Intelligent Control System of Asphalt Foaming Machine

A control system and a foaming machine technology, applied in the field of asphalt foaming, can solve problems such as the inability to intuitively reflect the amount of asphalt and the amount of water added, the quality accident and quality loss of asphalt roads, and the inability to effectively ensure the quality of asphalt foaming. Eliminate hidden quality risks, reduce hidden quality risks, and ensure the effect of heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

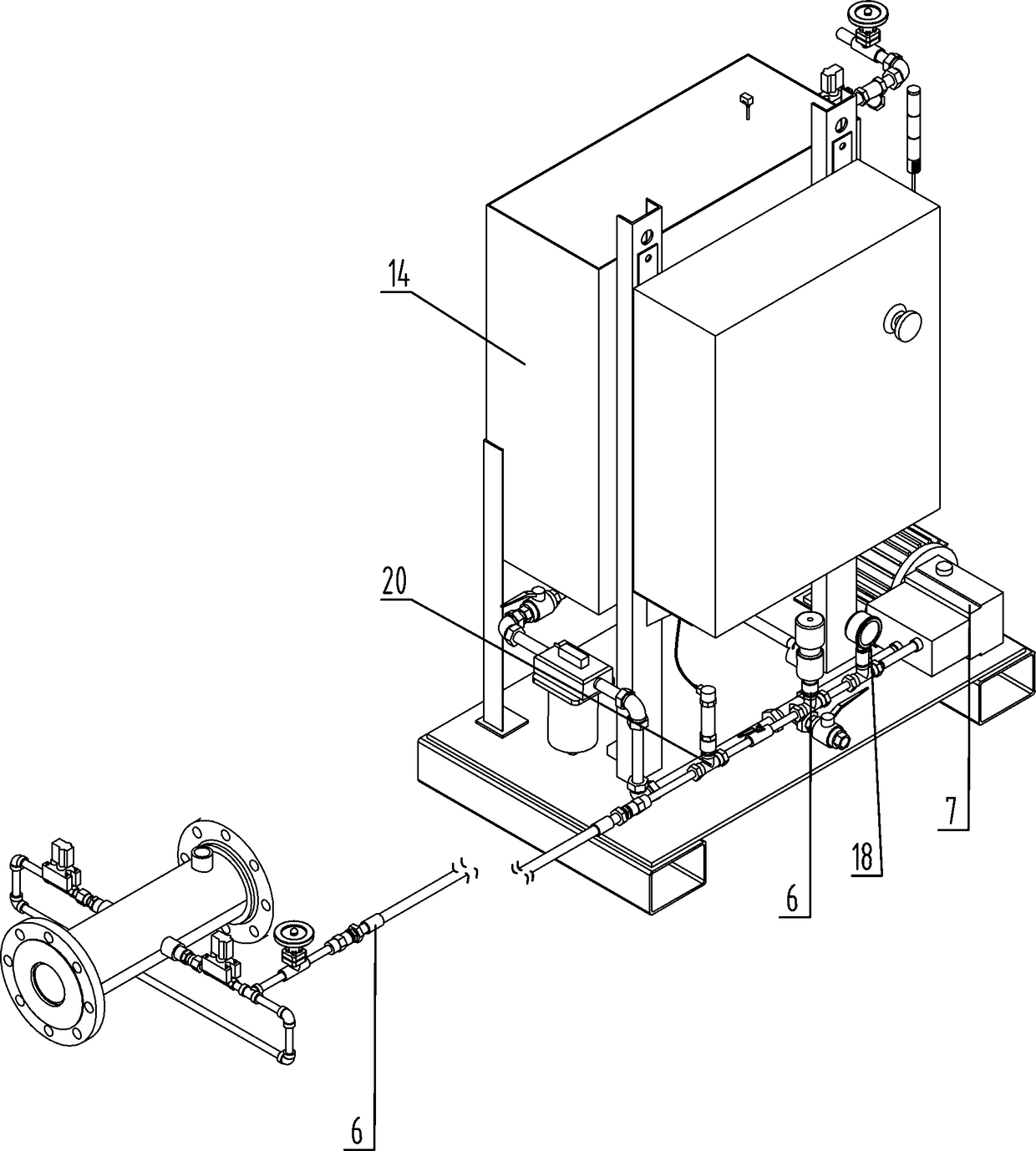

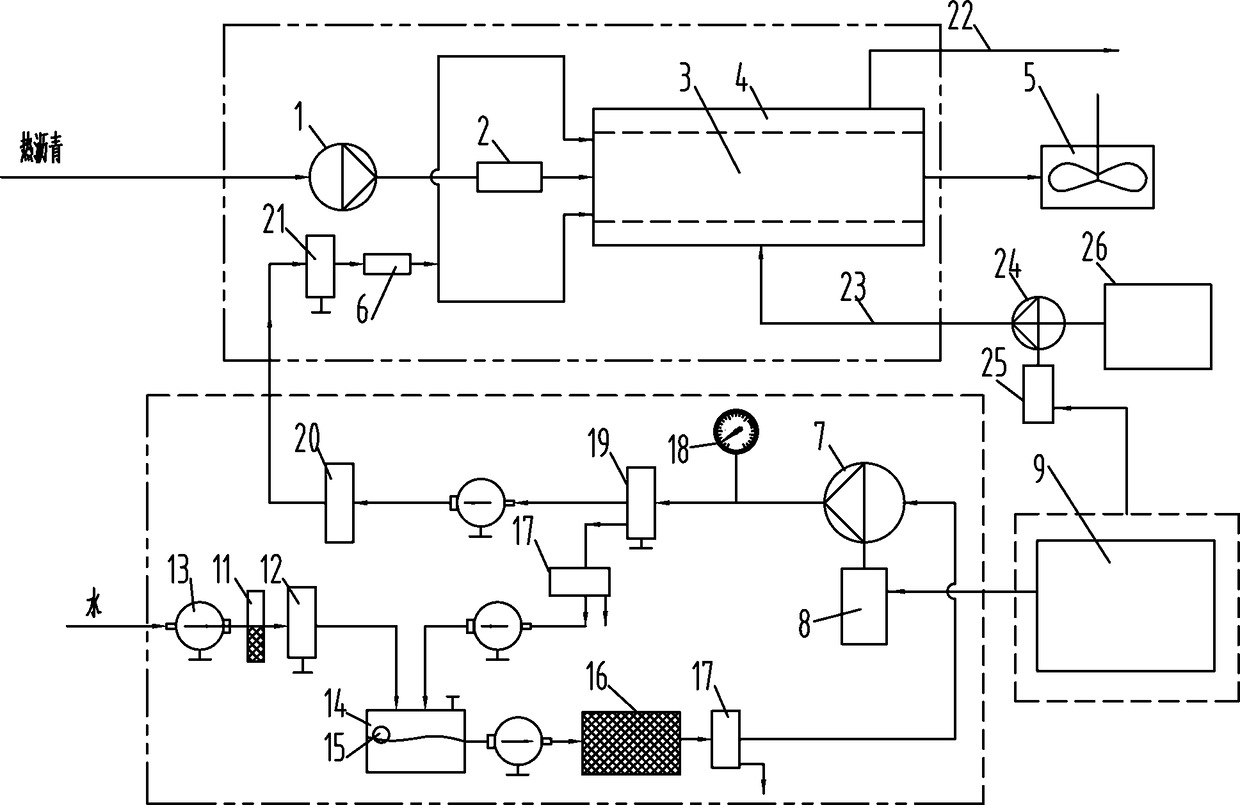

[0026] like Figure 1~3 Among them, an intelligent control system for an asphalt foaming machine, the output port of the asphalt pump 1 is connected to the inlet of the foaming pipe 3, and an asphalt flow sensor 2 is arranged between the output port of the asphalt pump 1 and the foaming pipe 3; The asphalt flow sensor 2 in the example adopts a dynamic difference target flowmeter, and the accuracy error is ±0.1%~0.2%.

[0027] The outer wall of foam pipe 3 is provided with jacket 4, and jacket 4 is connected with oil inlet pipe 23 and oil discharge pipe 22; In the constant heat furnace 26, heating oil at a constant temperature is output in circulation.

[0028] The output port of the water pump 7 is connected to the water inlet of the foam pipe 3, and a water flow sensor 6 is arranged between the output port of the water pump 7 and the foam pipe 3;

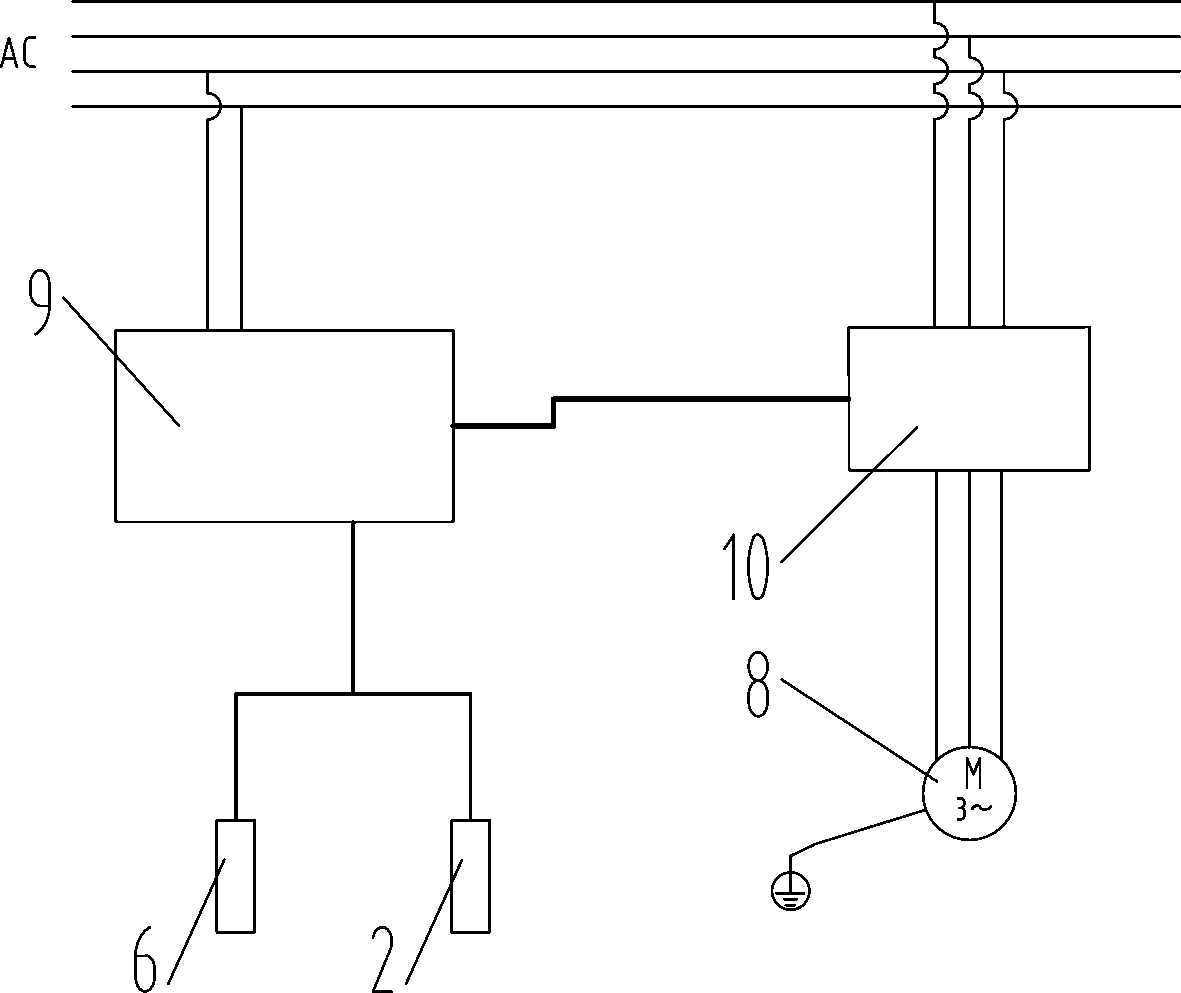

[0029] The water flow sensor 6 and the asphalt flow sensor 2 are connected to the control device 9 , the control device 9 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com