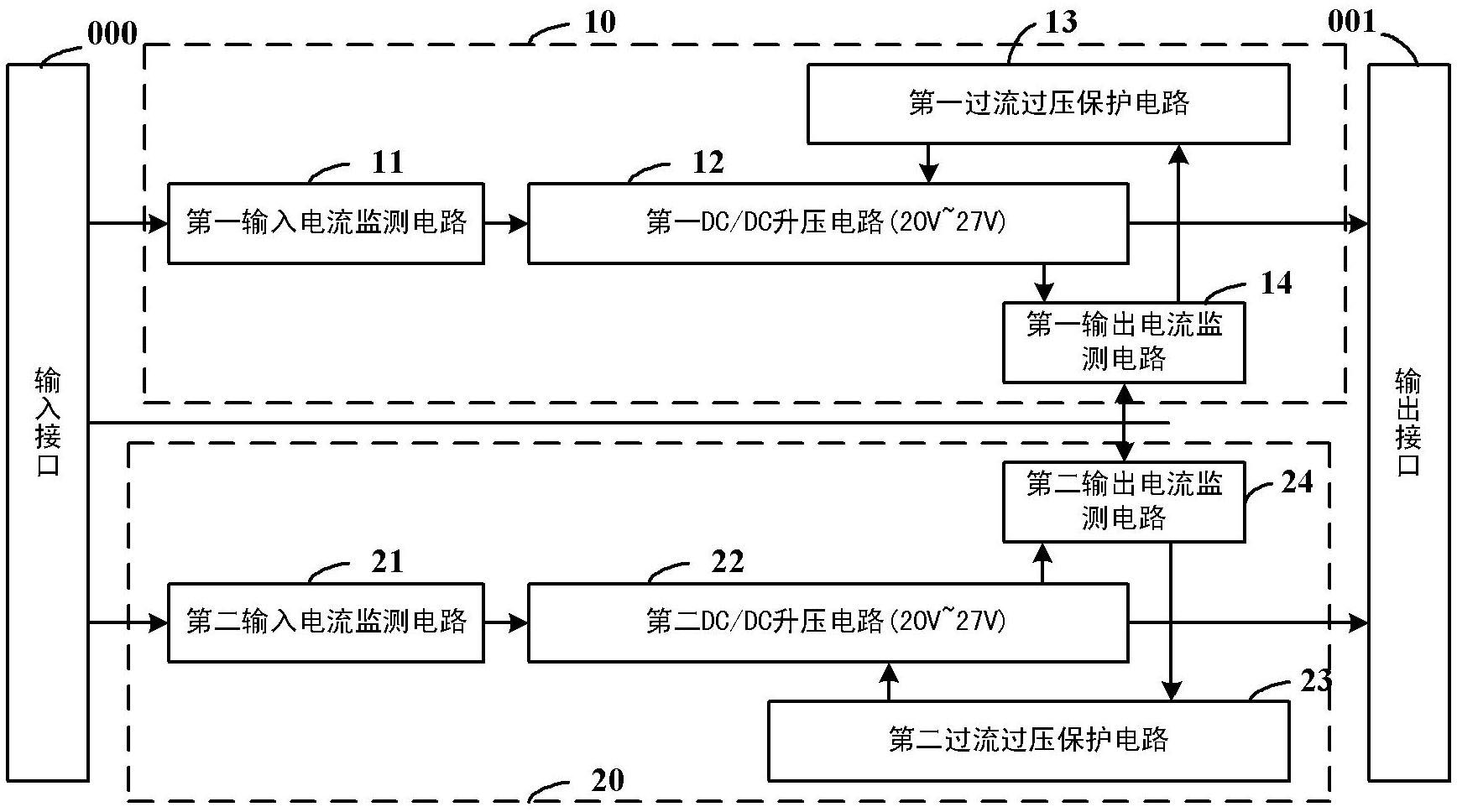

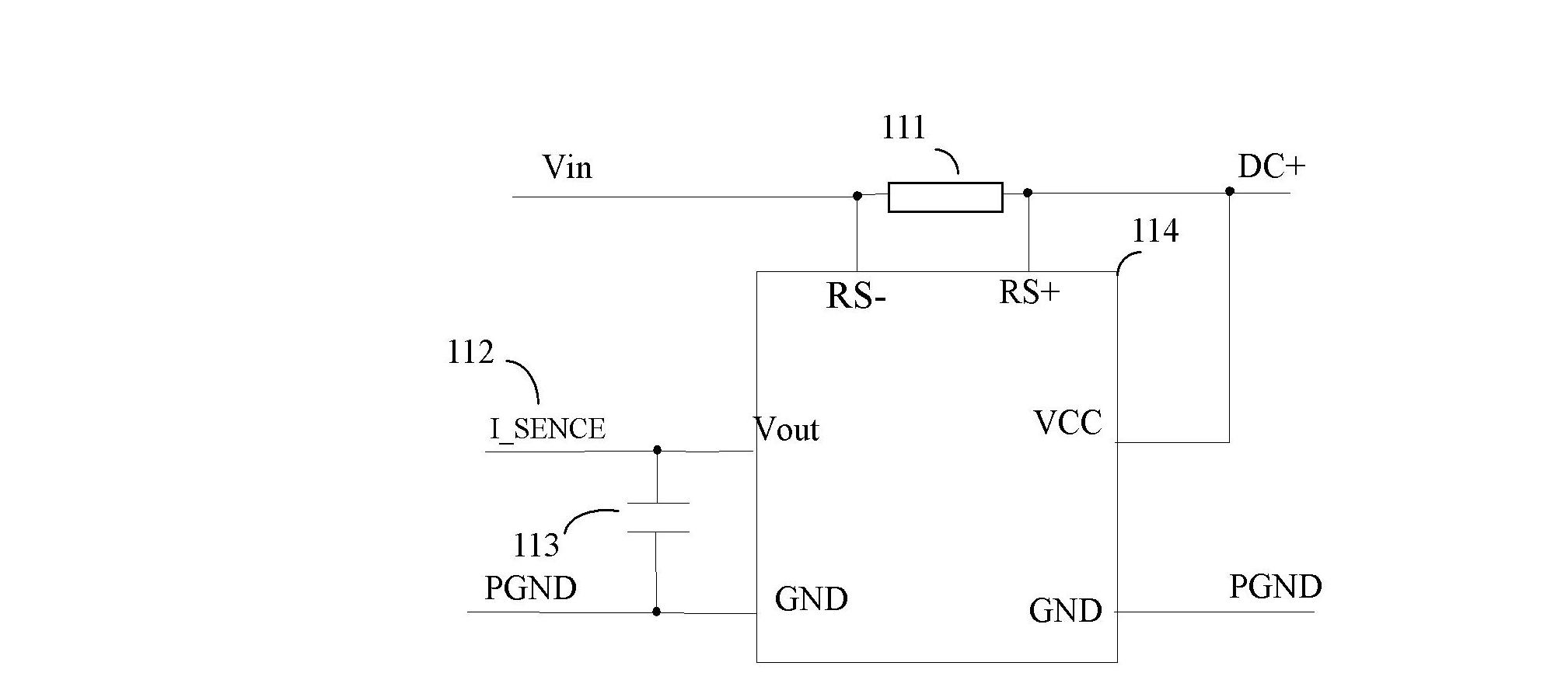

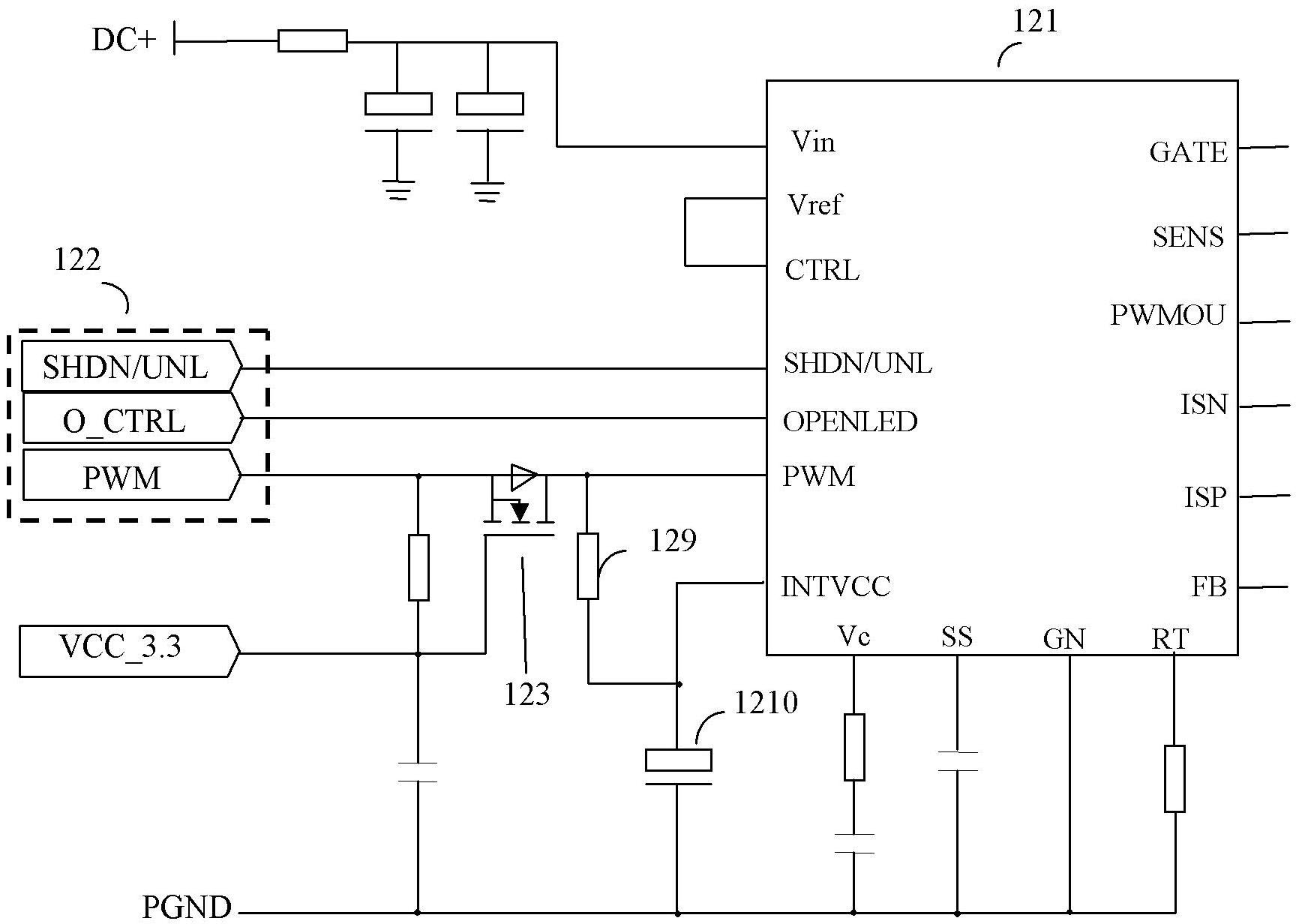

Drive circuit of laser source of laser projector

InactiveCN102646917AFor electrical needsReduce volumeExcitation process/apparatusSemiconductor lasersEngineeringLighting ratio

The invention discloses a drive circuit of a laser source of a laser projector, which comprises an input interface, a first drive generation circuit, a second drive generation circuit and an output interface, wherein the first drive generation circuit and the second drive generation circuit are two parallel drive generation circuits and are symmetrically distributed between the input interface and the output interface; and the two parallel drive generation circuits are integrated together and connected with an external power supply system through the input interface, and output a transformed voltage through the output interface. The invention satisfies the electric demands for the laser source of the laser projector, greatly reduces the volume of the drive circuit board, implements control on the power of the laser device, and has the function of current control for accurately controlling the emergent light ratio.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

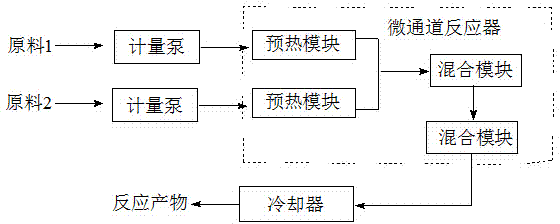

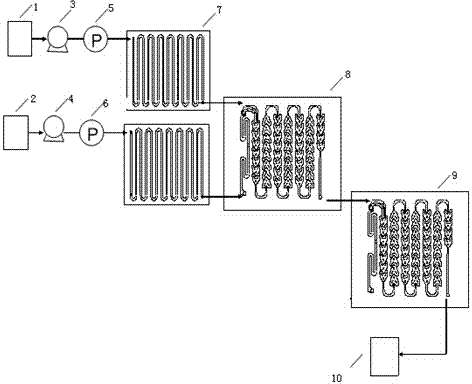

Method for producing biodiesel by adopting microchannel reactor

InactiveCN104745310AShort reaction timeImprove reaction efficiencyFatty acid esterificationBiofuelsTrans esterificationVegetable oil

The invention discloses a method for producing biodiesel by adopting a microchannel reactor, belonging to the technical field of green renewable energy resources. The method is a novel technology for producing biodiesel products, and in the high-flux continuous-flow microchannel reactor, renewable energy resources such as animal and vegetable oil, waste oil and refined oil as well as methyl alcohol are taken as raw materials, and are subjected to transesterification in the microchannel reactor for a short reaction time of dozens of seconds or several minutes under the catalysis of alkali or acid to produce a biodiesel product. The materials enter the continuous-flow microchannel reactor through a metering pump, and are preheated, mixed and subjected to aftertreatment in a transesterification module to obtain the biodiesel product. The method has the advantages that the operation is simple and safe, and the biodiesel product can be continuously produced with a high yield, and besides, the environment pollution caused by the technology is greatly lowered.

Owner:NANJING UNIV OF TECH +1

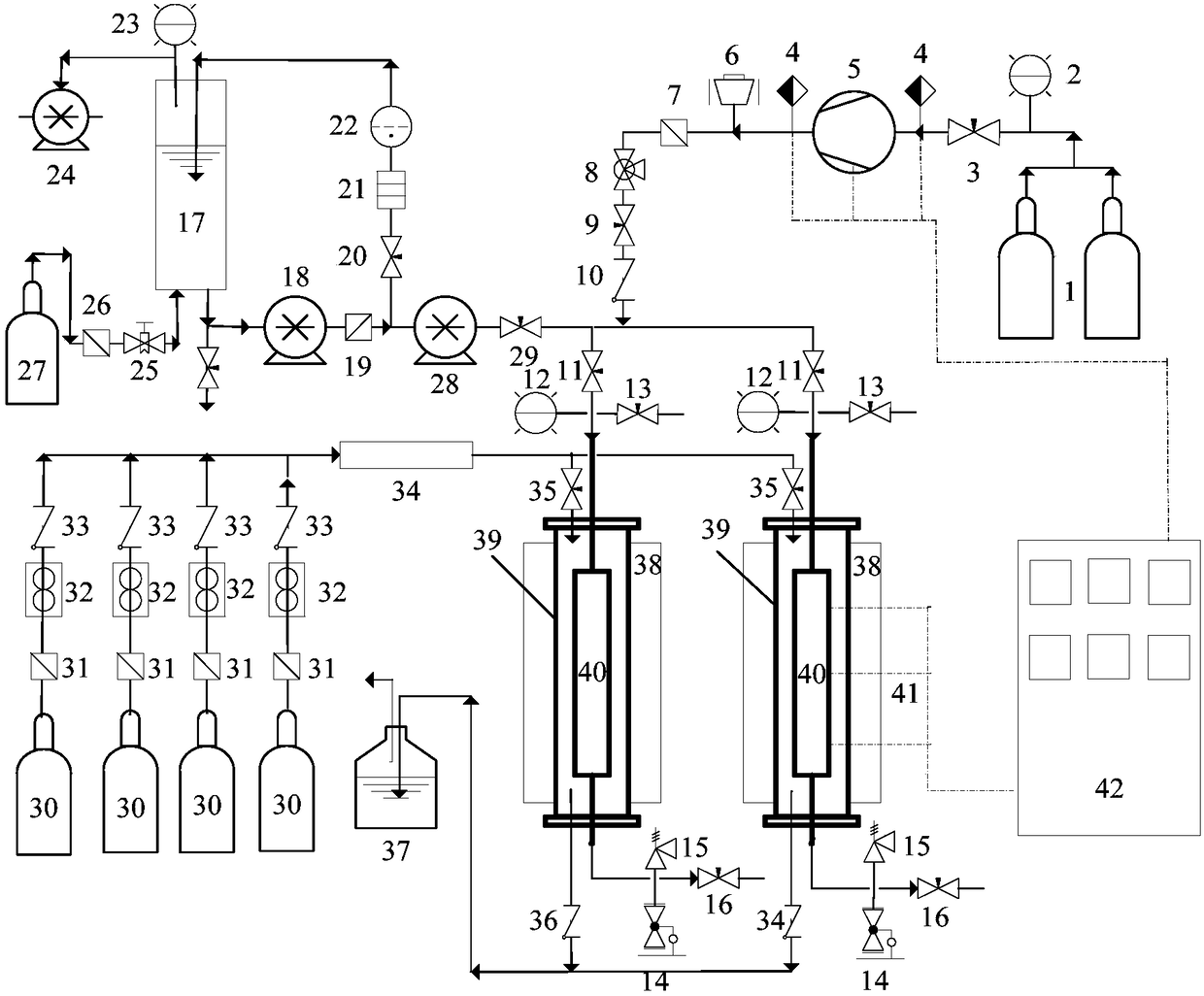

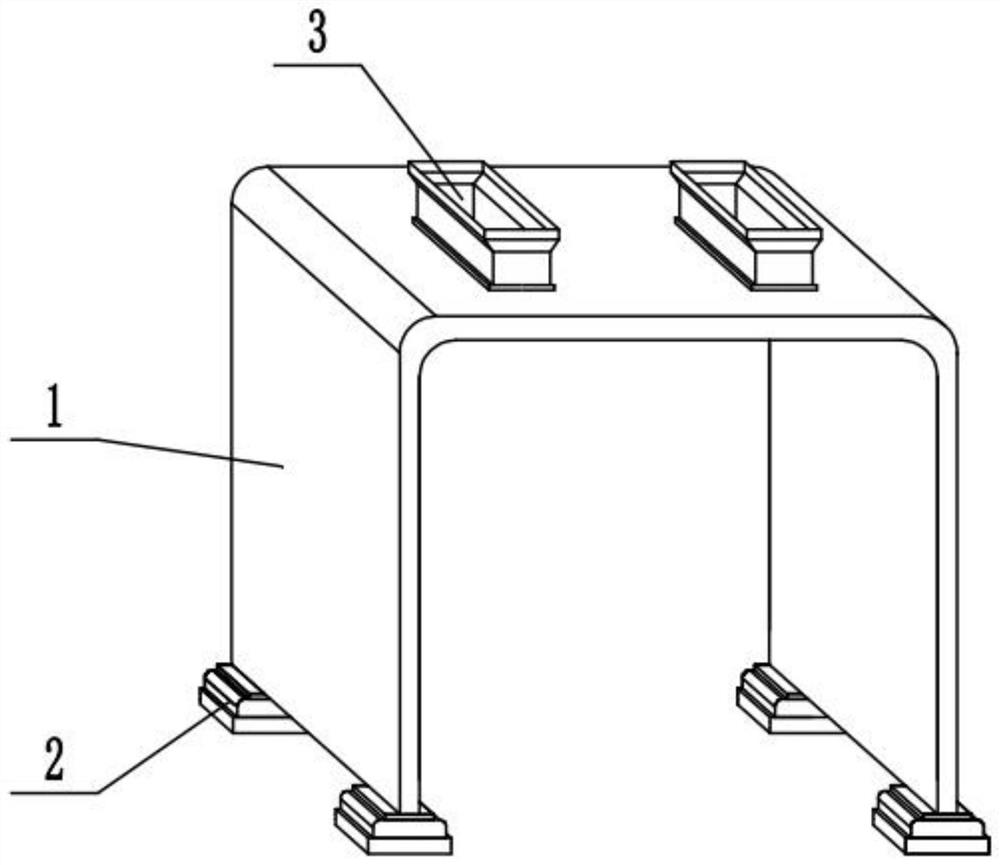

Internal pressure creep test device for simulating service environment of boiler tubes in coal-fired power plant, and using method of internal pressure creep test device

PendingCN108195688AReliable test resultsPrecisely control the ratioMaterial strength using tensile/compressive forcesInternal pressureWater vapor

The invention discloses an internal pressure creep test device for simulating the service environment of boiler tubes in a coal-fired power plant, and a using method of the internal pressure creep test device. The device comprises a gas pressurization system, a steam supply system, a flue gas supply system, a test heating system and a control cabinet. Compared with the prior art, the device and the method can realize an internal pressure creep test of the boiler tubes of the coal-fired power plant under various environment coupling actions such as high temperature, high pressure, outer wall corrosive flue gas and inner wall water vapor, so that the test environment is closer to the actual service environment of the boiler tubes of a coal-fired power stations, and the test results are moreaccurate and reliable. Furthermore, the temperature (0-1000 DEG C), pressure (0-200MPa), flue gas ratio and vapor dissolved oxygen content of the device can be adjusted, so that the device can meet the requirements of different test conditions; finally, according to the device, a plurality of sets of test heating units can be connected in parallel at the same time, so that a plurality of samples can be subjected to the internal pressure creep test at the same time.

Owner:HUANENG POWER INT INC +1

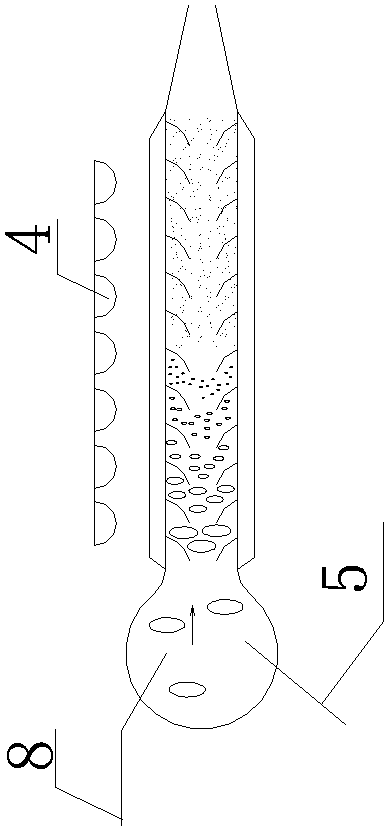

Trichlorosilane vaporization device

The invention relates to a polysilicon production device, in particular to a trichlorosilane vaporization device, and belongs to the technical field of polysilicon production. The trichlorosilane vaporization device of the present invention comprises an evaporator, a hydrogen delivery pipe, a trichlorosilane liquid delivery pipe, a trichlorosilane gas delivery pipe, a mixed gas delivery pipe, and a mixer, and the lower end of the evaporator is provided with trichlorosilane The silicon liquid inlet and the upper end are provided with a trichlorosilane gas outlet; the trichlorosilane liquid inlet is connected with the trichlorosilane liquid conveying pipe; the trichlorosilane liquid conveying pipe and the hydrogen conveying pipe are provided with a meter; the mixer They are respectively connected with the hydrogen gas delivery pipe, the trichlorosilane gas delivery pipe and the mixed gas delivery pipe. Using the trichlorosilane vaporization device of the present invention to vaporize trichlorosilane can obtain a mixed gas with a stable ratio and uniform mixing; the mixing of raw materials is more uniform, which is conducive to the uniform growth of silicon rods in the reduction reaction of the reduction furnace, The appearance quality of the produced crystal grains is better.

Owner:SICHUAN XINGUANG SILICON TECH

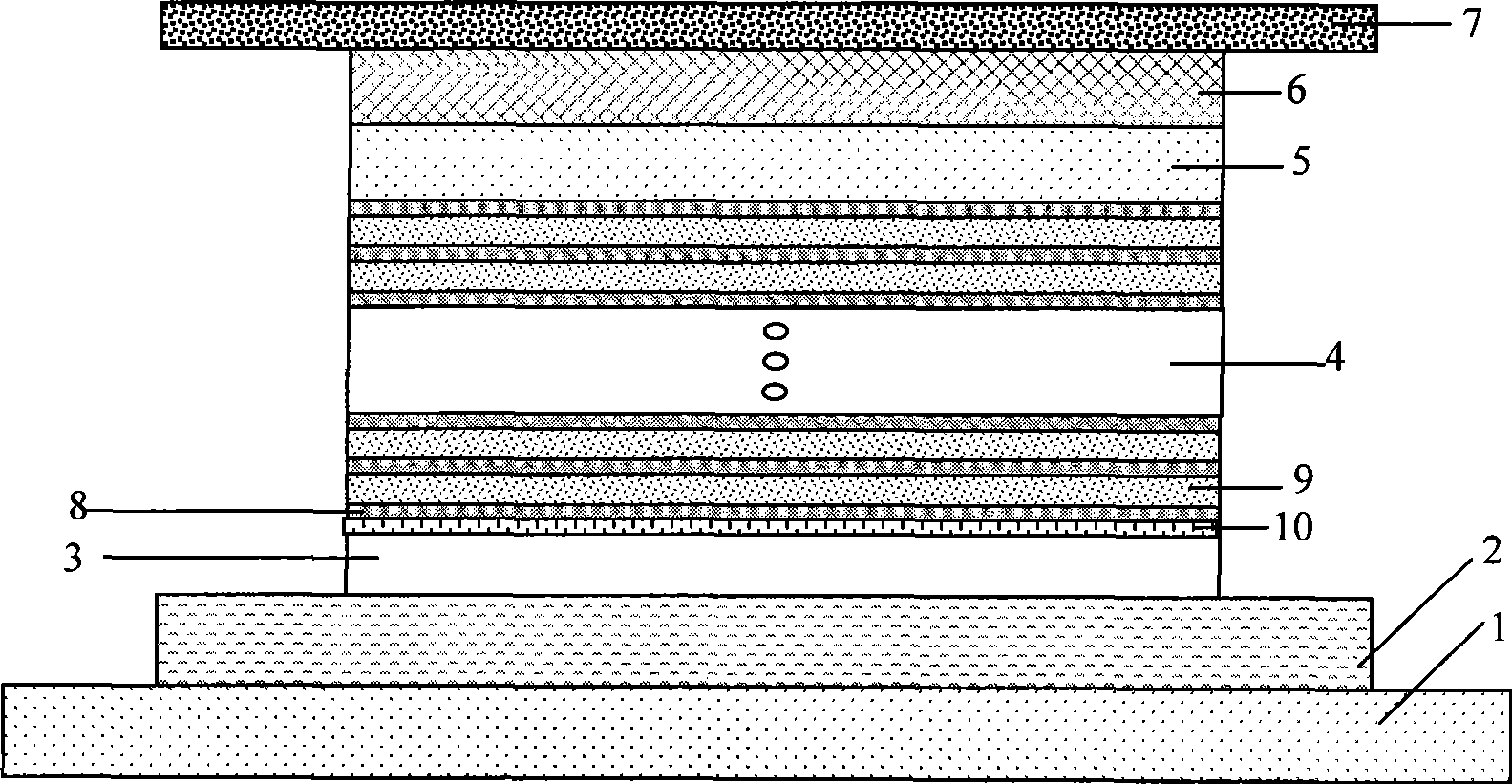

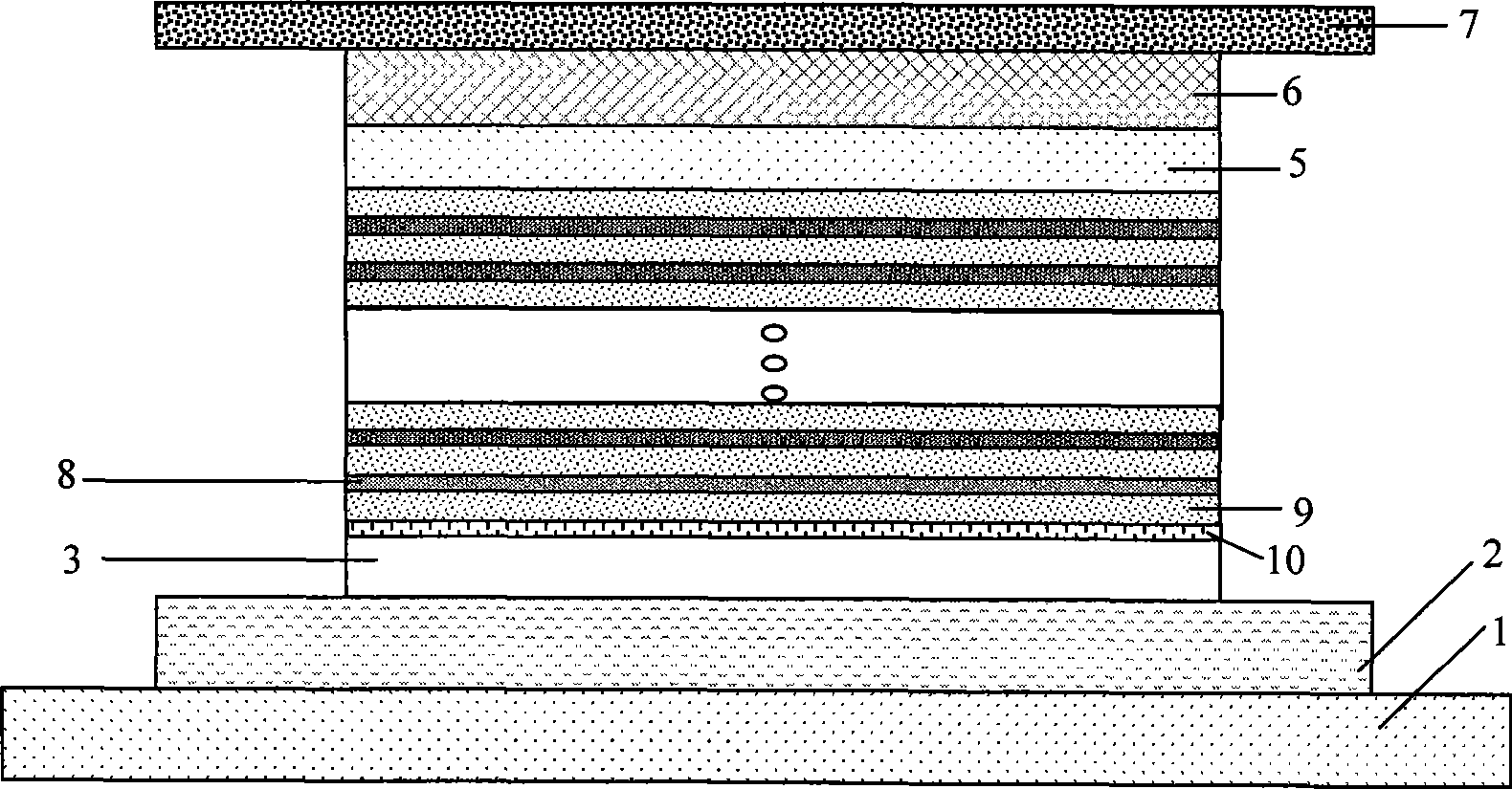

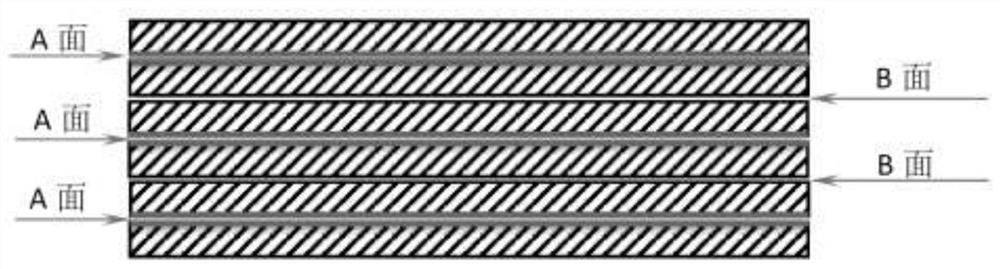

High-efficiency organic luminescent device and its production method

InactiveCN101499518AGuaranteed repeatabilityAvoid simultaneous evaporationSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionDisplay device

The invention relates to an efficient organic light-emitting device and a preparation method thereof, which belongs to the structural design of the organic light-emitting device and the preparation method thereof. The efficient organic light-emitting device is applicable to the light-emitting display and a flat light source. A substrate (1) is provided with an anode electrode (2); the anode electrode (2) is provided with a hole transmission layer (3); the hole transmission layer (3) is provided with a light-emitting layer (4) which comprises a donor layer (8) and a doped layer (9) which are prepared in the sequential steaming method and arranged periodically; the light-emitting layer is provided with a hole blocking layer (5); the hole blocking layer (5) is provided with an electronic transmission layer (6); and the electronic transmission layer (6) is provided with a cathode electrode (7). When the sequential doping method is used for preparing the efficient organic light-emitting device, the thickness of the donor layer, the thickness of the doped layer and the number of the periodic structures in the light-emitting layer are all design parameters which can be optimized. Therefore, the invention can be used for manufacturing the organic light-emitting device with higher efficiency, and can be applied to the full-color display, a solid-state light source, an LCD backlight source and a micro display device.

Owner:SOUTHEAST UNIV

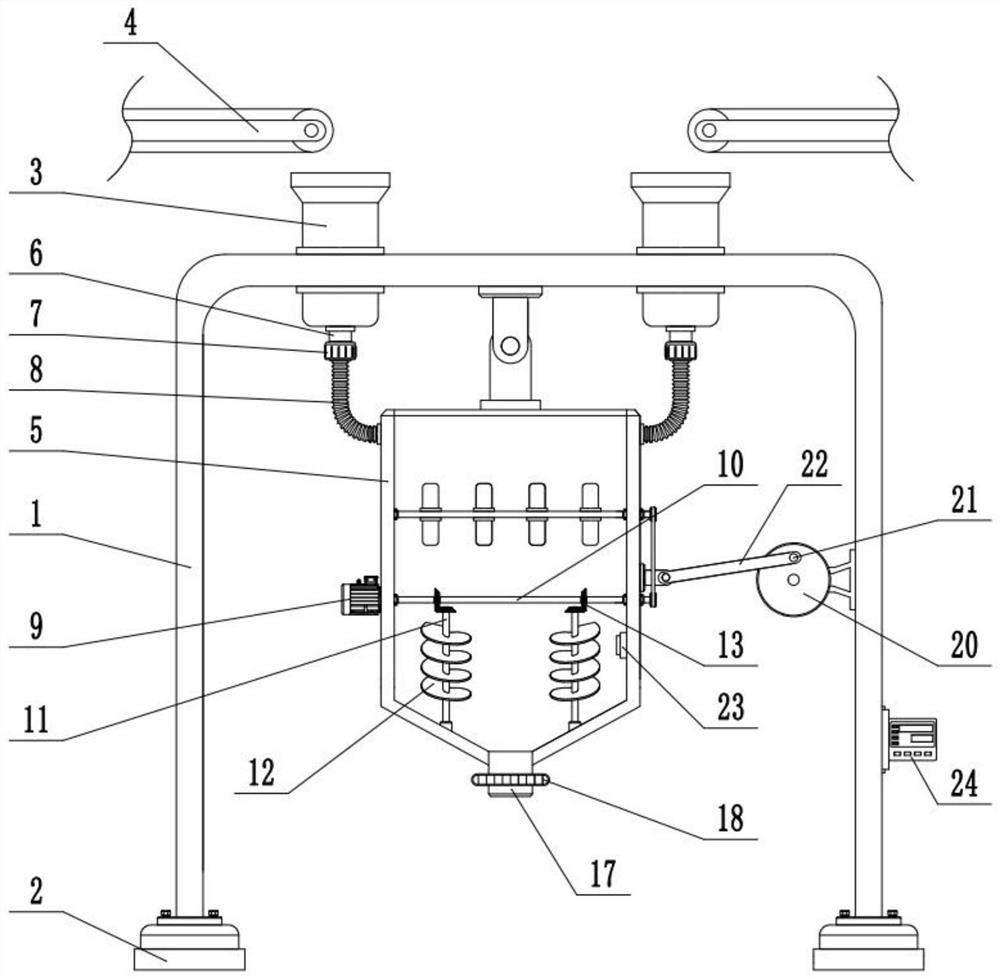

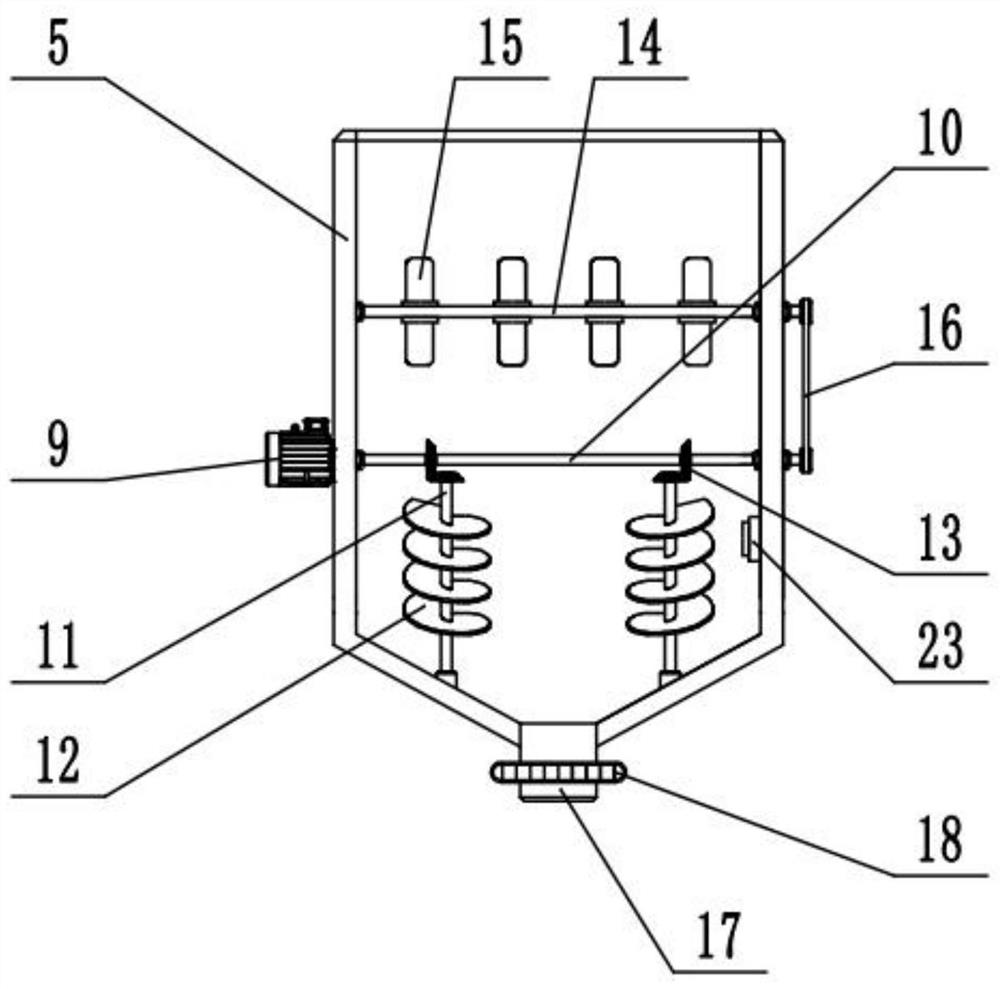

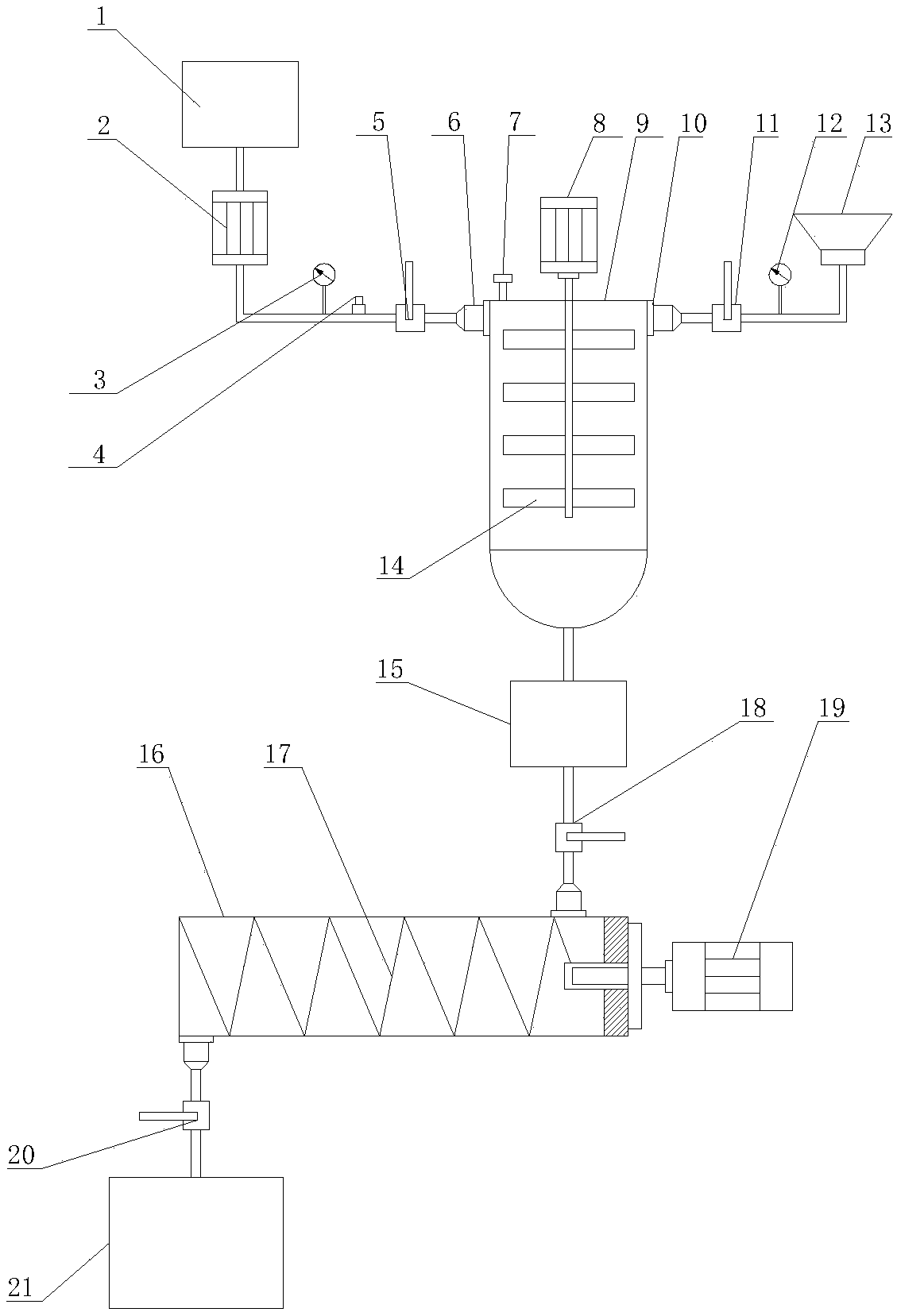

Mixing type tank body stirring device

InactiveCN104526881APrecisely control the ratioPrevent nonconformingMixing operation control apparatusMixing operation plantBiochemical engineeringElectric control

The invention relates to a mixing type tank body stirring device. The mixing type tank body stirring device comprises a powder tank body, a solution tank body, a stirring tank and a controller, wherein a feeding hole is formed in the top end of the powder tank body, a feeding pipe is communicated to a feeding hole, a discharging hole is formed in the bottom end of the powder tank body, a discharging pipe is communicated to the discharging hole, a power electric control flow valve is mounted on the discharging pipe, and the powder tank body is communicated with the stirring tank; a liquid inlet is formed in the top end of the solution tank body, a liquid inlet pipe is communicated to the liquid inlet, a liquid outlet is formed in the bottom of the solution tank body, a liquid outlet pipe is communicated to the liquid outlet, and a solution electric control flow valve is mounted on the liquid outlet pipe; the solution tank body is communicated with the stirring tank through the liquid outlet pipe; the powder electric control flow valve and the solution electric control flow valve are respectively connected with the controller; a remote transceiver is connected to the controller. According to the mixed type tank body stirring device, the ratio of powder to a solution can be wirelessly and accurately controlled, and a phenomenon that products are not qualified because the ratio is inaccurate is prevented.

Owner:GUANGXI PROVINCE NANNING CITY ZHIJIANZHIFAN TECH CONSULTING

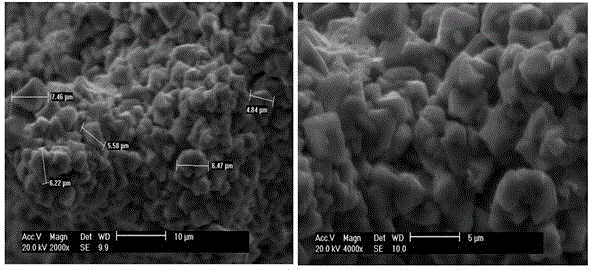

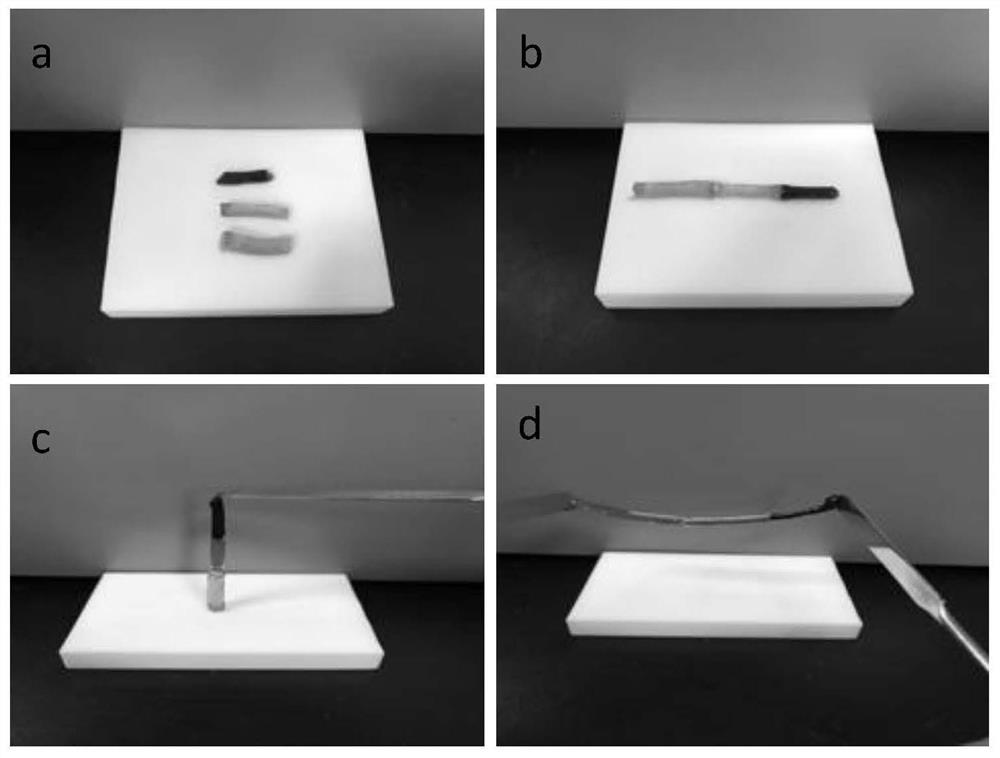

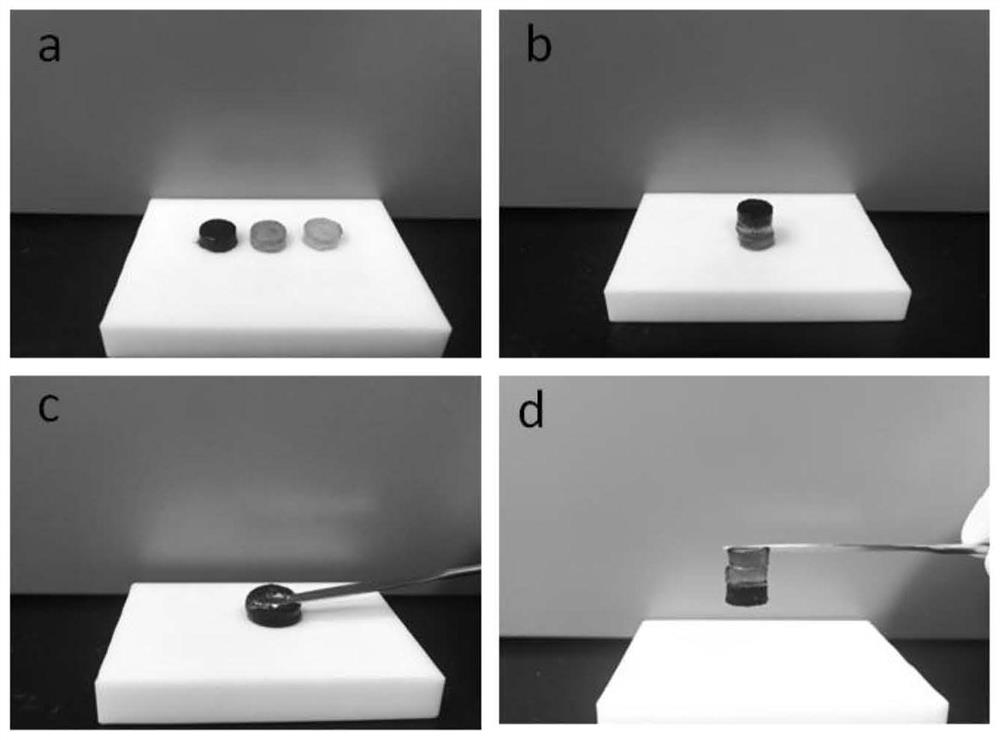

Preparation method of cobalt manganese oxide coating layer precursor

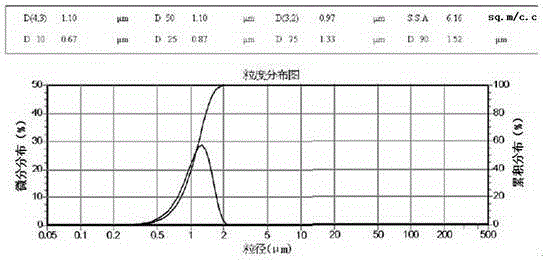

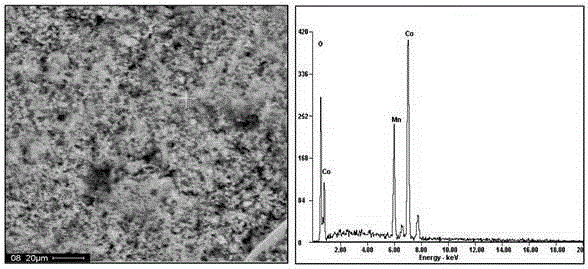

InactiveCN105236497ALow priceSmall sizeCobalt compoundsSolid electrolyte fuel cellsChemistryStoichiometry

The invention discloses a preparation method of a cobalt manganese oxide coating layer precursor, and belongs to the technical field of solid oxide fuel cell connector surface modification technologies. The preparation method overcomes the disadvantages of complex process, high cost and long reaction time of (Mn, Co)3O4 coating layer precursors prepared through electroplating, electrodeposition and physical vapor deposition methods. The (Mn, Co)3O4 coating layer precursor with easily controlled stoichiometry, small particle dimension, uniform granularity and large specific surface area, provided by the invention, is prepared through a sol-gel technology with manganese nitrate, cobalt nitrate, citric acid, polyvinyl alcohol, glycol, adipic acid and ammonia water as reagents. The method allows all reactions to be completed at room temperature, can accurately control the proportions of a coating layer, and realizes small dimensions, uniform granularity, large specific surface area, compactness and reliability of sintered coating layer particles.

Owner:KUNMING UNIV OF SCI & TECH

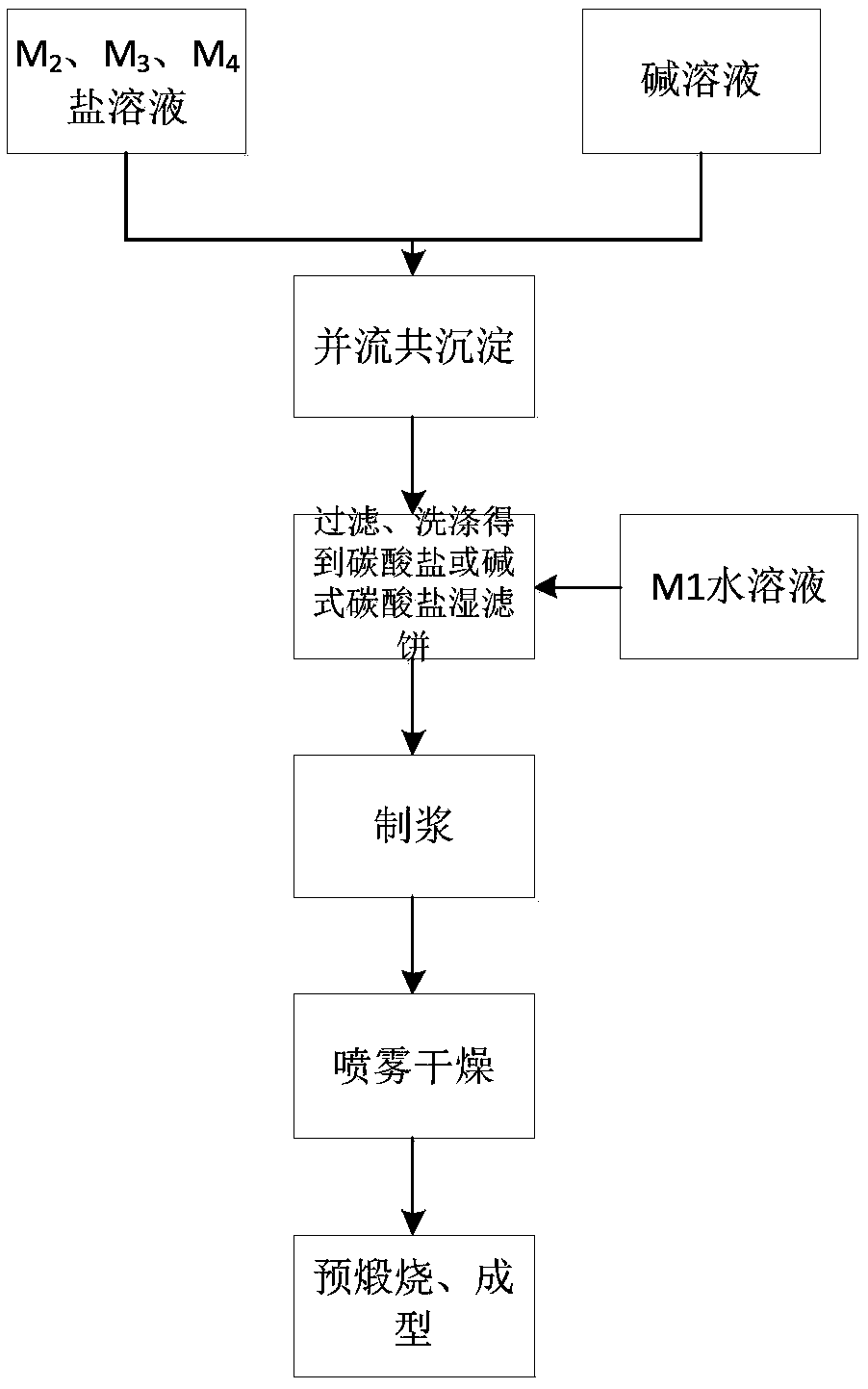

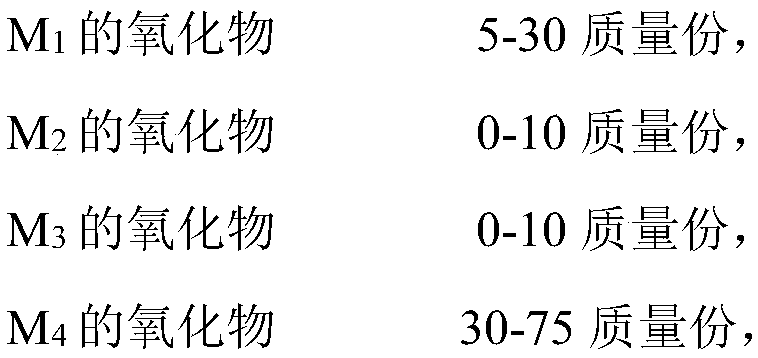

Sulfur tolerant methanation catalyst and preparation method thereof

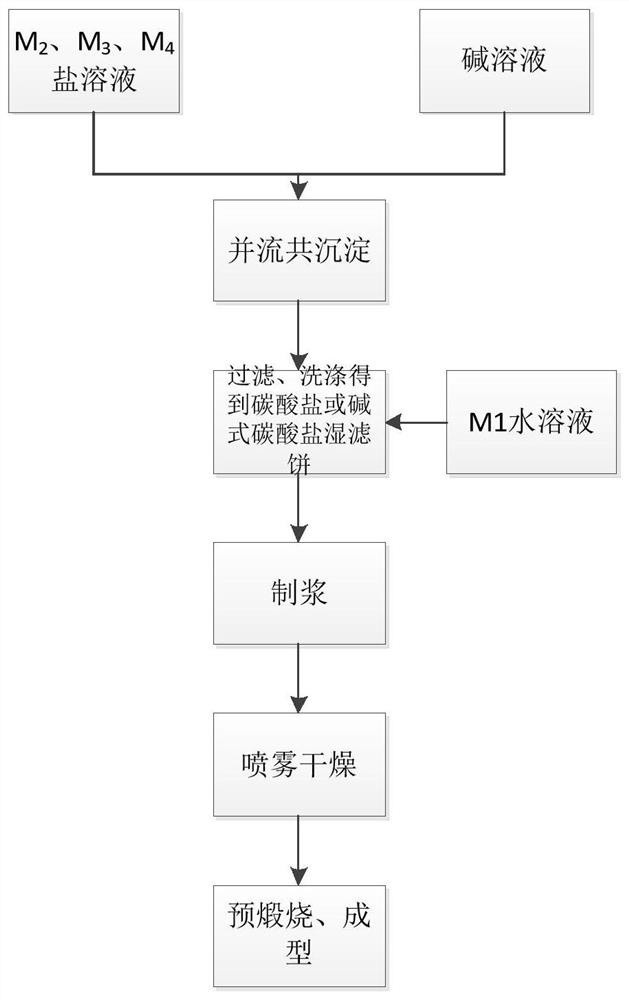

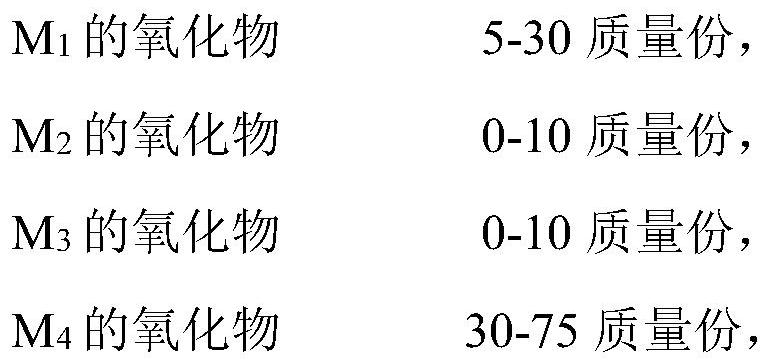

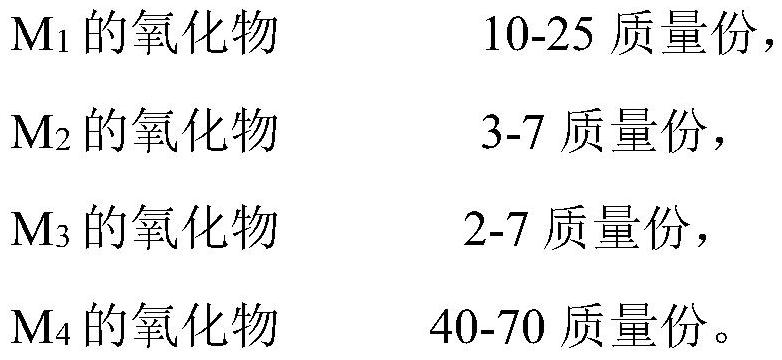

ActiveCN109433222AEnhanced interactionHigh activityHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsSyngasMethanation

The invention relates to a sulfur tolerant methanation catalyst and a preparation method thereof. A preparation method using a precipitation-load-spray drying-roasting preparation technology is concretely used. The catalyst can be applied to synthesis gas sulfur tolerance methanation for producing natural gas. The preparation method disclosed by the invention has the advantages that the ingredients are flexible and adjustable; the raw materials can be simply, conveniently and easily obtained; the preparation process is simple; the cost is low.

Owner:XINDI ENERGY ENG TECH

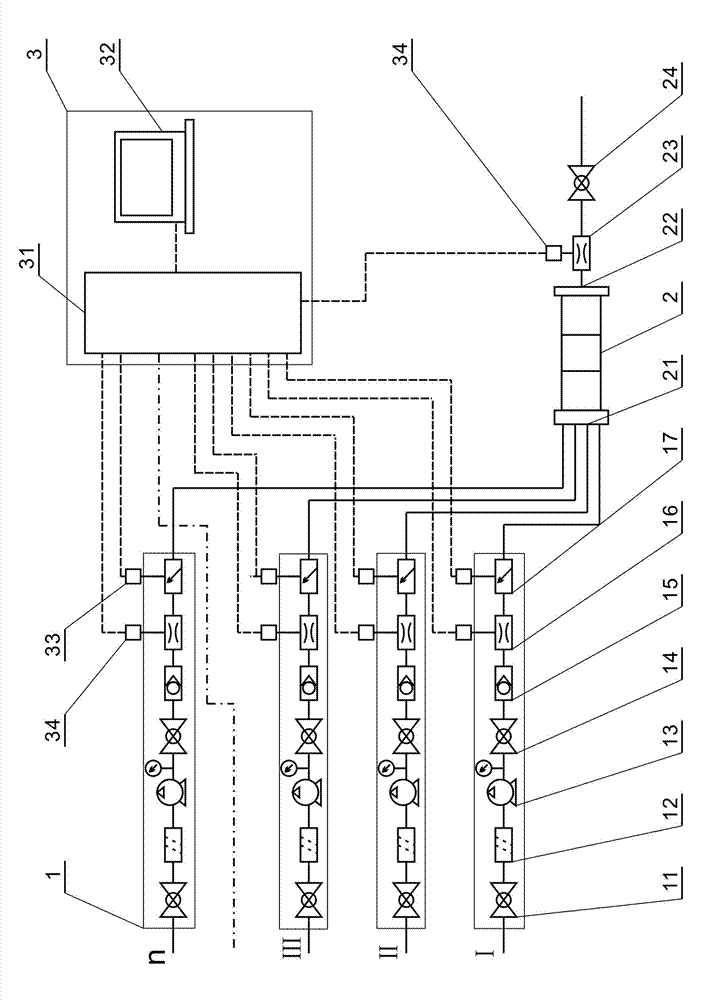

Multi-liquid continuous mixing device

InactiveCN103203803AWell mixedPrecisely control the ratioMixing operation control apparatusProgrammable logic controllerEngineering

The invention discloses a multi-liquid continuous mixing device which comprises feed pipelines, a pipeline static mixer and a control device, wherein each one of a plurality of feed pipelines is sequentially provided with a first manual valve, a filter, a material delivery pump, a second manual valve, a check valve, a flowmeter and a regulating valve. A formula is input into a PLC (Programmable Logic Controller), and after the multi-liquid continuous mixing device disclosed by the invention is started, the uniform mixing of multiple liquid is realized in such a way that the PLC controller automatically controls the opening of the regulating valve on line in real time according to the difference value of a set flow and the actual flow; and the multi-liquid continuous mixing device disclosed by the invention has the characteristics of accurate control of the proportioning of various materials, uniformity in mixing, high production efficiency, realization of continuous and stable production and labor intensity reduction.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

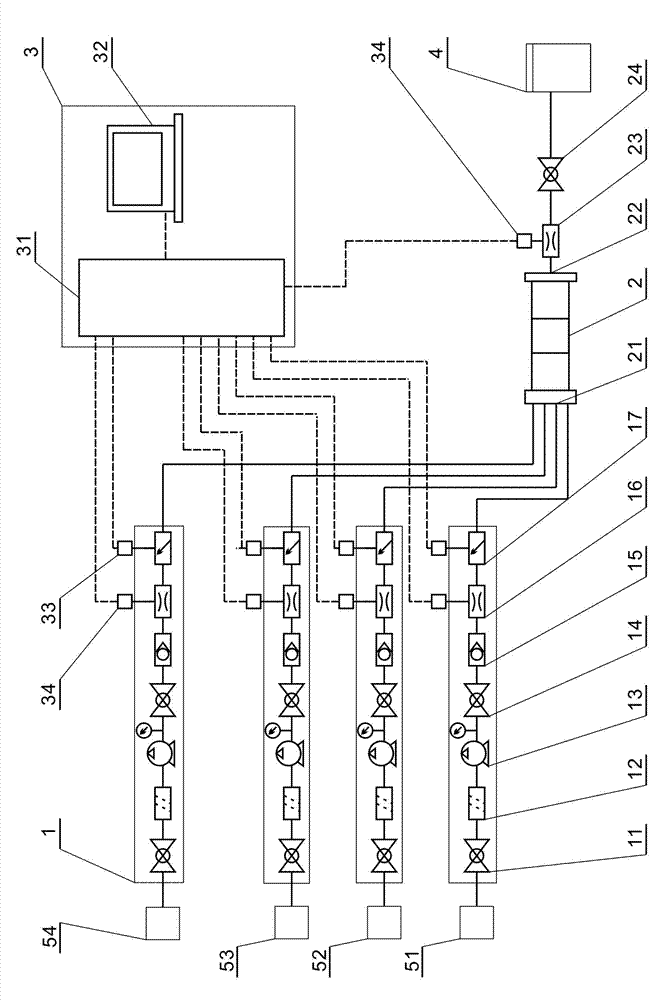

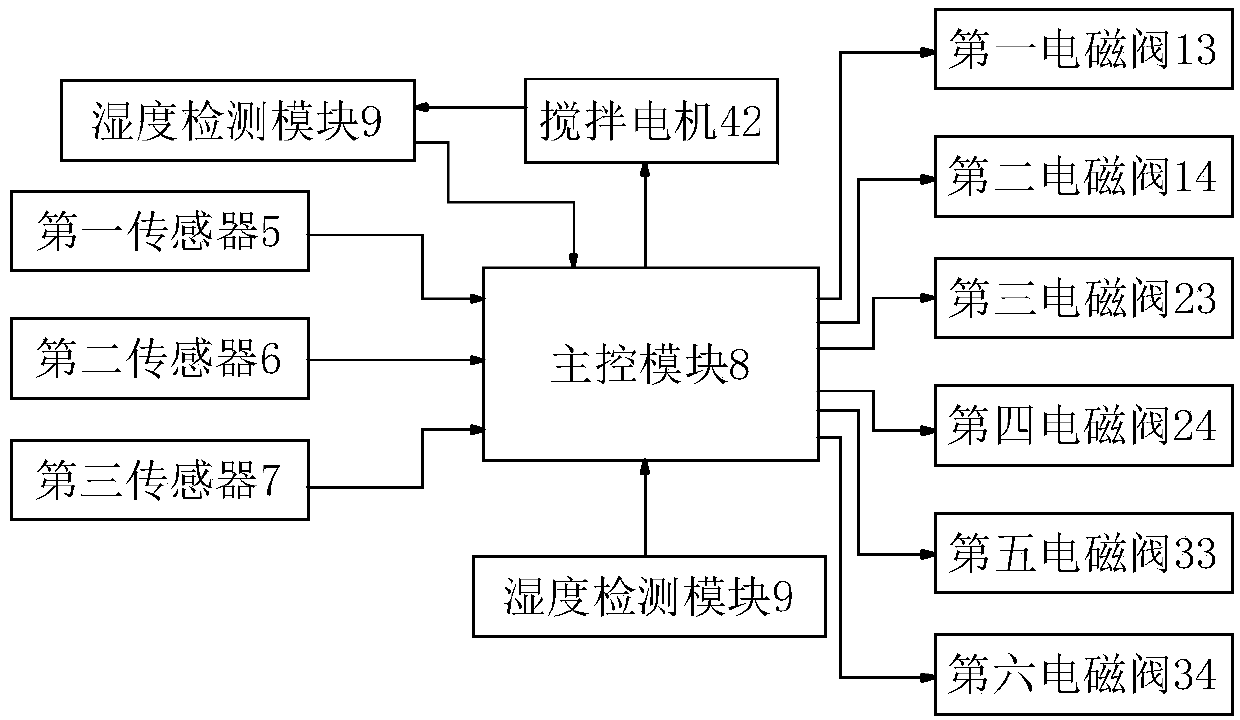

Intelligent concrete mixer

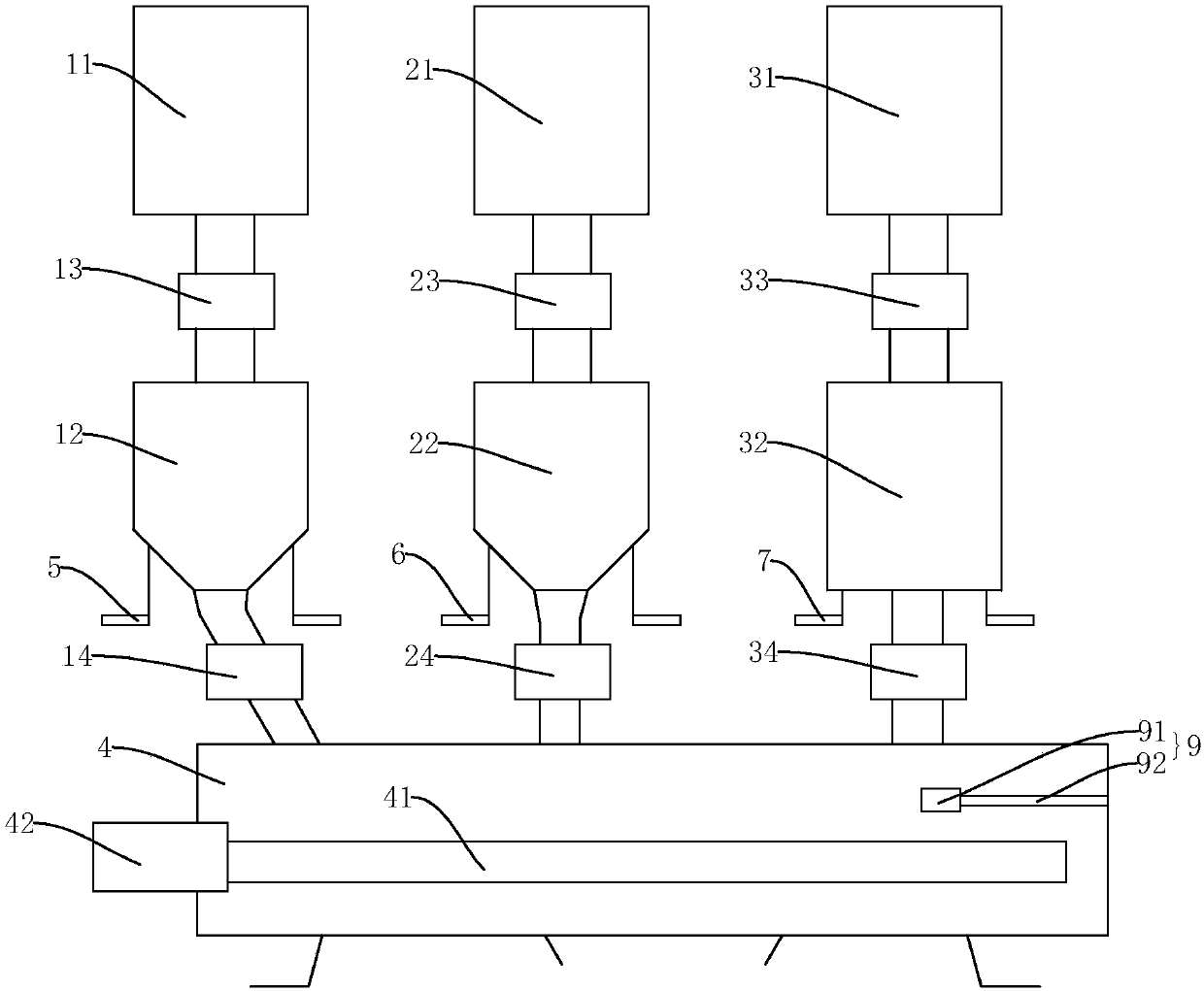

InactiveCN107901223AQuality assurancePrecisely control the ratioIngredients weighing apparatusIngredients storageWater storageAutomatic control

The invention discloses an intelligent concrete mixer which comprises a cementing material storage box, an aggregate storage box, a water storage box, a cementing material preloading box which is provided with a first weight sensor, an aggregate preloading box which is provided with a second weight sensor, a water preloading box which is provided with a third weight sensor, and a mixing box; the communication between the cementing material preloading box and the cementing material storage box, the communication between the cementing material preloading box and the mixing box, the communicationbetween the aggregate preloading box and the aggregate storage box, the communication between the aggregate preloading box and the mixing box, the communication between the water preloading box and the water storage box, and the communication between the water preloading box and the mixing box are controlled through electromagnetic valves; and a master control module is electrically connected with the various weight sensors and the various electromagnetic valves so as to control operation of the various electromagnetic valves according to proportions of three materials. By means of the design, the proportions of the three materials are controlled precisely and automatically, staff simply need to set data as required, the operation is simple, and the quality of concrete is ensured.

Owner:GUANGDONG HUILIPU ROAD & BRIDGE INFORMATION ENG

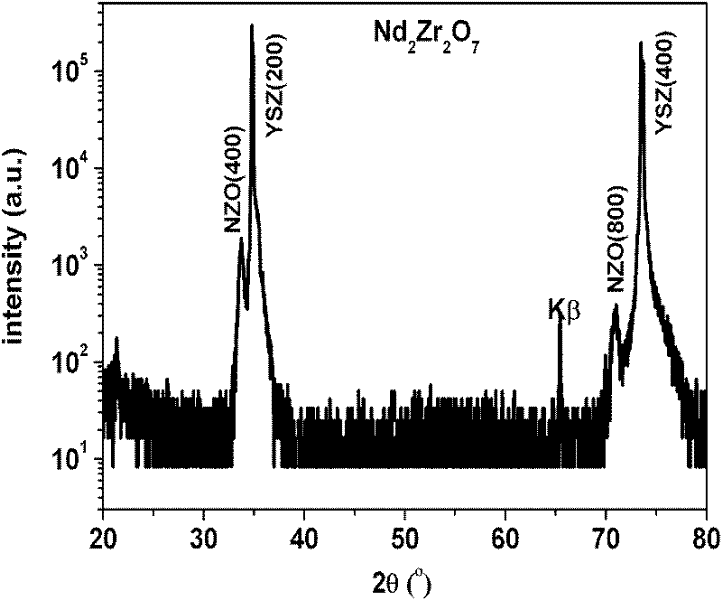

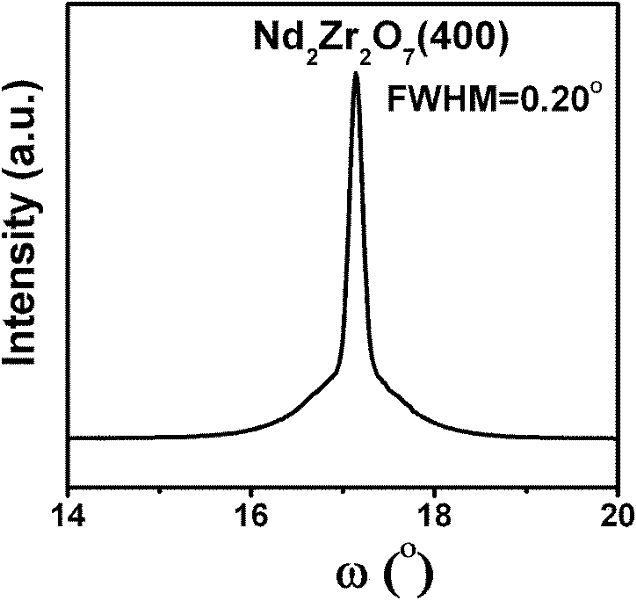

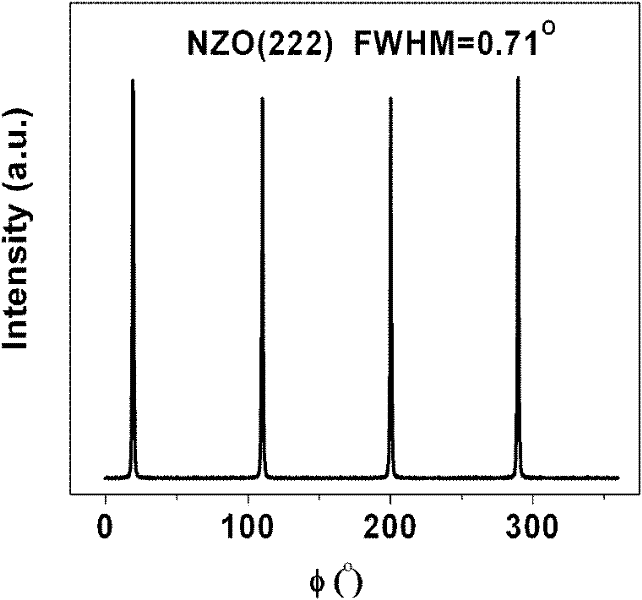

Preparation method of high temperature superconductive coating conductor buffer layer

The invention discloses a preparation method of a high temperature superconductive coating conductor buffer layer, which is characterized in that the invention comprises the following steps: neodymium acetylacetonate or samarium acetylacetone is mixed with zirconium acetylacetonate according to a mol ratio of 1:1, adding an organic solvent to prepare a precursory solution, then performing a spin coating of the precursory solution on a substrate and drying, then placing the dried substrate into a tubular furnace, performing a heat treatment step by step in the condition of flowing mixed atmosphere of argon and hydrogen to obtain a Nd2Zr2O7 buffer layer or a Sm2Zr2O7 buffer layer. The present invention has the advantages of simple technology, low cost, no environment pollution, easy operation and control, and is capable of applying to a large-scale production preparation. The Nd2Zr2O7 buffer layer and the Sm2Zr2O7 buffer layer prepared by using the method of the present invention has favorable c shaft texture and little surface roughness, smooth surface without micro-crack, which is beneficial to the growth of the high temperature superconducting layer on the texture of the buffer layers provided in the invention.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

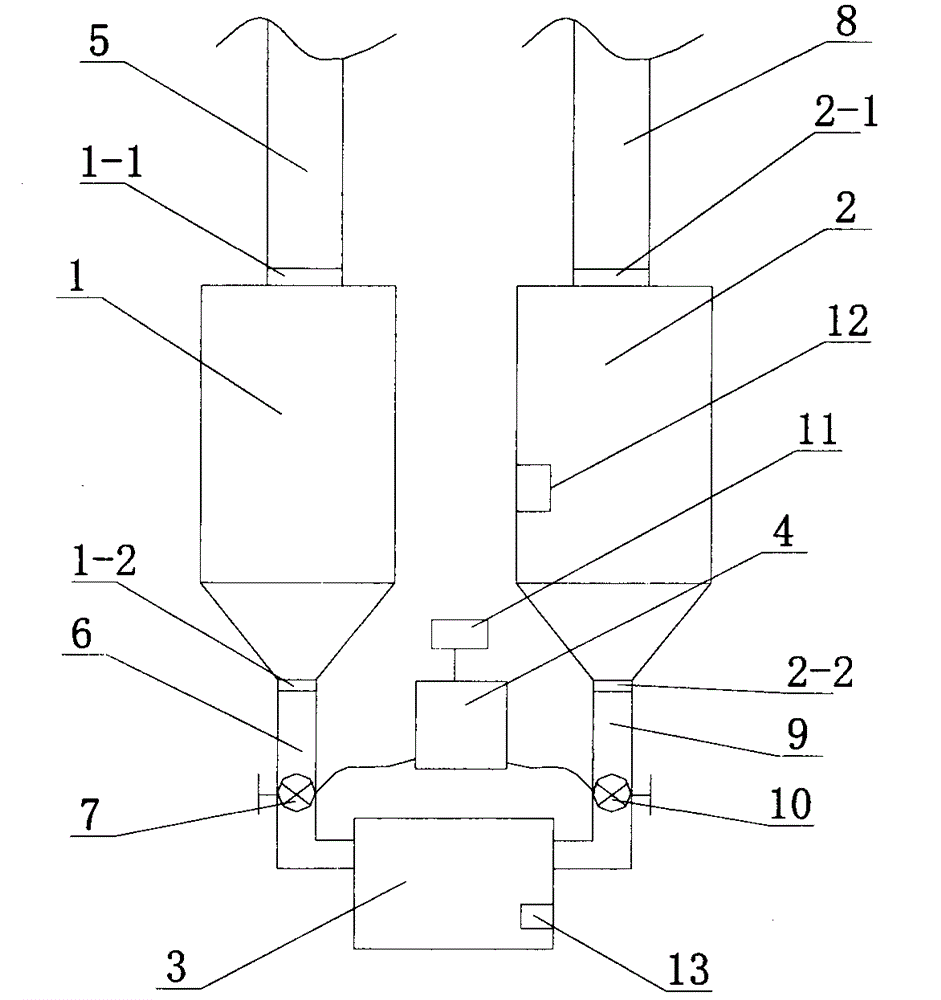

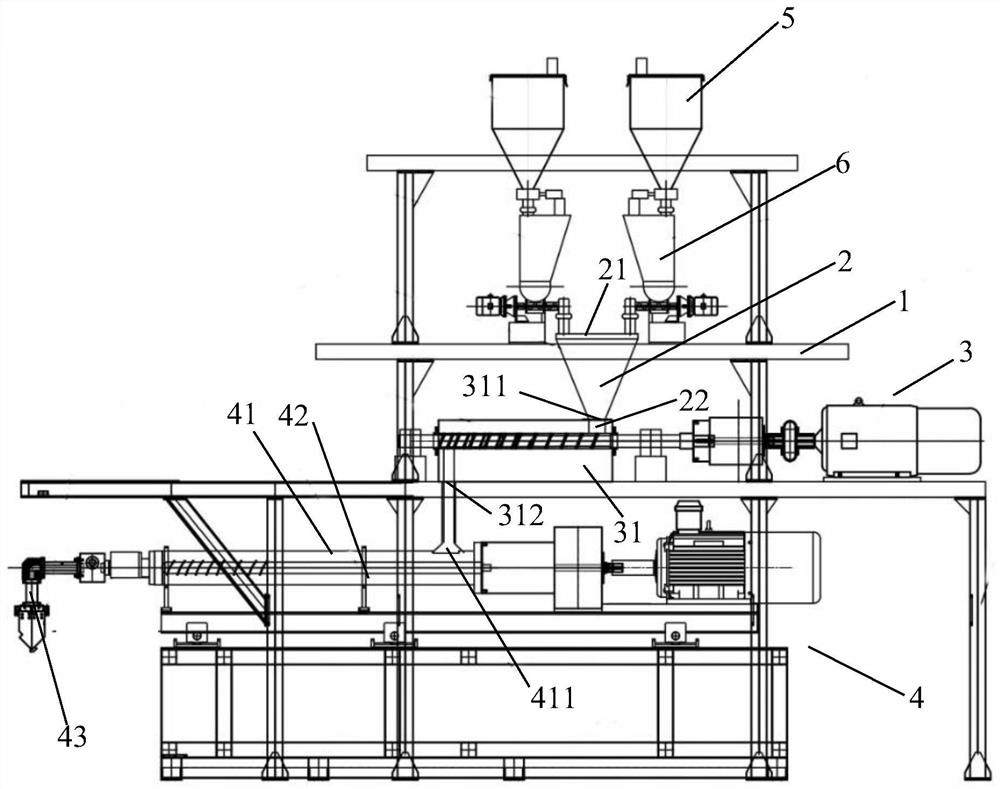

Measuring and mixing device

The invention discloses a measuring and mixing device comprising two material storage boxes. The upper side of each material storage box is provided with a bag opening device. The two material storageboxes are used for storing raw materials or precursors and monitor the weights of the materials in the two material storage boxes in real time correspondingly. The two material storage boxes both measure output materials in a weight reduction method and are connected with two stirring type measuring hoppers correspondingly. An iron remover is further arranged between each material storage box andthe corresponding stirring type measuring hopper. The two stirring type measuring hoppers are used for conducting cooperative measurement on the materials and are connected with a high-speed-flow mixing machine which is used for mixing the materials. The high-speed-flow mixing machine is connected with a transit material box which is used for conducting transit storage and measurement on the materials. The measuring and mixing device achieves production through the full-automatic process and can automatically mix the materials according to ratio and conduct weighing and measurement, all the links act harmoniously, and therefore the production efficiency is improved.

Owner:KAWATA MASCH MFG (SHANGHAI) CO LTD

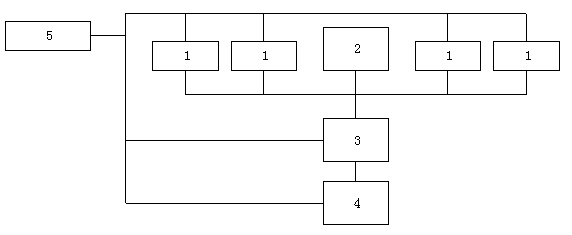

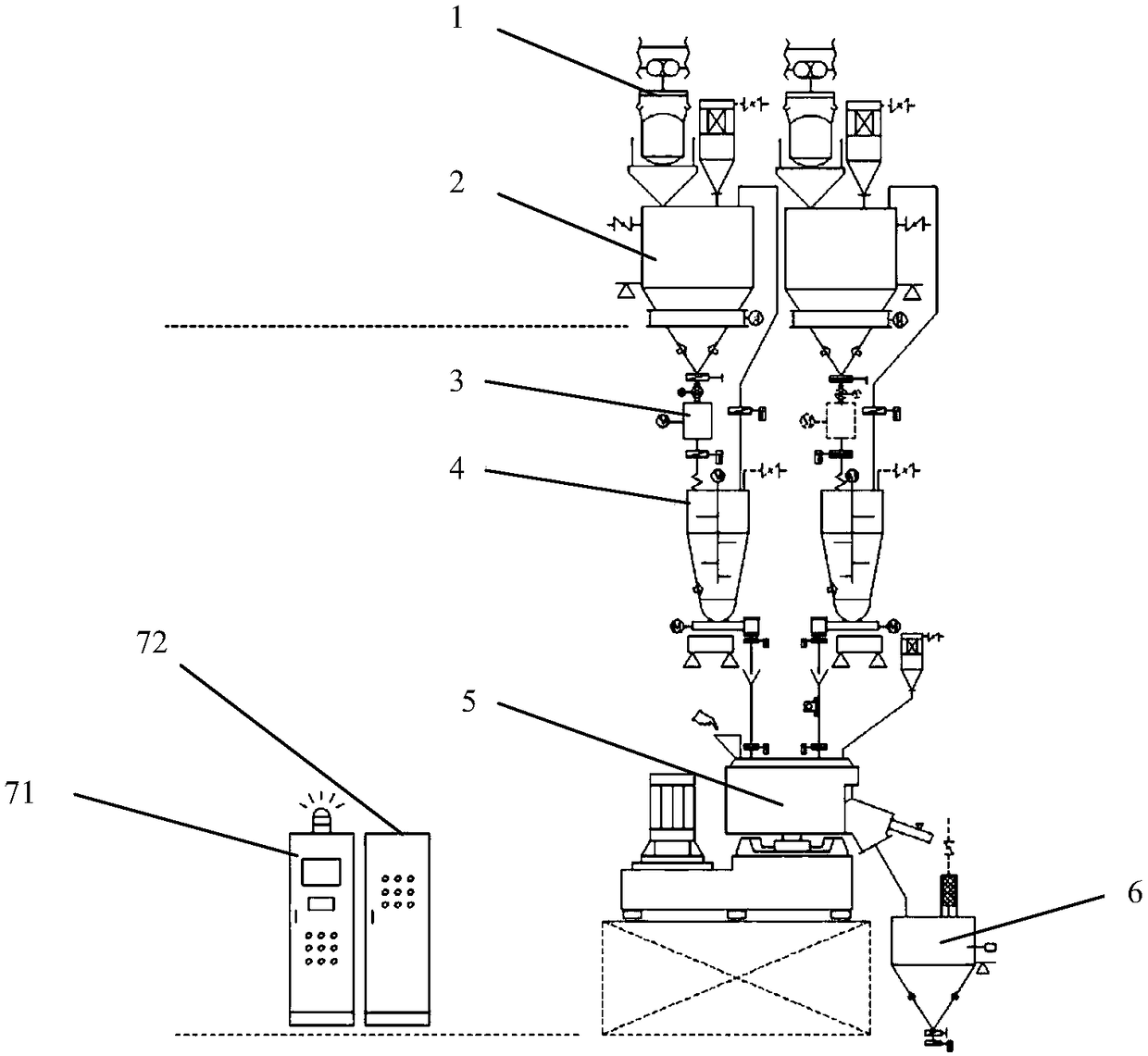

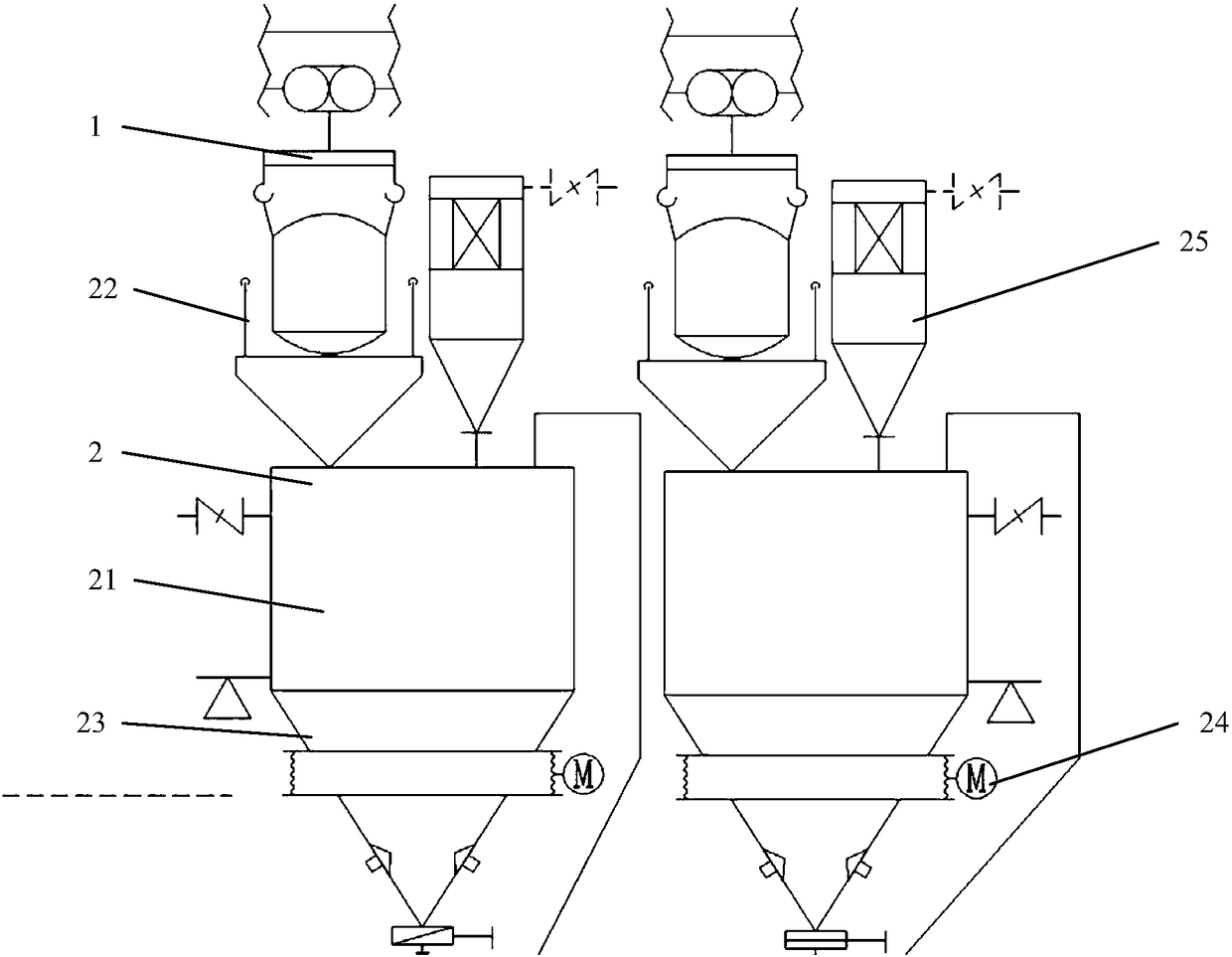

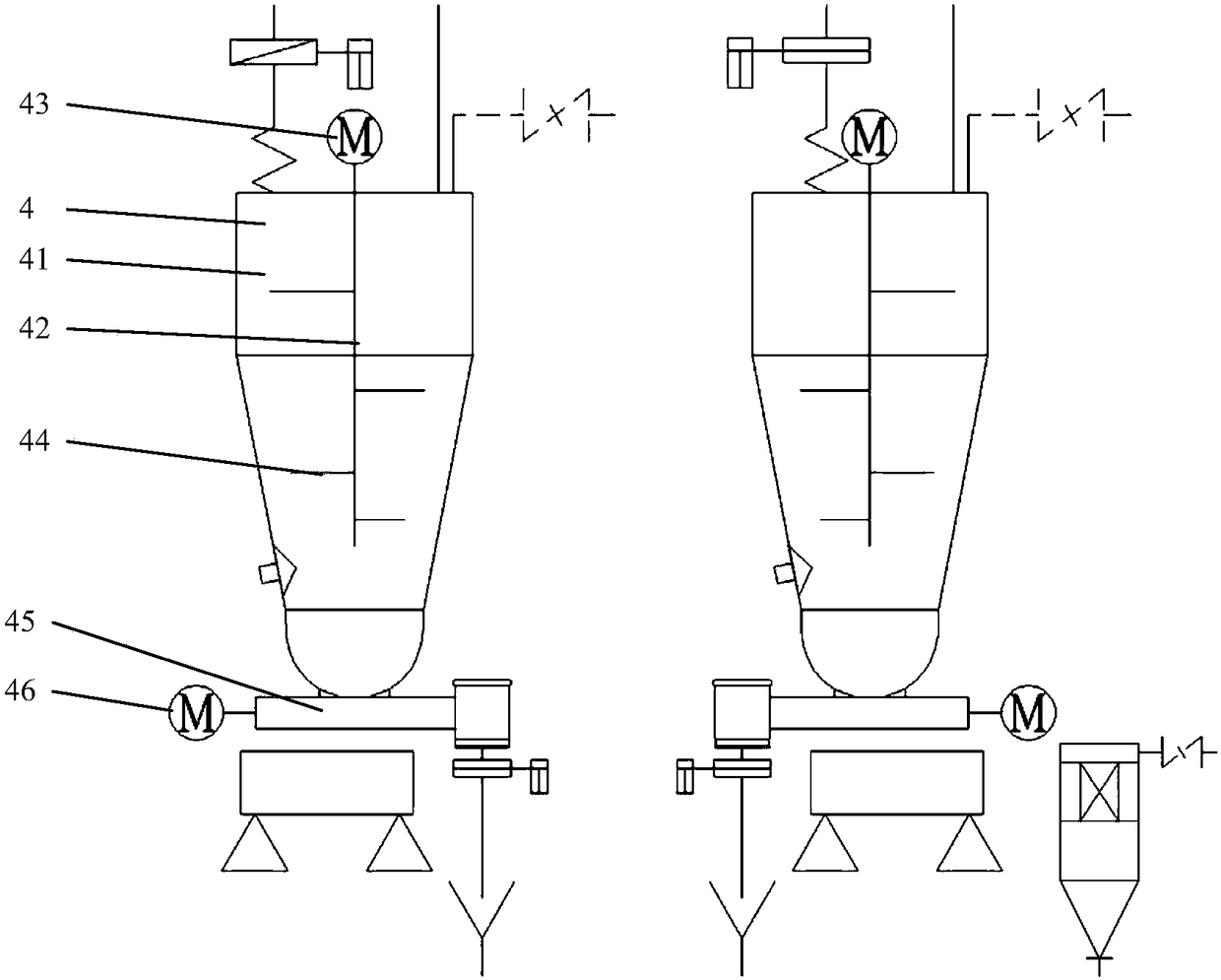

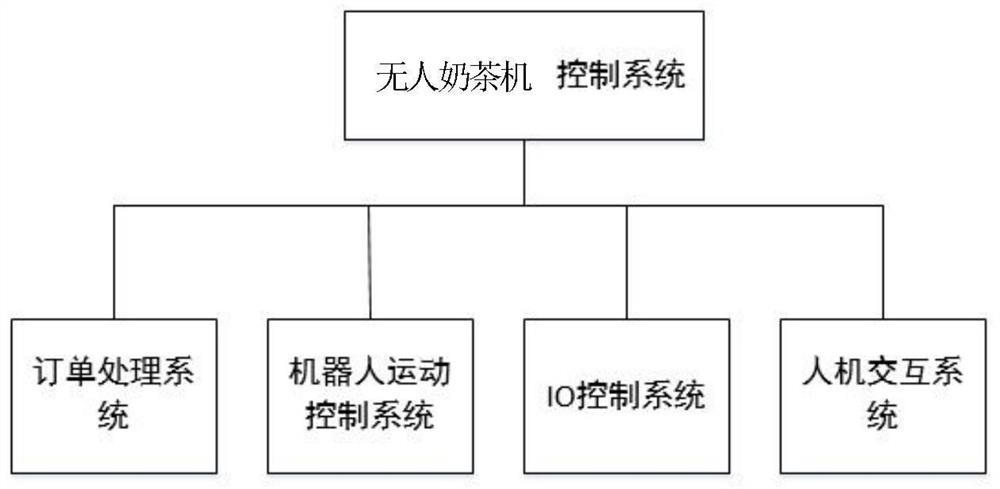

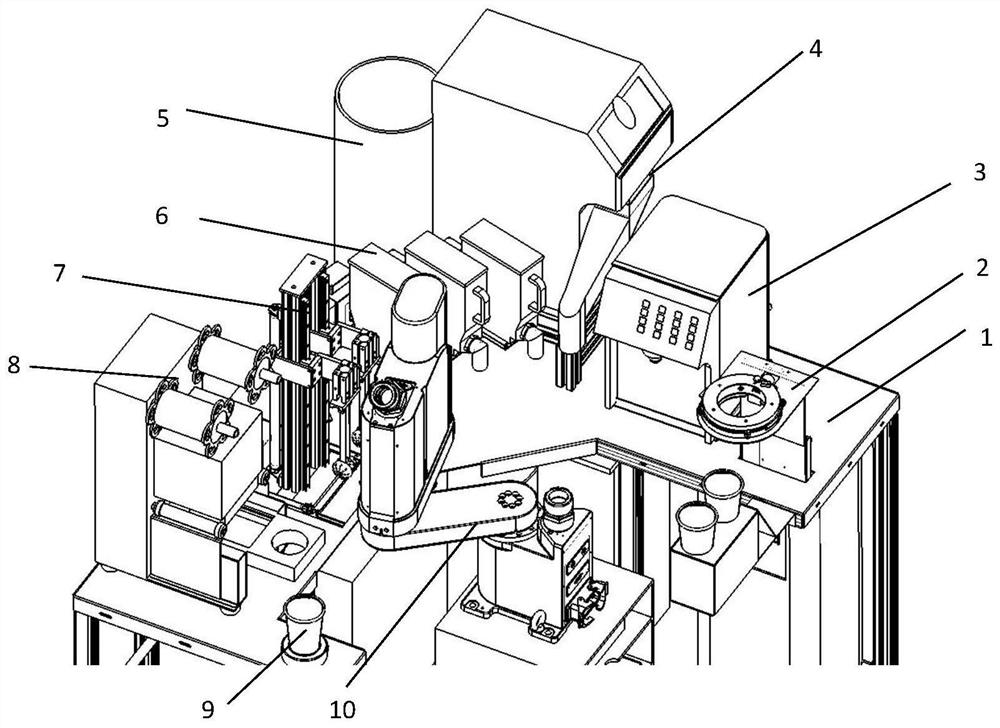

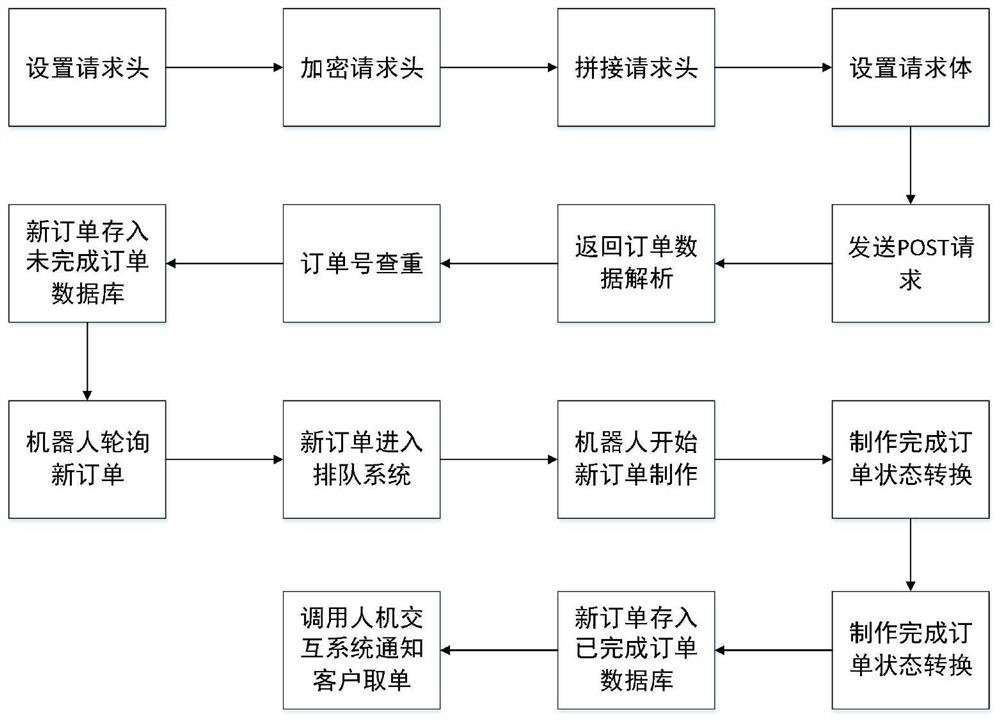

Control system for unmanned milk tea machine

PendingCN113724446ASmall footprintRich categoryBeverage vesselsBuying/selling/leasing transactionsFructoseSystems engineering

The invention discloses a control system for an unmanned milk tea machine, and belongs to the technical field of milk tea automation equipment control. The control system comprises an order processing system, a robot motion control system, an IO control system and a man-machine interaction system, the order processing system comprises an order acquisition system and an order analysis system; the robot motion control system firstly demonstrates and stores position information of different point positions of the robot into the robot controller, the order processing system analyzes and completes an order, the robot is controlled by the upper computer to do joint motion or linear motion to reach a designated position to wait or take materials, and the milk tea making process is completed; and the IO control system is used for controlling the cup falling control mechanism, a fructose quantitative discharging control mechanism, the ice discharging quantitative control mechanism, the solid-liquid separation control mechanism, the multiple liquid quantitative discharging mechanisms and the milk tea discharging port opening and closing mechanism. The equipment can control the quantitative output of various raw materials of milk tea, and the addition amount and the addition sequence of the raw materials can be freely added by matching with a robot.

Owner:杭州千岛湖瑞淳机器人研究院有限公司

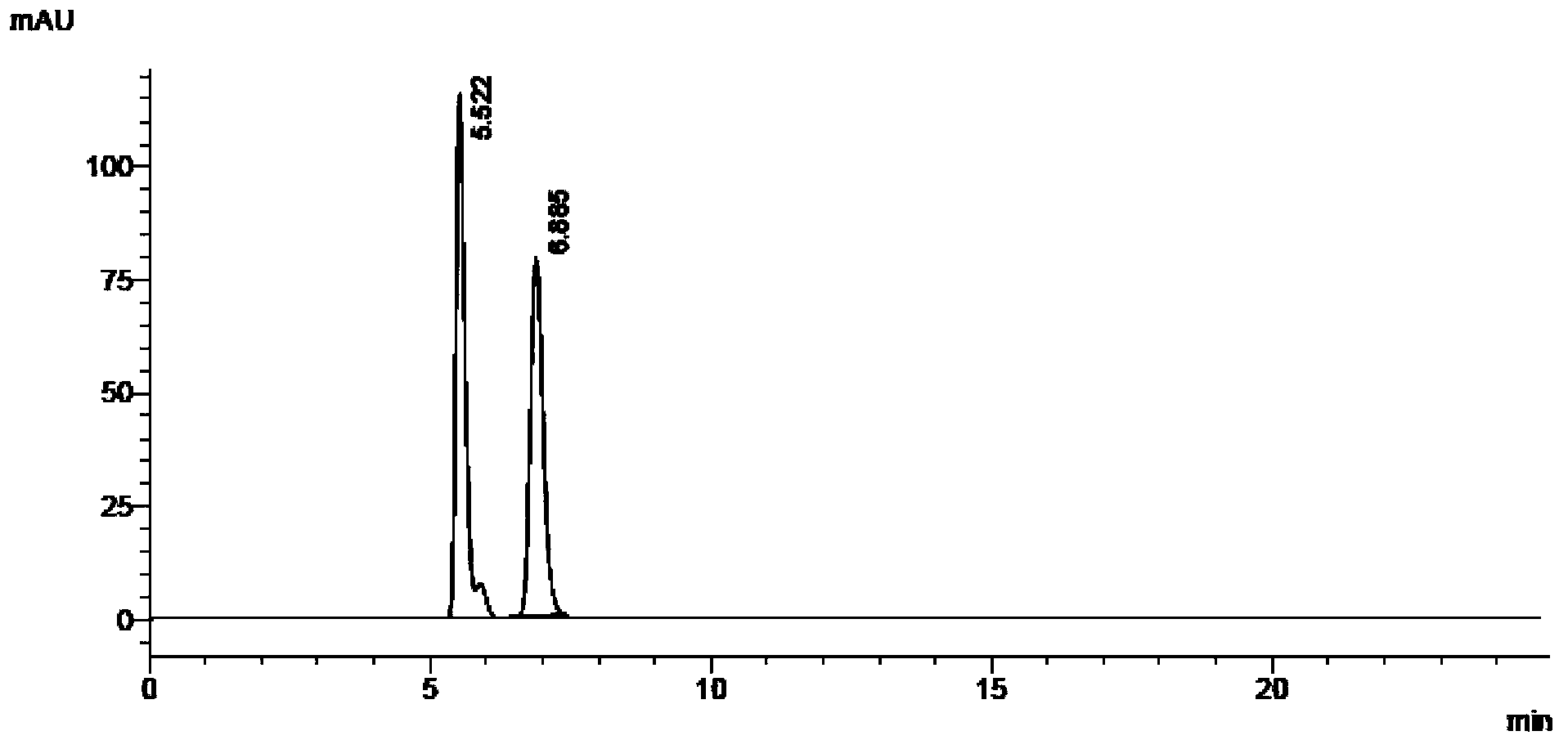

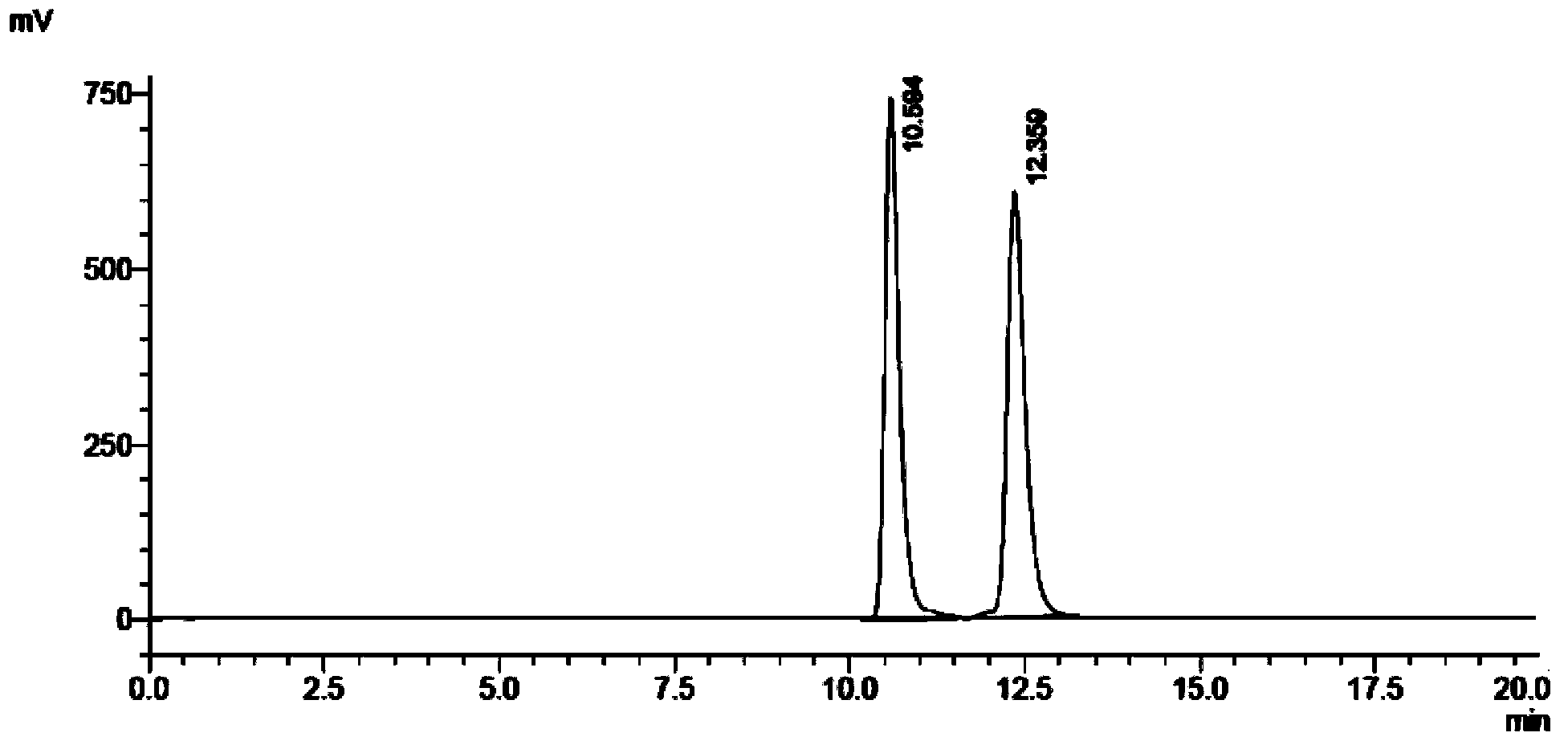

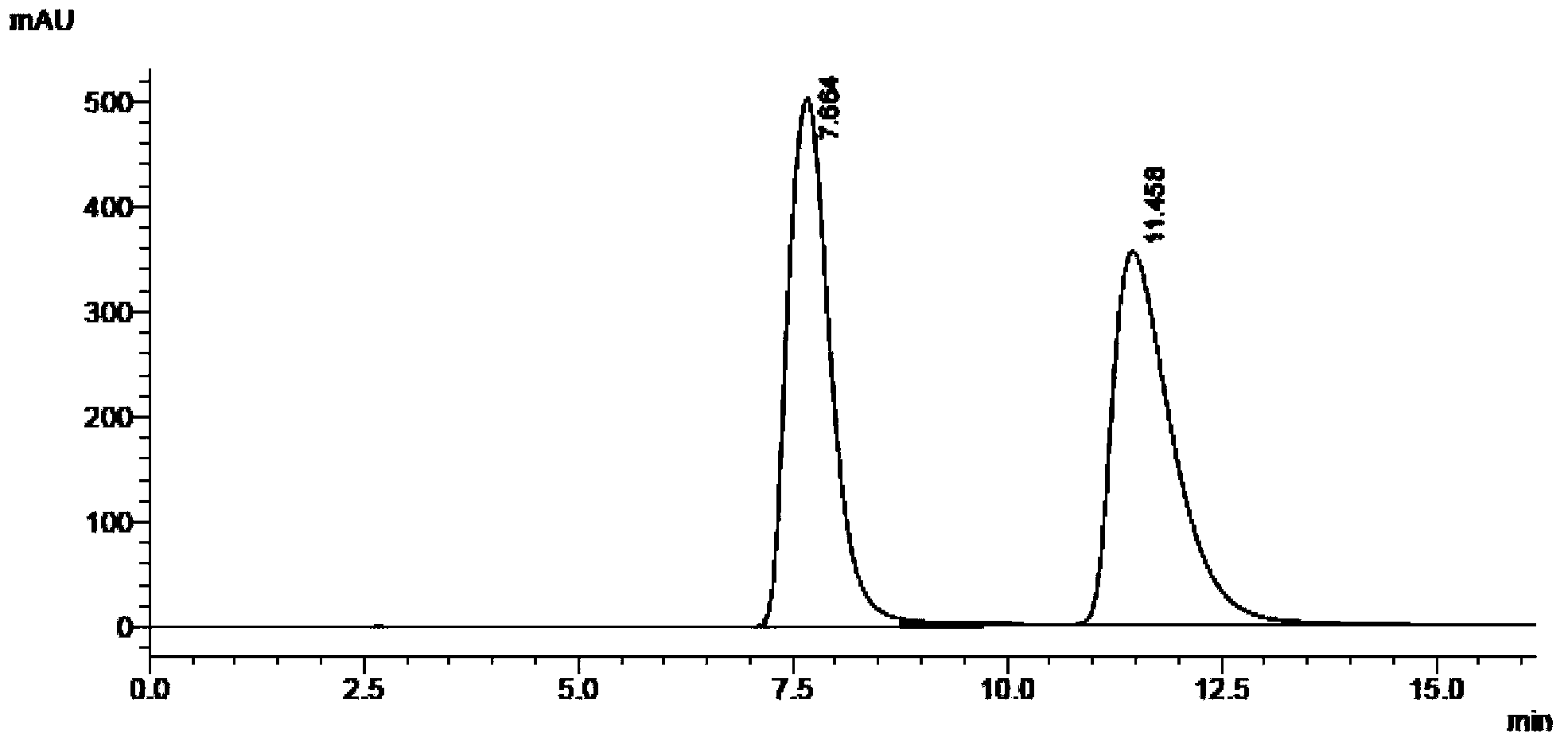

Analysis method for bisindole compound optical isomer

ActiveCN103383380ASimple and fast operationEasy to operateComponent separationSolventChromatography column

The invention aims to provide a high performance liquid chromatography method for analysis of a tetrahydroindole compound and realizes chiral analysis determination of the tetrahydroindole compound for the first time. According to a technical scheme adopted by the invention, the method for analysis of a bisindole compound optical isomer is characterized in that: the analysis method is high performance liquid chromatography, amylose or a cellulose derivative is taken as a stationary phase chiral chromatographic column, a normal phase solvent is adopted as a mobile phase, the detection wavelength is 254nm, and the analysis is carried out at room temperature. By employing different types of chiral columns to separate two bisindole compounds, the method provided in the invention has the advantages of simple and rapid operation. And a method for separation of medicine and pesticide intermediates is provided.

Owner:枣庄市新星钢结构有限公司

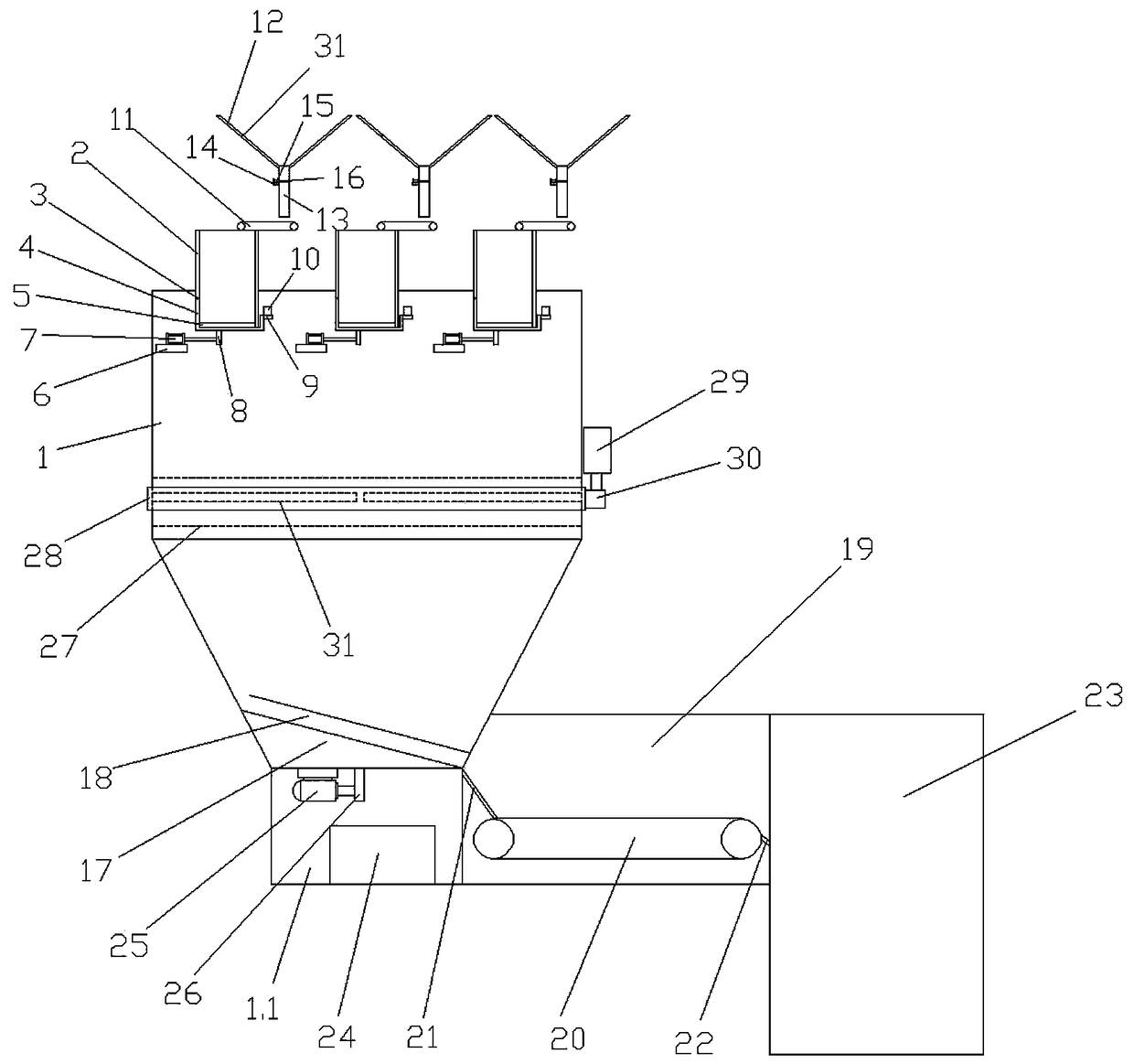

Automatic material weighing and agitating device for bubble blowing machine for glassware

InactiveCN108261961APrecise deliveryPrecisely control the ratioRotating receptacle mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses an automatic material weighing and agitating device for a bubble blowing machine for glassware. The automatic material weighing and agitating device comprises a material mixinghopper, wherein the material mixing hopper is provided with one group of weighing hoppers; discharge holes in the lower sides of the weighing hoppers are connected with end covers in a hinging manner; the end covers are connected with attraction plates; one group of electromagnets is also mounted in the material mixing hopper; the electromagnets all correspondingly attract the corresponding attraction plates; a first air cylinder is connected below each weighing hopper; the first air cylinders are connected with push plates; the push plates correspondingly cooperate with the end covers; weighing scales are mounted in the end covers; the upper sides of the weighing hoppers are provided with feed conveying belts; feed hoppers are correspondingly arranged above the feed conveying belts; thebottom of the material mixing hopper is provided with a discharge hole; the outer side of the discharge hole is provided with a material guide box; the material guide box is correspondingly cooperatively connected with an agitating device. The automatic material weighing and agitating device has the advantages that the device can be used for weighing and feeding various raw materials respectively,and is used for accurately controlling the feed quantity of each raw material, accurately controlling the mixing proportion of the raw materials and conveying the raw materials to the agitating device to carry out agitation through a material conveying device, and the work efficiency is improved.

Owner:蚌埠冠平机械有限公司

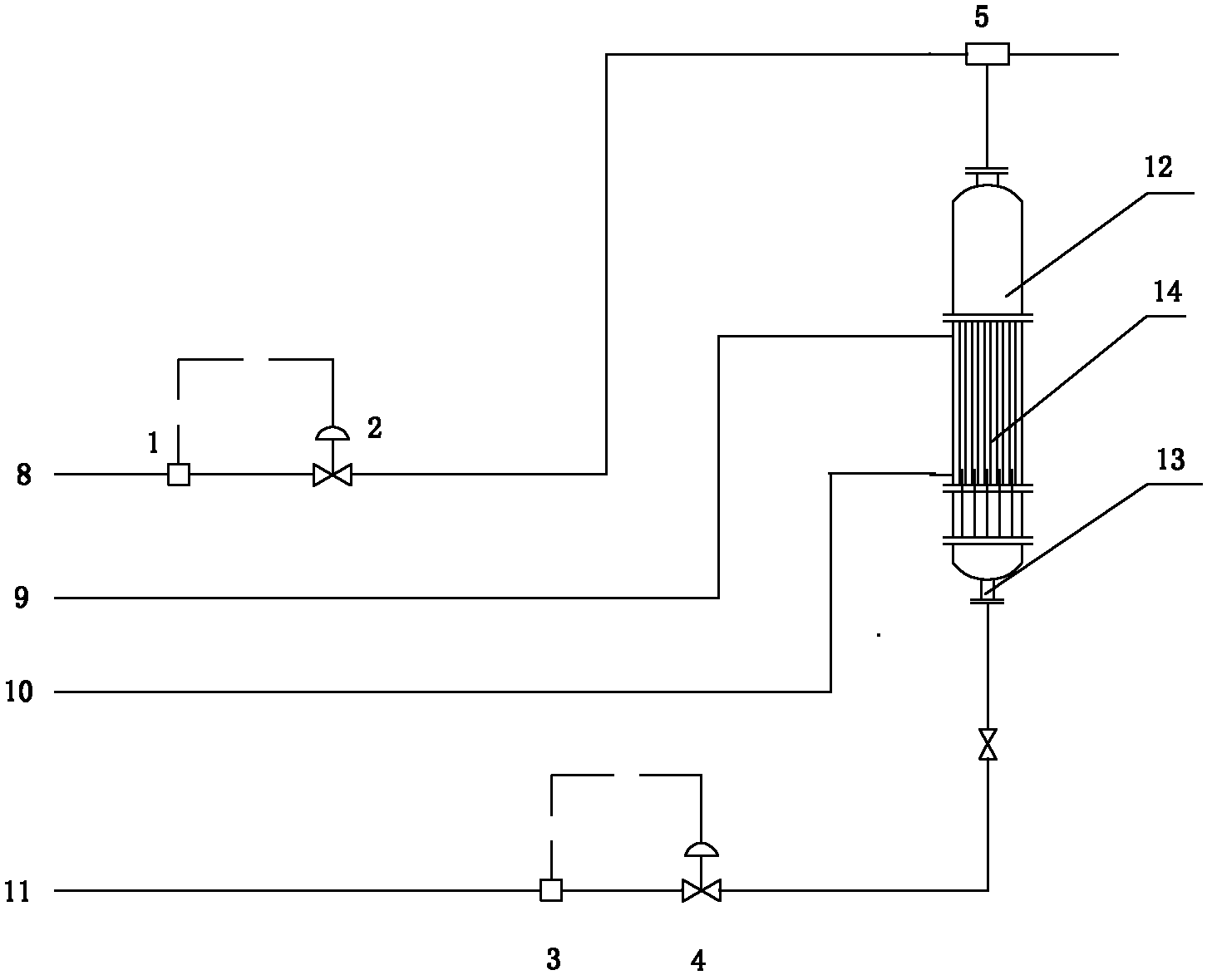

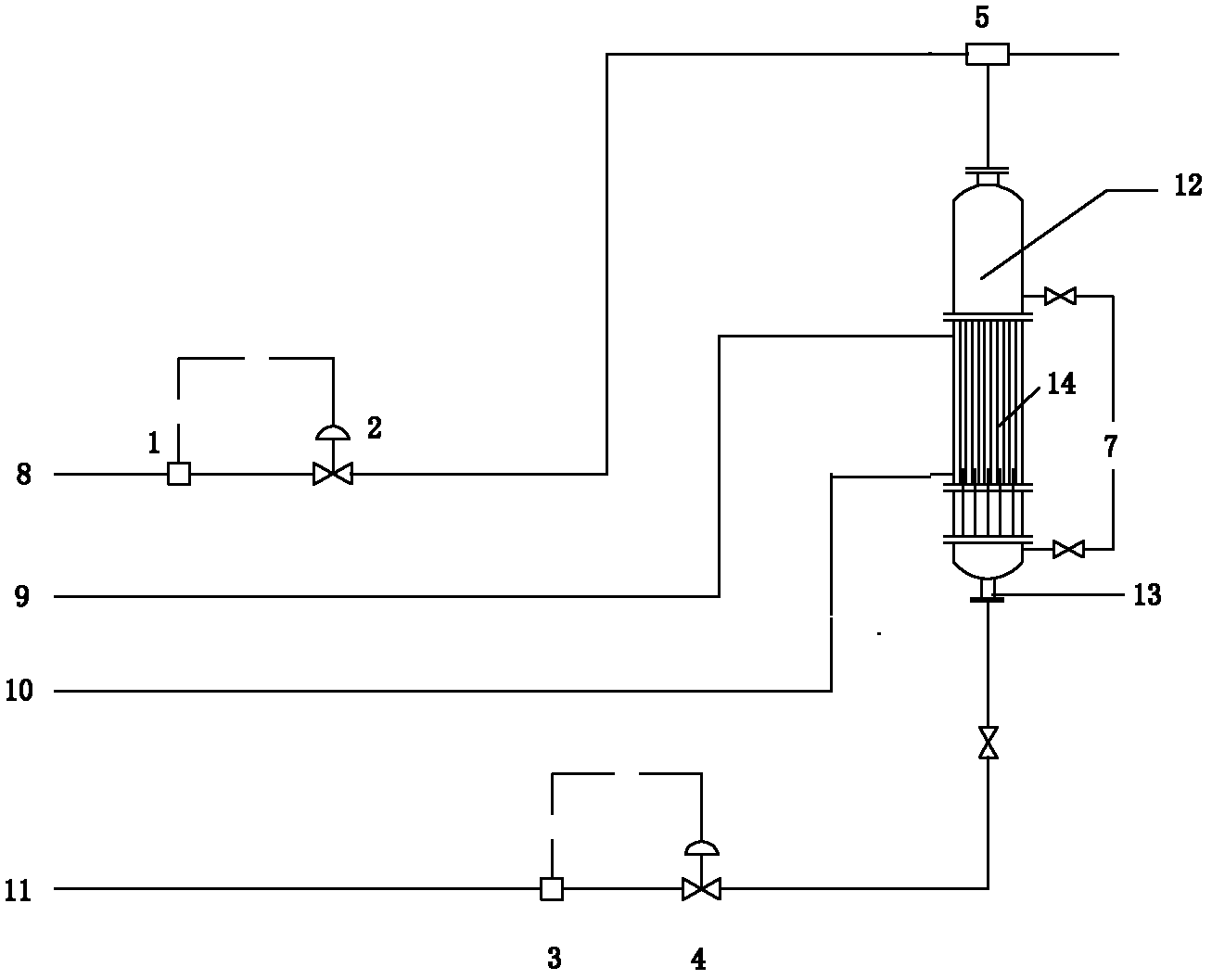

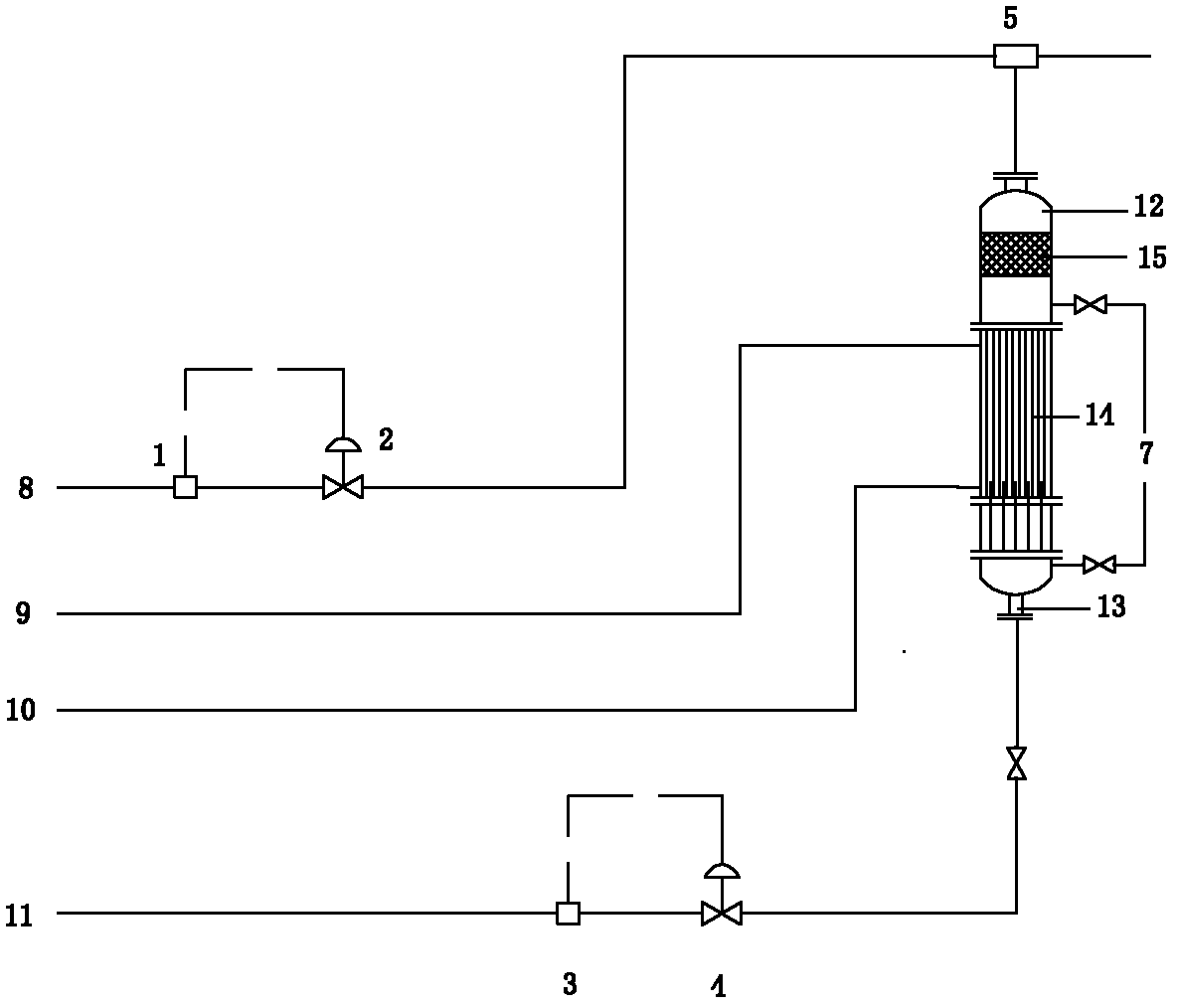

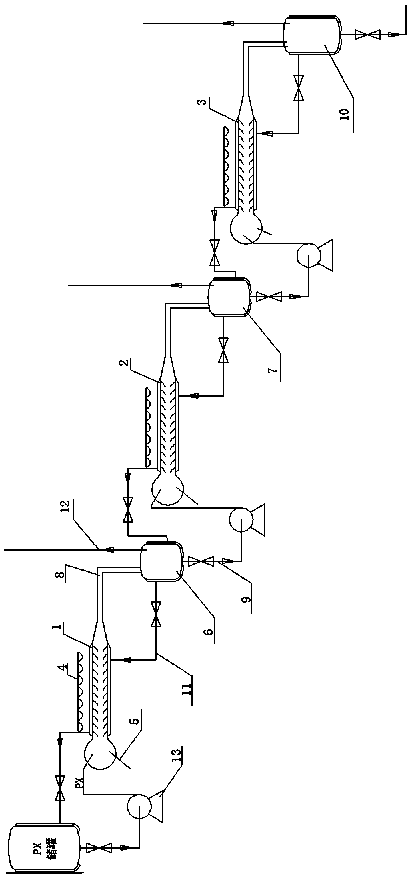

New process for preparing p-xylylene dichloride by adopting novel reaction equipment

PendingCN108409528AReduce by-product formationIncrease production capacityHalogenated hydrocarbon separation/purificationChemistryBenzyl chloride

The invention discloses a new process for preparing p-xylylene dichloride by adopting novel reaction equipment. The novel reaction equipment comprises a chlorinator, a gas-liquid separator, a crystallizer and the like. The process for preparing the p-xylylene dichloride by adopting the novel reaction equipment comprises the following steps: (1) reaction; and (2) separation by crystallization. Theprocess has the beneficial effects that by adopting the novel reaction equipment, p-xylene and chlorine gas can be thoroughly and uniformly mixed, and excessive chlorination caused by high local chlorine concentration is avoided; chlorination is carried out in three stages, a reactant proportioning ratio of each stage is accurately controlled, the single-pass conversion ratio of p-xylene is higherthan 96%, the total selectivity of p-xylylene dichloride and p-methyl benzyl chloride in a chlorination solution reaches up to 98%, and the content of p-xylylene dichloride reaches up to 70% or more;a used LED lamp, as a light source, for initiating reaction is proper in wavelength and is high in initiating efficiency, the reaction temperature can be greatly lowered, and side reactions can be effectively reduced; and the chlorination solution is low in impurity content, the product is not required to be purified by a vacuum rectification process, and the product with the content of 99% or more can be obtained by once simple crystallization.

Owner:青岛和兴精细化学有限公司

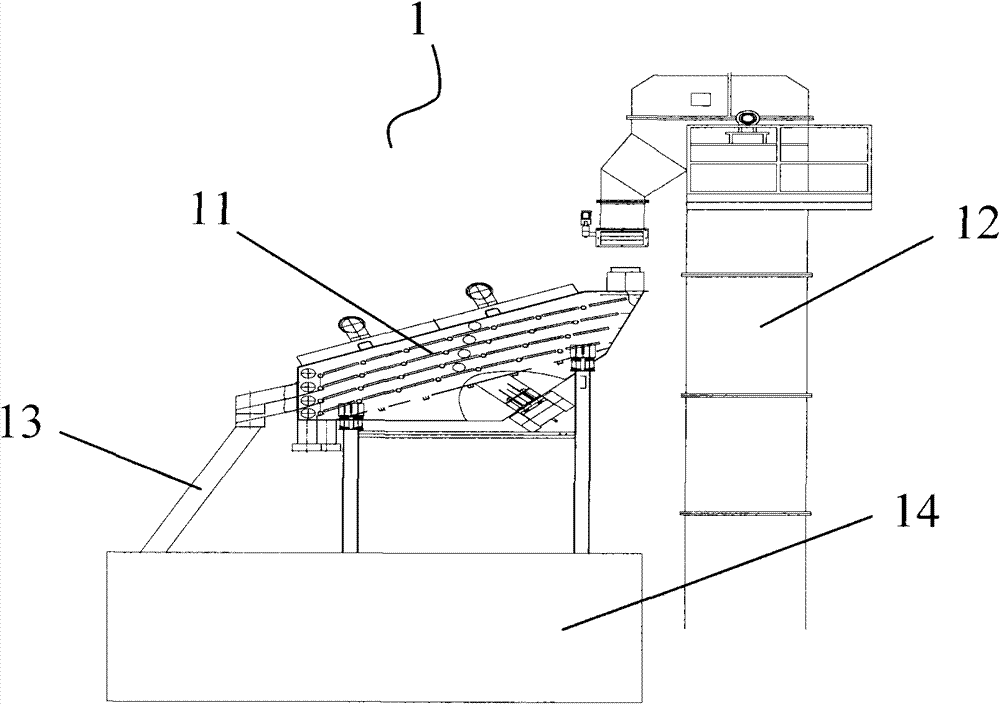

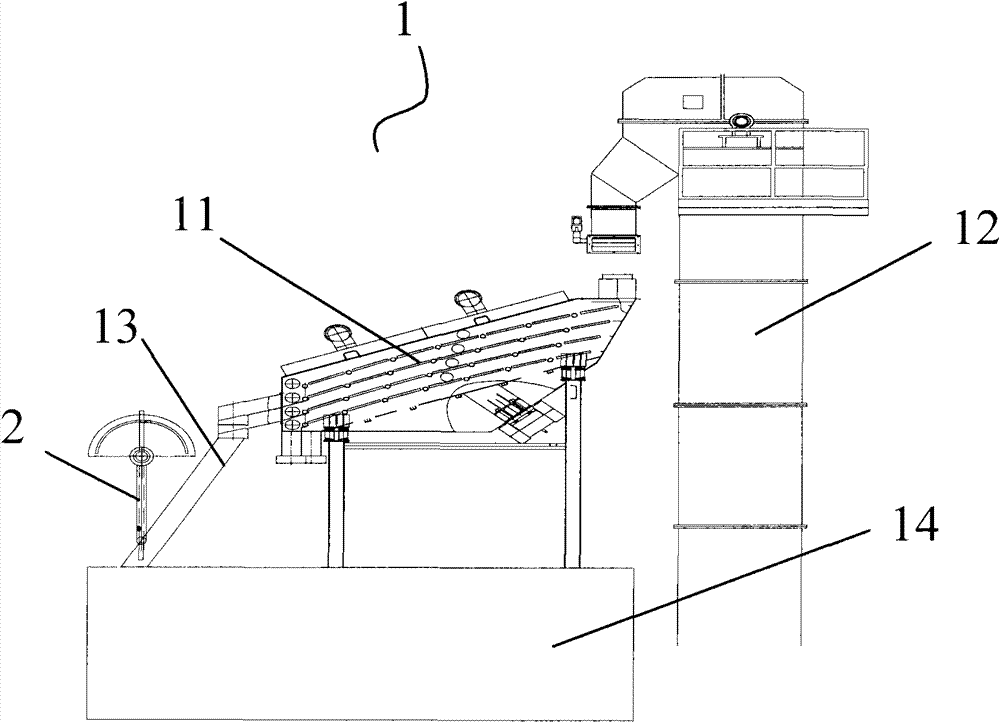

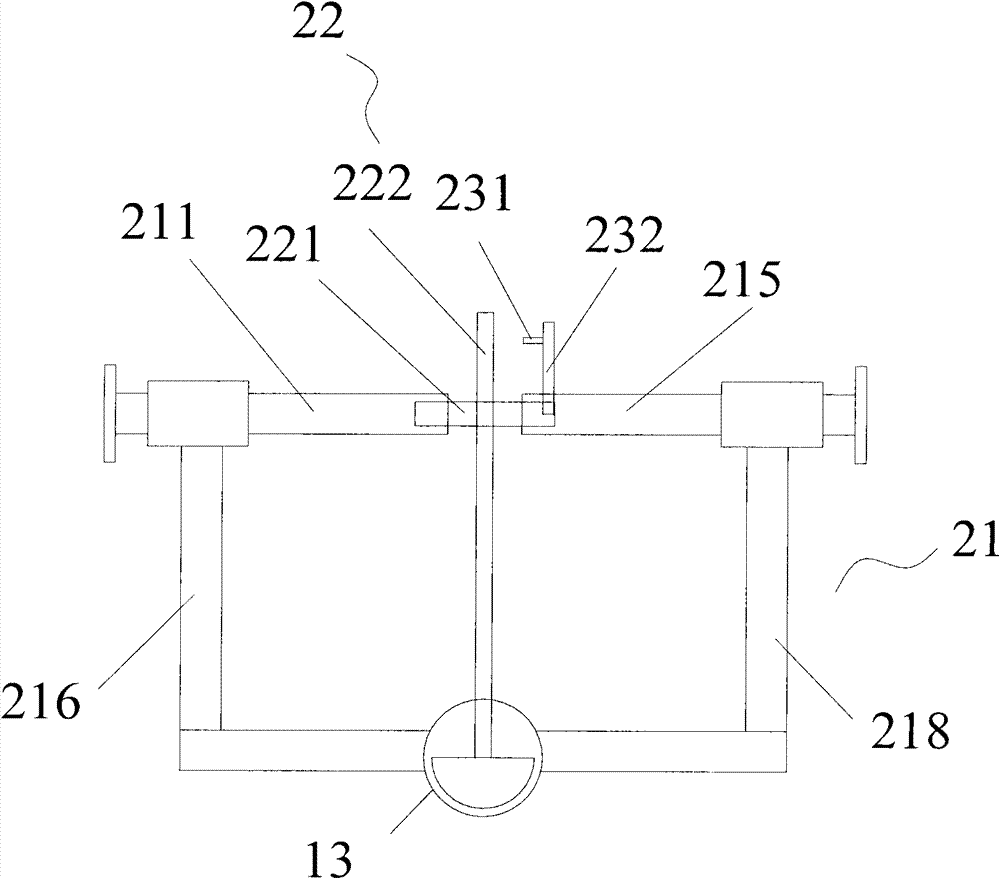

Vibration screening mechanism and early warning device for vibrating screen mesh rupture

InactiveCN101884977BTo achieve the early warning effectPrecisely control the ratioSievingScreeningScreening effectEngineering

The invention provides an early warning device (2) for vibrating screen mesh rupture in a vibration screening mechanism (1). The early warning device comprises a supporting part (21), a rotating arm part (22) and a sensor (231), wherein the supporting part (21) is fixed on a discharging conduit (13) of the vibration screening mechanism (1); the rotating arm part (22) is provided with a pivoting part which is pivoted with the supporting part (21), and a first end which is arranged in a flow path of screened materials; and the sensor (231) is arranged on the supporting part (21) or the rotatingarm part (22) and is used for sensing the pivoting position of the rotating arm part (22) and triggering an early warning signal. The early warning device realizes the early warning effect on the screen mesh rupture according to the flow rate of screened sand discharged from the discharging conduit, avoids inefficient work of a worker for checking the screen mesh every day, realizes real-time monitoring of the screening effect, can timely early warn when the screen mesh is failed, is convenient for the worker to timely repair and replace the screen mesh, and can more accurately control the proportioning of the mixed raw materials.

Owner:SANY HEAVY IND CO LTD (CN)

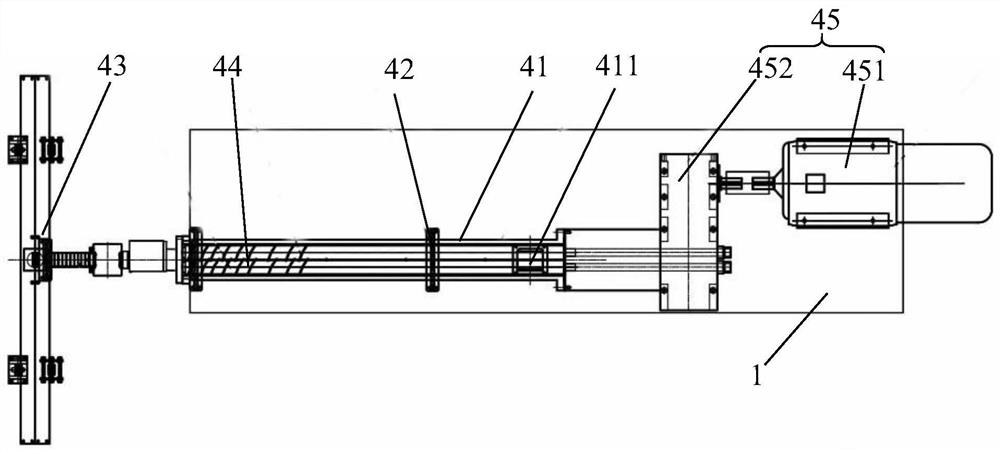

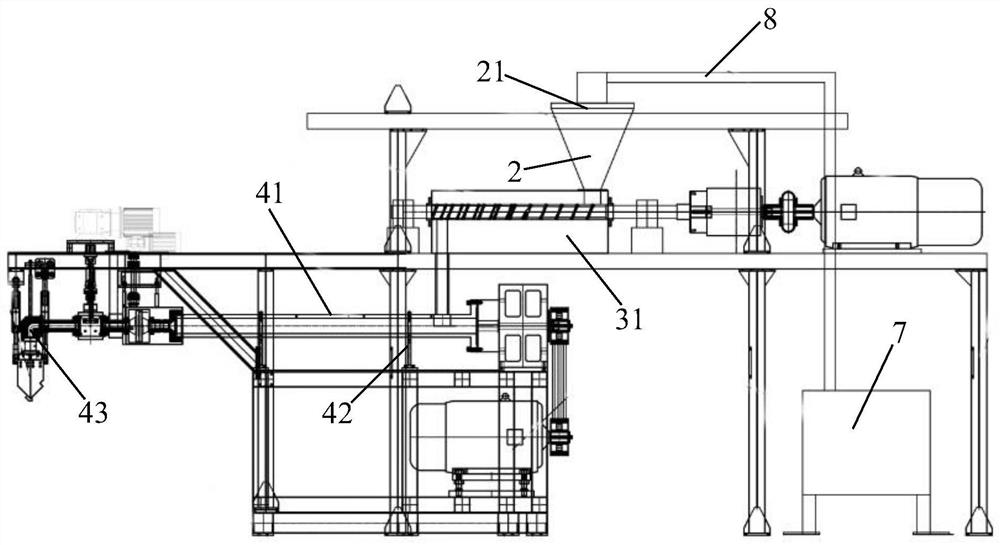

Production equipment and process for preparing breathable film through one-step method

PendingCN111660522AGood mixing and plasticizing effect at low temperatureReduce coke phenomenonMolten statePlasticulture

The invention discloses production equipment and process for preparing a breathable film through an one-step method. The production equipment comprises a rack, a collecting hopper, a double-rotor continuous internal mixer and a casting machine; the collecting hopper is fixedly installed on the rack, a feeding port is formed in the upper end of the collecting hopper, and a first discharging port isformed in the lower end of the collecting hopper; an internal mixing barrel on the double-rotor continuous internal mixer is fixedly installed on the rack, and the internal mixing barrel is located below the material collecting hopper; a first material receiving opening and a second material discharging opening are formed in the internal mixing barrel, and the first material receiving opening communicates with the first material discharging opening; a casting screw cylinder on the casting machine is arranged on the rack through a supporting frame, a second material receiving opening is formedin the casting screw cylinder, and the second material receiving opening communicates with the second discharging opening through a pipeline; and the tail end of the casting screw cylinder is connected with a casting mold. Through the stirring of the internal mixing cylinder, the raw material is fully and uniformly mixed and primarily plasticized, and continuously enters the casting screw cylinder in a semi-molten state in the mixing motion to be plasticized again, so that the raw material low-temperature mixing plasticizing effect is good, and the coke phenomenon in the casting screw cylinder and the casting mold can be reduced.

Owner:佛山市新三合塑料薄膜制造有限公司

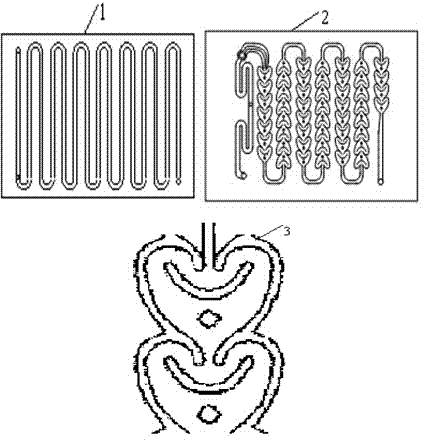

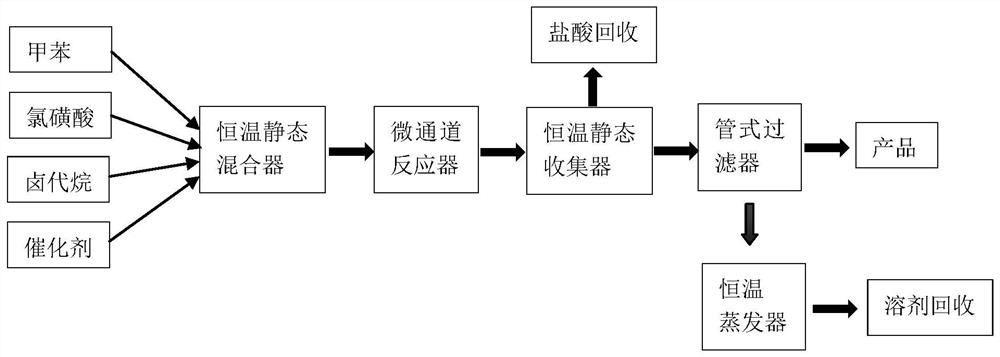

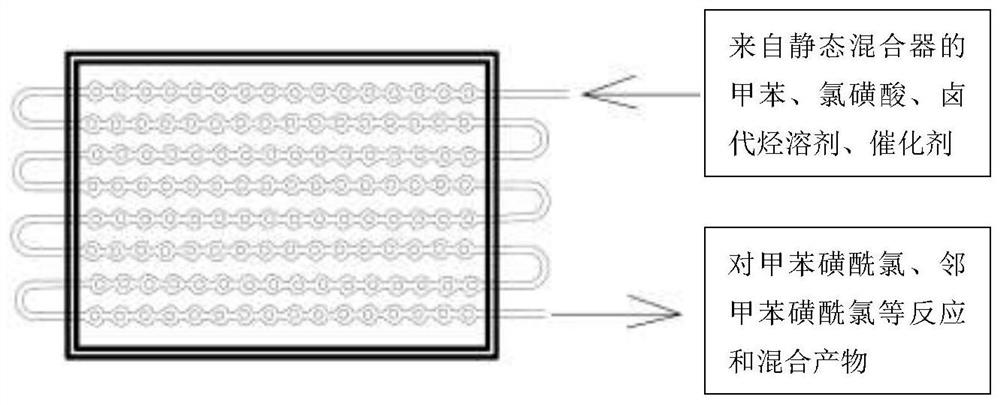

Method for continuously synthesizing paratoluensulfonyl chloride by using microchannel reactor

ActiveCN113277965APrecisely control the ratioWell mixedChemical/physical/physico-chemical microreactorsSulfonic acid preparationSulfonic acidAcyl chloride

The invention discloses a method for continuously synthesizing paratoluensulfonyl chloride by using a micro-channel reactor. The method comprises the following steps: by using alkyl halide as a solvent, toluene as a raw material, chlorosulfonic acid as a chlorosulfonating agent and a material obtained by mixing toluene, chlorosulfonic acid, alkyl halide and a catalyst as a reaction starting material, feeding the reaction starting material into a microchannel reactor, carrying out chlorosulfonation reaction, and performing post-treatment on a reaction product flowing out of the microchannel reactor to obtain paratoluensulfonyl chloride. According to the invention, continuous production of p-toluenesulfonyl chloride can be realized, the production efficiency can be greatly improved, and the output of waste acid can be greatly reduced.

Owner:JINHUA SHUANGHONG CHEM CO LTD

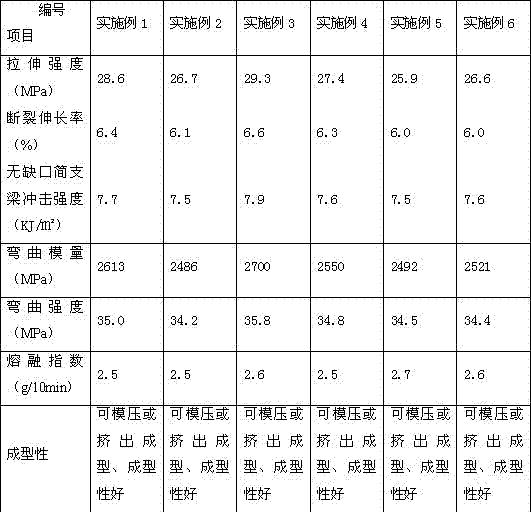

Rice hull powder master batch and preparation method thereof

The invention relates to a rice hull powder master batch which is mainly prepared from the following components in parts by weight: 1000 parts of rice hull powder, 8-12 parts of a siloxane coupling agent, 2-3 parts of ethanol solution, 110-130 parts of a thermoplastic resin, 45-55 parts of a plasticizer, 8-12 parts of an antioxidant and 18-21 parts of a lubricating agent, wherein a melting temperature of the thermoplastic resin is 120-180 DEG C. According to the master batch disclosed by the invention, the rice hull powder serves as a matrix, the surface of the rice hull powder is subjected tomodification treatment, the thermoplastic resin, the plasticizer, the antioxidant, the lubricating agent and the like are added into a high-speed mixer to be heated, mixed and stirred, and the mixture is subjected to extrusion granulation by a twin-screw extruder so as to obtain the rice hull powder master batch. The rice hull powder master batch disclosed by the invention has the characteristicsof being easy to process and capable of accurately controlling the material ratio, improving the product quality and reducing losses of raw materials, and the like.

Owner:XIAMEN HUSKS NEW MATERIAL TECH CO LTD

Online conveying and mixing device capable of achieving proportional mixing

The invention relates to the technical field of material mixing, in particular to an online conveying and mixing device capable of achieving proportional mixing. The device comprises a fixing frame, feeding hoppers are fixedly mounted at the top of the fixing frame, a mixing barrel is mounted in the fixing frame, a stirring motor is fixedly mounted on the outer side wall of the mixing barrel, anda driving shaft is mounted in the material mixing barrel. The end of the driving shaft is rotationally connected with the side wall of the mixing barrel, the shaft extension end of the stirring motoris connected with the end of the driving shaft, and a lower stirring shaft is installed in the mixing barrel. The upper end of the lower stirring shaft is connected with the driving shaft through a bevel gear set, and a discharging port is formed in the bottom of the mixing barrel. Through arranging the two feeding hoppers, a flow control valve is arranged, so that two materials can be poured intothe mixing barrel at the same time, the proportion of the materials can be accurately controlled by utilizing the flow control valve, the materials on the lower layer are stirred by utilizing a spiral plate, the materials are uniformly mixed, and the materials on the upper layer are stirred by utilizing a stirring structure, so that the mixing efficiency is improved.

Owner:DENG QUAN PLASTIC TECH HUNAN CO LTD

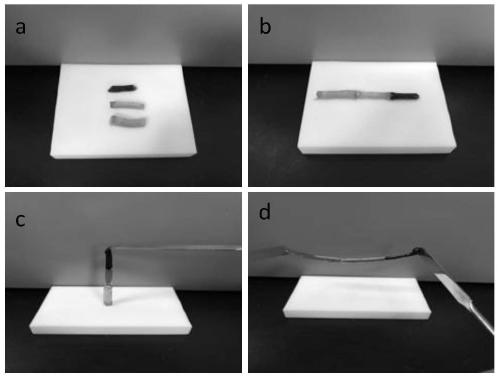

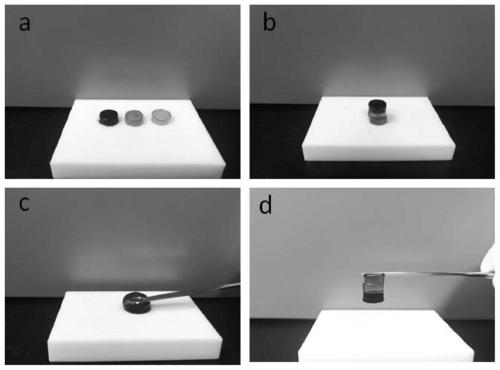

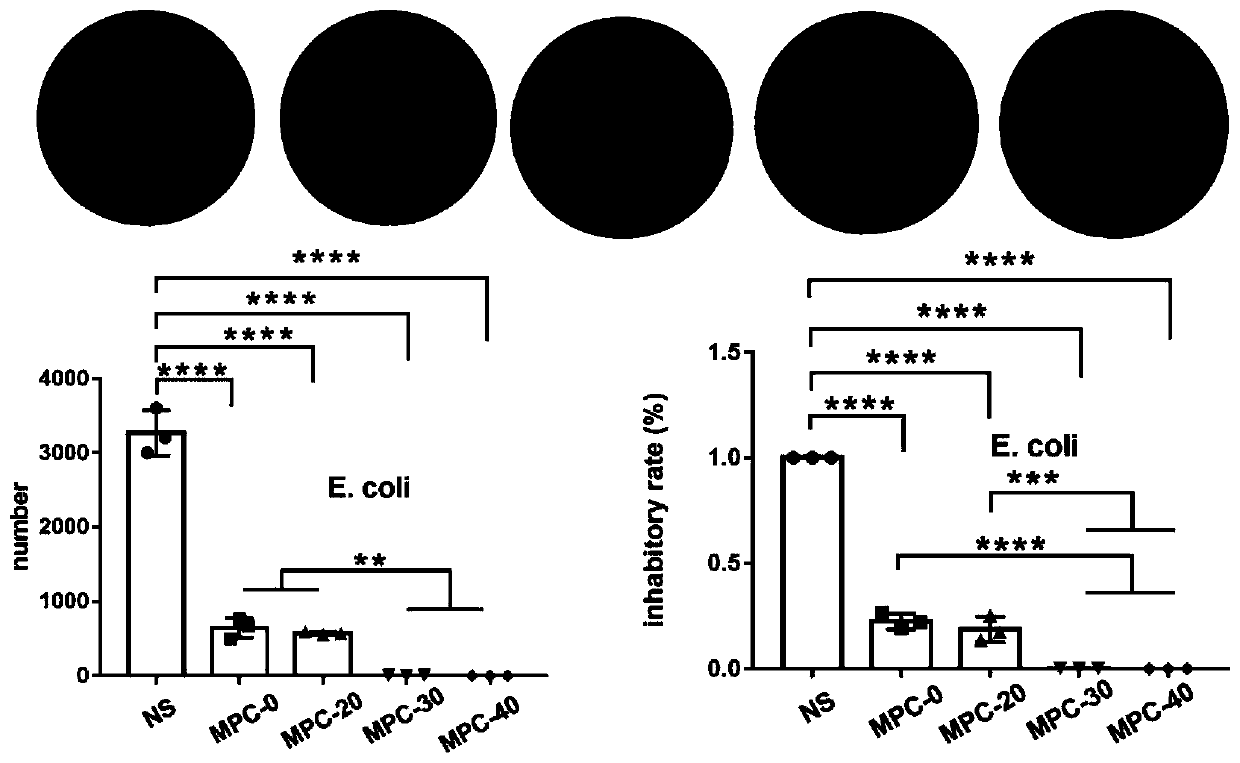

In-situ glue forming hydrogel as well as preparation method and application thereof

ActiveCN111205481AImprove water absorptionStrong water absorptionSurgical adhesivesPharmaceutical delivery mechanismSurgical operationPolymer science

The invention discloses in-situ glue forming hydrogel as well as a preparation method and application thereof. According to the in-situ gel forming hydrogel, dimethylaminopropyl acrylamide, (3-acrylamidopropyl)trimethyl ammonium chloride and 2-methacryloyloxyethyl choline phosphate are initiated by an initiator by utilizing free radical polymerization to quickly generate gel in situ, and the gel forming time is short, so that the effects of sealing and stopping bleeding are achieved. During preparation of the in-situ gelling hydrogel, the ratio of the raw materials can be accurately controlled, no cross-linking agent is used, reasonable gelling time can be achieved, the gelling time is shorter than 10 s, and meanwhile, the gel has high viscoelasticity and self-healing performance and can better meet the requirements of surgical operations.

Owner:XI AN JIAOTONG UNIV

A sulfur-resistant methanation catalyst and its preparation method

ActiveCN109433222BEnhanced interactionHigh activityHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsSyngasPtru catalyst

Owner:XINDI ENERGY ENG TECH

Sewage treatment neutralizer proportioning and feeding device based on visual detection

PendingCN113083148AReduce riskImprove productivity and safetyTransportation and packagingMixer accessoriesVision basedSewage treatment

The invention belongs to the field of sewage treatment, and particularly relates to a sewage treatment neutralizer proportioning and feeding device based on visual inspection. The sewage treatment neutralizer proportioning and feeding device comprises a visual detection mechanism, a blending tank and a storage box. The blending tank is provided with a first liquid inlet pipe and a discharging pipe, and the storage box is arranged at the top end of the blending tank. The visual detection mechanism comprises a visual sampling assembly, an indicator adding assembly and a visual detection assembly, the indicator adding assembly is arranged on the visual sampling assembly, and the working end of the visual detection assembly faces the visual side of the visual sampling assembly. The device further comprises a quantitative feeding mechanism, the storage box is arranged at the top end of the blending tank through the quantitative feeding mechanism, and the quantitative feeding mechanism is used for discharging a certain amount of neutralizer in the storage box and feeding the neutralizer into the blending tank. According to the device, the neutralizer can be fed into sewage in a manner of accurately controlling the proportion, and compared with manual proportioning, the device is higher in working efficiency, accuracy and safety.

Owner:王海军

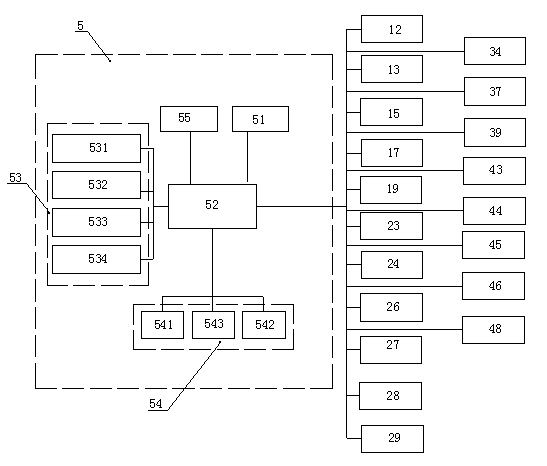

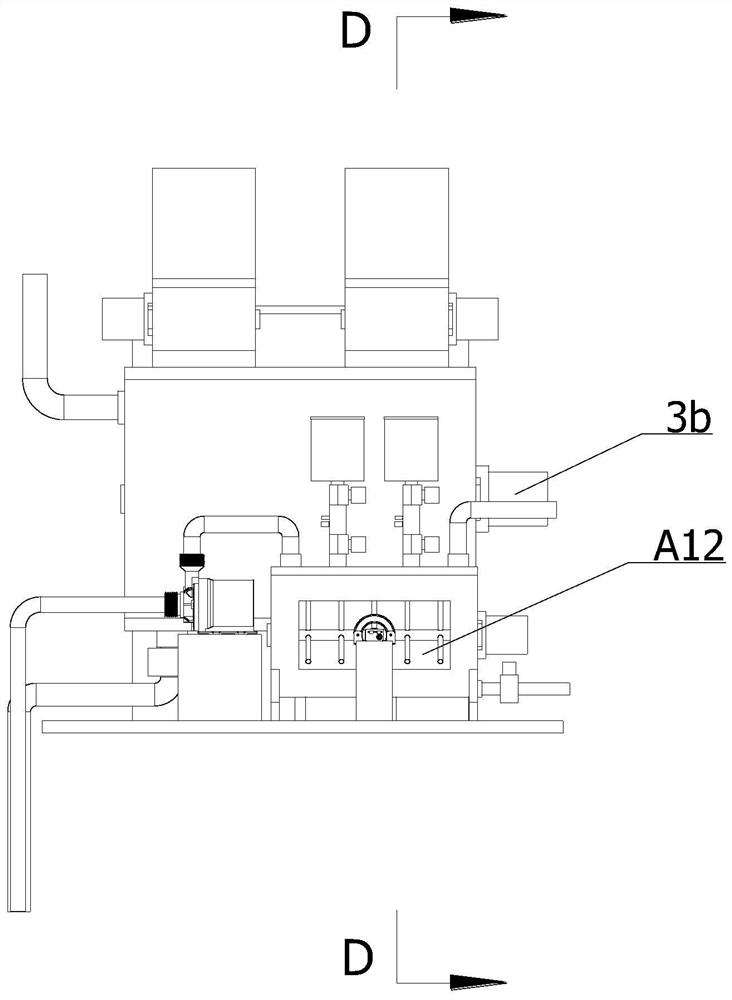

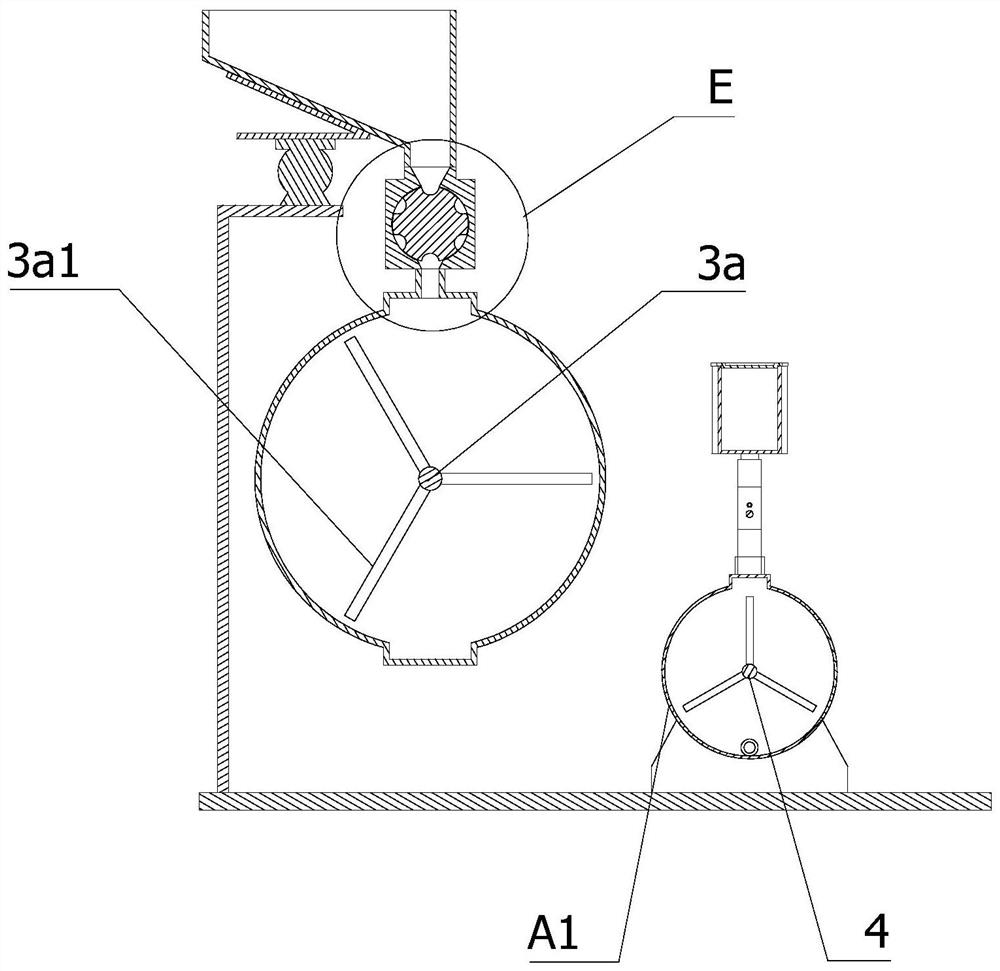

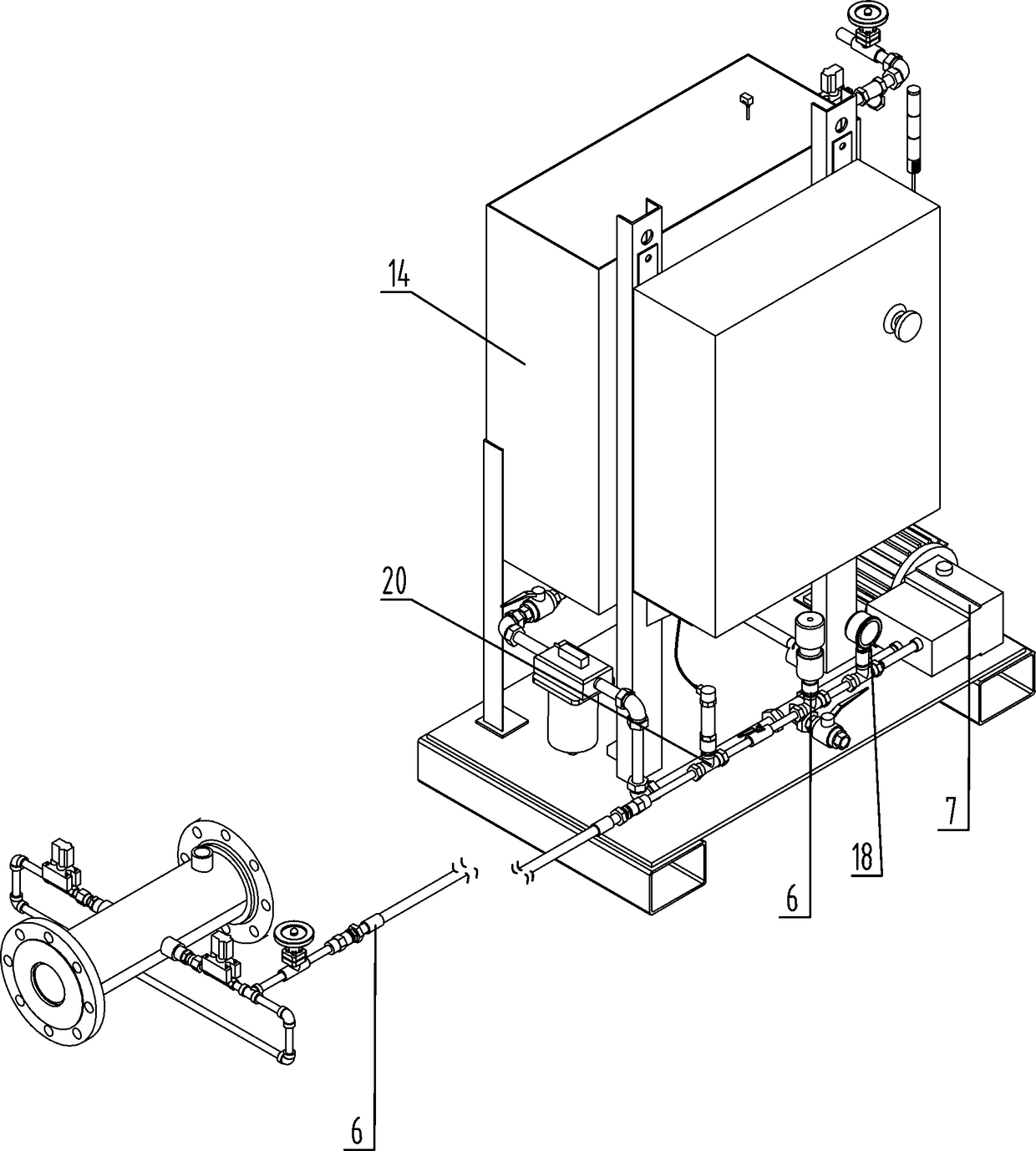

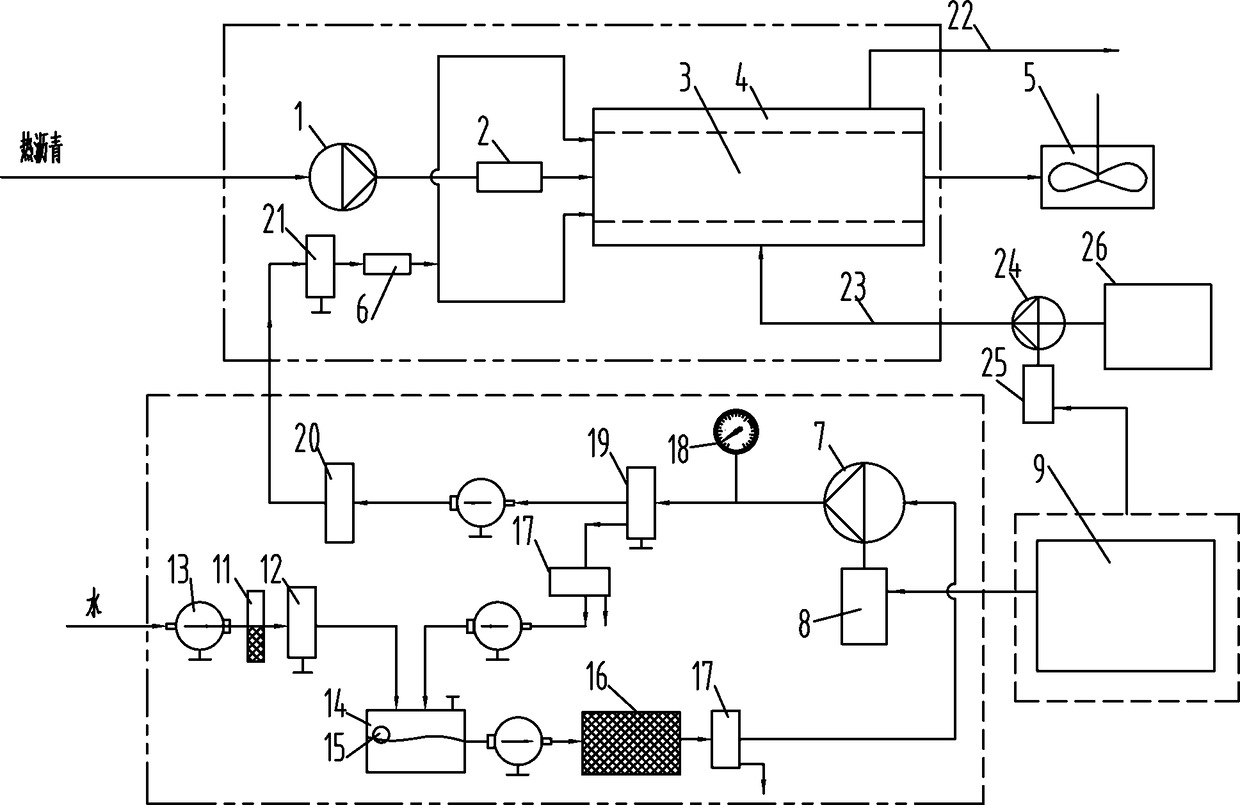

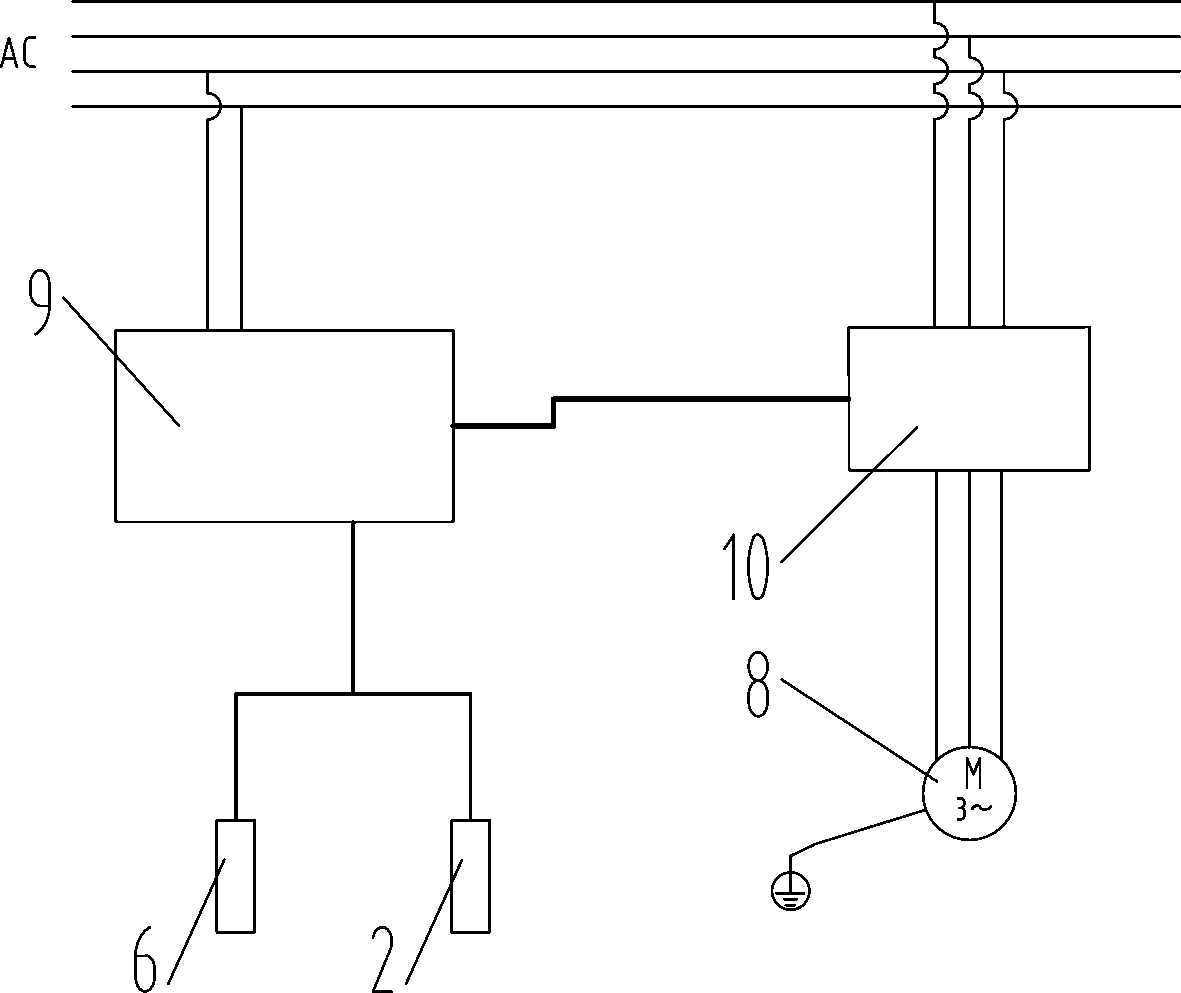

Intelligent Control System of Asphalt Foaming Machine

ActiveCN105511532BGuaranteed foaming qualityReliable supplyRoads maintainenceSimultaneous control of multiple variablesFrequency changerWater flow

The invention provides an intelligent control system for an asphalt foaming machine. The output port of the asphalt pump is connected to the inlet of the foaming pipe, and an asphalt flow sensor is arranged between the output port of the asphalt pump and the foaming pipe; the outer wall of the foaming pipe A jacket is provided, and the jacket is connected with the oil inlet pipe and the oil discharge pipe; the output port of the water pump is connected with the water inlet of the foaming pipe, and a water flow sensor is arranged between the output port of the water pump and the foaming pipe; the water flow sensor and the asphalt flow rate The sensor is connected with the control device, the control device is connected with the frequency converter, and the frequency converter is connected with the motor driving the water pump. By setting the asphalt flow sensor and the water flow sensor, the water flow is adjusted with the data of the asphalt flow sensor as a reference, so as to realize the precise control of the ratio of water and asphalt. Guarantee the quality of asphalt foaming and eliminate quality hazards.

Owner:YICHANG JIANGXIA MARINE MACHINERY

Water treatment agent raw material high-pressure mixing device

InactiveCN109012289AImprove mixing efficiencyImprove the mixing effectRotary stirring mixersTransportation and packagingEngineeringHigh pressure

The invention relates to a water treatment agent raw material high-pressure mixing device and belongs to the technical field of water treatment. The device includes a vertical stirring tank, a buffertank, a horizontal stirring tank, and a collection bucket. A stirring paddle is vertically arranged in the vertical stirring tank. A first feeding port and a second feeding port are formed on the sidewall of the upper end of the vertical stirring tank. A liquid material box is connected to the first feeding port through a pipeline, wherein a booster pump is arranged on the pipeline between the liquid material box and the first feeding port. A spiral shaft is horizontally arranged in the horizontal stirring tank. By means of the booster, the liquid material in the liquid material box is pressurized and then is fed into the vertical stirring tank at high speed, so that the liquid material, at high pressure and high speed, is quickly mixed with other materials. With assistance of the stirring paddle in the vertical stirring tank for mixing the materials, the device is good in mixing effect and high in mixing efficiency.

Owner:江苏天泽教育咨询有限公司

A kind of in-situ colloidal hydrogel and its preparation method and application

ActiveCN111205481BImprove water absorptionStrong water absorptionSurgical adhesivesPharmaceutical delivery mechanismSurgical operationMeth-

Owner:XI AN JIAOTONG UNIV

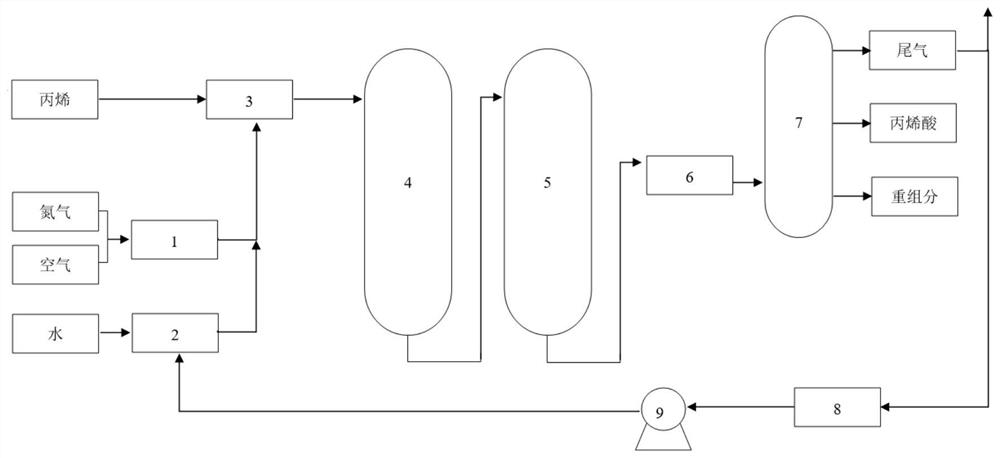

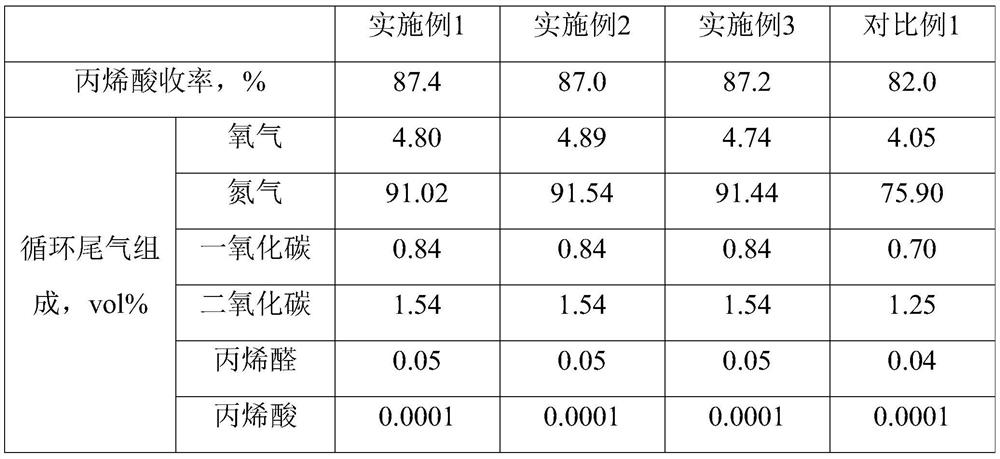

Pilot plant and process for preparing acrylic acid through propylene oxidation with tail gas circulation

PendingCN113636927AAvoid changes in exhaust compositionReal catalyst performanceOrganic compound preparationCarbonyl compound preparationExhaust gasProcess engineering

The invention discloses a pilot plant and process for preparing acrylic acid through propylene oxidation with tail gas circulation. The pilot plant comprises the following units: a feeding unit, a reaction unit, a reaction product separation unit and a tail gas treatment unit, the units are sequentially connected according to the flow direction of material flow; the reaction unit comprises a first reaction acrolein reactor and a second reaction acrylic acid reactor; and the tail gas treatment unit comprises a dryer and a gas circulation compressor, and the tail gas discharged by the reaction product separation unit enters the dryer, passes through the gas circulation compressor and returns to the feeding unit. According to the invention, pilot scale reaction feed simulates industrial grade feed composition using circulating tail gas, and the catalyst performance is truly evaluated while the reaction process is operated stably.

Owner:兰州金润宏成新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com