Refrigerator door body

A refrigerator door and door frame technology, which is applied to cooling fluid circulation devices, lighting and heating equipment, household appliances, etc., can solve the problems of high production cost and high cost of refrigerator doors, and improve production efficiency, production quality, and mold costs Reduction, production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

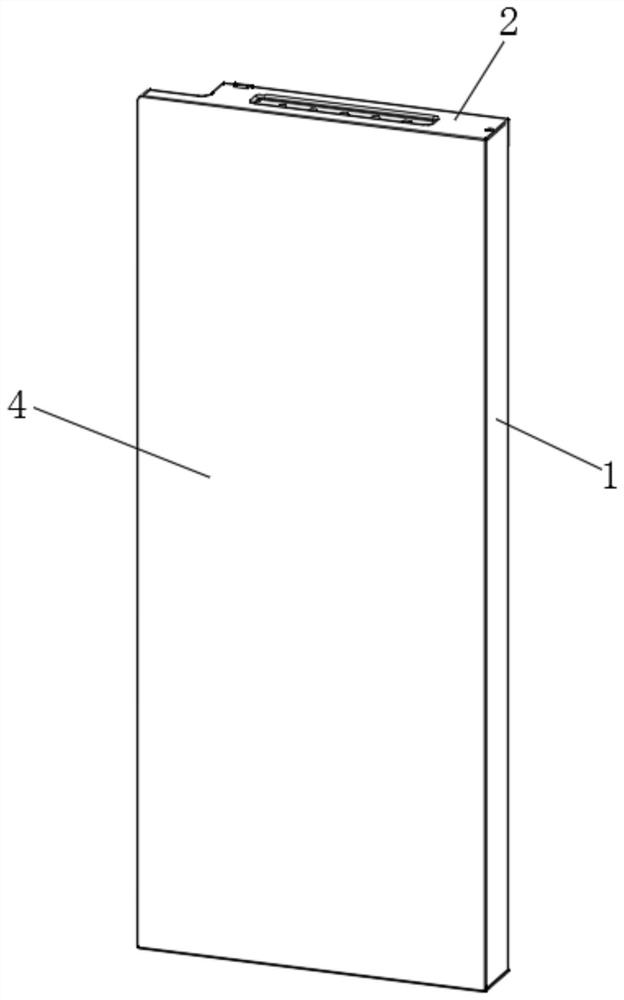

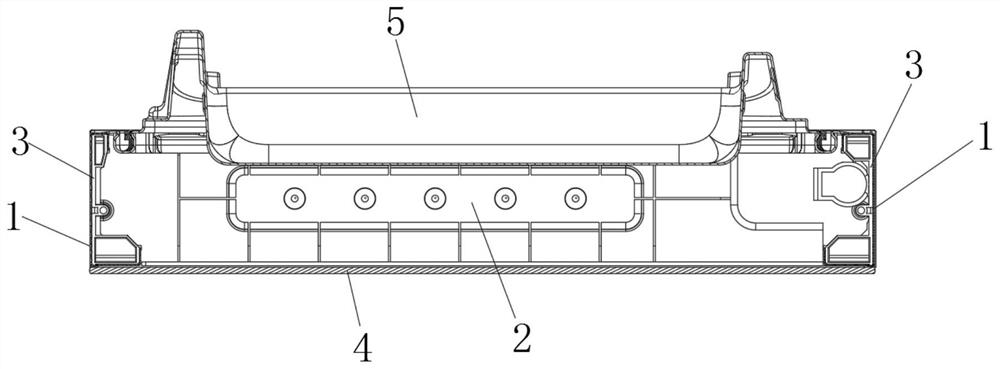

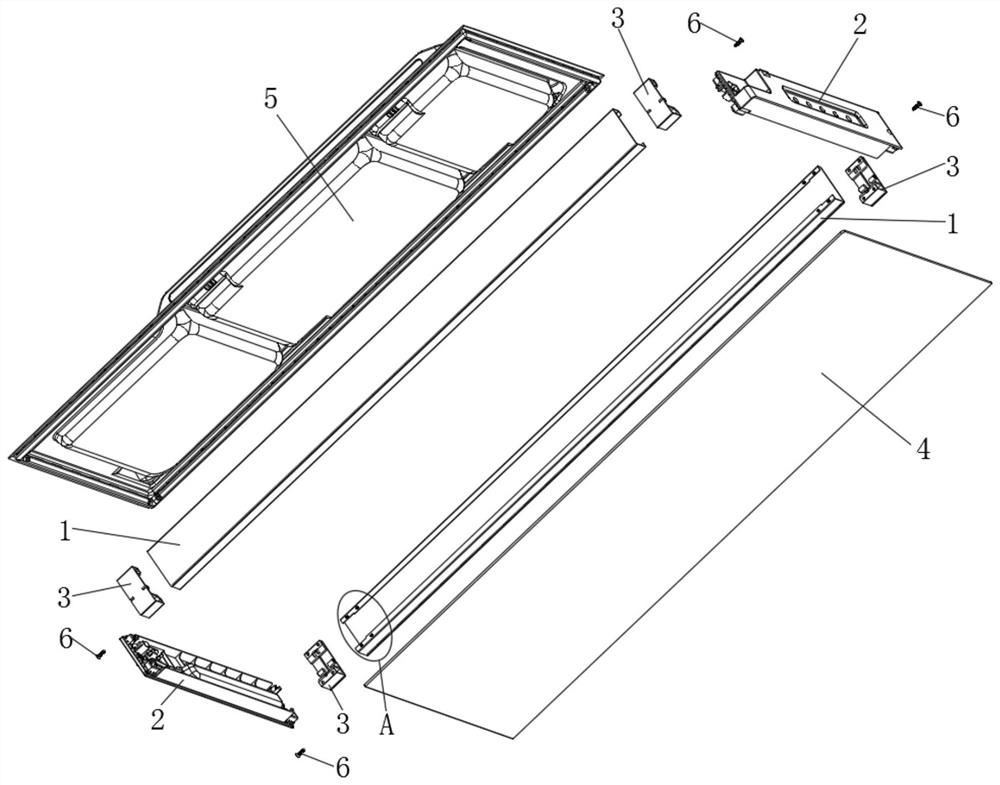

[0057] Such as Figure 1-3 As shown, a refrigerator door body includes a door frame, a glass plate 4, and a door liner 5;

[0058] The door frame includes end stops 1 on the left and right sides and trim strips 2 on the upper and lower sides that form a rectangular structure; The material cost of gold is lower than plastic materials such as aluminum alloy, injection molding and extrusion, such as Figure 4 As shown, the end block 1 includes an end plate 11, the front and rear sides of the end plate 11 are vertically turned over to the inside of the door frame to form a side plate 12, and the ends of the two side plates 12 are vertically turned over to form an end block flange 13 ; The end plate 11, the side plate 12, and the end retaining flanging 13 form an end retaining slot 14;

[0059] The upper and lower ends of the end stop slot 14 in the end stop 1 are provided with end stop inserts 3 that are compatible with the end stop slot 14; The corresponding outer end faces of t...

Embodiment 2

[0066] On the basis of Example 1, such as Figure 7 As shown, the end stop insert 3 has a vertically symmetrical structure; the end stop insert 3 has a vertically symmetrical structure, so the same end stop insert 3 can be used on the upper end of the end stop 1 or on the The lower end of 1 increases the versatility of end stop insert 3;

[0067] Positioning steps 15 are arranged at the upper and lower ends of the end retaining flanging 13;

[0068] The side of the end stop insert 3 facing the upper end stop flanging 13 of the corresponding end stop 1 is provided with a positioning protrusion 31 matched with the corresponding positioning step 15.

[0069] Preferably, two end-stop punching holes 16 are respectively provided at the upper and lower ends of the end-stop flanging 13;

[0070] The side of the end block insert 3 facing the upper end block flanging 13 of the corresponding end block 1 is provided with an insert connecting hole 32 corresponding to the corresponding en...

Embodiment 3

[0075] On the basis of Example 2, such as Figure 5-6 As shown, the two ends of the side of the decorative strip 2 facing the end stop 1 are respectively provided with two decorative strip card bodies 21;

[0076] The end stop insert 3 is provided with an insert slot 33 that is compatible with the trim card body 21 on the corresponding trim strip 2; specifically, the insert slot 33 is arranged symmetrically up and down;

[0077] The positioning protrusion 31 is disposed on the insert slot 33 .

[0078] Preferably, a decorative strip hook 22 is provided at one side outer end of the decorative strip card body 21;

[0079] One side of the insert slot 33 is provided with two up and down symmetrical insert slots 34 respectively matched with the hooks 22 of the corresponding trim 2 .

[0080] Preferably, both ends of the decorative strip 2 are respectively provided with a decorative strip threaded hole 23 extending axially along the vertical direction; the decorative strip threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com