Patents

Literature

43results about How to "Improve production efficiency and production quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

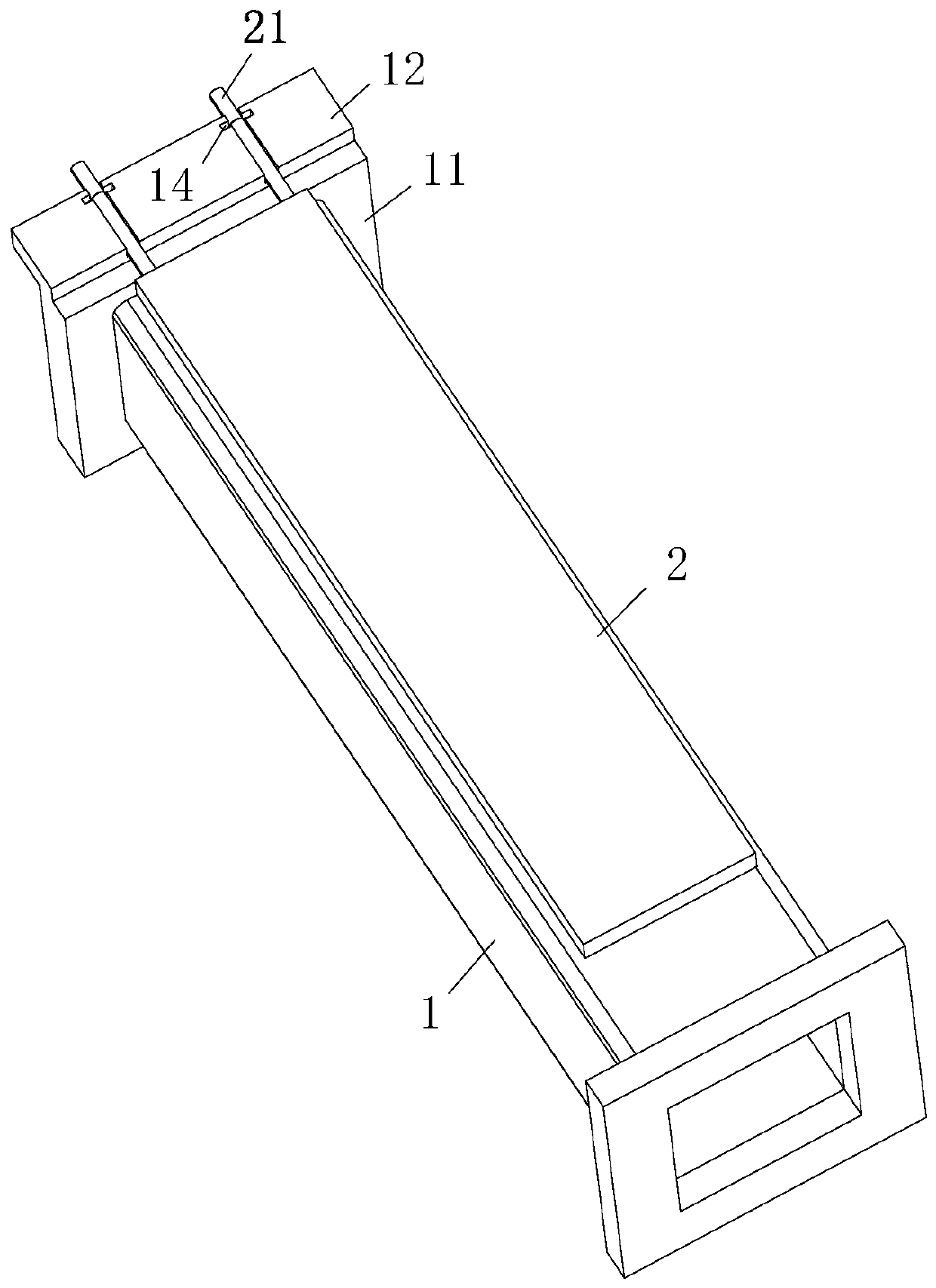

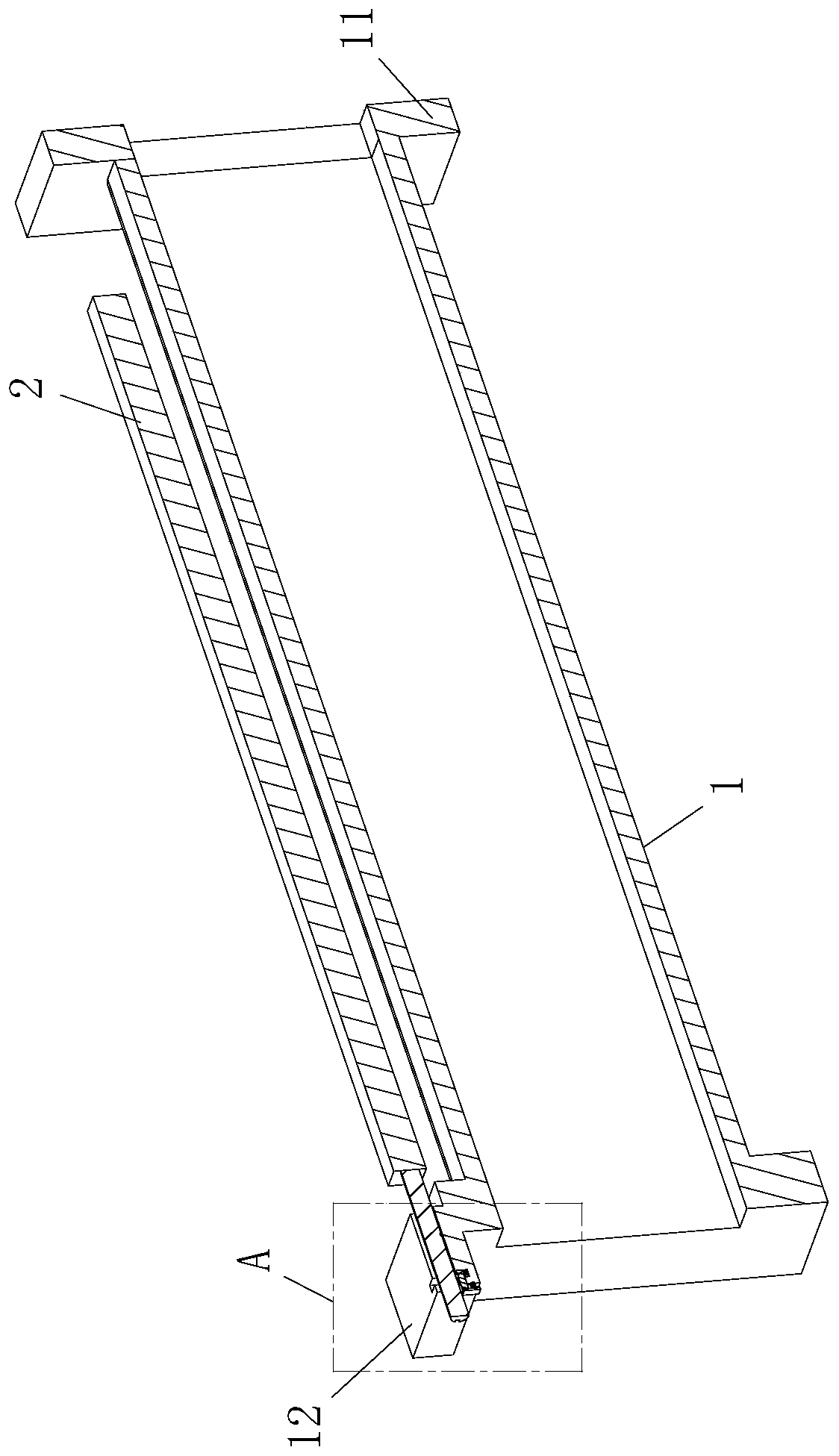

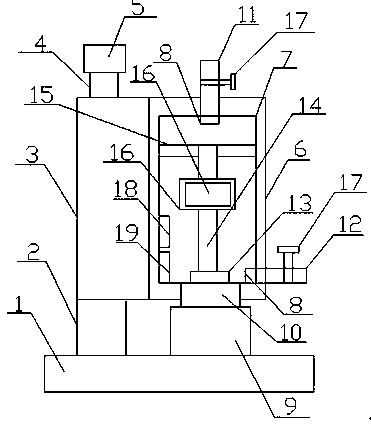

Wood board splicing machine and board splicing method thereof

InactiveCN103600384AImprove production efficiency and production qualitySave human effortPlywood pressesVeneer pressesProduction qualityNumerical control

A wood board splicing machine comprises a feeding device, a pressing device and a heating device. The feeding device is connected with the pressing device, and the heating device is arranged above the pressing device. The wood board splicing machine further comprises a numerical control device, and the numerical control device is connected with the feeding device, the pressing device and the heating device and controls operation of the feeding device, the pressing device and the heating device. By the wood board splicing machine, labor is liberated fully, boards are automatically processed and produced, and production efficiency and production quality are improved effectively.

Owner:刘吉超

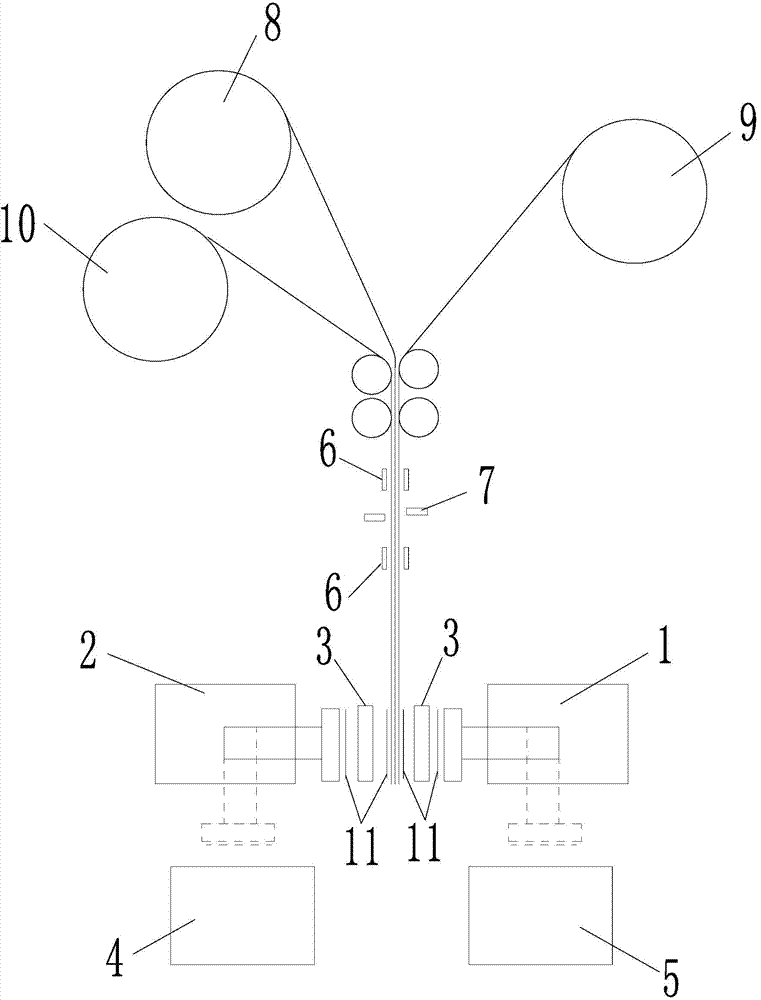

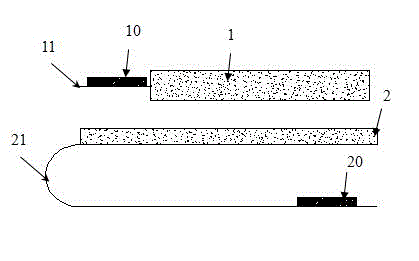

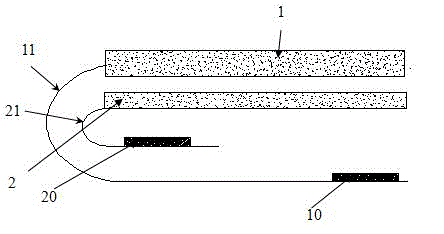

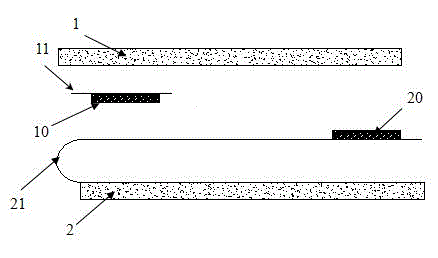

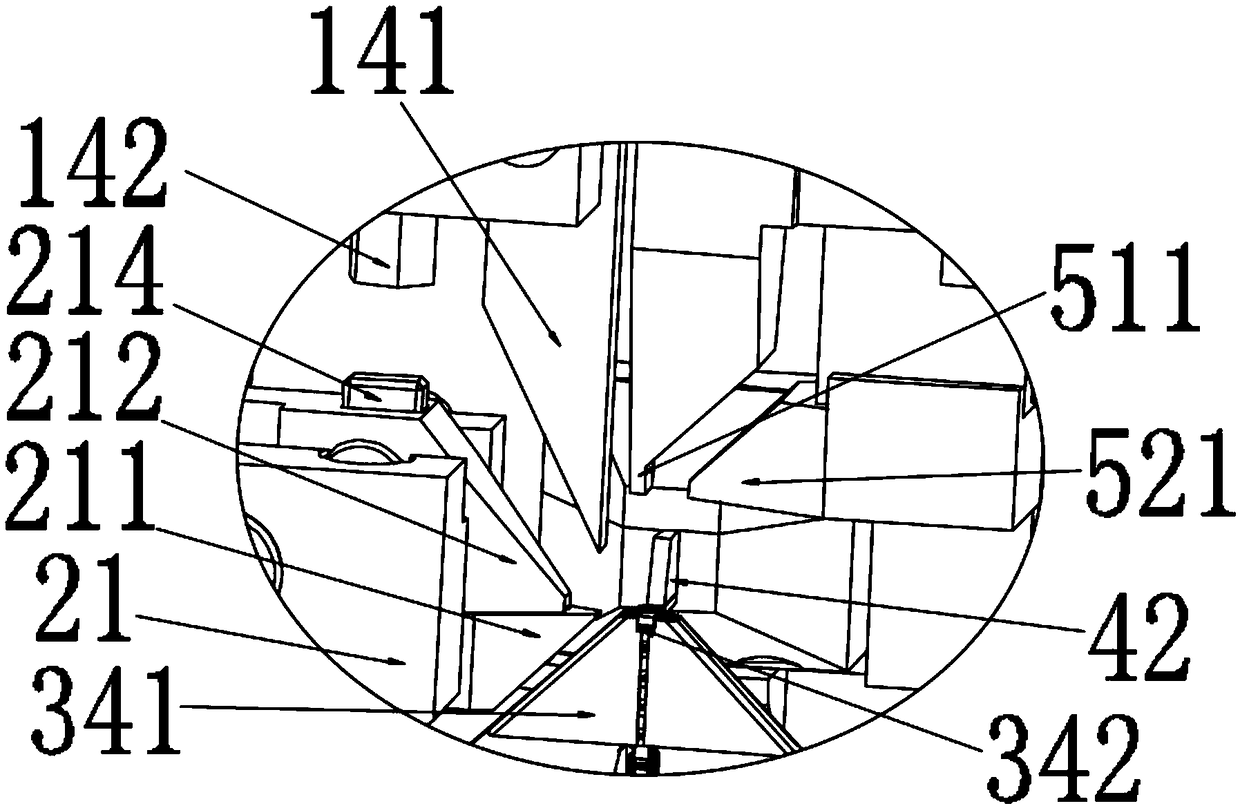

Laminator and lamination method thereof

ActiveCN103700888AImprove production efficiency and production qualityIncrease lamination speedAssembling battery machinesFinal product manufactureManipulatorEngineering

The invention relates to the technical field of lithium battery lamination, and provides a laminator and a lamination method thereof. The lamination method comprises the following steps: A. sequentially laminating a first diaphragm, a negative pole piece and a second diaphragm into an integral body, and continuously feeding to the position between a first rotary manipulator and a second rotary manipulator; B. sucking a positive pole piece from a first sub-locating table to the first diaphragm by using the first manipulator, and sucking the positive pole piece from a second sub-locating table to the second diaphragm by using the second rotary manipulator; and C. rotating the positive pole piece and negative pole piece together with the diaphragms by 360 degrees by a first clamping knife to perform coiling lamination. According to the method, the negative pole piece and the diaphragms connected into the integral body and continuously fed, the 360-degree or 180-degree coiling lamination is performed after the positive pole piece is arranged on the lateral side of the diaphragm, thereby increasing the lamination speed and enhancing the production efficiency and production quality of the laminator.

Owner:GEESUN AUTOMATION TECH

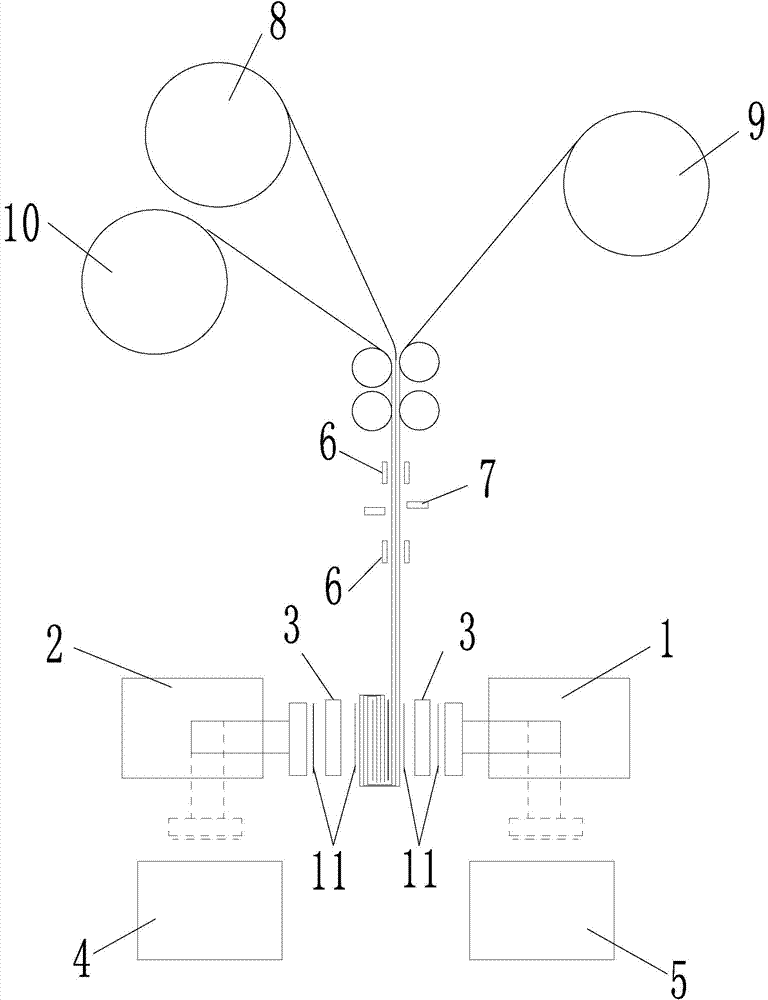

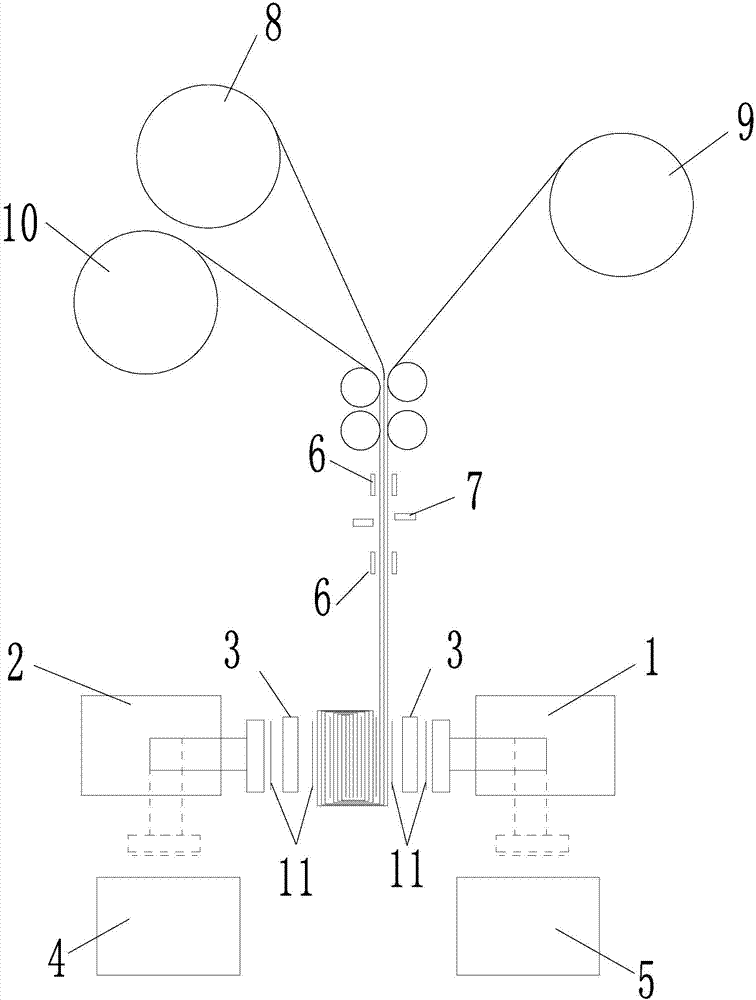

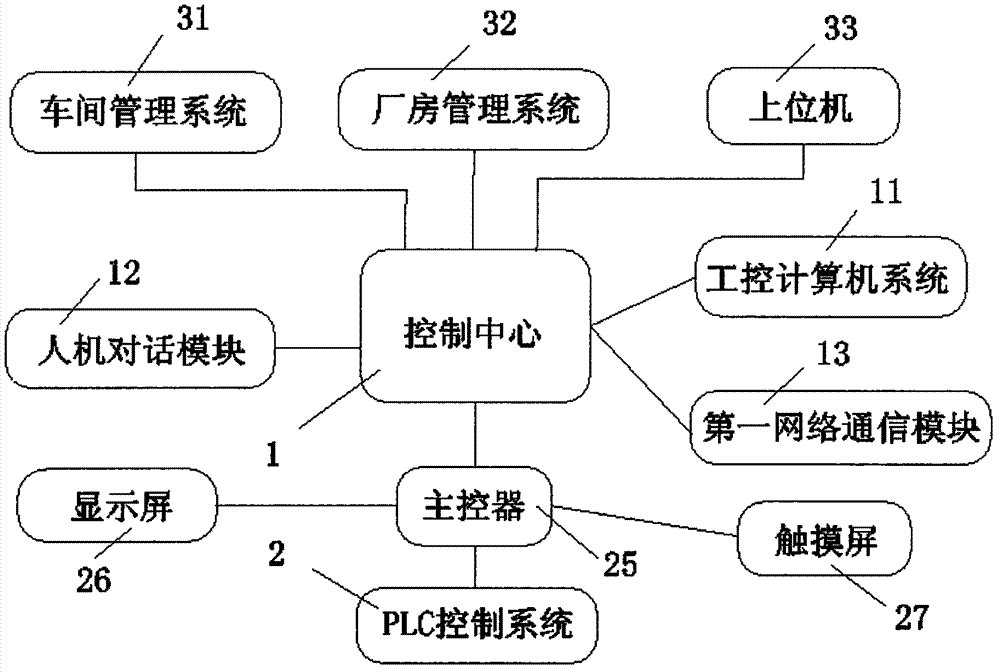

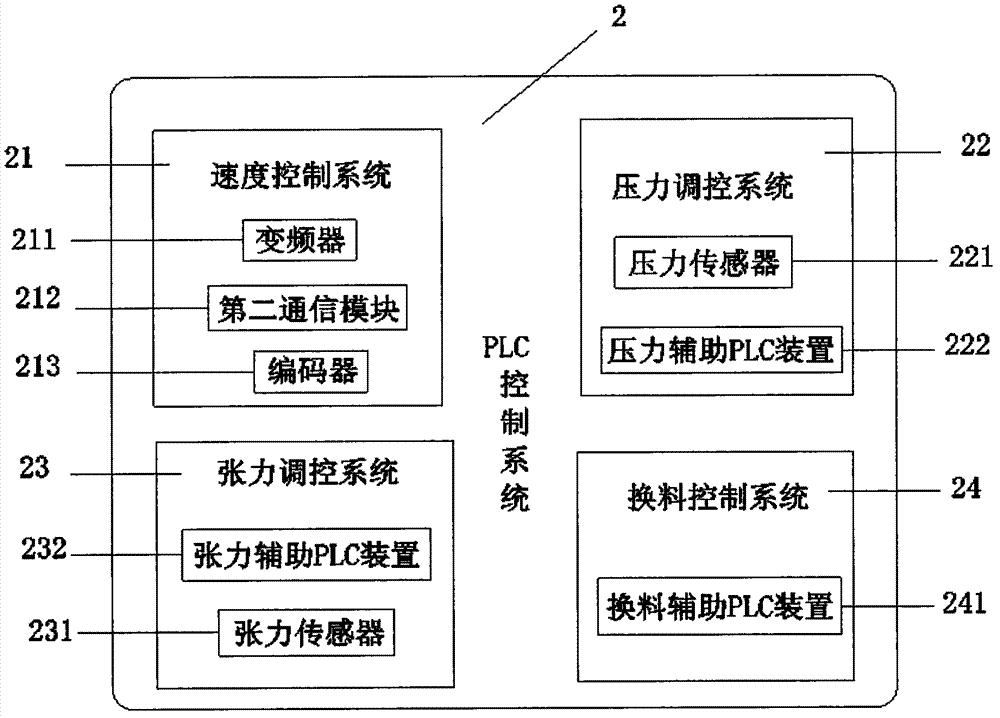

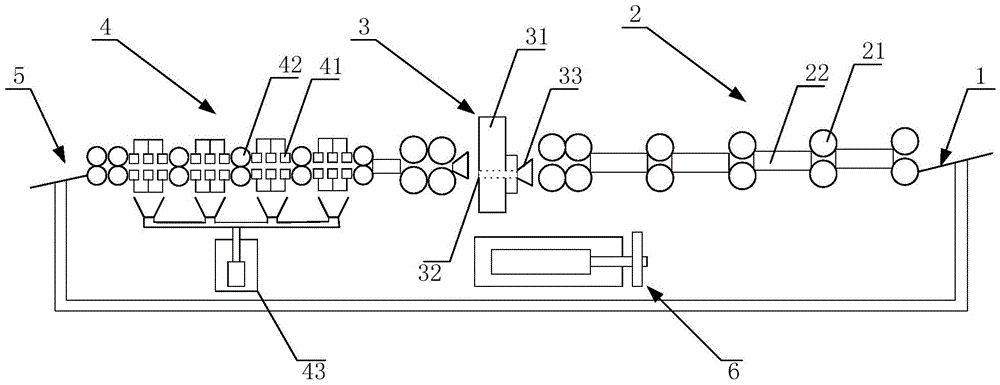

Corrugated paper production line control system

InactiveCN104765343AImprove production efficiency and production qualityImprove effectiveness and convenienceTotal factory controlProgramme total factory controlPaper productionSpeed control system

The invention discloses a corrugated paper production line control system. The corrugated paper production control system comprises a plurality of management systems for conducting operation management on corrugated paper production lines, a control center connected with the management systems through Ethernet and a PLC control system in communicating connection with the control center. The PLC control system comprises a speed control system, a tension regulation and control system, a pressure regulation and control system and a material change control system, wherein the speed control system achieves regulation and control on the operation speeds of the production lines, tension control of paper of the production lines is achieved through the tension regulation and control system, regulation and control on thermal pressures of corrugation rolls are achieved through the pressure regulation and control system, and corrugating base paper change is achieved through the material change control system. The corrugated paper production line control system achieves management and control integration, and production efficiency and production quality are improved.

Owner:SHENZHEN TIANTIANSHENG PAPER PROD

Multi-station rewinding cutting machine

ActiveCN107055164ASolve uneven adhesionImprove production efficiency and production qualityArticle deliveryWebs handlingPaper sheetEngineering

The invention discloses a multi-station rewinding cutting machine. The multi-station rewinding cutting machine is provided with a rack and characterized in that the rack is provided with a rotation shaft, the rotation shaft is driven by a motor, a plurality of paper tube rolls are arranged at the periphery of the rotation shaft, and a paper tube loading and unloading device, a winding device, a tailing collecting device and cutting devices are sequentially arranged along the rotation shaft; the paper tube loading and unloading device is provided with a material storing box, a material feeding cylinder, a paper tube moving rack, a conveying strip, a moving base, a limiting base and pneumatic chucks; the winding device is provided with a cut-off device and a winding press roll; the tailing collecting device is provided with a tailing collecting press roll; the cutting device is provided with a plurality of cutting knives. According to the multi-station rewinding cutting machine capable of automatically producing clean tape with tissue, the structure is simple, and the production efficiency is high.

Owner:上海华迪机械有限公司

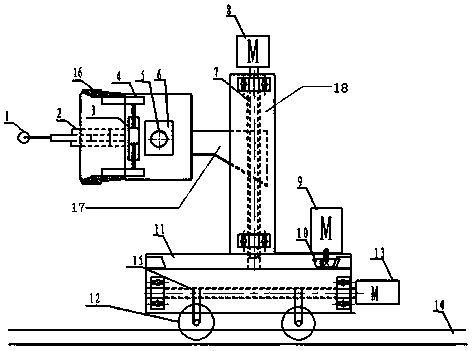

Drilling riser joint and riser body automatic butting device

InactiveCN107842326ASolve the large amount of wrong sideImprove production efficiency and production qualityDrilling rodsMetal working apparatusPistonPiping

The invention provides a drilling riser joint and riser body automatic butting device. Clamping jaws are fixed to the two ends of a piston of a hydraulic oil cylinder, a telescopic rod is fixedly connected with a left-right walking lead screw, a detection head is fixed to the top end of the telescopic rod, and the left-right walking lead screw is connected with an asynchronous servo motor; a clamping detection part is connected with an up-down walking lead screw through a transverse support, the up-down walking lead screw is fixed to a vertical support, and the asynchronous servo motor is installed at the top end of the vertical support, and connected with the up-down walking lead screw; a device walking lead screw, a reduction gear and the asynchronous servo motor are fixed to the upper portion of an equipment base, the vertical support is fixed to the device walking lead screw, and the device walking lead screw is connected with the asynchronous servo motor; and front-back walking wheels are fixed to the lower portion of the equipment base, and the front-back walking wheels are matched with a rail. The drilling riser joint and riser body automatic butting device has the advantages that the requirement for straightness of a drilling riser is sufficiently ensured through automatic six-orientation adjusting and rotating, the situation that the drilling riser joints are hoisted to look for the riser body is replaced, the problem that the unfitness of butt joint is high is solved, the production quality and the production efficiency are improved, safety and reliability are achieved, and the safety of butting construction of the drilling riser joints and the riser body is guaranteed.

Owner:SHANDONG QILONG OFFSHORE PETROLEUM STEEL PIPE

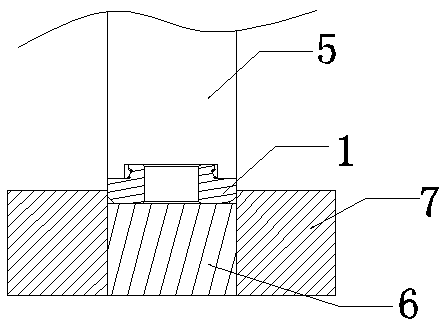

Pole group structure for flexibly packaged polymer batteries

ActiveCN102983364AImprove production efficiency and production qualityEnhance product experienceFinal product manufactureSecondary cellsElectrical batteryEnergy density

The invention discloses a pole group structure for flexibly packaged polymer batteries, which comprises a positive plate (1) and a negative plate (2), wherein the positive plate (1) and the negative plate (2) are wound together in a preset winding mode so as to form a battery pole group. The pole group structure for flexibly packaged polymer batteries, disclosed by the invention, can conveniently and reliably carry out effective control on the thickness of batteries to satisfy the production needs of batteries with different thicknesses and energy densities, and can significantly improve the production quality and production efficiency of batteries, enhance the product application feelings of users and facilitate the improvement of the market competitiveness of flexibly-packaged polymer batteries, therefore, the pole group structure has great production practice significance.

Owner:天津聚元新能源科技有限公司

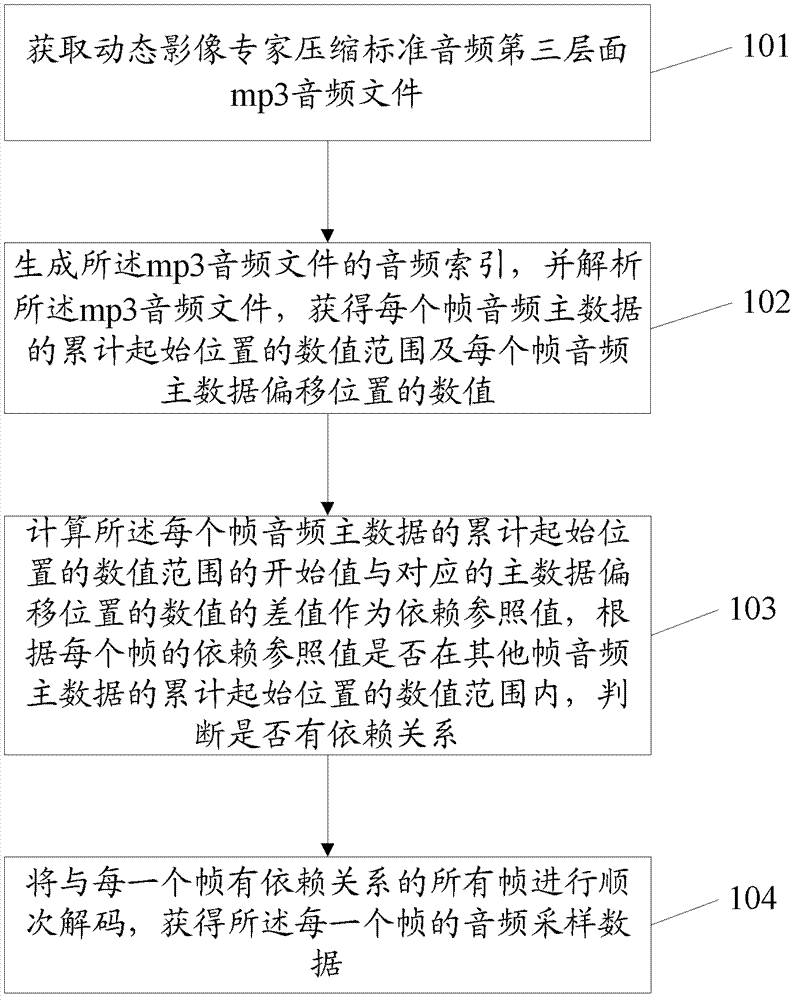

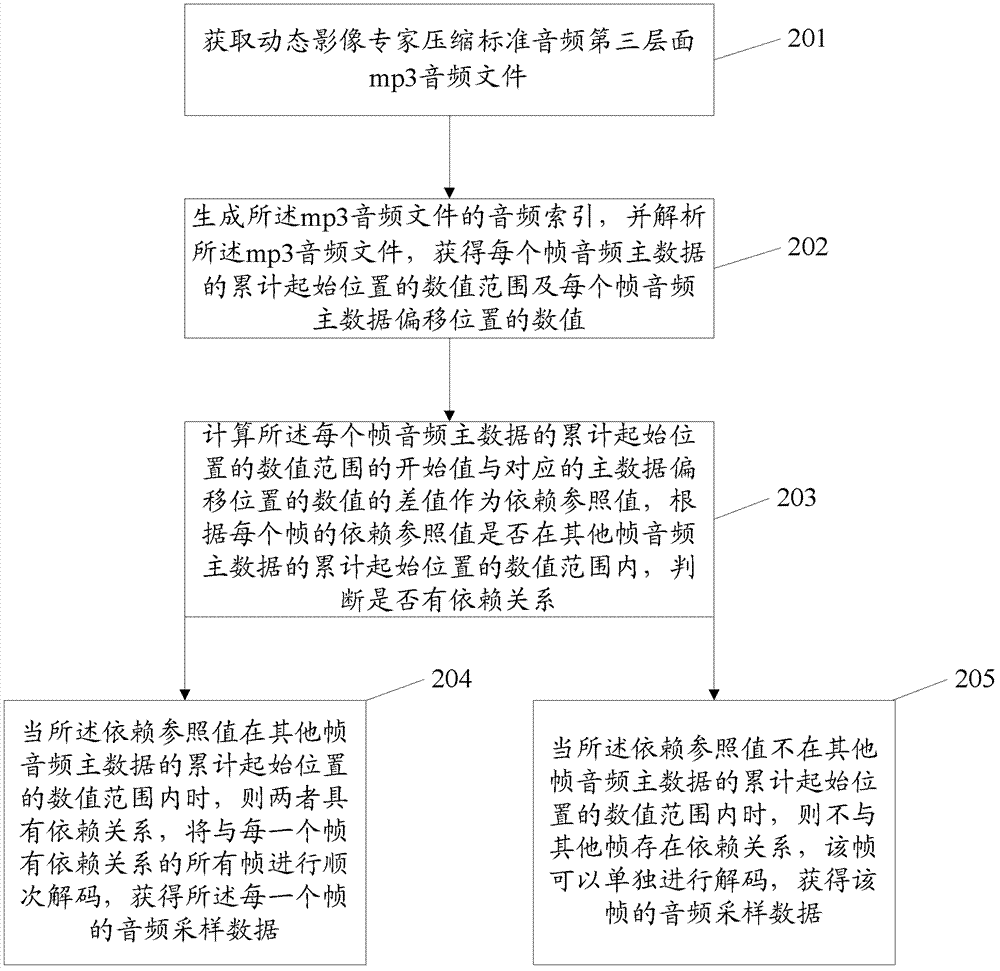

Method for decoding audio frequency frames

InactiveCN102768834AImprove production efficiency and production qualityAccurate decodingSpeech analysisAudio frequencyExpert group

The invention discloses a method for decoding audio frequency frames, which comprises the following steps: obtaining an mp3 (Moving Picture Experts Group-1 Layer 3) audio file; generating an audio index of the mp3 audio file, analyzing the mp3 audio file, and obtaining the value range of accumulative initial positions of each frame of audio master data as well as values of offset positions of each frame of audio master data; calculating the difference value between a initial value of the value range of the accumulative initial positions of each frame of audio master data and a value of the offset position of corresponding master data, taking the difference value as a dependence reference value, judging that the dependence relation exists or not based on that whether the dependence reference value of each frame is within the value range of the accumulative initial positions of other frames of audio master data; sequentially decoding all frames having the dependence relation with each frame, and obtaining audio sample data of each frame. Through the audio frame decoding method provided by the invention, the producing efficiency and quality are significantly improved.

Owner:CHINA DIGITAL VIDEO BEIJING

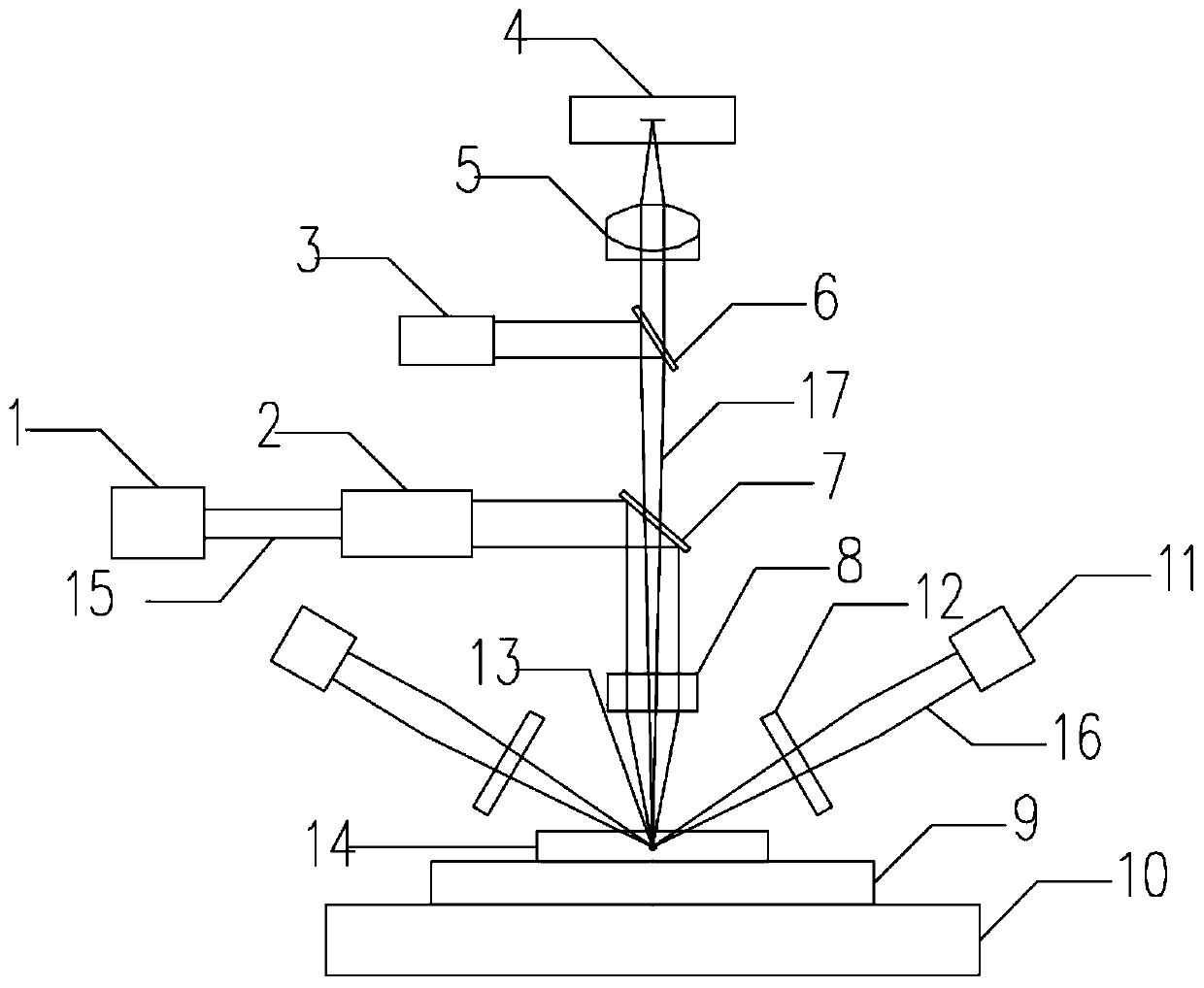

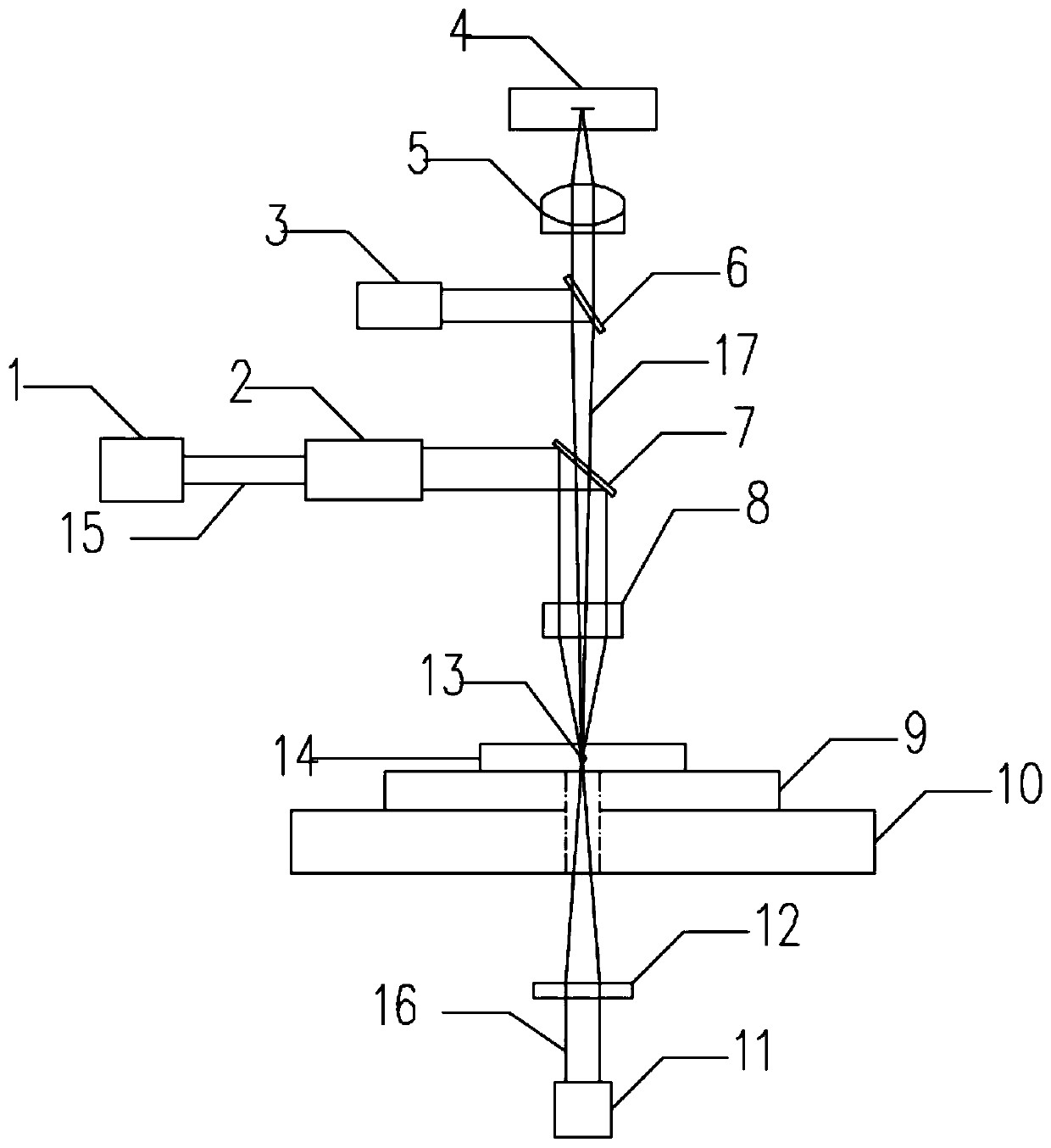

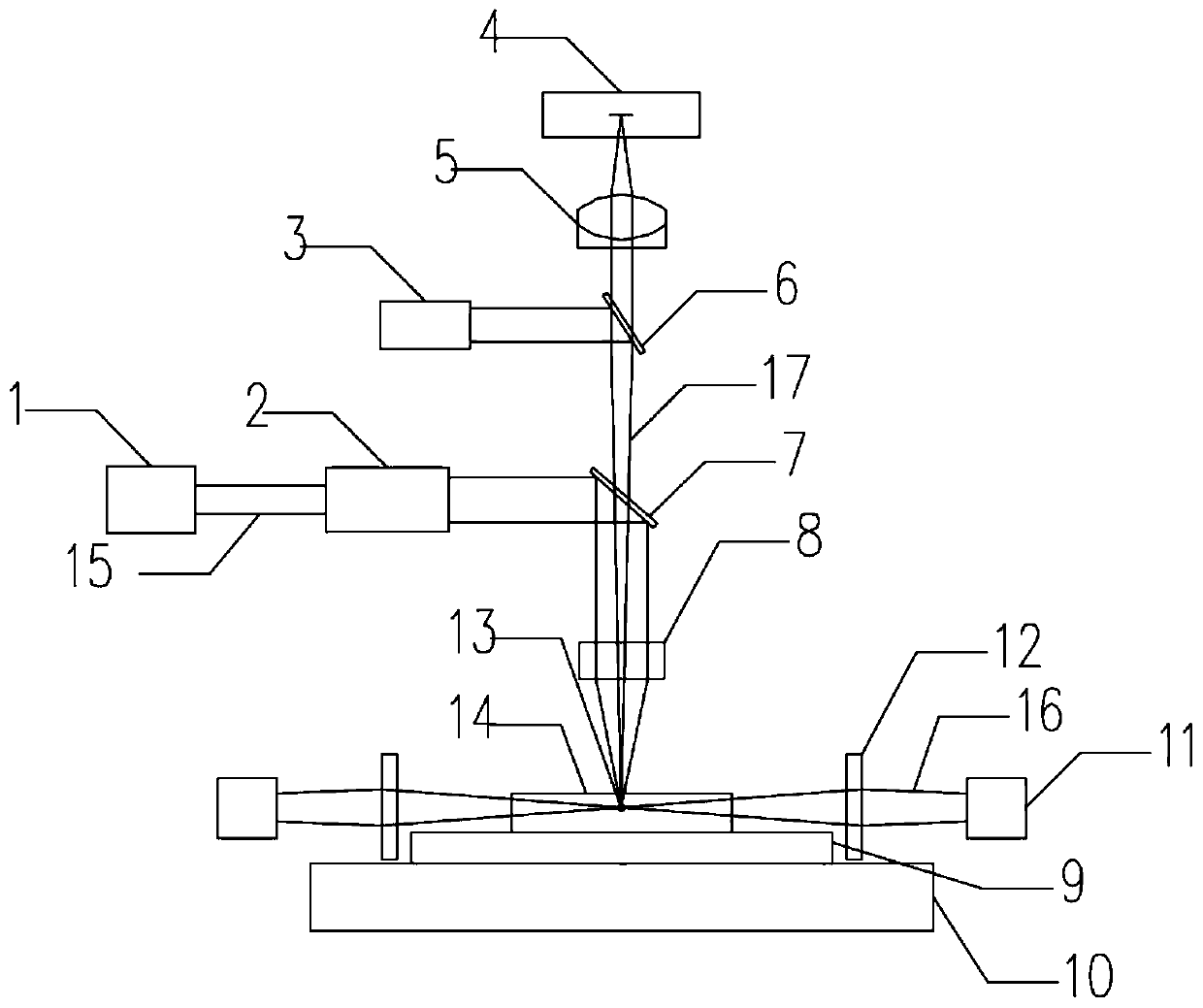

Laser cutting device capable of forming extendable controllable crack based on plasma and laser cutting method

InactiveCN111055028AImprove production efficiency and production qualityImprove flatnessMetal working apparatusLaser beam welding apparatusPhysicsEngineering

The invention discloses a laser cutting device capable of forming an extendable controllable crack based on plasma and laser cutting method. The laser cutting device comprises a multi-axis mobile platform (9), an imaging system, an invisible cutting device and one or more auxiliary laser devices, wherein the imaging system is used for acquiring a surface image of a to-be-machined workpiece (14) onthe multi-axis mobile platform (9), the invisible cutting device is used for generating a laser beam (15), the laser beam (15) converges into the to-be-machined workpiece (14) to make a workpiece material at an invisible cutting laser focal spot (13) be gasified and ionized to form the plasma, and the plasma expands and impacts the material to form the crack, the one or more auxiliary laser devices are used for generating an auxiliary laser beam (16), and the focal spot of the auxiliary laser beam (16) converges to a plasma and crack area inside the to-be-machined workpiece (14) to accelerateexpansion of the plasma to further impact the formed crack to make the crack be extended. According to the device and the method, by controlling the position and the energy of the auxiliary laser beam (16), the crack extension length and direction are controllable.

Owner:WUHAN UNIV

Bamboo arrow rod straightening machine

ActiveCN106142275AImprove production efficiency and production qualityIncrease production capacityWood compressionWood treatment detailsContinuous operationAgricultural engineering

The invention discloses a bamboo arrow rod straightening machine. The bamboo arrow rod straightening machine comprises a feeding opening, a heating softening device, a fiber kneading softening device, a cooling shaping device, a discharge opening and a transmission motor, wherein the heating softening device comprises a plurality of transmission wheels arrayed at intervals and heating tubes; the transmission wheels are respectively positioned at two ends of each heating tube; the fiber kneading softening device comprises a rotating plate, an eccentric hole and a conical nozzle arranged at the front end of the eccentric hole; the cooling shaping device comprises a plurality of press fitting shapers, a plurality of transition wheels and an air cooling device; the press fitting shapers and the transmission wheels are arrayed at intervals; and the transmission motor is in transmission connection with the transmission wheels, the rotating plate and the transition wheels. By the structure, a bamboo arrow rod extends in a feeding opening, is heated and softened, kneaded and softened through fibers, cooled and shaped, and then is discharged through the discharge opening; straightening of the bamboo arrow rod is finished at one step, continuous operation can be realized, and production effect and production quality are greatly improved; and meanwhile, the straightness of the made bamboo arrow rod is the same as that of a white wood rod, and further, the bamboo arrow rod has quite high hardness and toughness.

Owner:FUJIAN FENGFEI SPORTS DEV CO LTD

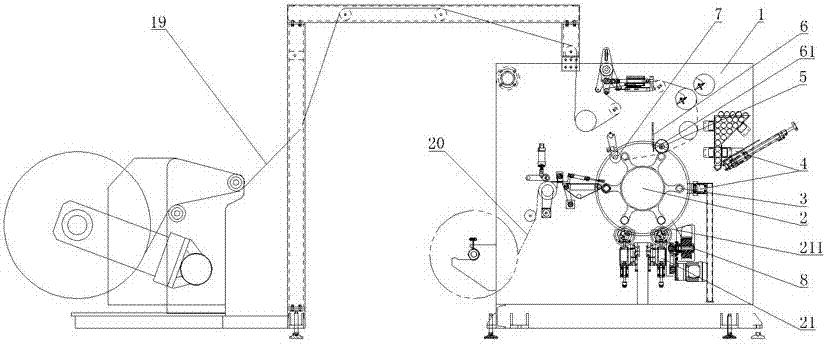

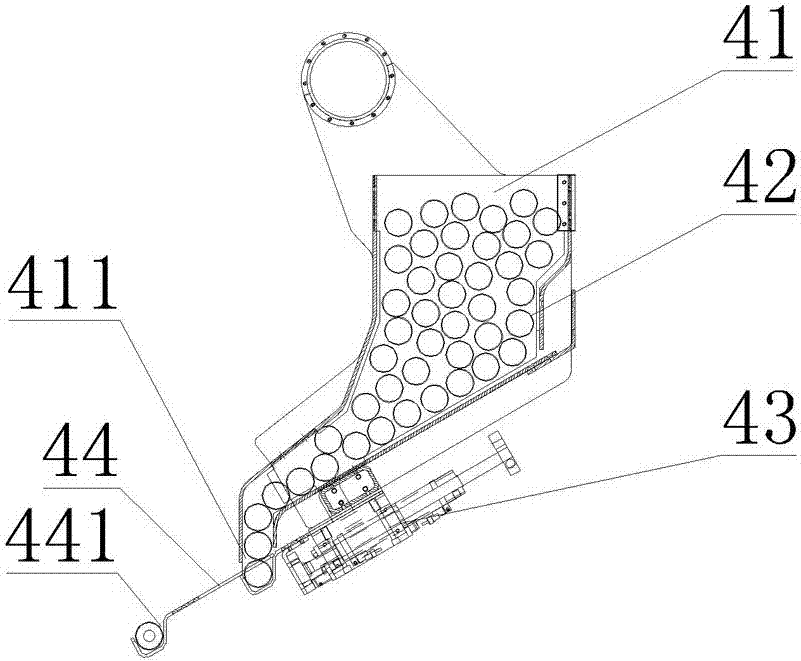

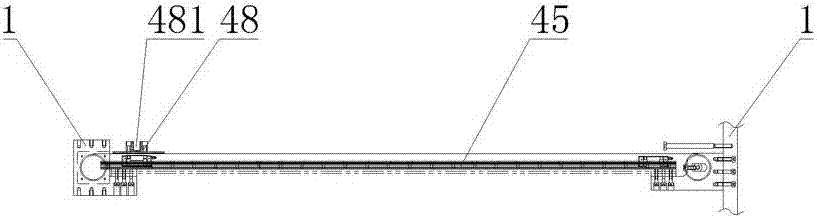

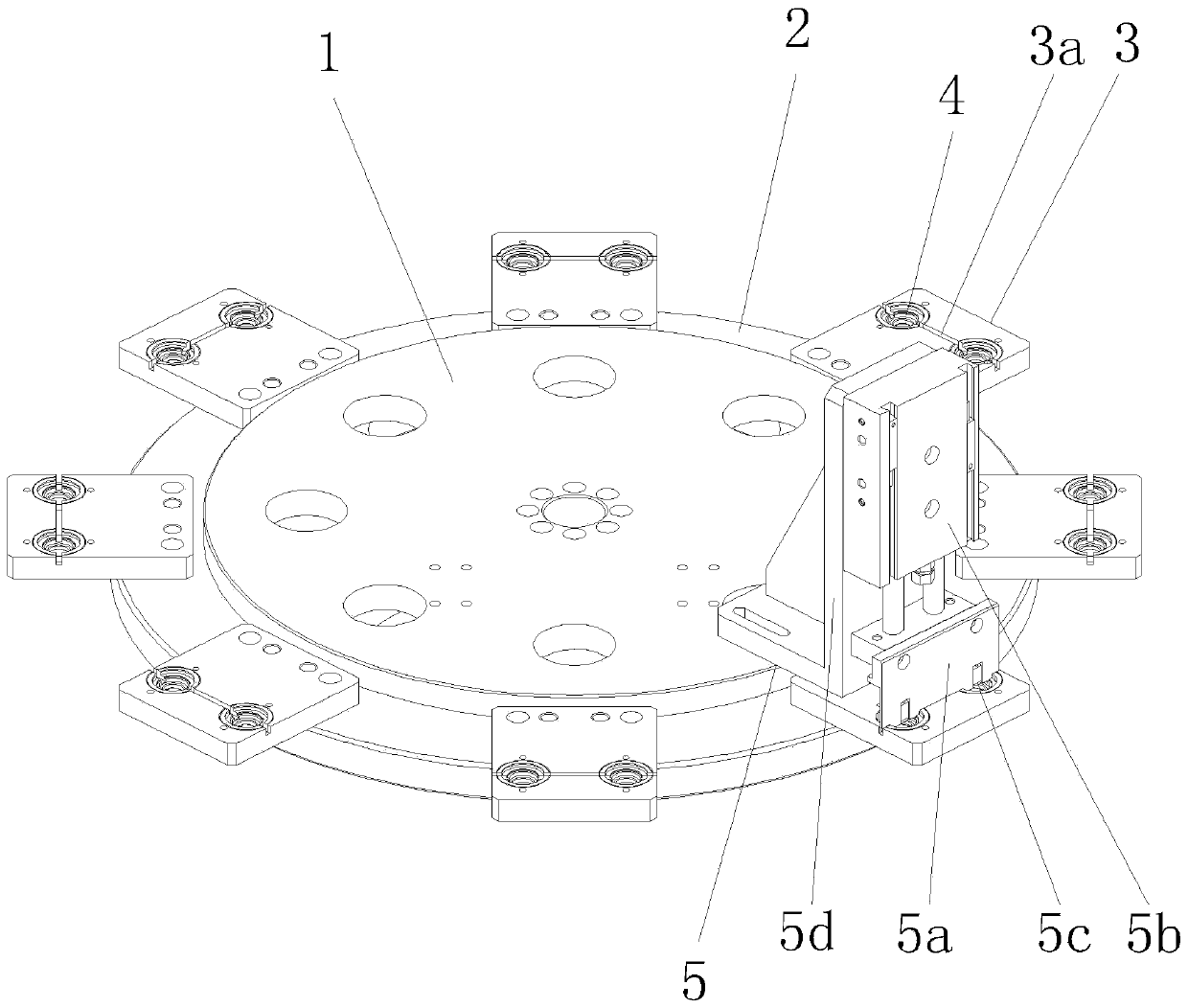

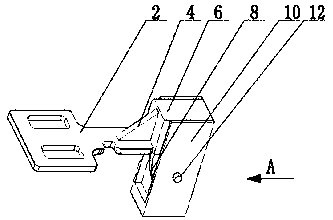

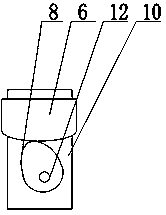

Automatic lithium battery cap assembling and discharging device with discharging detection mechanism

PendingCN109732312AImprove production efficiency and production qualityAvoid affecting the progress of assembly processingMetal working apparatusSheet steelEngineering

The invention discloses an automatic lithium battery cap assembling and discharging device with a discharging detection mechanism. The automatic lithium battery cap assembling and discharging device with the discharging detection mechanism comprises a fixed disk and a machining rotary disk. The machining rotary disk is provided with machining bases which outwards extend out, and extending parts ofthe machining bases are provided with material placement grooves. The automatic lithium battery cap assembling and discharging device with the discharging detection mechanism further comprises a rubber gasket feeding mechanism, an aluminum sheet steel cap feeding mechanism, a pressing fit mechanism, a resistance detection mechanism, a discharging mechanism and the discharging detection mechanism.The discharging detection mechanism comprises a detection clamping plate and a drive air cylinder which is connected with the detection clamping plate and drives the detection clamping plate. The machining bases are provided with clamping grooves, and the clamping grooves communicate with the material placement grooves in the corresponding machining bases. The detection clamping plate is providedwith a vacuum slot, the vacuum slot is clamped to the bottom of the detection clamping plate, the lower end of the vacuum slot is flush to the detection clamping plate, and the other end of the vacuum slot is connected with a vacuumizing device through a sealing hose. According to the automatic lithium battery cap assembling and discharging device, whether discharging actions are qualified or notcan be easily and effectively judged, caps left in the material placement grooves are rapidly discharged, the effect on following machining schedules is avoided, and the production quality and the production efficiency are improved.

Owner:苏州中悦行自动化机械科技有限公司

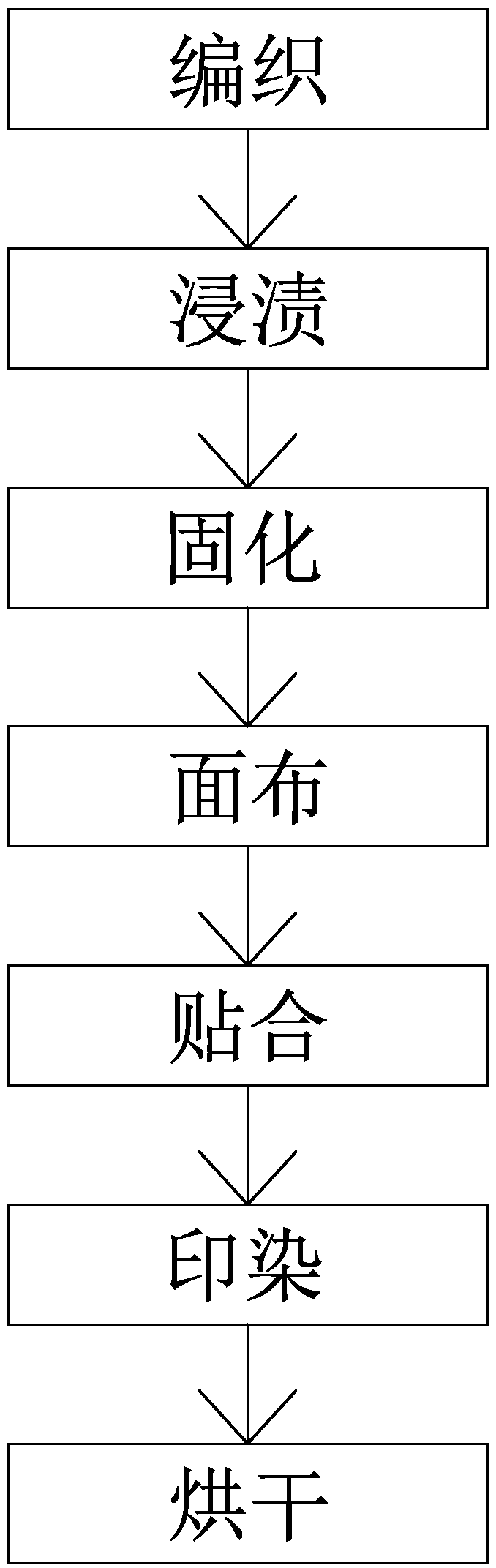

Production process for corrosion-resistant glass fiber composite fabric

InactiveCN108638623AImprove production efficiency and production qualityReduce labor intensityLamination ancillary operationsLaminationCorrosion resistantWoven fabric

The invention provides a production process for a corrosion-resistant glass fiber composite fabric, belonging to the technical field of the textile industry. The production process of the invention overcomes the problem of low production quality in the prior art. The production process for the corrosion-resistant glass fiber composite fabric comprises the following steps: a, weaving: subjecting glass fiber monofilaments to plain weaving so as to obtain a basic glass fiber fabric; b, impregnating: impregnating the basic glass fiber fabric obtained in the step in slurry for 5-6 hours; c, curing:subjecting the basic glass fiber fabric impregnated in the step b to ultraviolet curing; d, preparation of a surface fabric: processing a commercially available non-woven fabric, coating the non-woven fabric with a corrosion-resistant coating, and carrying out drying so as to obtain the corrosion-resistant surface fabric; e, lamination: laminating the UV-cured glass fiber fabric obtained in the step c with the corrosion-resistant surface fabric by using a laminating device so as to obtain a corrosion-resistant semi-finished glass fiber fabric; f, printing and dyeing; and g, drying. The production process of the invention has the advantage of capacity of improving production quality.

Owner:海宁市纵达新材料股份有限公司

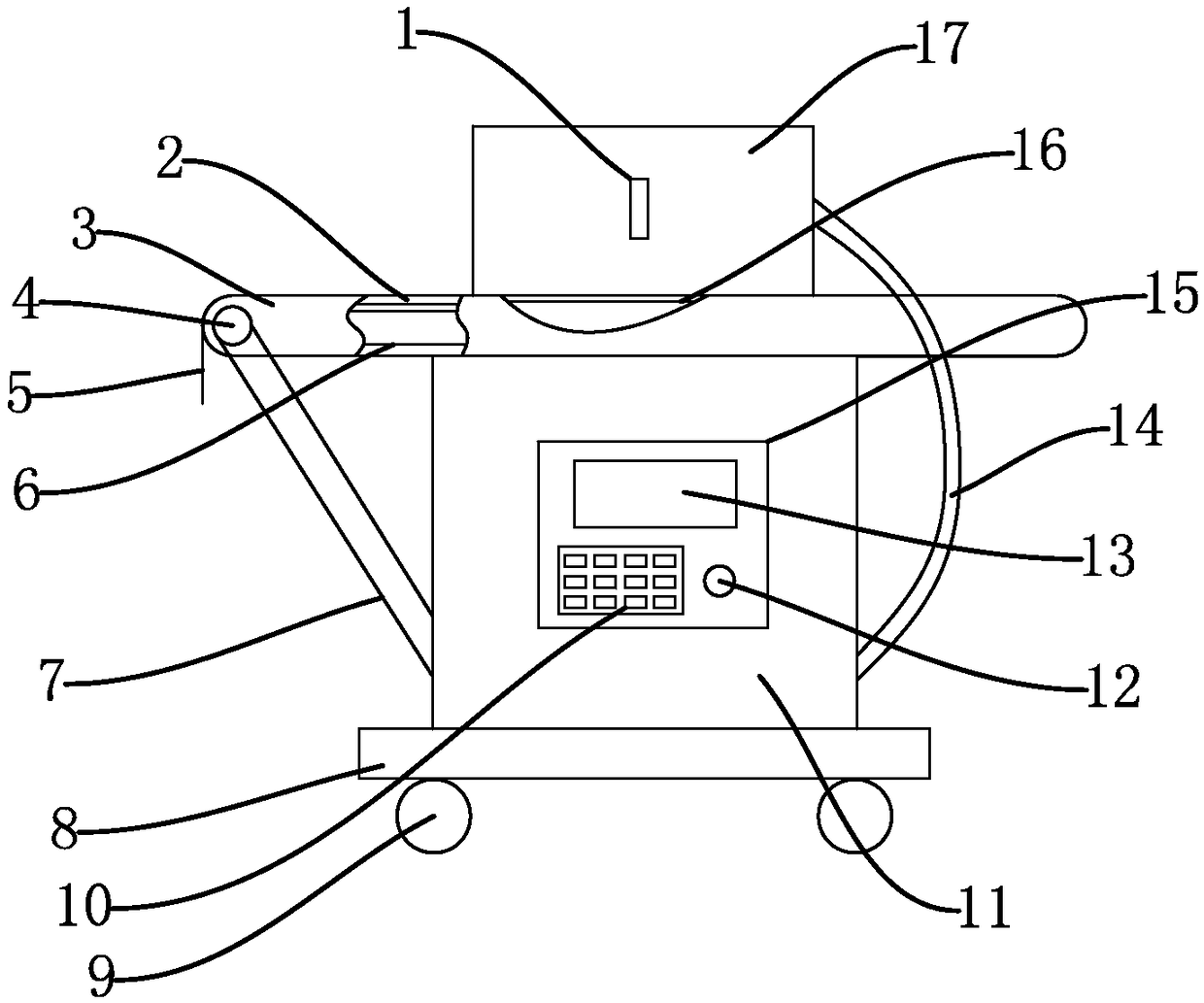

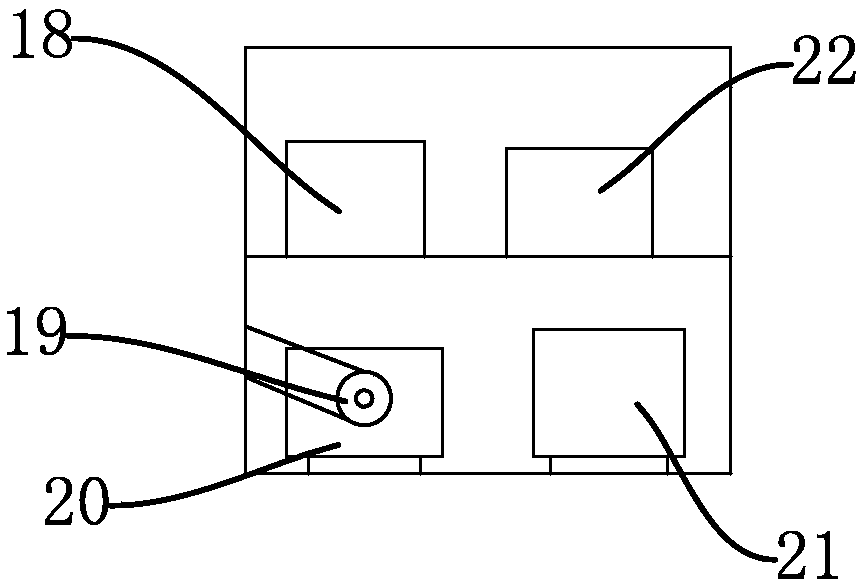

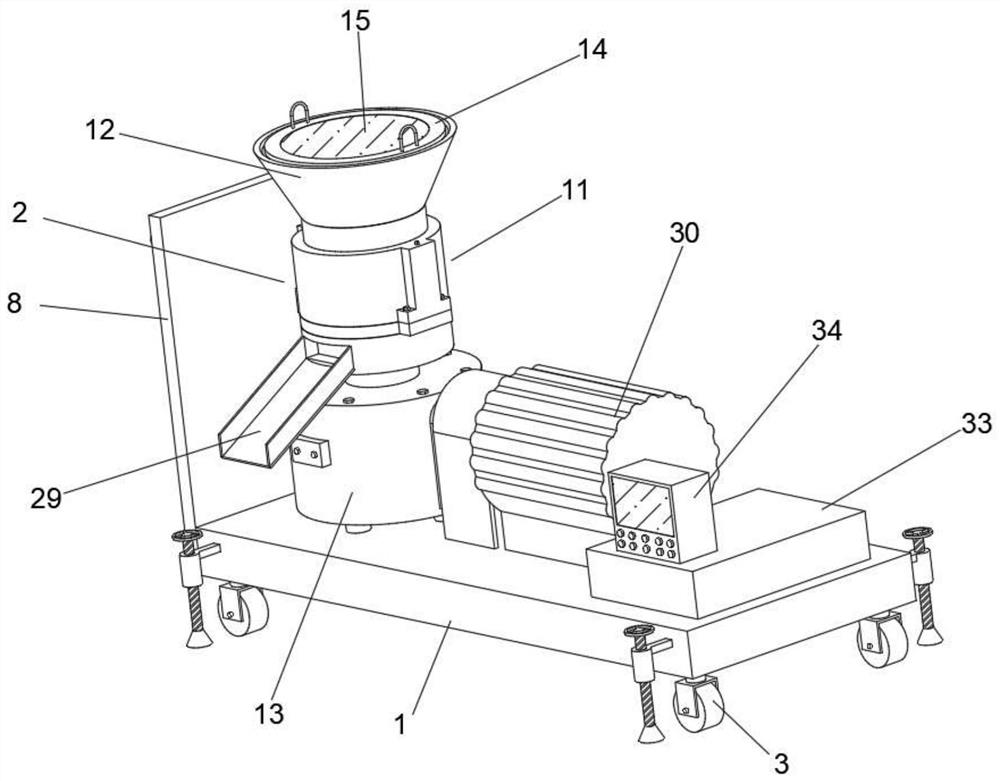

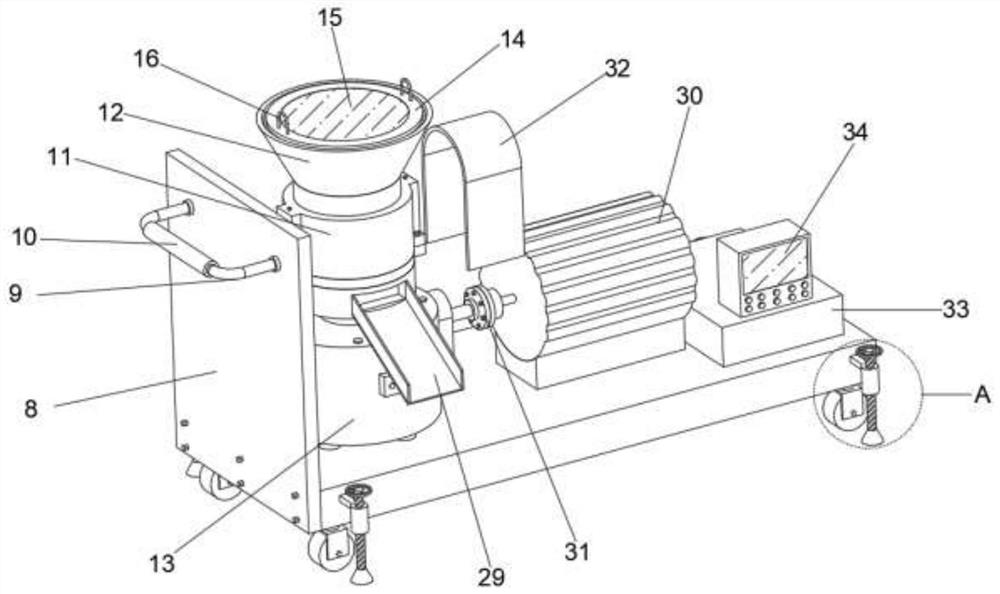

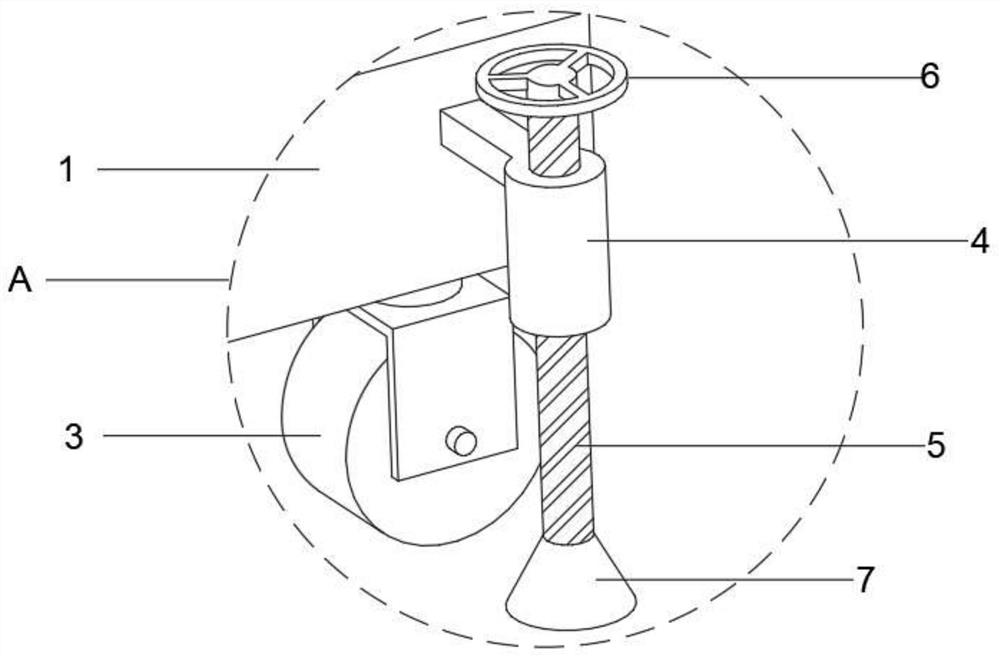

Granulator for dust pollution prevention coating material

InactiveCN112619553AImprove versatilityImprove production efficiency and production qualityGranulation by material expressionHand carts with multiple axesElectric machineryPelletizing

The invention belongs to the technical field of granulators, and relates to a granulator for a dust pollution prevention coating material. The granulator comprises a vehicle plate and a granulation mechanism, wherein an adjusting screw rod is in threaded connection in a fixed screw sleeve, the bottom of a material box is fixedly communicated with a transmission box, the top of the material box is fixedly communicated with a feeding hopper, a transmission shaft is rotatably connected in the transmission box, the transmission shaft is fixedly sleeved with a spiral conveying blade, the transmission shaft is fixedly sleeved with a granulating disc, a fixing rod is rotatably sleeved with a rolling wheel, the transmission shaft is fixedly connected with two cutters, the right end of the transmission box is rotatably connected with a connecting shaft, the front end of the material box fixedly communicates with a discharging hopper, the top of the vehicle plate is fixedly connected with a driving motor, the driving motor is positioned on the right side of the granulation mechanism, the output end of the driving motor is fixedly connected with a coupler, the right side of the top of the vehicle plate is fixedly connected with a storage battery, and a controller is arranged at the top of the storage battery. According to the invention, the granulator can automatically granulate a dust pollution prevention coating material, is high in granulation efficiency and good in quality, and can effectively prevent the dust pollution prevention coating material from splashing out in the granulation process.

Owner:厦门古墨化工有限公司

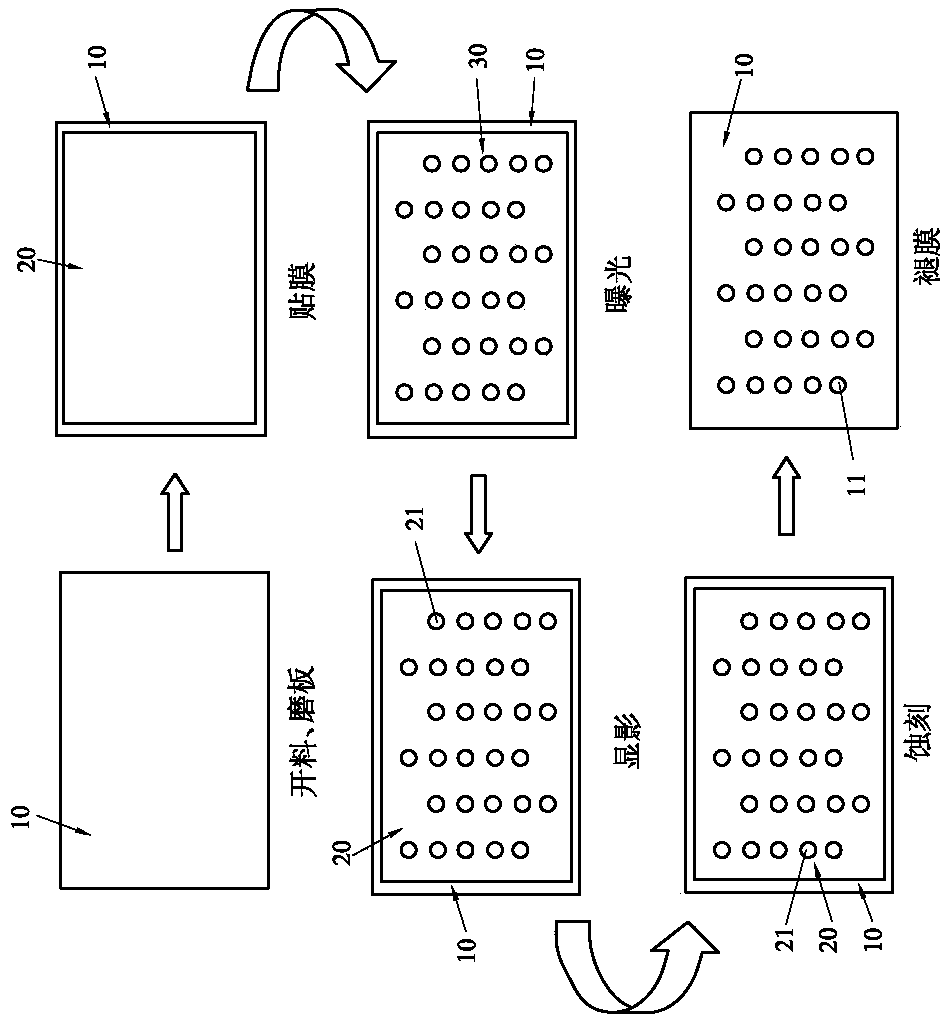

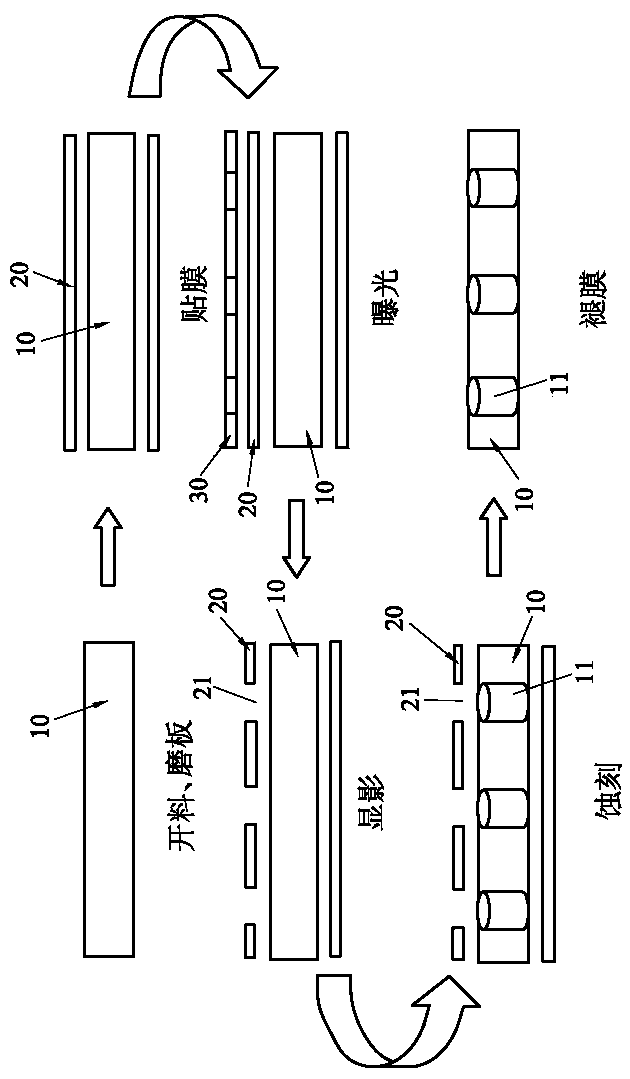

Thick-copper copper substrate etching process

InactiveCN109587953AReduce processing costsImprove production efficiency and production qualityConductive material chemical/electrolytical removalCircuit metal processingSubstrate surfaceCopper substrate

The invention discloses a thick-copper copper substrate etching process. The thick-copper copper substrate etching process comprises the following steps of: (1) cutting; (2) plate grinding: grinding athick-copper copper substrate to properly improve the roughness of a surface of the thick-copper copper substrate, and cleaning the substrate surface; (3) pad pasting: attaching anti-corrosion ink ora dry film to substrate surface of the thick-copper copper substrate; (4) exposure; (5) development; (6) etching: employing acidic etching medicinal liquid to perform redox reaction with the exposedthick-copper copper substrate to etch the corrosion of the thick-copper copper substrate at the through hole so as to obtain accurate through holes with various shapes; and (7) film removing. The anti-corrosion ink or the dry film is attached to the thick-copper copper substrate, various required through hole graphs are preset on the anti-corrosion ink or the dry film, an etching copper removal mode is employed to achieve processing of the through holes with various shapes to replace a traditional machining mode of drilling and drill-in and drill-out so as to greatly reduce the processing costand improve the production efficiency and the production quality.

Owner:东莞市若美电子科技有限公司

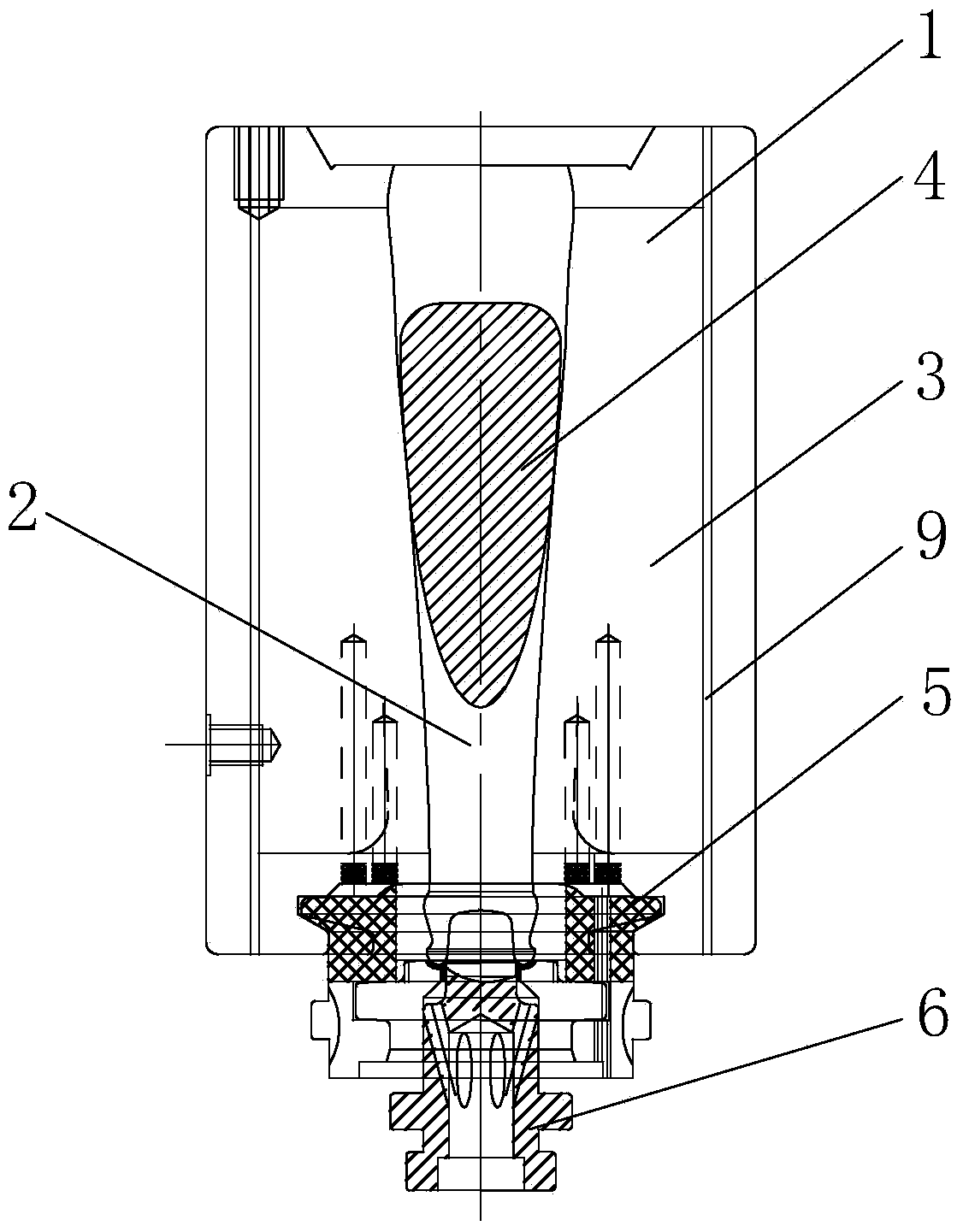

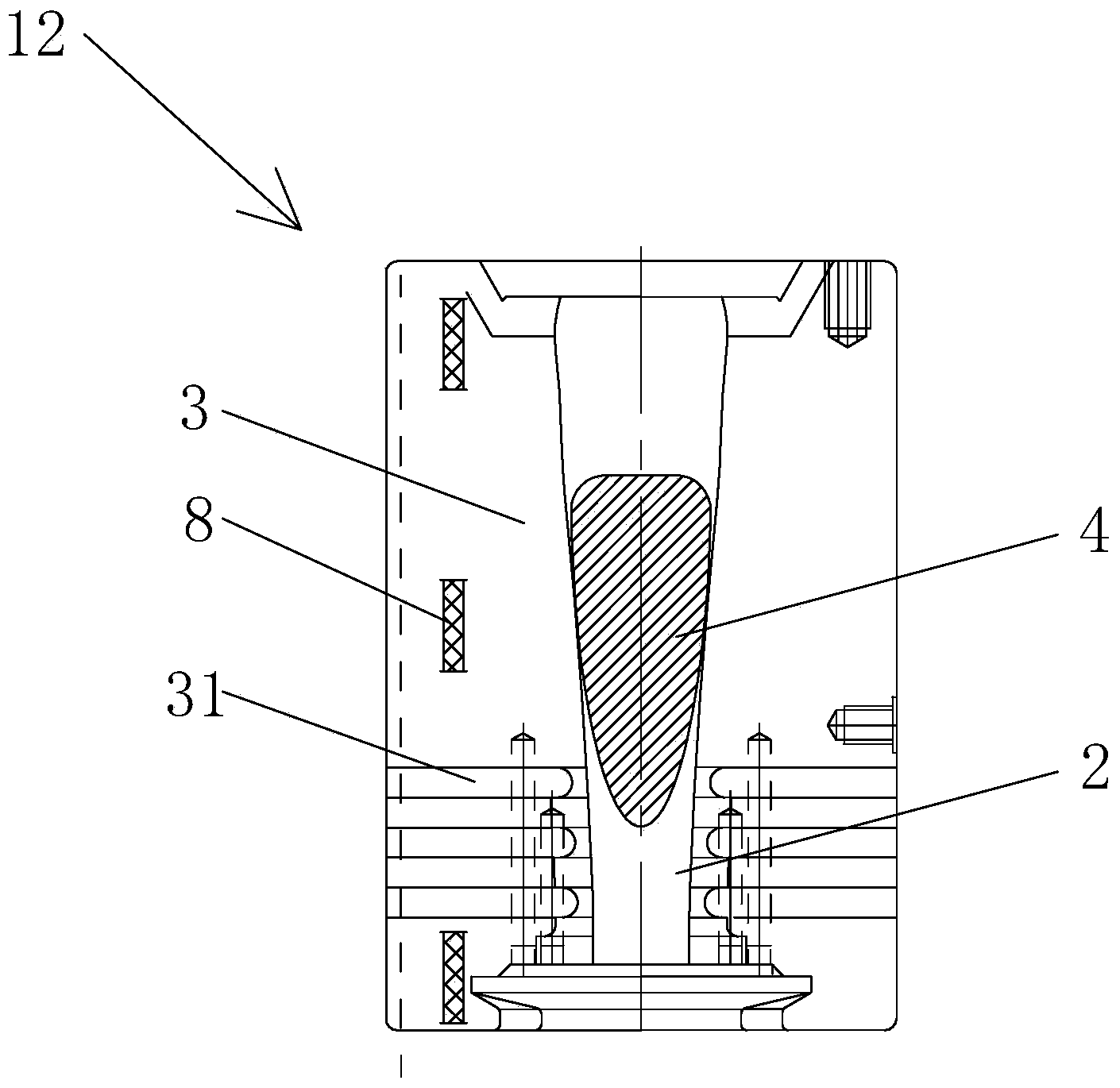

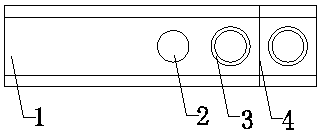

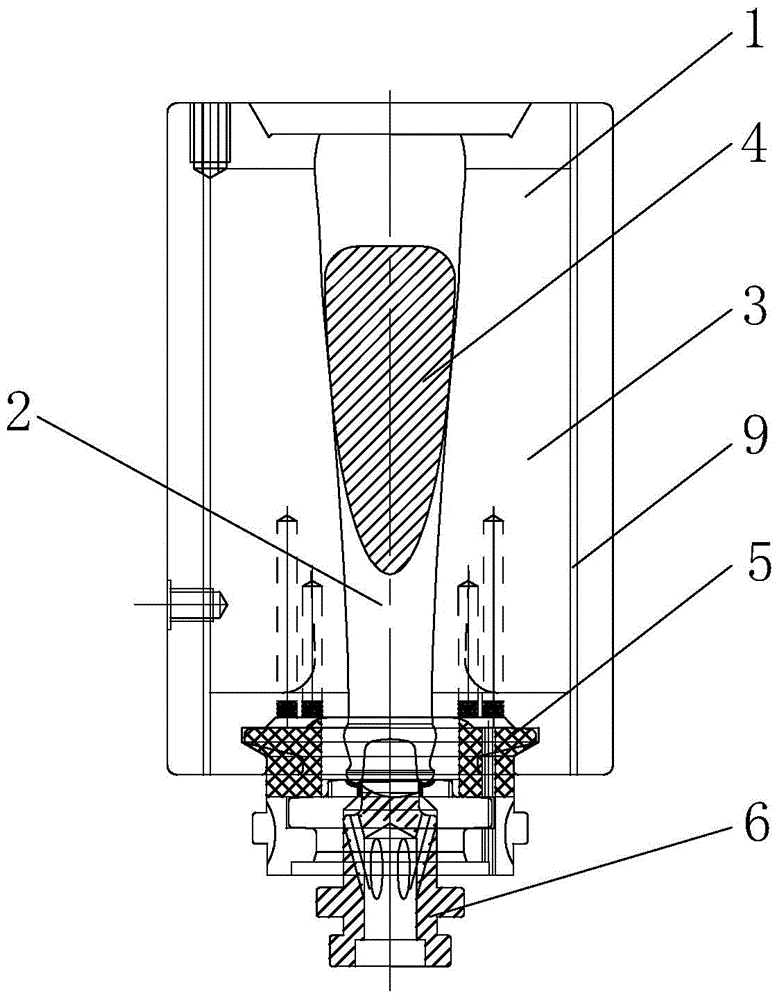

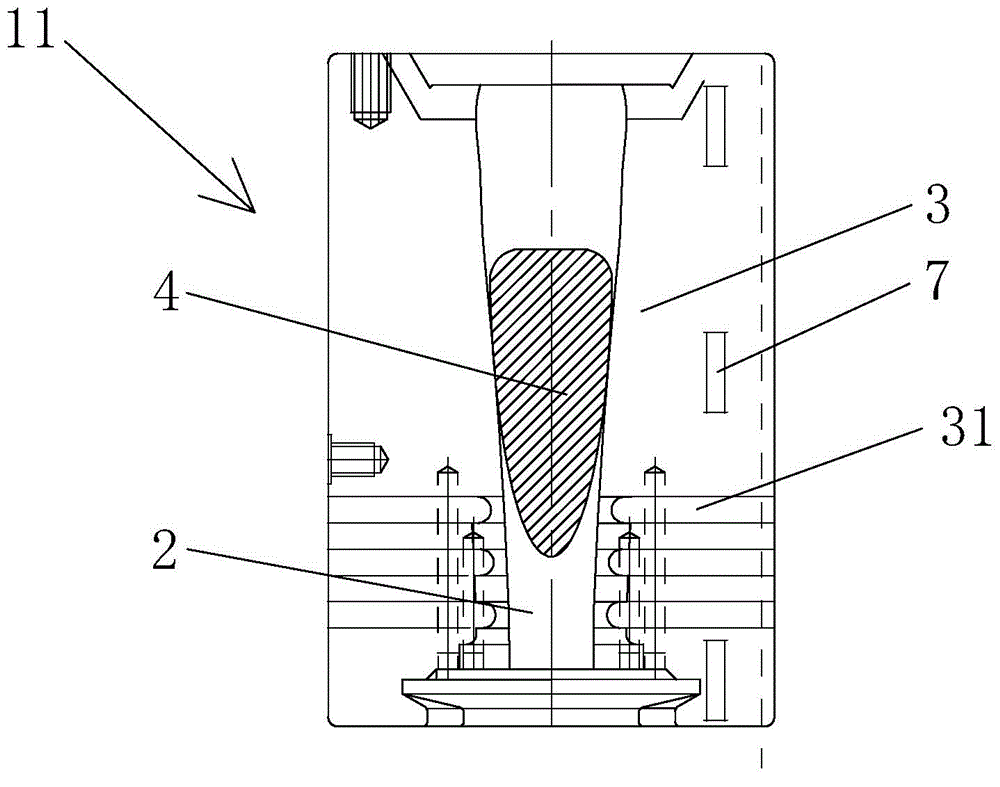

Primary die facilitating exhausting

ActiveCN104098253AQuality improvementImprove production efficiency and production qualityBlowing mouldsEngineeringLower half

The invention relates to a primary die facilitating exhausting. The primary die comprises a male die and a female die which are matched with each other, a cavity communicated from top to bottom is formed in each of the male die and the female die, the two cavities are matched with each other so as to form a bottle-shaped cavity in the primary die, tight clinging surfaces of the male die and the female die which are matched are seam joining surfaces. The primary die facilitating the exhausting is characterized in that a plurality of exhausting grooves communicated with the air inside and outside the bottle-shaped cavity are formed in the seam joining surfaces, and are located in the lower half parts of the seam joining surfaces. Compared with the prior art, the exhausting grooves are formed in the lower half parts of the seam joining surfaces of the primary die, as a result, the phenomenon that vacuum is created in the bottle-shaped cavity to cause material jumping when a glass material is discharged, is avoided, and further the production quality and production efficiency of glass bottles are improved; moreover, the male die and the female die are connected via triangular ribs, so that the air in the bottle-shaped cavity firstly flows through the exhausting grooves, then flows through gaps between every two adjacent triangular ribs, and finally is smoothly exhausted into the environment.

Owner:DEQING CAIFU GLASS

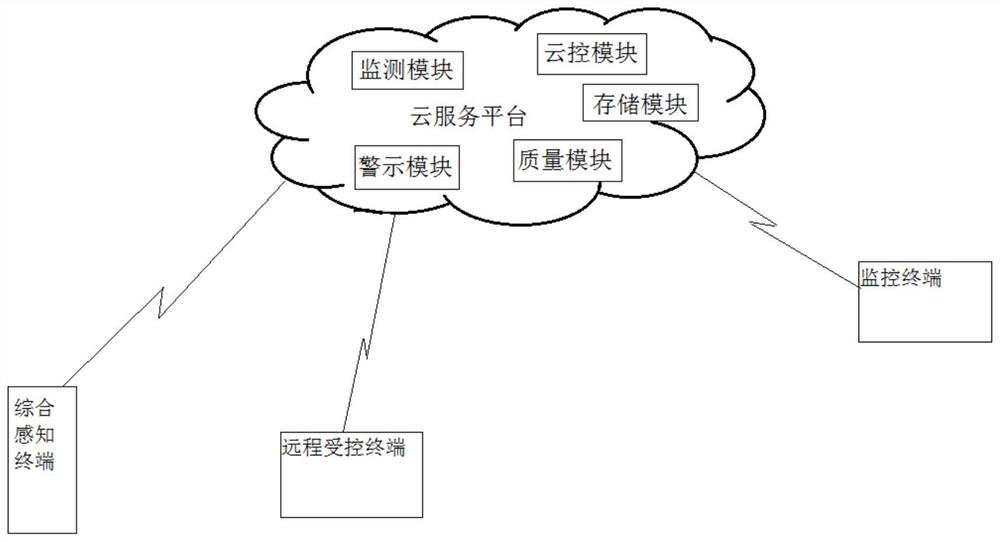

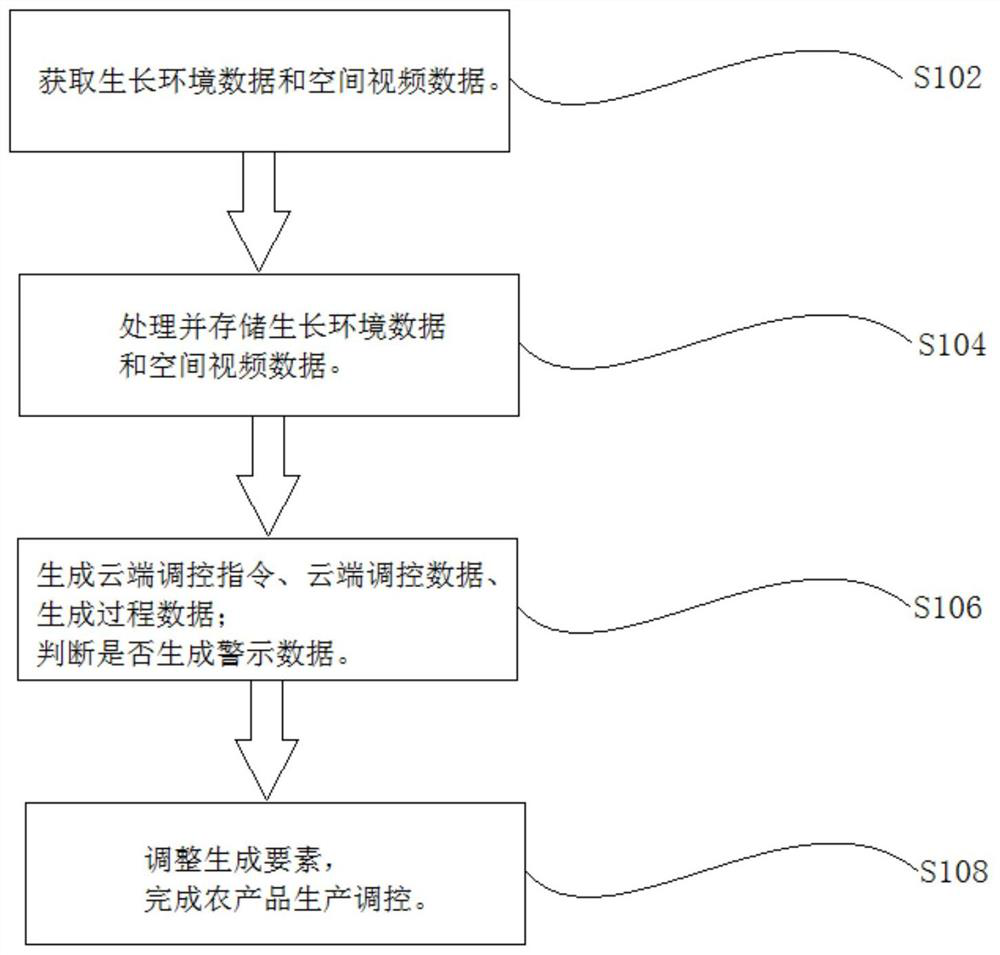

Agricultural product production regulation and control system and method based on Internet of Things

InactiveCN113467553AMeet the needs of the growing environmentImprove production efficiency and production qualitySimultaneous control of multiple variablesEnvironmental geologyAmbient data

The invention discloses an agricultural product production regulation and control system and method based on the Internet of Things. The system comprises a cloud service platform, a comprehensive sensing terminal, a remote controlled terminal and a monitoring terminal, the comprehensive sensing terminal obtains growth environment data and space video data of an agricultural product production area, the cloud service platform processes and stores the two data, generates a cloud regulation and control instruction and cloud regulation and control data, and the remote controlled terminal adjusts production elements; and the cloud service platform generates crop generation process data based on the growth environment data, the space video data and the cloud regulation and control data, and the crop generation process data is inquired by the monitoring terminal. The method comprises the following steps: acquiring data, generating a regulation and control instruction by a cloud service platform, and adjusting production elements by a remote controlled terminal. According to the invention, automatic regulation and control of the crop growth environment and instant query of the monitoring terminal are realized, detailed production data in the crop production process are accumulated, quality traceability big data are established, and data support is provided for continuously improving the crop production efficiency and quality.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Production process for press-riveting nuts on punch press

InactiveCN111085626AReduce glitchesImprove production efficiency and production qualityNutsProcess engineeringManufacturing engineering

The invention relates to a production process for press-riveting nuts on a punch press. The process comprises the steps that a raw material strip is sequentially punched, chamfered and cut off, and thus is processed into semi-finished nuts, and finally the semi-finished nuts are machined into the finished nuts through tapping. Through arrangement of the production process, burrs can be reduced effectively under the situation of ensuring the size, and the production efficiency and the production quality are improved; through setting of the feeding precision of a servo motor, the precision of punching, chamfering and material cutting is ensured; and through limit setting of the distance between a side face cut by a punch and a side face cut by a lower die, the burrs are reduced effectively.

Owner:山东九佳紧固件股份有限公司

Novel pressing attaching device

InactiveCN103419983AImprove production efficiency and production qualityRealize automated productionLabelling machinesCamVertical distance

The invention discloses a novel pressing attaching device, which comprises a pressing board with the plane bottom surface, and a lifting board connecting onto the side face of the pressing board, and is characterized in that a cam is arranged at the lower part of the lifting board; the vertical distance from the lifting board to the rotary center of the cam is less than the distance from the rotary center of the cam to the farthest point of the profile face. The device has simple structure, effectively lowers the attachment cost during outer packing manufacturing, and improves the attachment quality.

Owner:SUZHOU SUTENG ELECTRONICS TECH

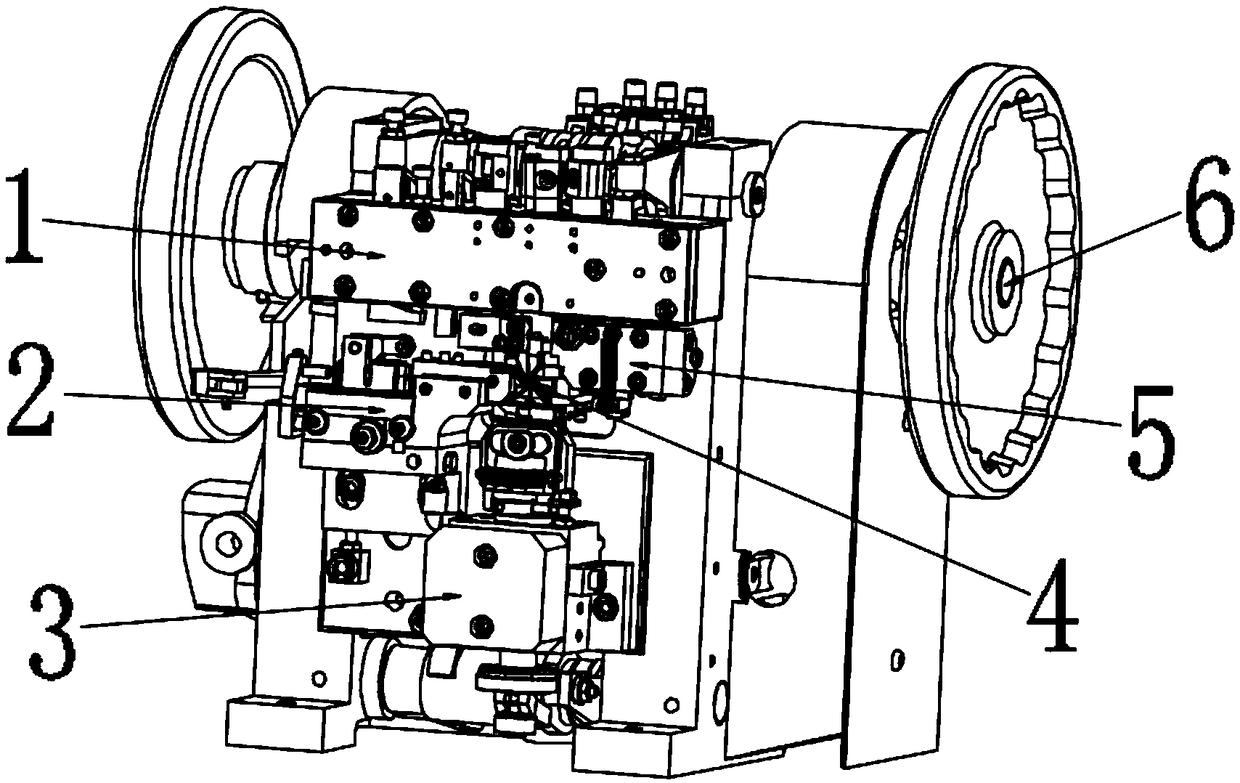

Die-cutting equipment and driving cam for lifting moving platform of die-cutting equipment

ActiveCN108582243AImprove speed and effectImprove production efficiency and production qualityMetal working apparatusEngineeringCam

The invention discloses die-cutting equipment and a driving cam for lifting a moving platform of the die-cutting equipment. The driving cam comprises a cam main body, wherein the contour line of the cam main body comprises an ascending curve and a declining curve; and a far-end stopping curve is connected between the far end of the ascending curve and the far end of the declining curve. The die-cutting equipment comprises a base table and the movable platform which are connected by a lifting mechanism; the lifting mechanism comprises a lower oscillating arm and an upper oscillating arm; the upper end of the lower oscillating arm is articulated with the lower end of the upper oscillating arm; the lower end of the lower oscillating arm is articulated with the top surface of the base table; the upper end of the upper oscillating arm is articulated with the bottom surface of the moving platform; the lifting mechanism is in transmission connection with a cam mechanism; and the cam mechanismcomprises the driving cam as described above. When the moving platform is in a high position, the die-cutting equipment has remaining time, thus greatly increasing the speed and effect of deeply embossing and stamping products.

Owner:唐山嘉谊印刷机械有限公司

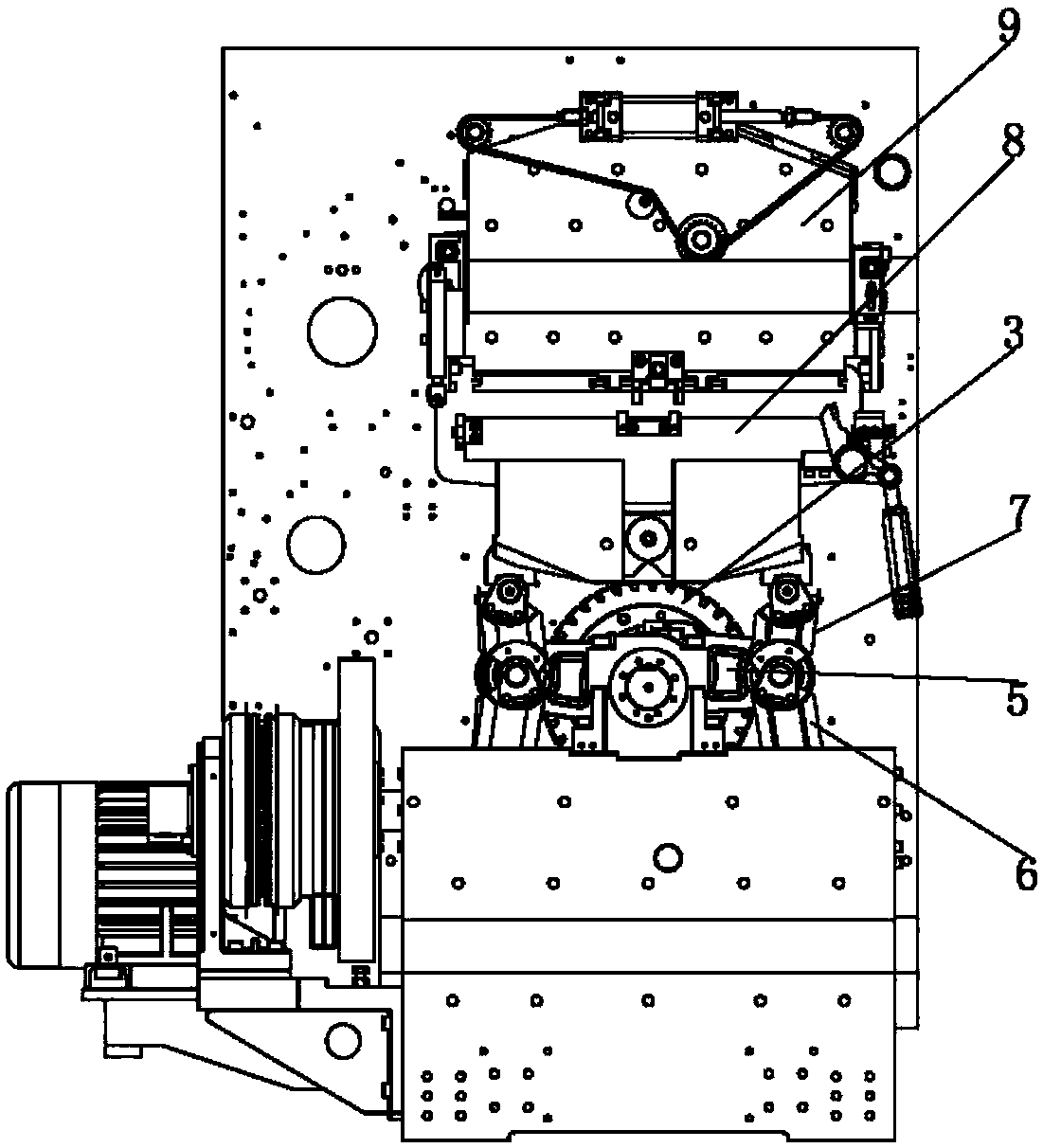

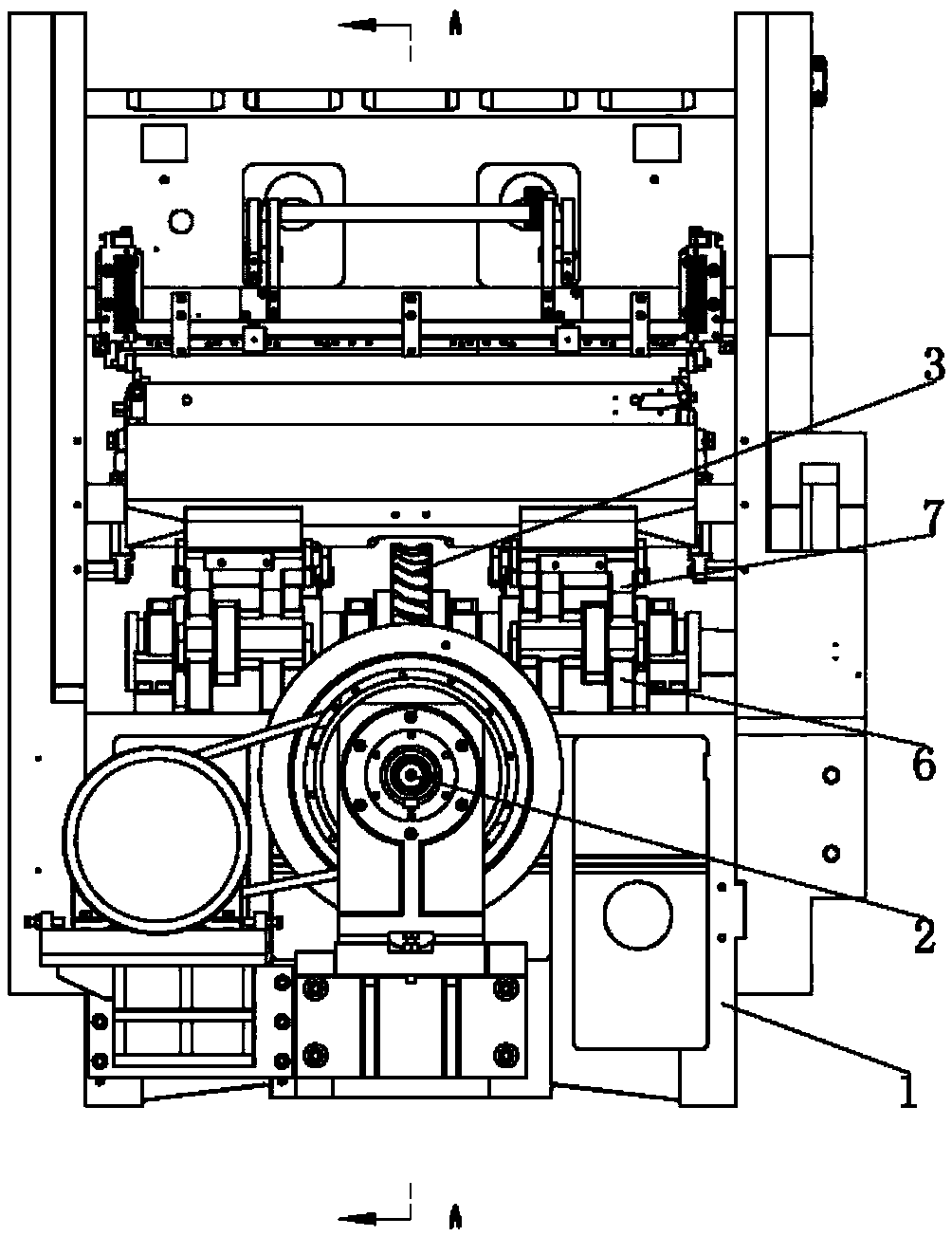

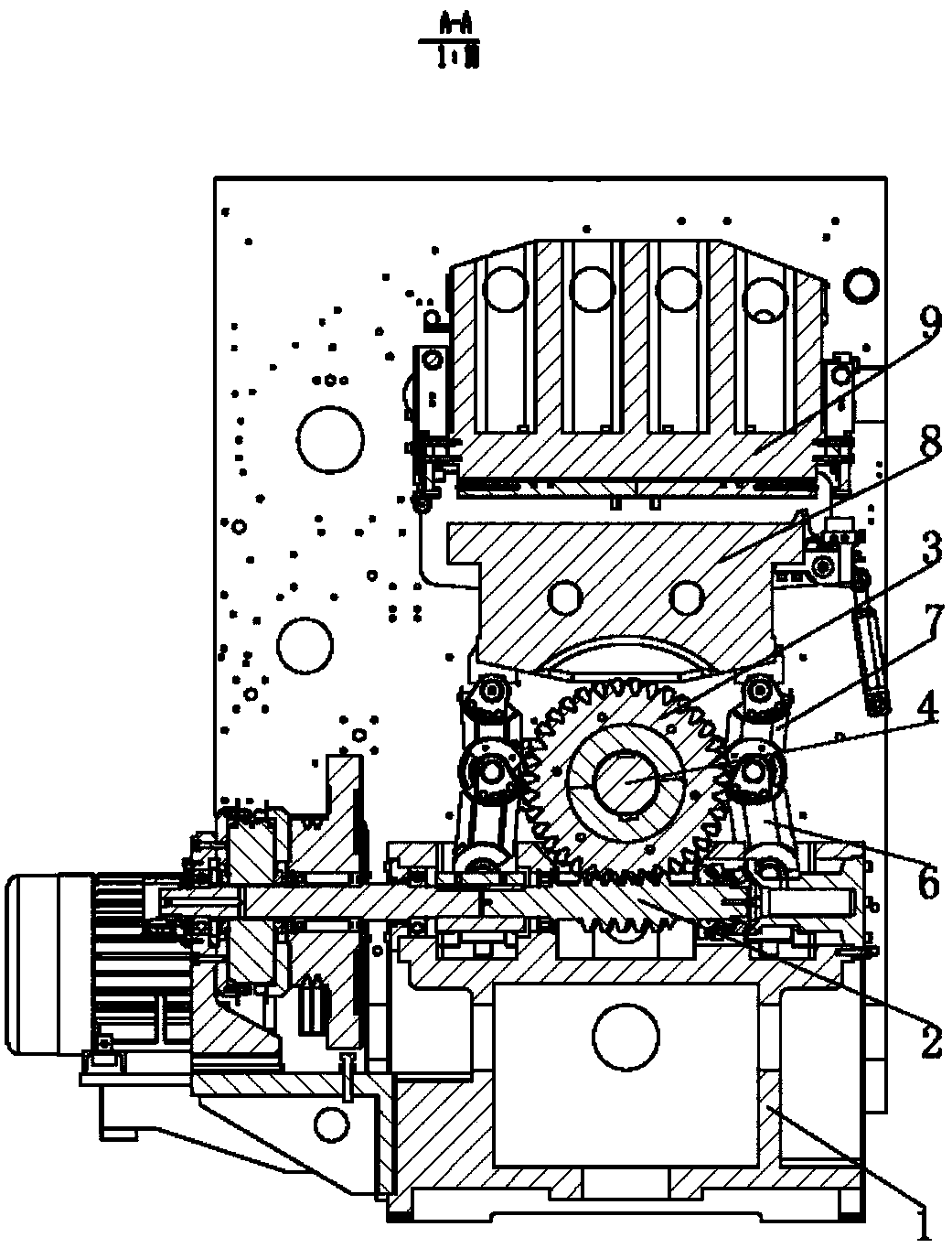

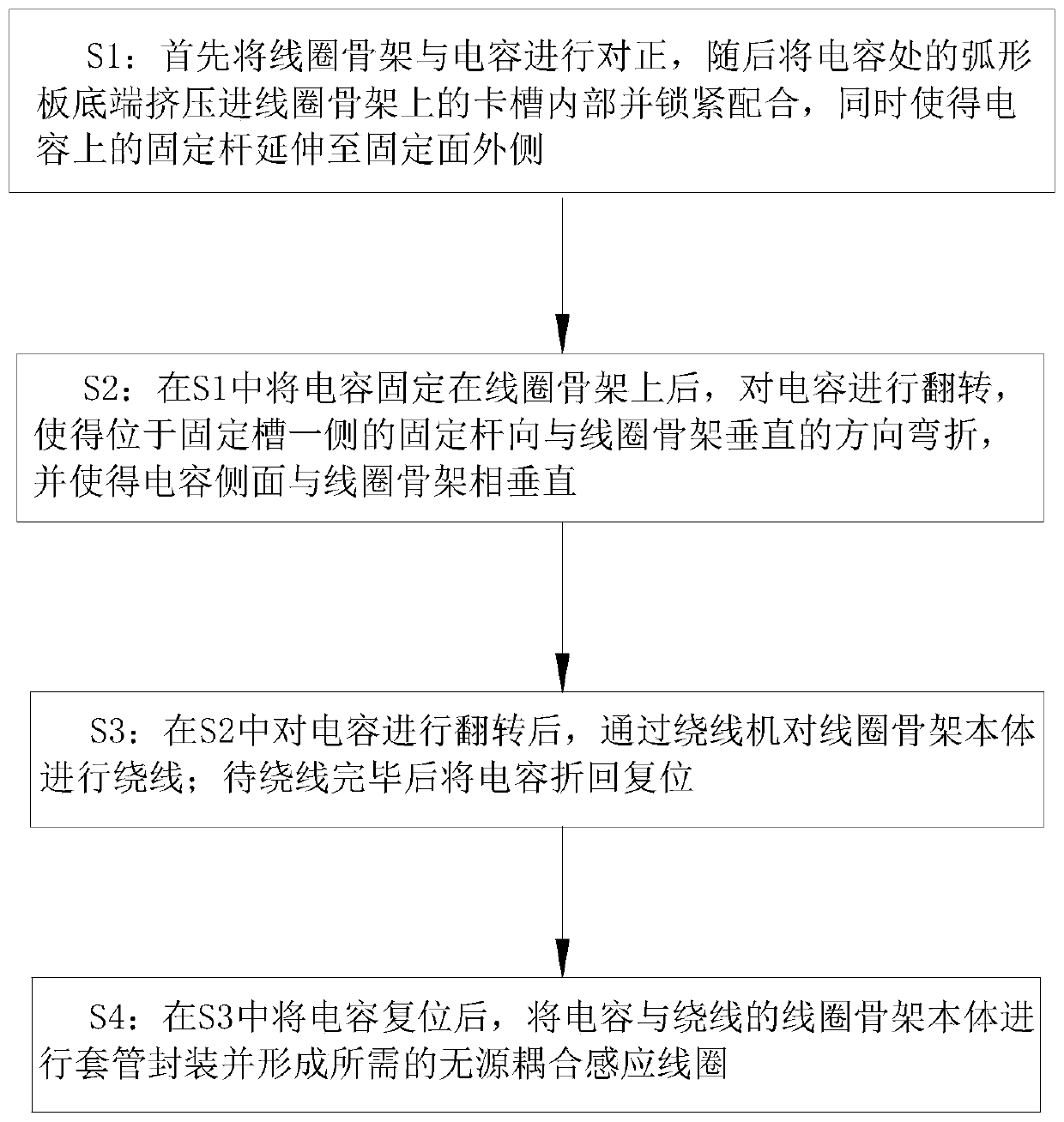

Manufacturing method of passive coupling induction coil

InactiveCN111430149AReduce cumbersomeness and instabilityImprove production efficiency and production qualityTransformersInductances/transformers/magnets manufacturePhysicsCapacitance

The invention belongs to the technical field of induction coil manufacturing, and particularly relates to a manufacturing method of a passive coupling induction coil. A coil framework in the method comprises a body, step plates are arranged at the two ends of the body, and a fixed surface is arranged on the side surface of each step plate. A fixing groove is formed on the end surface of the fixingsurface, a clamping groove is formed in the fixing groove, and a first locking groove is formed at the bottom end of the clamping groove. A locking rod is slidably connected into the first locking groove, a capacitor is arranged at one side of the body and is connected with a fixing rod, an arc-shaped plate is connected to the end of the fixing rod, and a second locking groove is formed at the bottom end of the arc-shaped plate. According to the induction coil, the capacitor and the coil framework are provided with the locking structures which are matched with each other, so that the complexity and instability of the coil framework and the capacitor during assembly in the production process are reduced, the coil framework and the capacitor can be effectively disassembled and maintained, and the production efficiency and the production quality of the induction coil are improved.

Owner:黄友梅

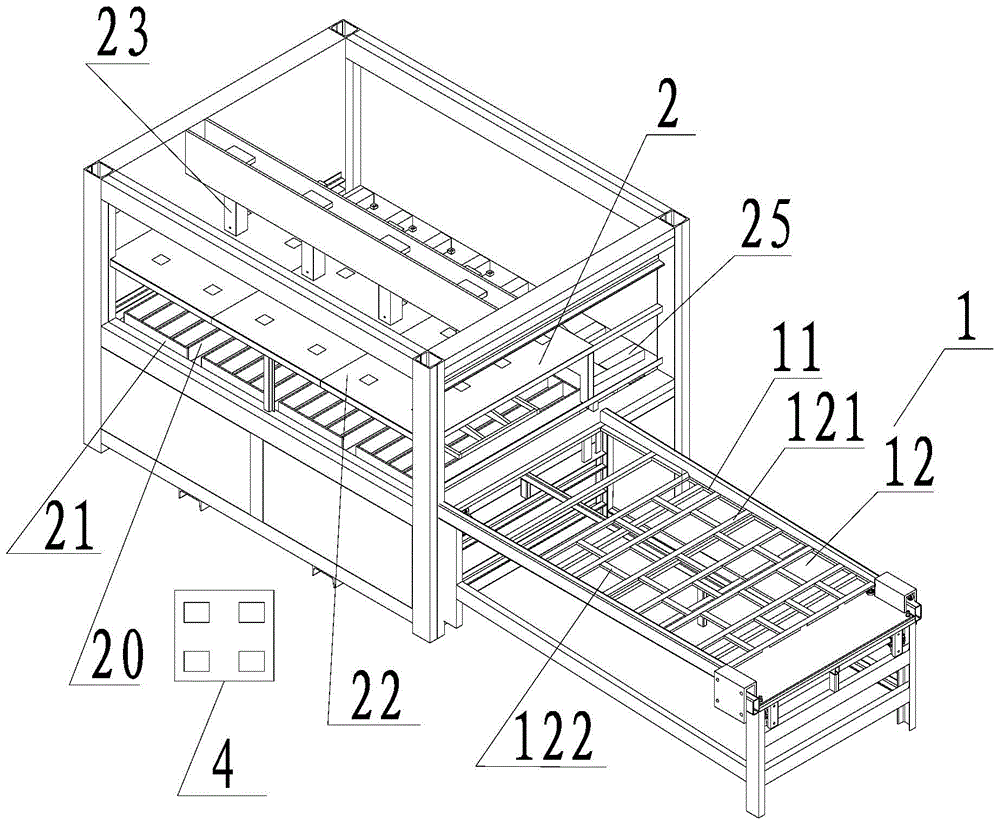

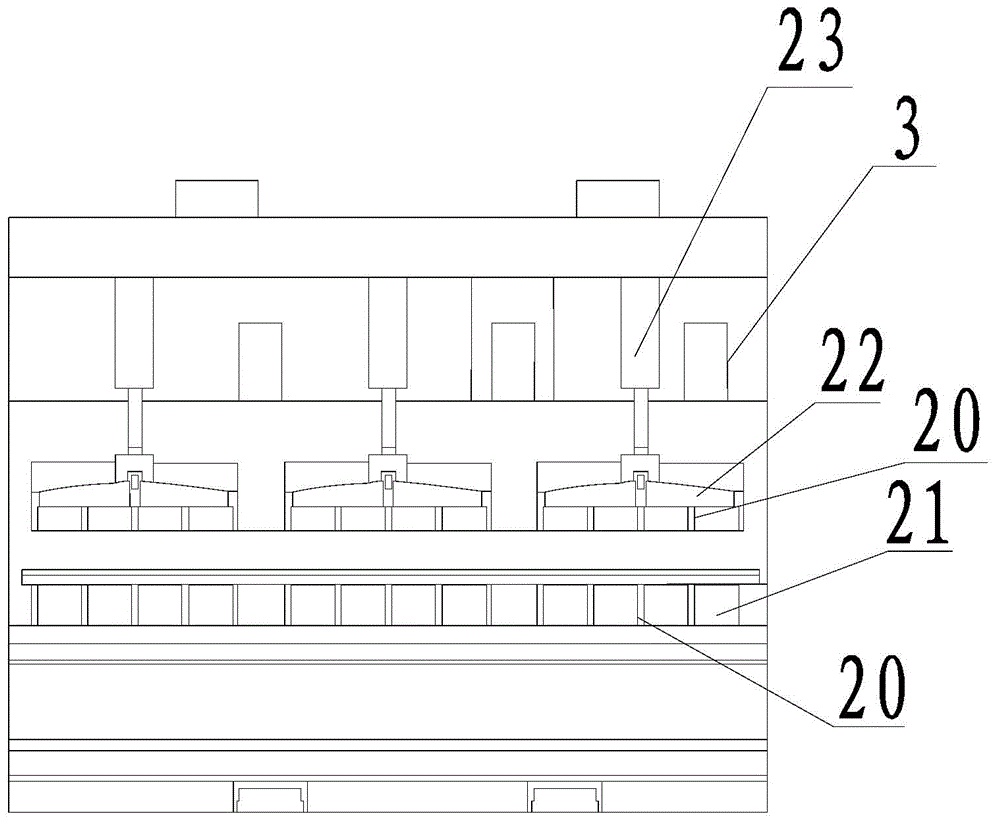

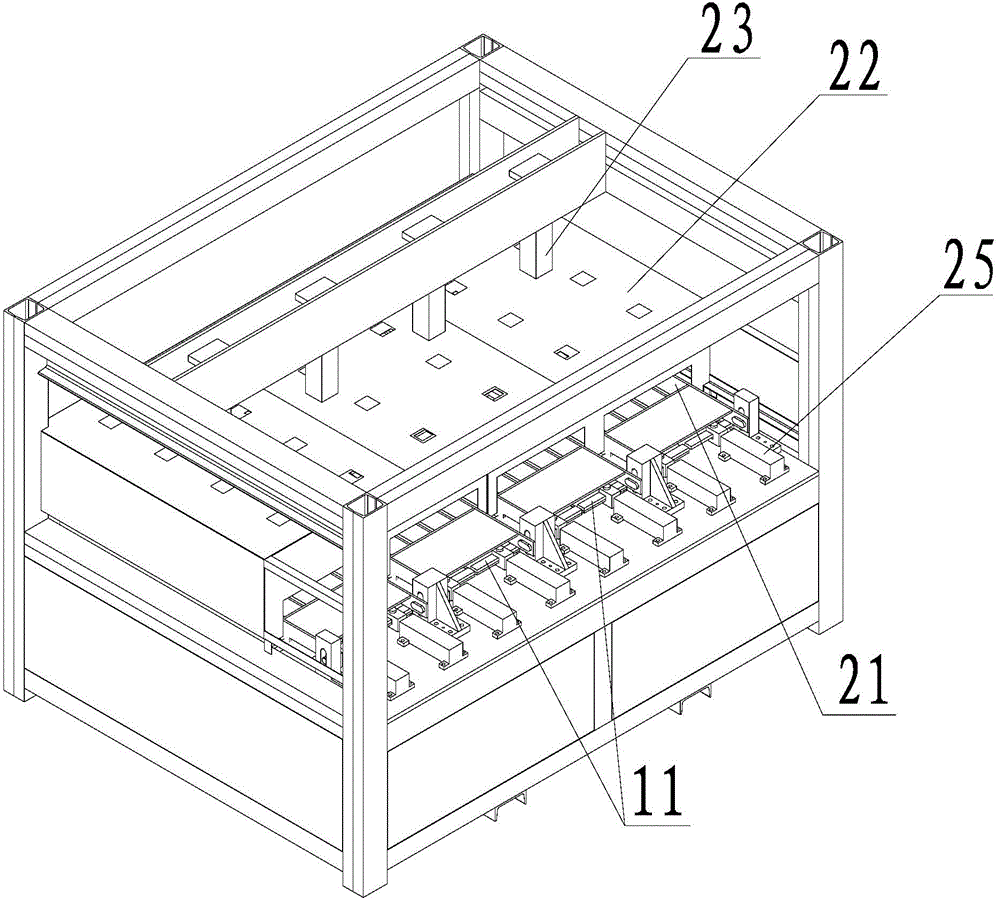

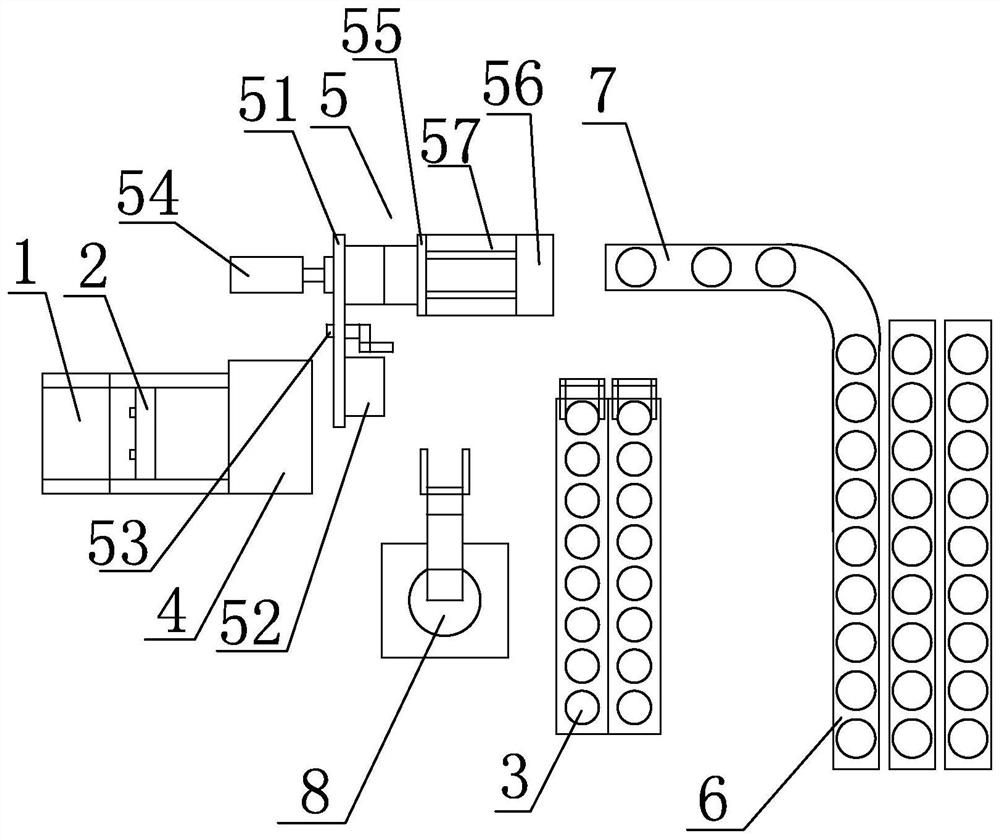

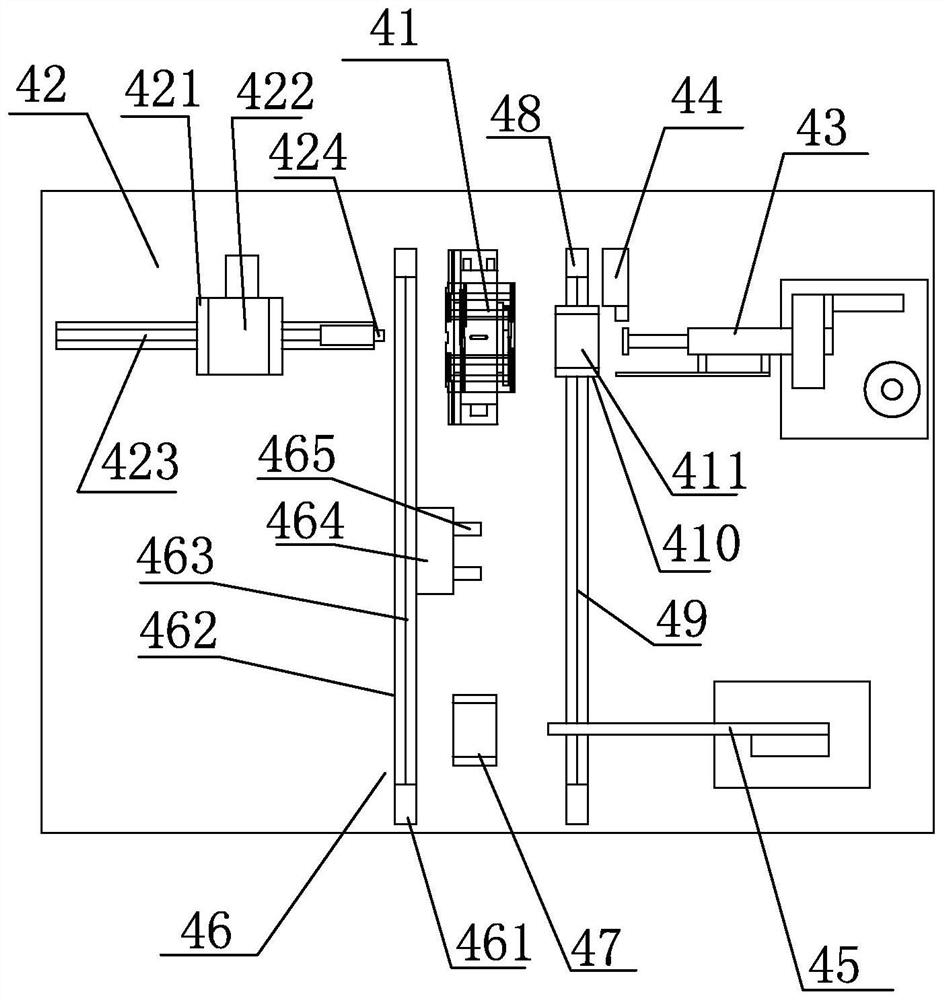

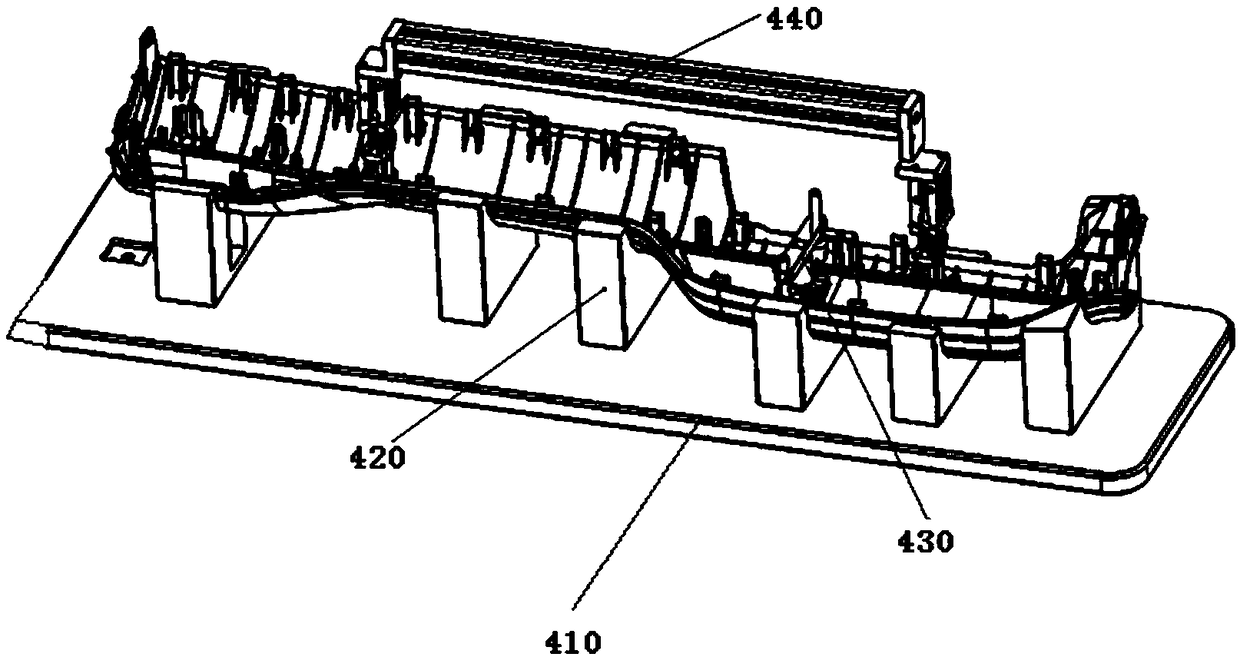

Automatic core filling production line for three-way catalytic converters

PendingCN113291838AReasonable structural designImprove production efficiency and production qualityStacking articlesDe-stacking articlesConvertersStructural engineering

The invention relates to an automatic core filling production line for three-way catalytic converters. The production line structurally comprises a transfer robot, a liner stacking mechanism, a carrier liner feeding, discharging and wrapping device, a core filling mechanism, a carrier stacking and conveying frame and a shell stacking and conveying frame, wherein the liner stacking mechanism, the carrier liner feeding, discharging and wrapping device, the core filling mechanism, the carrier stacking and conveying frame and the shell stacking and conveying frame are sequentially arranged on one side of the transfer robot, the shell stacking and conveying frame is connected with one end of a shell conveying belt, the other end of the shell conveying belt is close to the core filling mechanism, and a liner grabbing mechanism is arranged above the liner stacking mechanism and is close to the carrier liner feeding, discharging and wrapping device. The production line has the advantages that the structural design is reasonable, automatic feeding and moving of carriers, liners and shells are achieved, the liners are automatically wrapped on the outer sides of the carriers, the shells are filled with the carriers wrapped with the liners, automatic core filling production of the three-way catalytic converters is achieved, the production efficiency and production quality are effectively improved, and the production requirements can be effectively met.

Owner:中雍智能装备(无锡)有限公司

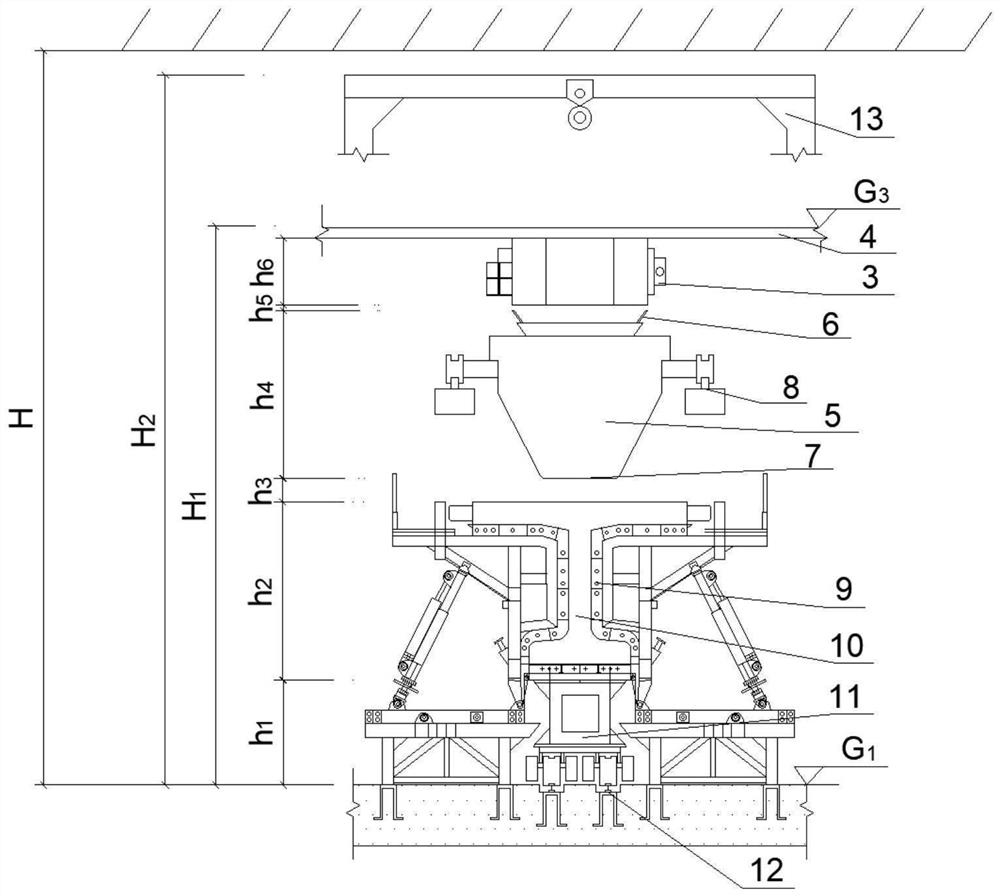

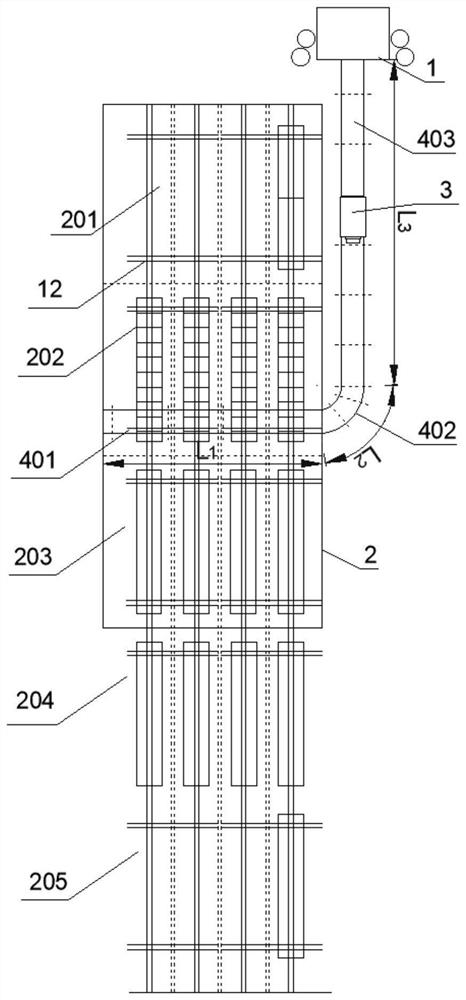

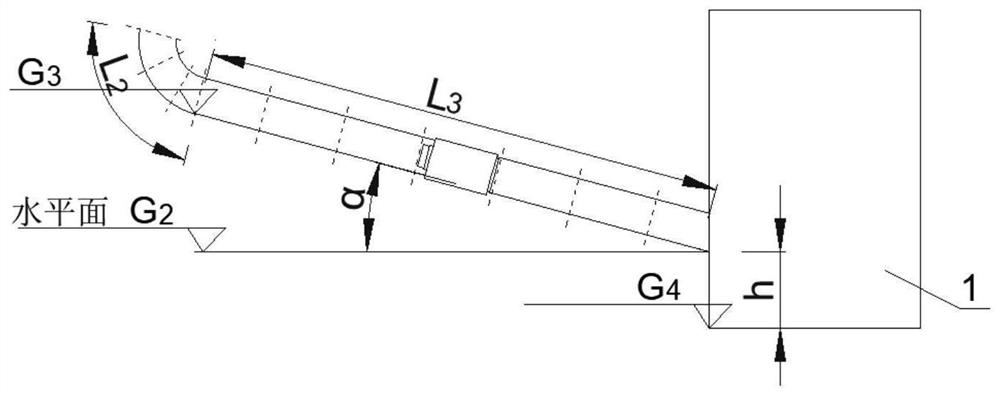

System for automatically transporting concrete and pouring and preparing precast beam

PendingCN114102837AImprove production efficiency and production qualityEconomic cost is lowCeramic shaping plantsFeeding arrangmentsEngineeringStructural engineering

The invention relates to a system for automatically transporting concrete and pouring and preparing a precast beam, which is used for transporting the concrete in a mixing station to a precast beam pouring area of a plant area and realizing the pouring preparation of the precast beam in the precast beam pouring area, and comprises an automatic concrete transporting unit and an automatic concrete pouring unit, the concrete automatic transportation unit comprises a feeder rail and a torpedo tank, and the torpedo tank is connected to the feeder rail and used for conveying concrete in the mixing station to a precast beam pouring area; the automatic concrete pouring unit comprises a material distributing machine, a material distributing machine track, a steel mold system, a transferring trolley and a ground track, the material distributing machine is used for receiving concrete of the torpedo ladle and pouring the concrete into the steel mold system, the steel mold system is used for pouring and forming the precast beam, and the transferring trolley is used for transferring the precast beam formed through pouring out. By the adoption of the technical scheme, optimization of matching of construction mechanical efficiency and construction resources is achieved.

Owner:安徽省路港工程有限责任公司 +1

Rotary heating boiler

InactiveCN110686403AImprove production efficiency and production qualityHeating evenlyHollow article cleaningWater heatersCombustion chamberEngineering

The invention provides a rotary heating boiler which comprises a base. A burner is arranged on the base, a combustion chamber is arranged on the burner, a smoke exhaust pipe is arranged at the top endof the combustion chamber, an air purifier is arranged above the smoke exhaust pipe, a shell is arranged on the right side of the combustion chamber, a water tank is arranged in the shell, opening and closing doors are arranged on the top of the water tank and the right side of the lower end of the water tank, the base is provided with a first motor, the first motor is provided with a first motorrod passing through the shell to be connected to the water tank, and the top of the shell and the right side of the lower end of the shell are correspondingly provided with a water inlet pipe and a water outlet pipe which are opposite to the opening and closing doors. The production quality and the production efficiency of water are greatly improved.

Owner:戴林涛

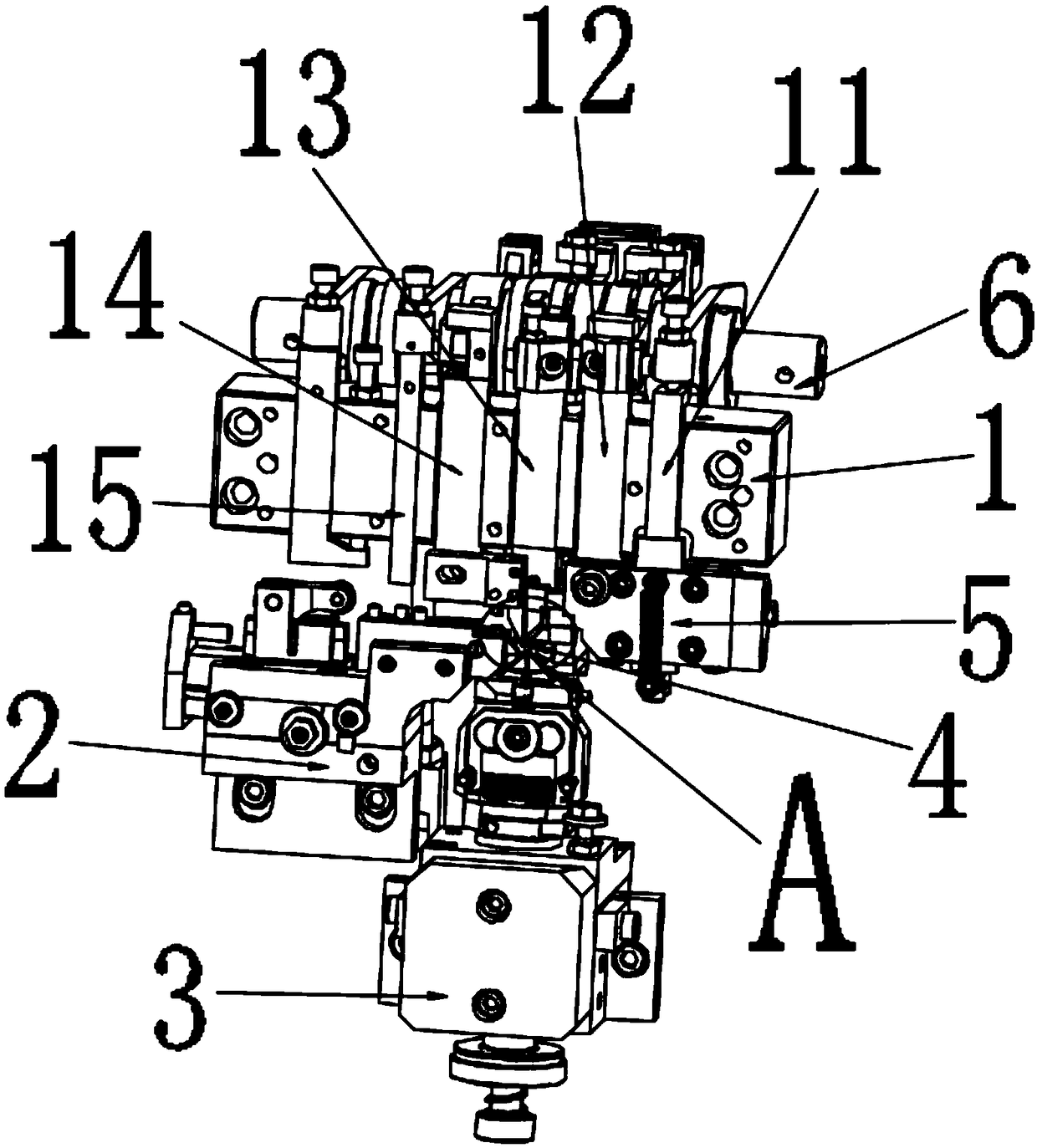

Automatic high-speed box chain machine

PendingCN109333072AImprove production efficiency and production qualityReduce manufacturing costOther manufacturing equipments/toolsEngineeringWire rod

The invention provides an automatic high-speed box chain machine. The automatic high-speed box chain machine comprises a control box, a guide frame, a forming frame, an auxiliary frame and a sealing frame. A supporting table and a pressing table are connected to the guide frame, and a material track is arranged at the center of the supporting table and the center of the pressing table. A hammeringhead and a locking rod are movably connected to the center of the pressing table. A clamping head is arranged at the upper end of the forming frame. Clamping jaws are arranged in the clamping head. Acore-pulling rod is arranged in the auxiliary frame. A core plate is connected to the end of the core-pulling rod. A left sealing head and a right sealing head are arranged at the end of the sealingframe. A left sealing block connected with the left sealing head and a right sliding block connected with the right sealing head are arranged in the sealing frame. A moving rod used for driving the left sliding block and the right sliding block to slide is arranged at the center of the sealing frame. According to the automatic high-speed box chain machine, chains can be automatically produced andassembled through wire rods, the problem that the quality is affected by non-standard formation, staggered installation, stacking and the like in a conventional box chain production process is solved,and the production efficiency of box chains is improved.

Owner:浙江立新珠宝科技股份有限公司

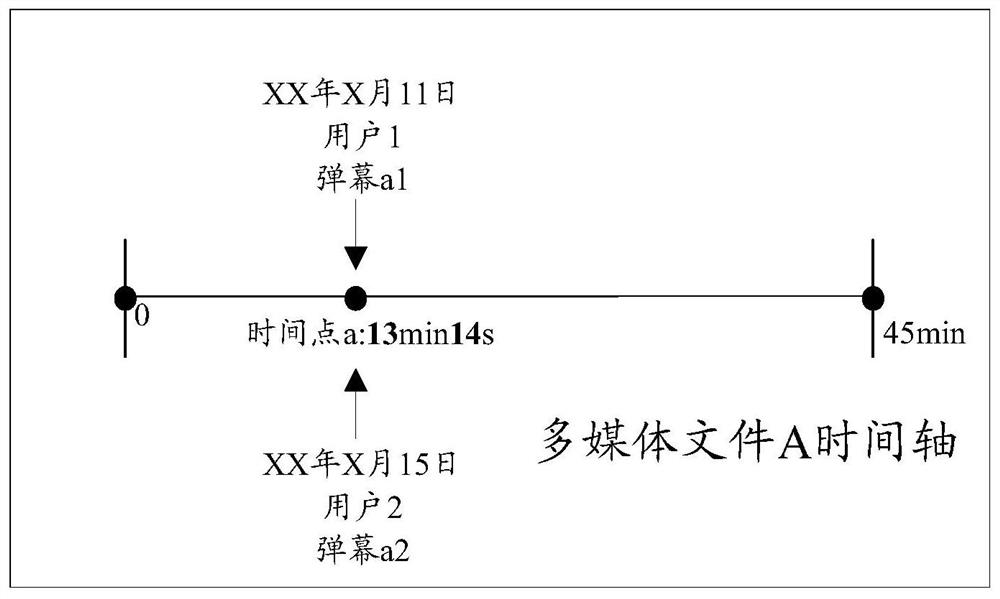

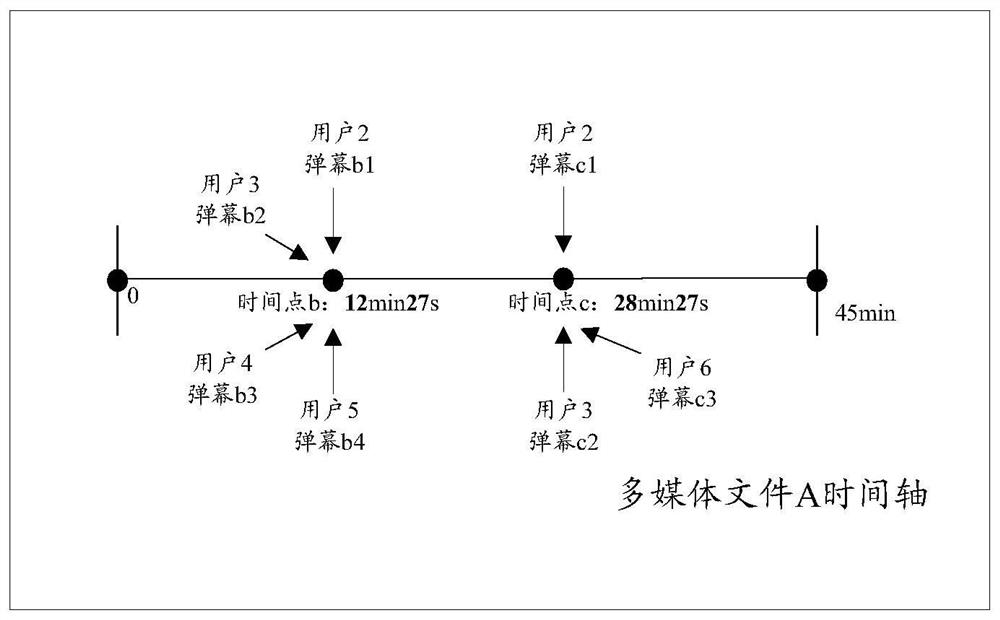

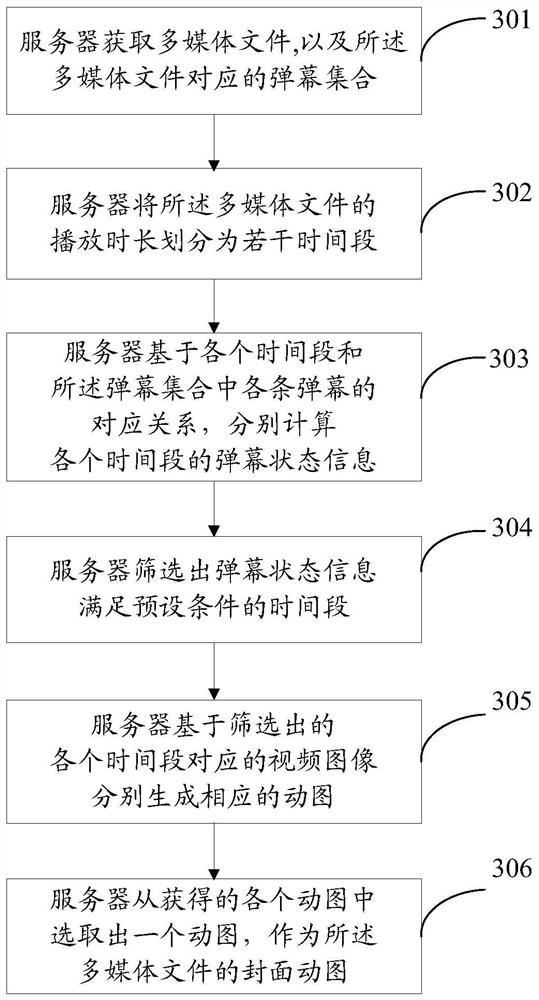

Method and device for generating cover moving picture of multimedia file

PendingCN112584199AReduce labor costsImprove production efficiency and production qualityElectronic editing digitised analogue information signalsUsing non-detectable carrier informationComputer graphics (images)Kinemage

The invention relates to the field of video processing, in particular to a method and a device for generating a cover moving picture of a multimedia file, which are used for generating the cover moving picture of the multimedia file. The method comprises the steps: after a multimedia file and a bullet screen set corresponding to the multimedia file are obtained, dividing the playing duration of the multimedia file into a plurality of time periods, and calculating the bullet screen state information of each time period based on the corresponding relation between each time period and each bulletscreen in the bullet screen set; screening out a time period when the bullet screen state information meets a preset condition, generating corresponding moving pictures based on video images corresponding to the screened time period, and finally selecting one moving picture from the obtained moving pictures to serve as a cover moving picture of the multimedia file. Thus, the cover moving pictureis generated without depending on manually intercepted image frames, the labor cost is greatly reduced, the generation efficiency of the cover moving picture is improved, and the cover moving picturecan display the essence content of the multimedia file as much as possible.

Owner:SHANGHAI BILIBILI TECH CO LTD

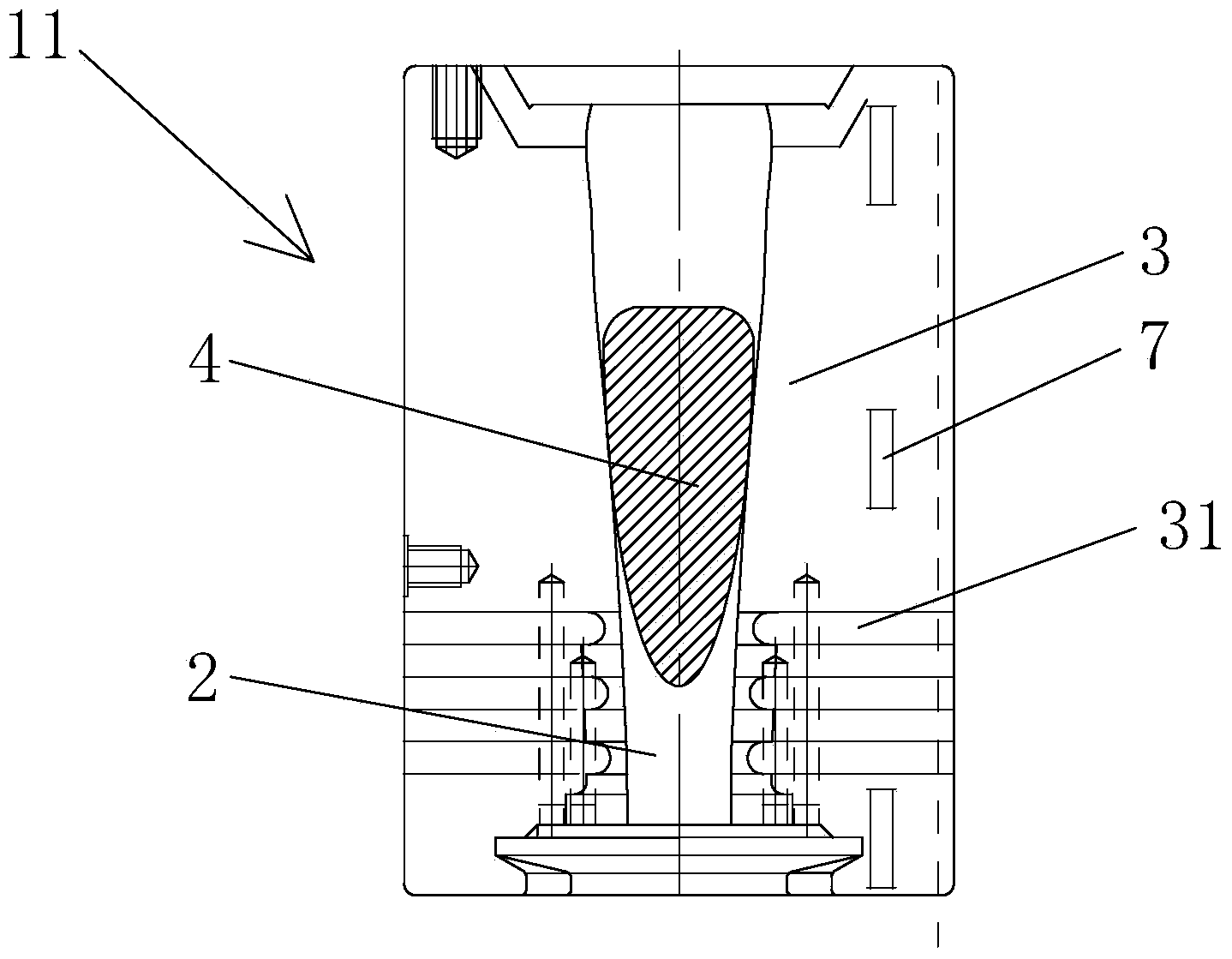

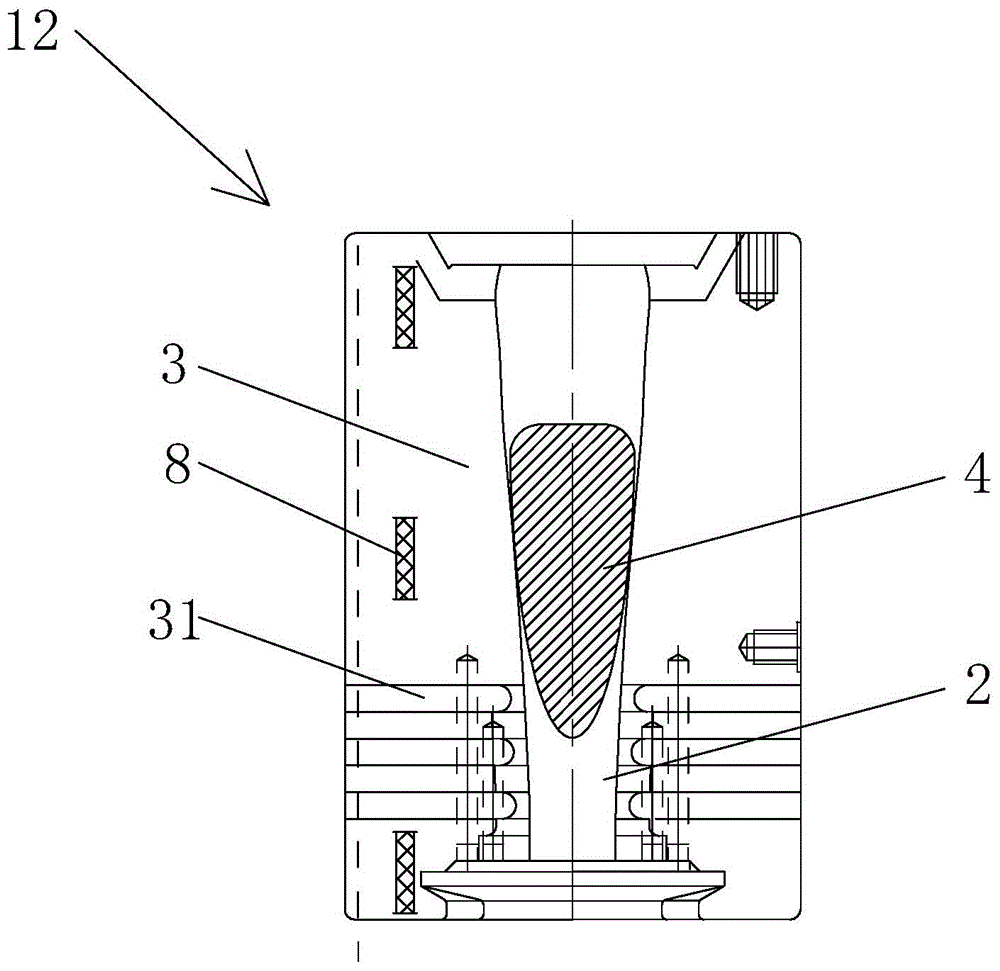

Making method of blank mould

InactiveCN104129901AImprove glass bottle qualityImprove production efficiency and production qualityGlass pressing apparatusBlowing mouldsEngineeringLower half

The invention relates to a making method of a blank mould. The method includes: 1. processing a vertically perforating cavity on the planar part of a male die and a female die respectively, with the closely attached planar parts of the male die and the female die being seam close surfaces; 2. firstly milling several air exhaust slots on the seam close surfaces by 0.1-0.2mm lower than the planar parts, with the air exhaust slots used for connecting the inside of a bottle cavity and the outside air and disposed at the lower halves of the seam close surfaces; 3. disposing a plurality of triangular ribs and punching grooves matching with the triangular ribs on the seam close surfaces, and arranging the plurality of triangular ribs on a straight line in the longitudinal direction. Compared with the prior art, the lower halves of the seam close surfaces are provided with the air exhaust slots, thus avoiding material skip and other phenomena caused by vacuum formed in the cavities, and improving the production quality and production efficiency of glass bottles. Also, the male die and the female die are connected through triangular ribs, thus providing air exhaust space for the air exhaust slots.

Owner:DEQING CAIFU GLASS

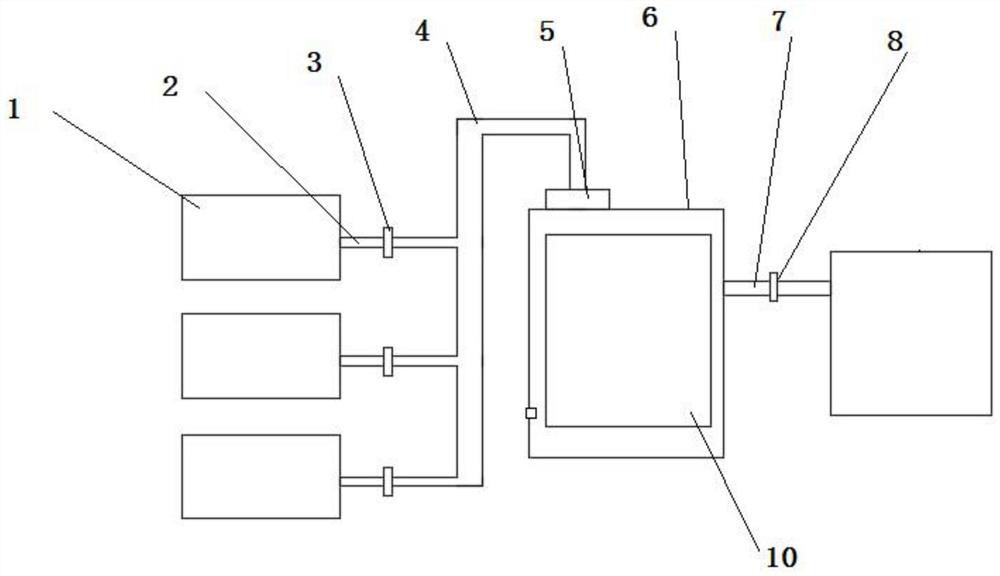

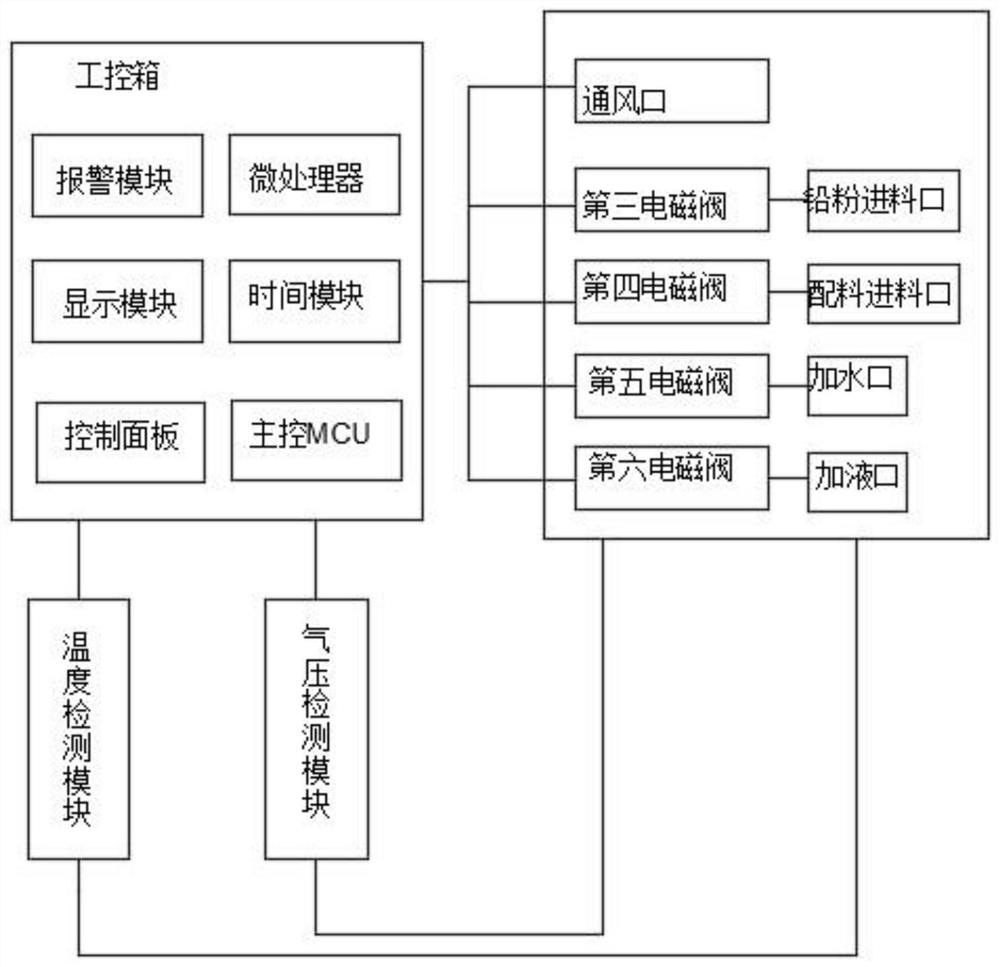

Automatic paste mixing machine control system and method for preparing lead paste

InactiveCN111921448AImprove production efficiency and production qualityAvoid temperature deviationTransportation and packagingMixing methodsProcess engineeringMachine control

The invention discloses an automatic paste mixing machine control system and method for preparing lead paste. The automatic paste mixing machine control system comprises three air coolers, a temperature detection module and an air pressure detection module. Any air cooler is communicated with a main air pipe through a cold air pipe; any cold air pipe is provided with a first electromagnetic valve;the main air pipe is communicated with an air blowing box; an industrial control box is mounted on the peripheral side surface of the air blowing box; the air blowing box is communicated with a pastemixing machine through an air blowing pipe; a second electromagnetic valve is arranged on the air blowing pipe; an industrial control board for controlling is also arranged in the industrial controlbox; a cold air compressor is arranged between the main air pipe and the air blowing box; the industrial control board comprises a control panel, a main control MCU, a time module, a display module, an alarm module and a microprocessor. The industrial control board is arranged to control the operation of the paste mixing machine, so that the automatic stable control of the set of equipment can berealized, humanized alarm processing is carried out on the industrial control board, and the accurate control of the whole temperature and air pressure in the operation process of the paste mixing machine is realized.

Owner:JIESHOU HUAYU POWER SUPPLY

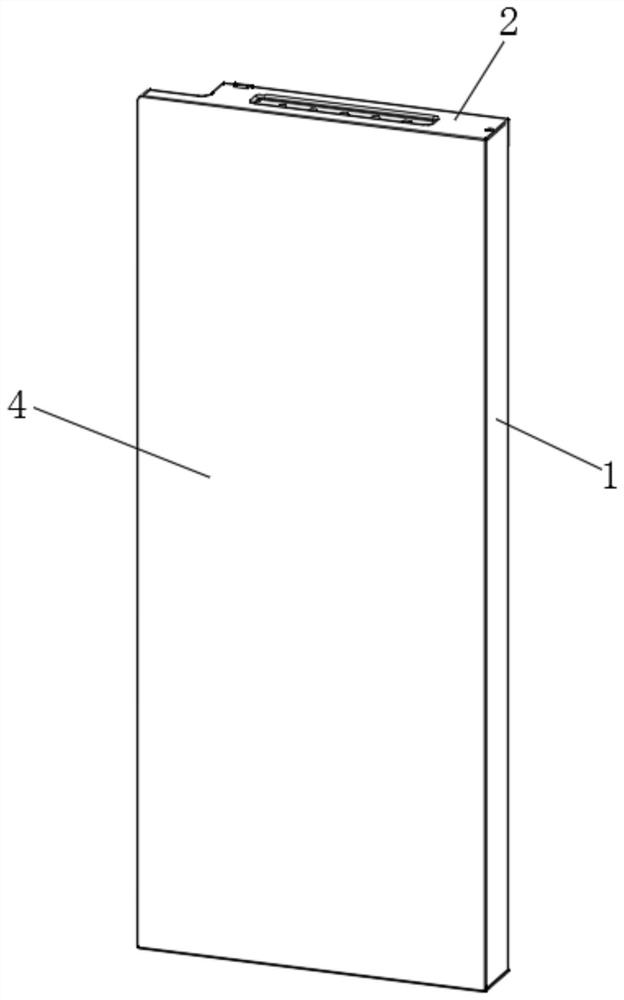

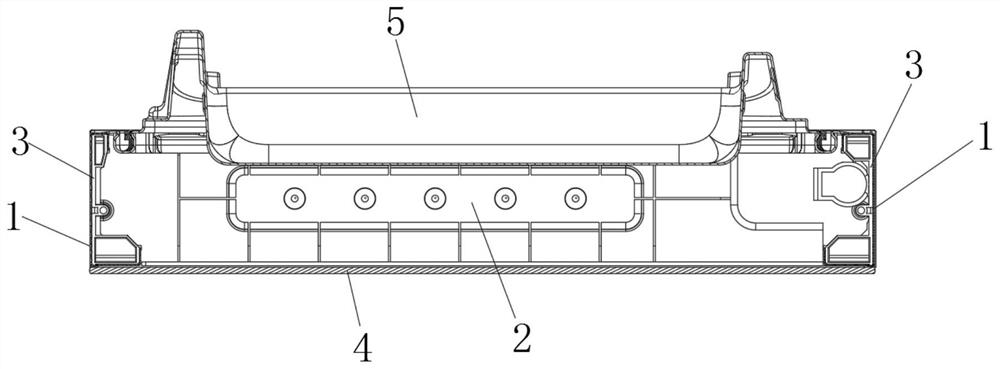

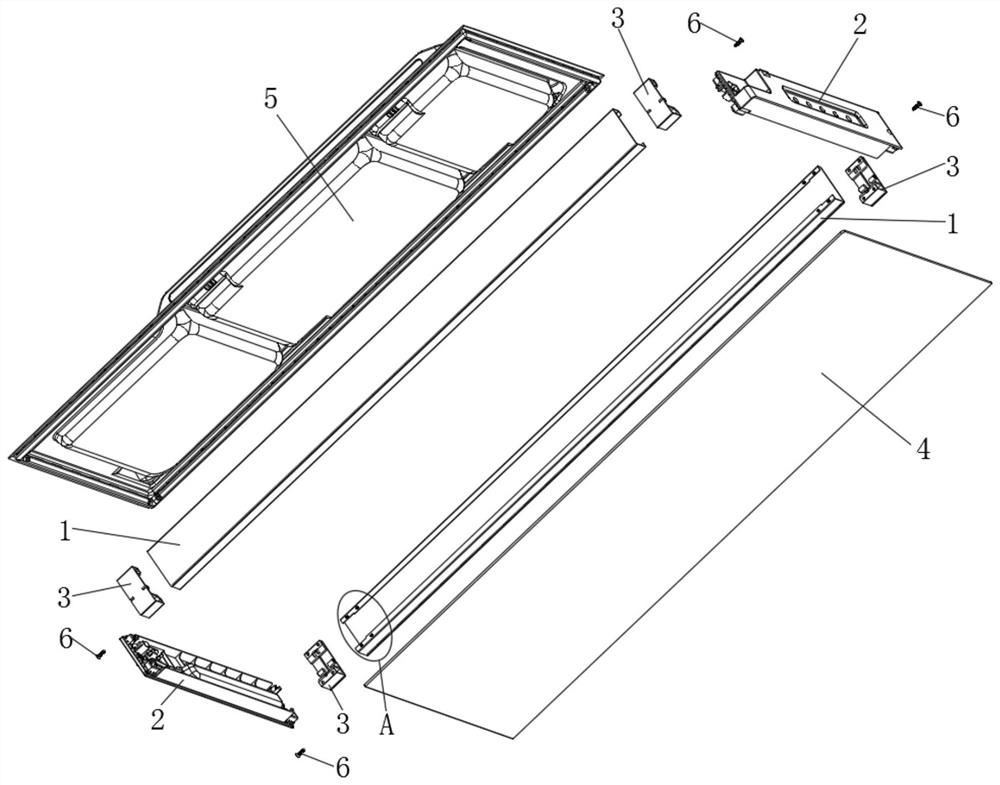

Refrigerator door body

ActiveCN112432421AImprove versatilityReduce tooling costsLighting and heating apparatusCooling fluid circulationStructural engineeringMechanical engineering

The invention discloses a refrigerator door body which comprises a door frame, a glass plate and a door lining. The door frame comprises end baffles located at the left side and the right side and decoration strips located at the upper side and the lower side; each end baffle adopts a sheet metal part and comprises an end plate, side plates and end baffle flanges; the end plates, the side plates and the end baffle flanges form end baffle clamping grooves in an enclosing manner; end baffle inserts matched with the end baffle clamping grooves are arranged at the upper ends and the lower ends ofthe end baffle clamping grooves in the end baffles; the upper ends and the lower ends of the end baffles are connected with the corresponding decorative strips through the end baffle inserts; the doorlining is pressed at one side of the door frame, and the glass plate is pressed at the other side of the door frame; and a cavity for foaming is formed among the door frame, the glass plate and the door lining. According to the refrigerator door body, each end baffle in the refrigerator door body adopts the sheet metal part, and compared with an existing door body end baffle which is an injectionmolding part or an extrusion part and needs a corresponding die, and each end baffle in the refrigerator door body adopts the sheet metal part, so that the die cost is reduced, and the manufacturingcost of the refrigerator door body is reduced; and meanwhile, the forming process is simple, and the production efficiency is improved.

Owner:AUCMA

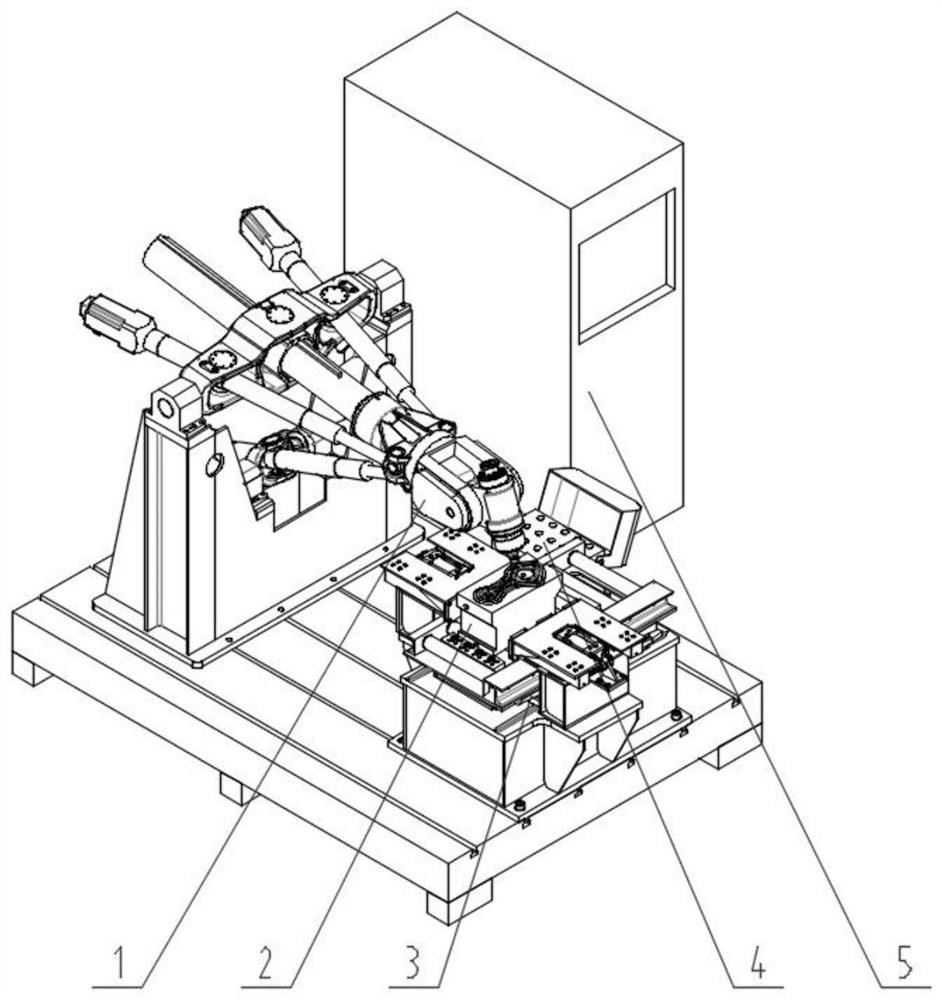

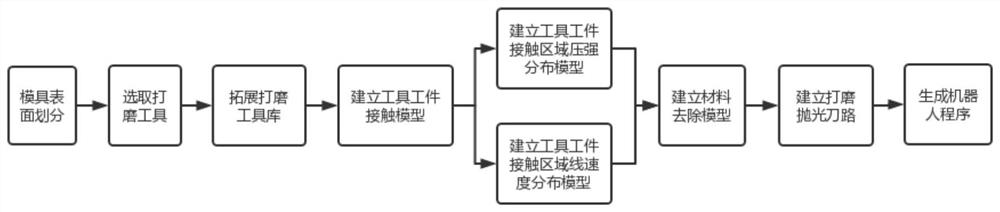

Automatic mold grinding method based on complex curved surface feature division

ActiveCN113649909AImprove production efficiency and production qualityReduce wasted time and costsGrinding drivesGrinding feed controlProcess engineeringManufacturing engineering

The invention discloses an automatic mold grinding method based on complex curved surface feature division. The method comprises the following steps of setting the curvature of a concave curved surface as a negative value and the curvature of a convex curved surface as a positive value, and dividing the surfaces of molds into multiple surface categories according to a principal curvature value; matching the mold surface categories with grinding tools to construct a tool library of a grinding robot; formulating a grinding path according to the surface shapes of the molds, the tool library and a grinding process; establishing an automatic grinding program according to the grinding path, the tool library and the grinding process; and downloading the automatic grinding program to the grinding robot, and starting the grinding robot for automatic grinding. According to the method, through analysis of the complex surface molds such as automobile connecting rods, the grinding tools and material removal models, the grinding robot is controlled to realize multi-tool constant material removal grinding and polishing of the complex surface molds such as the automobile connecting rods, so that the production quality and the production efficiency of the complex surface molds such as the automobile connecting rods are improved, and time and cost consumed by grinding and polishing of the complex surface molds such as the automobile connecting rods are greatly reduced.

Owner:TIANJIN UNIV

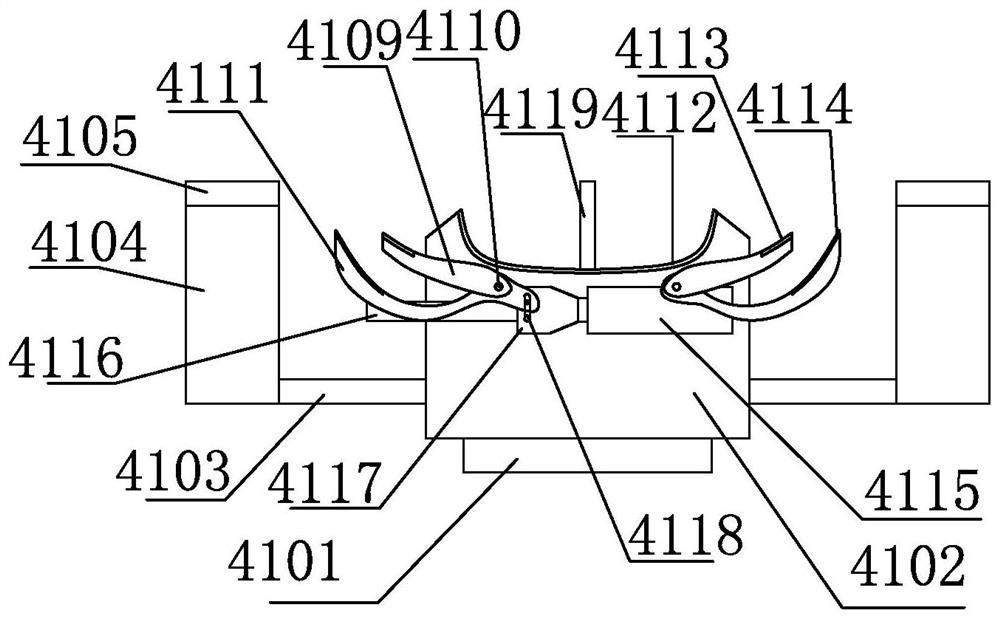

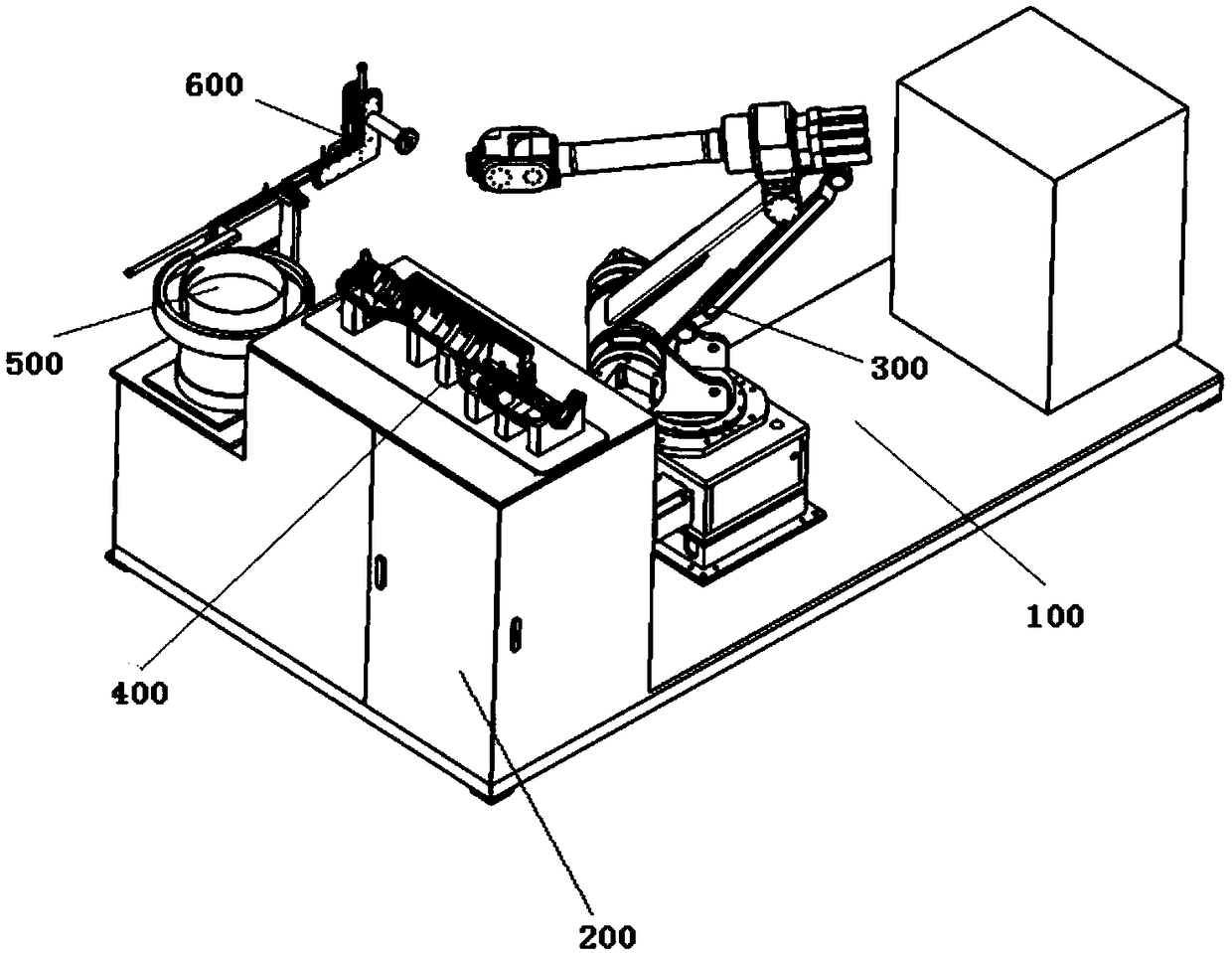

V-shaped buckle installing device

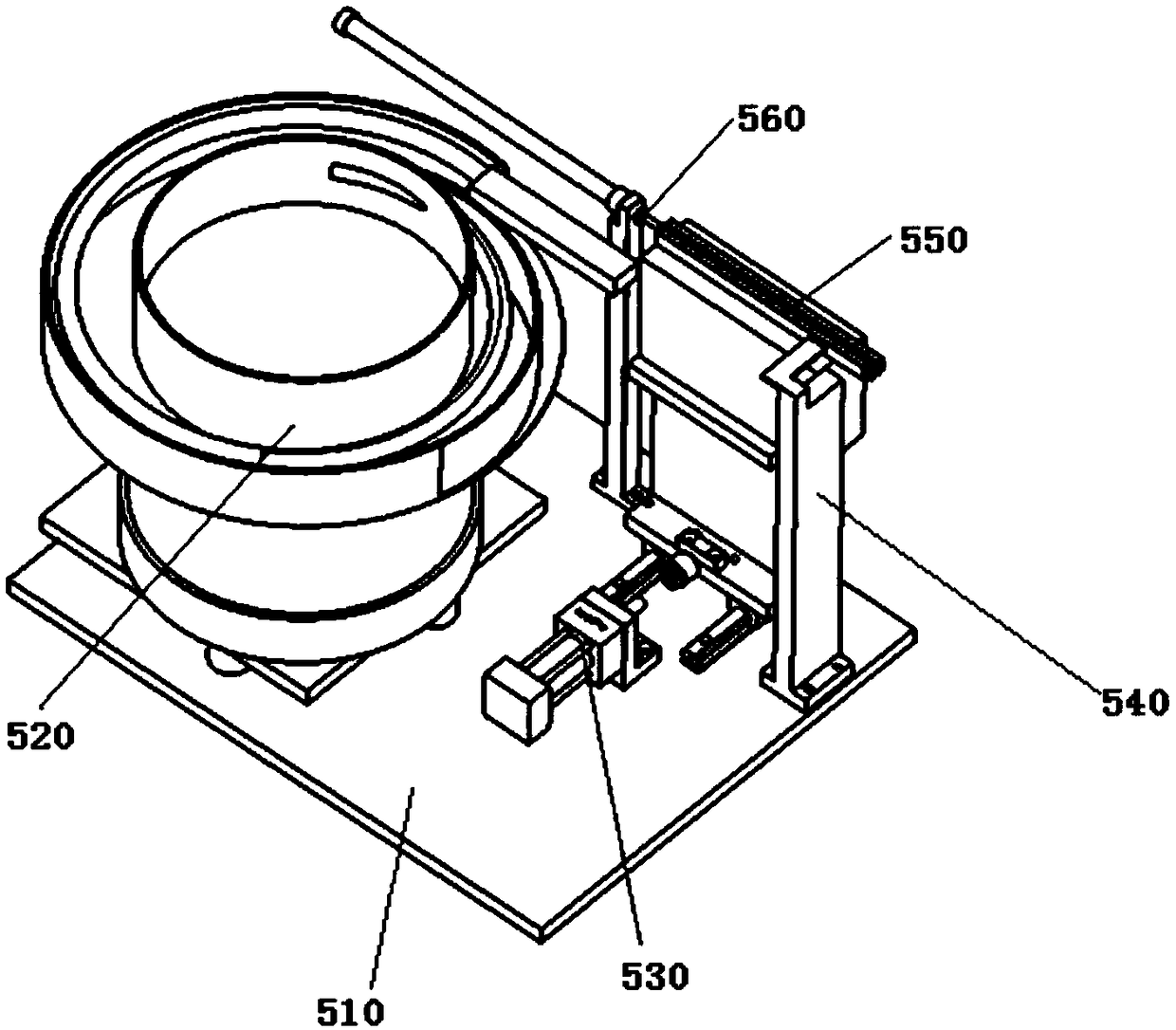

PendingCN108656571AGuaranteed uniformityImprove production efficiency and production qualityEngineeringRobot

The invention provides a V-shaped buckle installing device. The V-shaped buckle installing device comprises a tool base and a rack arranged on the tool base. The V-shaped buckle installing device further comprises a robot arranged on the tool base, a positioning moulding bed mechanism, a vibration disk mechanism and a buckle grabbing mechanism, and the positioning moulding bed mechanism, the vibration disk mechanism and the buckle grabbing mechanism are arranged on the rack; the rack is a step type rack which comprises a first step rack body and a second step rack body; the positioning moulding bed mechanism is fixedly installed on the first step rack body; and the vibration disk mechanism is fixedly installed on the second step rack body. A vibration disk is used for arranging buckles, acylinder is used for driving, the robot is used for positioning, the buckles can be installed at the same time, consistency of installing is effectively guaranteed, and the production quality and theproduction efficiency are improved.

Owner:QINGDAO INJELIC PRECISION MOLD

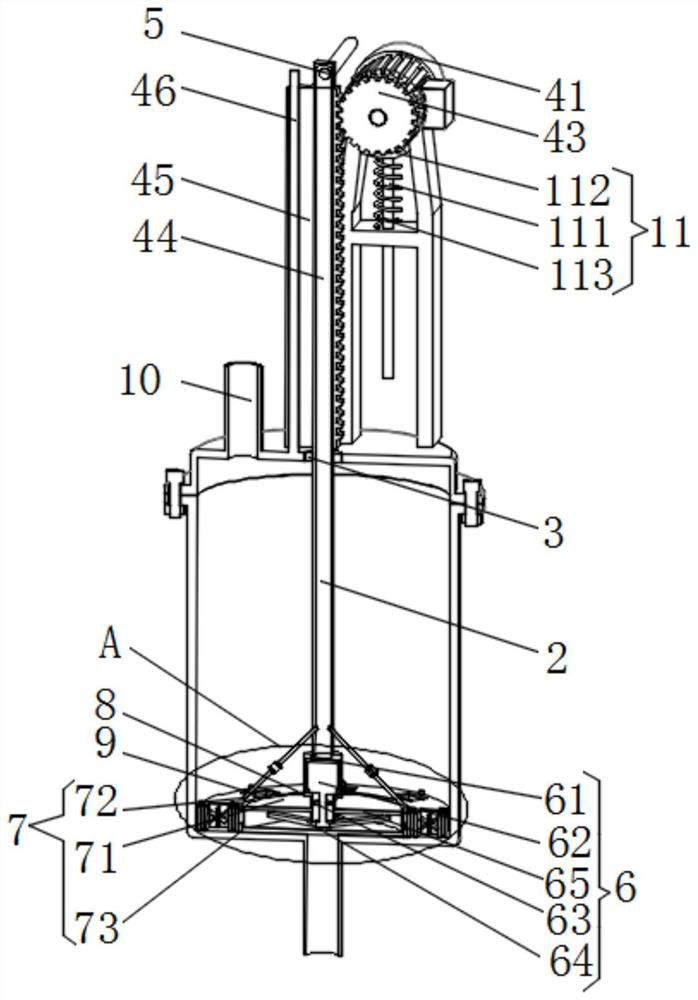

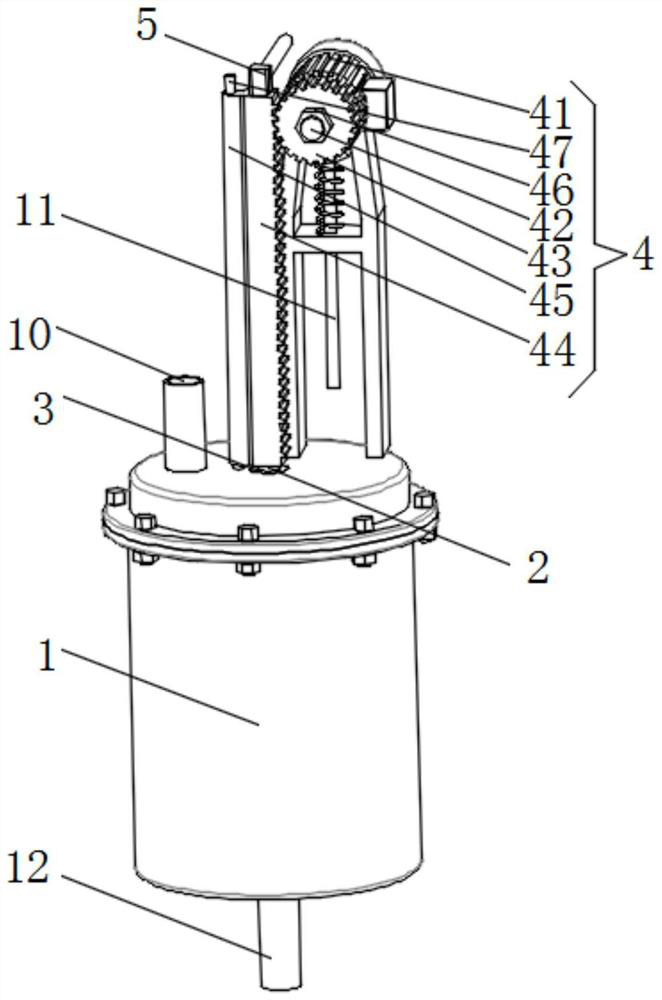

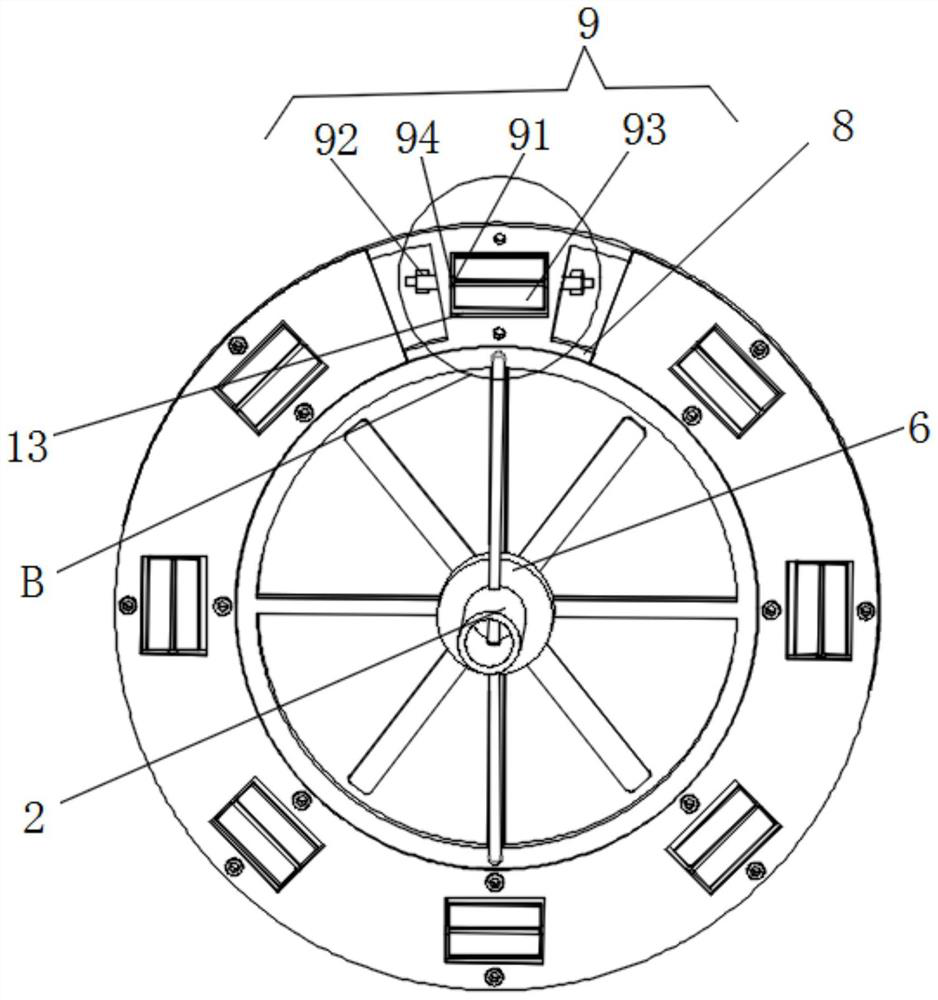

Polyurethane foaming machine for artificial limb production

PendingCN113927816AImprove production efficiency and production qualityQuick installationChemistryProcess engineering

The invention relates to the technical field of foaming machines, and discloses a polyurethane foaming machine for artificial limb production. The polyurethane foaming machine comprises a foaming machine raw material tank, the inner side of the middle of the foaming machine raw material tank is movably sleeved with a transition hollow rod, and a first shaft sealing ring is mounted at the joint of the middle of the transition hollow rod and the inner side of the top of the foaming machine raw material tank; and a first power mechanism and an air inlet connector are installed on the surface of the top and the top end of the transition hollow rod correspondingly, and a first stirring mechanism is connected to the bottom of the transition hollow rod. According to the polyurethane foaming machine, after the transition hollow rod, the first shaft sealing ring, the first power mechanism, the gas inlet connector, the first stirring mechanism, a gas inlet mechanism and a hollow composite disc which are arranged are matched for use, a multifunctional stirring structure with comprehensive stirring, multiple mixing modes and one gas stirring function is formed, raw materials in the foaming machine raw material tank can be sufficiently stirred subsequently, no mixing dead angle is left, and the production efficiency and the production quality of polyurethane foaming are improved.

Owner:朱利群

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com