Patents

Literature

40results about How to "Guaranteed foaming quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming agent of waterproof foam concrete, preparation method and construction method

InactiveCN101698581AFormula refiningImprove stabilityBuild-up roofsBuilding insulationsFoam concreteFoaming agent

The invention relates to foaming agent of waterproof foam concrete, a preparation method and a construction method, which belongs to the fields of construction materials, a preparation method thereof and an architectural method thereof. The foaming agent of the invention comprises the following raw materials in part by weight: 30 to 35 parts of keratinous albumen powder, 4 to 5 parts of Ca(OH)2, 1.5 to 2.5 parts of NaHSO3, 270 to 320 parts of water, 0.8 to 1.5 parts of sodium dodecyl benzene sulfonate (SDBS), 0.2 to 0.7 part of sodium dodecyl sulfate, 0.8 to 1 part of gelatin and 0.5 to 1 part of trolamine. The weight of sulphamic acid is matched with that of Ca(OH)2 and NaHSO3, and the pH value of the mixed three materials reaches 7.

Owner:廖传海

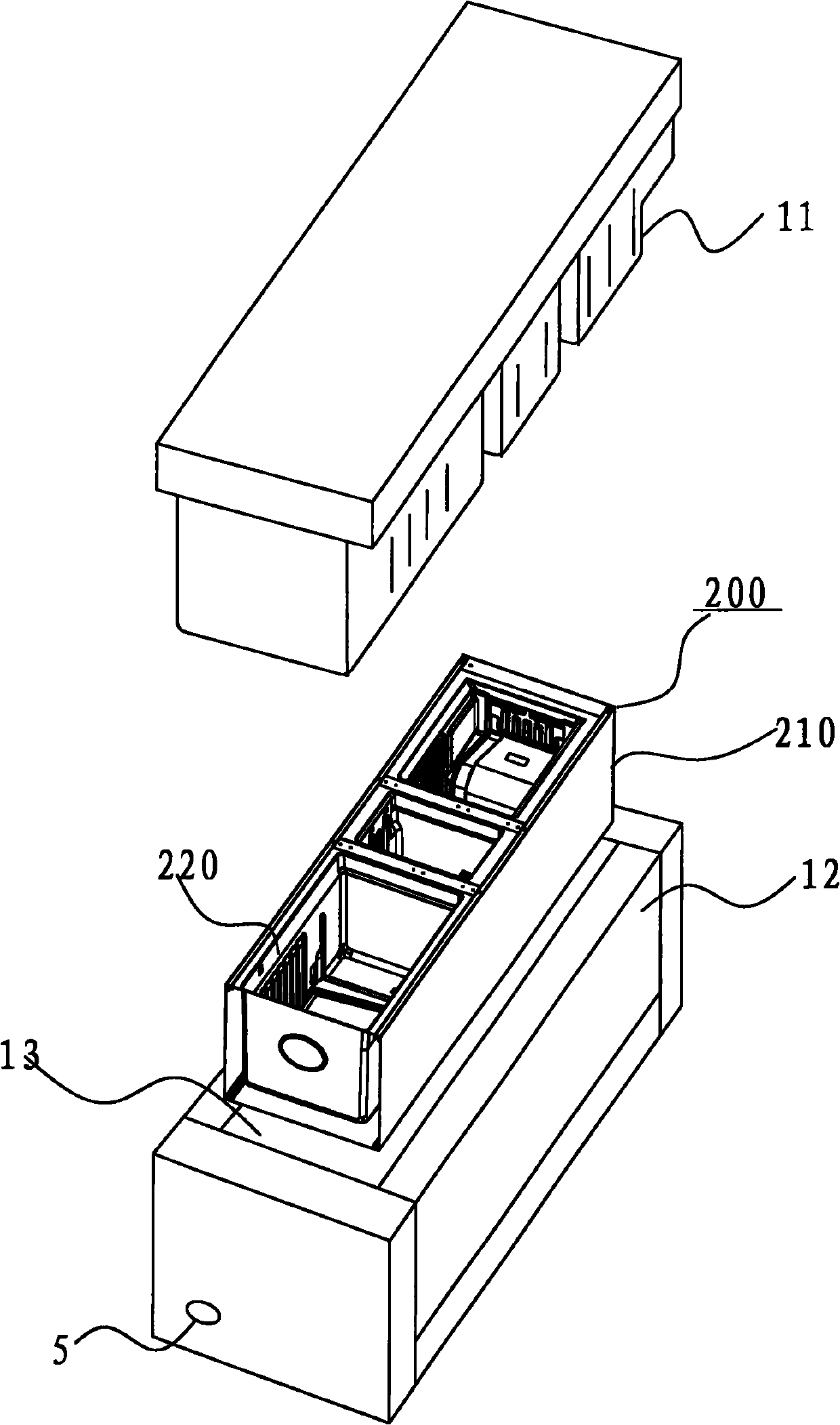

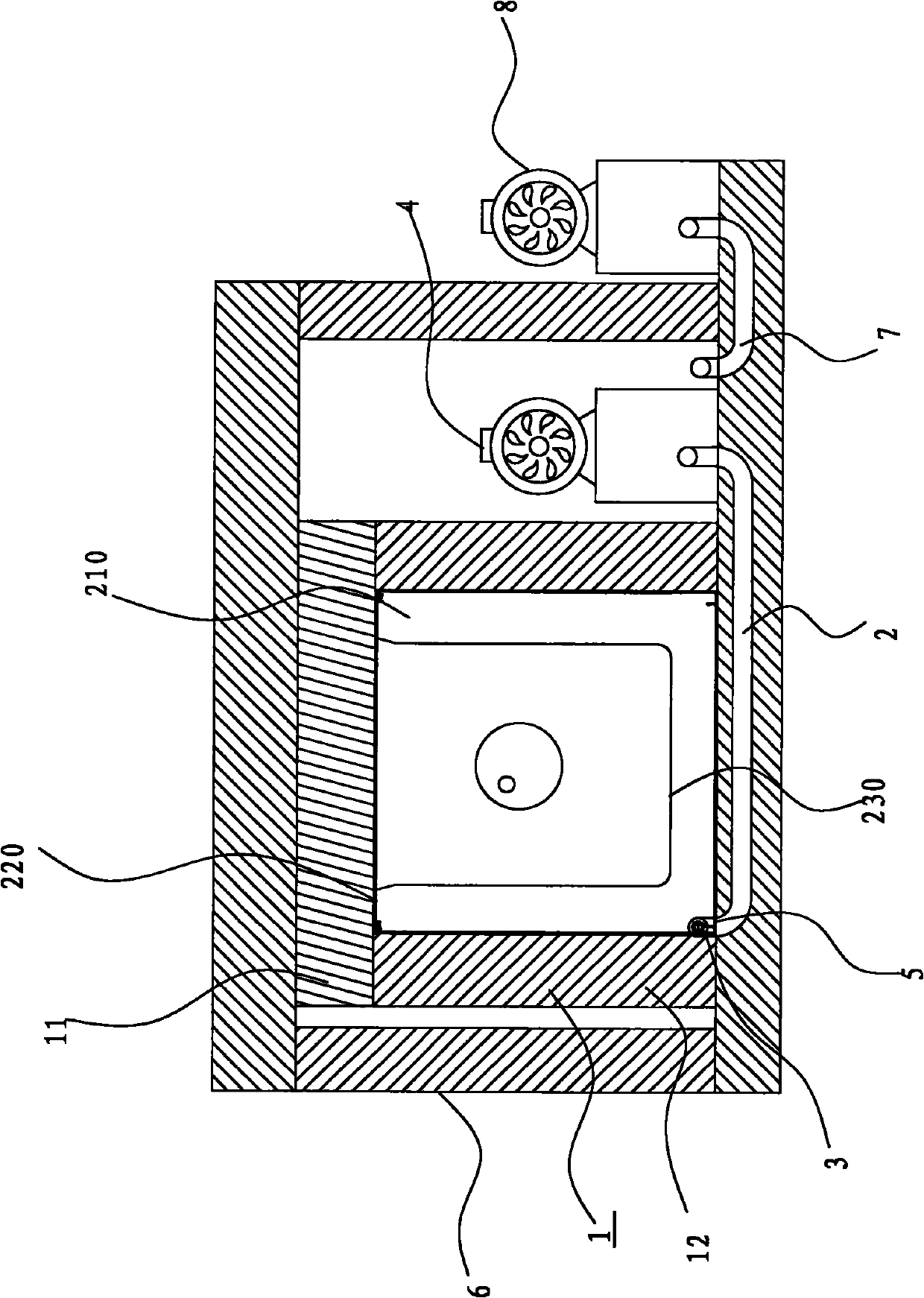

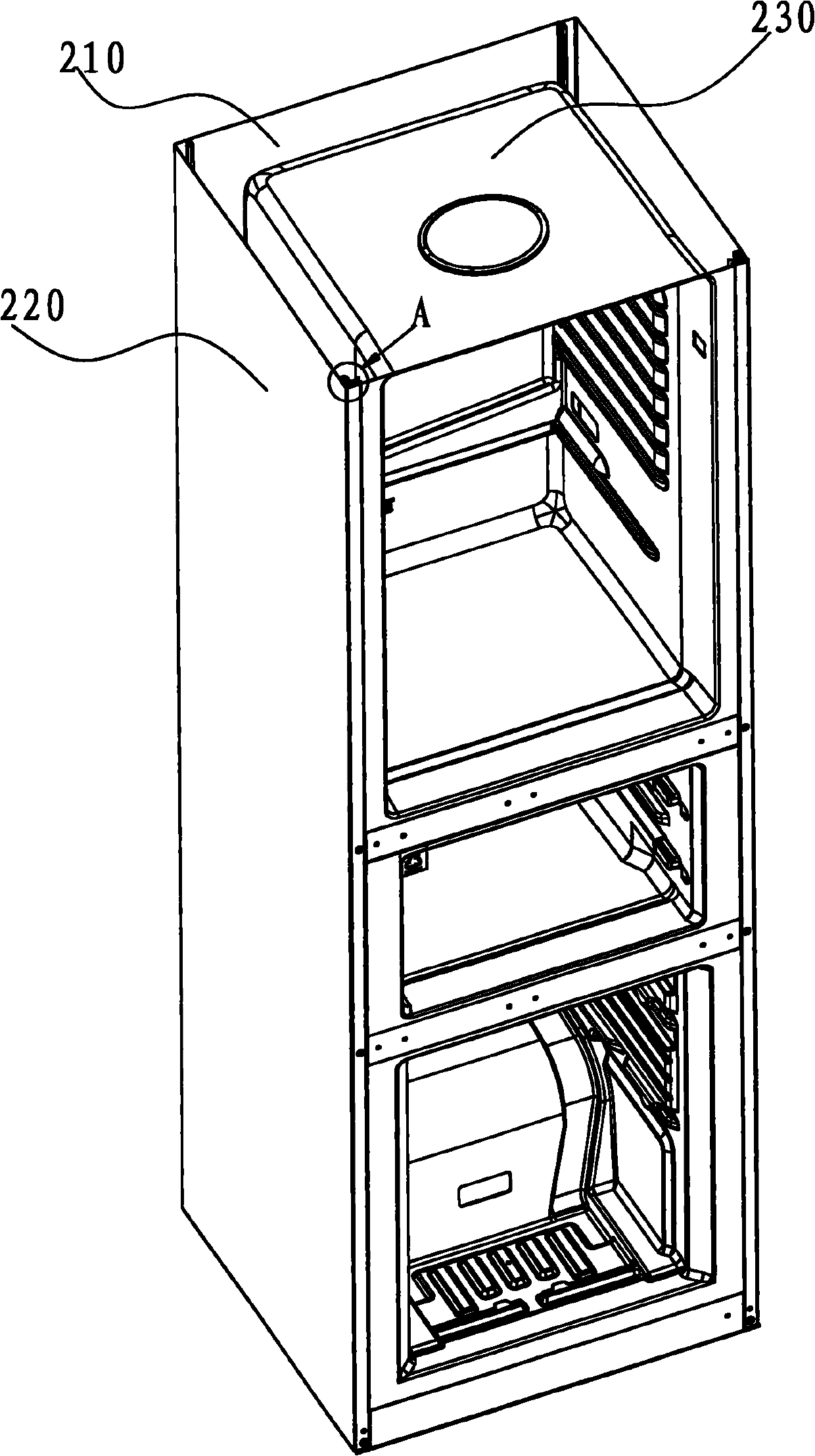

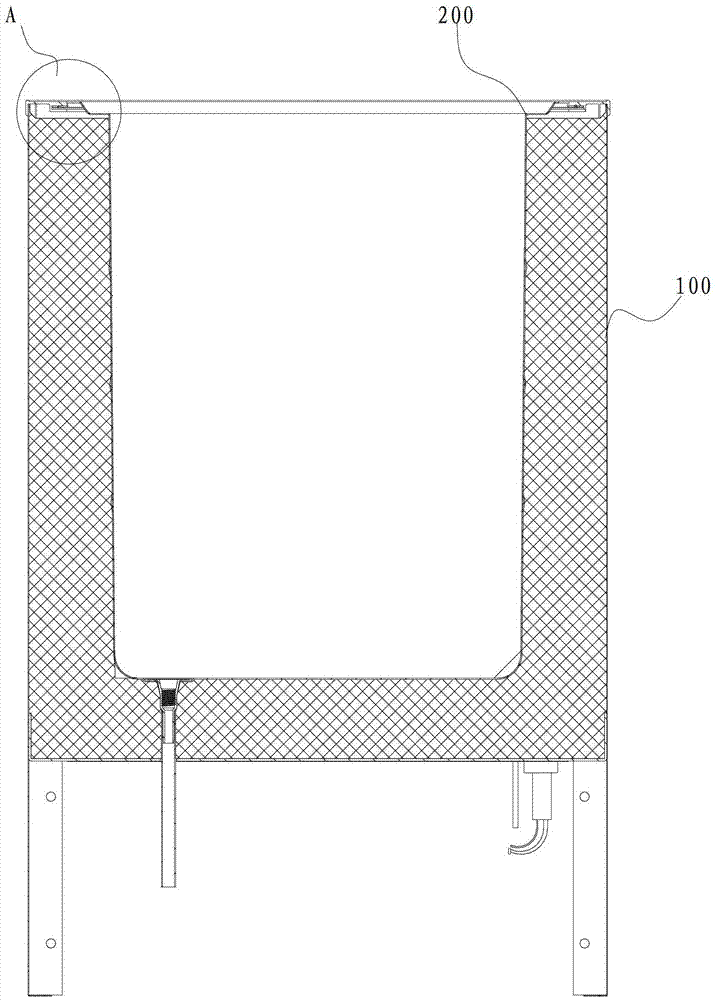

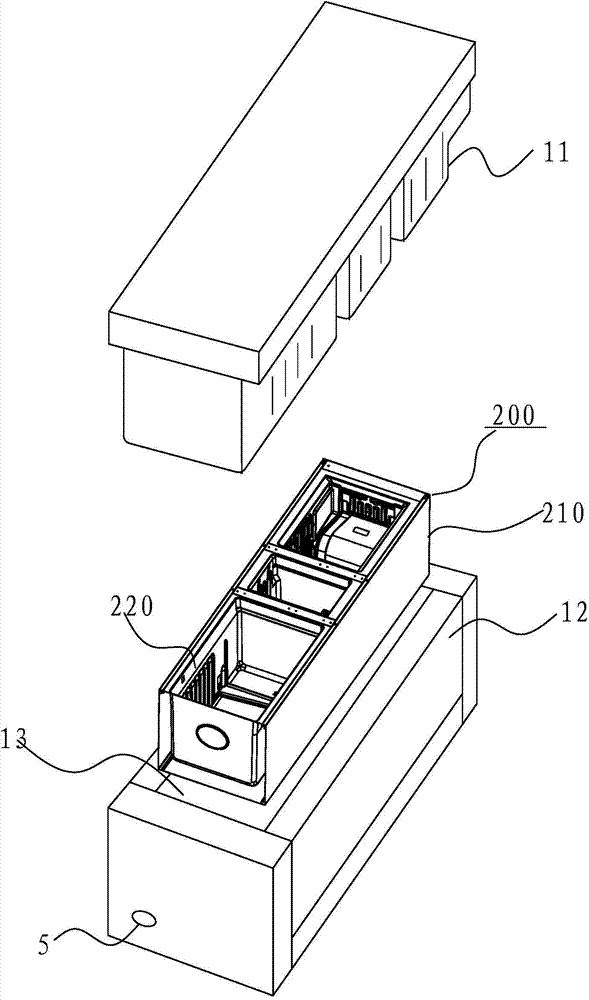

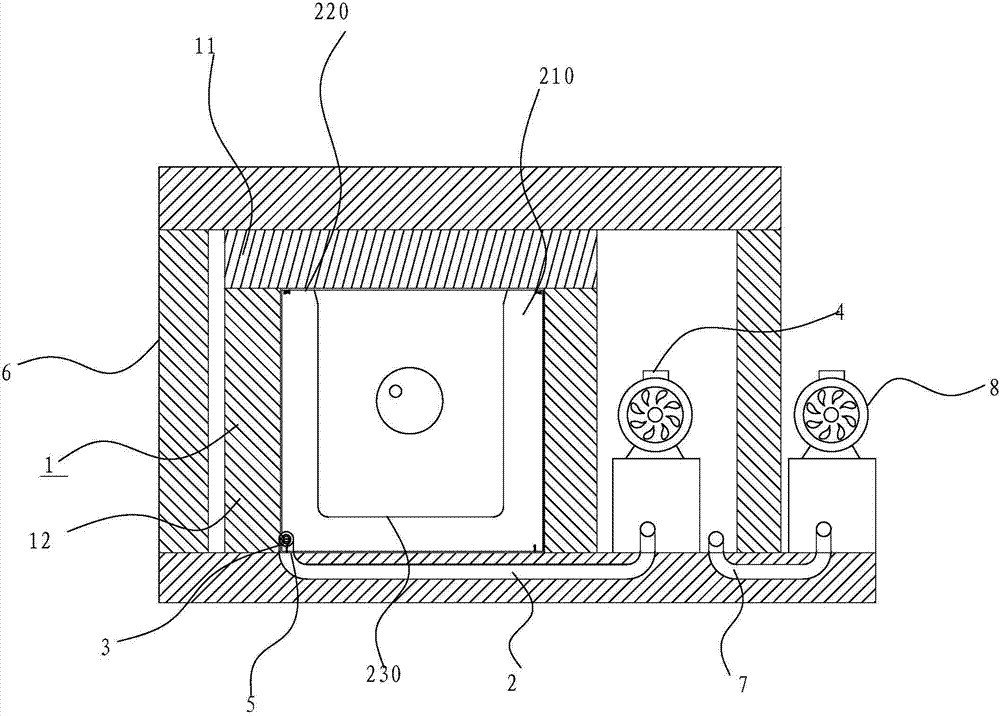

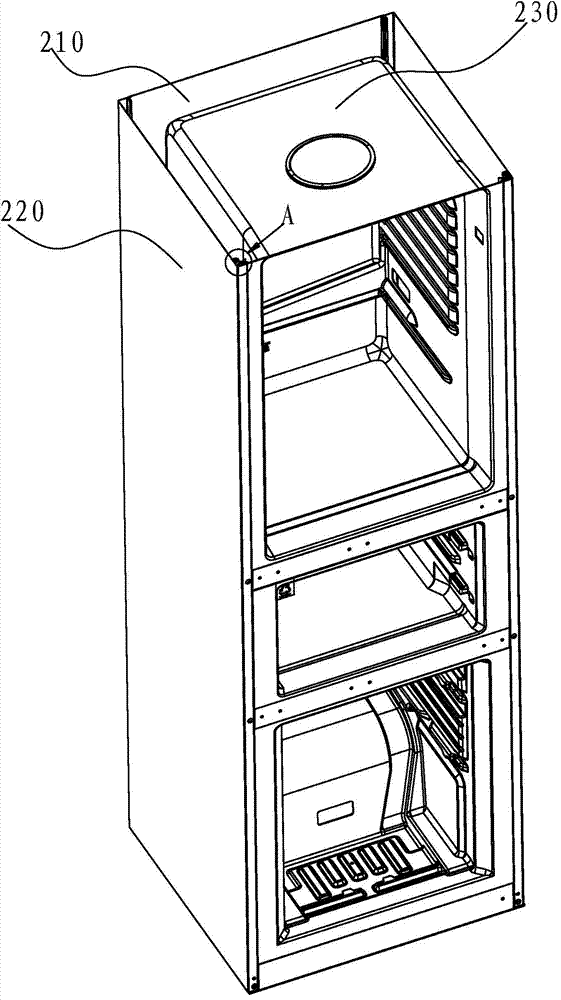

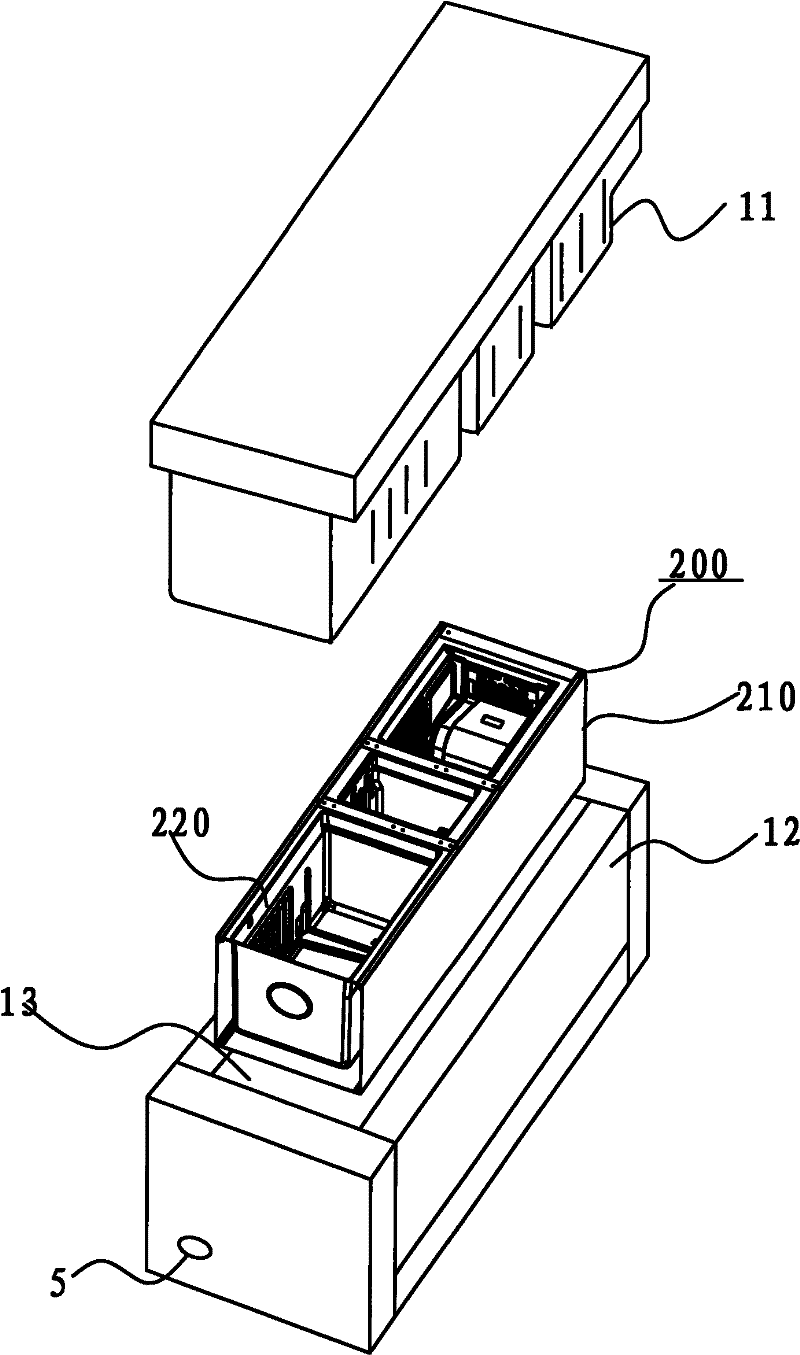

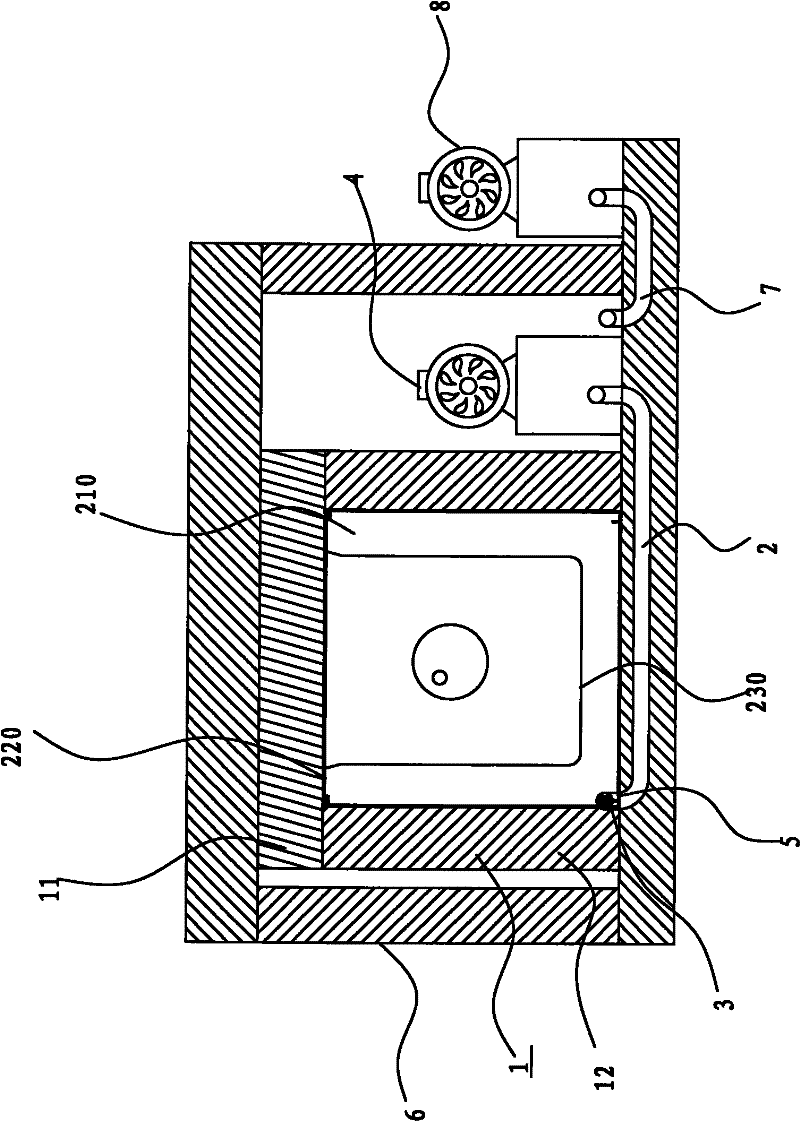

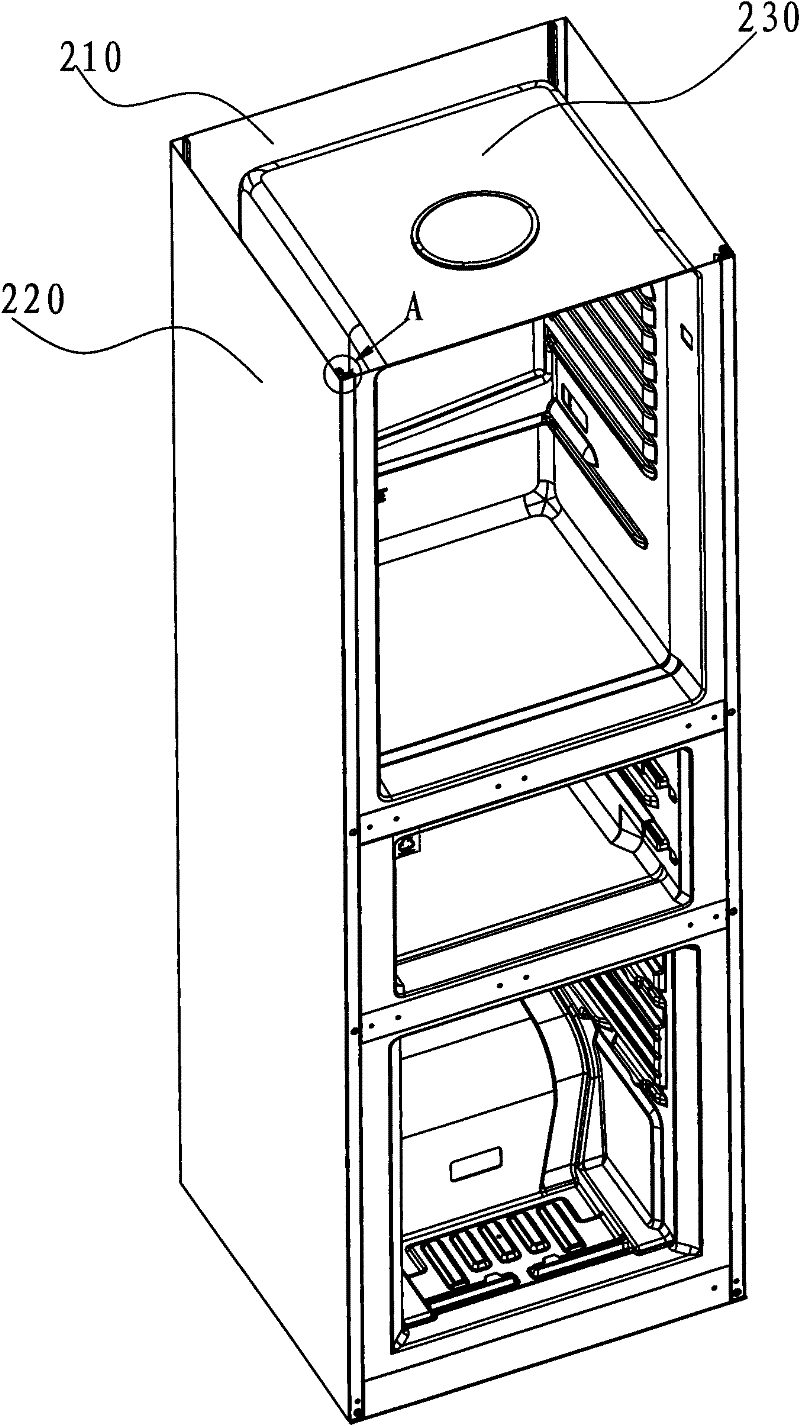

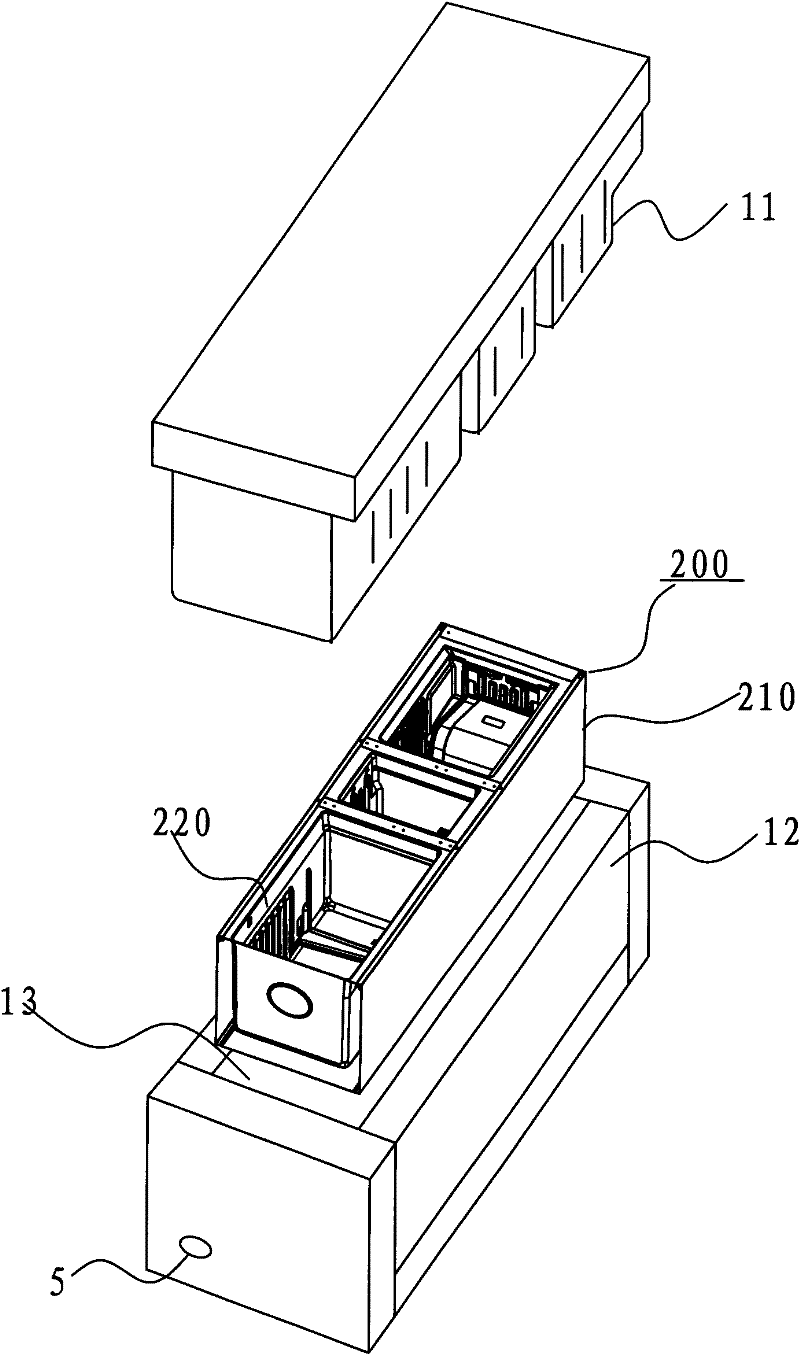

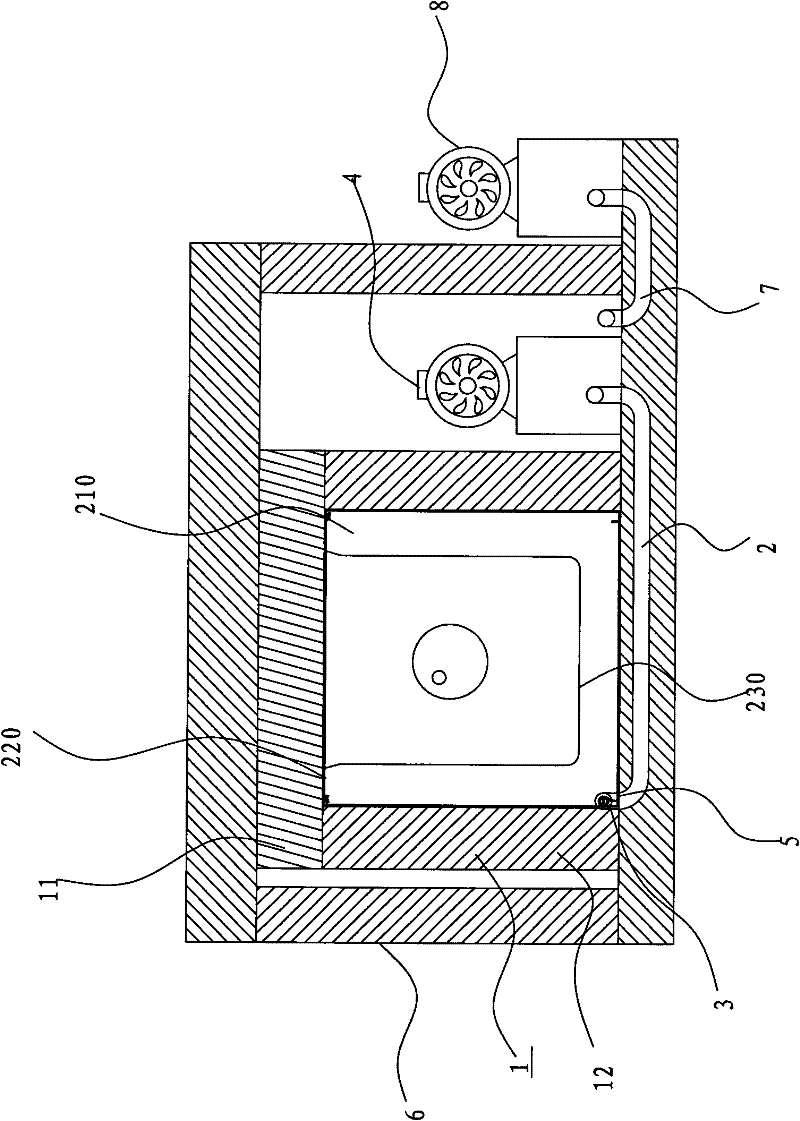

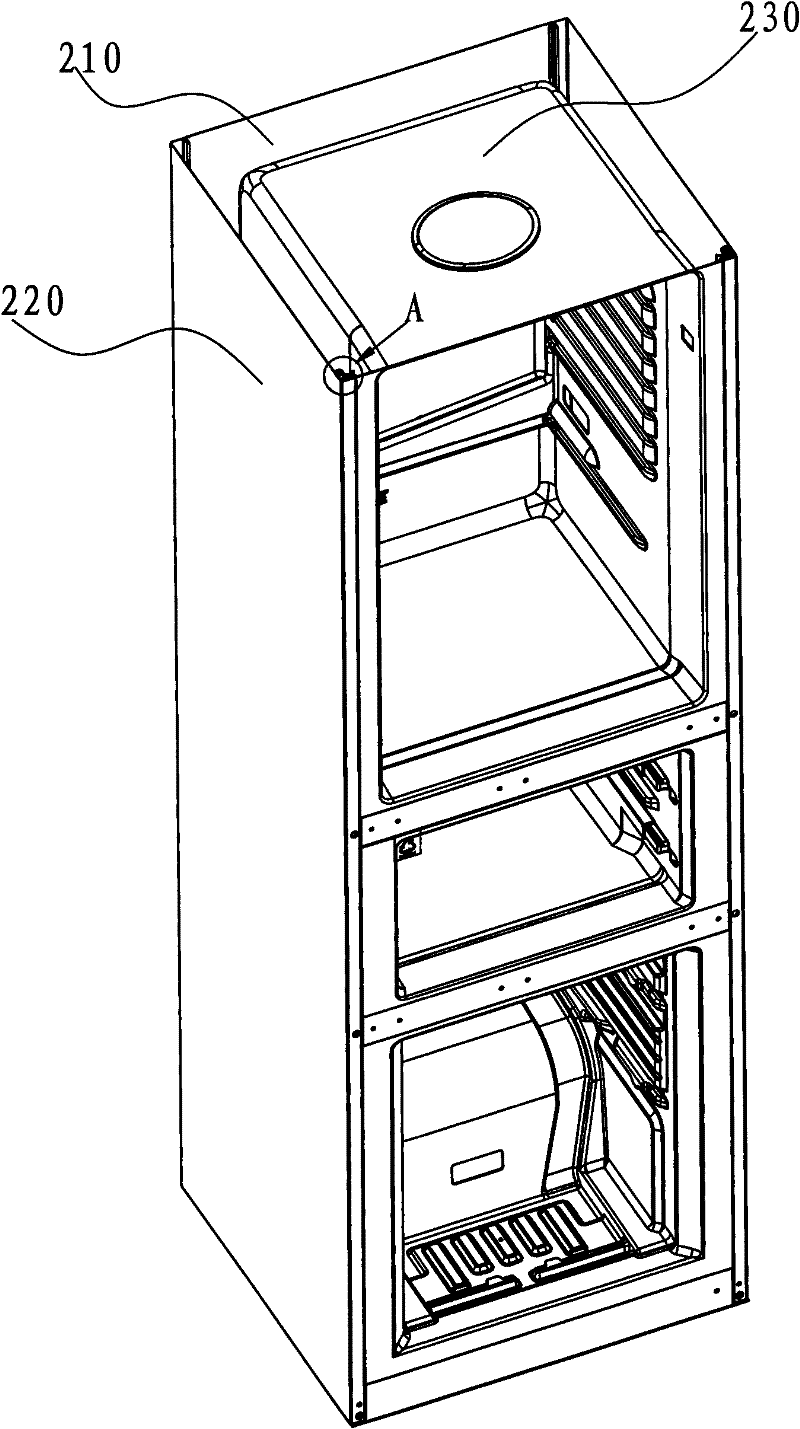

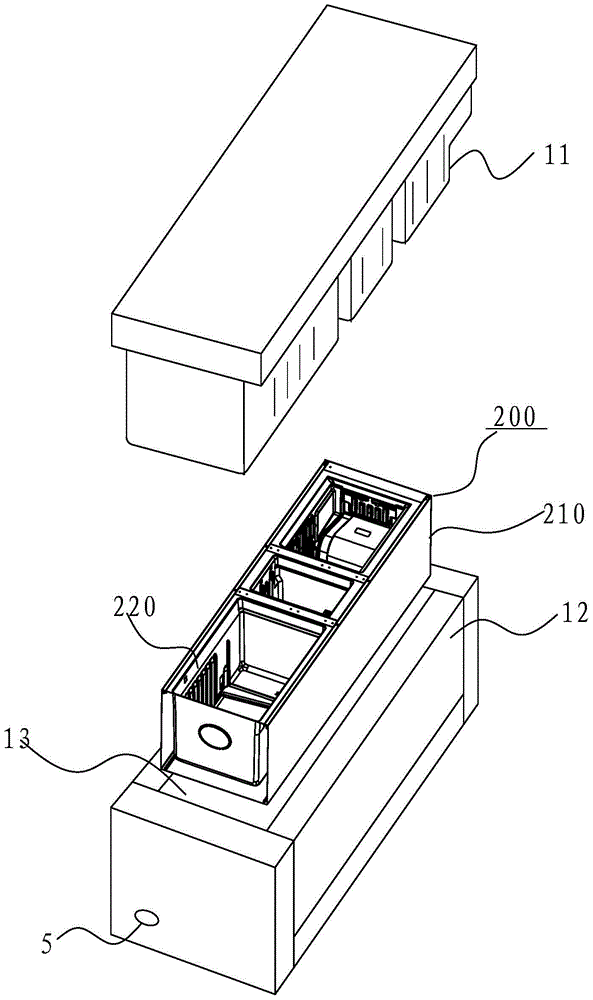

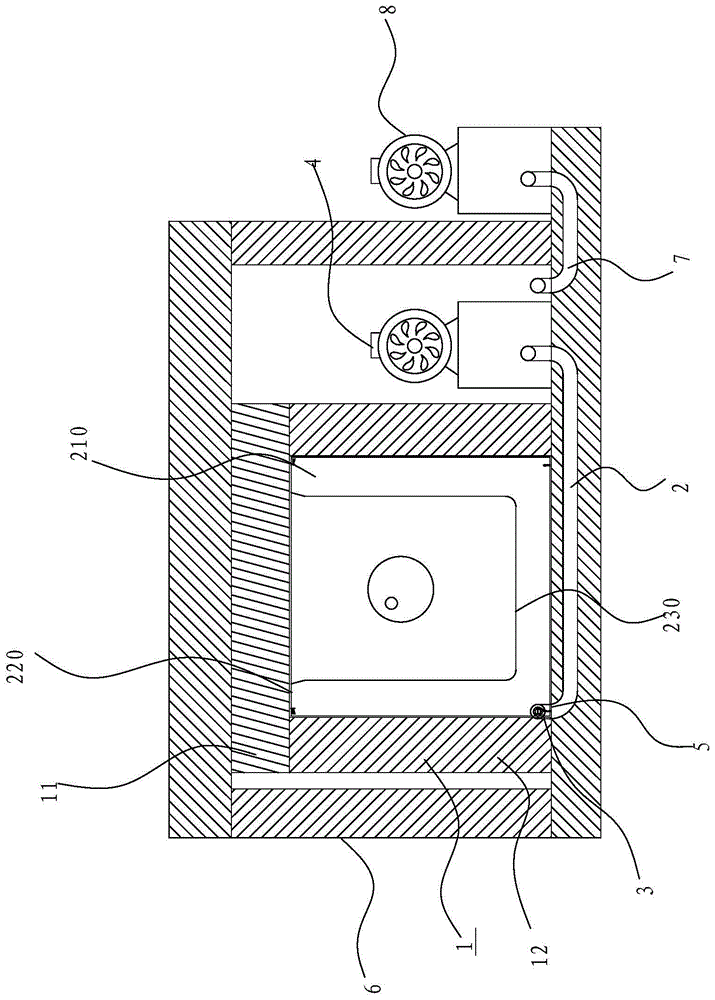

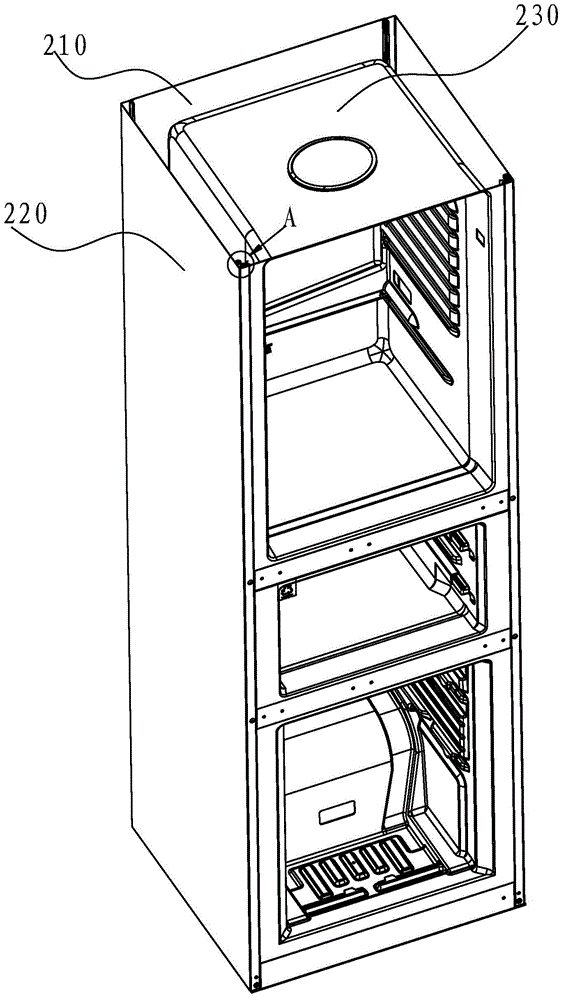

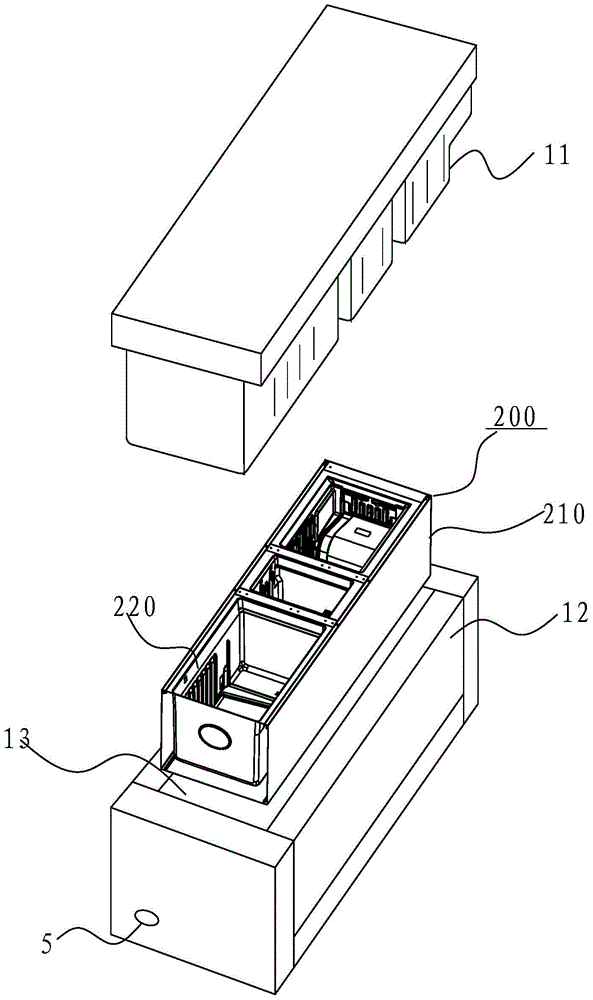

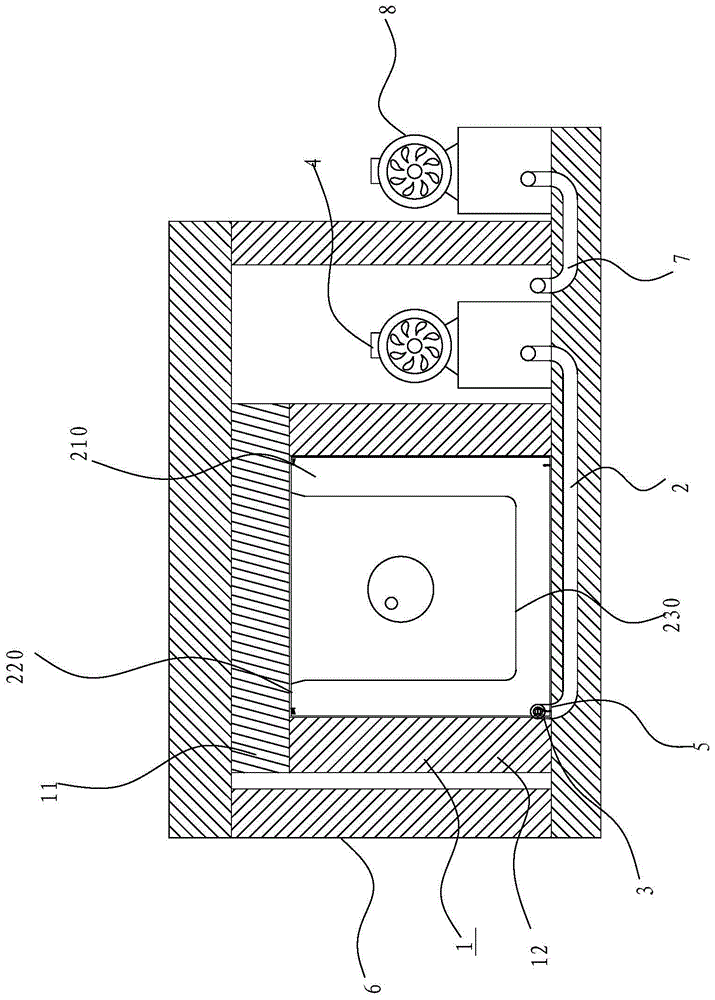

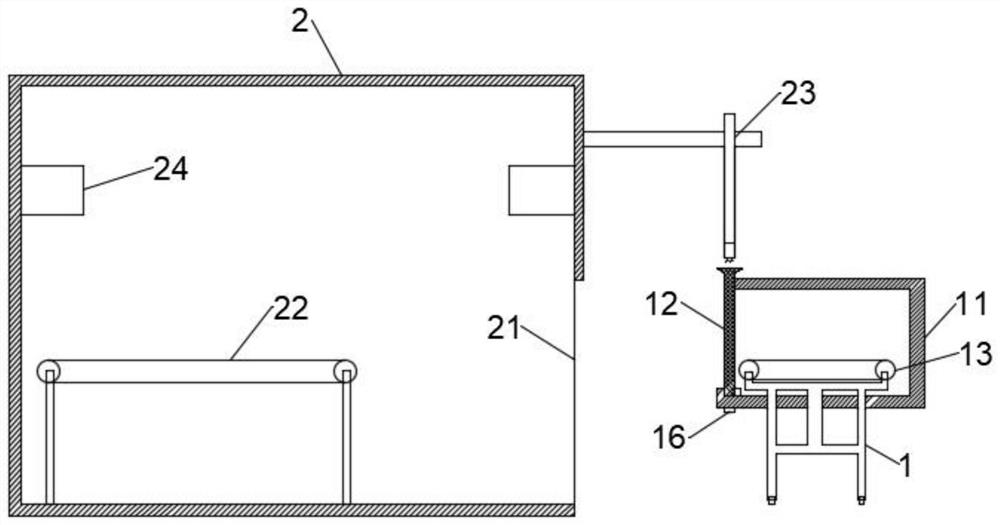

Foaming apparatus, foaming process and foaming process of refrigerating device

The invention discloses a foaming machine which is used for foaming a preassembled assembly that is provided with a foaming space defined therein. The foaming apparatus comprises a foaming die for defining a die cavity, a first air exhauster mechanism communicated with the die cavity, a second air exhauster mechanism arranged in the foaming space in an extending manner, a first negative pressure providing device and a sealing member, wherein the second air exhauster mechanism is communicated with the die, the first negative pressure providing device is connected with the first air exhauster mechanism and used for forming negative pressure in the foaming space; and the sealing member is arranged on a contact surface between a first die and a second die and used for sealing the die cavity. According to the foaming apparatus provided by the embodiment of the invention, by adopting the second air exhauster mechanism, air negative pressure can be uniformly transmitted into the foaming space, therefore, an obtained insulation layer has better performance, foaming raw materials can be saved, and cost is lowered. In addition, the sealing member can ensure that low pressure is kept in the foaming space in a foaming process and the foaming quality is further ensured. The invention also discloses a foaming process by adopting the foaming apparatus and a foaming process of a refrigerating device.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

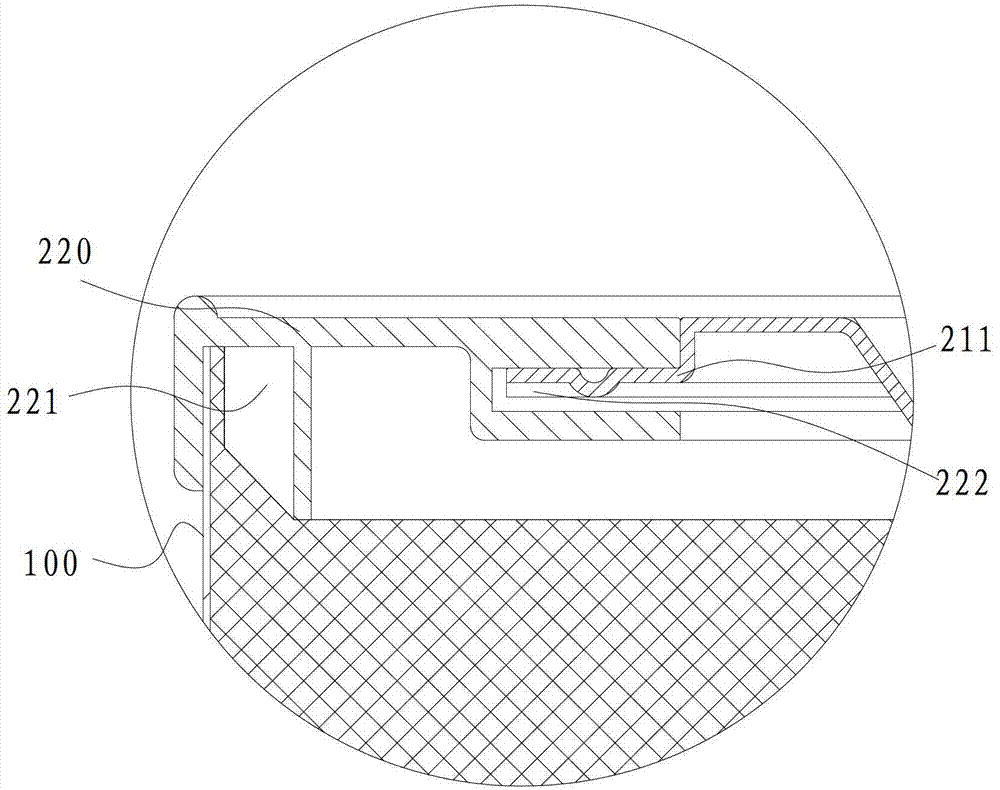

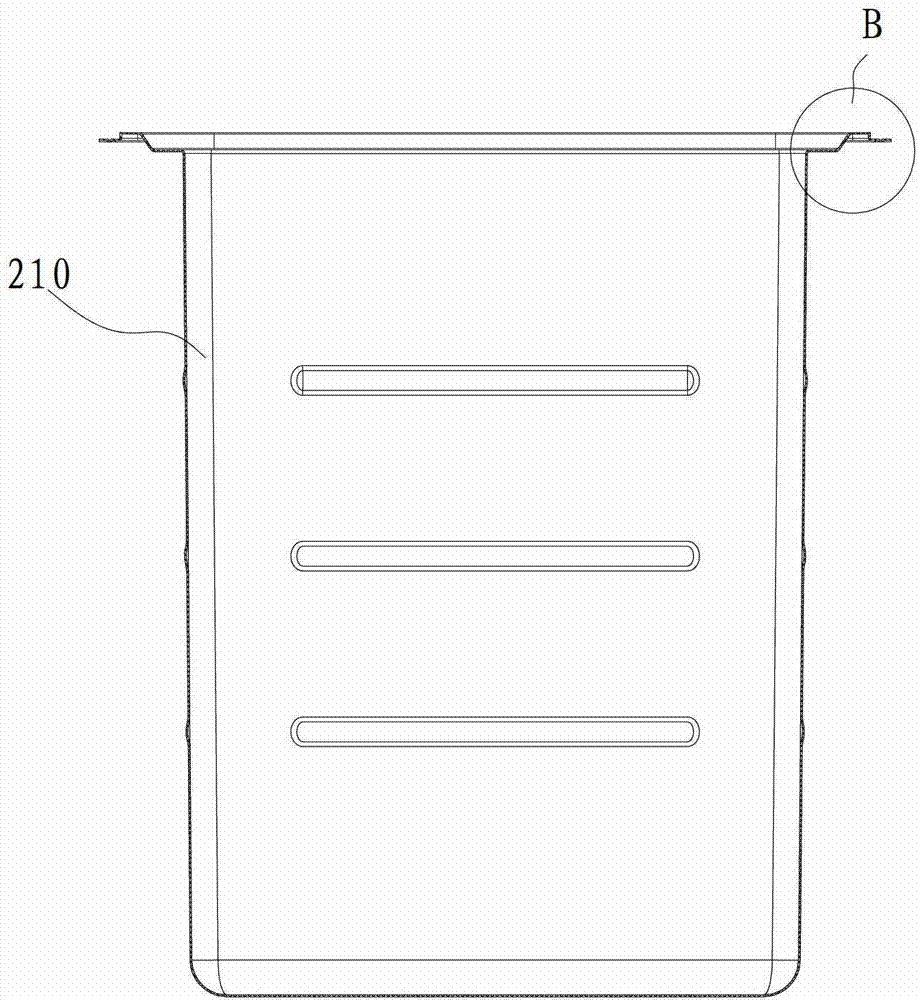

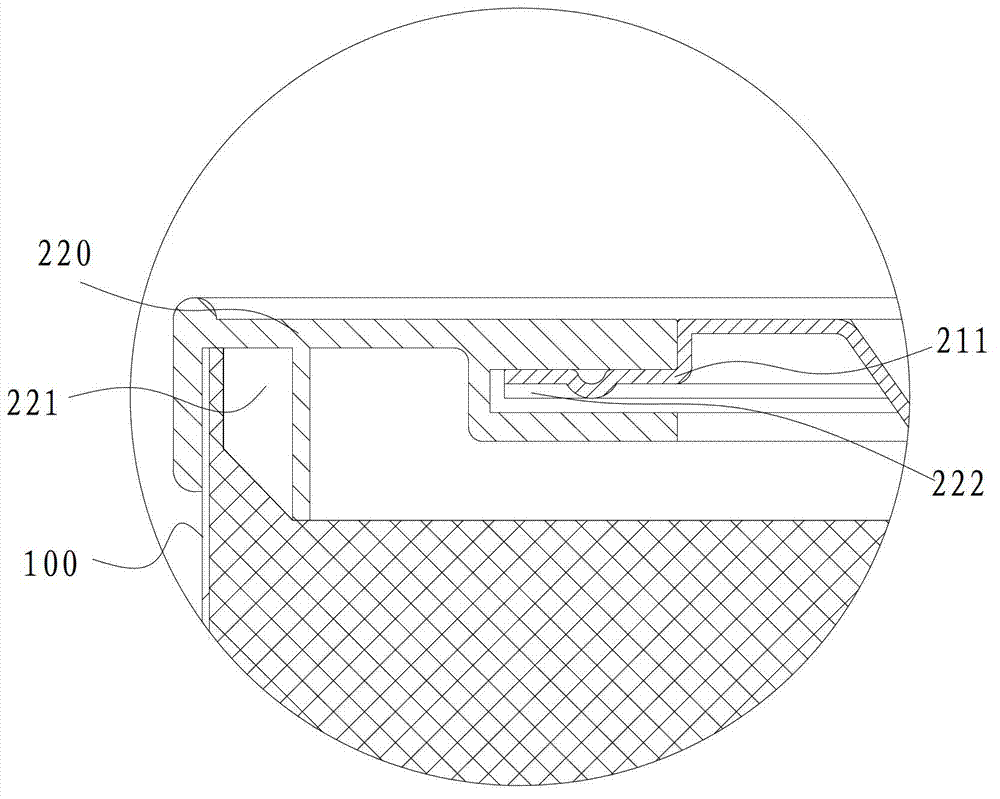

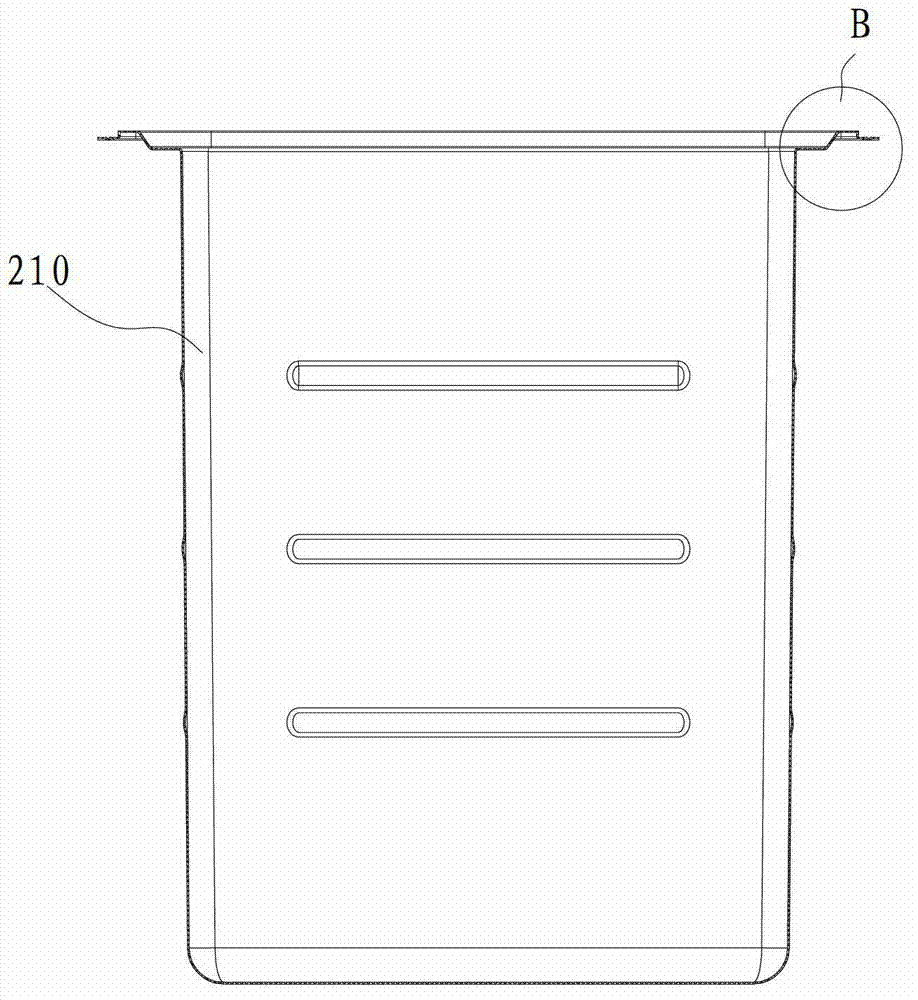

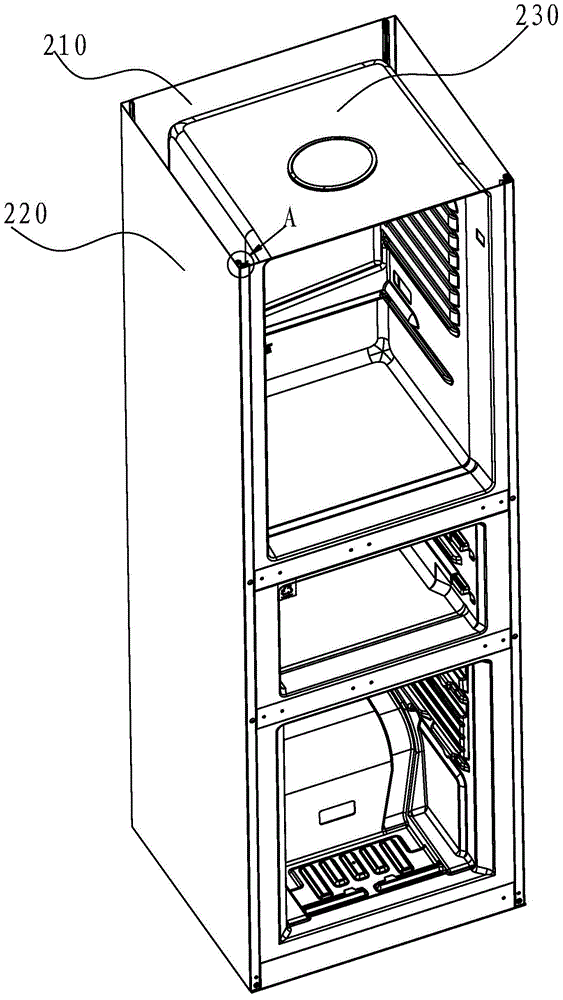

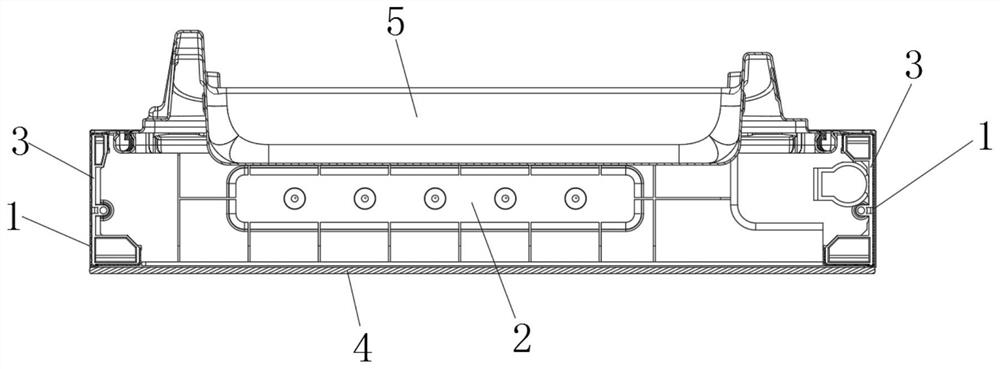

Freezer and inner container assembly thereof

ActiveCN102778100AEasy production and assemblyReduce scrap rateLighting and heating apparatusDomestic refrigeratorsEngineeringRejection rate

The invention discloses a freezer and an inner container assembly for the same. The inner container assembly comprises an inner container and an opening frame, a ribbed ring which extends along the horizontal direction is arranged at the outer peripheral edge of the inner container, a first slot matched with the ribbed ring is arranged at the inner peripheral edge of the opening frame, a second slot which extends along the vertical direction and is adjacent to the outer peripheral edge of the opening frame is arranged on the lower surface of the opening frame, and the ribbed ring of the inner container is fittingly arranged in the first slot of the opening frame. According to the inner container assembly in an embodiment of the invention, the first slot and the second slot can be respectively matched with the inner container and a shell, and the position of the inner container is limited in the vertical direction, so that production and assembly of the freezer are facilitated. In addition, the inner container is prevented from falling off, a foam layer of the freezer has a preset thickness, the rejection rate of the freezer is reduced, the freezer is attractive, the foaming quality of the freezer is guaranteed, the freezer is simple in structure, assembly efficiency is improved, and cost is lowered.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

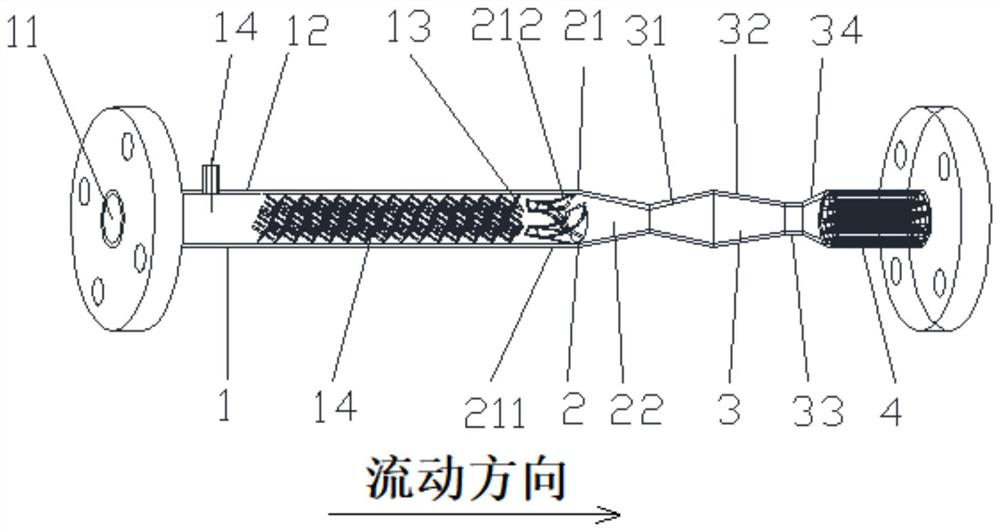

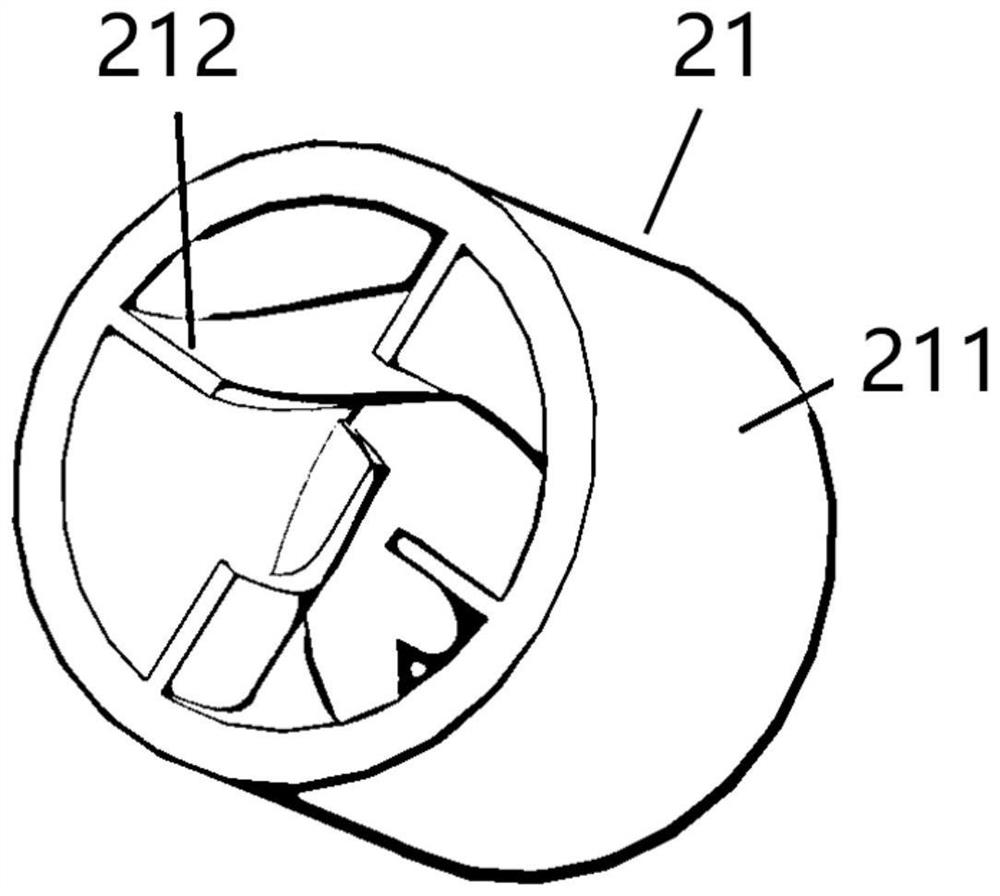

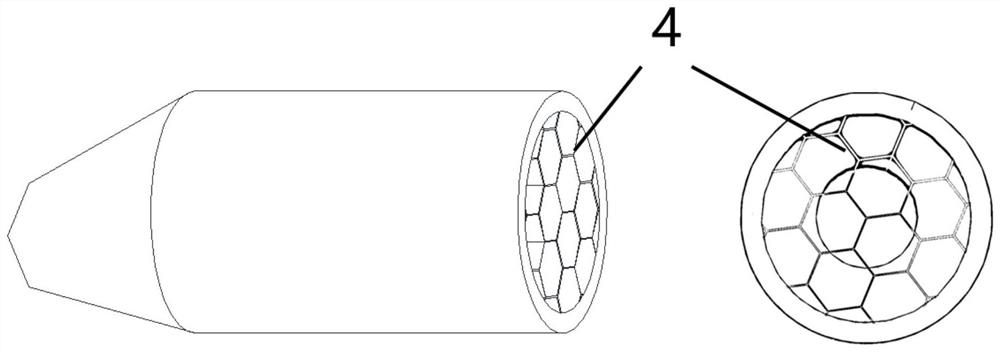

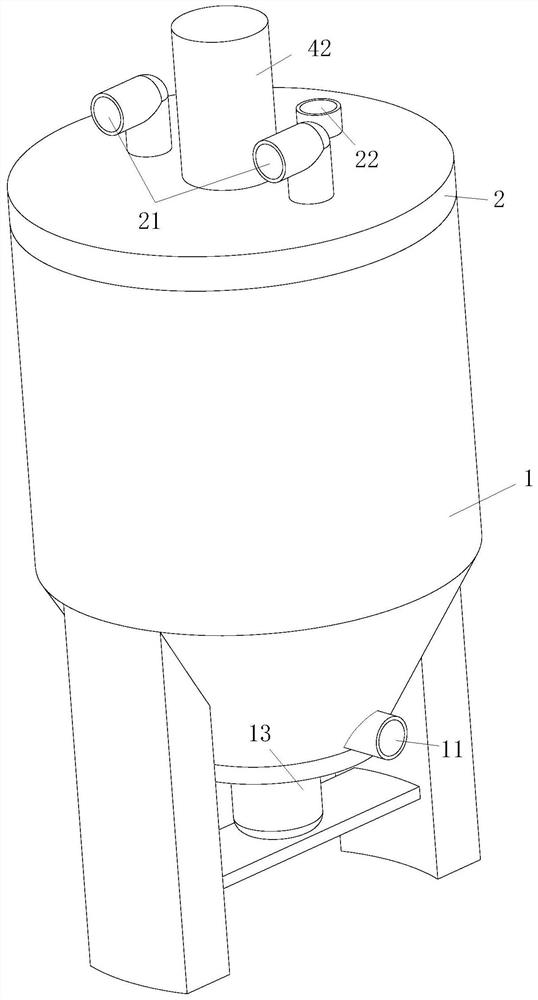

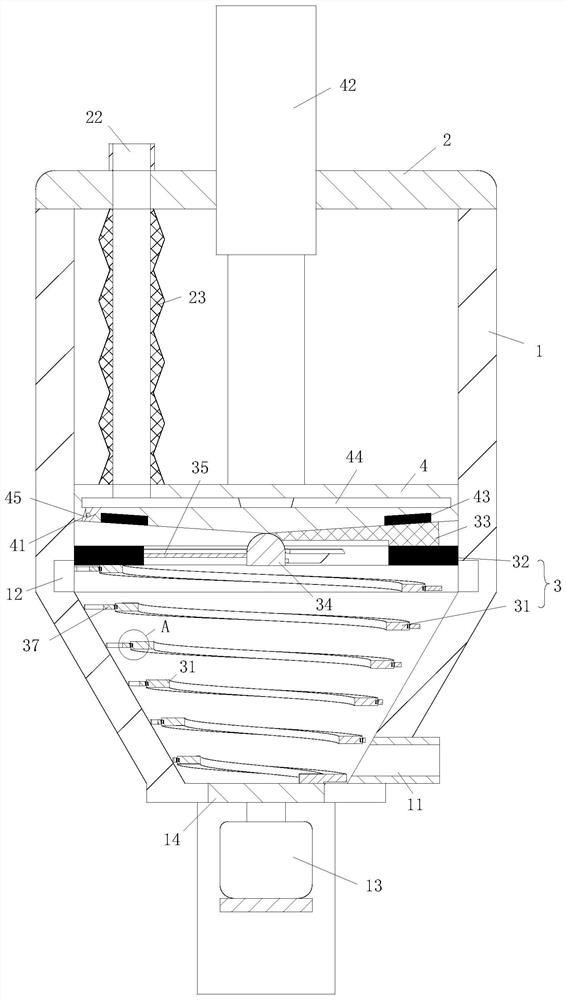

Premixing and homogenizing coupling type bubble generator

ActiveCN113144929AGuaranteed mixing effectReduce stratified flowFlow mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a premixing and homogenizing coupling type bubble generator. The bubble generator comprises a gas-liquid premixing section, a gas-liquid intensified mixing section, a gas-liquid homogenizing section and a vortex breaking section which are connected in sequence; the gas-liquid pre-mixing section is configured to perform primary shearing dispersion on gas-liquid two phases by utilizing high-speed turbulent flow to form a gas-liquid mixing dispersion field; the gas-liquid reinforced mixing section comprises a swirling section and a contraction section which are sequentially distributed, and a multi-dimensional swirling flow field is formed in the swirling section and is configured to induce the gas-liquid mixed phase from the gas-liquid premixing section to generate swirling flow motion; a flow channel of which the diameter is gradually reduced along the flowing direction of the gas-liquid mixed phase is formed in the contraction section; at least two stages of venturi tube-shaped flow channels which are connected in series are formed in the gas-liquid homogenizing section; and a micro-channel is formed in the vortex breaking section.

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

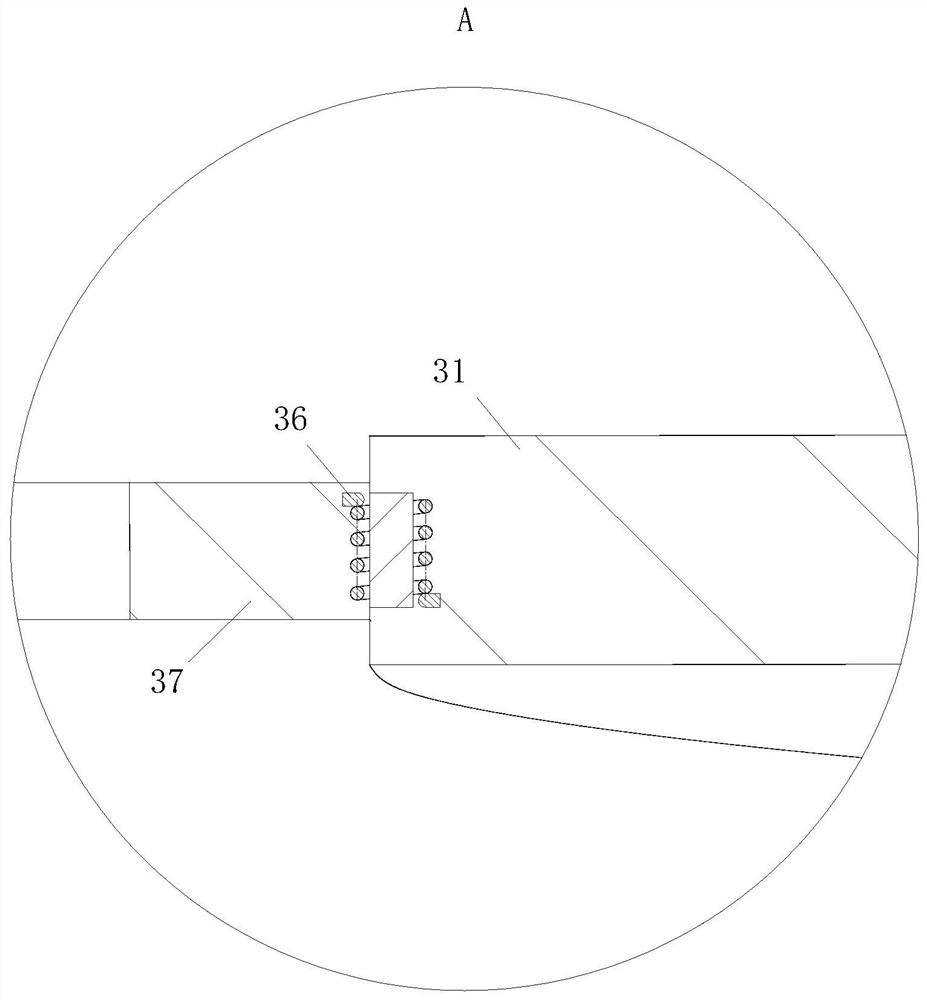

Foaming equipment, foaming technology and foaming technology of refrigeration plant

The invention discloses foaming equipment, a foaming technology and a foaming technology of a refrigeration plant. The foaming equipment is used for foaming a pre-assembling component; a foaming space is limited in the pre-assembling component; the foaming equipment comprises a foaming mould, a first air exhaust mechanism, a second air exhaust mechanism and a first negative pressure providing device. The foaming mould comprises a first mould body and a second mould body; the first mould body and the second mould body are matched to limit a mould cavity; the first air exhaust mechanism is communicated with the mould cavity; the second air exhaust mechanism comprises an air guide pipe fixedly arranged in the foaming space; the air guide pipe comprises an opening pipe and a clamping strip, an opening extending in the axial direction of the opening pipe is formed in the pipe wall of the opening pipe, and the clamping strip can be arranged on the opening pipe in a sliding mode to seal the opening. The first negative pressure providing device is connected with the first air exhaust mechanism and used for forming negative pressure in the foaming space. According to the foaming equipment, air negative pressure can be evenly transmitted to the foaming space, and therefore the heat preservation performance of a heat preservation layer obtained after foaming is better, foaming raw materials can be saved, and the cost is reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Foaming equipment, foaming process and foaming process of refrigerating equipment

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

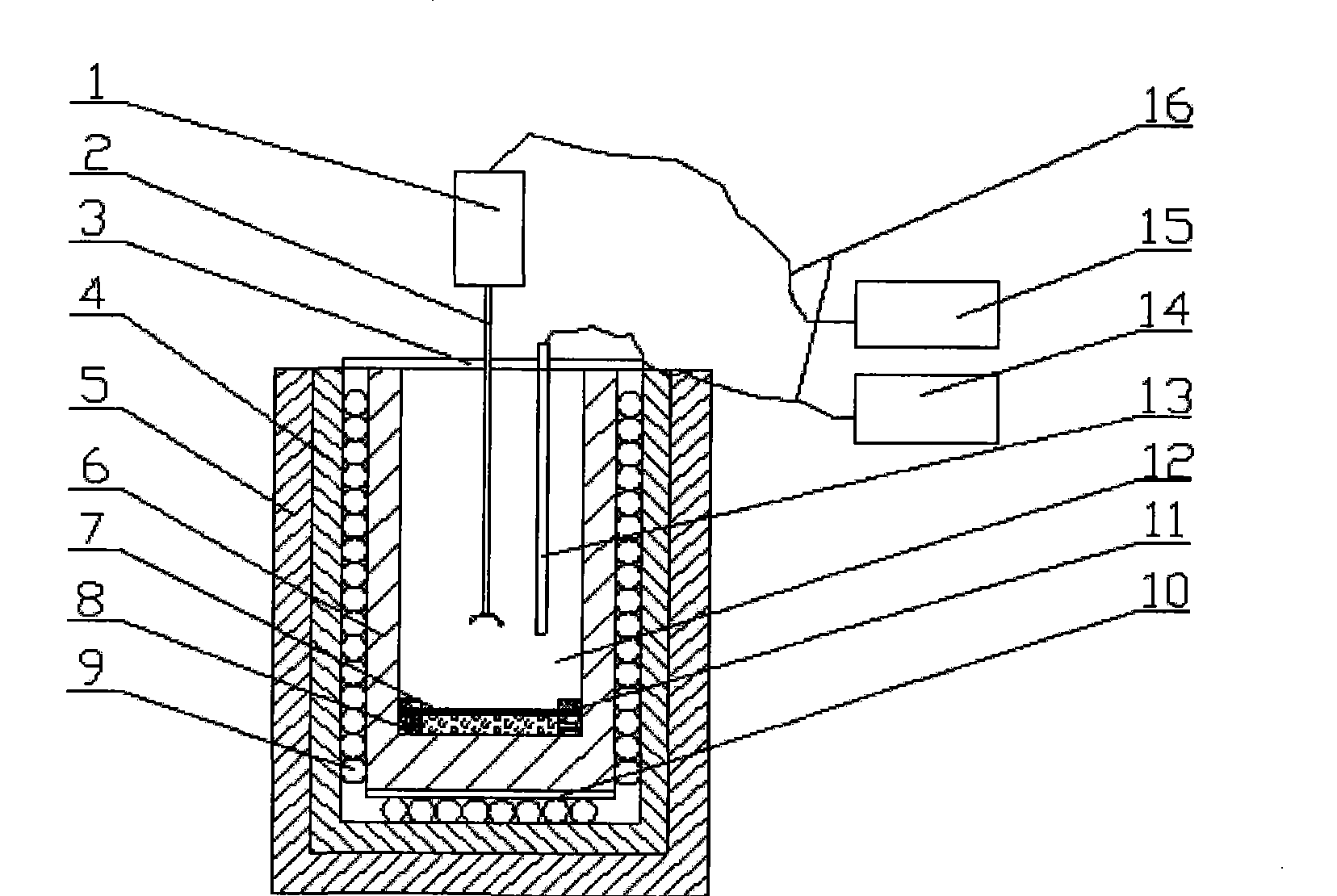

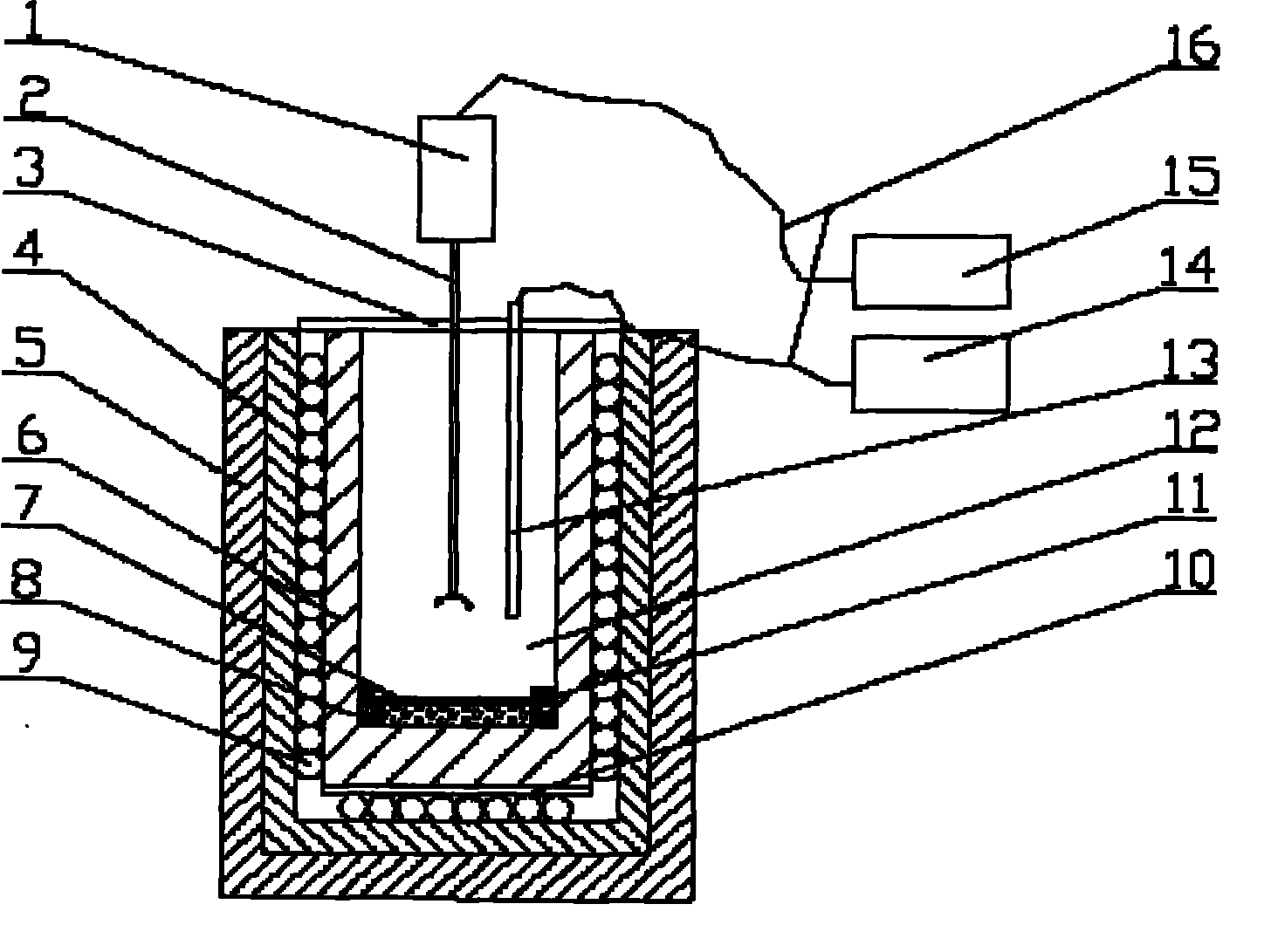

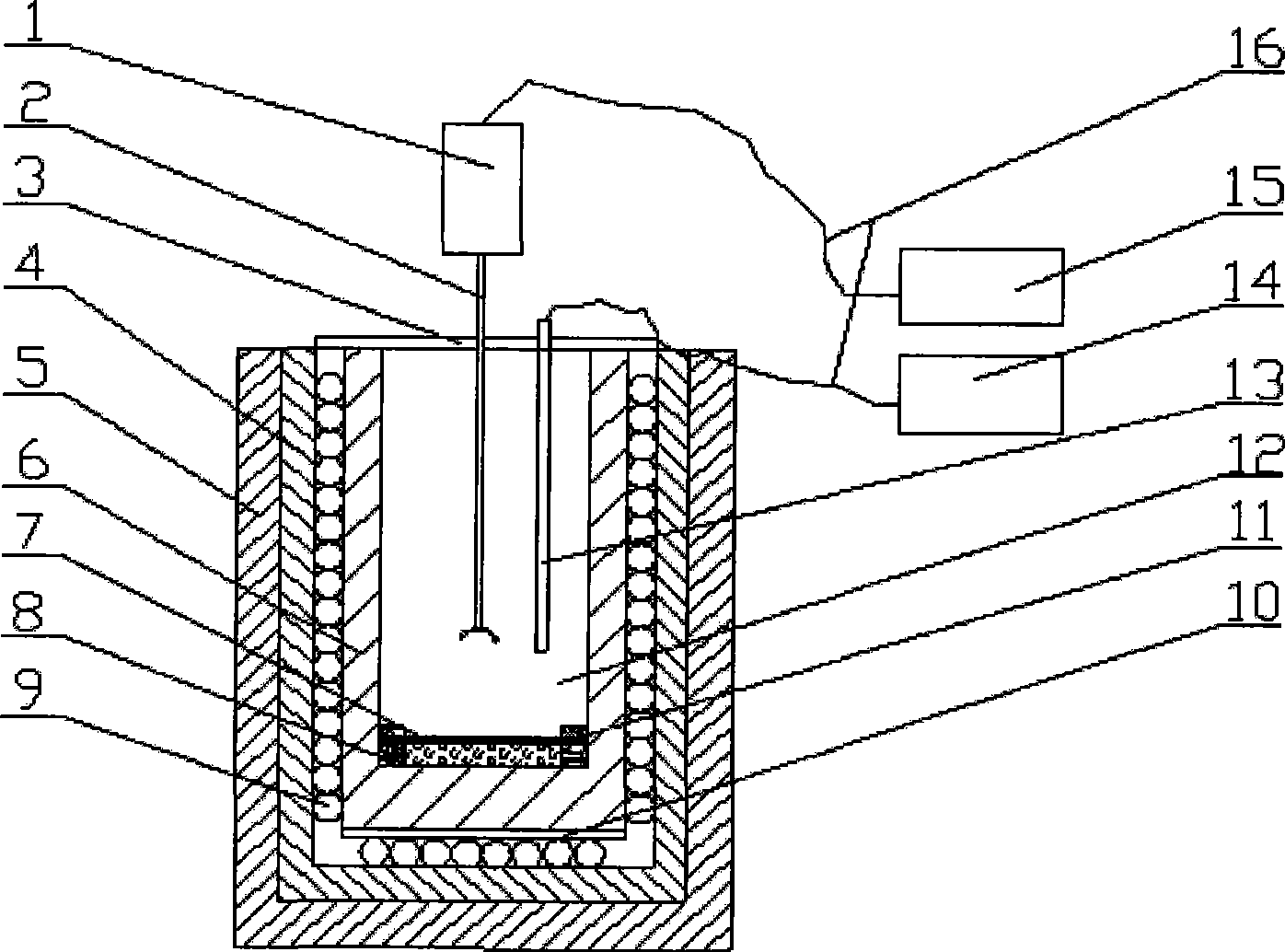

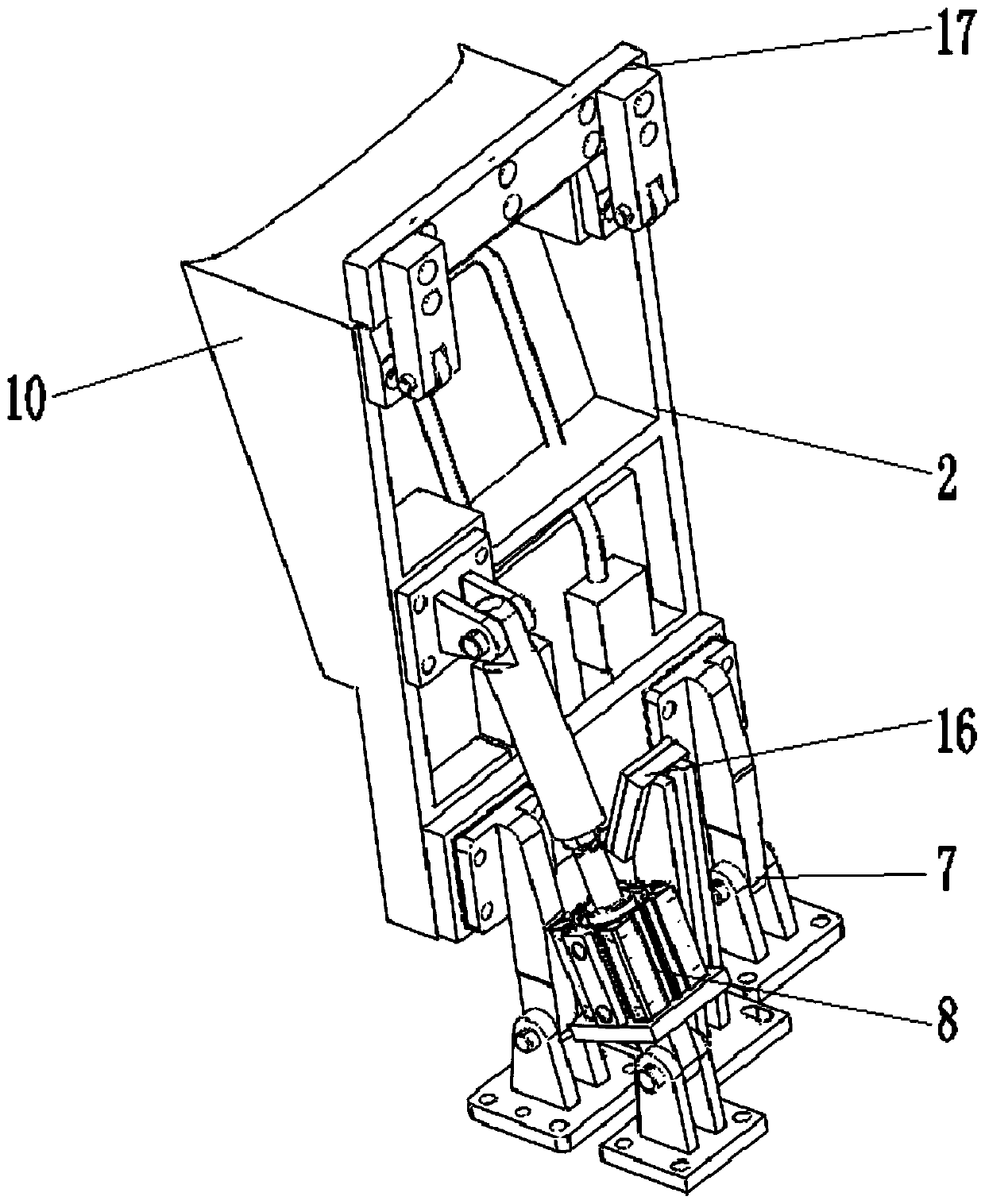

Method for preparing porous foam steel by melt foaming process and apparatus thereof

The invention provides a method and a device for preparing porous blister steels through foaming of fused masses. The method comprises the following steps: firstly, a foaming agent is flatly laid at the bottom of a crucible and covered with a stainless steel mesh, so as to prevent the foaming agent from floating upward; secondly, the crucible is placed into a heating furnace for heating until thetemperature is 50 to 100 DEG C lower than the temperature that the foaming agent begins to discompose, and molten steels are poured into the crucible; thirdly, a heat-insulated heating device is utilized to adjust the temperature of the molten steels in the crucible until the temperature is 250 to 350 DEG C above the temperature that the foaming agent begins to discompose; and fourthly, after heat preserved stirring for 1 to 2 minutes, the crucible is taken out and air-cooled to the room temperature, and the porous blister steel materials are obtained. The method and the device can increase the residence time of the molten steels within a temperature region for decomposing the foaming agent, prevent the foaming agent from floating upward, and improve the structural characteristics and thedistribution characteristics of holes of prepared samples, has simple technique, is easy to operate, and is an ideal method for preparing the porous blister steels.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing porous foam steel by melt foaming process and apparatus thereof

The invention provides a method and a device for preparing porous blister steels through foaming of fused masses. The method comprises the following steps: firstly, a foaming agent is flatly laid at the bottom of a crucible and covered with a stainless steel mesh, so as to prevent the foaming agent from floating upward; secondly, the crucible is placed into a heating furnace for heating until the temperature is 50 to 100 DEG C lower than the temperature that the foaming agent begins to discompose, and molten steels are poured into the crucible; thirdly, a heat-insulated heating device is utilized to adjust the temperature of the molten steels in the crucible until the temperature is 250 to 350 DEG C above the temperature that the foaming agent begins to discompose; and fourthly, after heat preserved stirring for 1 to 2 minutes, the crucible is taken out and air-cooled to the room temperature, and the porous blister steel materials are obtained. The method and the device can increase the residence time of the molten steels within a temperature region for decomposing the foaming agent, prevent the foaming agent from floating upward, and improve the structural characteristics and the distribution characteristics of holes of prepared samples, has simple technique, is easy to operate, and is an ideal method for preparing the porous blister steels.

Owner:KUNMING UNIV OF SCI & TECH

Foaming equipment, foaming process and foaming process for refrigeration equipment

The invention discloses foaming equipment used for foaming a pre-assembled component. A foaming space is defined in the pre-assembled component. The foaming equipment comprises a foaming mold, a first pumping mechanism, a second pumping mechanism and a first negative pressure providing device, wherein the foaming mold comprises a first mold and a second mold; the first mold and the second mold are mutually matched to define a cavity; the first pumping mechanism is communicated with the cavity; the second pumping mechanism is arranged in the foaming space, extends in the foaming space, and is communicated with the cavity; and the first negative pressure providing device is connected with the first pumping mechanism and is used for forming negative pressure in the foaming space. In the foaming equipment, through the second pumping mechanism extending in the foaming space, the negative air pressure can be uniformly transmitted to the foaming space, so that a heat insulation layer obtained through foaming has better heat insulation effect; moreover, a foaming raw material can be saved and the cost is reduced. The invention discloses a foaming process employing the foaming equipment, and a foaming process for refrigeration equipment.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

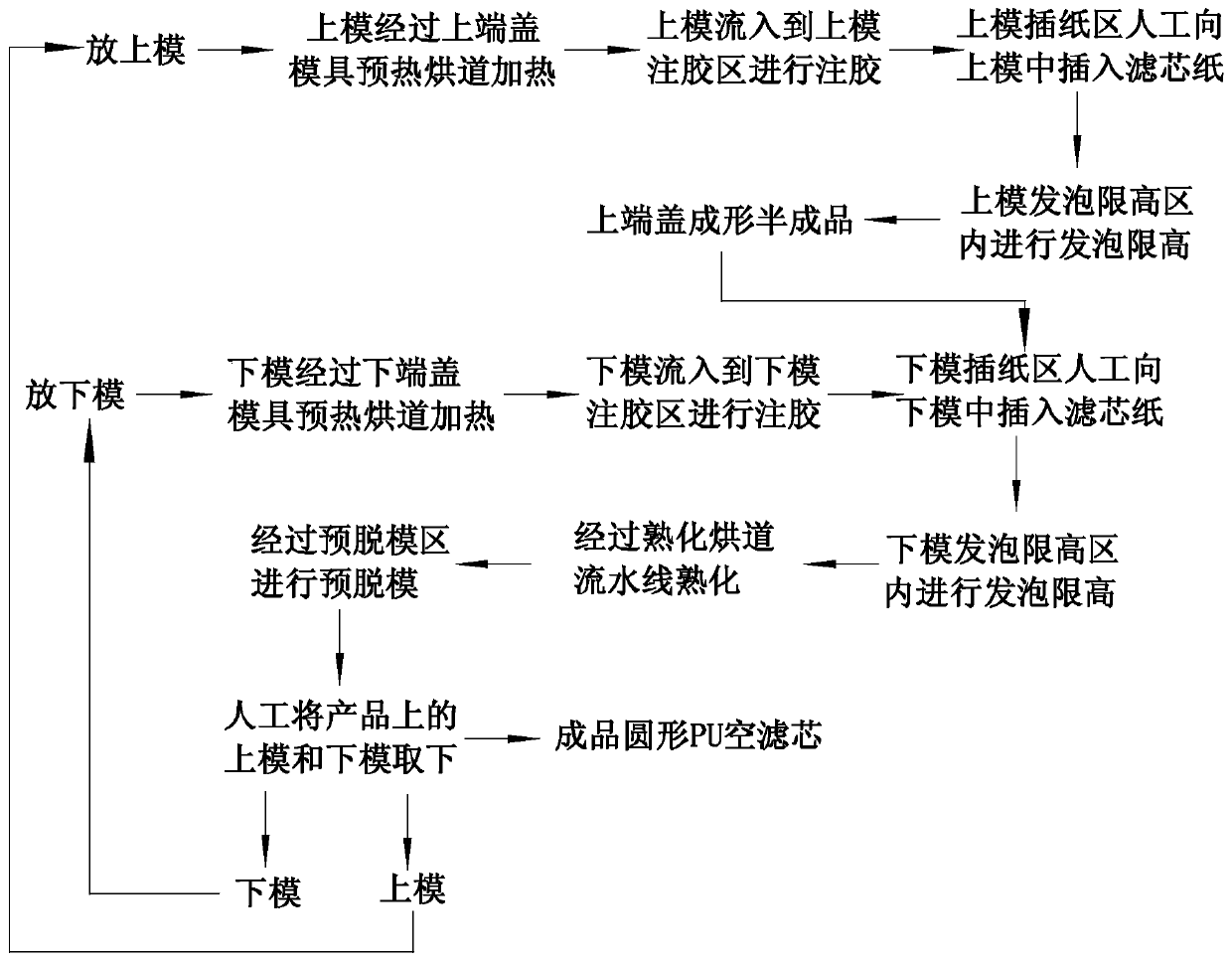

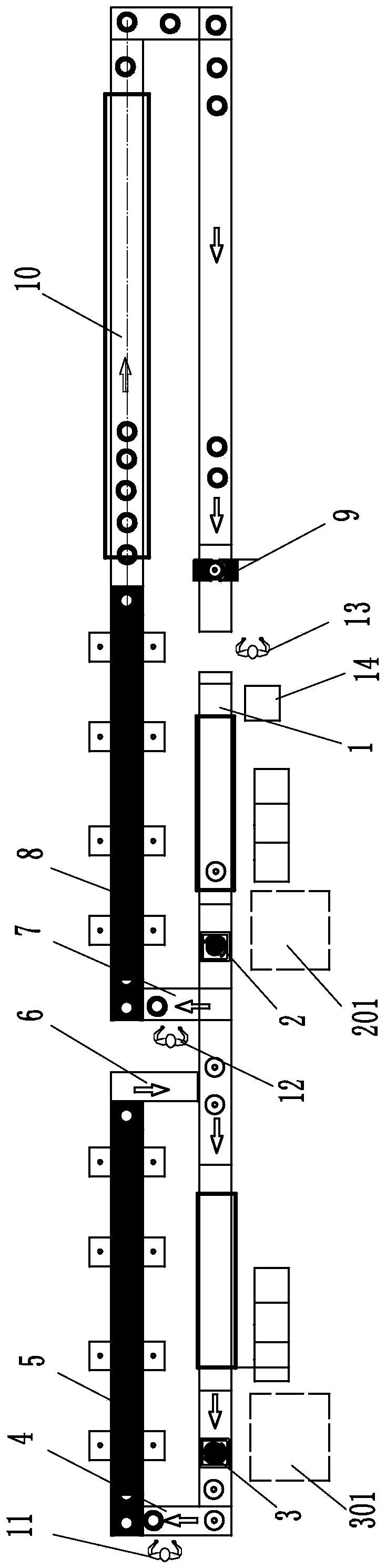

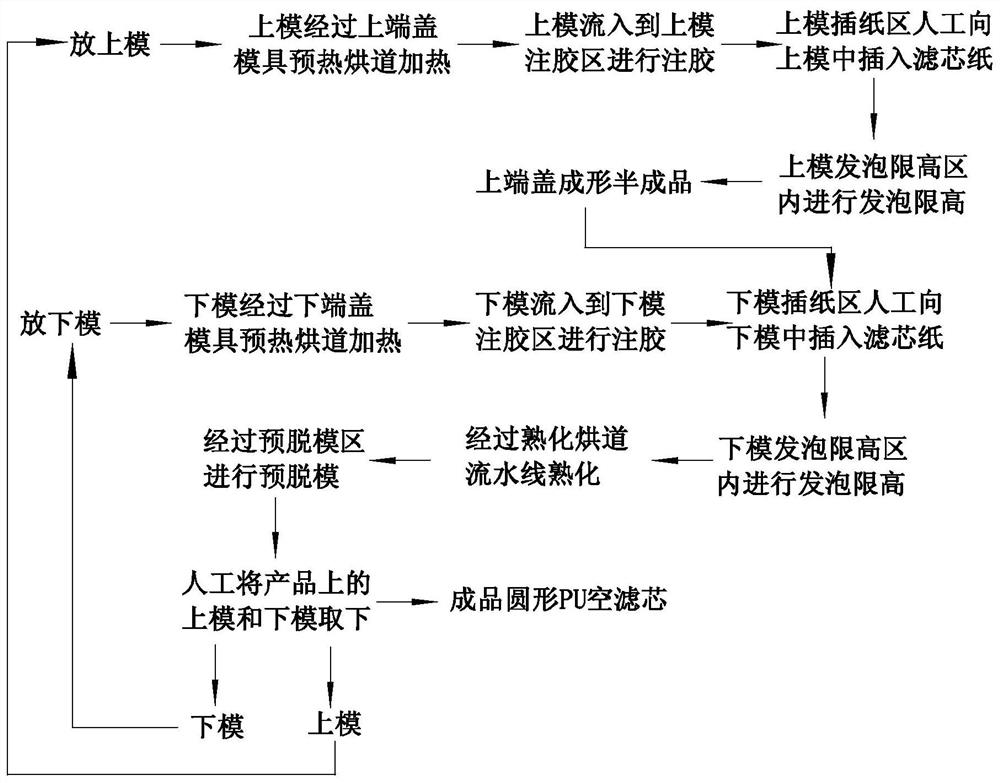

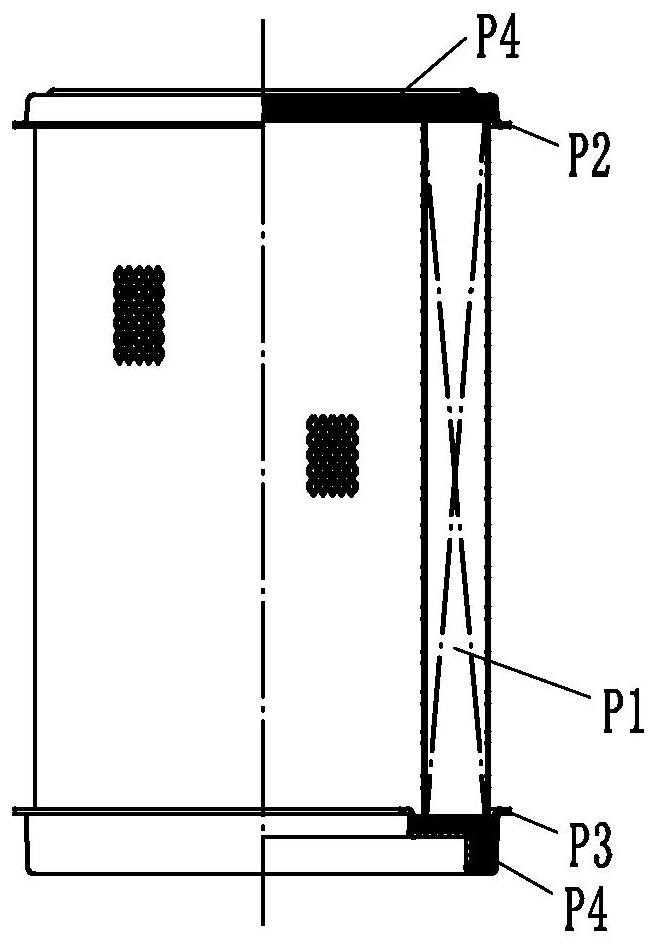

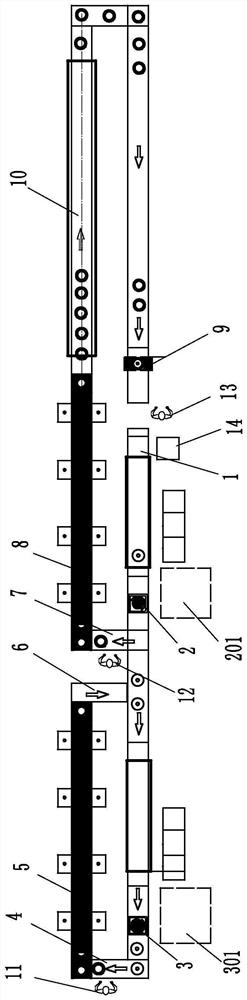

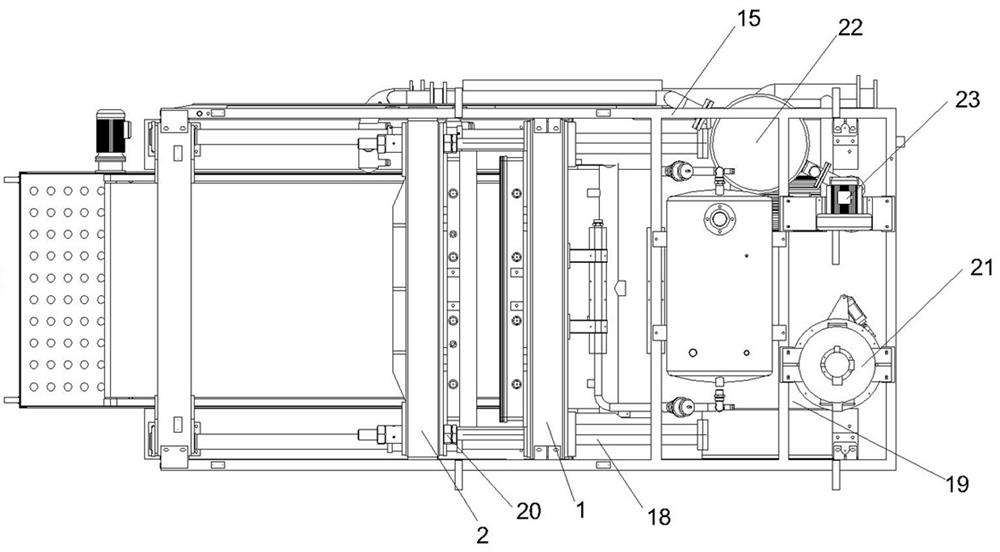

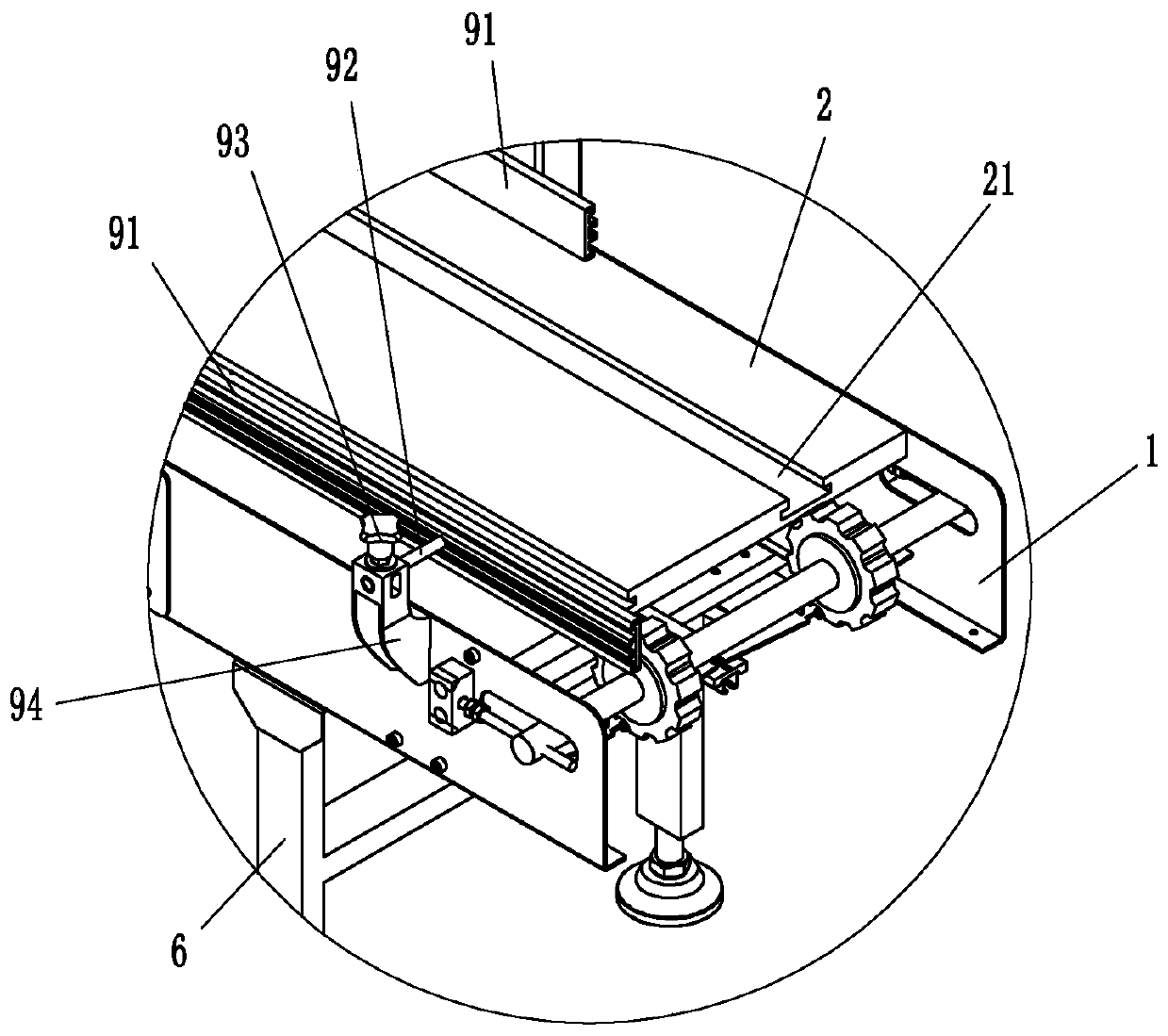

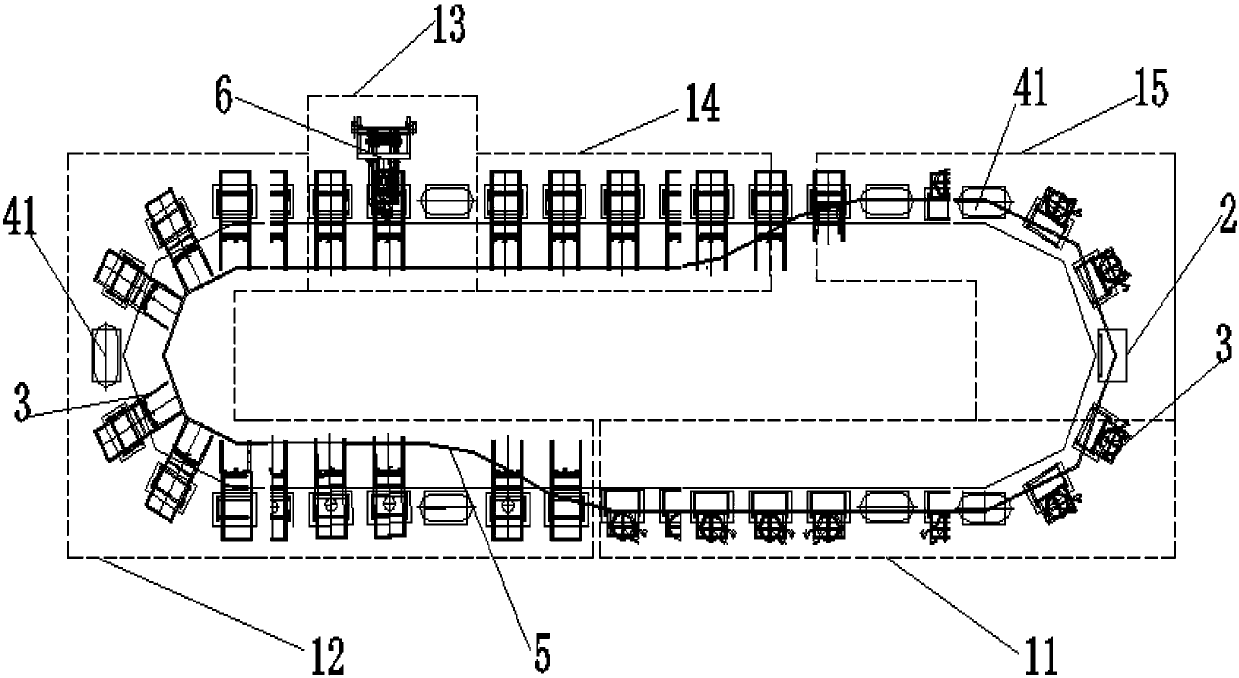

Circular PU air filter element production method

The invention relates to a circular PU air filter element production method including the following steps that firstly, upper molds are put onto a mold conveying assembly line to be heated and then flow into an upper mold glue injection area to be subjected to glue injection, the upper molds completely subjected to glue injection flow into an upper mold paper insertion area to be subjected to manual paper insertion, and then upper end cover formed filter element semi-finished products are obtained after the upper molds pass an upper mold foaming solidifying heat preservation and height limitation area; secondly, the upper molds are continuously put onto the mold conveying assembly line, and the first step is unceasingly repeated; thirdly, lower end covers are formed at the other ends of the semi-finished products, and the forming process is basically the same as that in the first step; and fourthly, after curing and demolding, finished product circular PU air filter elements are obtained. According to the circular PU air filter element production method, the circular PU air filter elements are produced through a continuous production method, assembly line production is adopted forkey working procedure points, including glue injection, foaming solidifying heat preservation and height limitation, curing heat preservation and pre-demolding, in PU air filter element production, the production efficiency can be improved, the labor intensity can be lowered, raw material waste can be reduced, and quality stability can be improved.

Owner:柳州日高滤清器有限责任公司

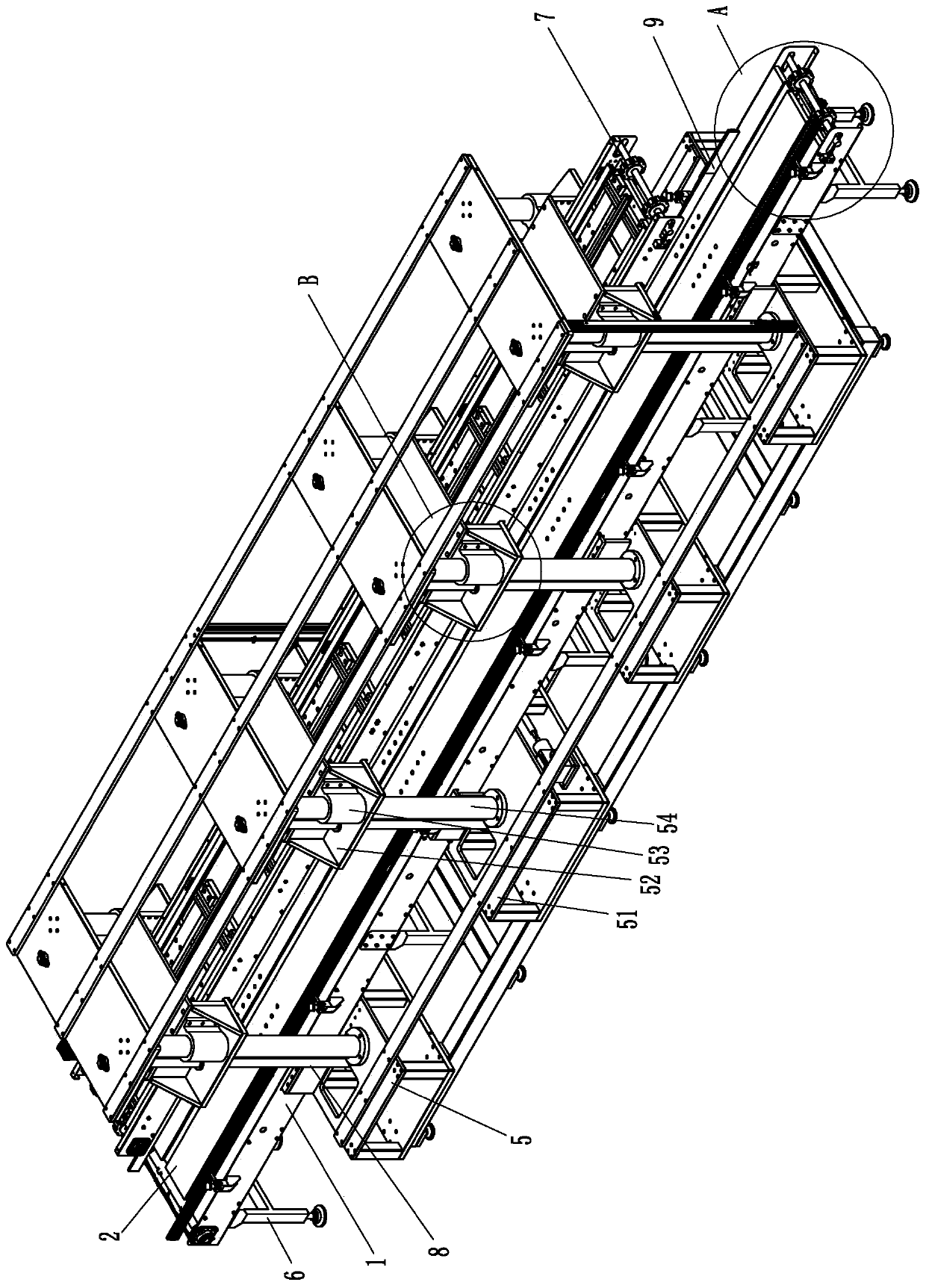

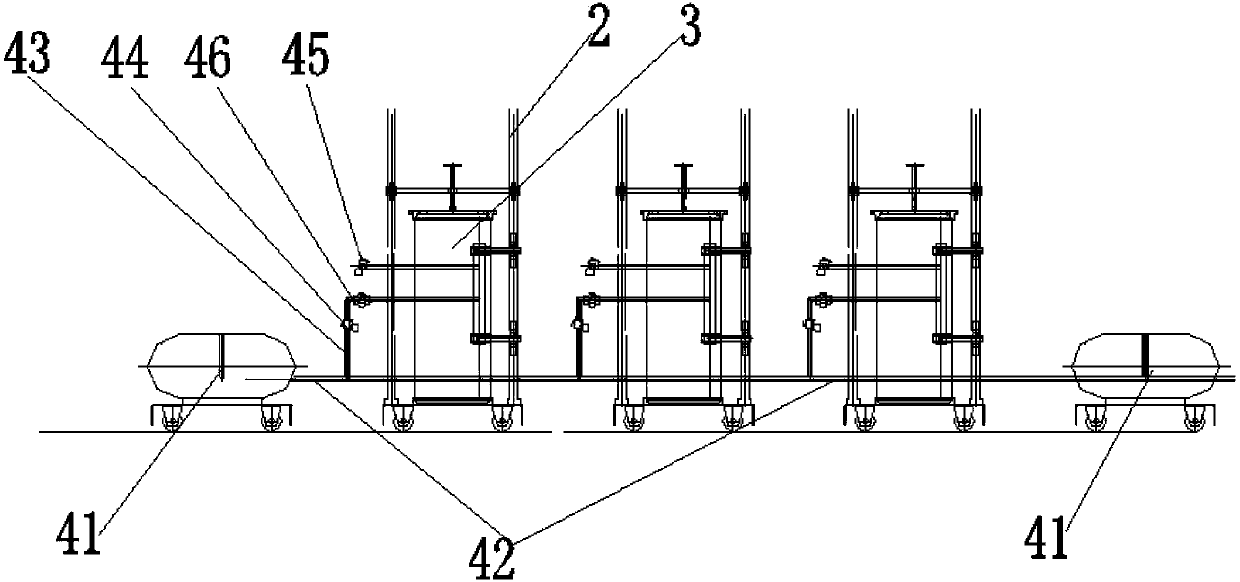

Automatic foaming production line for car mats

The invention discloses an automatic foaming production line for car mats. The automatic foaming production line comprises a stirring tank; the axis at the top of the stirring tank is fixedly connected with a first motor; an output end of the first motor penetrates through the top of the stirring tank and extends to the inner cavity of the stirring tank; the bottom of the output end of the first motor is fixedly connected with a transmission rod; and stirring rods are fixedly connected with two sides of the surface of the transmission rod. Through cooperative using of the stirring tank, the first motor, the transmission rod, the stirring rod, a vulcanizing agent cabin, a foaming agent cabin, a heating block, a bottom plate and a feeding pipe, rubber materials can be dynamically vulcanized,so that the foaming effect is better ensured, rubber compounds can be pre-formed and then the forming work of rubber products is better ensured; and vulcanization and foaming are carried out on the pre-formed rubber products through a conveyer belt and a drying box, so that the foaming quality is better ensured, the working difficulty is reduced, the production cost is reduced and the product yield is improved.

Owner:吴燕

Polyurethane insulation board foaming system

The invention belongs to the technical field of insulation board foaming, and particularly relates to a polyurethane insulation board foaming system. The polyurethane insulation board foaming system comprises a material distributing device, a metering device, a foaming device, a spraying device and a forming device; the material distributing device is used for storing different distributed materials; and the metering device is used for metering and transporting the distributed materials stored by the material distributing device to the foaming device. According to the polyurethane insulation board foaming system, through cooperation of a pressing plate and a hydraulic push rod, the pressing plate can scrape off materials adhering to the inner wall of a shell, on the one hand, the situation that the materials adhere to the inner wall of the shell is reduced, and the labor intensity of workers is relieved, on the other hand, the residual quantity of the materials is reduced, and thus the mixing quality of the distributed materials is improved; and through arrangement of the pressing plate, the sealing effect in the shell is improved, the air inlet quantity is reduced, the quantity of oxidized polyether polyol in the distributed materials is reduced, the quality of the distributed materials is improved, then the foaming effect of the mixed materials is improved, and the quality of products generated through foaming is improved.

Owner:范心宇

Foaming equipment, foaming process and foaming process of refrigeration equipment

The invention discloses foaming equipment, a foaming process and a foaming process of refrigeration equipment. The foaming equipment is used to foam the pre-assembled components. The pre-assembled components define a foaming space, including: a foaming mold, the foaming mold includes a first mold and a second mold, and the first mold and the second mold cooperate with each other To define the mold cavity; the first air pumping mechanism communicated with the mold cavity; the second air pumping mechanism arranged in the foaming space and extending in the foaming space, wherein the second air pumping mechanism communicates with the mold cavity and includes : an air guide tube fixed in the foaming space, an air groove extending along its axial direction is formed on the tube wall of the air guide tube; and a first negative tube connected with the first pumping mechanism for forming a negative pressure in the foaming space pressure supply device. According to the foaming equipment of the embodiment of the present invention, the negative air pressure can be evenly transmitted into the foaming space, so that the thermal insulation layer obtained after foaming has better thermal insulation performance, and can save foaming raw materials and reduce costs.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

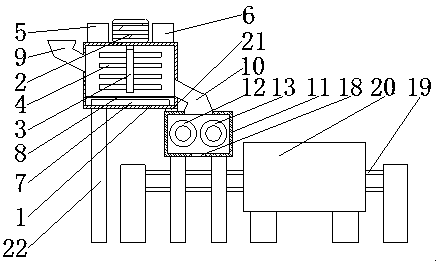

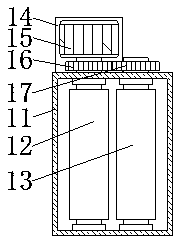

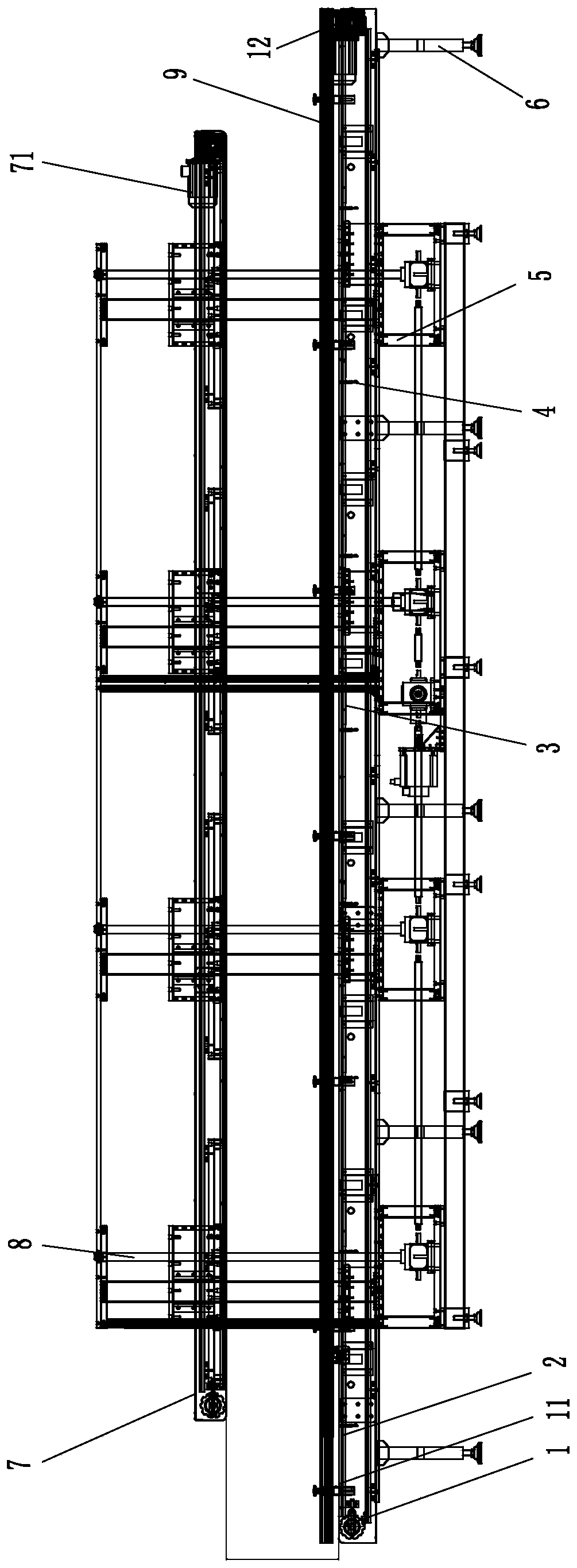

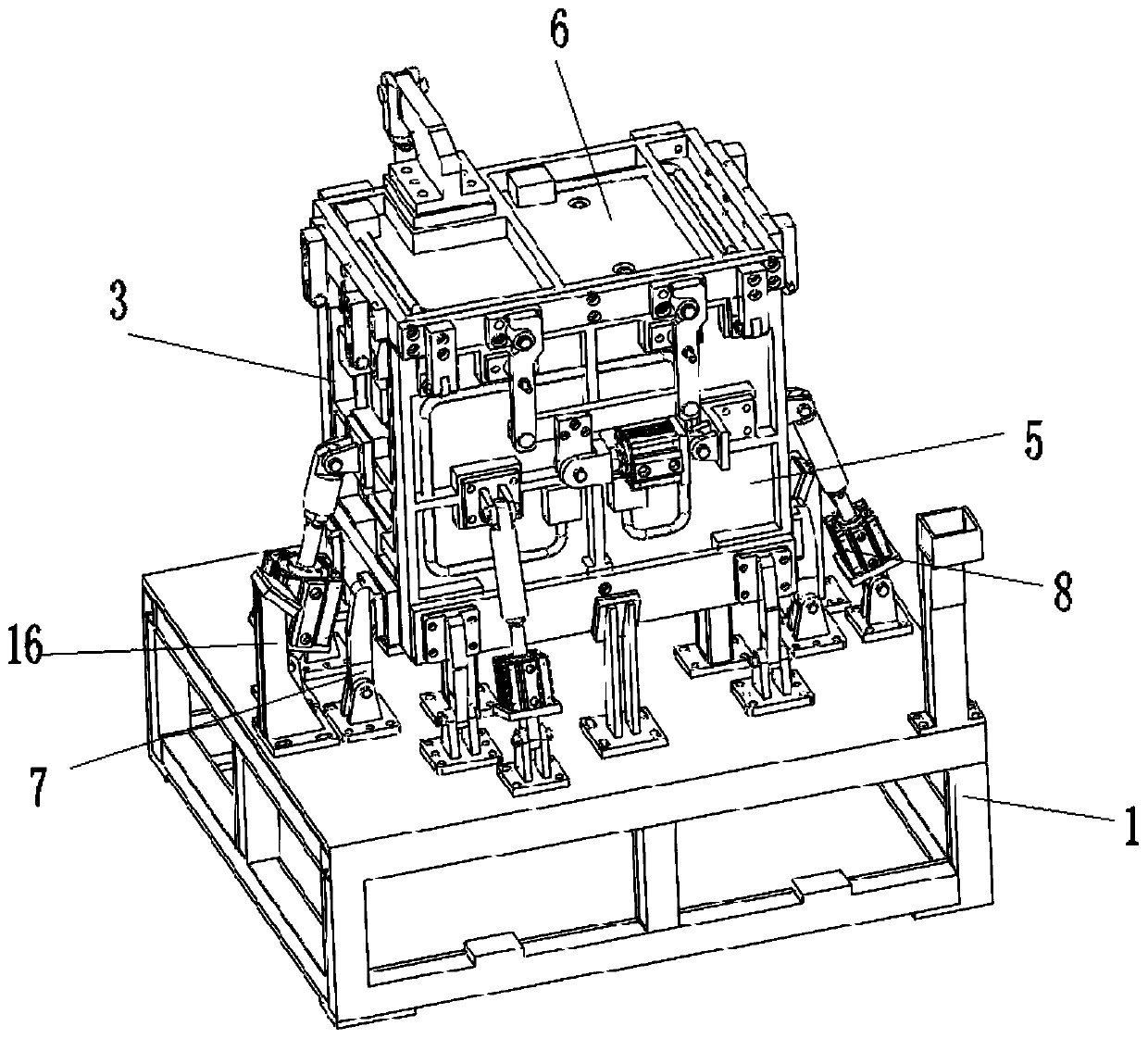

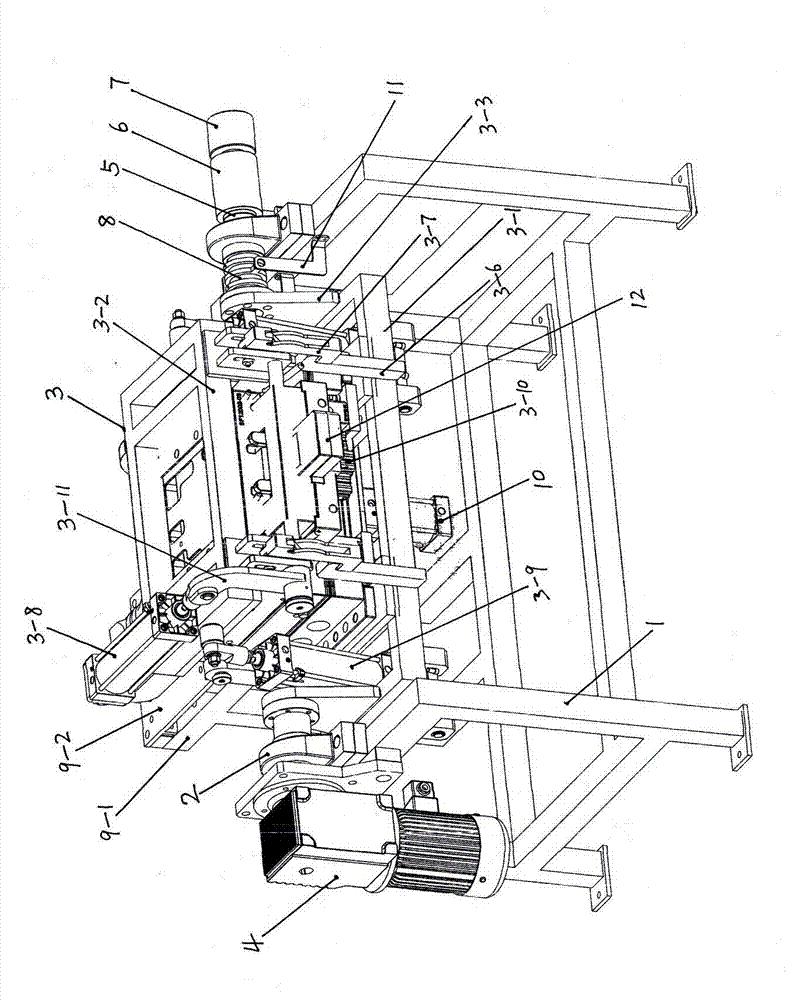

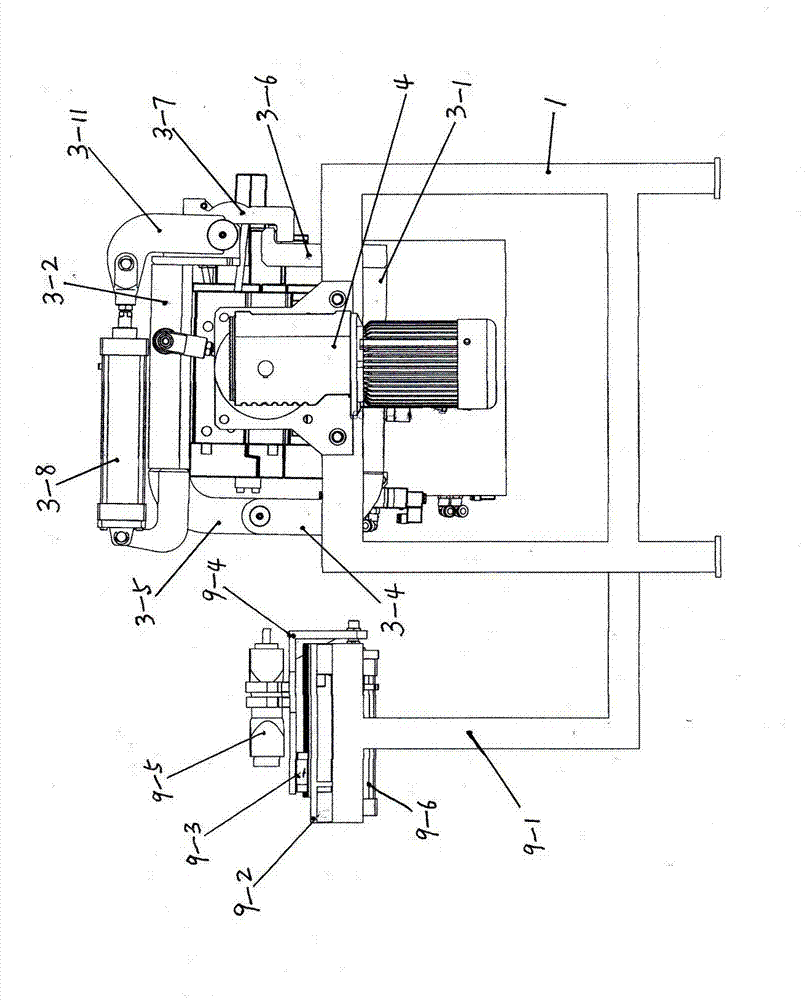

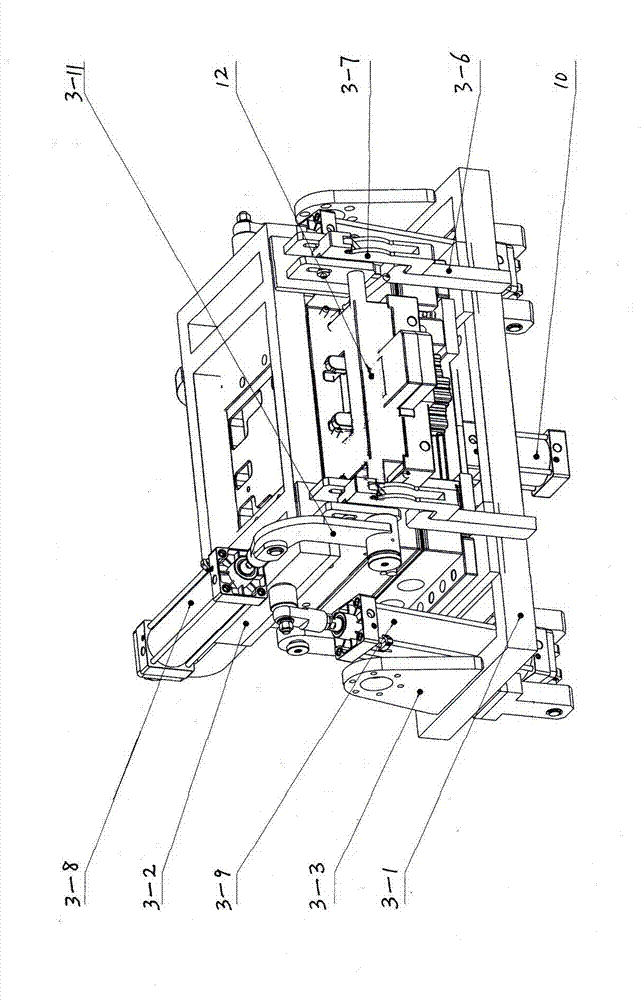

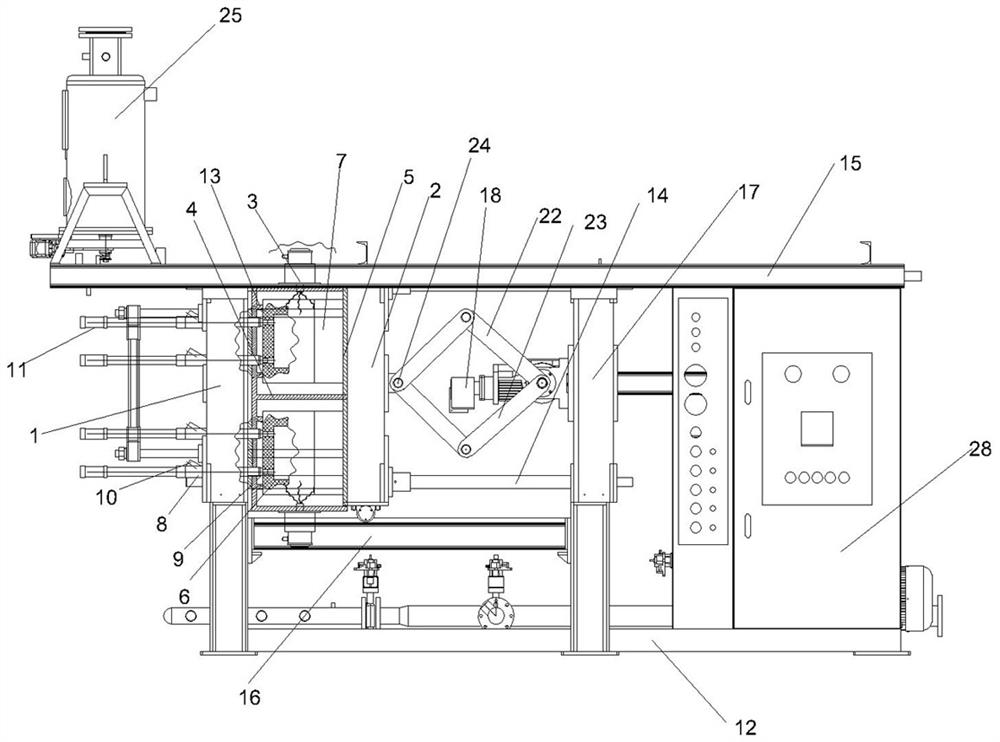

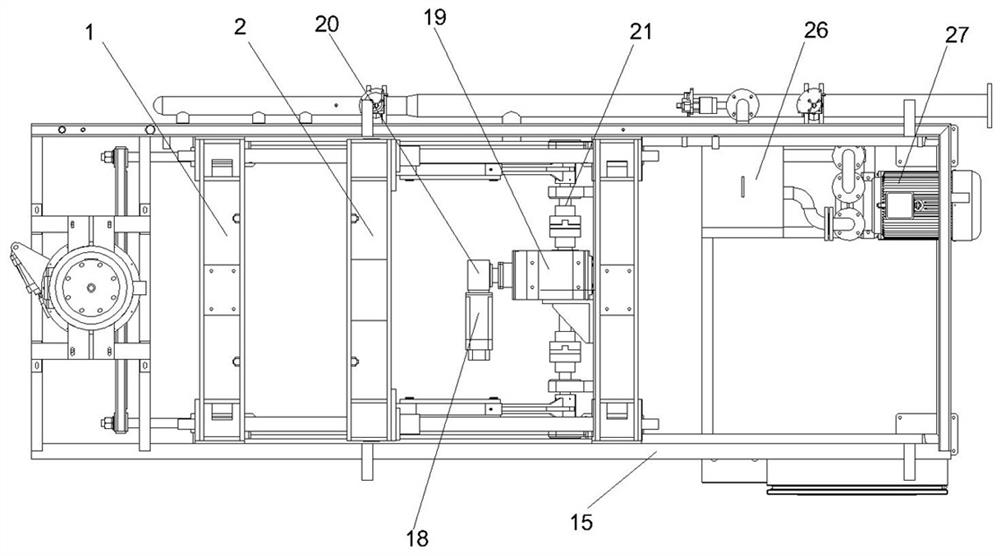

Electric-drive pull-back type microwave heating foaming forming machine and foaming forming method thereof

The invention discloses an electric-drive pull-back type microwave heating foaming forming machine and a foaming forming method thereof. The electric-drive pull-back type microwave heating foaming forming machine comprises a rack, a foaming forming mechanism, a charging basket, a vacuum cooling device, an electric cabinet, a driving motor and a transmission mechanism, wherein the foaming forming mechanism comprises fixed dies, movable dies, fixed die frames, movable die frames and foaming material injection pipes; each fixed die frame and the corresponding movable die frame are combined to form a complete die cavity; each die cavity corresponds to at least one foaming material injection pipe; at least one microwave shielding cover is arranged on each fixed die; at least one microwave shielding cover matched with the microwave shielding cover is arranged on each movable die; the movable die frames and the fixed die frames are made of high-temperature-resistant insulating materials; the fixed dies are positioned between the movable dies and the driving motor; and the driving motor drives the movable dies to move horizontally. According to the electric-drive pull-back type microwave heating foaming forming machine, microwave heating liquid is adopted to generate steam to be matched with foaming plastic for foaming, the structure is simple and compact, the overall size of the foaming forming machine is reduced, the energy consumption is relatively low, no pollution is caused, and the manufacturing and using costs are low.

Owner:杭州高福机械制造有限公司

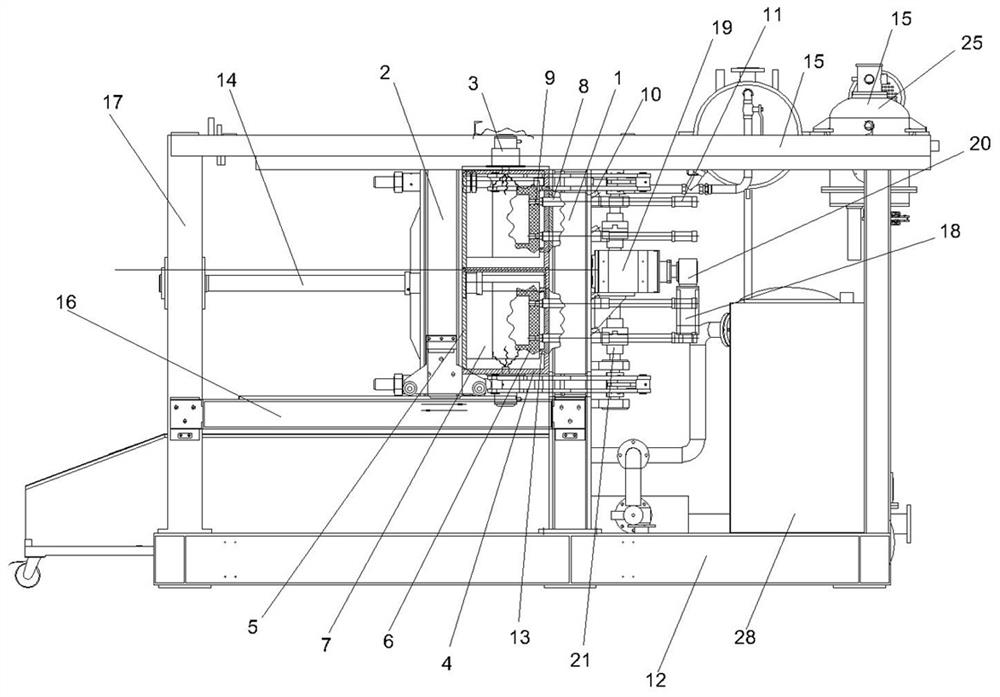

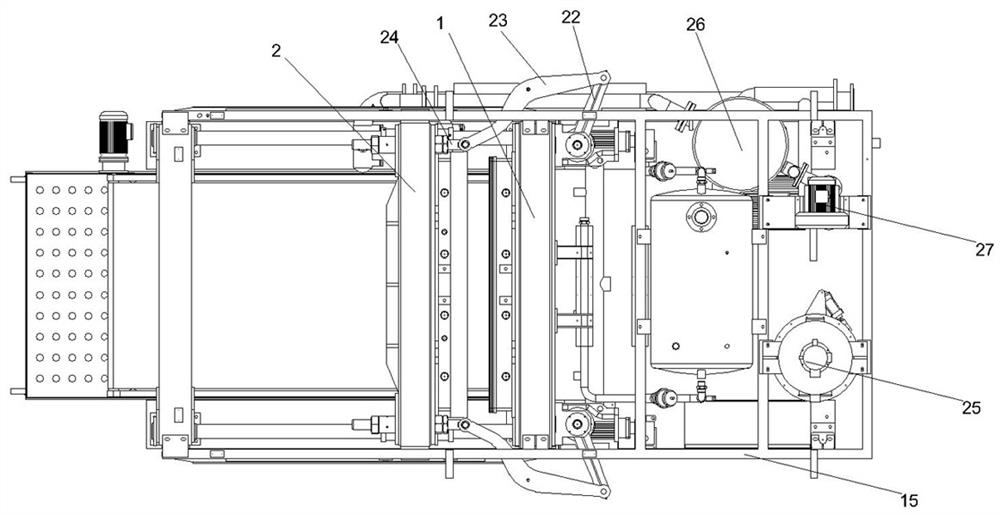

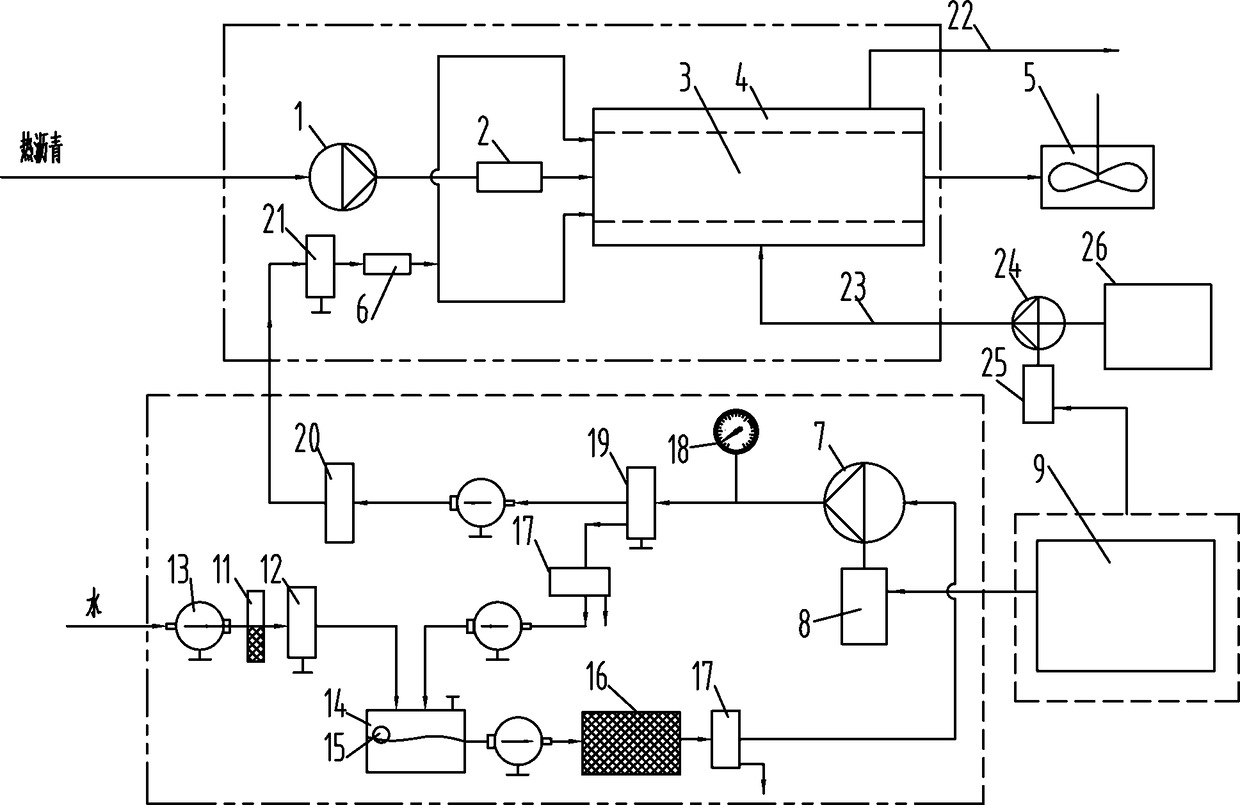

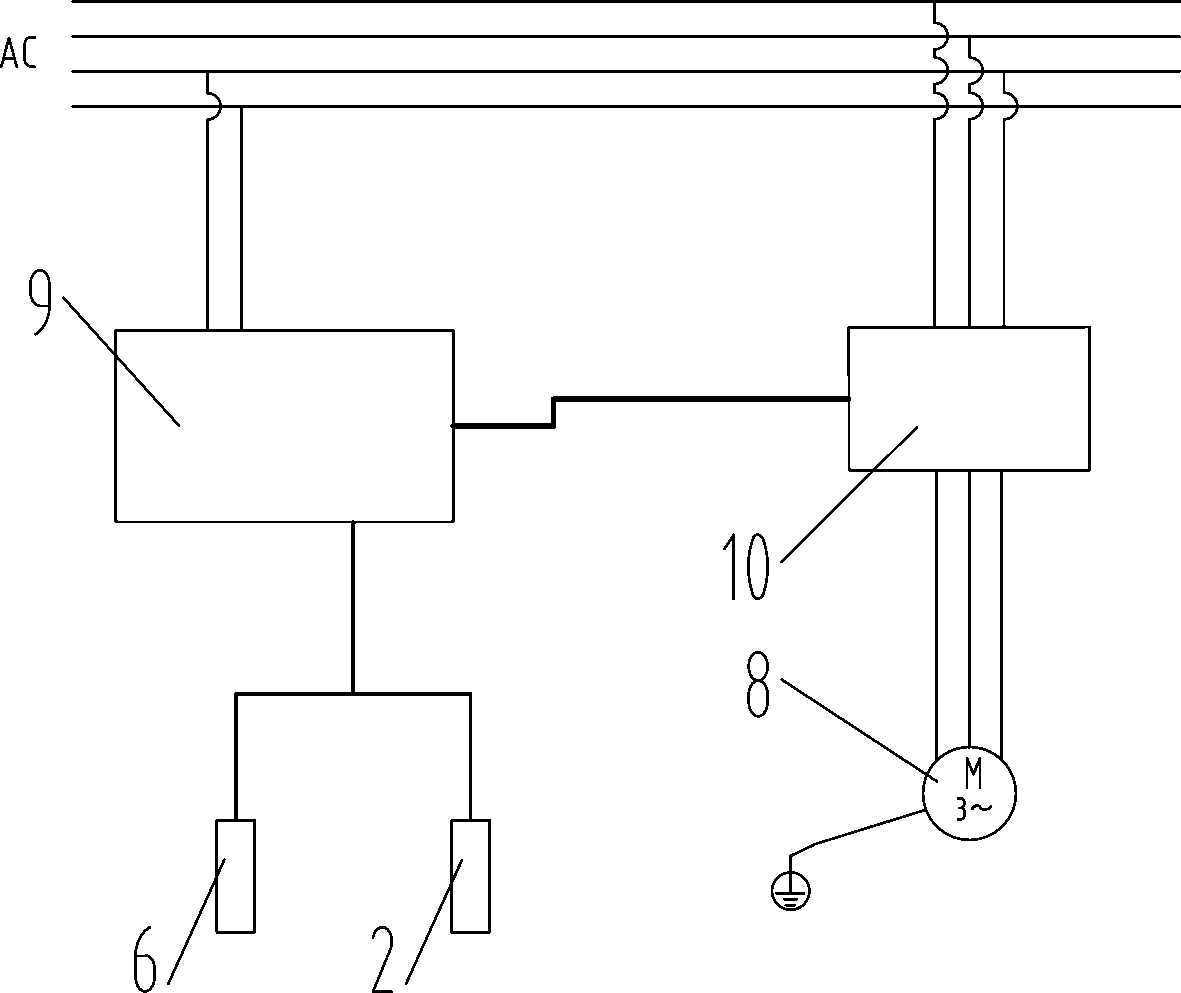

Intelligent Control System of Asphalt Foaming Machine

ActiveCN105511532BGuaranteed foaming qualityReliable supplyRoads maintainenceSimultaneous control of multiple variablesFrequency changerWater flow

The invention provides an intelligent control system for an asphalt foaming machine. The output port of the asphalt pump is connected to the inlet of the foaming pipe, and an asphalt flow sensor is arranged between the output port of the asphalt pump and the foaming pipe; the outer wall of the foaming pipe A jacket is provided, and the jacket is connected with the oil inlet pipe and the oil discharge pipe; the output port of the water pump is connected with the water inlet of the foaming pipe, and a water flow sensor is arranged between the output port of the water pump and the foaming pipe; the water flow sensor and the asphalt flow rate The sensor is connected with the control device, the control device is connected with the frequency converter, and the frequency converter is connected with the motor driving the water pump. By setting the asphalt flow sensor and the water flow sensor, the water flow is adjusted with the data of the asphalt flow sensor as a reference, so as to realize the precise control of the ratio of water and asphalt. Guarantee the quality of asphalt foaming and eliminate quality hazards.

Owner:YICHANG JIANGXIA MARINE MACHINERY

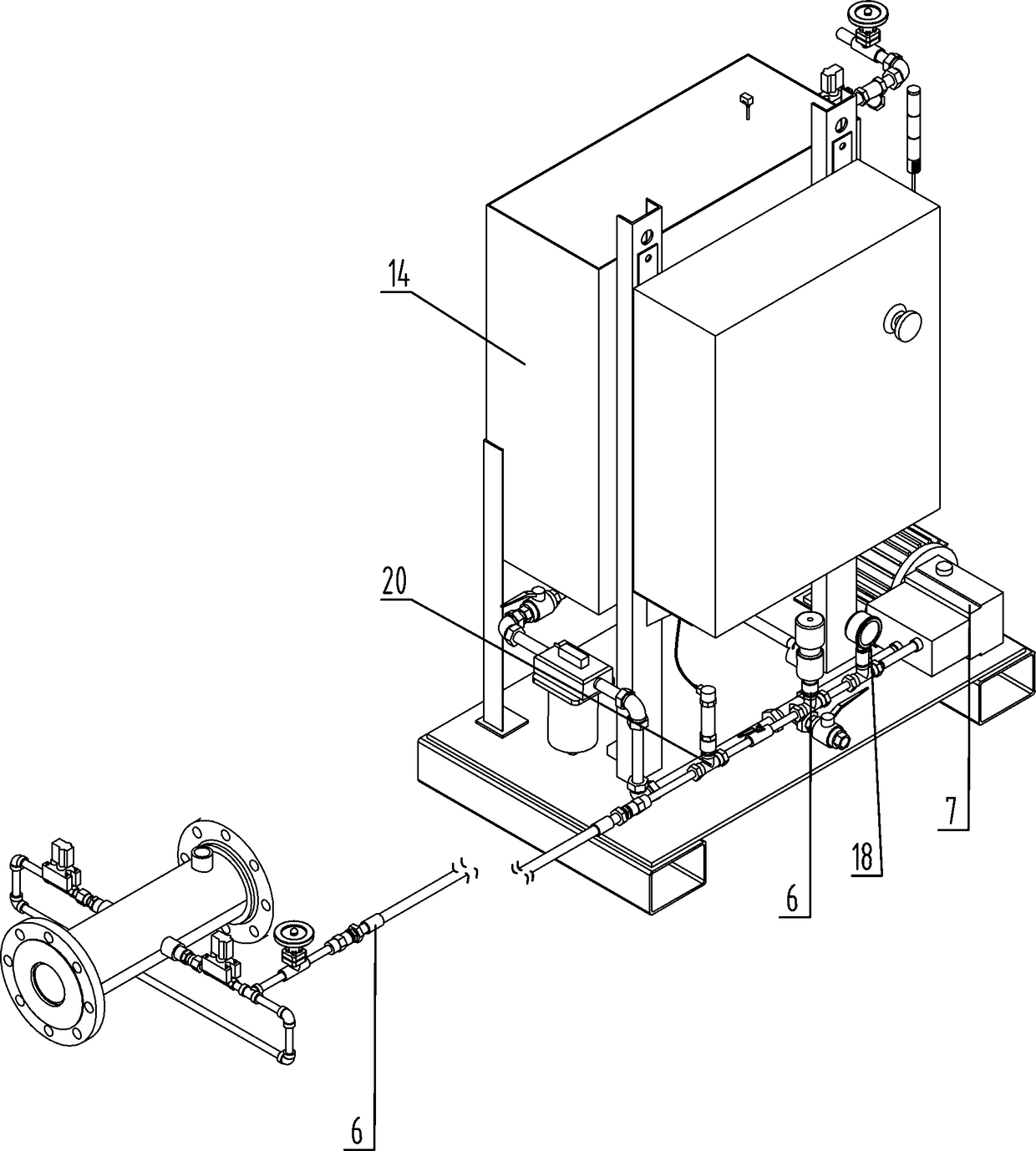

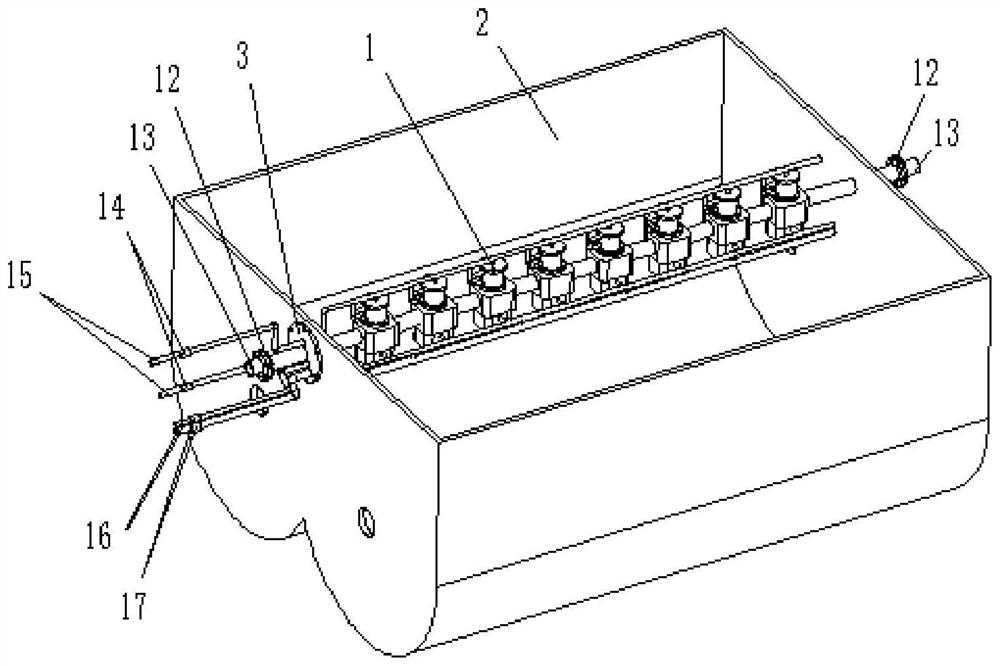

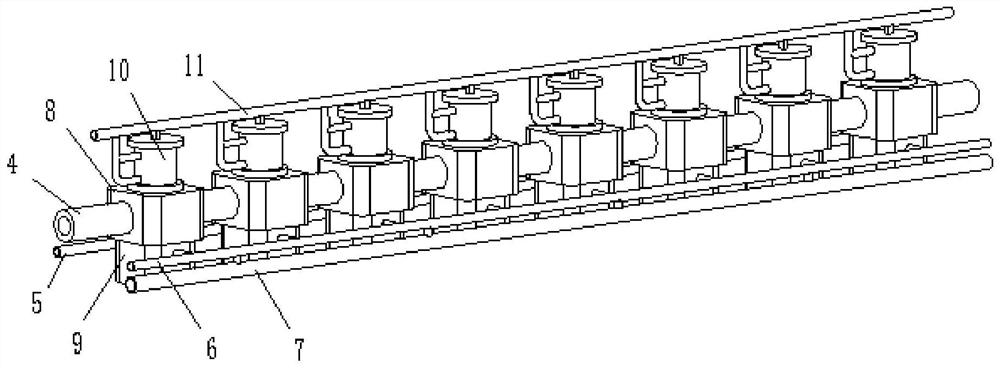

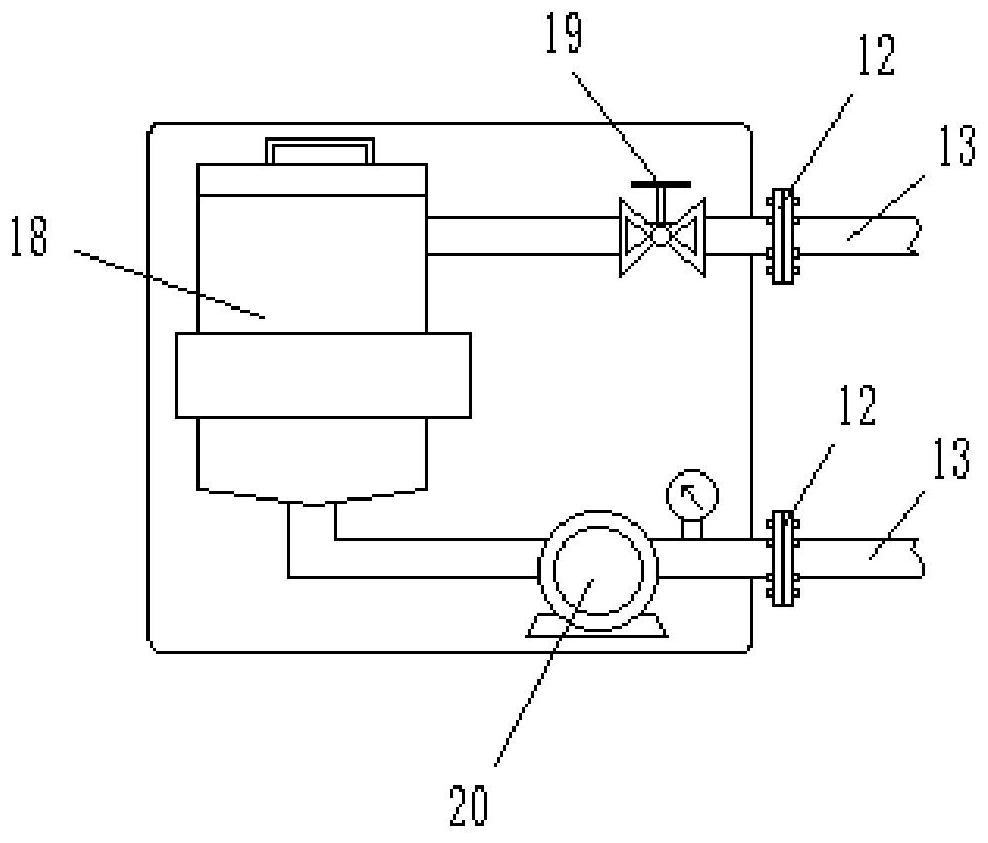

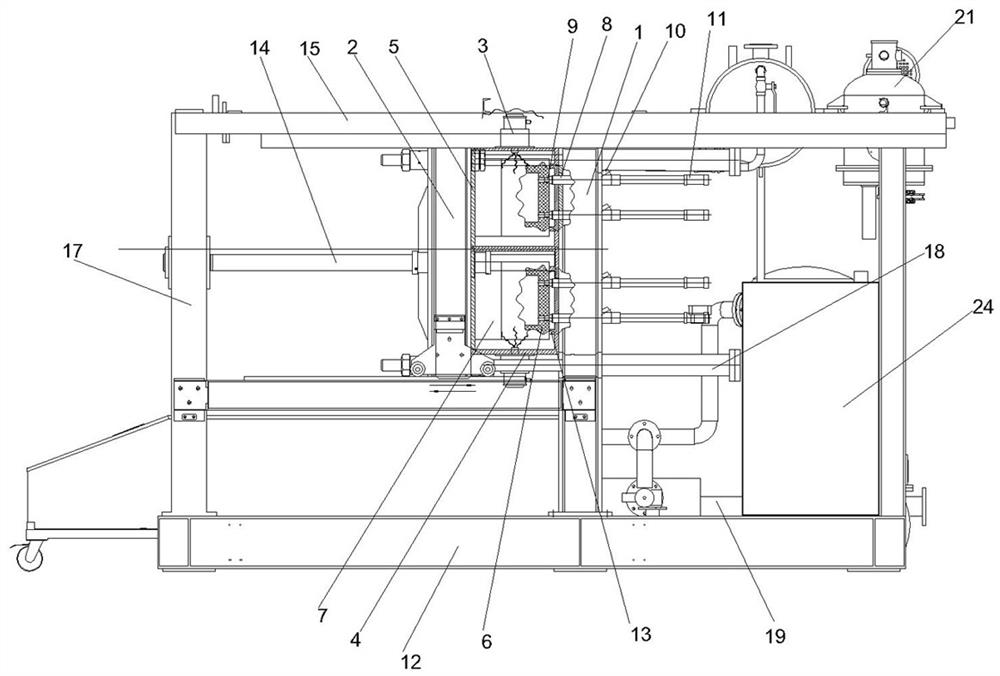

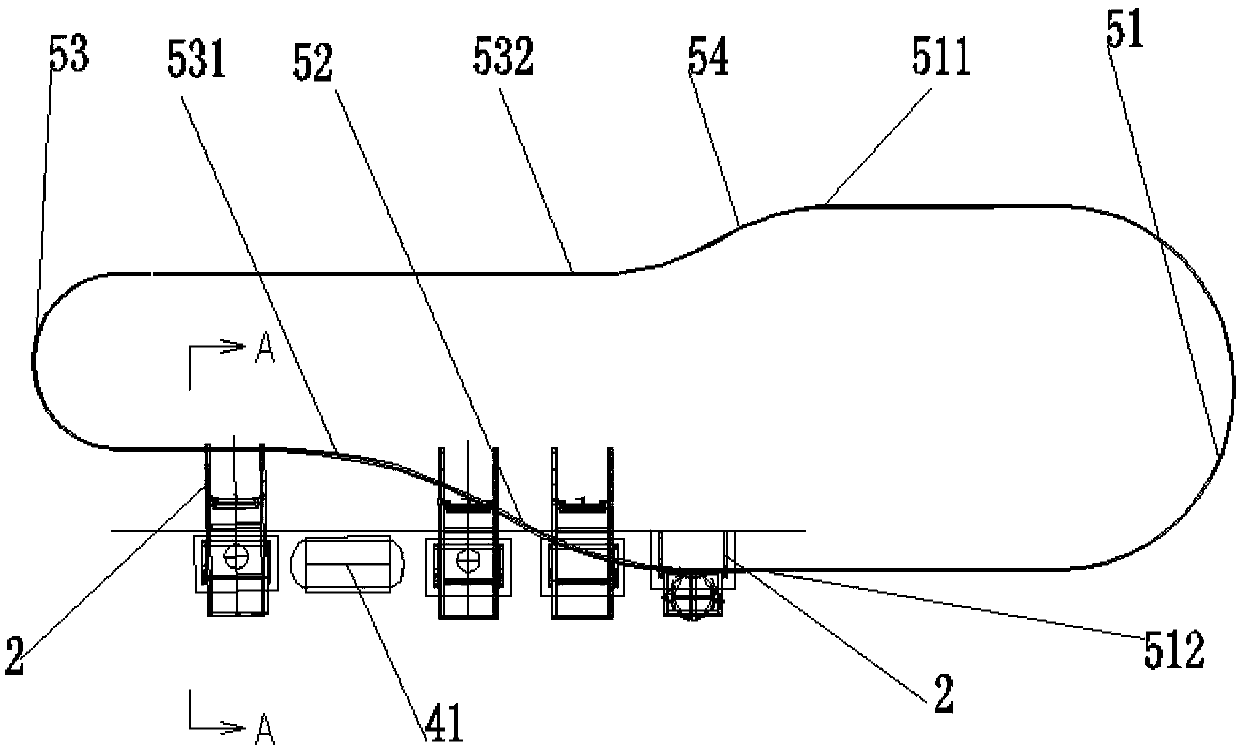

A Modular Design Asphalt Foaming Equipment and Its Automatic Control System

ActiveCN108660894BEasy to assemble and disassembleEasy to transportRoads maintainenceAutomatic controlControl system

The invention relates to modular designed asphalt foaming equipment and an automatic control system thereof. The asphalt foaming equipment is composed of an asphalt supply system, a foaming water supply system, a humidification water supply system, an air supply system and a foamed asphalt spraying rod, wherein the asphalt supply system, the foaming water supply system, the humidification water supply system and the air supply system are independent modules separately. The automatic control system of the asphalt foaming equipment can automatically calculate the amount of asphalt, foaming waterand compressed air which are required for the preparation of foamed asphalt through a piping graphic design unit preinstalled in a computer or a touch screen and according to the input data such as the type of road building construction equipment, and can automatically calculate main design parameters of an asphalt pipeline, a foaming water pipeline and an air pipeline. The modular designed asphalt foaming equipment is convenient to disassemble and assemble and can be combined with various road building construction equipment; and the automatic control system can accurately control the flow rate of the asphalt and the amount of the foaming water, the foaming quality of the asphalt is ensured, and mixing is realized while foaming is carried out.

Owner:INNER MONGOLIA UNIV OF TECH

Polyurethane raw material temperature control method for refrigerator

InactiveCN110303631AGuaranteed foaming qualityAvoid exceeding the rated rangeDomestic articlesRefrigerated temperatureRate difference

The invention discloses a polyurethane raw material temperature control method for a refrigerator, and relates to the technical field of polyurethane foaming. The method comprises the following steps:(1) a rated temperature range T1 of raw materials in a raw material tank and a rated temperature range T2 of raw materials in an injection gun head are set; and a raw material temperature differencevalue in the raw material tank and in the injection gun head is a rated difference value delta T; (2) actual temperatures of the raw materials in the raw material tank and in the injection gun head are detected; (3) a difference value of the actual temperatures of the raw materials in the raw material tank and in the injection gun head is calculated; and (4) the temperature of the raw materials inthe raw material tank is controlled according to a difference value between the actual temperature difference and the rated difference value. The temperature of the raw material tank is controlled through detection of the difference value of the actual temperatures of the raw materials in the raw material tank and in the injection gun head, so that the temperature of the raw materials in the injection gun head can be timely adjusted, and the problem of influence on the foaming quality due to easy exceeding of the set range caused by larger temperature change of the raw materials in a traditional injection gun head is solved.

Owner:CHANGHONG MEILING CO LTD

A kind of production method of circular PU air filter element

The invention relates to a production method of a circular PU air filter element, comprising the following steps: (1) put the upper mold on the mold conveying line for heating, then flow into the upper mold glue injection area for glue injection, and the upper mold after the glue injection is completed Flow into the upper mold paper insertion area for manual paper insertion, and then pass through the upper mold foaming and curing heat preservation height limit area to obtain the upper end cover forming filter element semi-finished product; (2) The upper mold is continuously put on the mold conveying line, and the step (1) is repeated continuously ; (3) Forming the lower end cover on the other end of the semi-finished product, the forming process is basically the same as step (1); (4) Finally, after aging and demoulding, the finished circular PU air filter element is obtained. The invention adopts a continuous production method to prepare circular PU air filter elements, and the key process points in the production of PU air filter elements: glue injection, foaming and curing heat preservation and height limit, aging heat preservation, and pre-demolding are produced by assembly lines, which can improve production. Efficiency, reduce labor intensity, reduce raw material waste, and improve quality stability.

Owner:柳州日高滤清器有限责任公司

Freezer and inner container assembly thereof

ActiveCN102778100BEasy to assembleReduce scrap rateLighting and heating apparatusDomestic refrigeratorsEngineeringRejection rate

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Foaming equipment, foaming process and foaming process of refrigeration equipment

The invention discloses foaming equipment, a foaming technology and a foaming technology of a refrigeration plant. The foaming equipment is used for foaming a pre-assembling component; a foaming space is limited in the pre-assembling component; the foaming equipment comprises a foaming mould, a first air exhaust mechanism, a second air exhaust mechanism and a first negative pressure providing device. The foaming mould comprises a first mould body and a second mould body; the first mould body and the second mould body are matched to limit a mould cavity; the first air exhaust mechanism is communicated with the mould cavity; the second air exhaust mechanism comprises an air guide pipe fixedly arranged in the foaming space; the air guide pipe comprises an opening pipe and a clamping strip, an opening extending in the axial direction of the opening pipe is formed in the pipe wall of the opening pipe, and the clamping strip can be arranged on the opening pipe in a sliding mode to seal the opening. The first negative pressure providing device is connected with the first air exhaust mechanism and used for forming negative pressure in the foaming space. According to the foaming equipment, air negative pressure can be evenly transmitted to the foaming space, and therefore the heat preservation performance of a heat preservation layer obtained after foaming is better, foaming raw materials can be saved, and the cost is reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

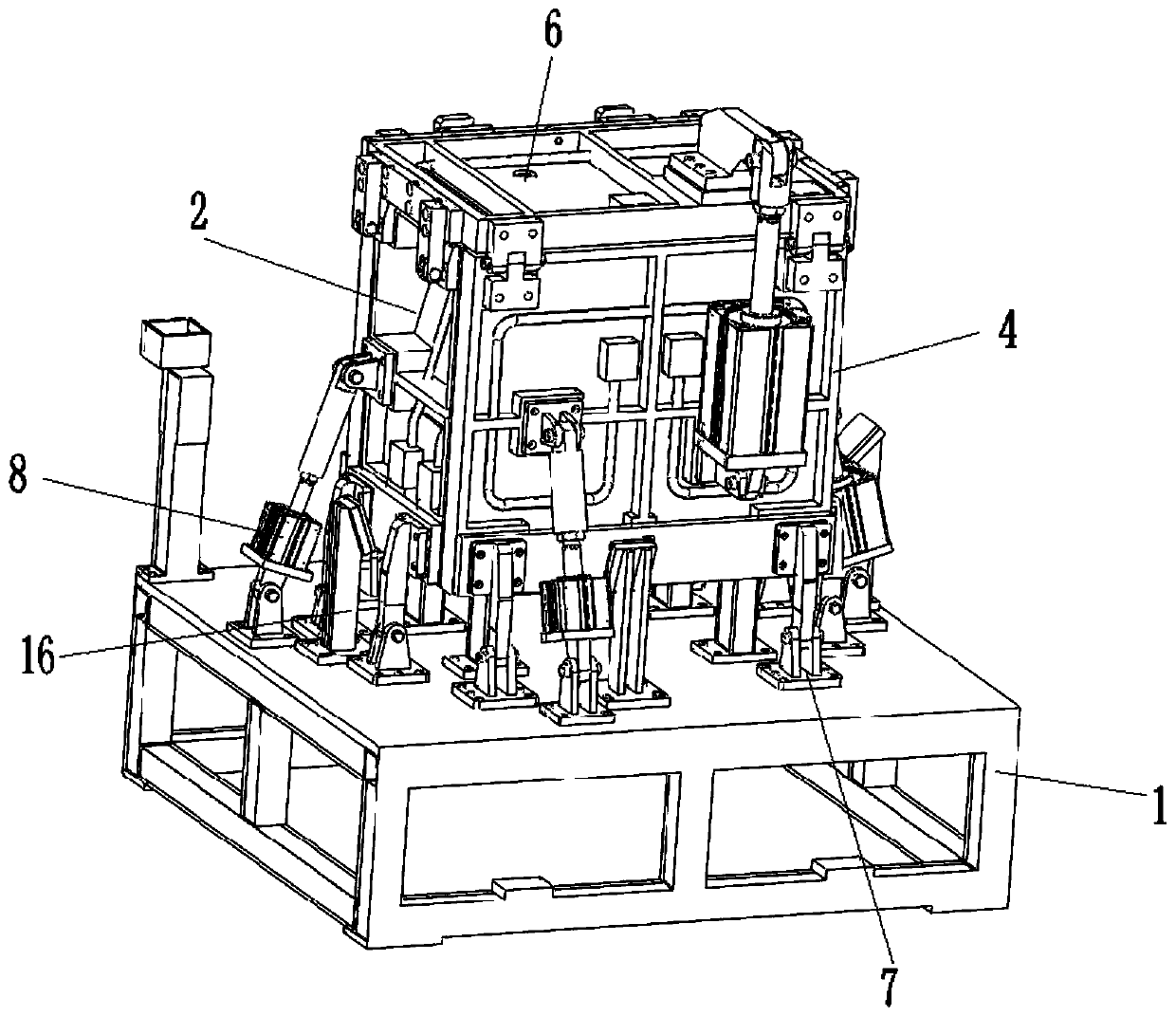

Hydraulically-driven pull-back microwave heating foam forming machine and foam forming method thereof

The invention discloses a hydraulically-driven pull-back microwave heating foam forming machine and a foam forming method thereof. The machine comprises a rack, a foam forming mechanism, a material barrel, a vacuum cooling device, an electric cabinet, an oil cylinder and a hydraulic station, wherein the foam forming mechanism comprises a fixed mold, a movable mold, fixed mold frames, movable mold frames and foaming material injection pipes; each fixed mold frame and the corresponding movable mold frame are combined to form a complete mold cavity, each mold cavity corresponds to at least one foaming material injection pipe, at least one microwave shielding hood is arranged on the fixed mold, and at least one microwave shielding cover matched with the corresponding microwave shielding hood is arranged on the movable mold; the movable mold frames and the fixed mold frames are all made of a high-temperature-resistant insulating material; and the fixed mold is located between the movable mold and the oil cylinder, and the oil cylinder drives the movable mold to move horizontally. According to the machine, microwave heating liquid is adopted to generate steam for foaming in cooperation with foaming plastic , the structure is simple and compact, the overall size of the foam forming machine is reduced, energy consumption is low, pollution is avoided, and the manufacturing and using cost is lowered.

Owner:杭州高福机械制造有限公司

Foaming agent of waterproof foam concrete, and preparation method

InactiveCN101698581BFormula refiningImprove stabilityBuild-up roofsBuilding insulationsFoam concreteDodecane

Owner:廖传海

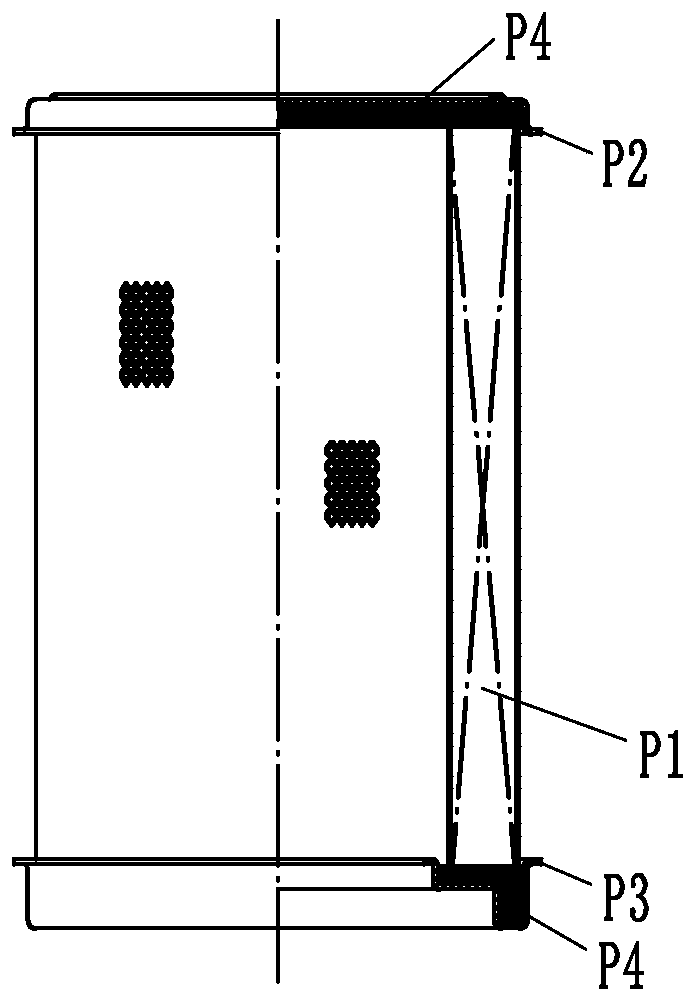

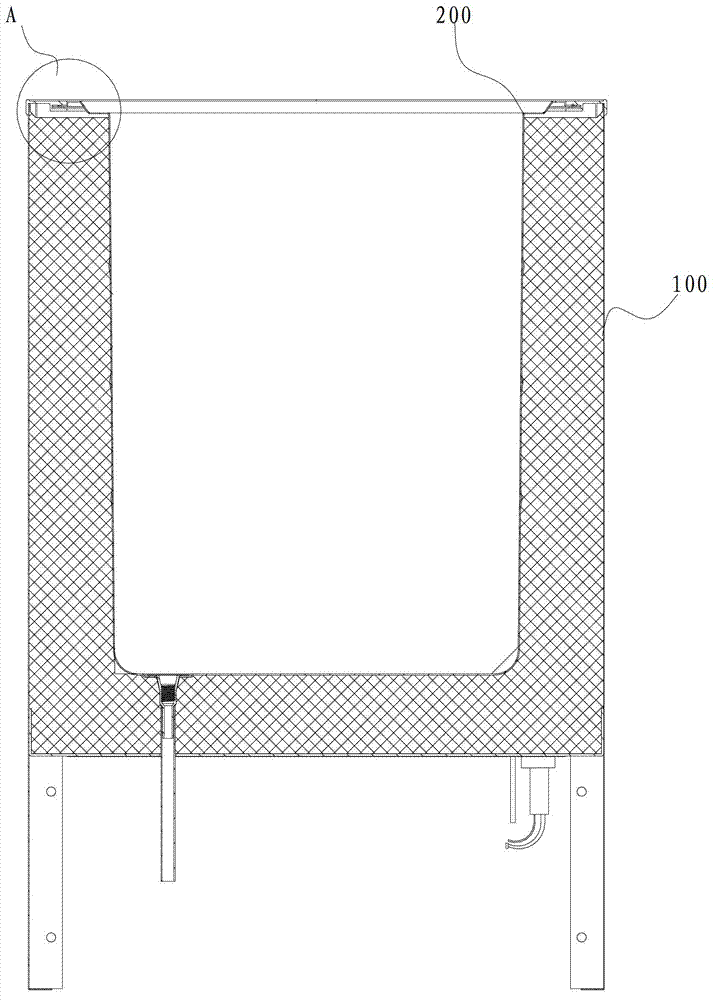

Air filter element polyurethane (PU) end cover foaming, curing and height-limiting device

PendingCN111168917AReduce labor intensityReduce labor costsDispersed particle filtrationAir filterEngineering

The invention relates to an air filter element polyurethane (PU) end cover foaming, curing and height-limiting device which comprises a lower-layer assembly line, an upper-layer assembly line, screw rod synchronous lifting mechanisms, positioning mechanism and multiple heating plates. The positioning mechanisms comprise bases, guide pillars and upper-layer fixing frames arranged on two sides of the upper-layer assembly line; guide sleeves are arranged on the upper-layer fixing frames; the guide pillars are arranged on the bases; the upper-layer fixing frames are arranged on the guide pillars through the guide sleeves in a sleeving way; the lower-layer assembly line is arranged on the base and comprises a conveyor chain plate; a chain plate supporting plate is arranged under the upper-end conveyor chain plate; a heating plate is arranged on the lower end face of the chain plate supporting plate; and the screw rod synchronous lifting mechanisms comprise screw rod servo motors, speed reducers, screw rods and couplers. According to the device, the foaming height of a filter element is limited through the height between the upper-layer assembly line and the lower-layer assembly layer, so that the consistency of the filter element height is good, the foaming quality is good, the appearance of the product is not affected, and the labor intensity of workers is reduced.

Owner:柳州日高滤清器有限责任公司 +1

Full-automatic ice maker shell foaming clamp

Owner:CHUZHOU MODERN MOLD MFG

Rotary foaming mold frame

The invention discloses a rotary foaming mold frame, relates to a rotatable foaming mold frame, and mainly aims to solve the problems of limited overturning angle of an existing foaming mold frame and the like. The rotary foaming mold frame comprises a main frame, bearing seats and a material injection mechanism, wherein a rotary mechanism comprises a lower frame and an upper frame; the lower frame is provided with connection plates; a lower hinge is connected with an upper hinge through a hinge shaft; a lower locking hook and an upper locking hook are arranged on the lower frame and the upper frame respectively; a cylinder rod of a locking air cylinder is connected with a locking arm; a locking shaft is arranged in a shaft sleeve of the locking arm; a limiting seat comprises two vertical plates; the locking shaft penetrates through the two vertical plates; a shaft hole of a swinging block is sleeved in the locking shaft; holes are formed in the two vertical plates; connection sheets are arranged between the two vertical plates; the swinging block is connected with the connection sheets; a limiting pin shaft on the swinging block is in contact with the locking hook; a mold opening and closing air cylinder is arranged on the lower frame; a material sealing air cylinder is arranged on a mold; ejection air cylinders are arranged on the lower frame; a transmission shaft of a motor speed reducer is connected with the connection plates; an air water separator, a conductive sliding ring and a sensor induction block are arranged on an air water separator shaft. The rotary foaming mold frame has the advantage that an angle can be randomly adjusted.

Owner:宁波万众汽车零部件有限公司

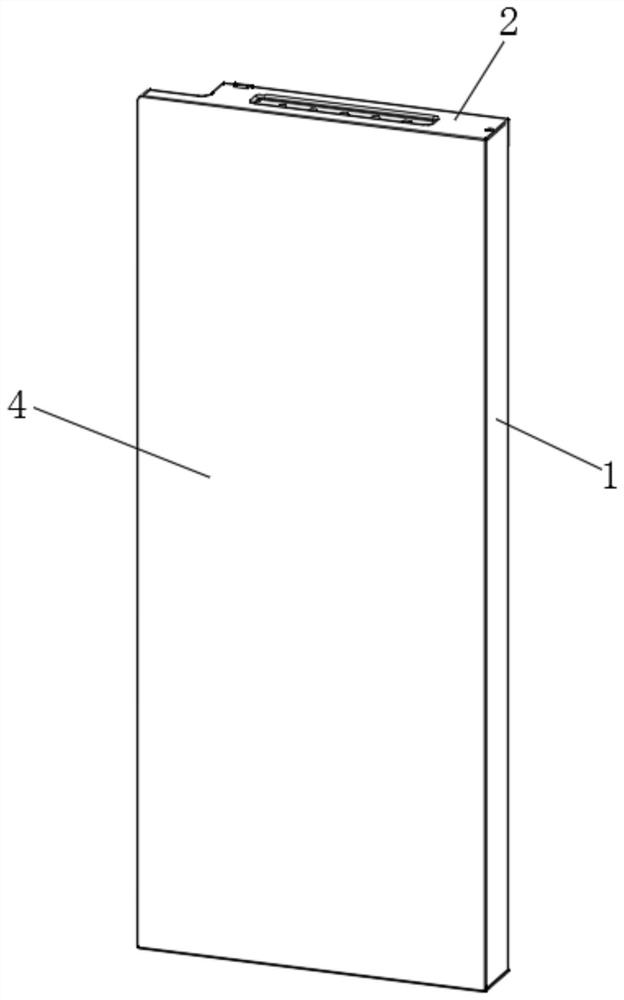

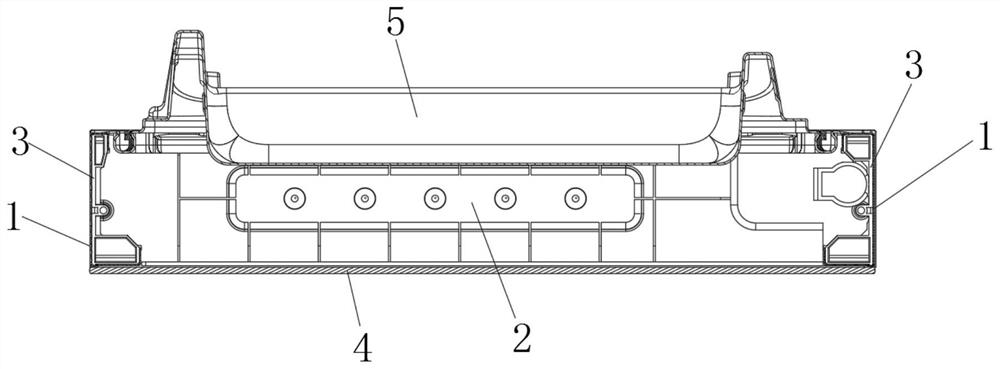

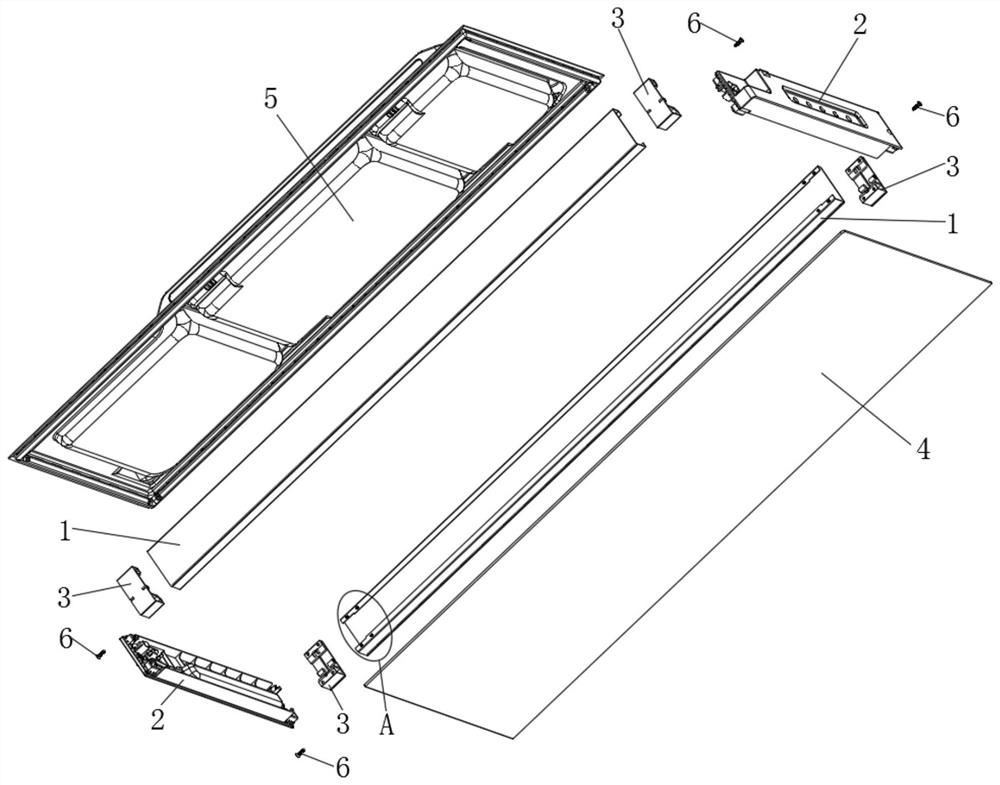

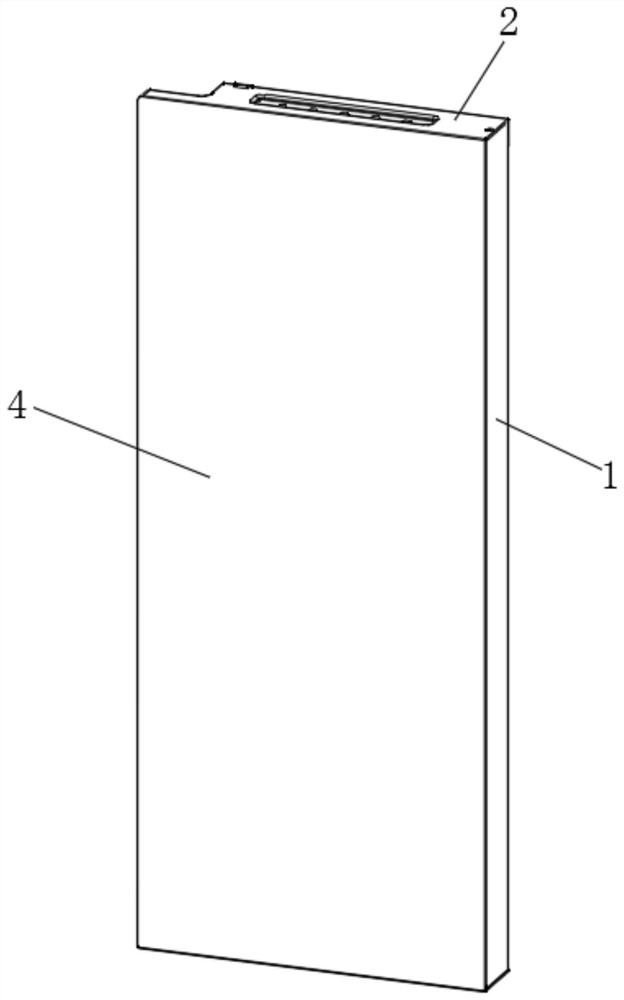

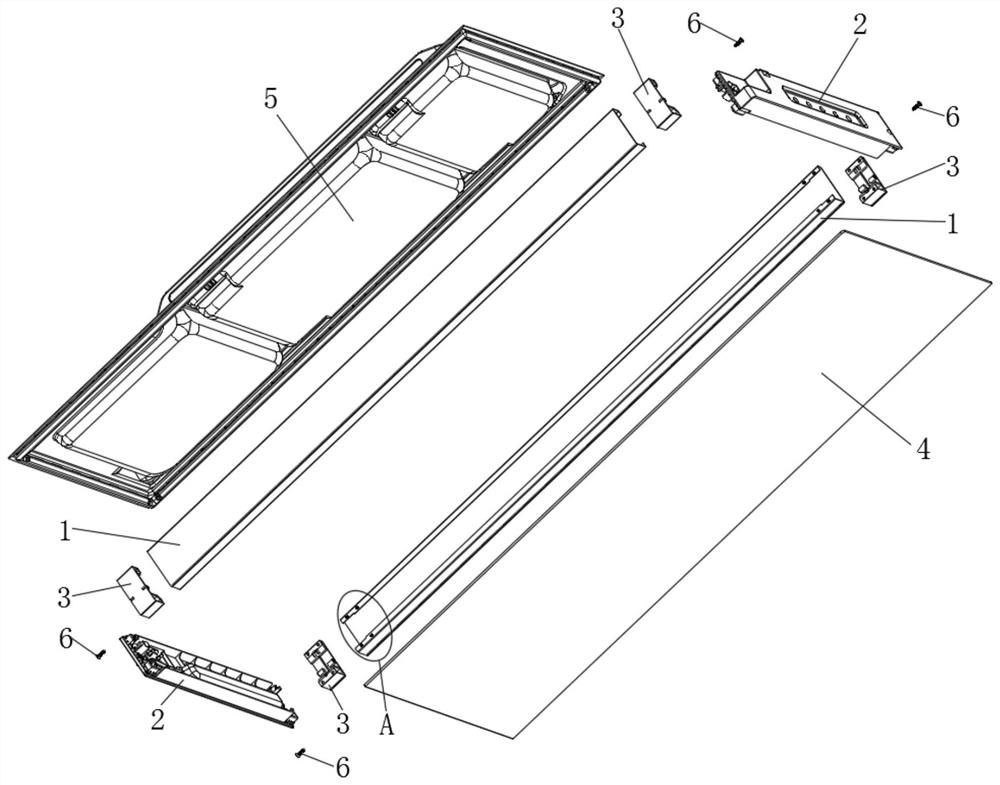

Refrigerator door body

ActiveCN112432421AImprove versatilityReduce tooling costsLighting and heating apparatusCooling fluid circulationStructural engineeringMechanical engineering

The invention discloses a refrigerator door body which comprises a door frame, a glass plate and a door lining. The door frame comprises end baffles located at the left side and the right side and decoration strips located at the upper side and the lower side; each end baffle adopts a sheet metal part and comprises an end plate, side plates and end baffle flanges; the end plates, the side plates and the end baffle flanges form end baffle clamping grooves in an enclosing manner; end baffle inserts matched with the end baffle clamping grooves are arranged at the upper ends and the lower ends ofthe end baffle clamping grooves in the end baffles; the upper ends and the lower ends of the end baffles are connected with the corresponding decorative strips through the end baffle inserts; the doorlining is pressed at one side of the door frame, and the glass plate is pressed at the other side of the door frame; and a cavity for foaming is formed among the door frame, the glass plate and the door lining. According to the refrigerator door body, each end baffle in the refrigerator door body adopts the sheet metal part, and compared with an existing door body end baffle which is an injectionmolding part or an extrusion part and needs a corresponding die, and each end baffle in the refrigerator door body adopts the sheet metal part, so that the die cost is reduced, and the manufacturingcost of the refrigerator door body is reduced; and meanwhile, the forming process is simple, and the production efficiency is improved.

Owner:AUCMA

Solar water heater water storage tank foaming production line

Owner:HIMIN SOLAR

Electric-drive front-pushing type microwave heating foaming forming machine and foaming forming method thereof

The invention discloses an electric-drive front-pushing type microwave heating foaming forming machine and a foaming forming method thereof. The electric-drive front-pushing type microwave heating foaming forming machine comprises a rack, a foaming forming mechanism, a charging basket, a vacuum cooling device, an electric cabinet, a driving motor and a transmission mechanism, wherein the foaming forming mechanism comprises fixed dies, movable dies, fixed die frames, movable die frames and foaming material injection pipes; each fixed die frame and the corresponding movable die frame are combined to form a complete die cavity; each die cavity corresponds to at least one foaming material injection pipe; each fixed die is provided with at least one microwave shielding cover; each movable die is provided with at least one microwave shielding cover matched with the microwave shielding cover; the movable die frames and the fixed die frames are made of high-temperature-resisting insulating materials; the movable dies are located between the fixed dies and the driving motor; and the driving motor drives the movable dies to move horizontally. According to the electric-drive front-pushing type microwave heating foaming forming machine, microwaves are used for heating liquid to generate steam and the steam is matched with foaming plastic to foam; and the electric-drive front-pushing type microwave heating foaming forming machine has a simple and compact structure, the whole volume of the foaming forming machine is reduced, the energy consumption is relatively small, no pollution is caused and the manufacturing and utilization cost is reduced.

Owner:杭州高福机械制造有限公司

Box foaming and conveying system with heat preservation function

The invention discloses a box foaming and conveying system with a heat preservation function, and relates to the technical field of refrigerator production and manufacturing. The device comprises a heat preservation box and a drying box which are carried on a transport vehicle, wherein one side of the heat preservation box is provided with a heat preservation box door body which can be pulled up and down; the heat preservation box and the heat preservation box door body are both made of heat preservation materials. A conveying belt mechanism A used for placing a box body to be foamed is arranged in the heat preservation box; a heating fan device is arranged at the top in the drying oven, an inlet is formed in one side of the drying oven, and a conveying belt mechanism B used for containing a box body to be foamed is arranged in the drying oven. The thermal insulation box is arranged on the transport vehicle for carrying the to-be-foamed box body, so that the thermal insulation function is provided, the thermal loss in the box body foaming and conveying process is reduced, the to-be-foamed box body is kept at the temperature, the product foaming quality is guaranteed, meanwhile, the product consistency is improved, and the rejection rate is reduced.

Owner:CHANGHONG MEILING CO LTD

A refrigerator door

ActiveCN112432421BImprove versatilityReduce tooling costsLighting and heating apparatusCooling fluid circulationStructural engineeringMechanical engineering

The invention discloses a door body of a refrigerator, which comprises a door frame, a glass plate, and a door liner; the door frame includes end blocks on the left and right sides and decorative strips on the upper and lower sides surrounding a rectangular structure; the end blocks are sheet metal parts, and the end blocks are The baffle includes end plates, side plates, and end baffle flanges; the end plate, side plates, and end baffle flanges form an end baffle slot; the upper and lower ends of the end baffle slot are provided with Matched end stop inserts; the upper and lower ends of the end stop are connected to the corresponding decorative strips through the end stop inserts; the door lining is pressed on one side of the door frame, and the glass plate is pressed on the other side of the door frame; the door frame, glass A cavity for foaming is formed between the board and the door liner. The end stop in the door body of the refrigerator of the present invention adopts sheet metal parts. Compared with the existing door body end stop which is an injection molded part or an extruded part and needs a corresponding mold, the end stop in the present application adopts sheet metal parts, and the cost of the mold is reduced, so that The manufacturing cost of the refrigerator door body is reduced; at the same time, the forming process is simple, and the production efficiency is improved.

Owner:AUCMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com