Solar water heater water storage tank foaming production line

A solar water heater and production line technology, applied in the field of water heater processing, can solve problems such as unguaranteed effect, poor consistency, and inability to continue flow operation, etc., and achieve the effects of good consistency, guaranteed inflation, and prevention of rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

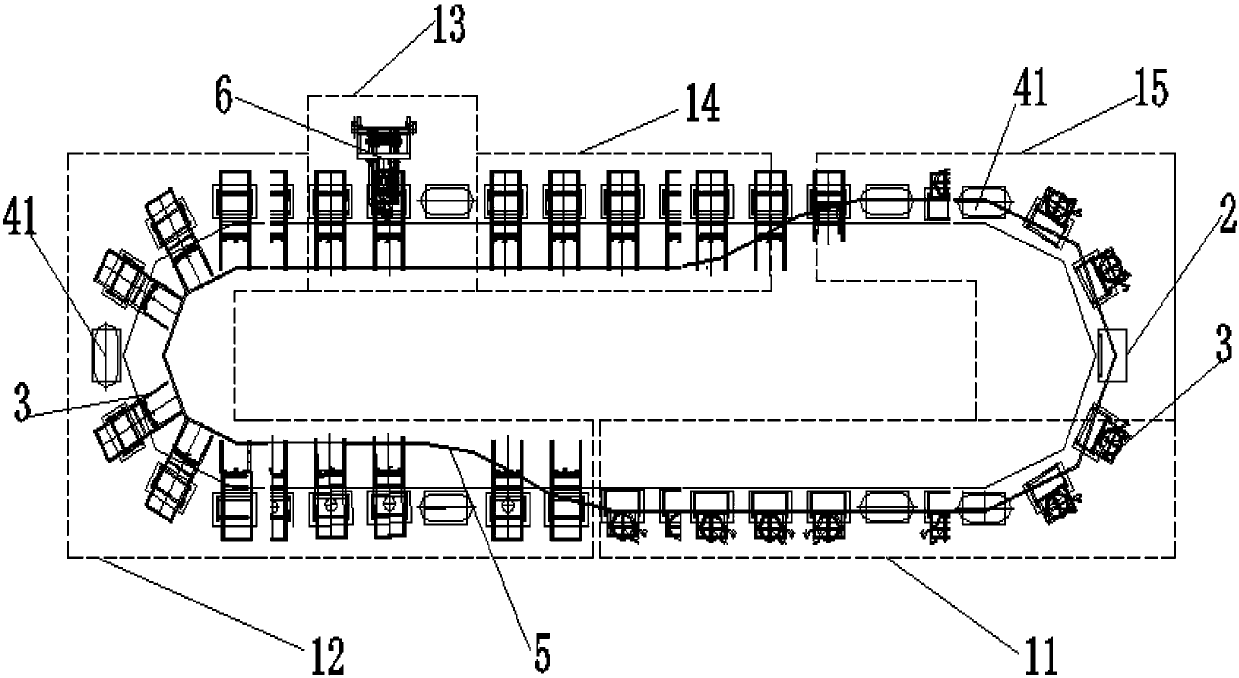

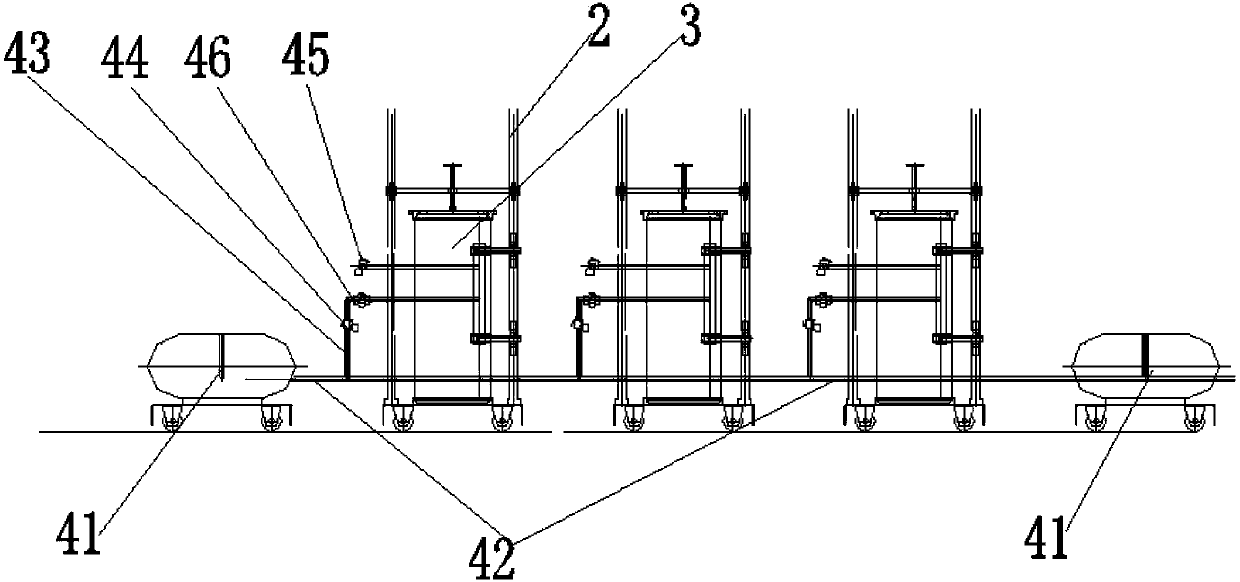

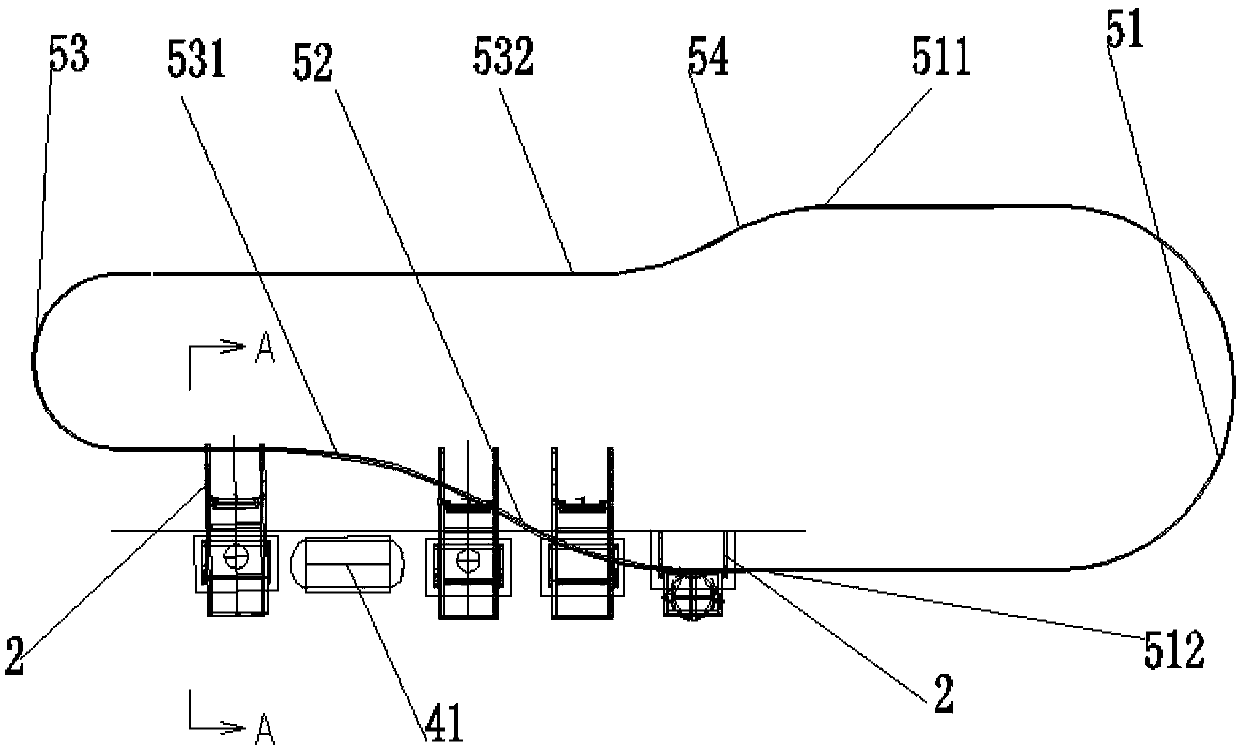

[0038] like figure 1 shown, see also figure 2 , a foaming production line for a solar water heater water storage tank 3 described in the embodiment of the present invention, the foaming production line includes in turn: an assembly area 11, a preheating area 12, a material injection area 13, a curing area 14 and a disassembly area 15, The foaming production line is provided with a tooling car 2 that can roll, and the water storage tank 3 is installed on the tooling car 2 and passes through each area of the foaming production line in turn. The foaming production line also includes an inflator. The inflatable device includes a plurality of air storage tanks 41, a main air pipe 42, a plurality of bronchus 43 and a plurality of one-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com