Electric-drive front-pushing type microwave heating foaming forming machine and foaming forming method thereof

A foam molding machine and microwave heating technology, applied in the field of plastic product processing, can solve the problems of increased production and use costs, large energy consumption, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

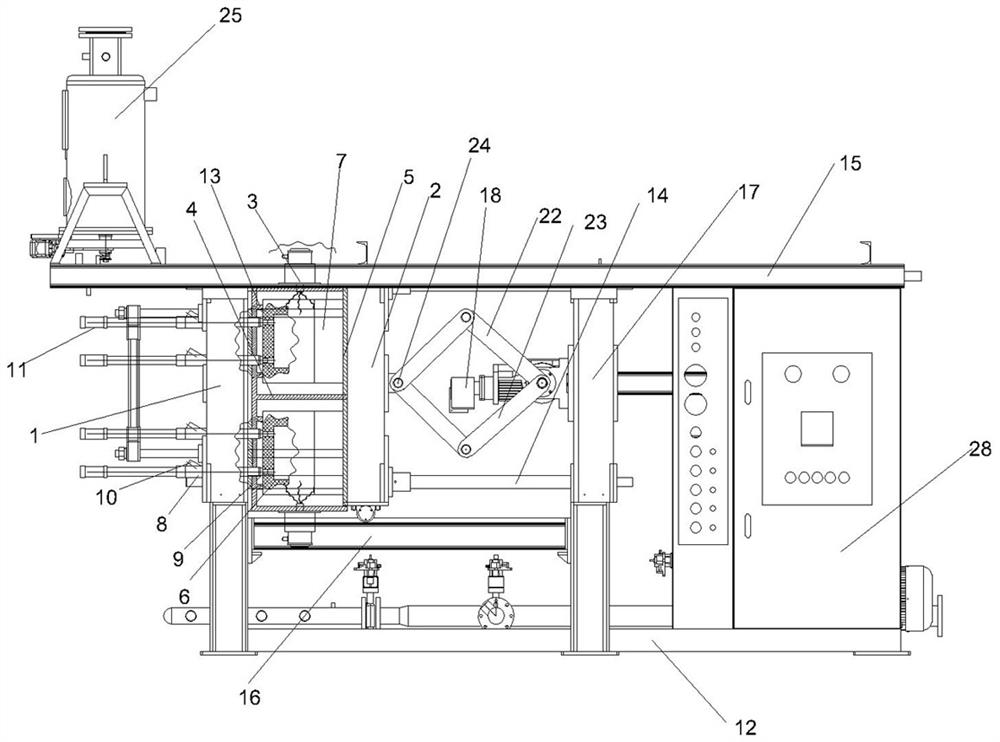

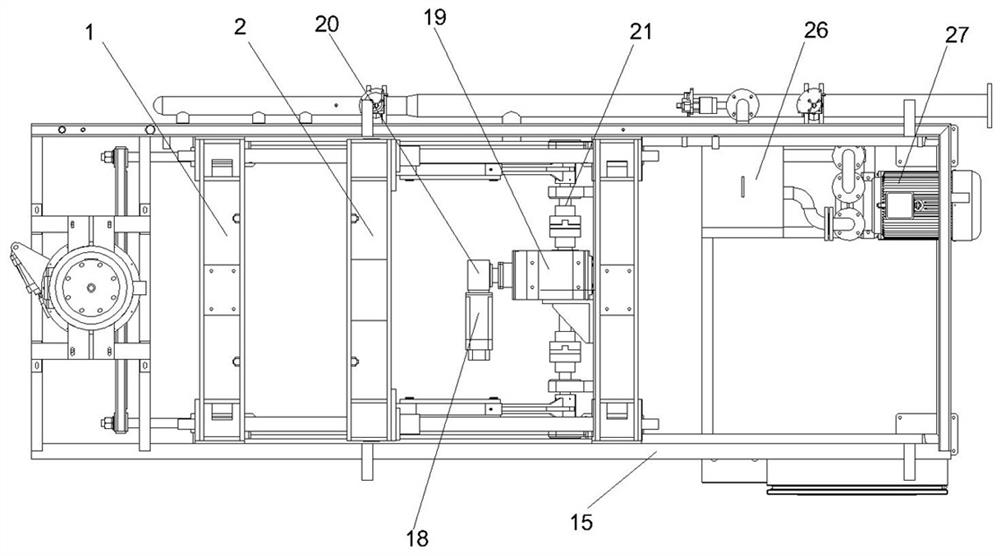

[0032] like figure 1 and 2As shown, an electric drive forward microwave heating foam molding machine includes a frame, a foam molding mechanism installed on the frame, a material barrel 25, a vacuum cooling device, an electric control box 28, a drive motor 18 and a connection Drive motor 18 and the transmission mechanism of foaming molding mechanism, foaming molding mechanism comprises solid mold 1, moving mold 2, two solid mold frames 6 fixed on solid mold 1 and two moving molds fixed on moving mold 2 Mold frame 7 and 4 foaming material injection pipes 8 installed on the solid mold 1, each solid mold frame and its corresponding moving mold frame together form a complete mold cavity, each mold cavity Corresponding to two foaming material injection pipes 8, the foaming material in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com