Foaming equipment, foaming process and foaming process of refrigerating equipment

A foaming equipment and process technology, applied in the field of refrigeration equipment manufacturing, can solve the problems of limited production capacity, high cost, weak box insulation, etc., and achieve the effects of ensuring foaming quality, reducing time cycle, and saving foaming raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

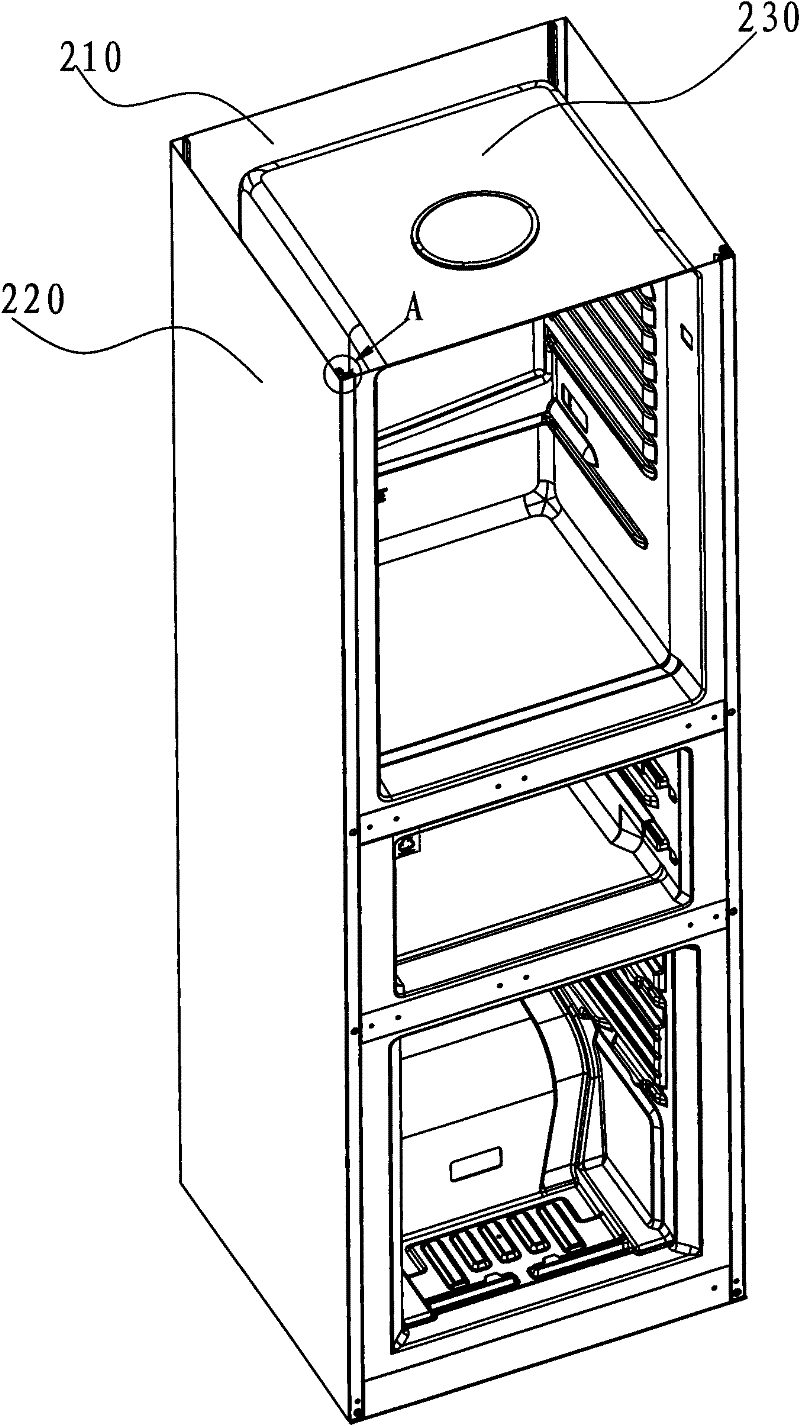

[0107] In this embodiment, the air duct is marked with 30a. Such as Figure 5-Figure 8 As shown, the air guide tube 30a is provided with a partition 301a, which extends along the axial direction of the air guide tube 30a to divide the inner cavity of the air guide tube 30a into at least two spaces, and can support the strength of the air guide tube 30a effect. A plurality of air holes 302a are formed on the wall of the air guide pipe 30a to enhance the air extraction effect of each area in the foaming space 210. Optionally, the air holes 302a are distributed linearly or spirally along the axial direction of the air guide tube 30a.

[0108] Such as Figure 5 with Image 6 As shown, in an example of the present invention, the cross section of the partition 301a is rectangular, that is, the partition 301a can be a flat plate so that the cross section of the air duct 30a is approximately a "day" shape, that is, the partition 301a The inner cavity of the air duct 30a is divided into...

Embodiment 2

[0119] In this embodiment, the air duct is marked with 30b. Such as Figure 9-16 As shown, the wall of the air guide tube 30b is formed with an air groove 301b extending along its axial direction, so that the cross section of the air guide tube 30b is "C"-shaped to enhance the air extraction effect of each area in the foaming space 210. Optionally, in an example of the present invention, the air groove 301b has a flange extending radially outward along the air duct 30b, such as Picture 9 with Picture 10 Shown.

[0120] Such as Picture 9 As shown, in an example of the present invention, from the first end of the air duct 30b (that is, the end close to the suction port 211) to the second end opposite to the first end (that is, the end far from the suction port 211), the air groove The width of 301b is uniform along the axial direction of the air duct 30b. Optionally, the width of the air groove 301b is 1-3 mm. Further optionally, the width of the air groove 301b is 1.5 mm.

[0...

Embodiment 3

[0127] In this embodiment, the air duct is marked with 30c. Such as Figure 17-18 As shown, the air guide tube 30c includes an opening tube 301c and a clip 302c. The wall of the opening tube 301c is provided with an opening 3010 extending along its axial direction. The clip 302c is slidably arranged on the opening tube 301c to open and The opening 3010 is closed. Optionally, the clip bar 302c and the opening tube 301c are connected in a sliding groove fitting manner.

[0128] Similar to the inner sleeve in the second embodiment, when it is necessary to extract air in the foaming space 210, the clip 302c is drawn out. As a result, the gas in each area in the foaming space 210 is drawn out through the open tube 301c, thereby negative The pressure can be evenly transmitted everywhere. When the gas in the foaming space 210 is exhausted, the clip 302c is inserted and snapped onto the opening 3010 of the opening pipe 301c, thereby closing the air duct 30c, thereby preventing the fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com