Primary die facilitating exhausting

A technology of exhaust groove and male mold, which is applied in the direction of glass blowing mold, etc., can solve the problems of glass frit rebound, safety hazard, sticking wire in the bottle, etc., and achieve the effect of improving quality, production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

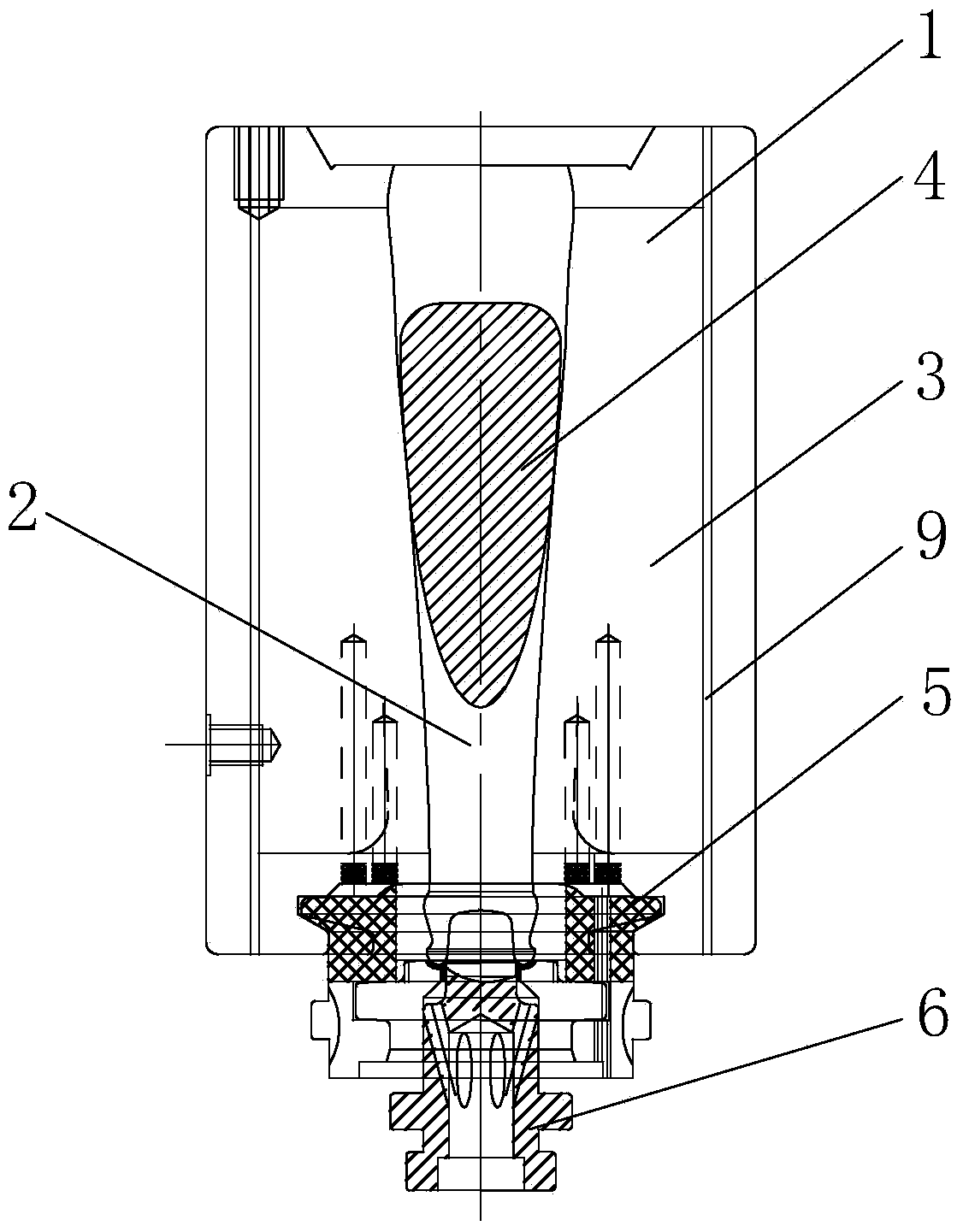

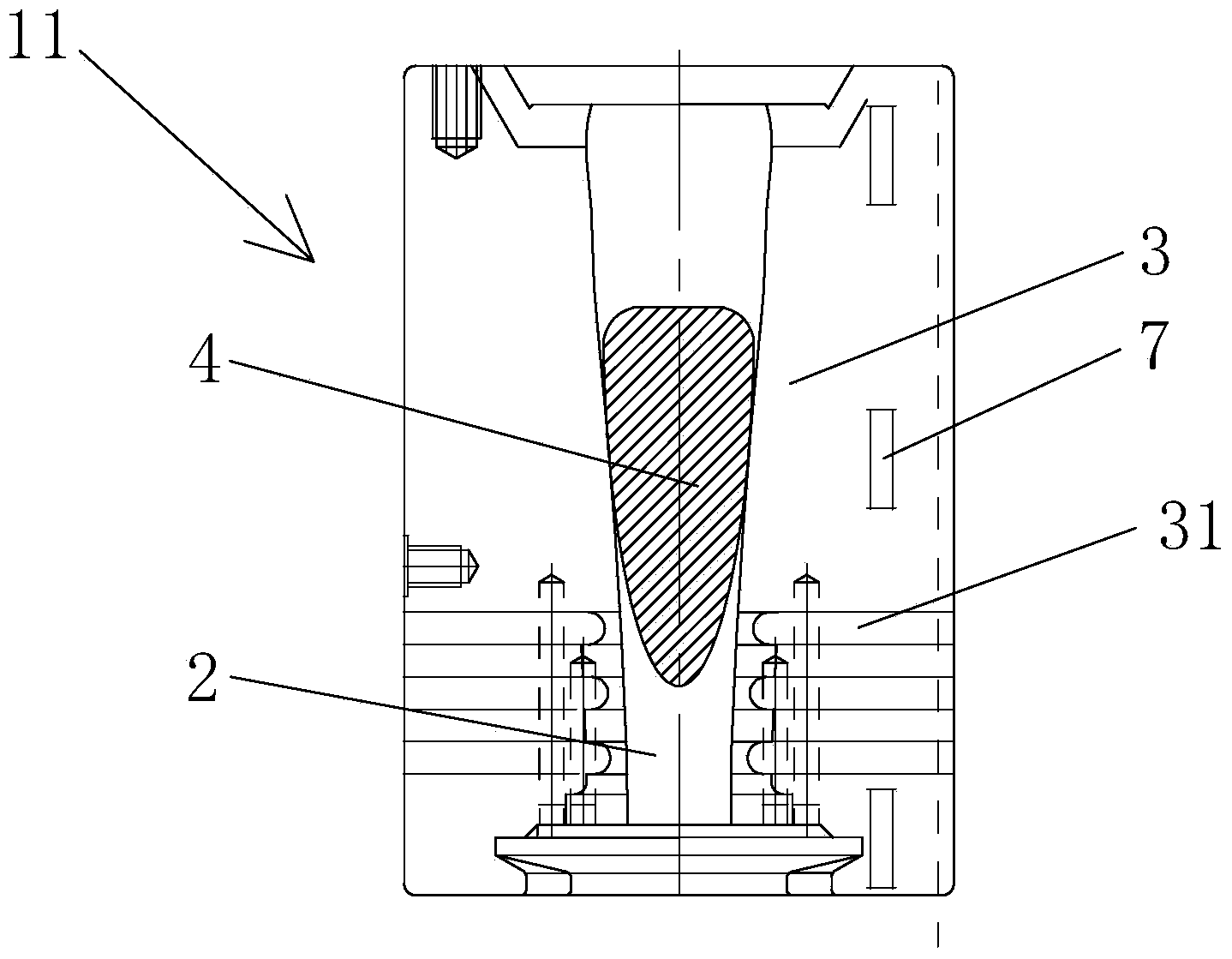

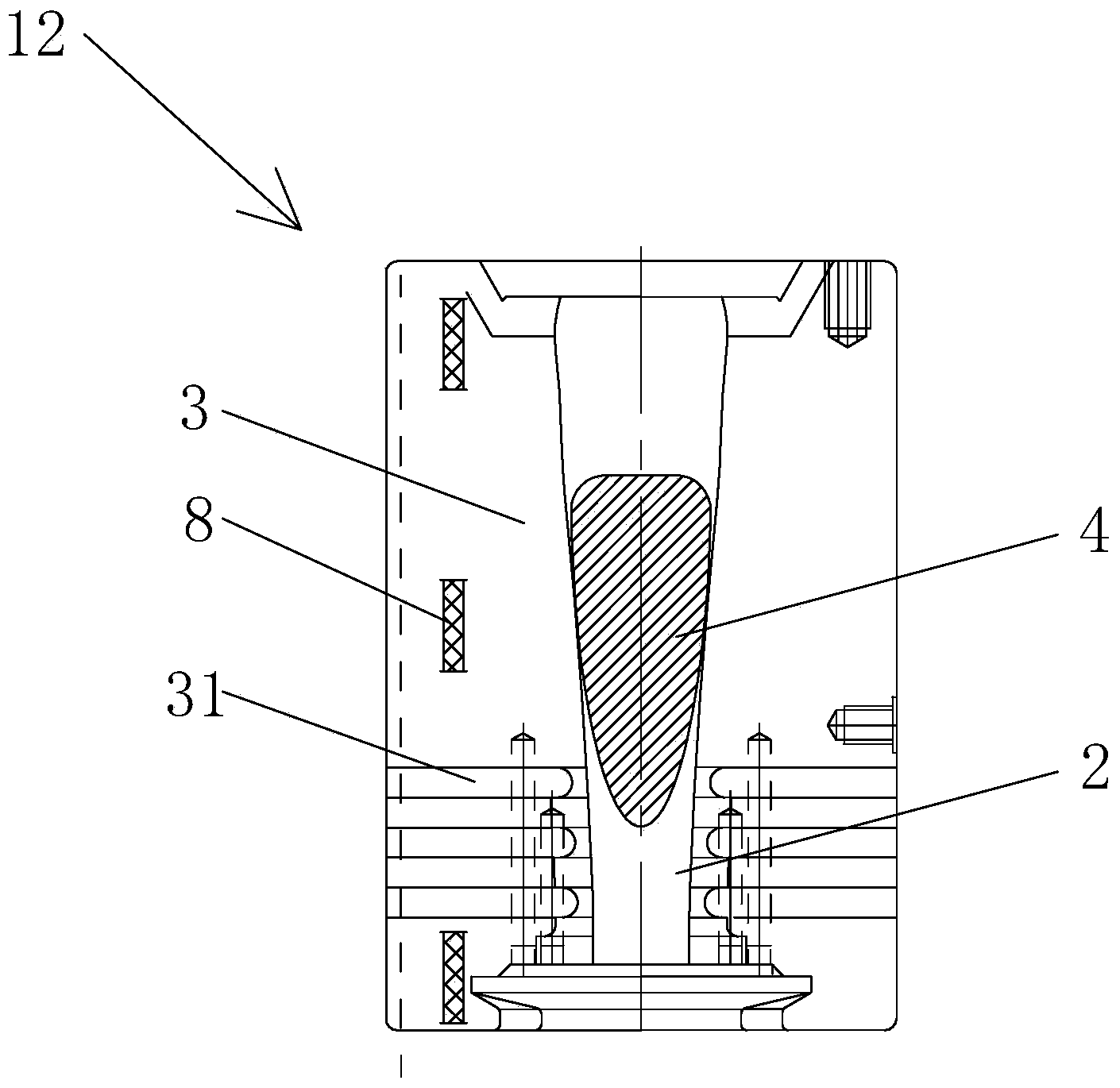

[0017] Embodiment: a kind of initial mold that is beneficial to exhaust, as Figure 2-4 As shown, the primary mold 1 is composed of two male molds 11 and female molds 12 that fit together, and a cavity 2 that penetrates up and down is provided in the male mold 11 and the female mold 12, and the two mold cavities 2 cooperate with each other so that in the A bottle body cavity is formed inside the primary mold 1, and the surface on which the male mold 11 and the female mold 12 fit together is the seam surface 3, and there are several openings on the seam surface 3 that communicate with the inside of the bottle body cavity and the outside world. Air exhaust groove 31, the exhaust groove 31 is located in the lower half of the joint surface 3; the depth of the exhaust groove 31 is 0.15mm.

[0018] Specifically, the male mold 11 and the female mold 12 are tightly fitted through the cooperation between a plurality of triangular ribs 7 and grooves 8, and the triangular ribs 7 and groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com