Patents

Literature

172results about "Blowing moulds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

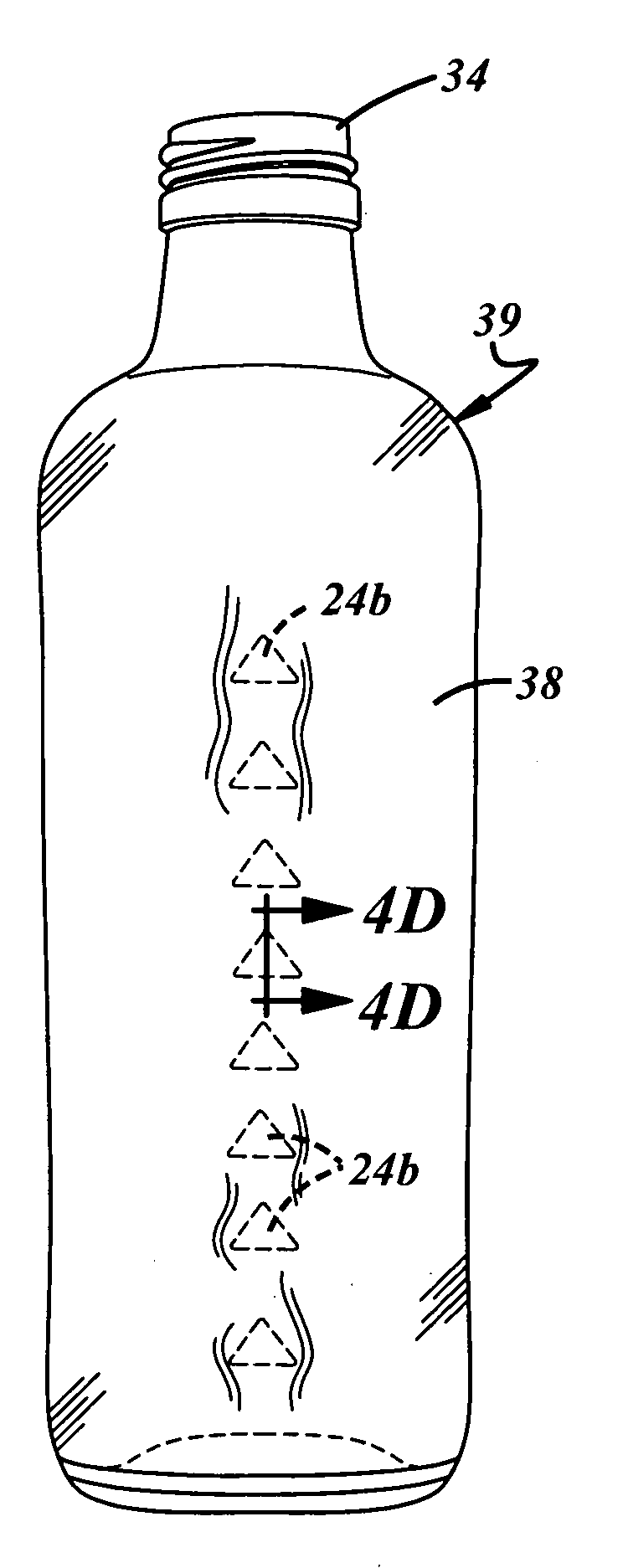

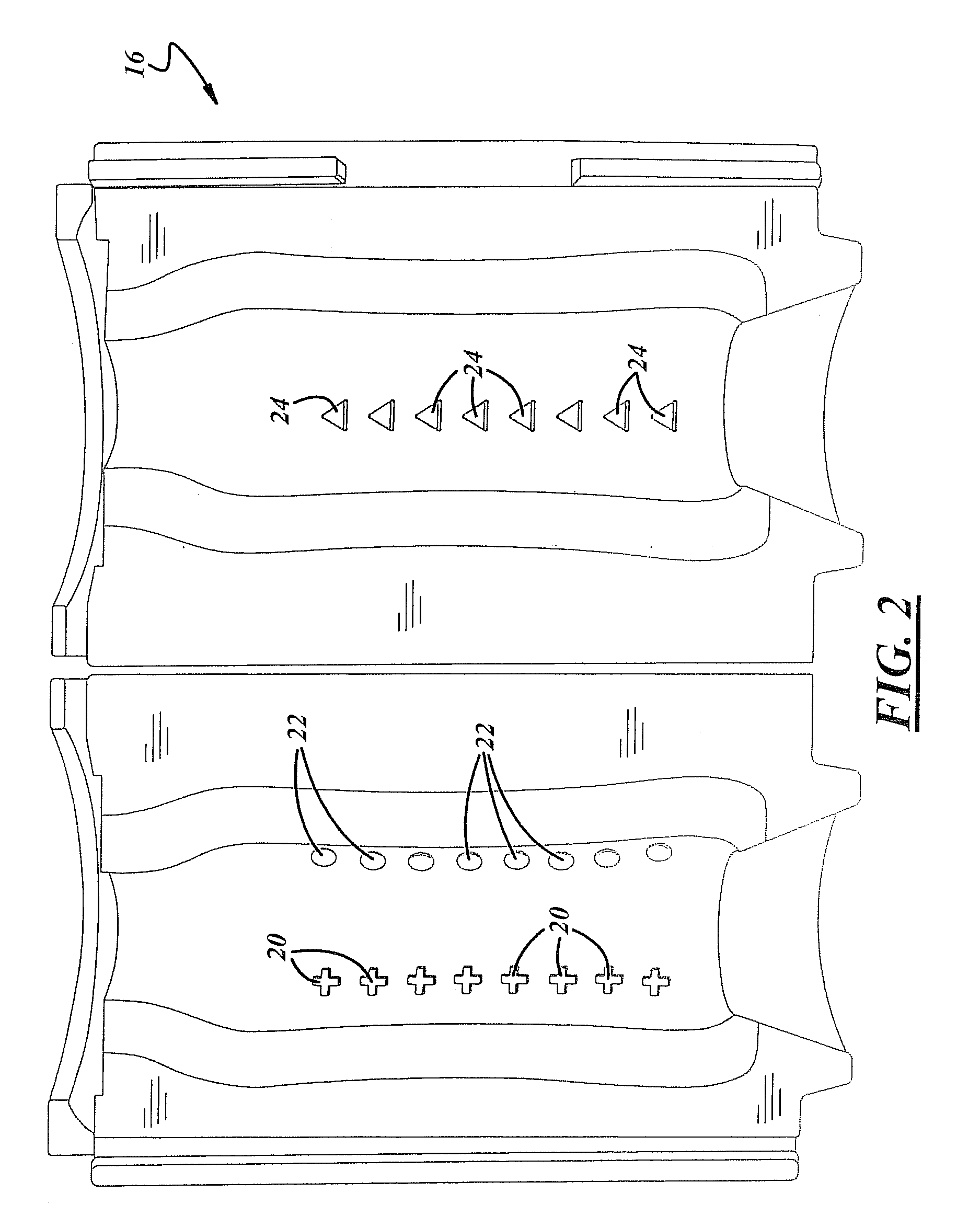

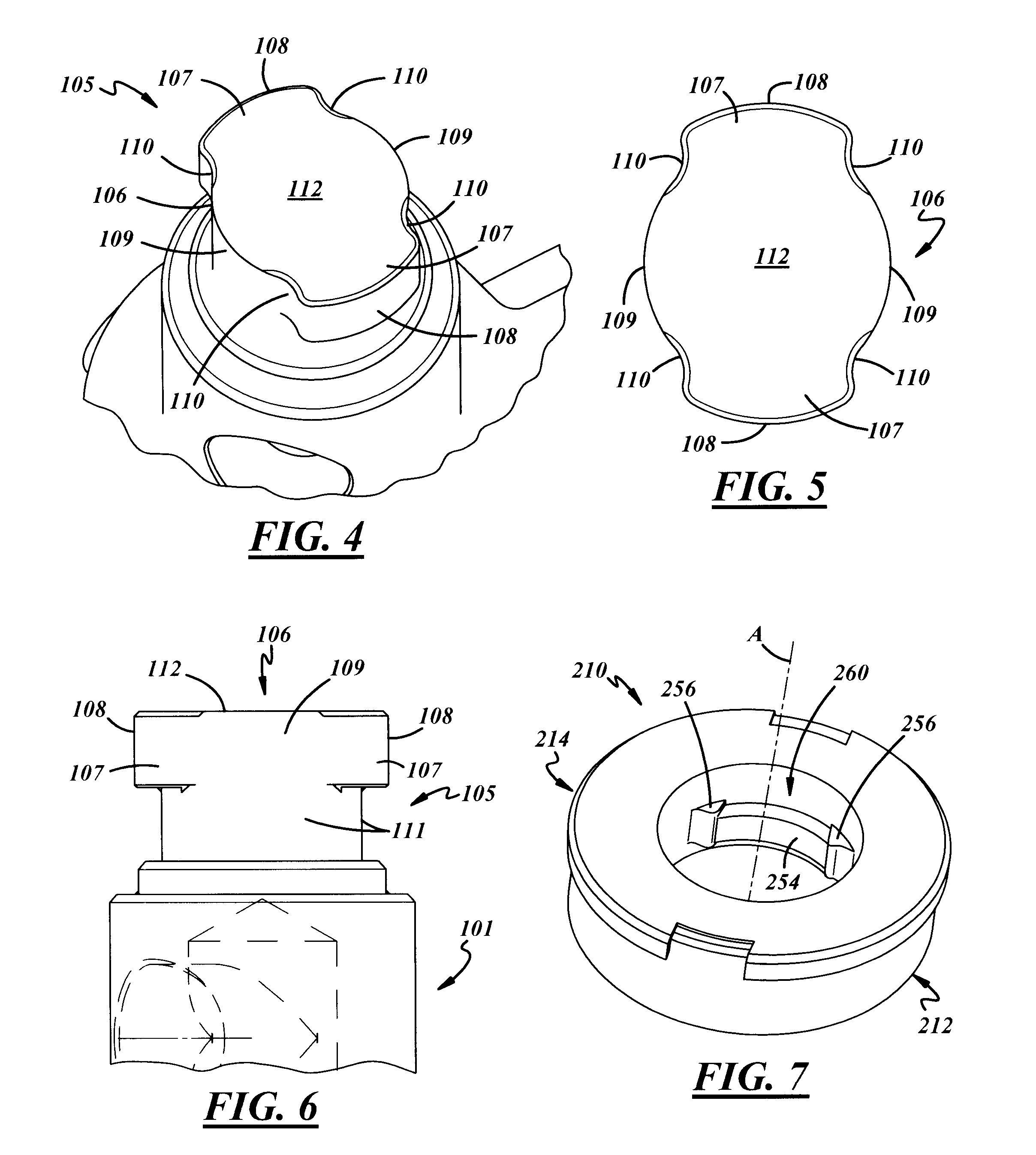

Narrow neck glass container with internal embossments and method of manufacture

InactiveUS20090084799A1Large containersPress and blow machinesMechanical engineeringGeometric pattern

A narrow neck glass container includes a container body and a container neck finish. The container neck finish has an external closure attachment diameter of not more than 36 mm, and the container body has at least one internal embossment of predetermined geometry. The at least one internal embossment preferably comprises a plurality of internal embossments in a geometric pattern.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

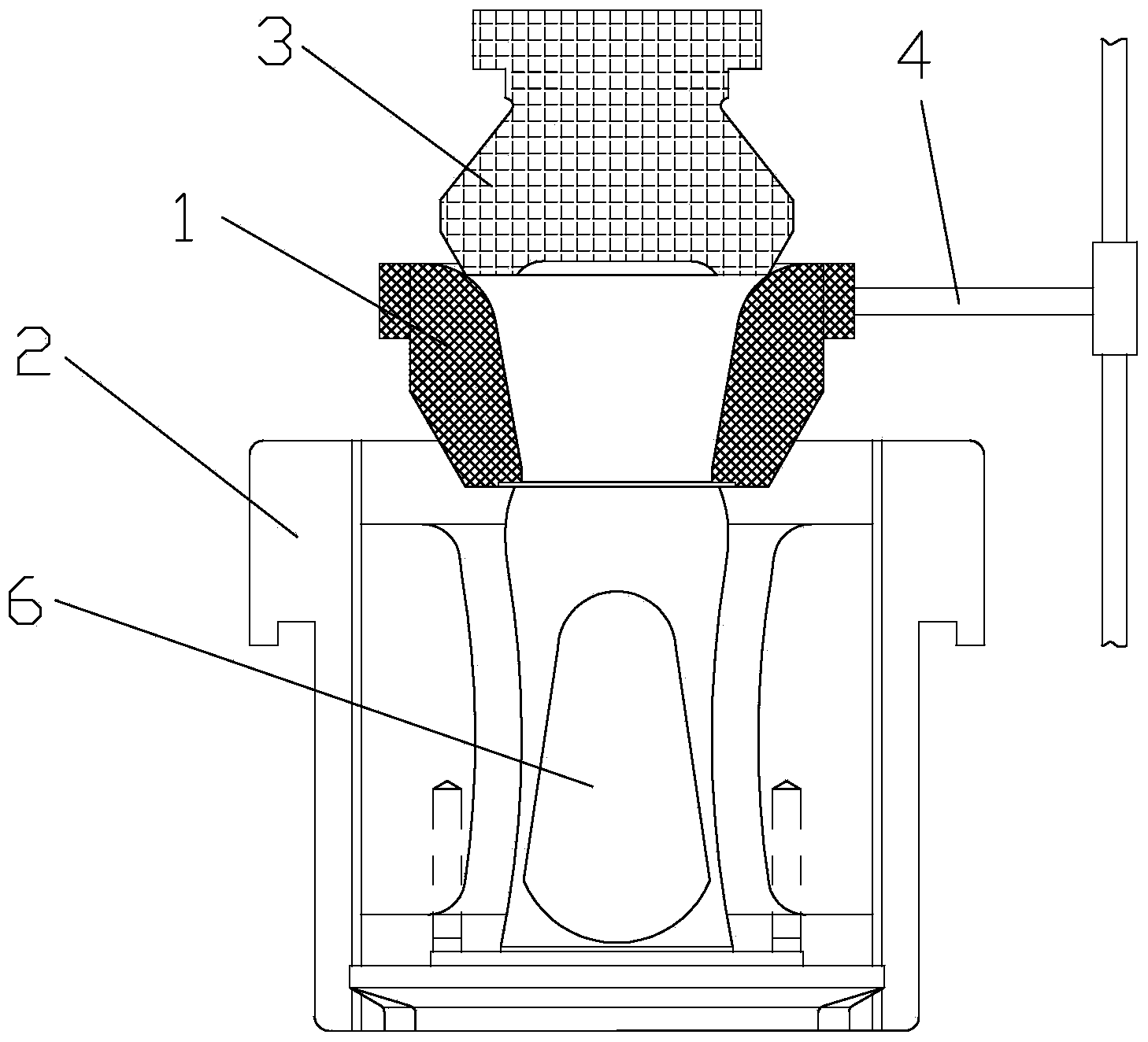

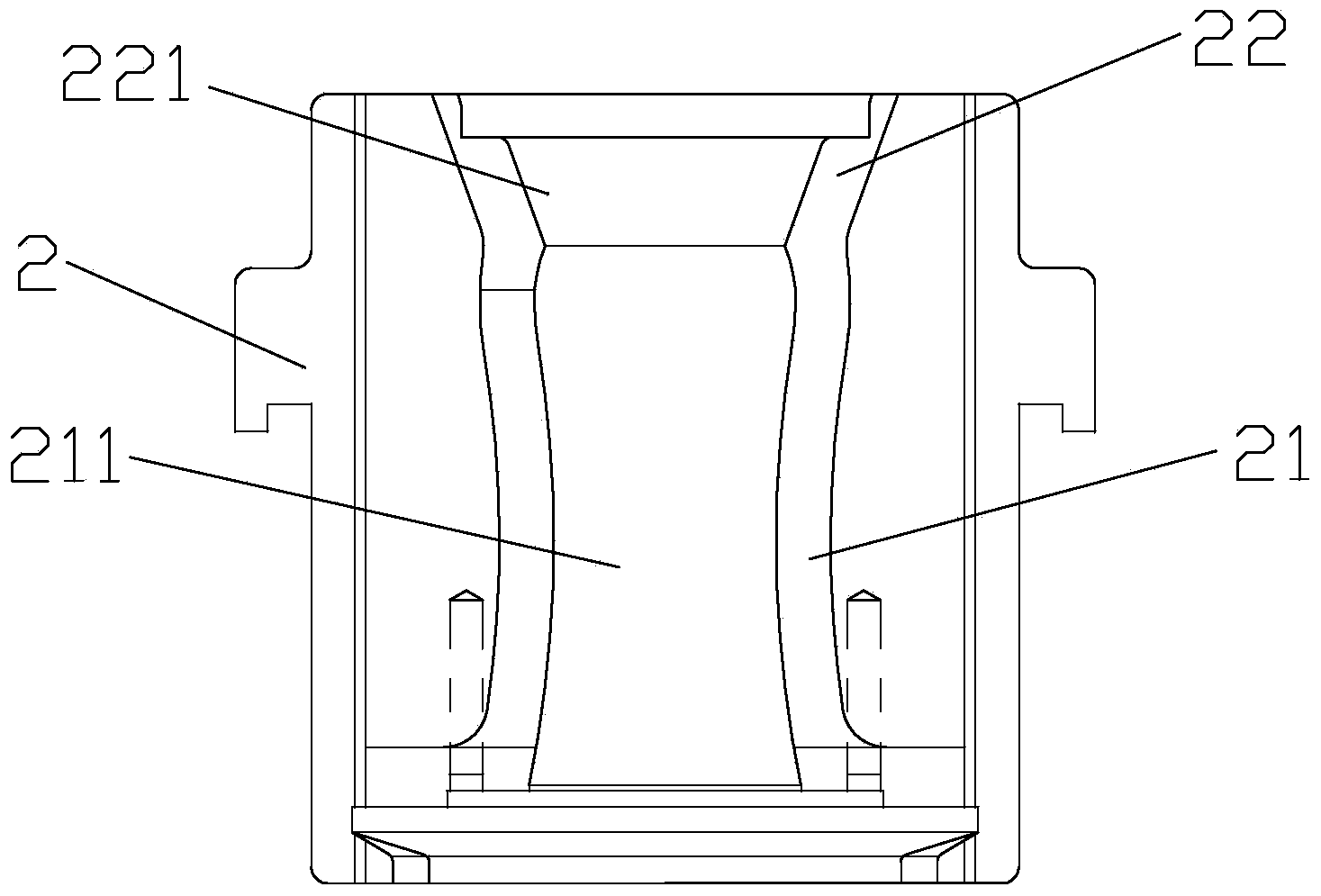

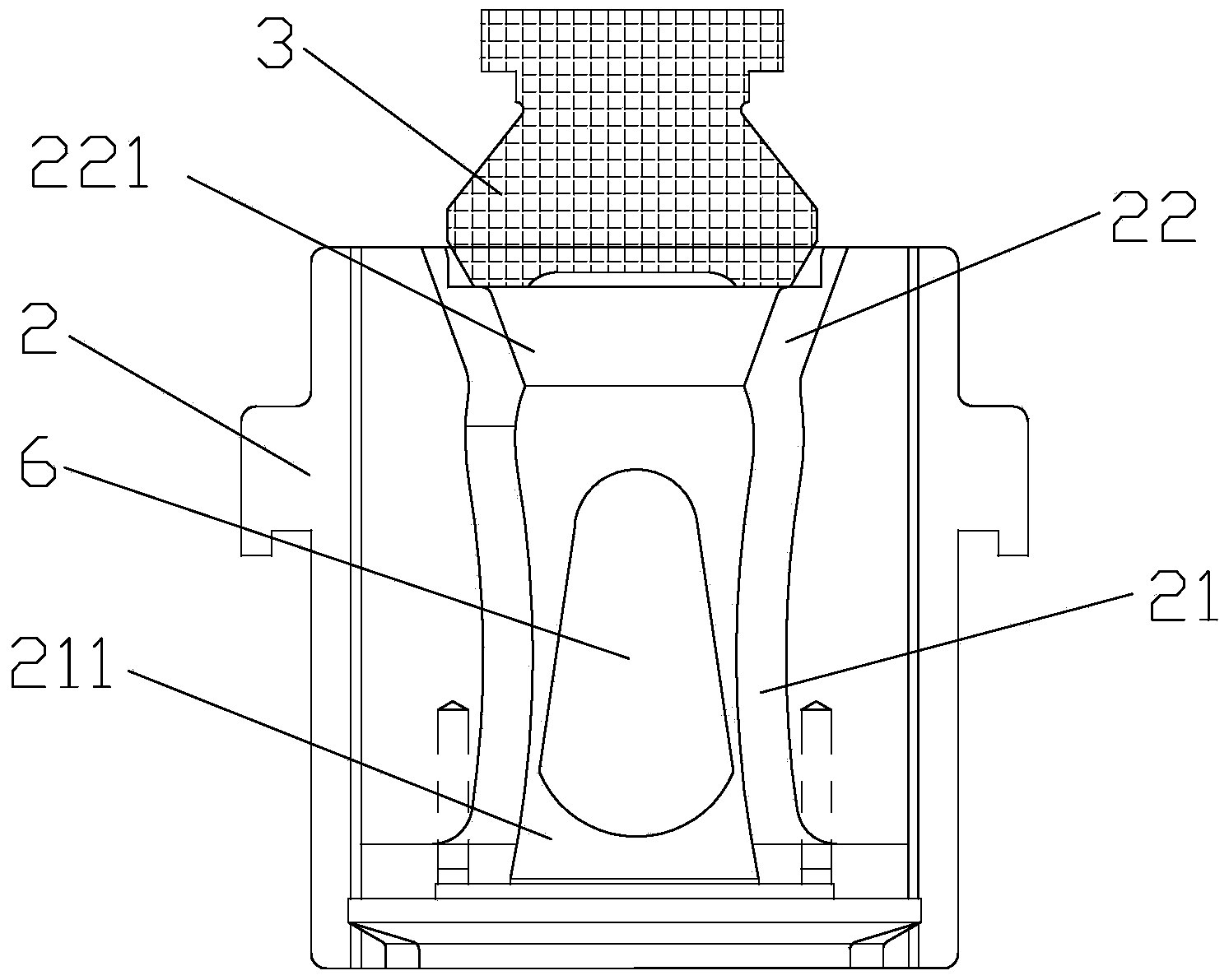

Mould for manufacturing bottle and jar glass containers

Owner:CHANGSHU JIANHUA MOLD TECH

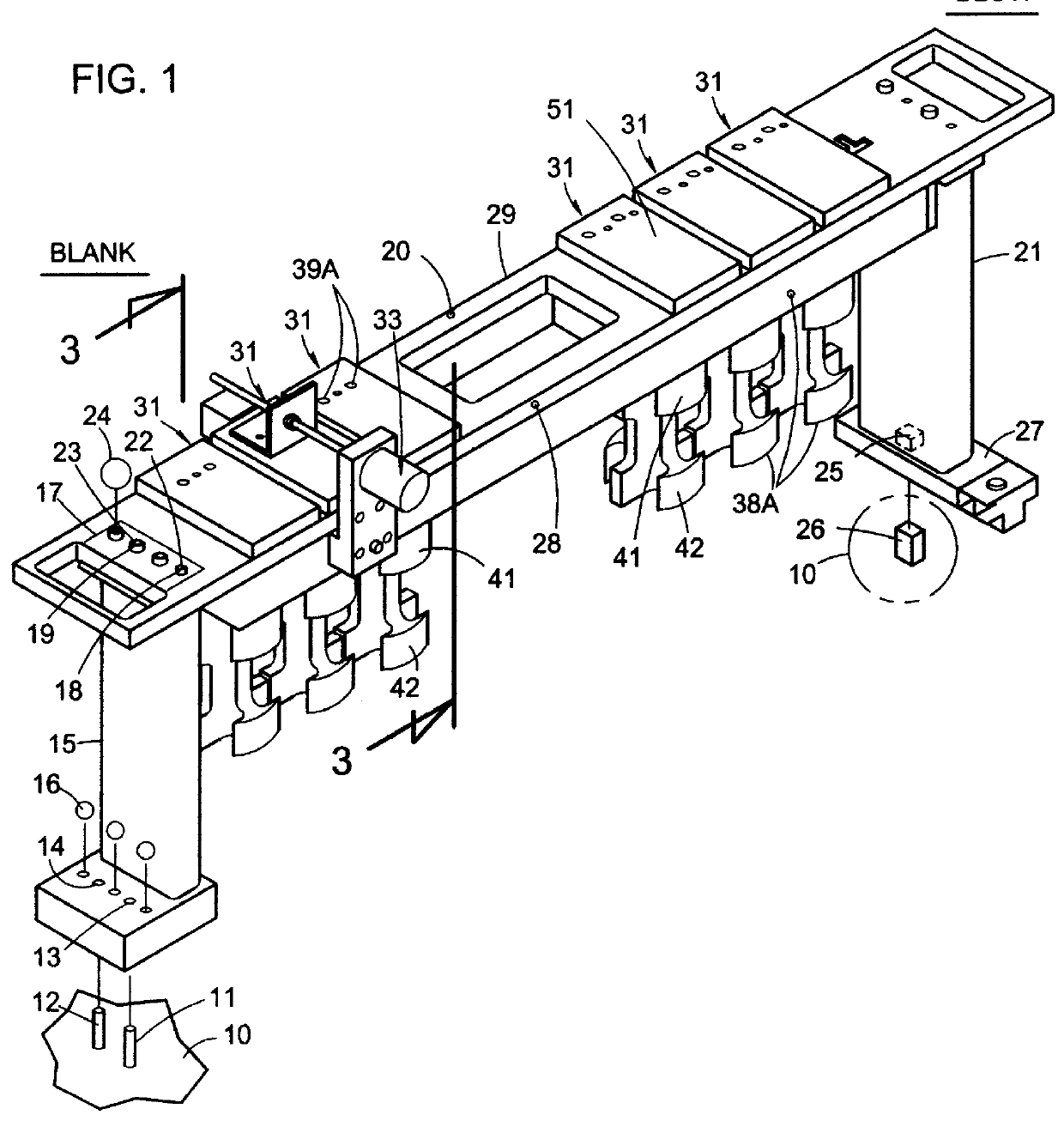

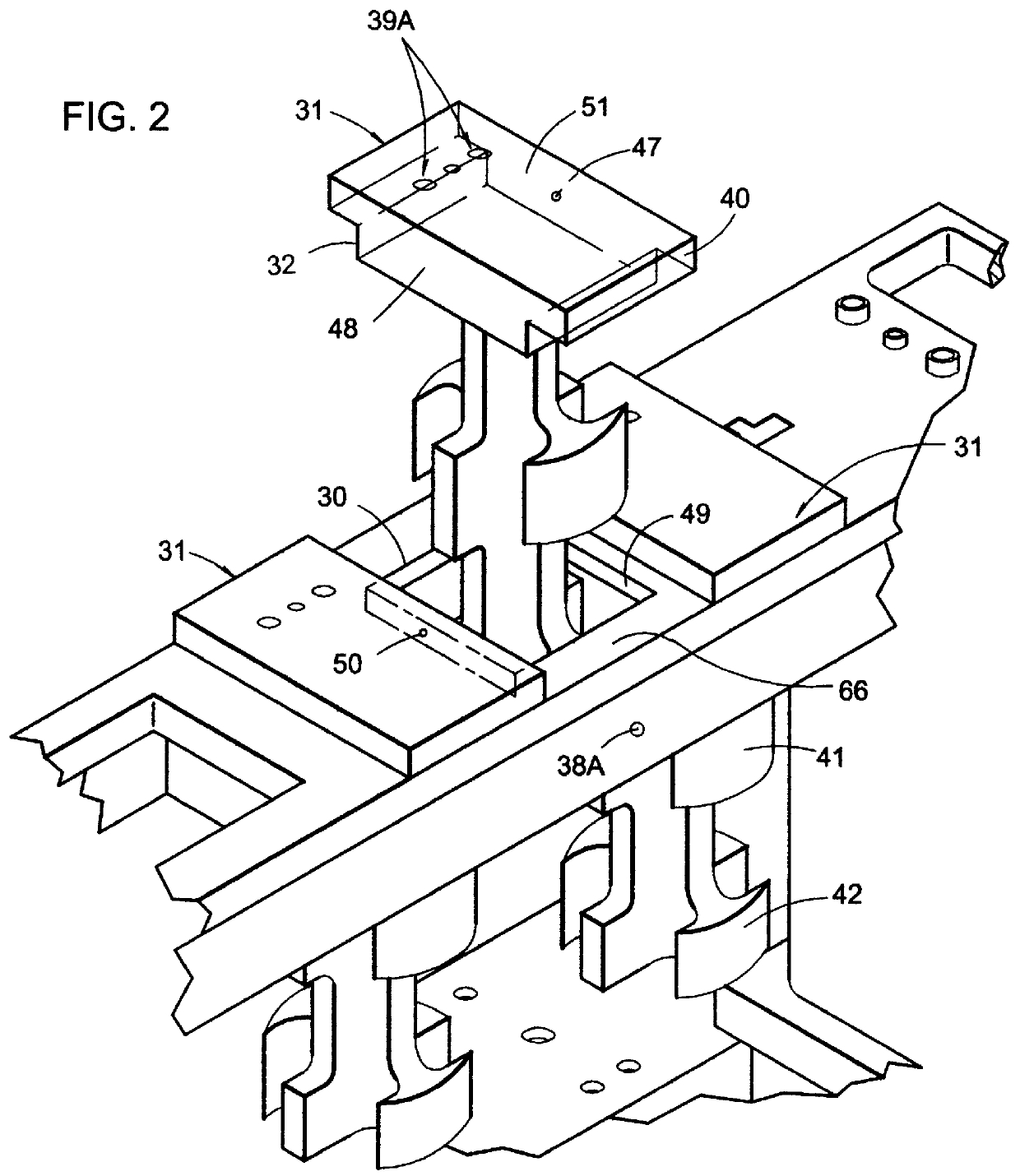

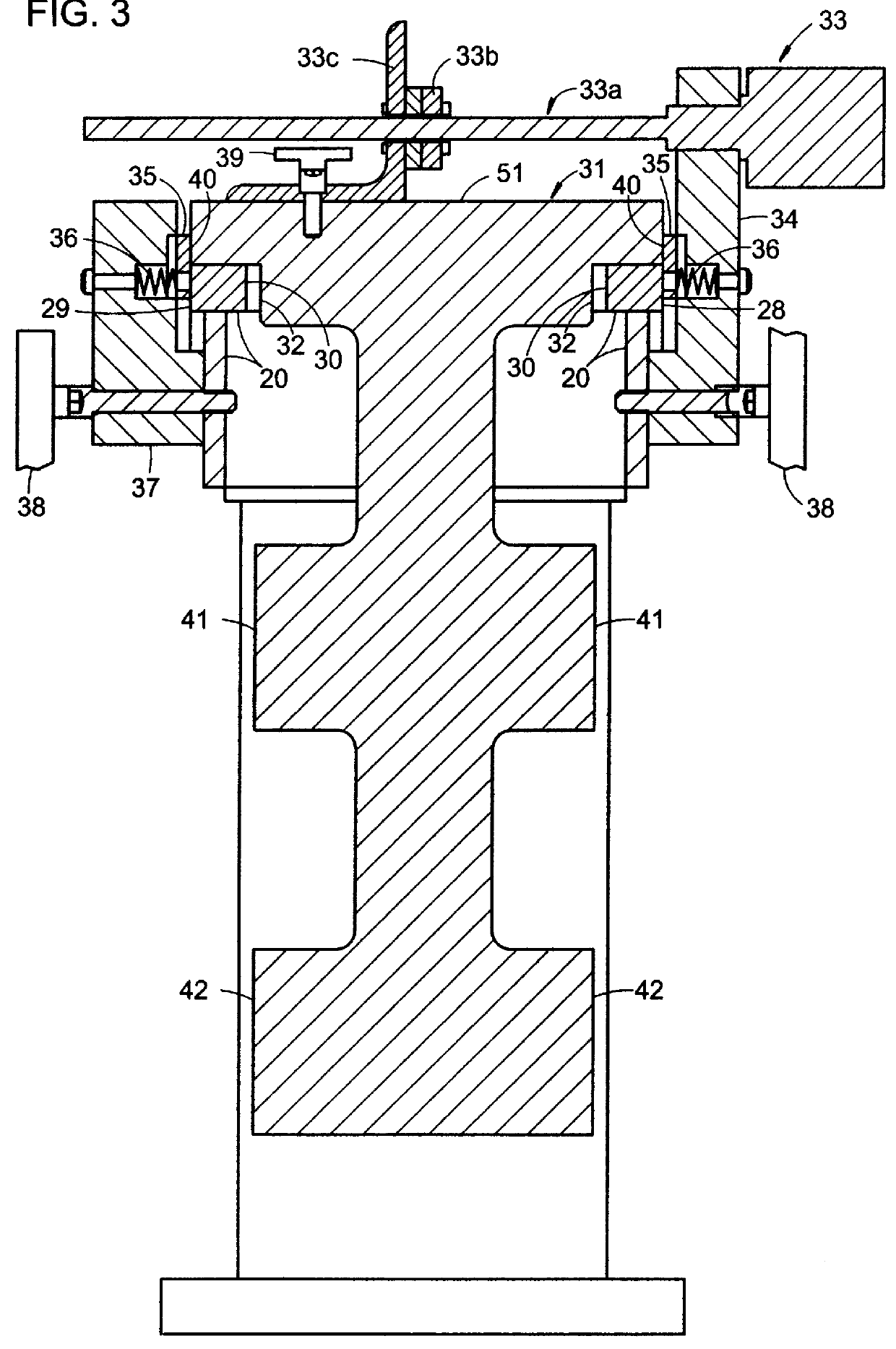

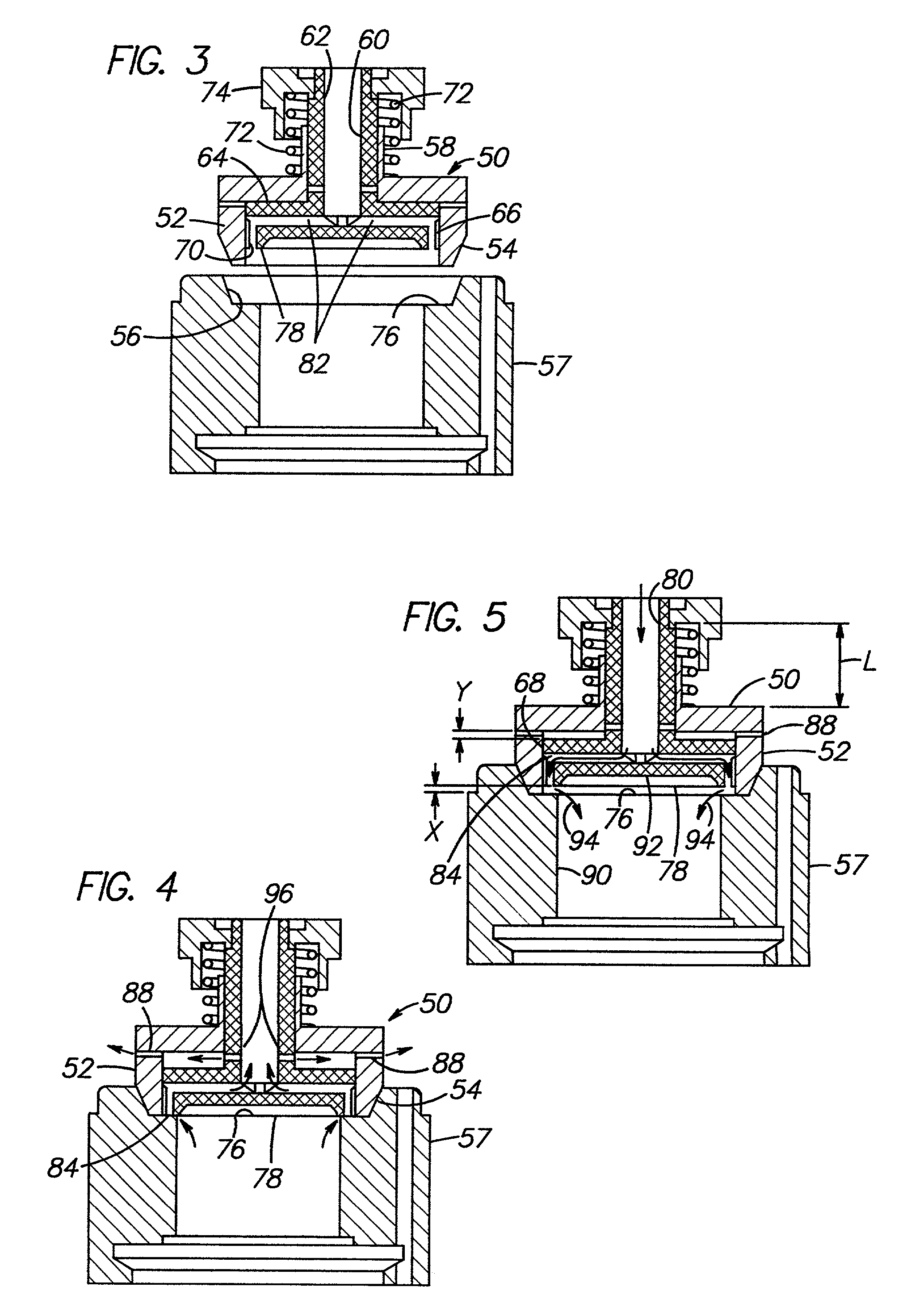

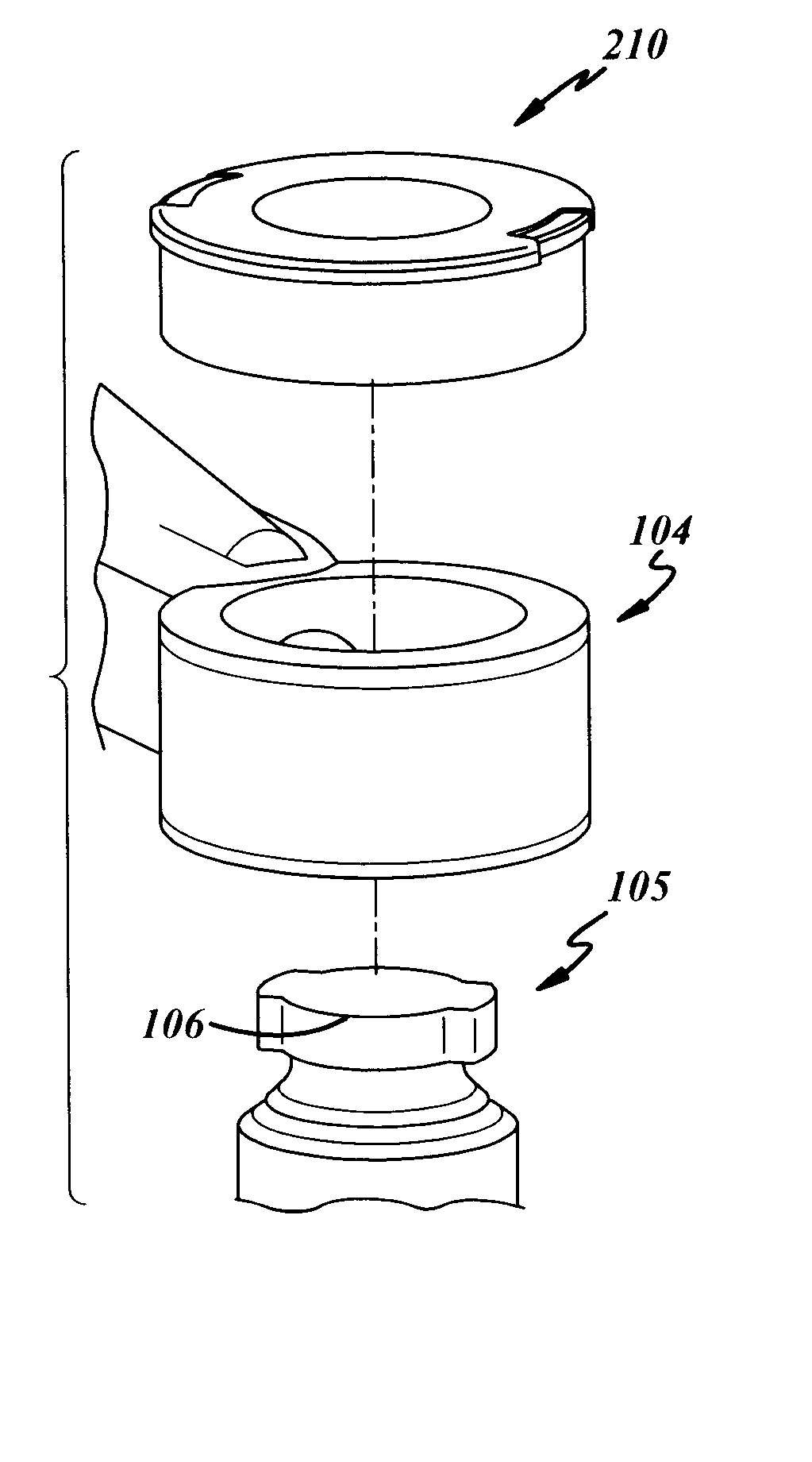

Floating mount bottom plate holder in a glassware forming machine

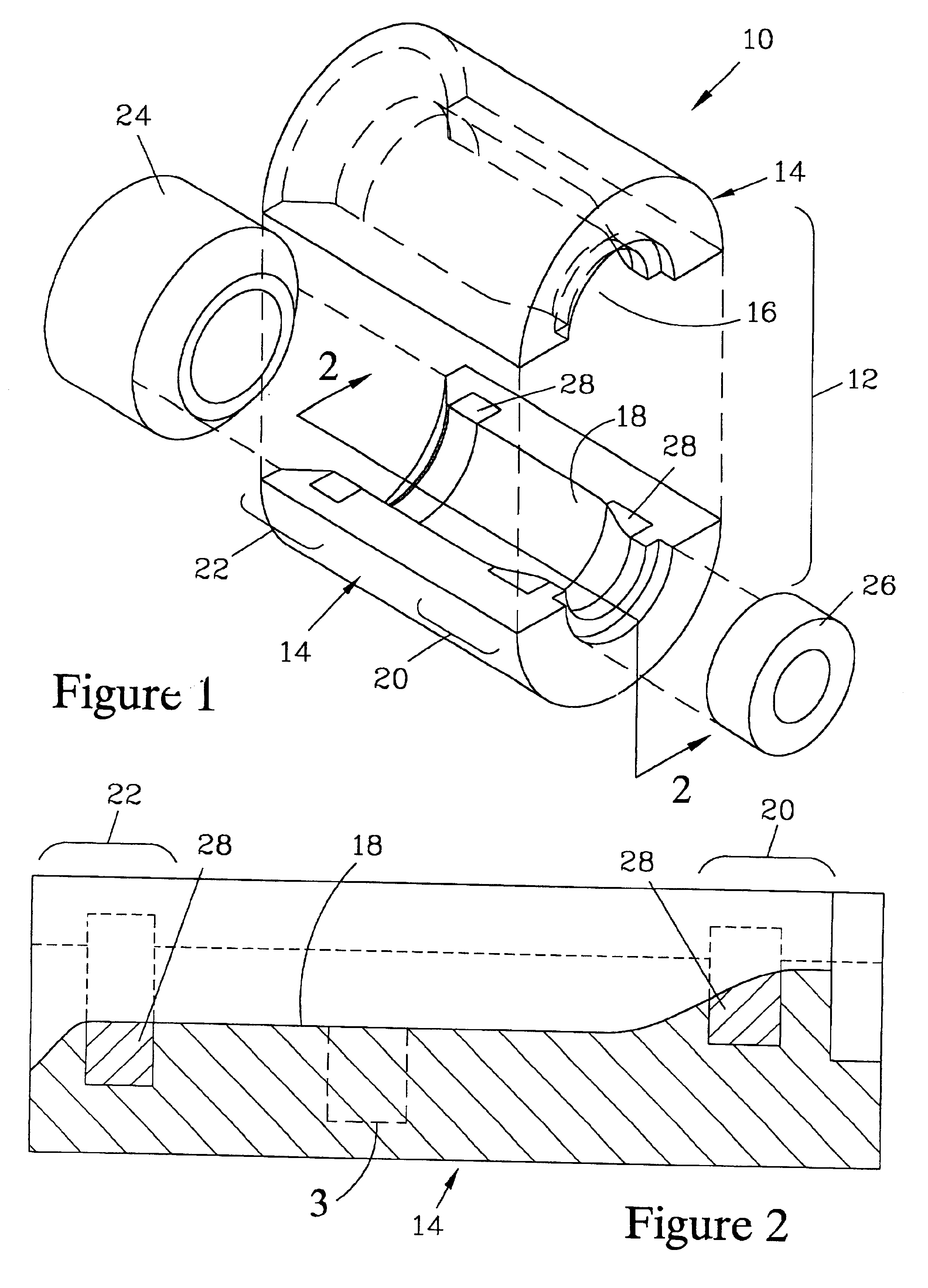

A glassware mold bottom plate mounting arrangement in a glassware forming machine includes a floating ring captured by a cap plate on a base for limited lateral movement with respect to the base and the cap plate. A hollow spud is rigidly secured to and extends from the ring. A cooling wind passage in the base opens through the hollow spud, and a vacuum passage in the base opens through the ring at a position spaced from the spud. A glassware mold bottom plate is removably telescopically received over the ring and the spud. The bottom plate has a central air passage received over the spud, an annular recess received over the ring, and a peripheral air passage that opens into the annular recess such that the central and peripheral air passages open to the cooling wind and vacuum passages in the base through the spud and the ring respectively. The spud and the ring preferably have external seals in respective sliding sealing engagement with the central air passage and the annular recess in the bottom plate. There preferably are face seals between the base and the floating ring, and between the ring and an undersurface of the cap plate.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

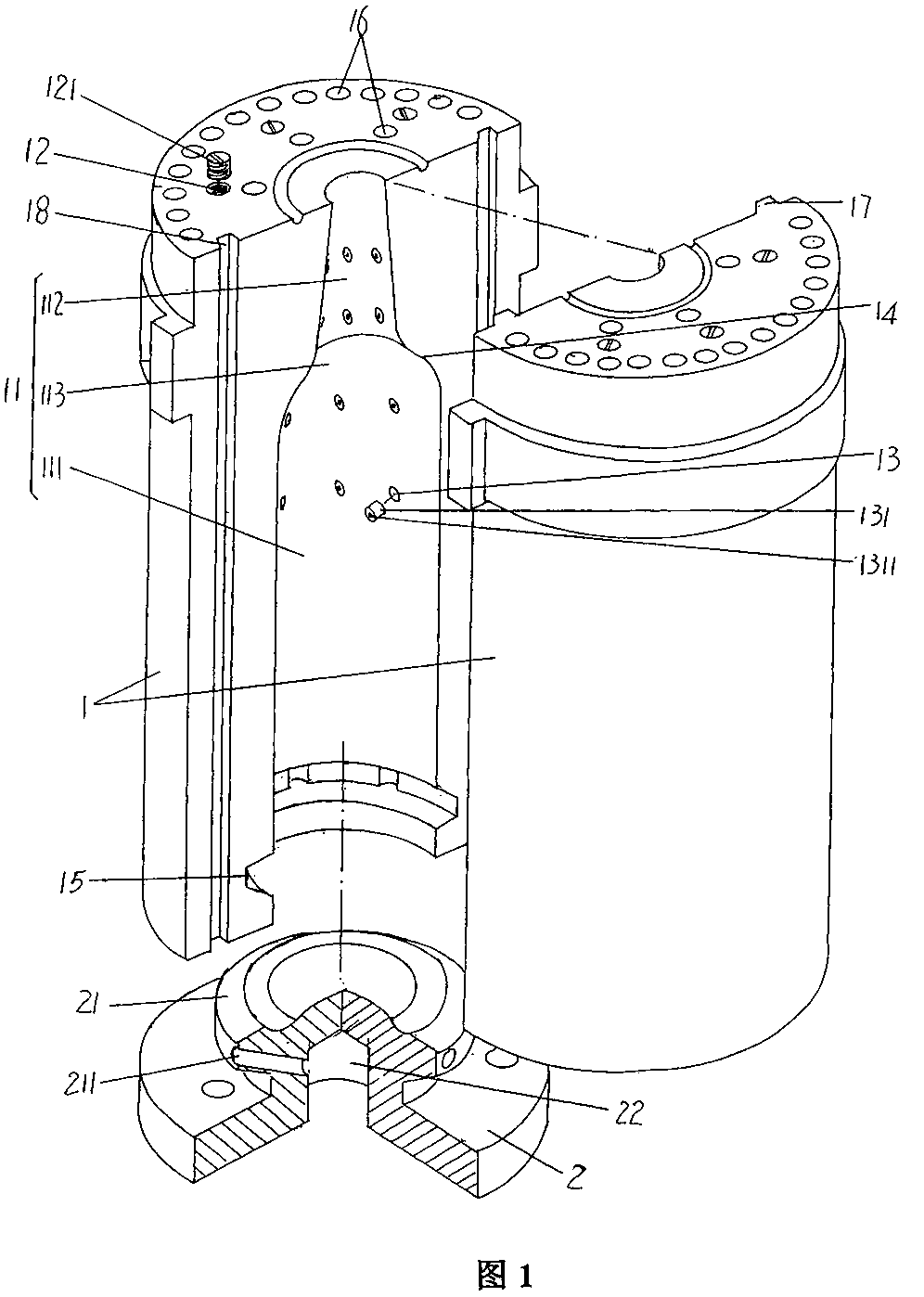

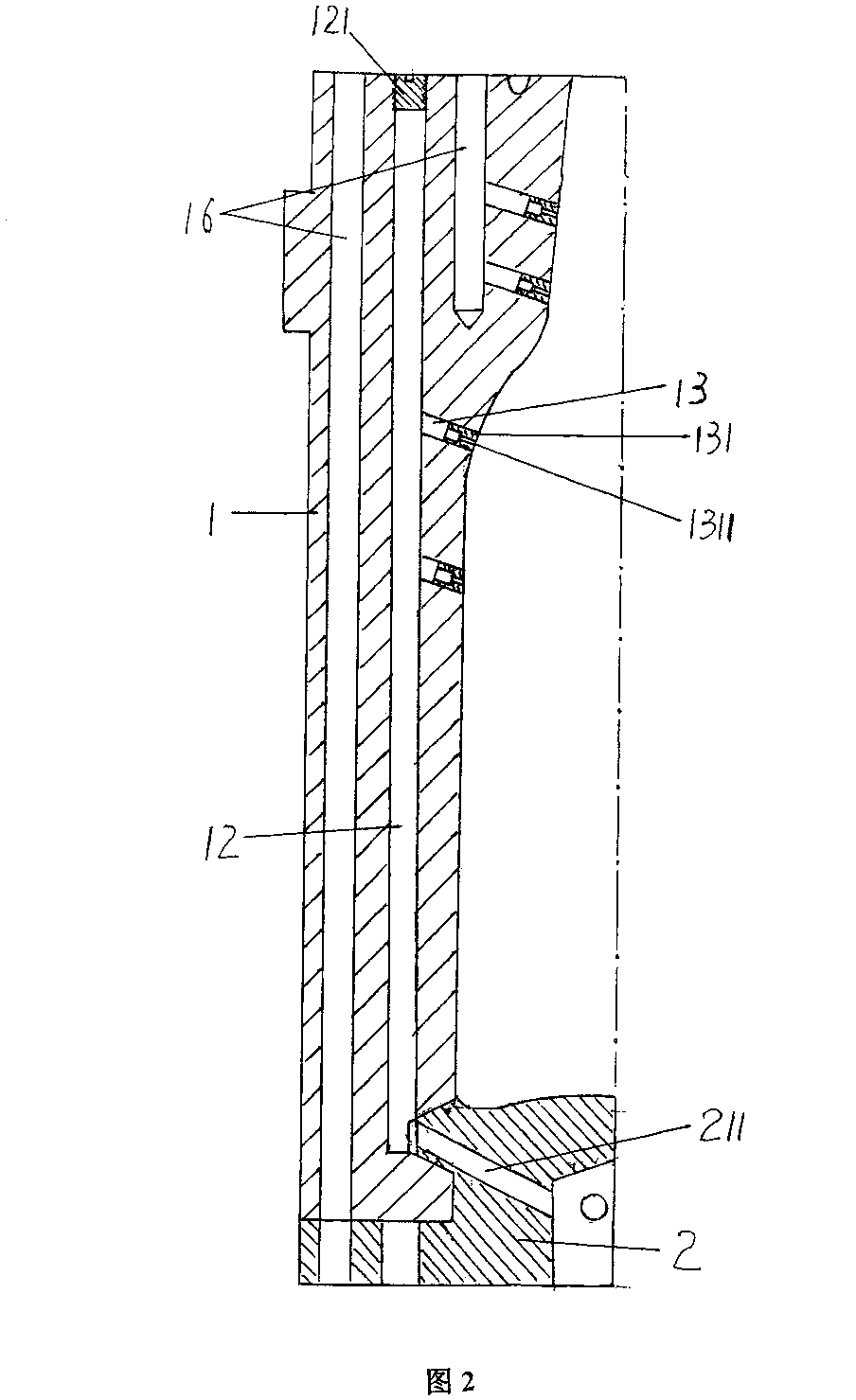

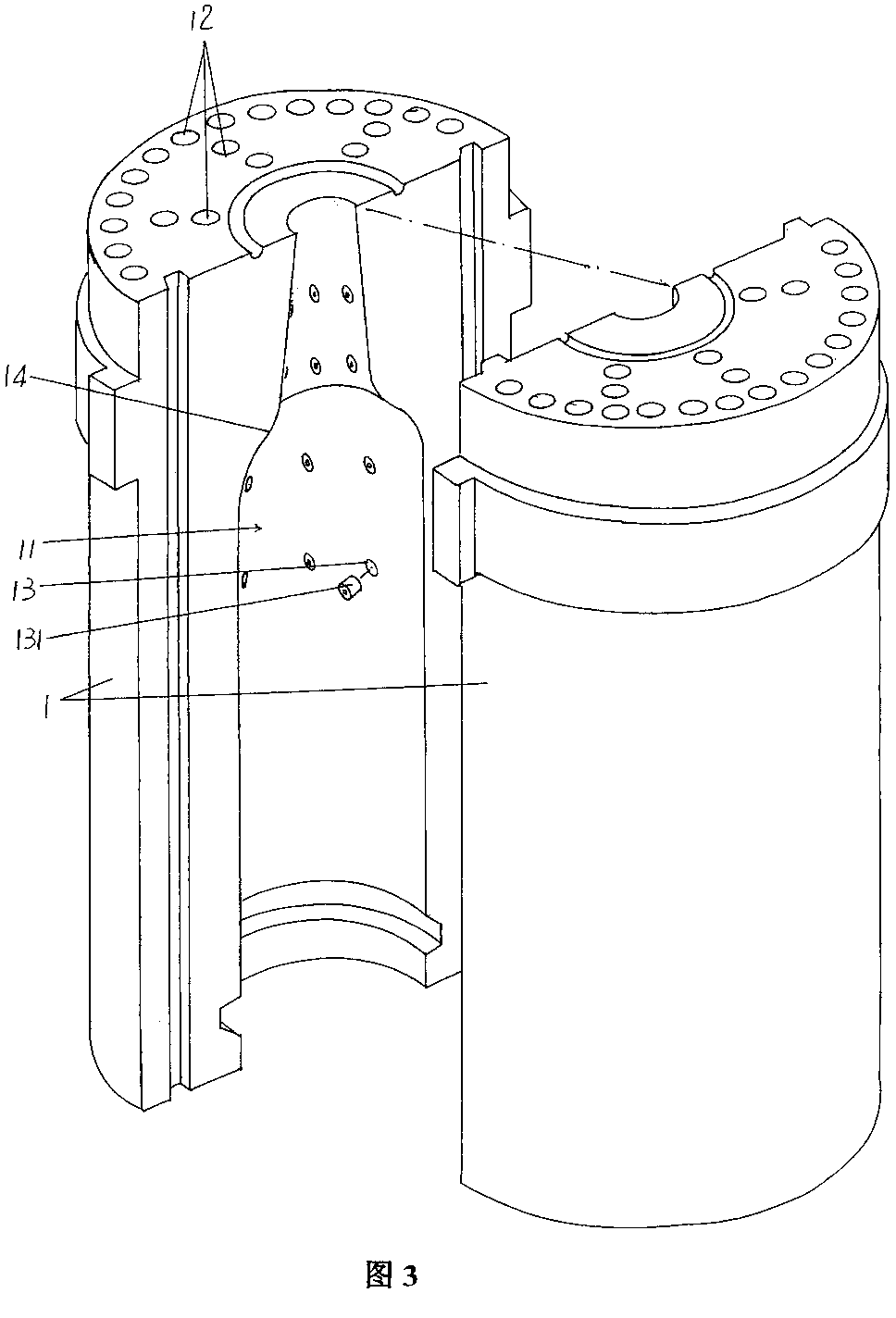

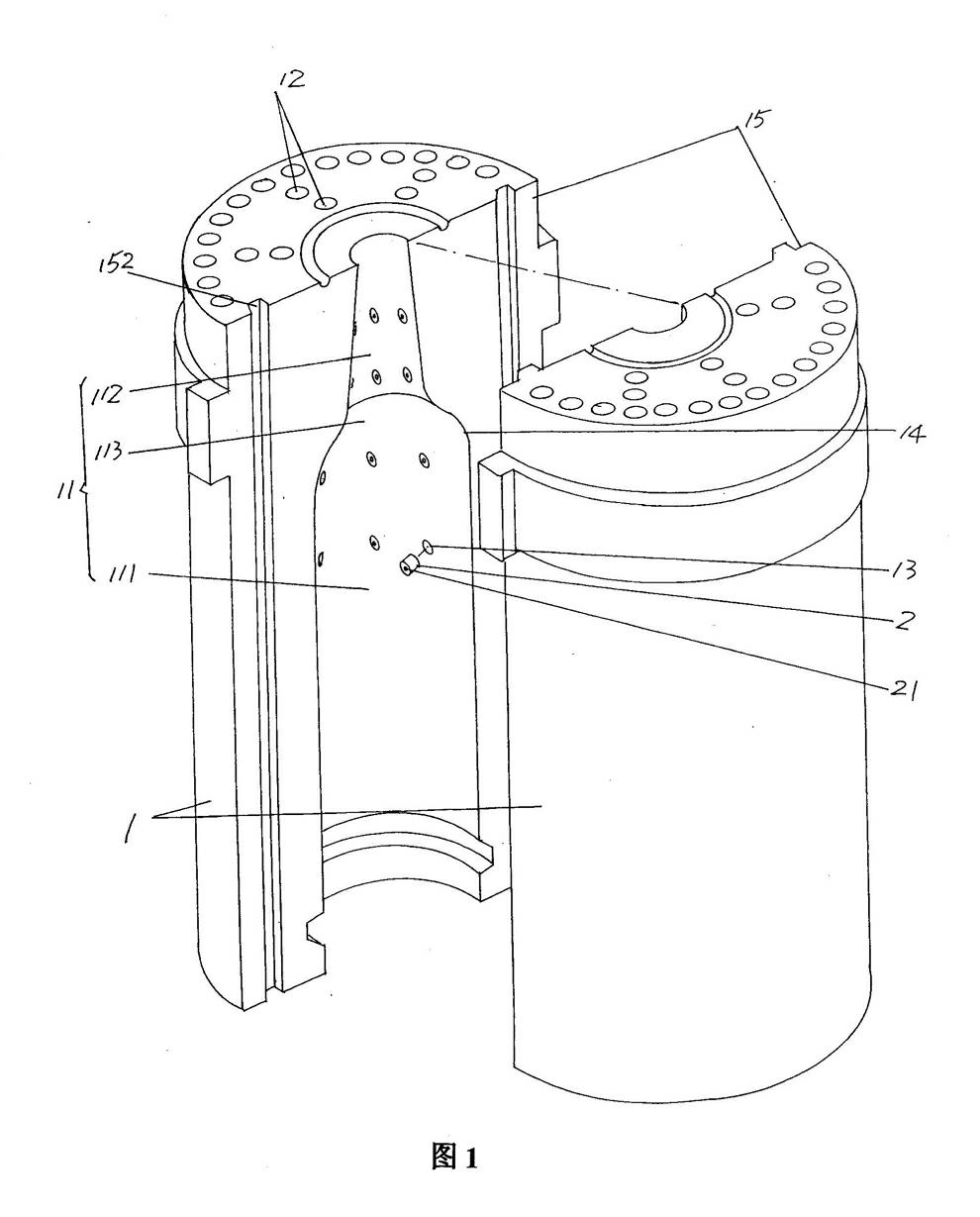

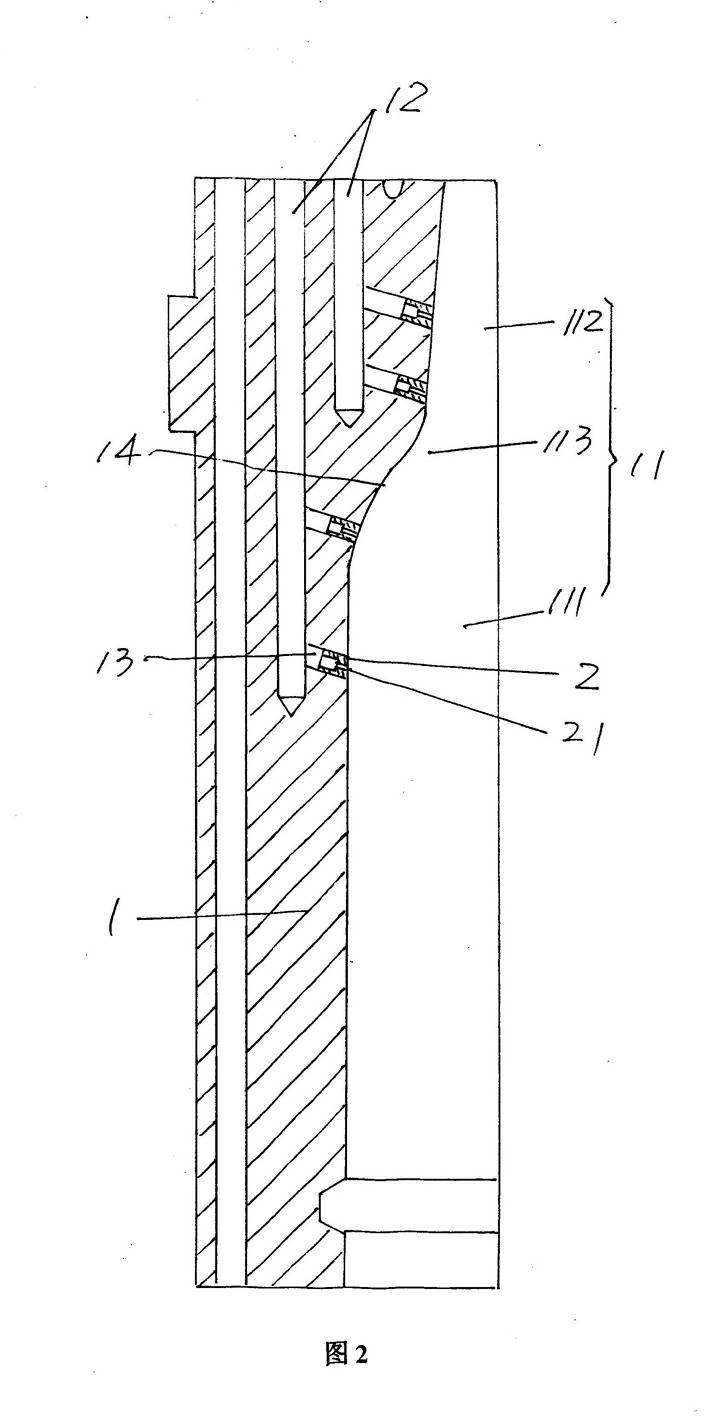

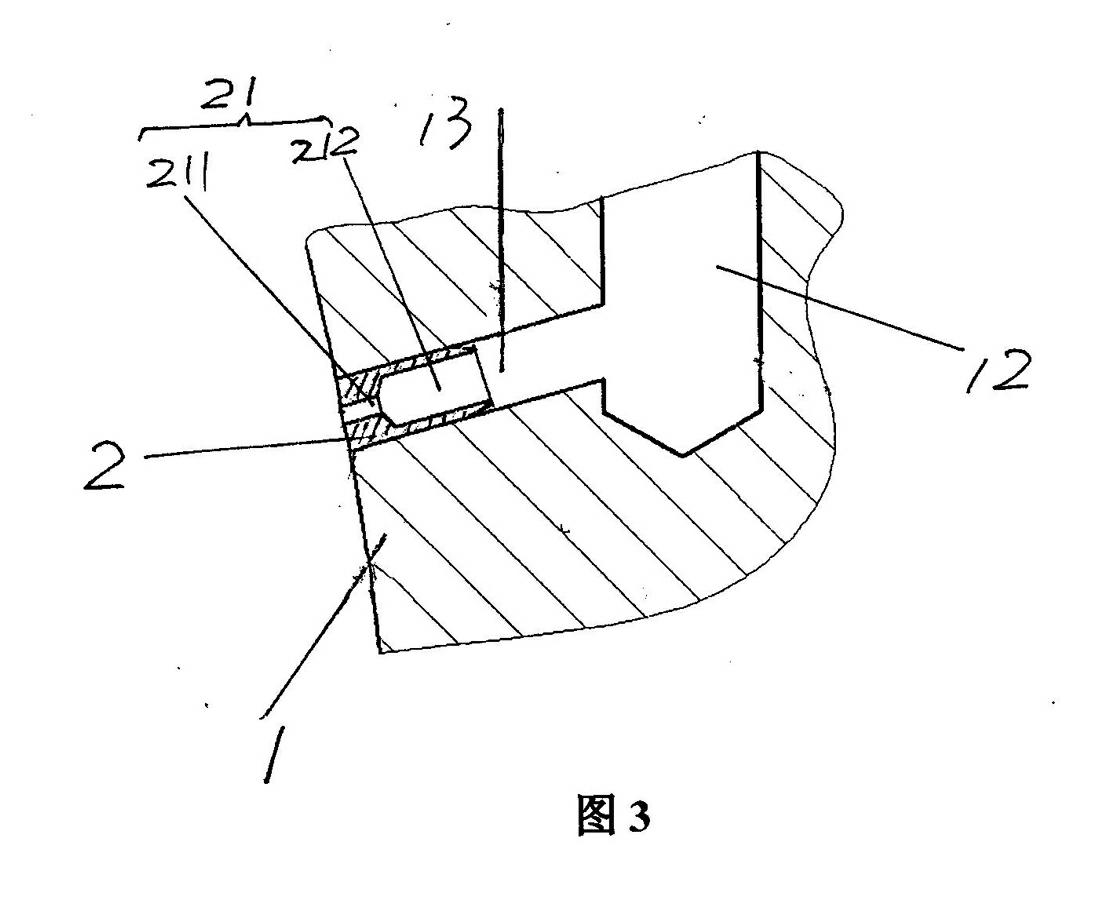

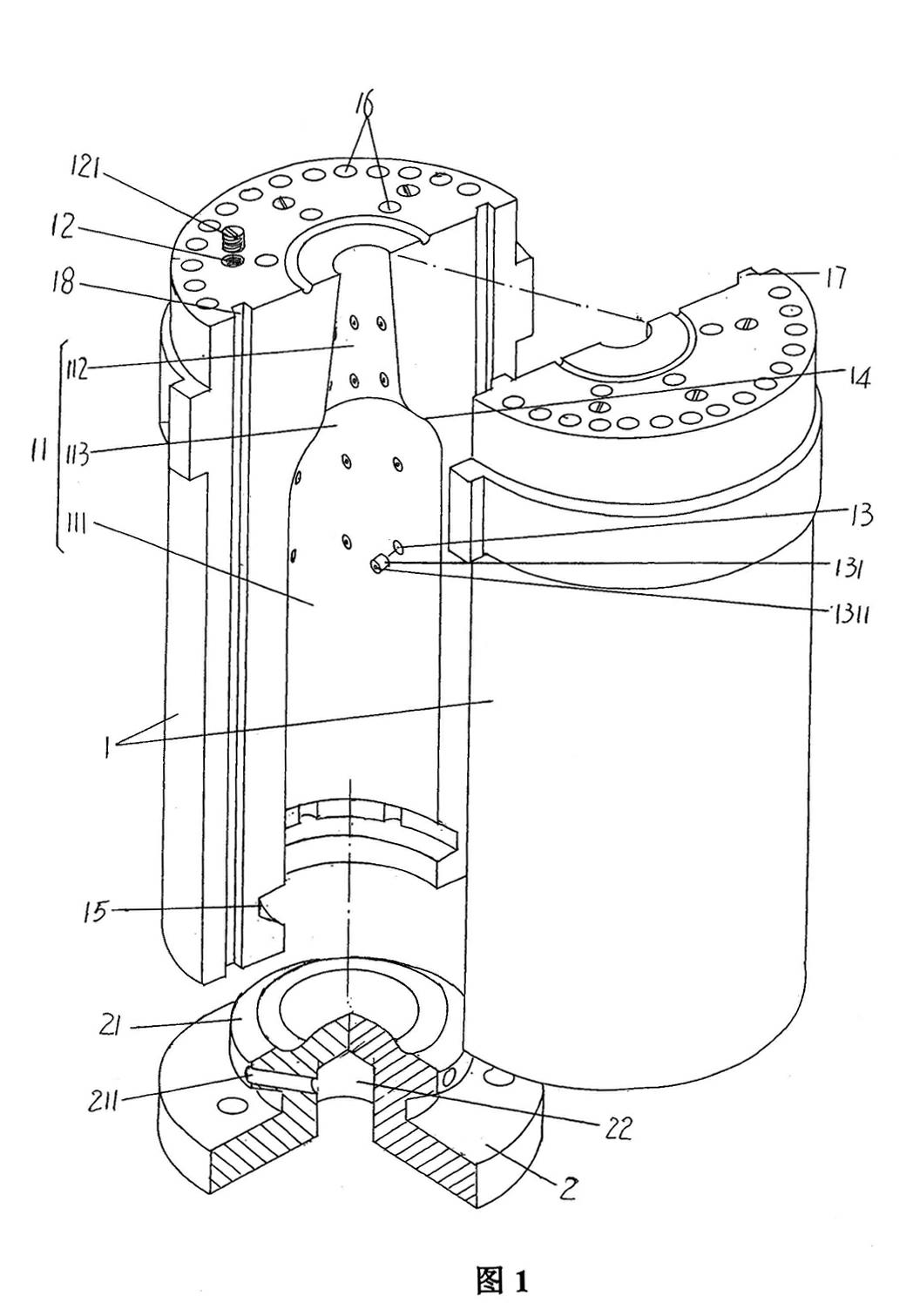

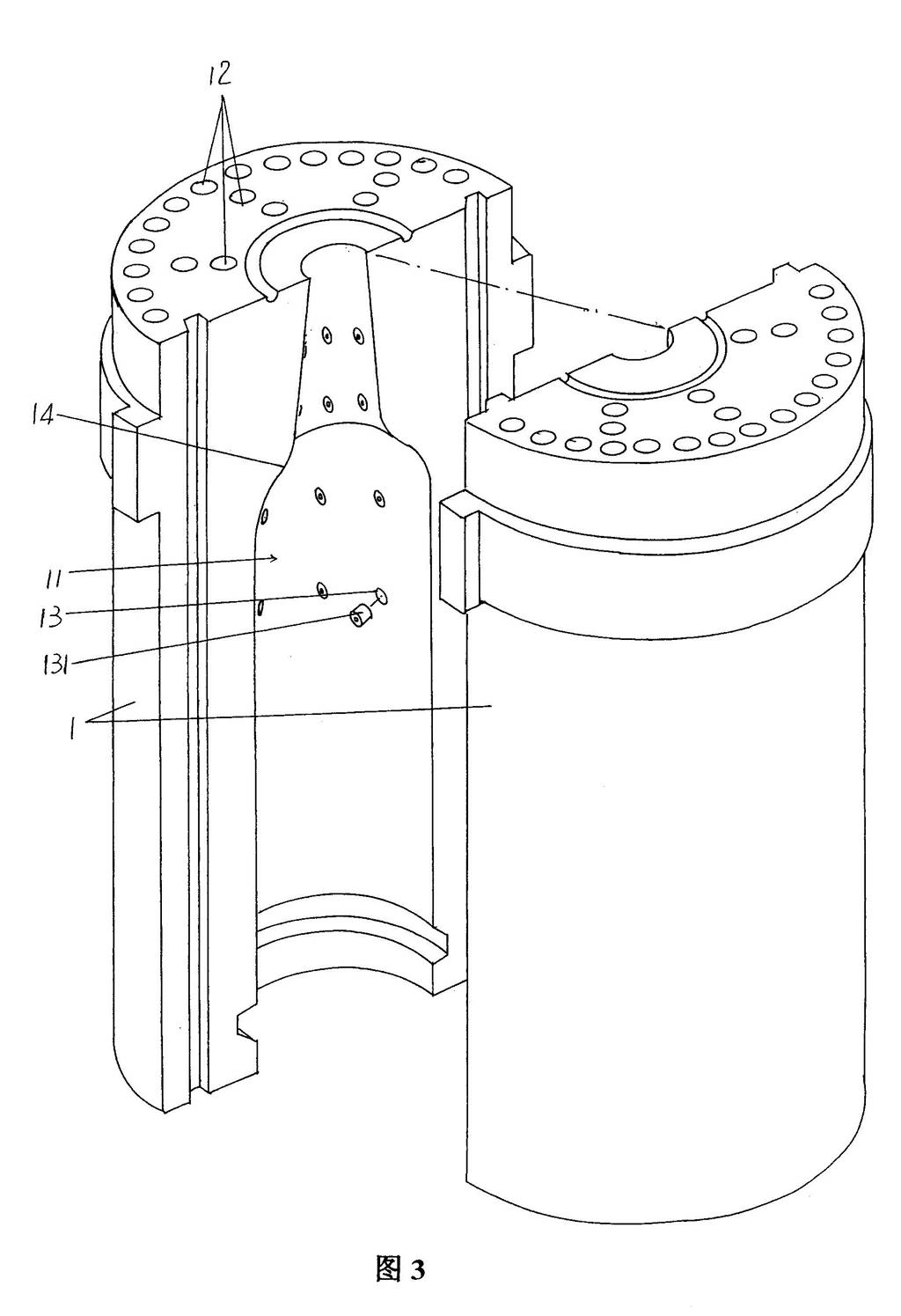

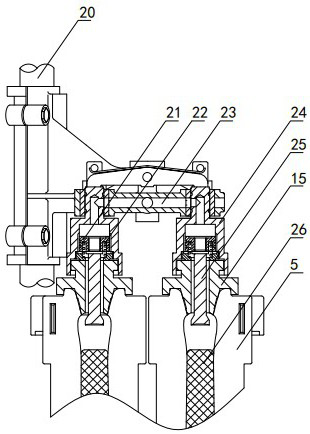

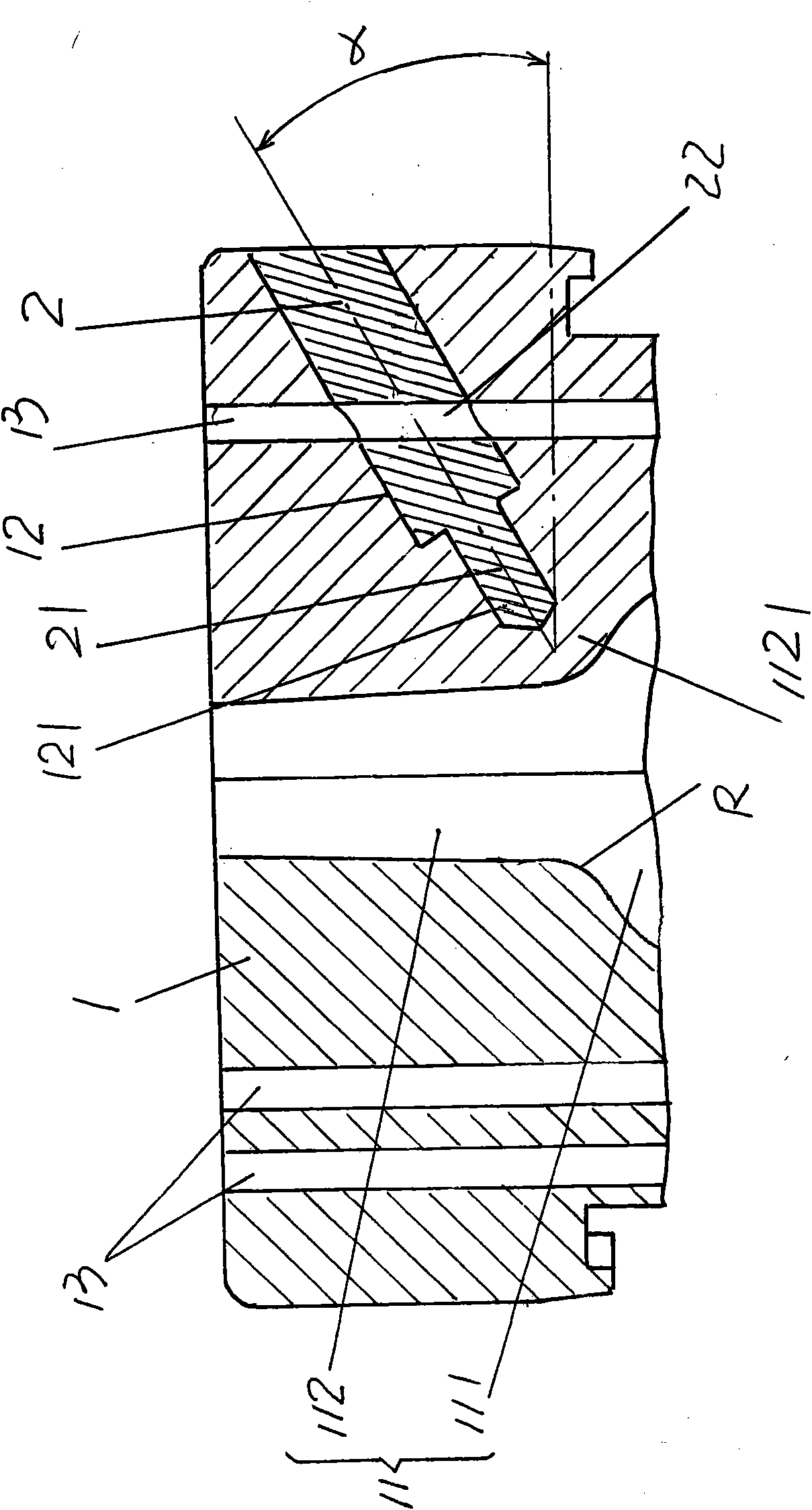

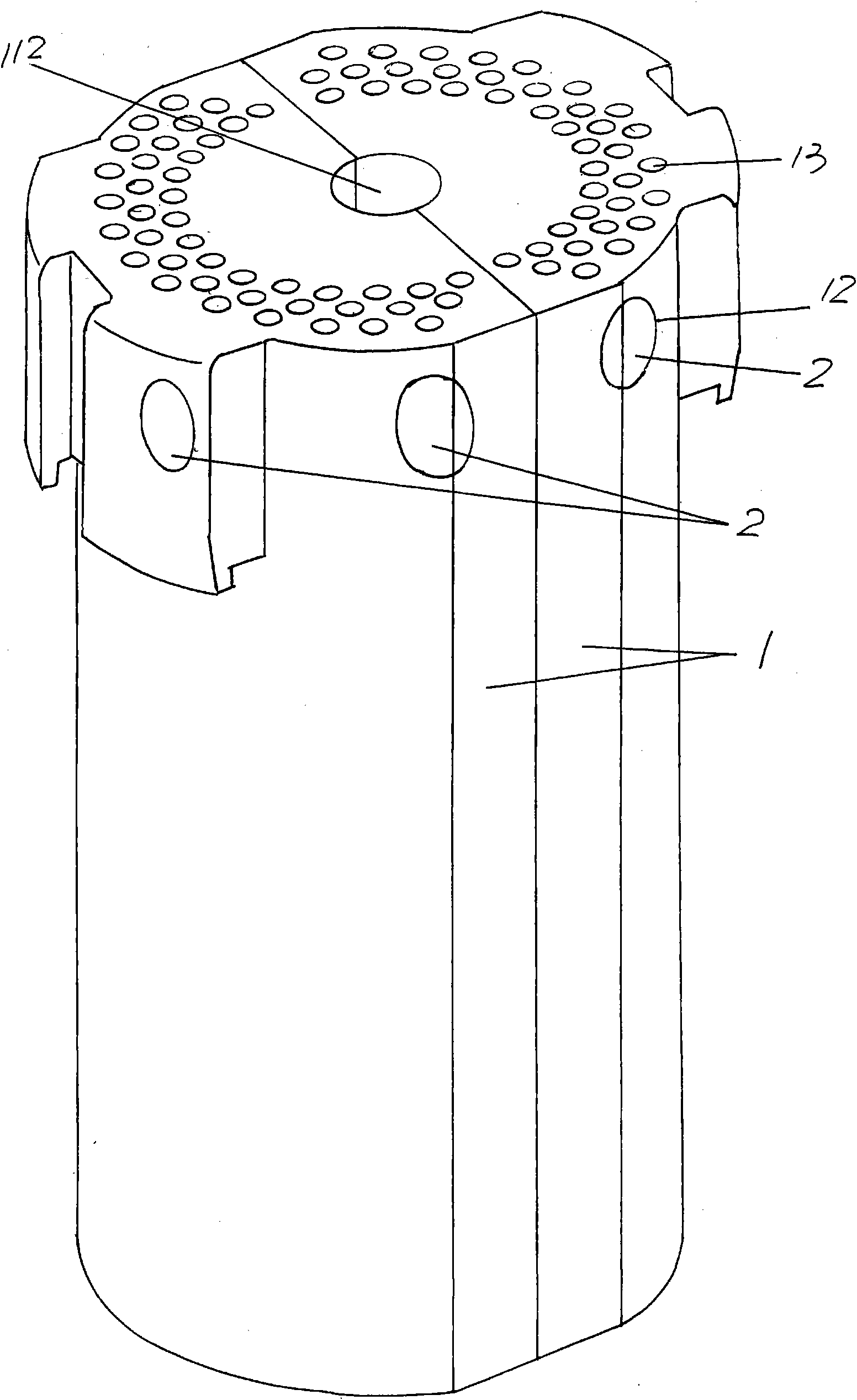

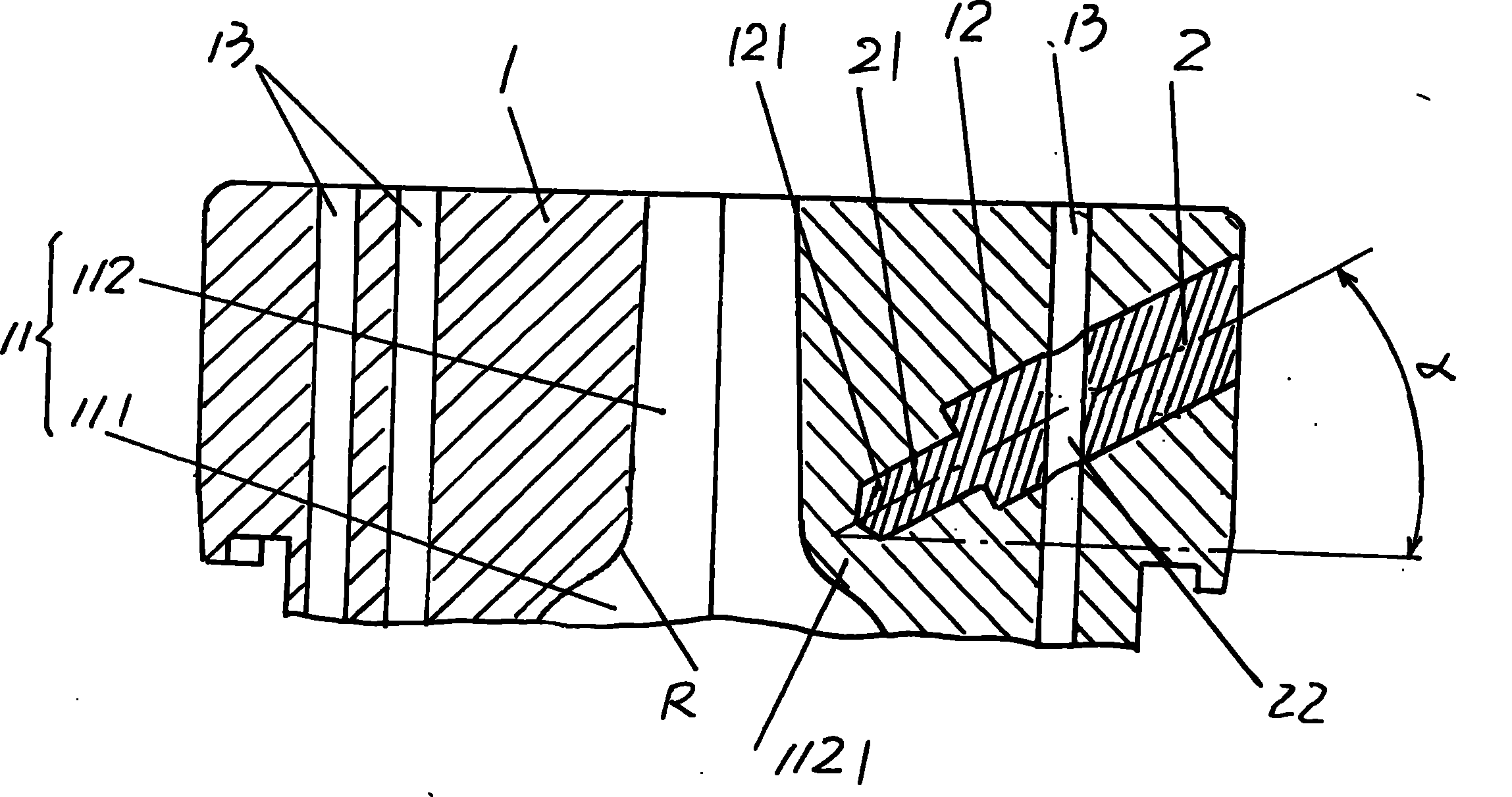

Mold for preparing glass container

The invention relates to a mold for preparing a glass container, and belongs to the technical field of glass mold. The mold comprises a pair of bottle half-molds, wherein the bottle half-molds are arranged relatively. Each bottle half-mold is provided with a bottle half-mold cavity and axial vent holes, wherein the axial vent holes are axially parallel to the bottle half-mold cavity, and are communicated with the outside environment. The mold is characterized in that: each bottle half-mold is further provided with radial vent holes adopted as channels, wherein the bottle half-mold cavity and the axial vent holes are communicated through the channels. The radial vent holes are arranged around neck regions and shoulder regions of the bottle half-molds, and have plural columns, wherein the plural columns are arranged separatedly. Each column has plural radial vent holes, wherein the plural radial vent holes are arranged separatedly. A valve core is fixedly arranged on a hole opening position of each radial vent hole, wherein the center of the valve core is provided with a core hole, the hole opening position of the radial vent hole is toward the bottle half-mold cavity. The mold has the following advantages that: the uniformity effects of the wall thicknesses of the neck region and the shoulder region can be ensured; the overall structure is simple, the mold is easy to manufacture and install; the valve core is not easily be blocked.

Owner:CHANGSHU JIANHUA MOLD TECH

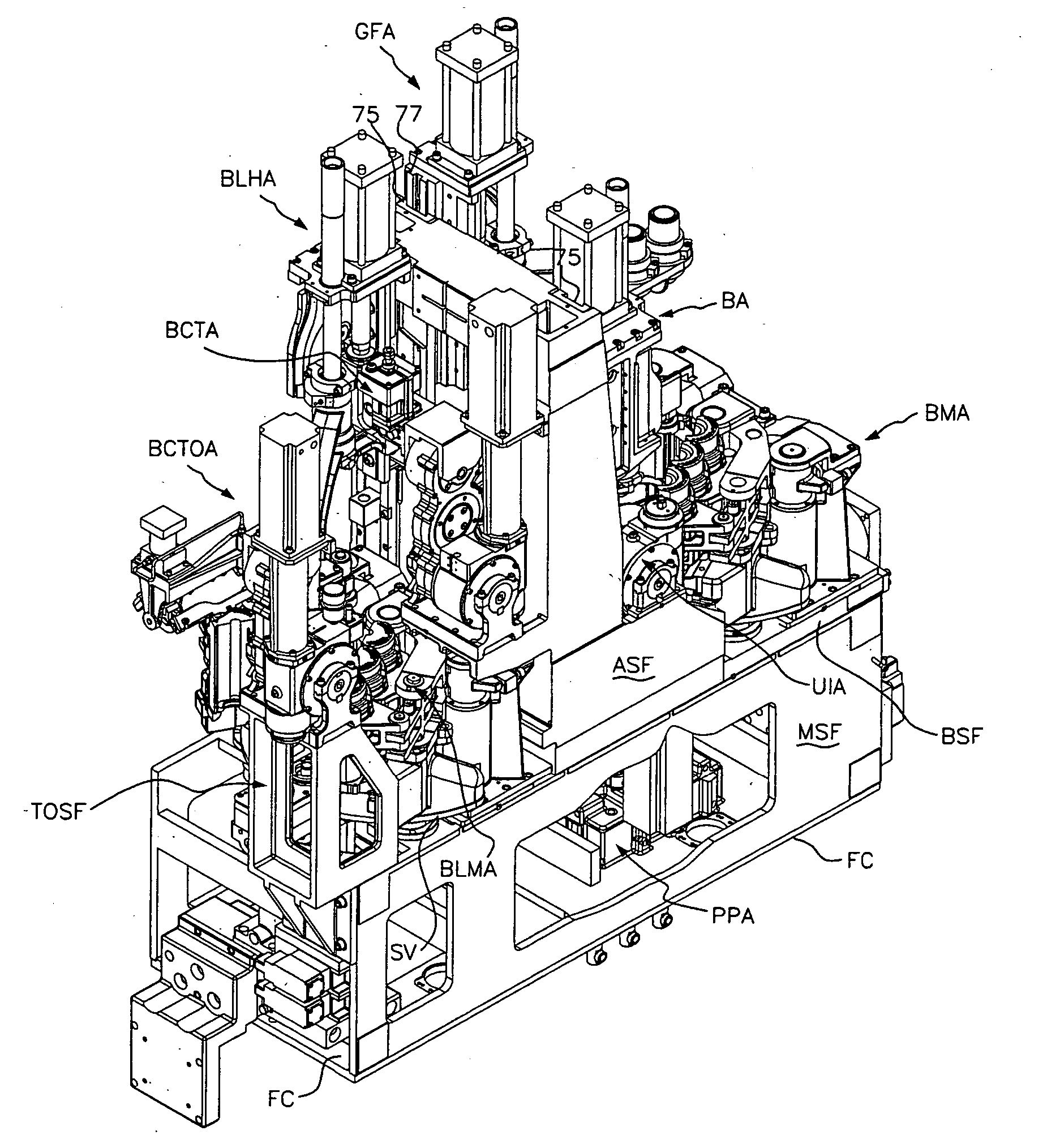

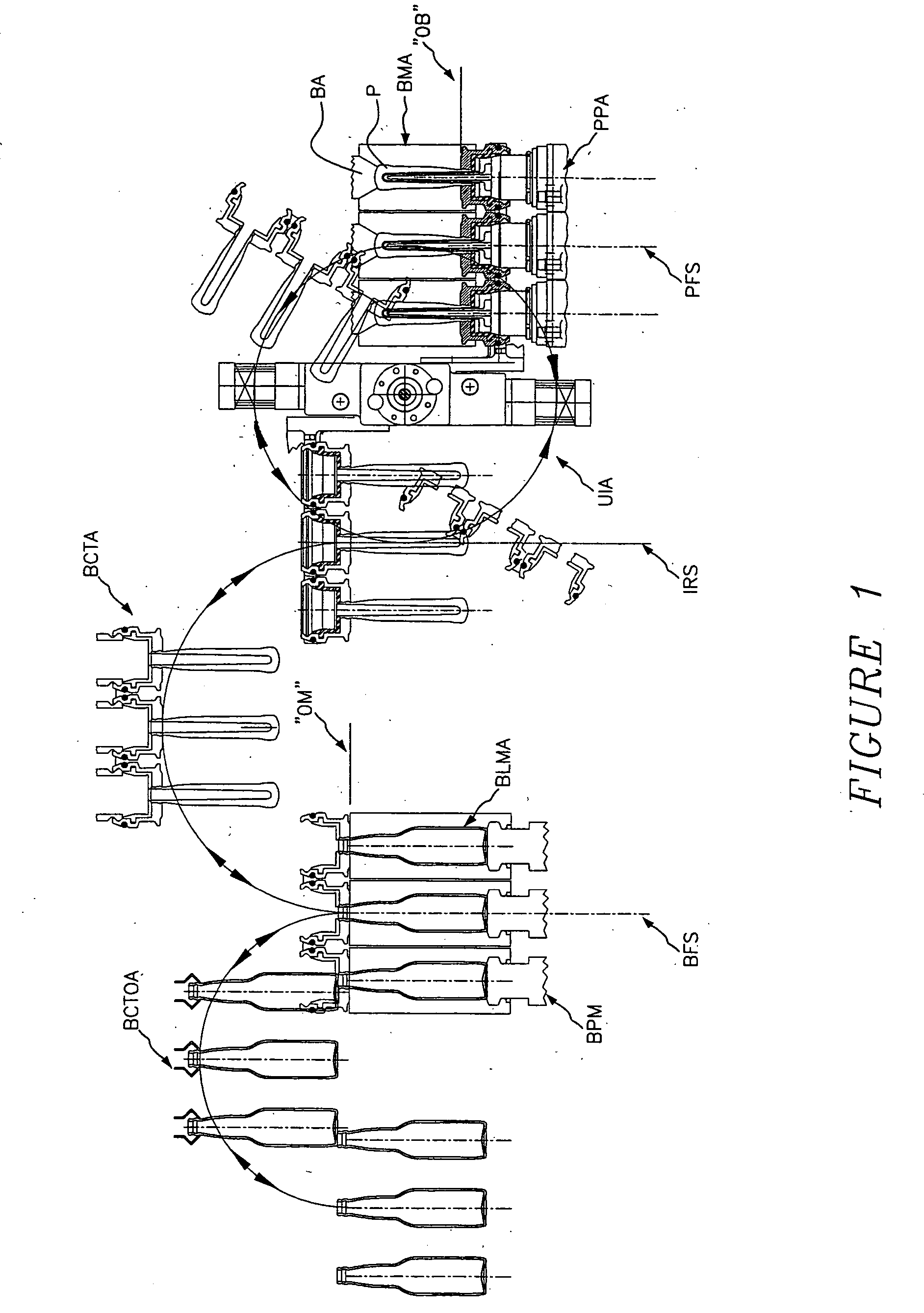

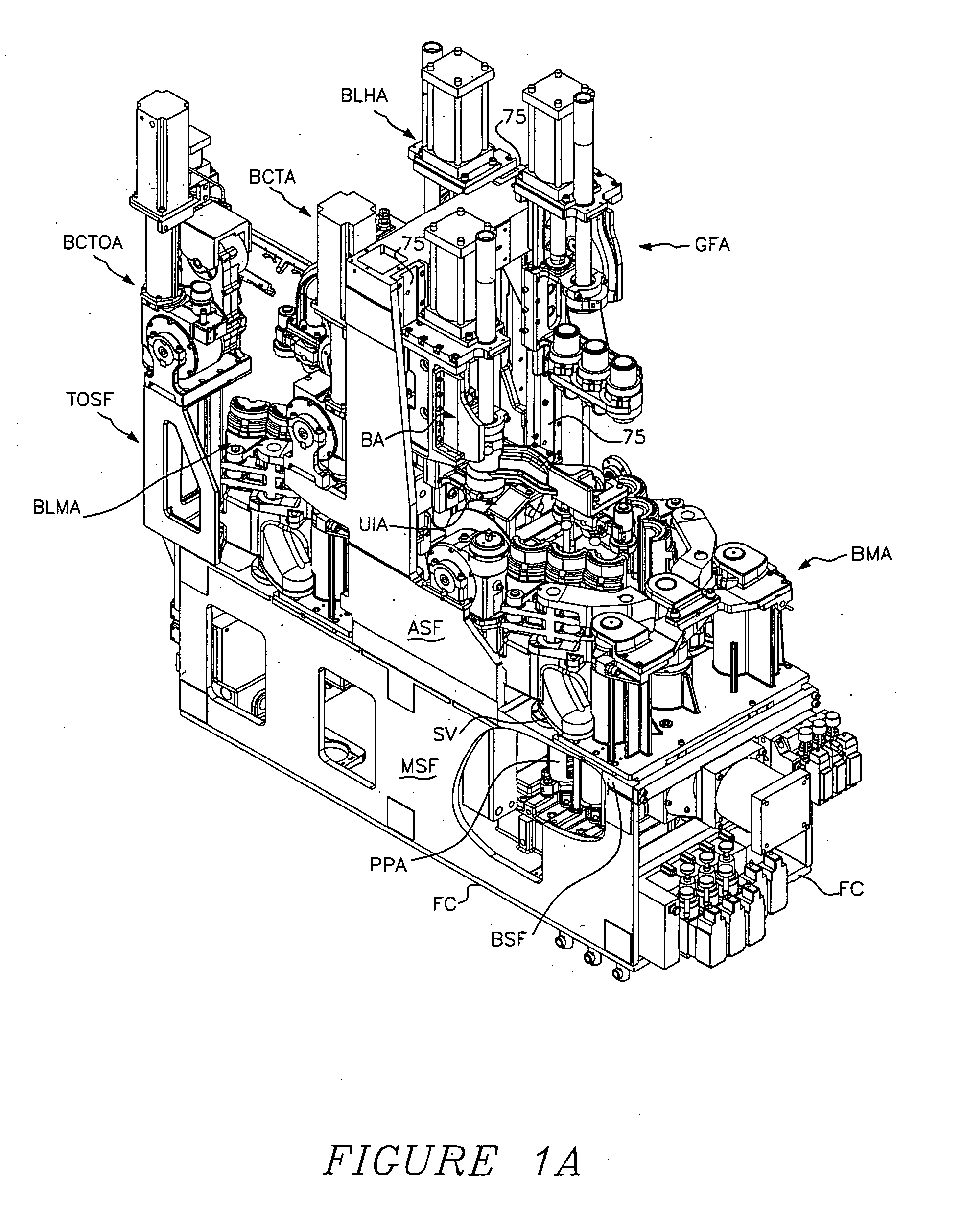

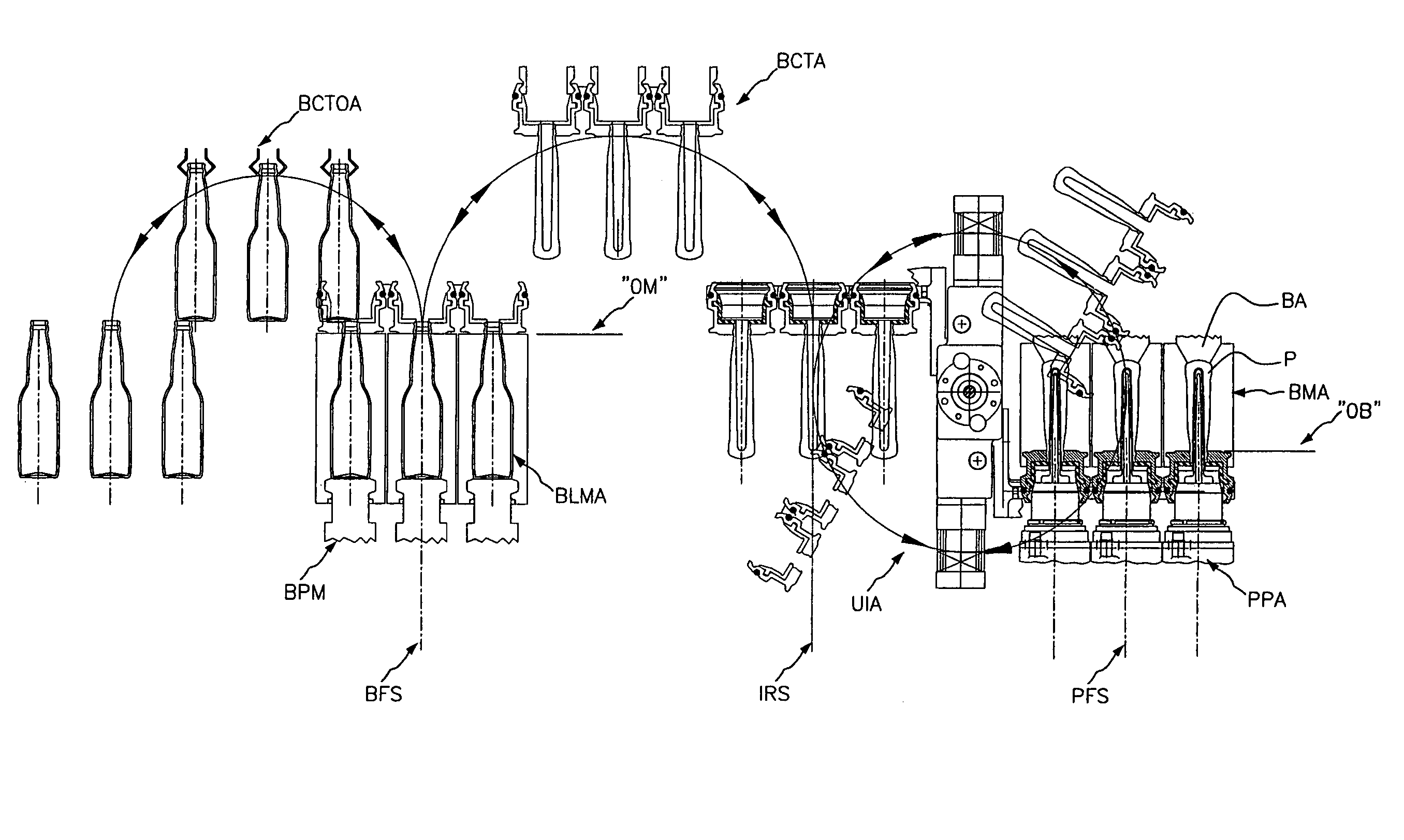

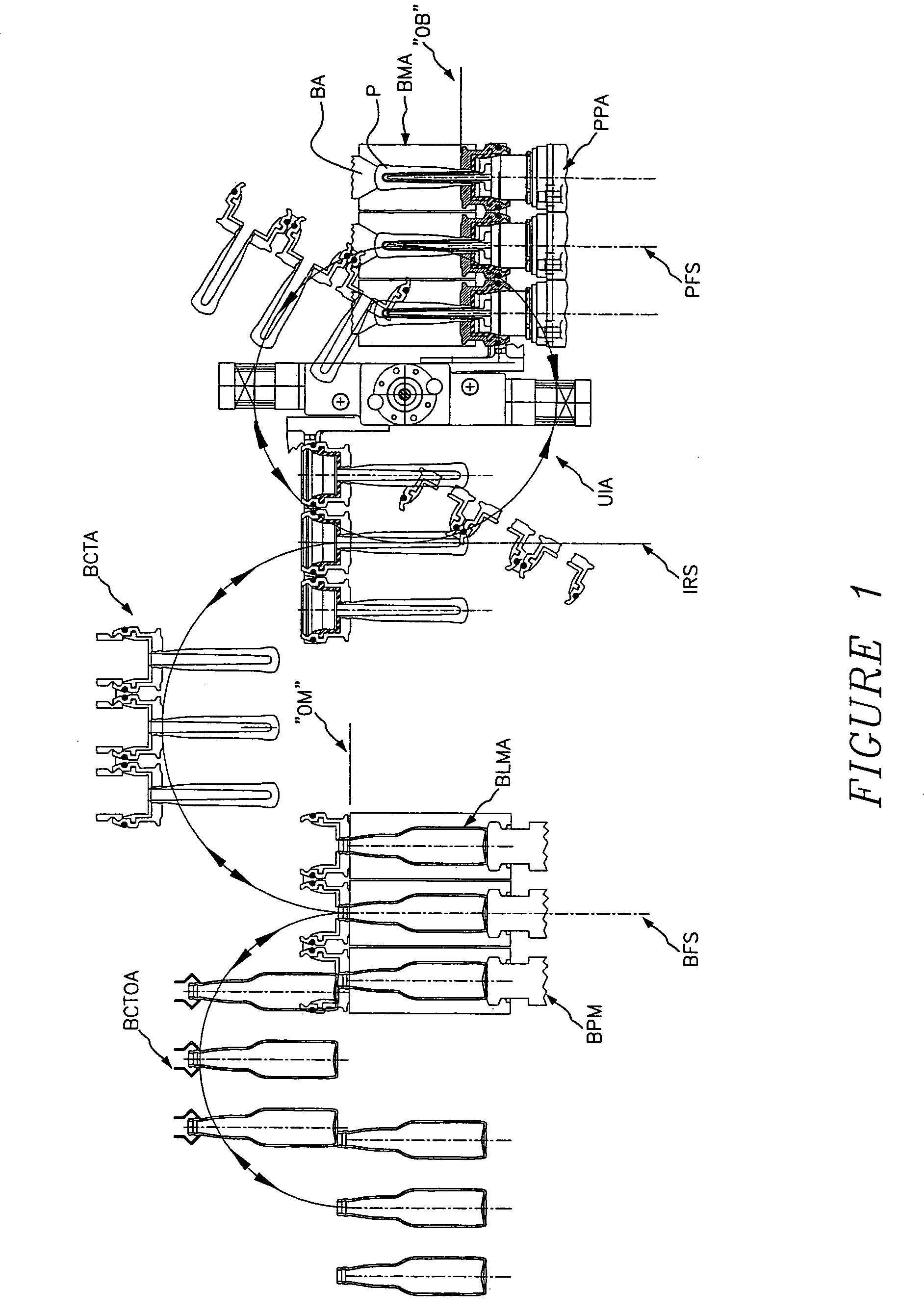

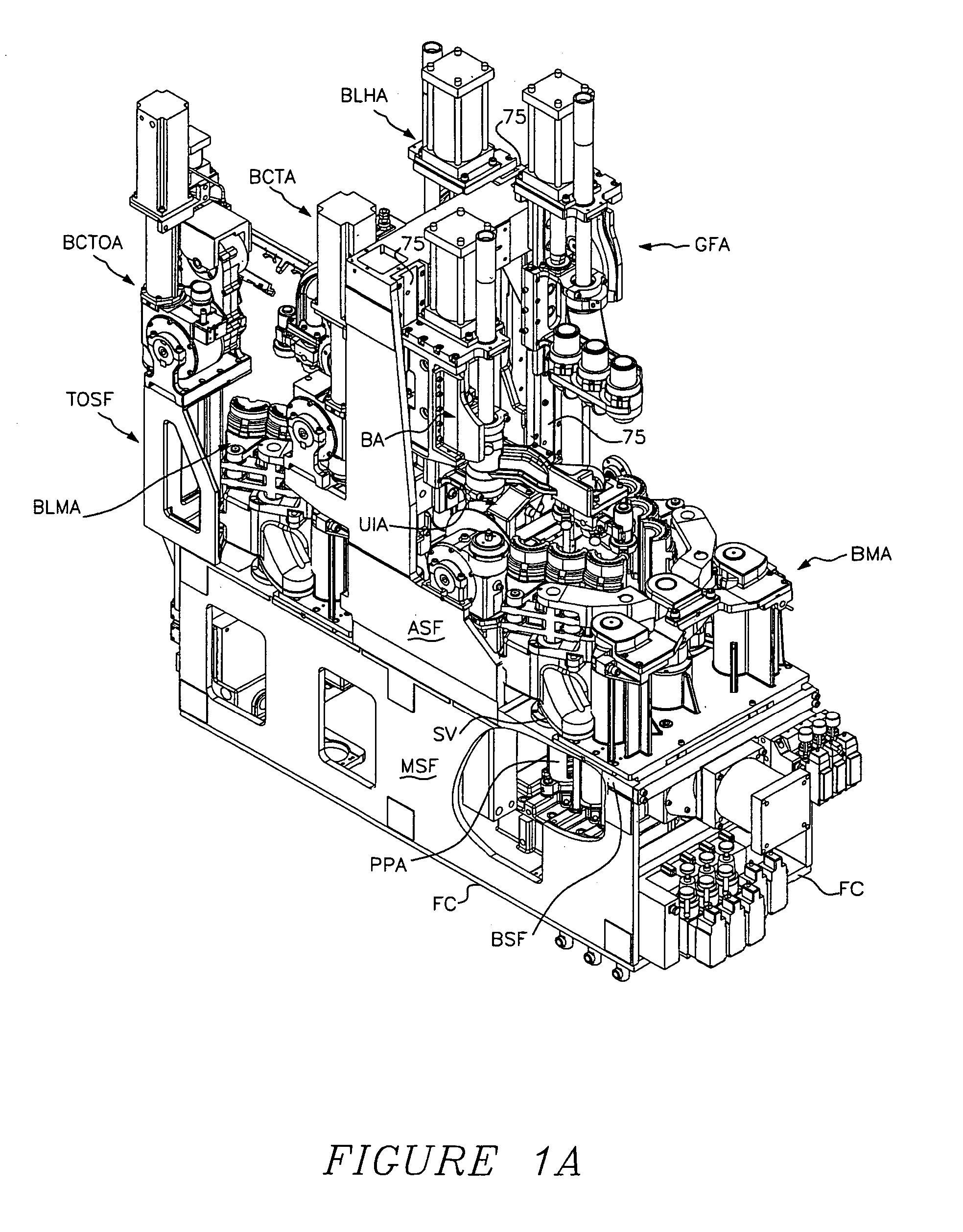

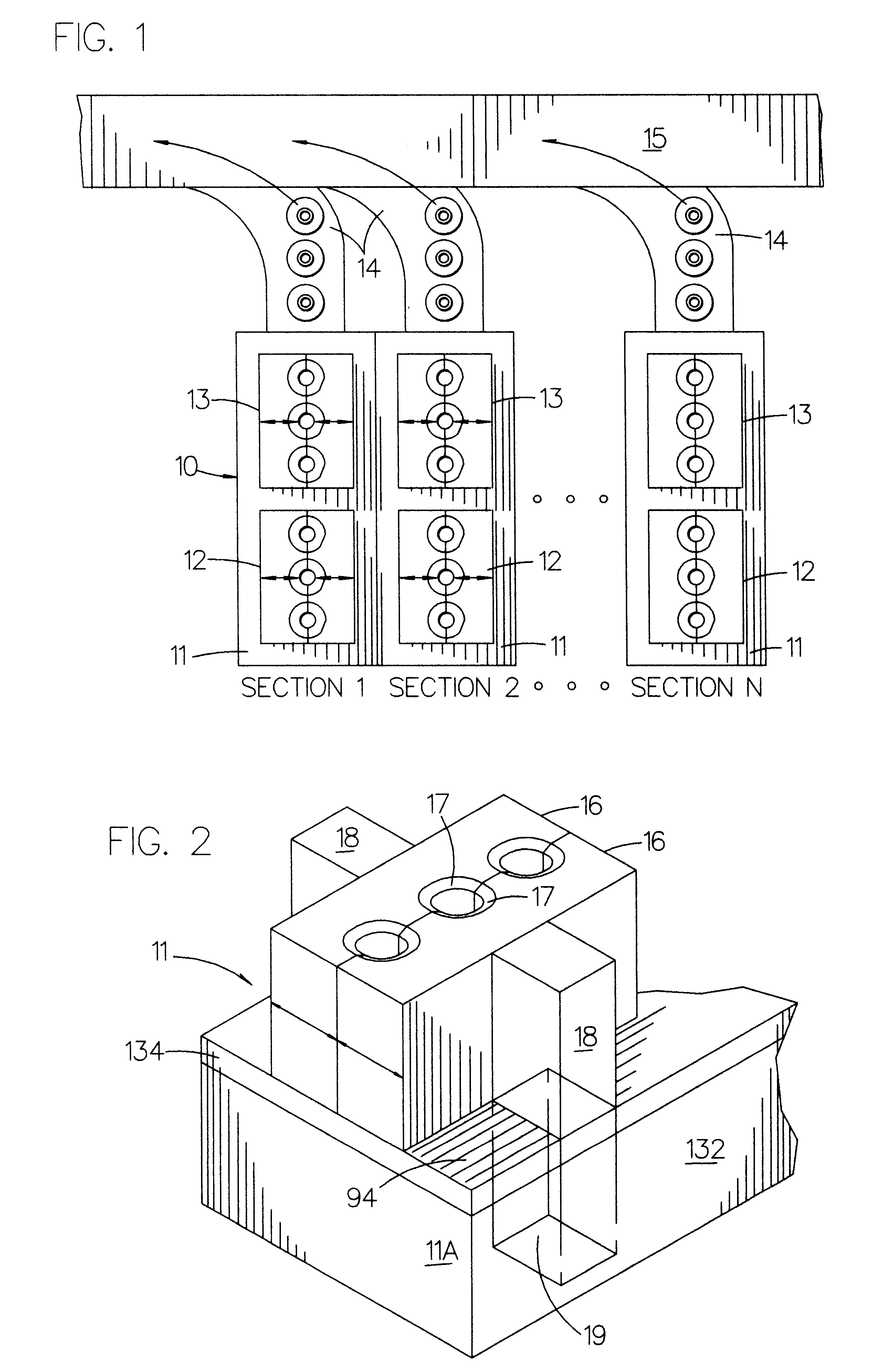

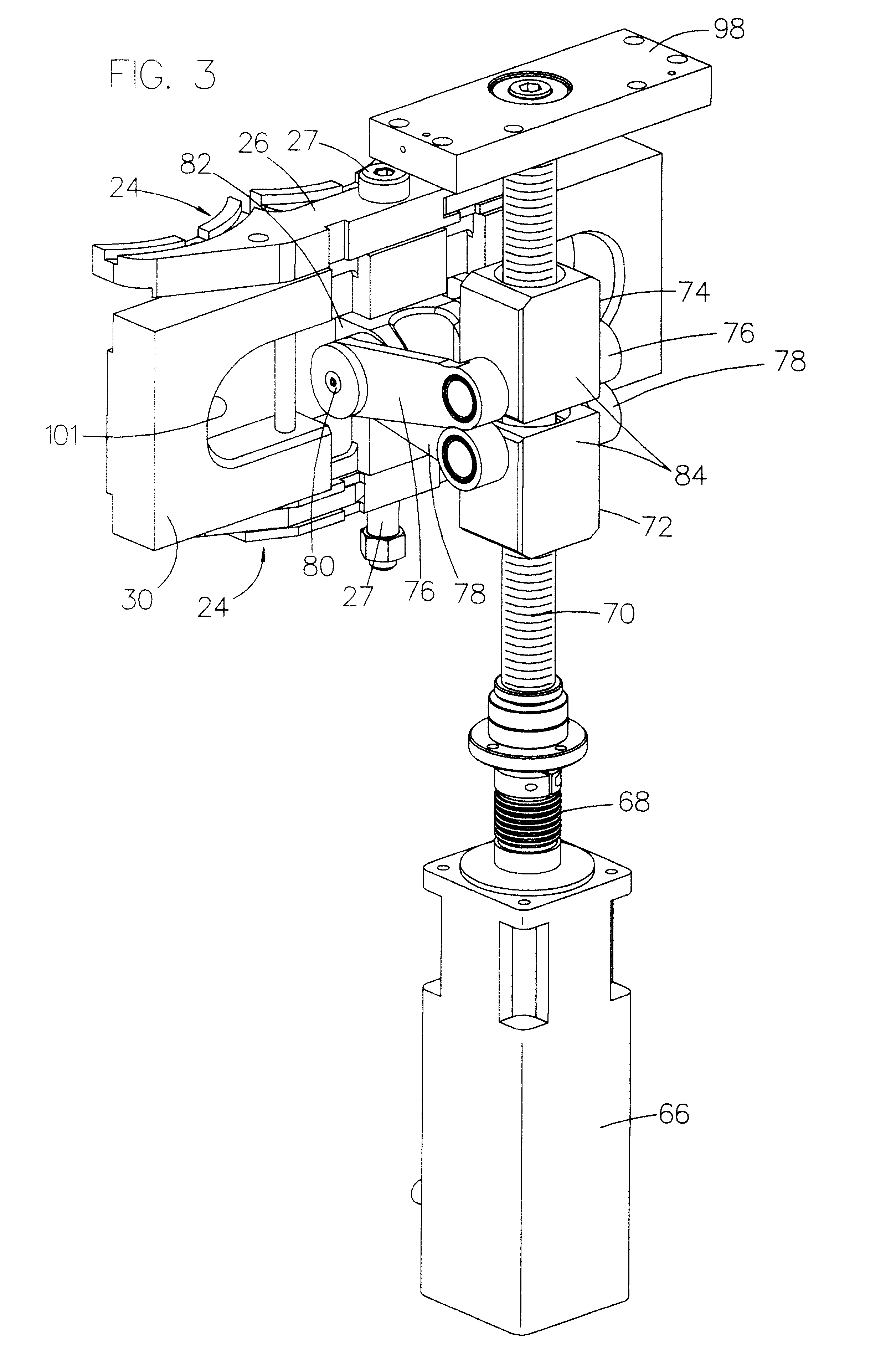

Method and a machine for the production of hollow glassware articles

InactiveUS20050235697A1Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusMolding machineGlass vessel

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO SAB DE CV

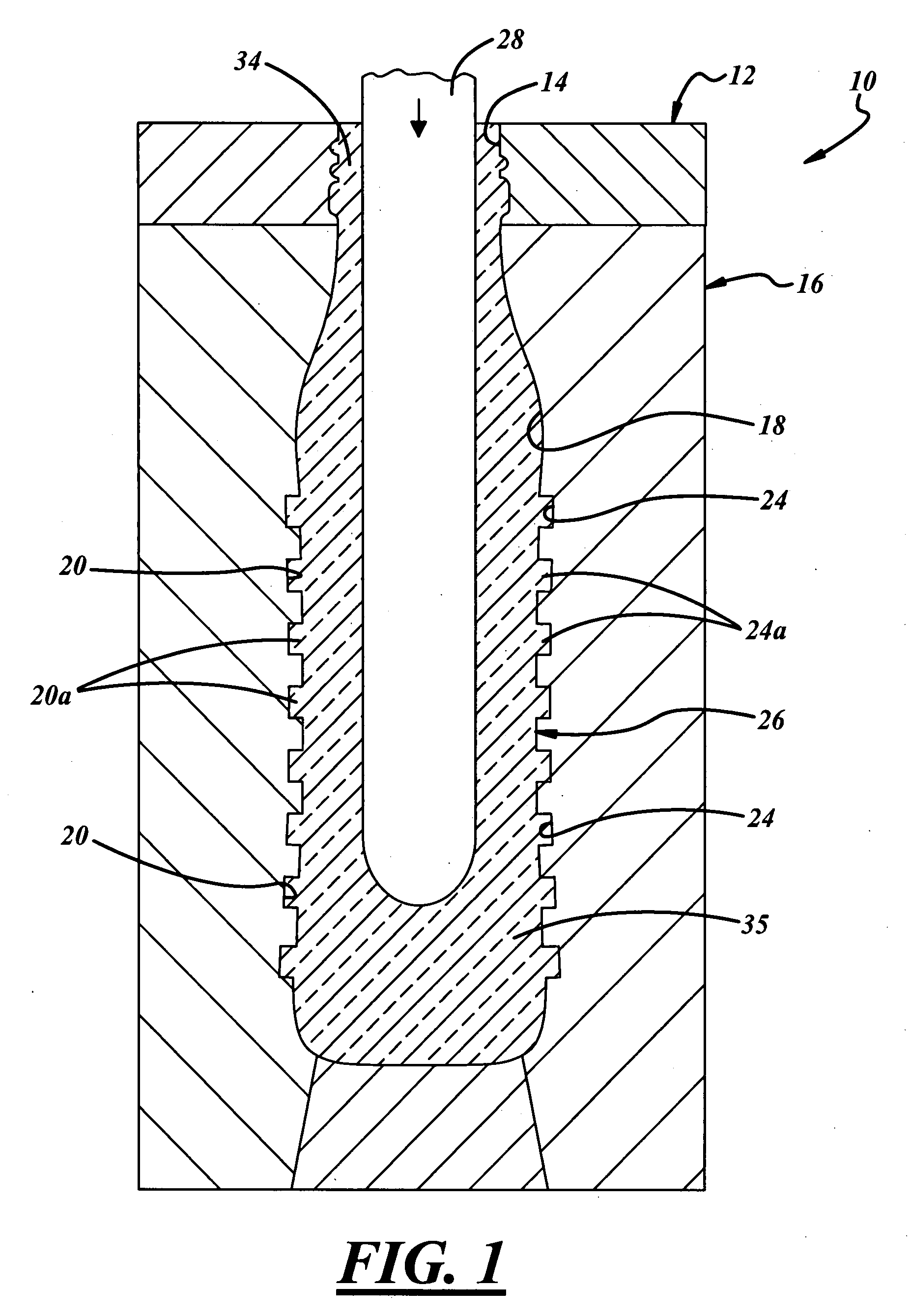

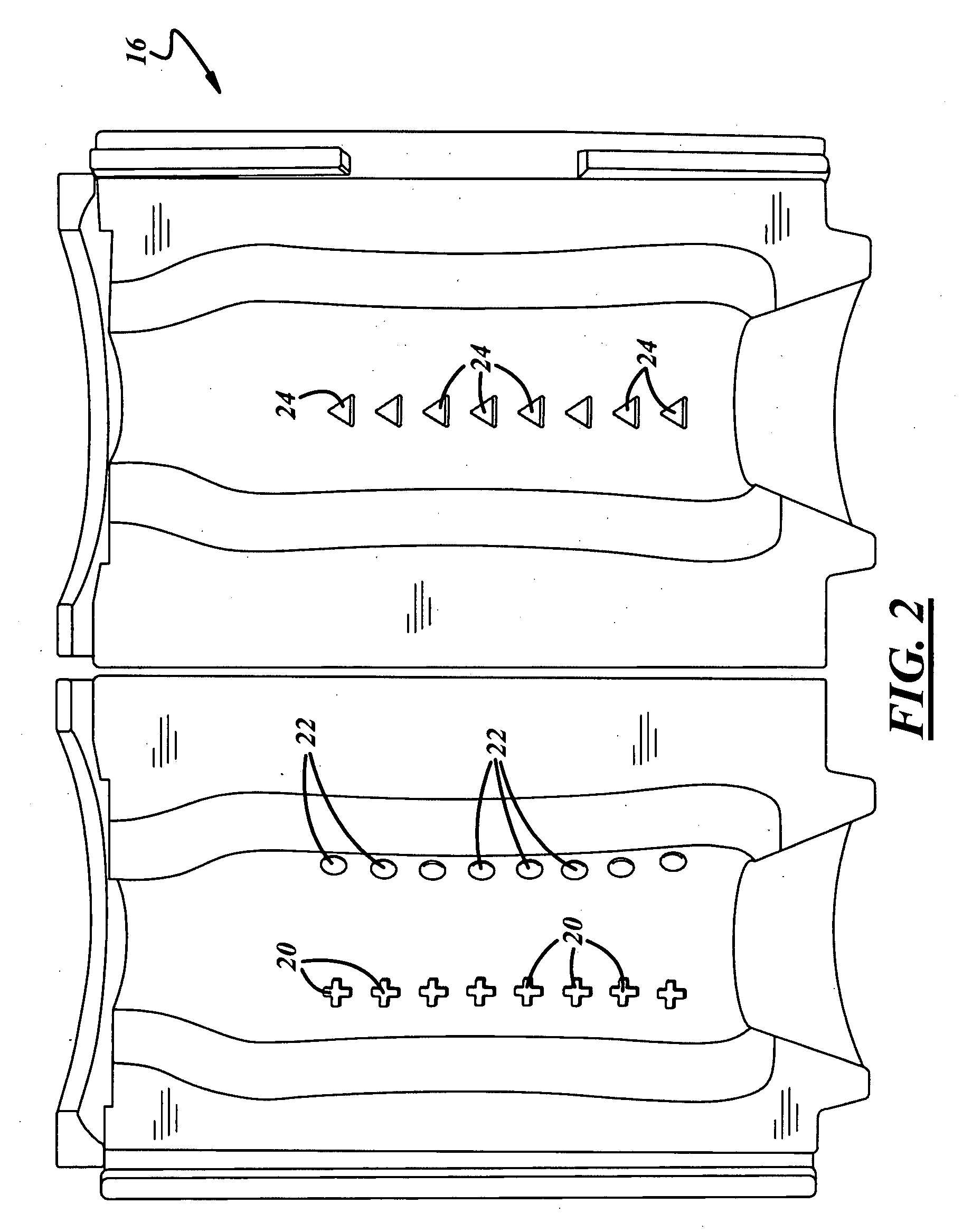

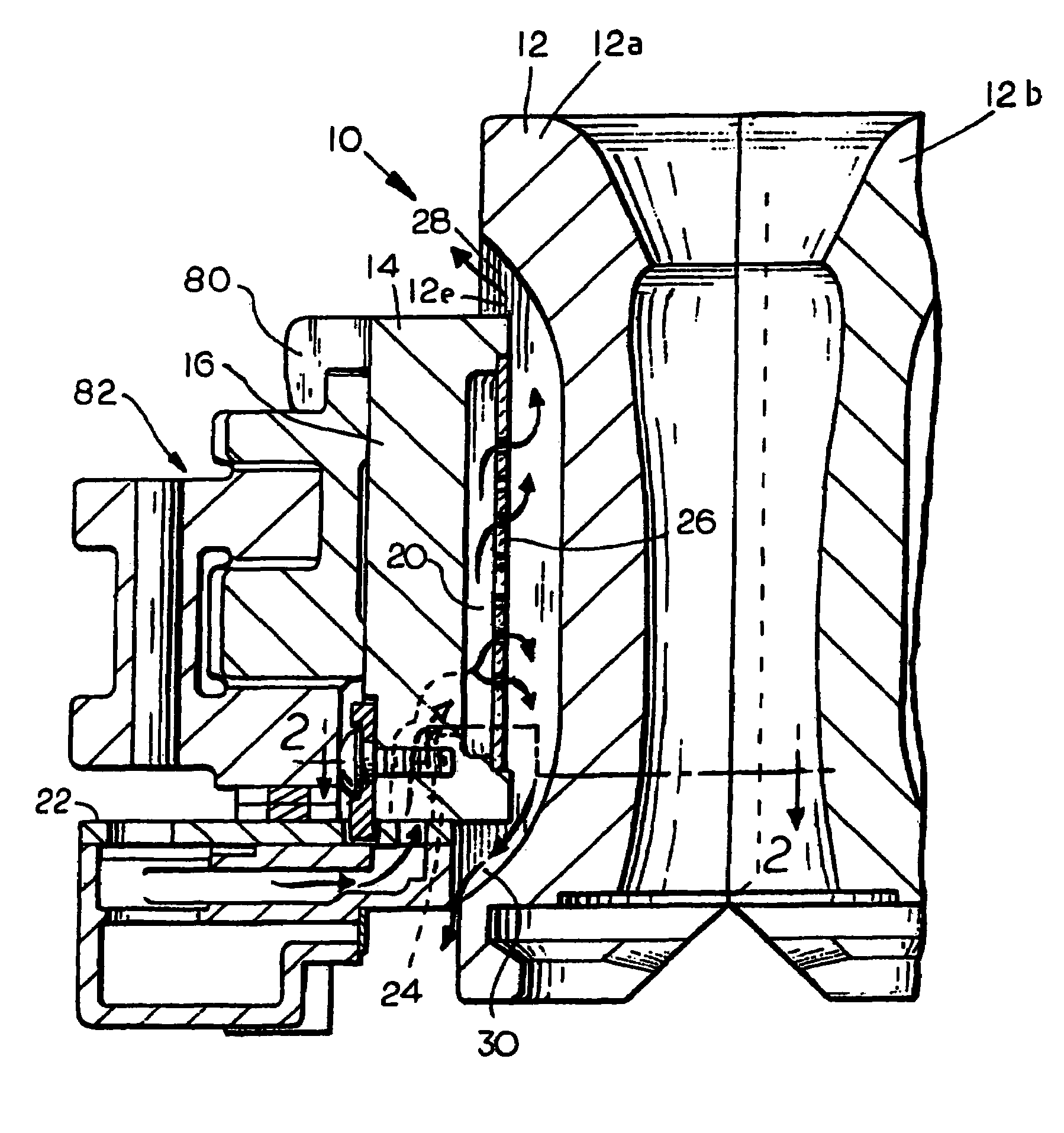

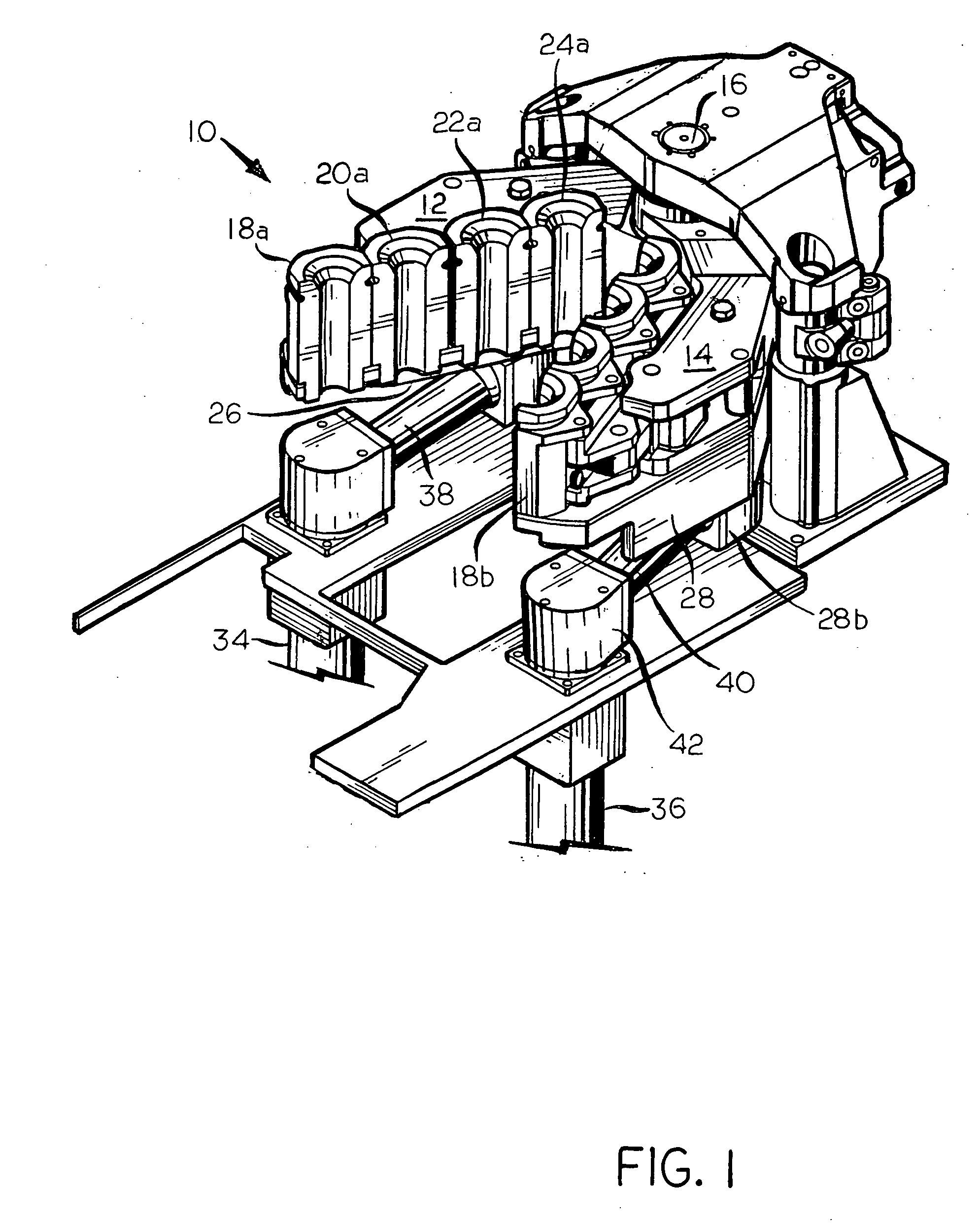

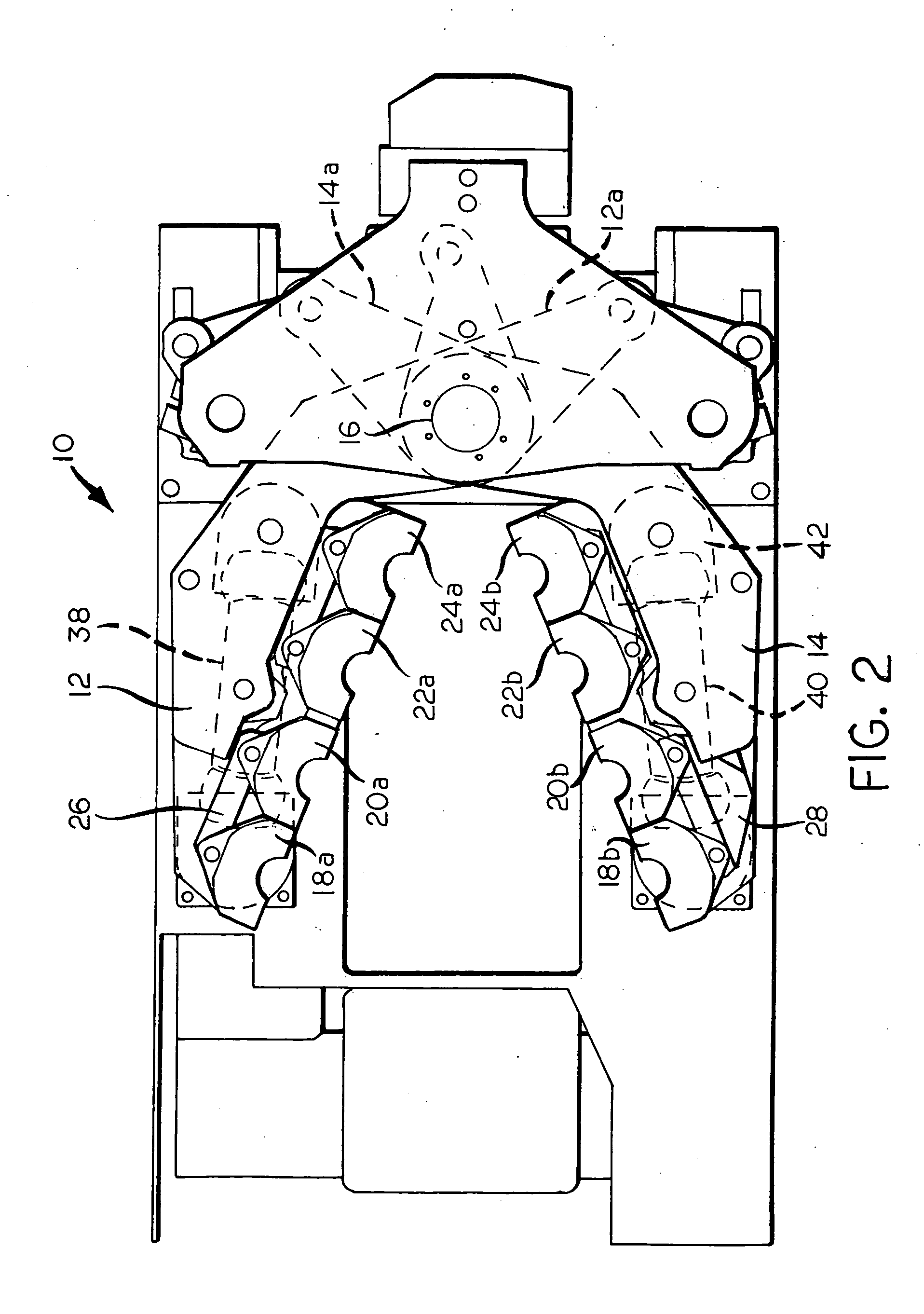

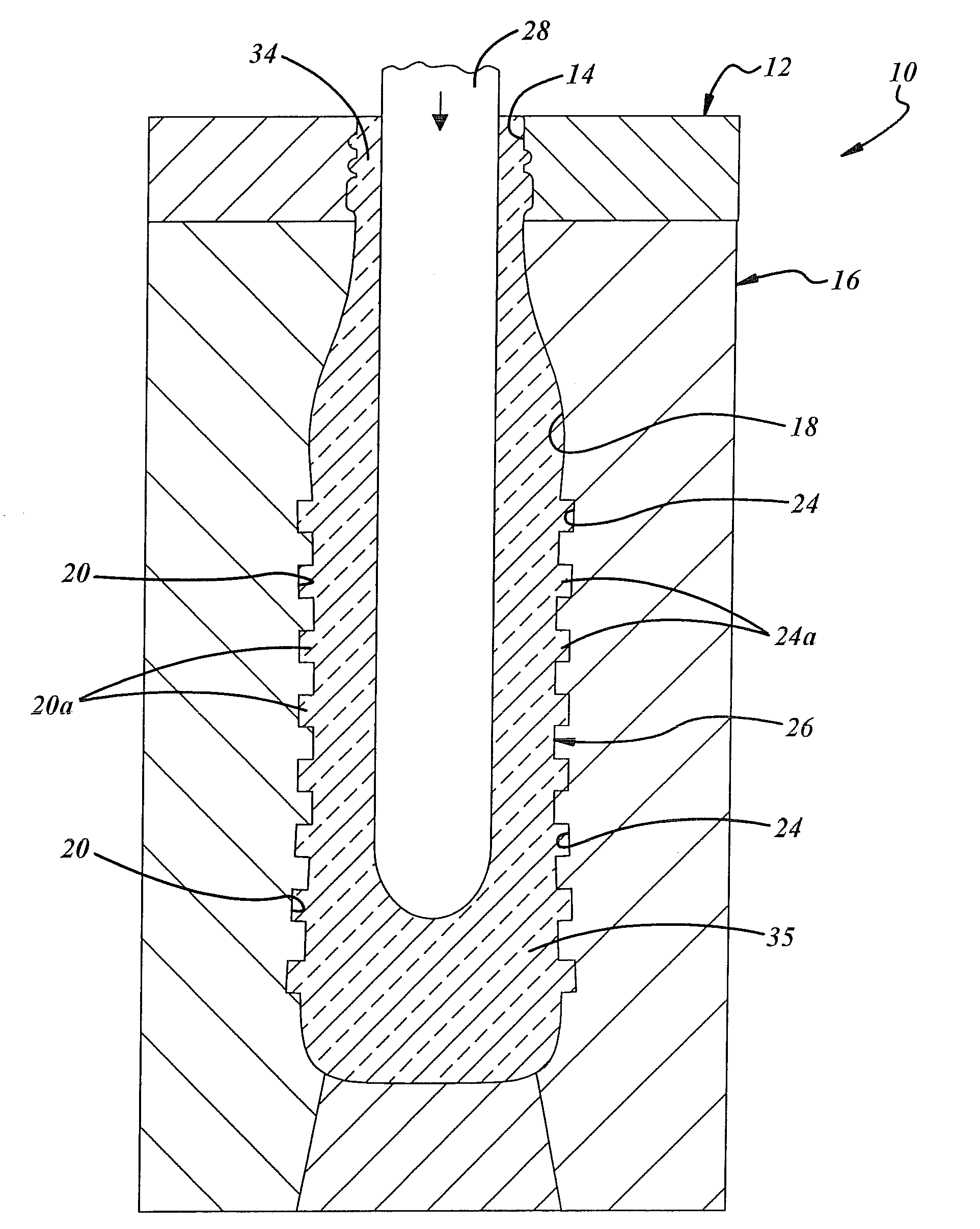

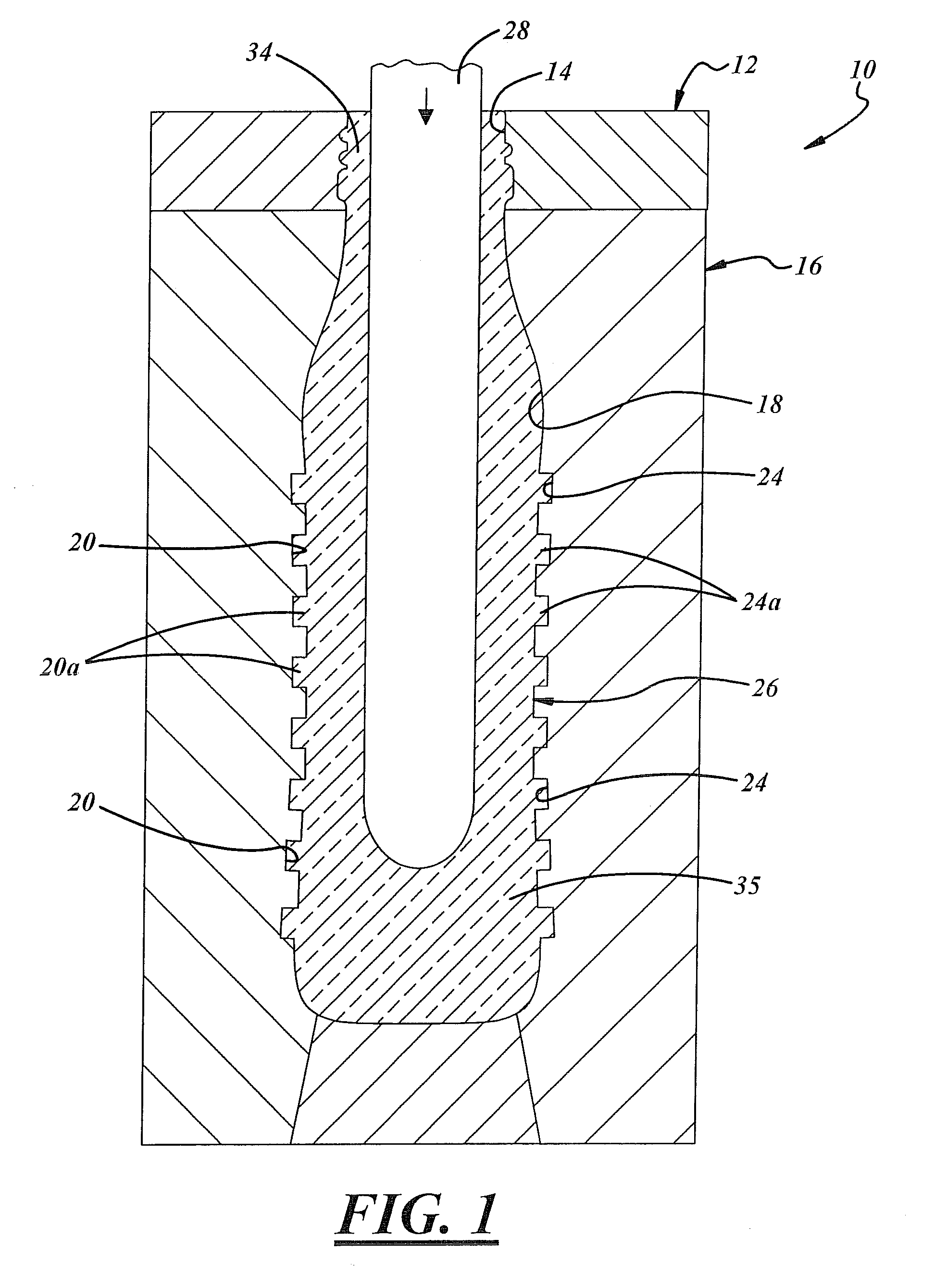

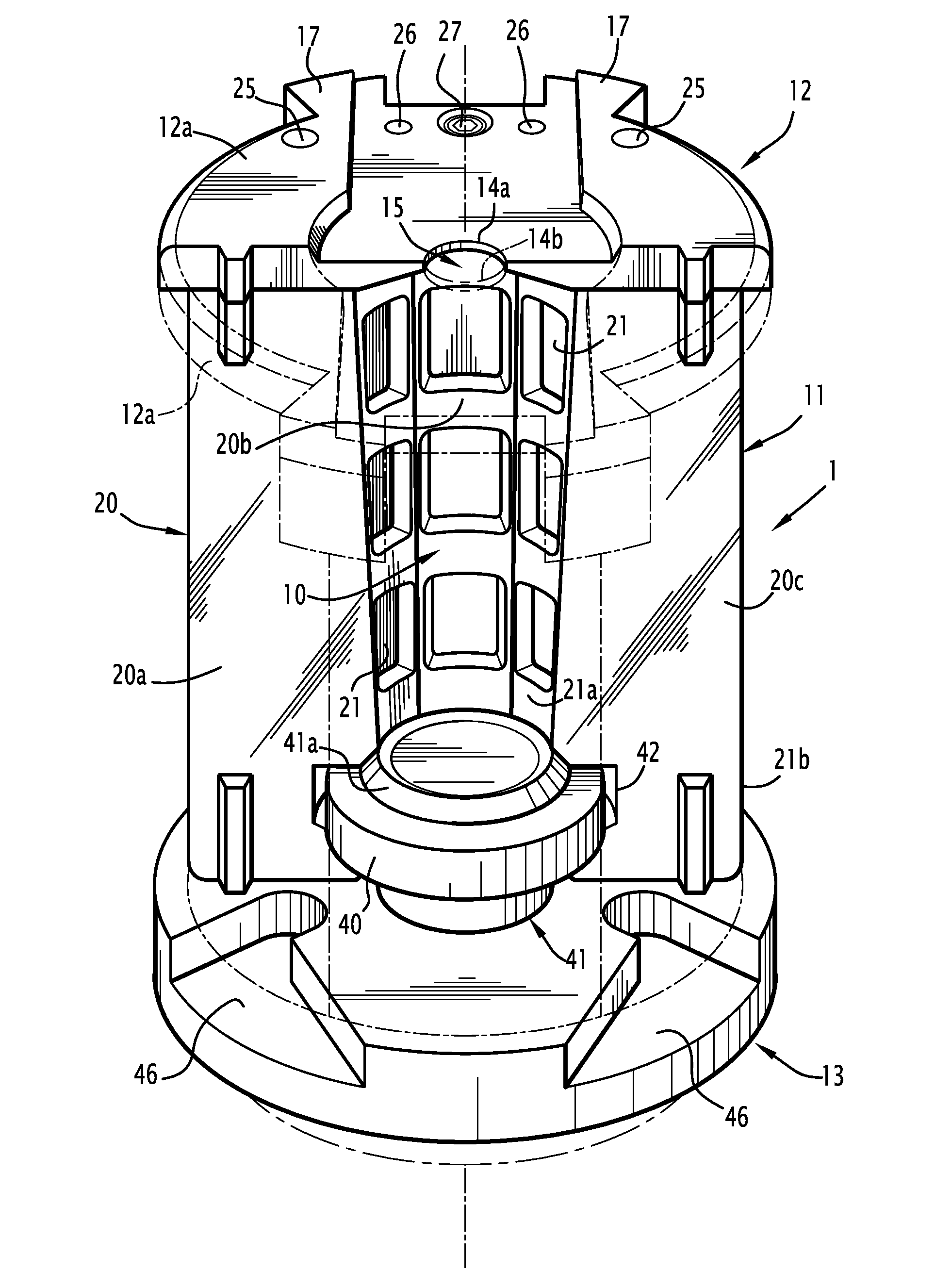

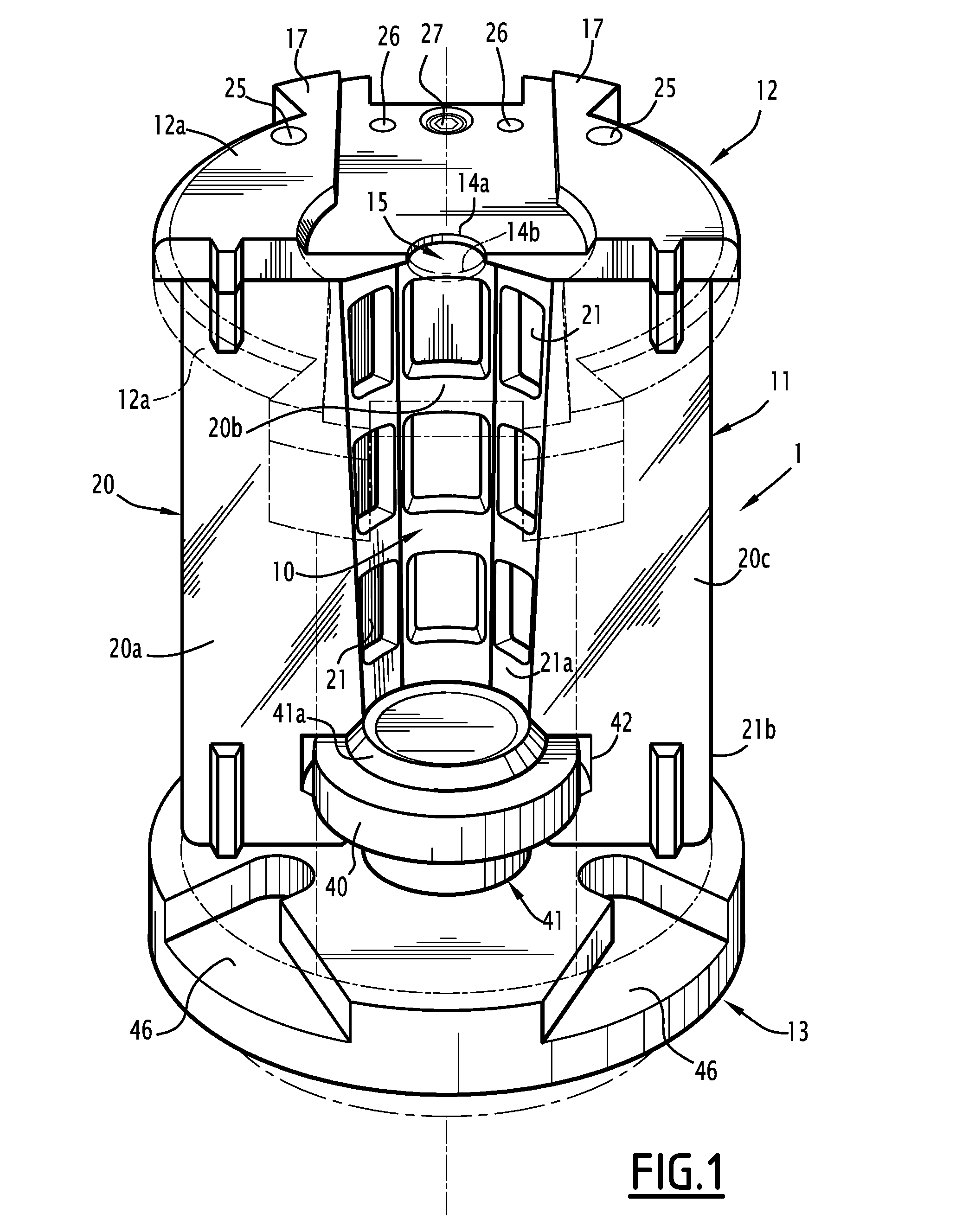

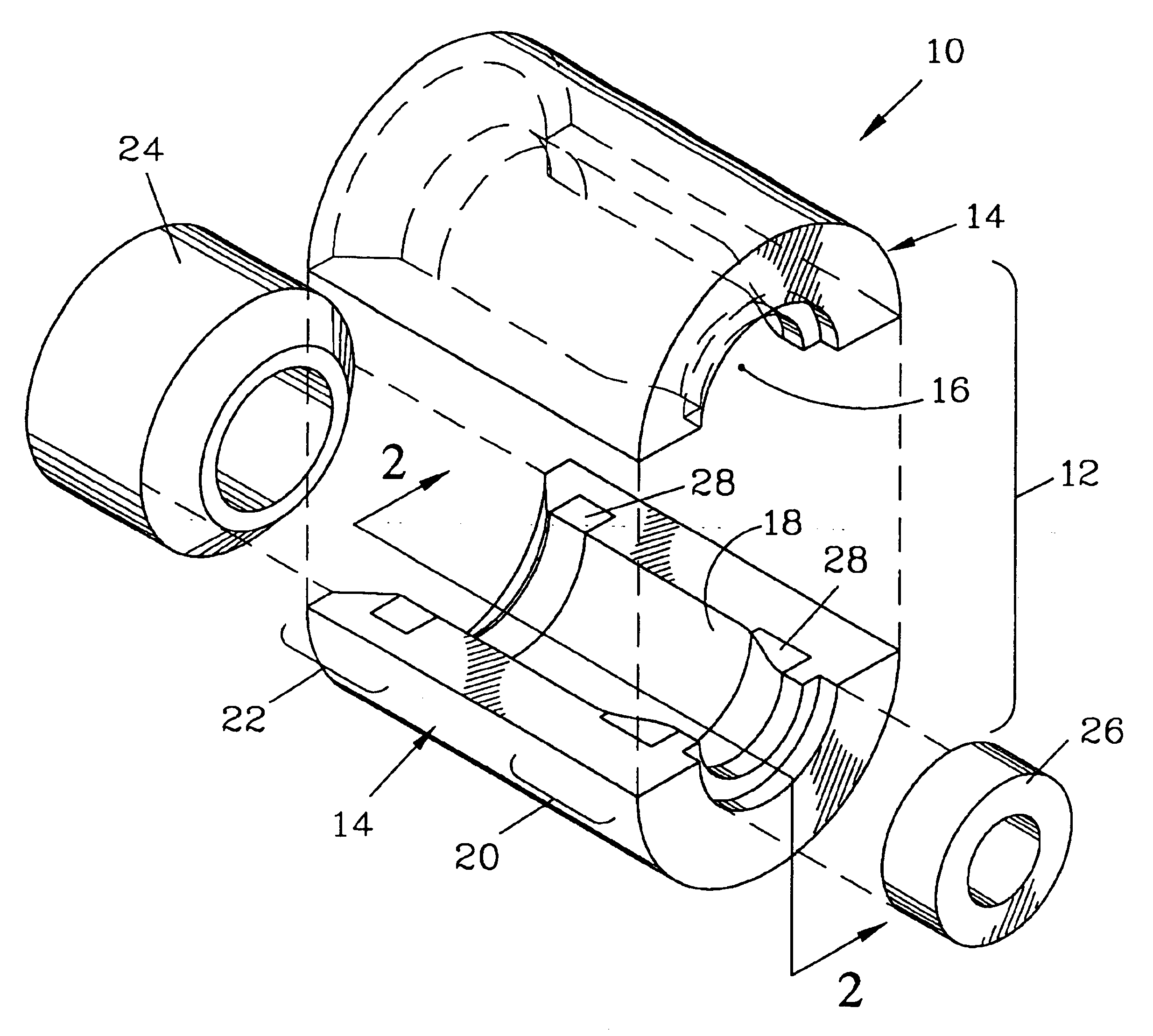

Mold assembly for glass articles

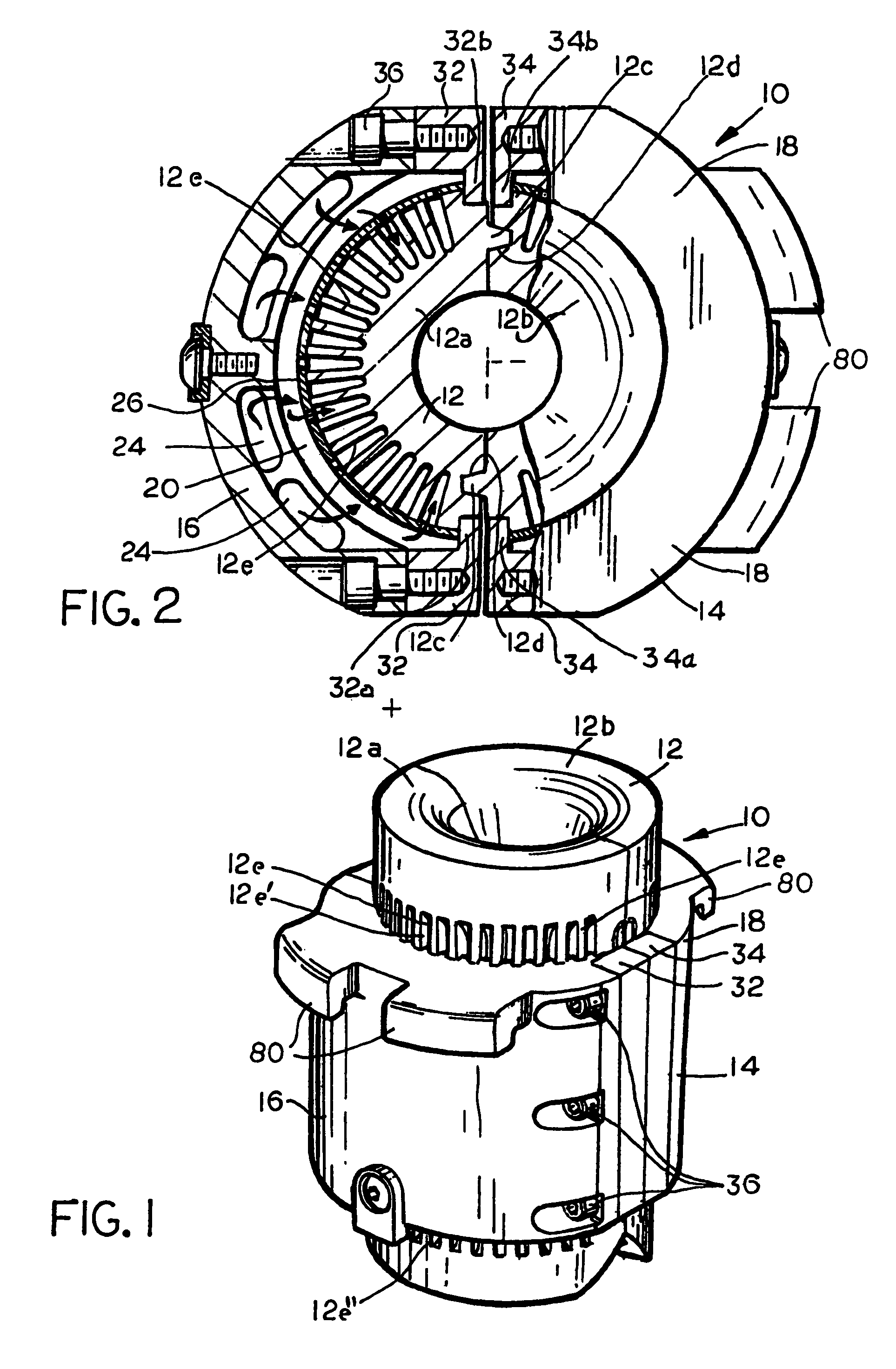

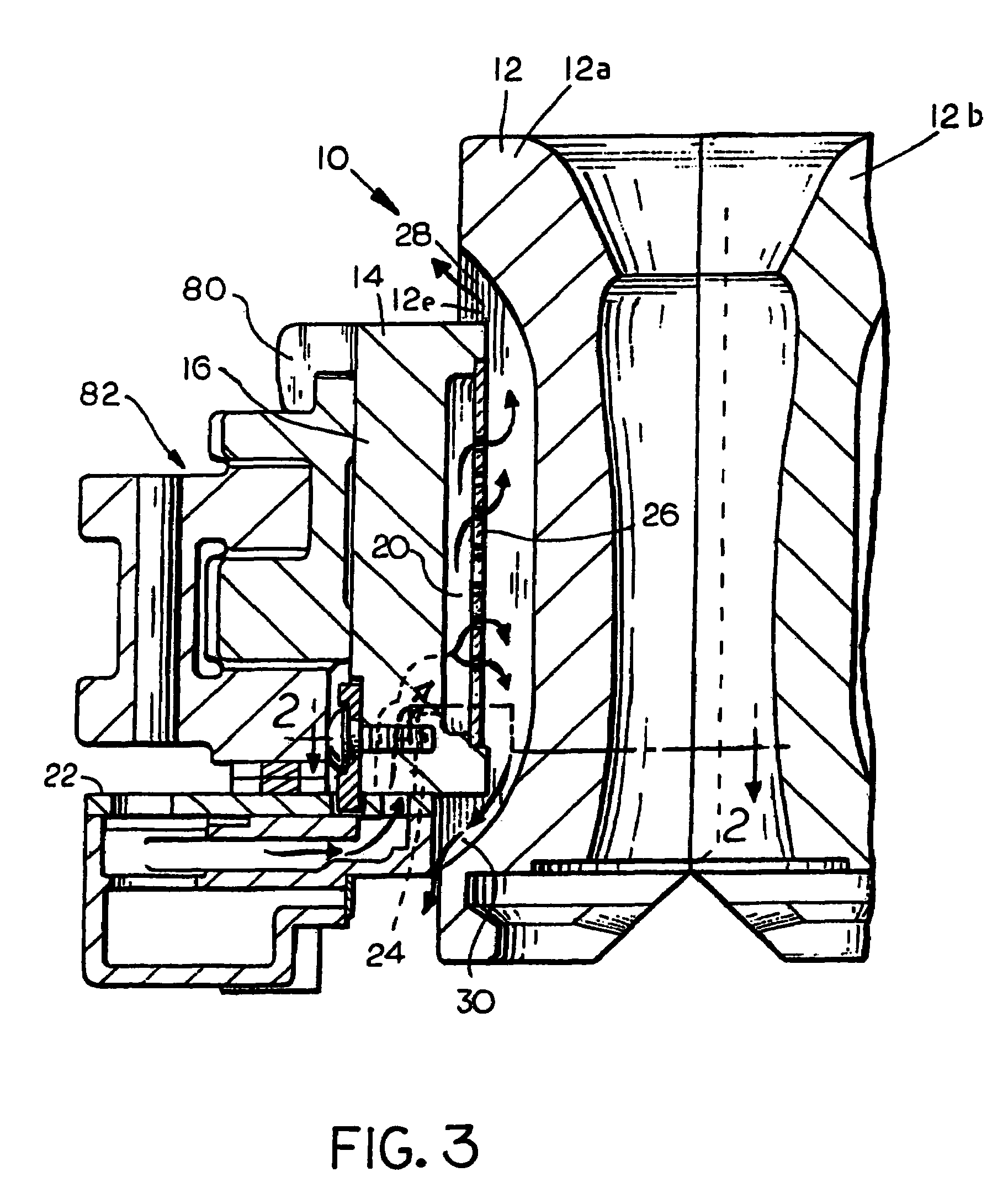

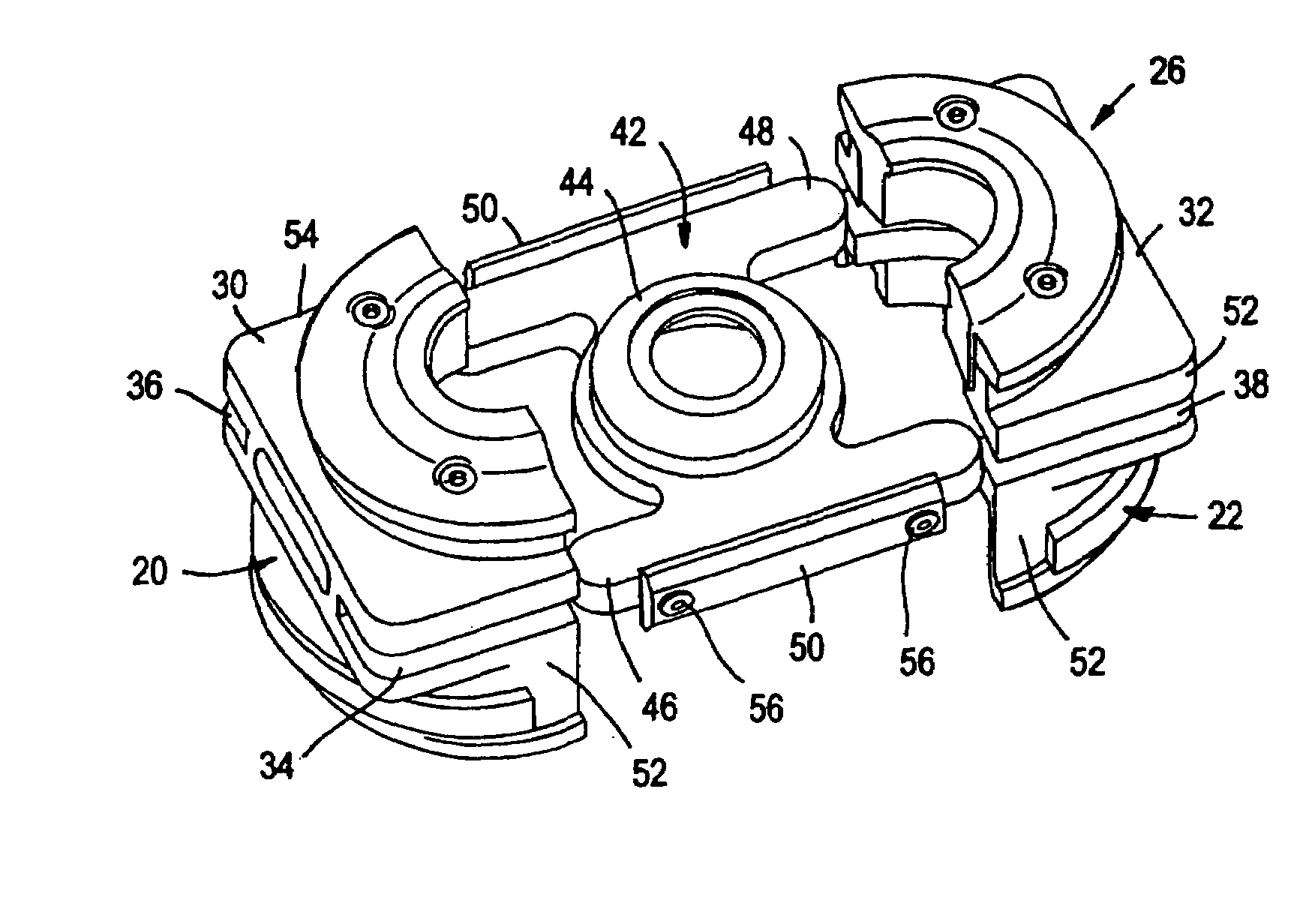

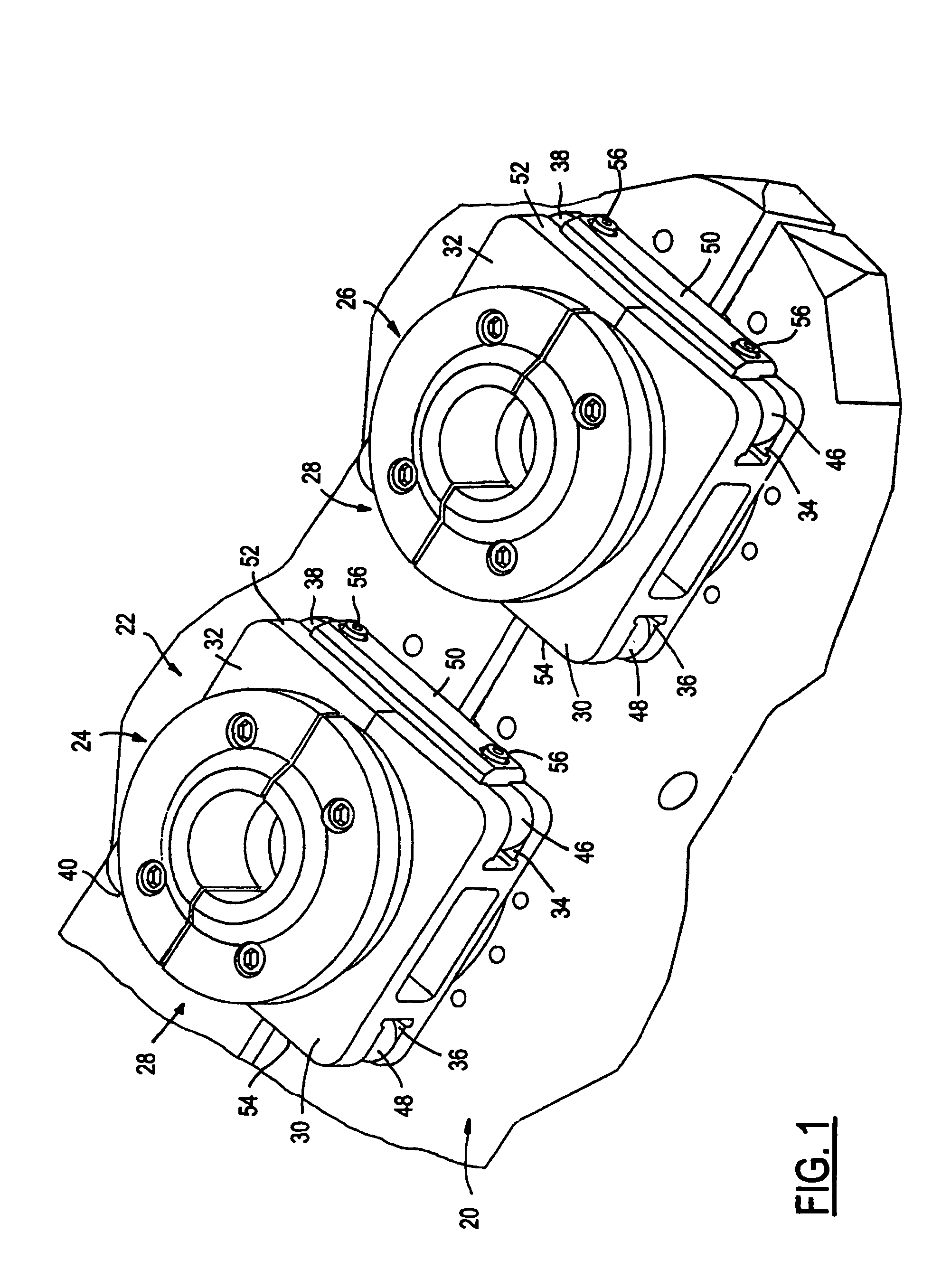

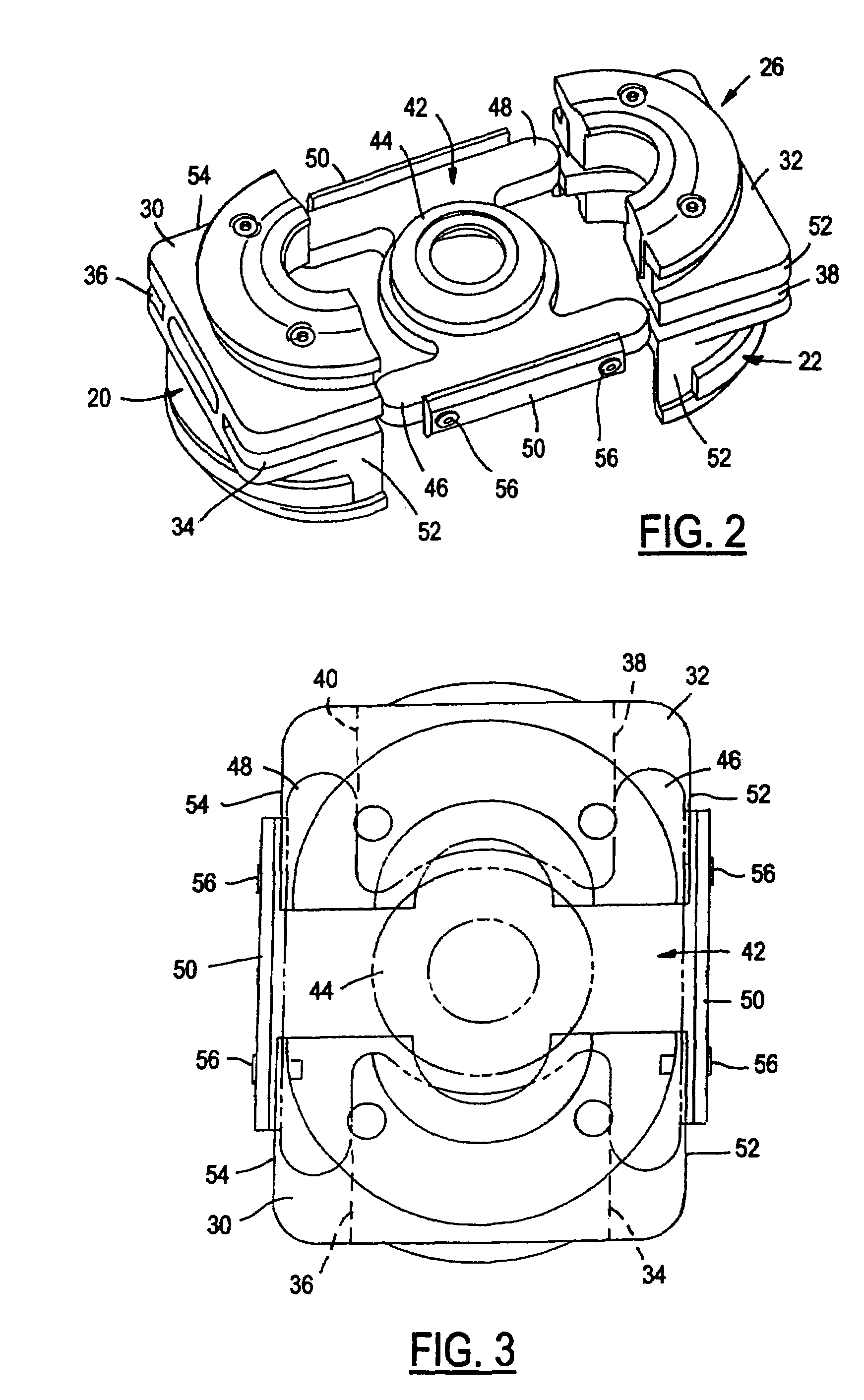

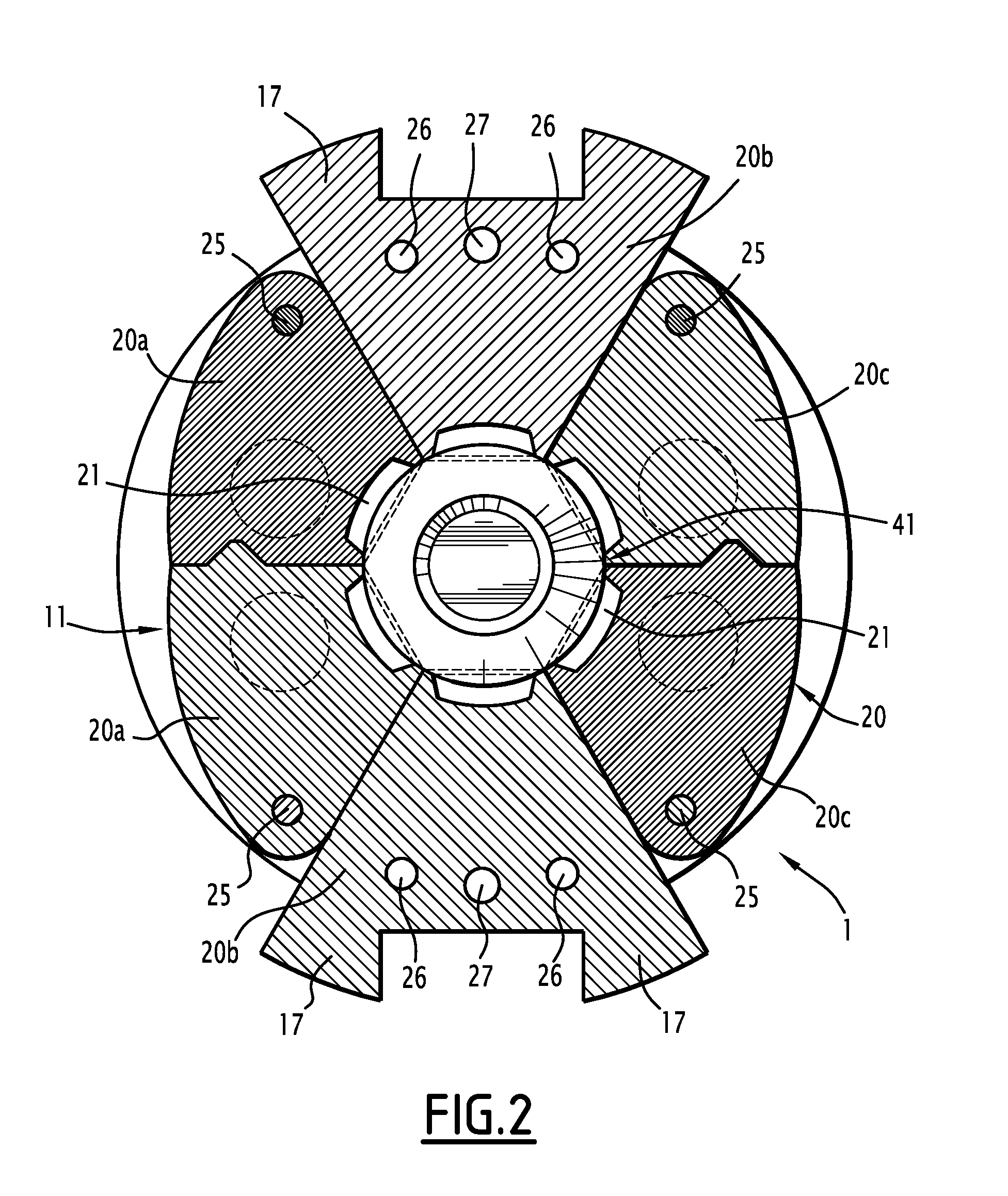

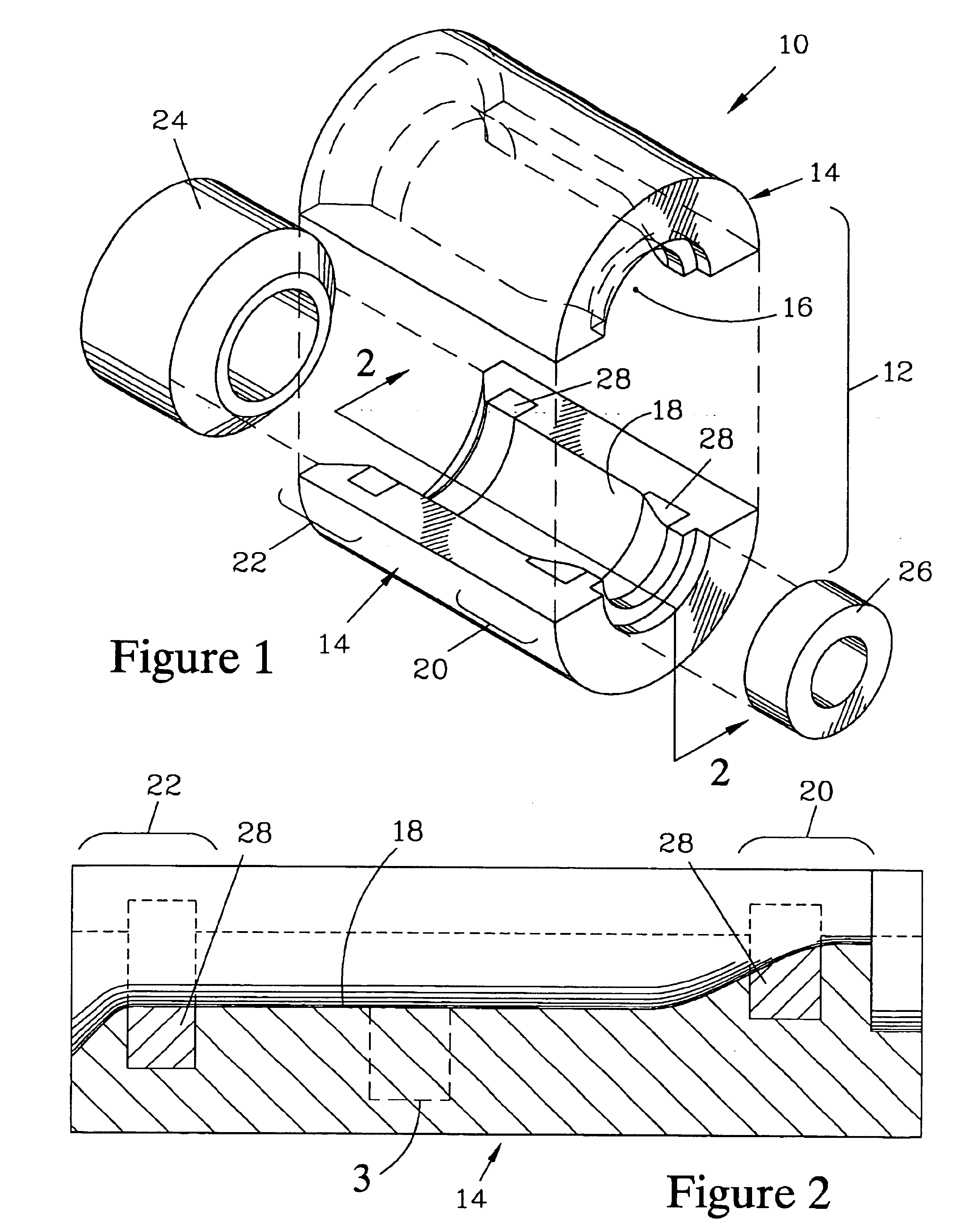

InactiveUS7698907B1Increase ratingsReduce manufacturing costGlass drawing apparatusGlass transportation apparatusMaterials scienceAxial length

A mold assembly (10; 40) for molding a hollow glass article comprising a mold (12) that is made up of a separable pair of mold elements (12a, 12b; 42) and a mold holder (14; 44) that surrounds a portion of the mold of substantial axial length. The mold is separable from the mold holder, and the exterior of each mold segment is provided with a plurality of cooling fins (12e; 42e). The mold holder is made up of a separable pair of mold holder sections (16, 18; 46), and each mold holder section has a fluid flow passage (20; 50) extending therethrough. The fluid flow passage is radially open to permit fluid flowing therethrough to flow inwardly against the fins of an adjacent mold element. Each mold holder section has a perforated screen (26; 56) affixed thereto to vary the distribution of the flow of fluid from the mold holder section against the fins of the adjacent mold element.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

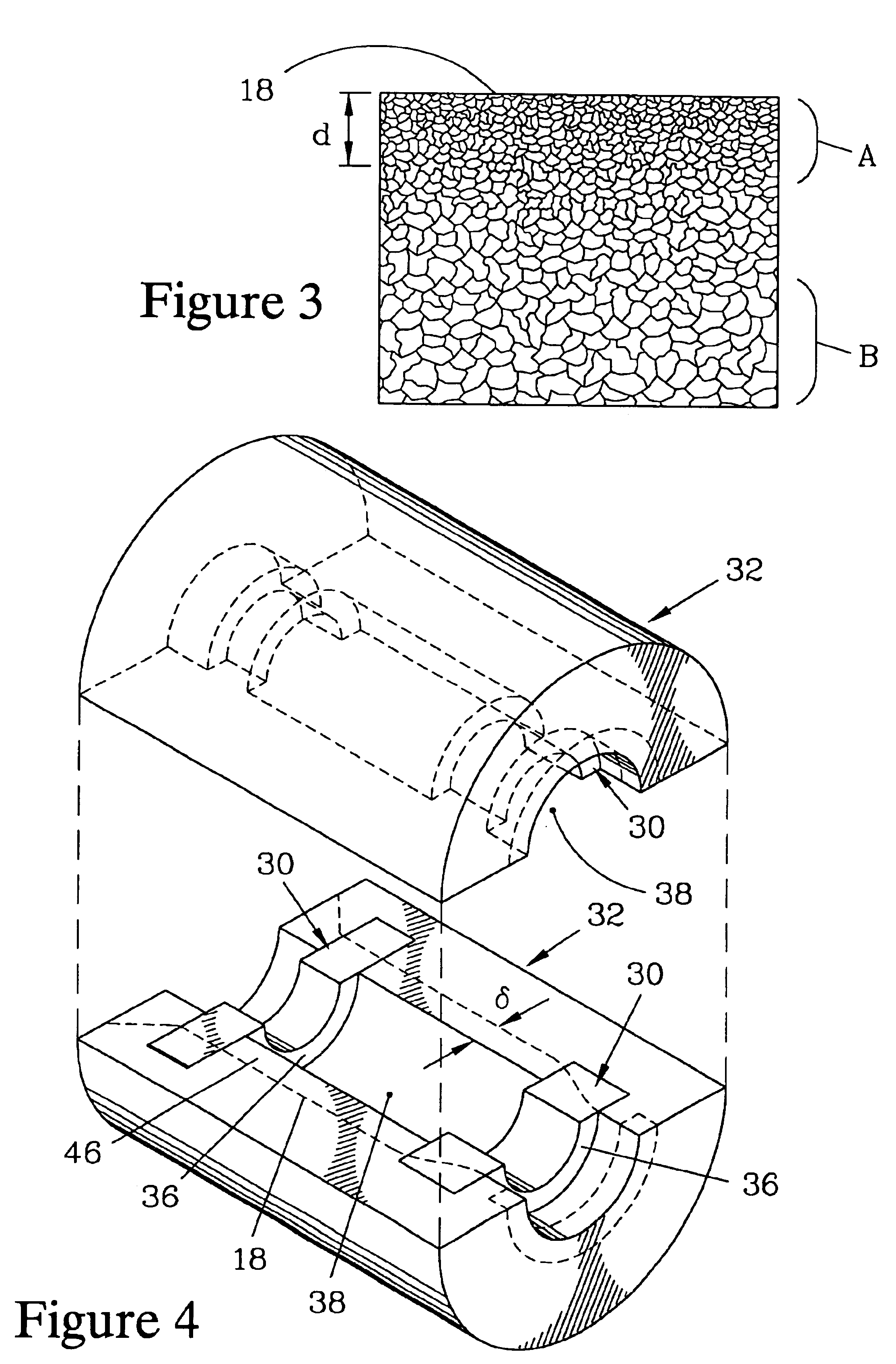

Glass bottle molds and method for making the same

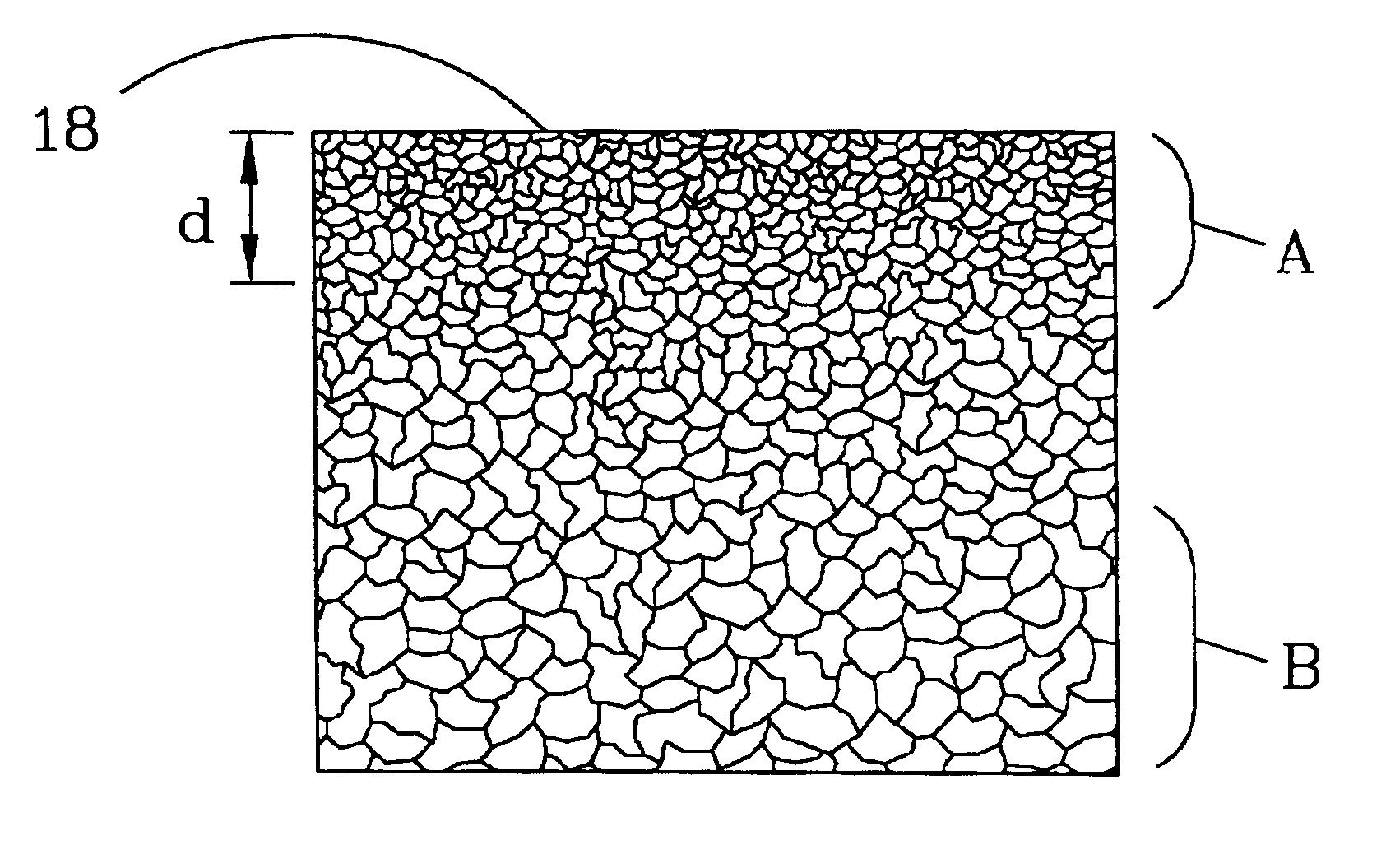

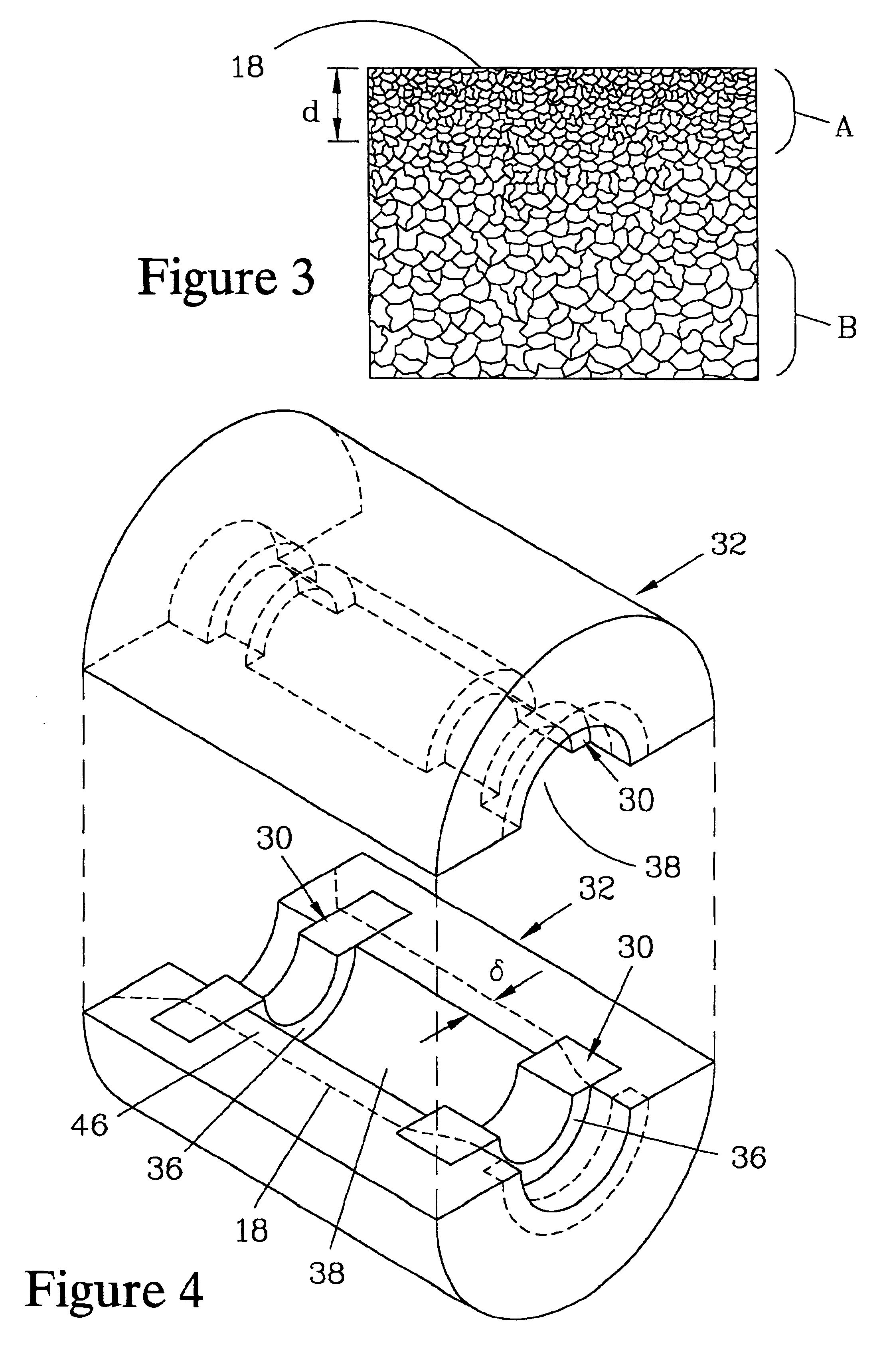

InactiveUS6840062B1Improve mold lifeAdded fabricationGlass pressing apparatusBlowing mouldsBottleMachining

The bottle mold has dissimilar metal inserts embedded in regions where the bottle mold is most subject to attack by hot glass, such as the neck region and the baffle region, and has a glass contact surface with refined grain size. To fabricate the bottle mold, rough castings are made by pouring cast-iron into a composite mold having dissimilar metal insert blanks fixably positioned therein. The dissimilar metal insert blanks become embedded in the cast-iron matrix to form rough dissimilar metal inserts in the rough casting. The composite mold has regions which are formed by metal chills that are partially embedded in a sand mix. The chills and the exposed surfaces of the rough dissimilar metal inserts define a cavity surface of the rough casting, which is subsequently machined to provide the glass contact surface of the bottle mold. The chills serve to refine the grain size of the cast iron at the glass contact surface. Preferably the dissimilar metal insert blanks have protrusions to assure that they become fixably engaged in the resulting rough casting.

Owner:KELLY MACHINE & FOUNDRY

Method for packing nickel base alloy into glass mold cavity adopting silicon-copper alloy as base metal matrix

The invention relates to a method for packing a nickel base alloy into a glass mold cavity adopting silicon-copper alloy as a base metal matrix, which belongs to the technical field of glass mold cavity processing. The method comprises the steps of mold cavity preprocessing, preheating, pre-welding treatment, welding, annealing and finish machining. The method has the advantages that the nickel bas alloy can be reliably combined with the glass mold cavity adopting the silicon copper alloy as the base metal matrix, the characteristics of the copper alloy and the nickel base alloy are fully utilized to meet the requirements of high machine speed and long service life to the mold expected by glass product manufacturers, the method is simple, the cost is low, and the industrialized production requirement can be satisfied.

Owner:ORI MOLD TECH SUZHOU

Neck ring guide for glassware making machine

A neck ring guide for aligning neck ring sections in a glassware forming machine has a center body and a pair of spaced parallel runners coupled to the center body for receipt in guide slots in the neck ring sections. Keepers on the outboard sides of the runners retain the runners in the guide slots. Instead of keepers, the runners may be retained in the guide slots by roll pins on the neck ring sections engaged in retainer slots in the runners.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

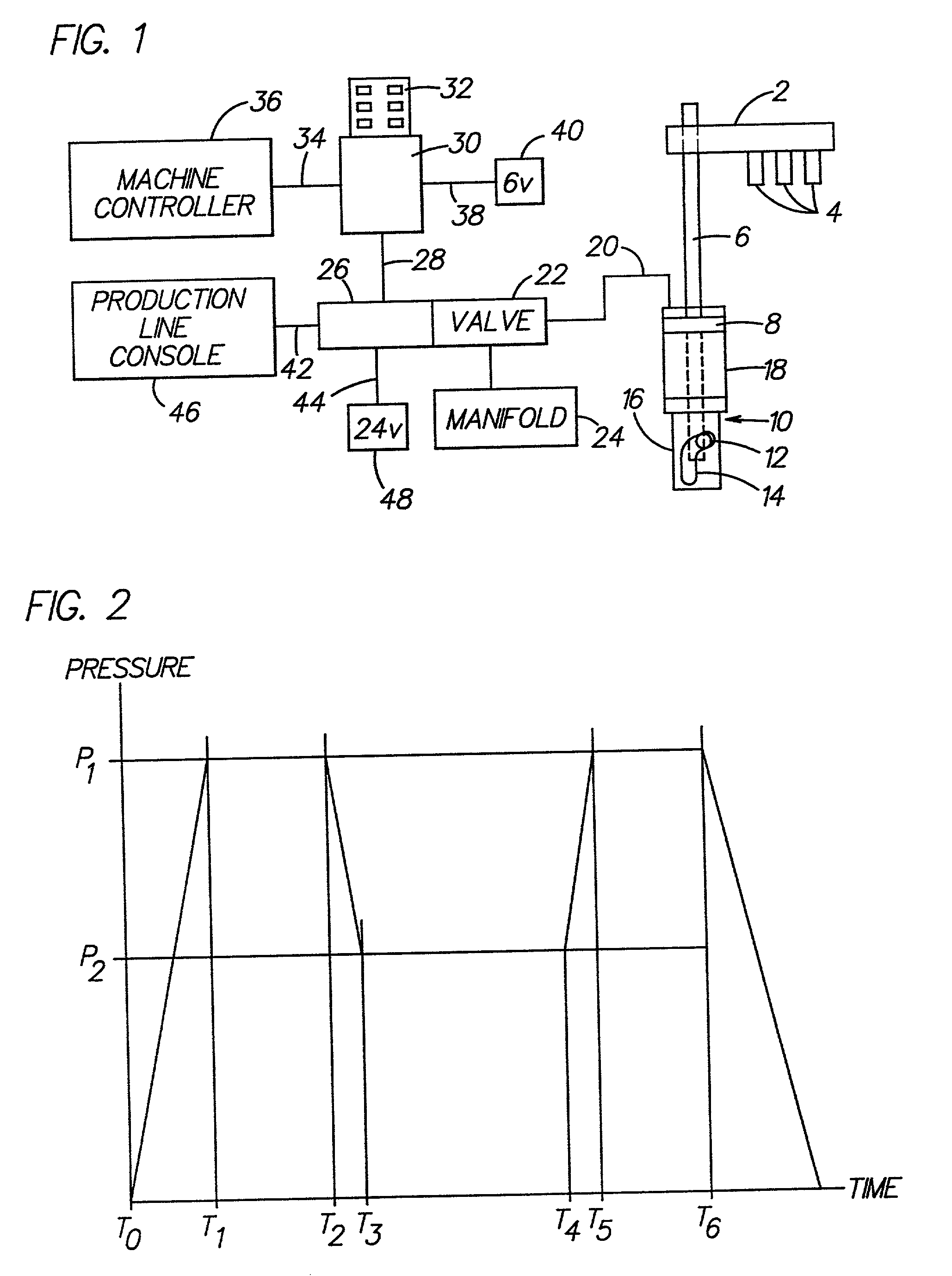

Baffle mechanism for I.S. machine

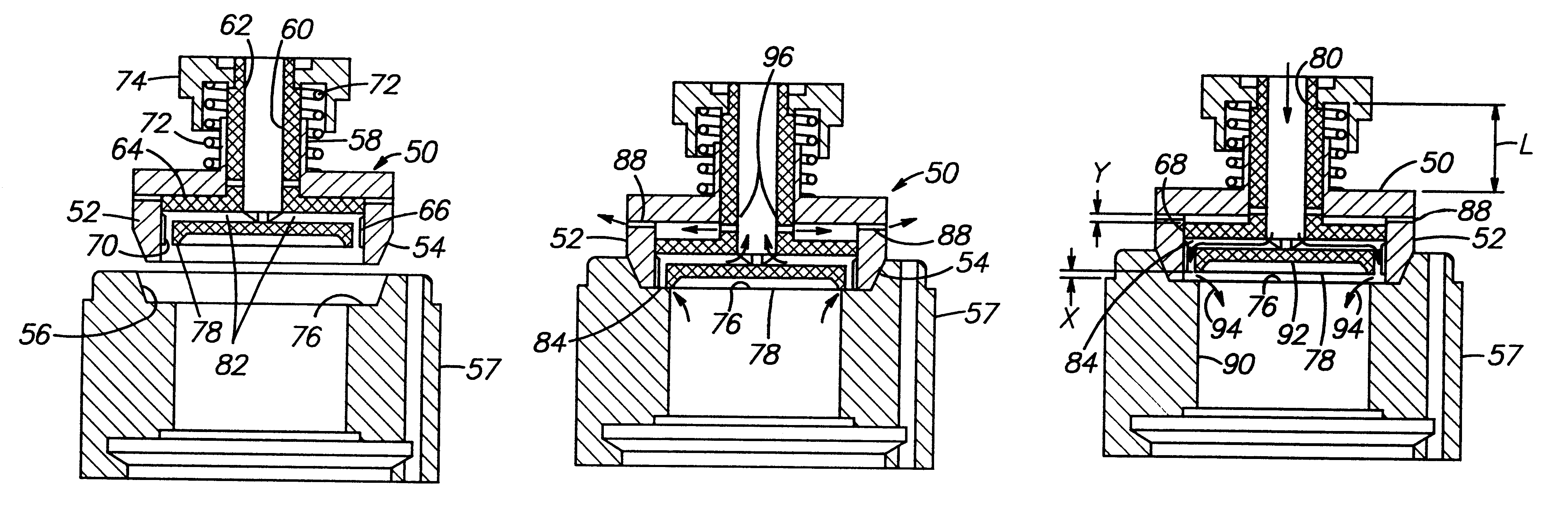

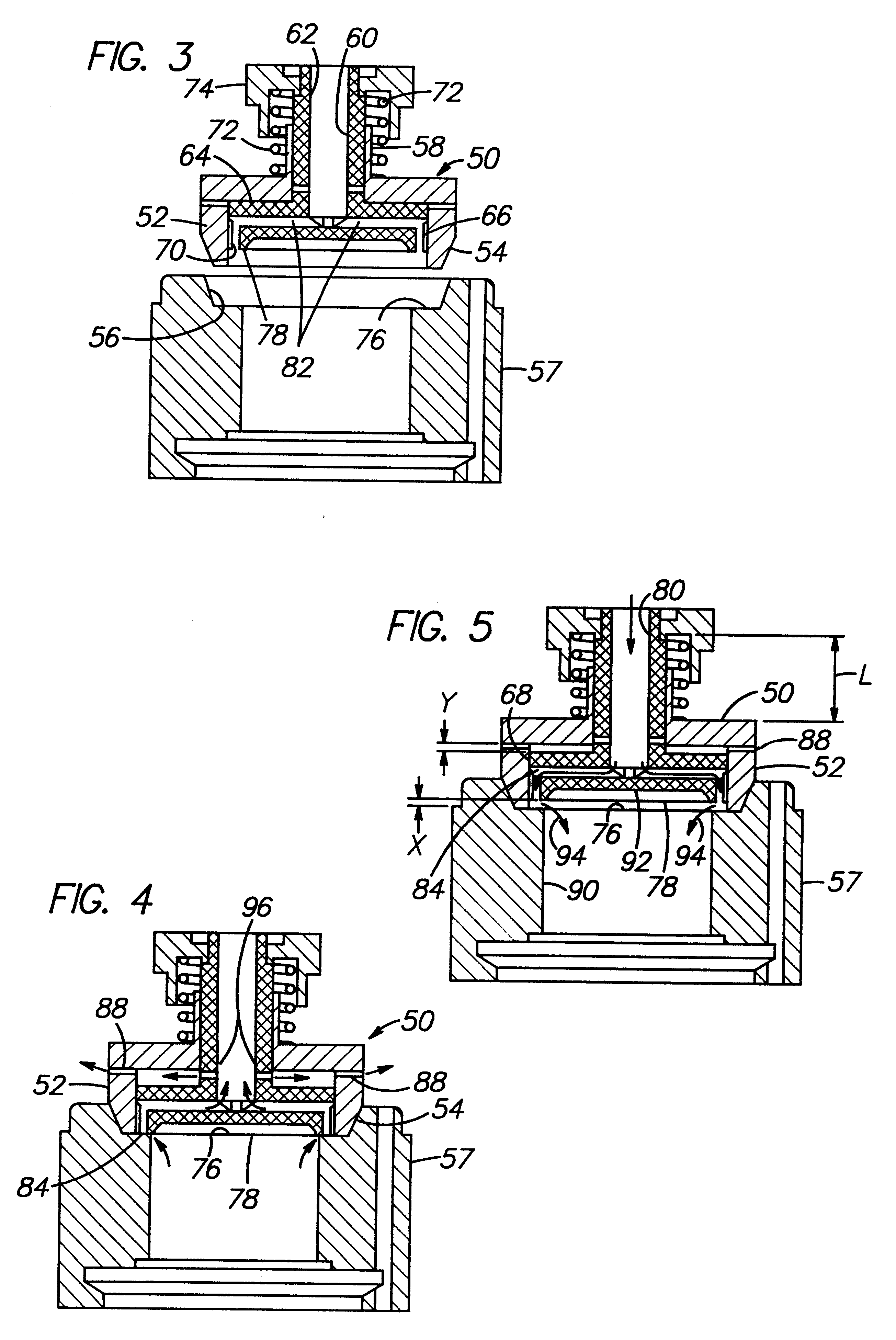

An I.S. machine has a blankmold which is open at the top and includes inner and outer annular top sealing surfaces. Associated with the blankmold is a baffle including a body having a cup shaped portion closed with a vertical cylindrical bore open at the bottom, an annular bottom sealing surface for sealingly engaging the blankmold outer annular top sealing surface, and a top having a hole. A tubular sleeve communicates with the hole and extends vertically upwardly from the top of the body. A piston has a cylindrical head including a top surface, a cylindrical sealing surface and an annular bottom sealing surface having a plurality of radial notch means across the bottom thereof. A tubular rod extends vertically upwardly from the top surface for slidable displacement in the tubular sleeve, and a collar is secured to the top of the rod. A spring located between the collar and the cup shaped portion urges the cylindrical head vertically upwardly to a position whereat the cylindrical head top surface engages the top of the cup shaped portion. The collar is pneumatically displaced vertically downwardly at a high pressure to bring the cup shaped portion annular surface into sealing engagement with the blankmold outer annular sealing surface. The pressure is then reduced so that a predetermined distance separates the cylindrical head annular bottom sealing surface and the blankmold inner annular sealing surface so that settle air can be introduced into the mold, and then the pressure is again raised to the high pressure for parison formation.

Owner:EMHART GLASS SA

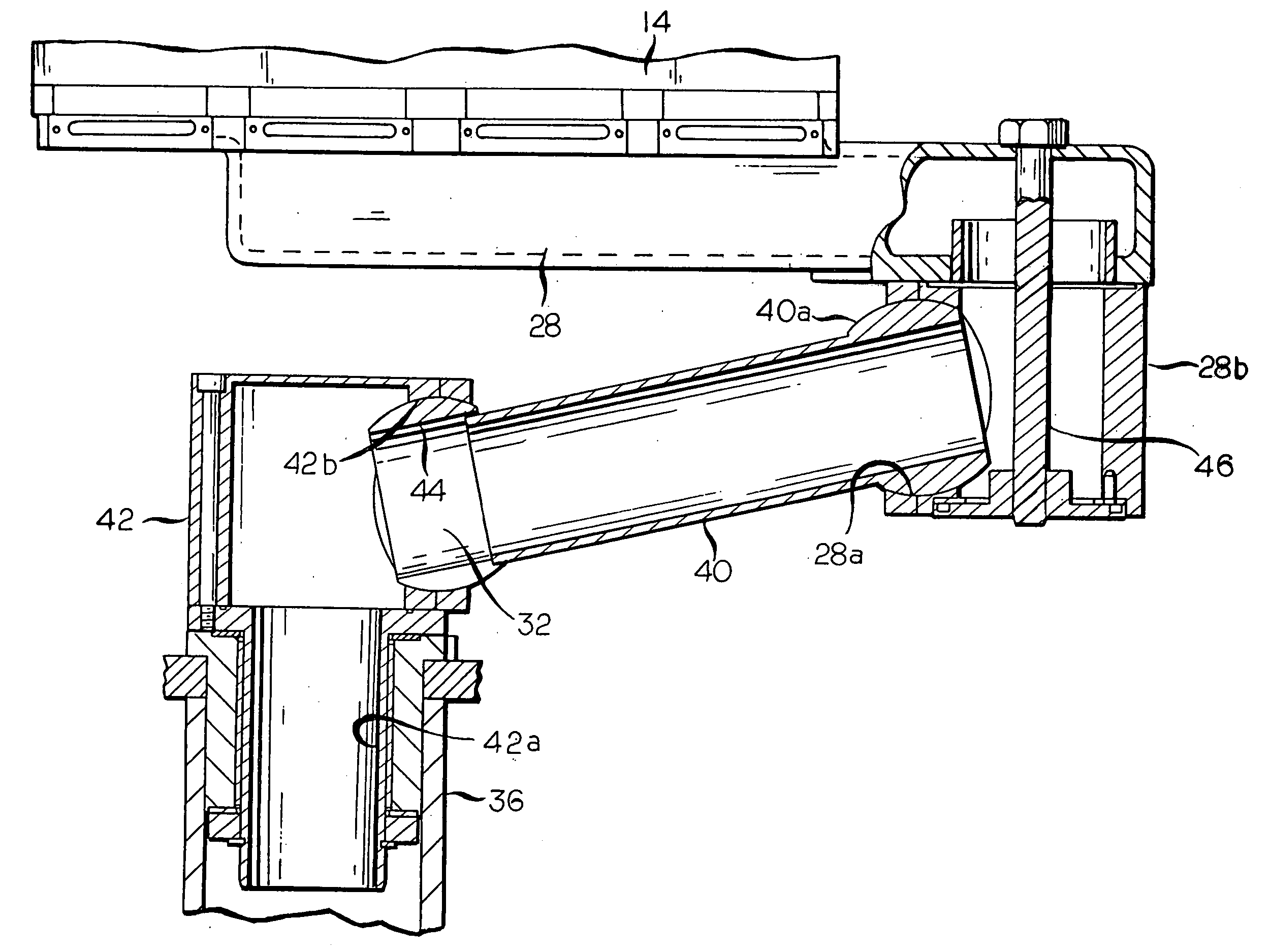

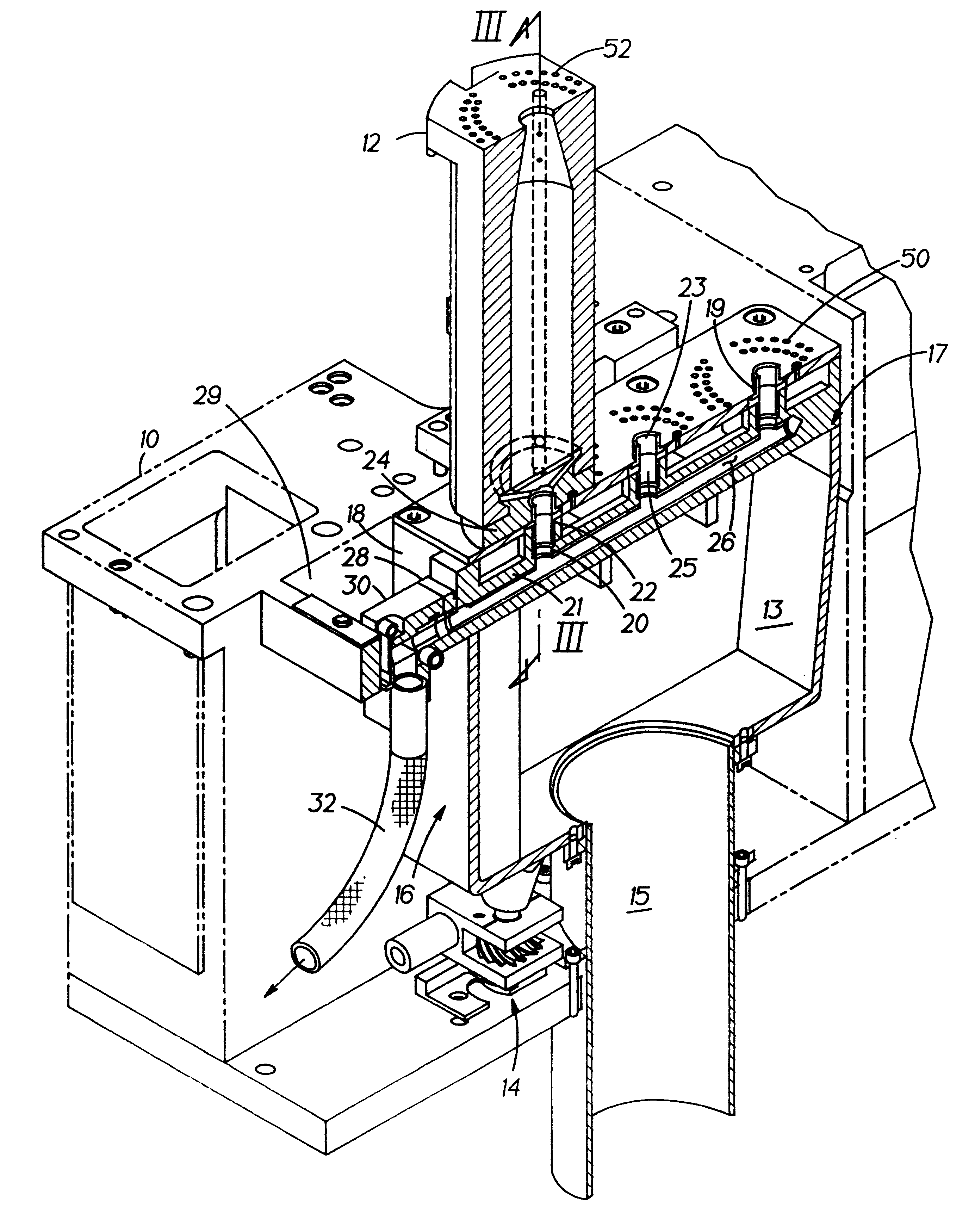

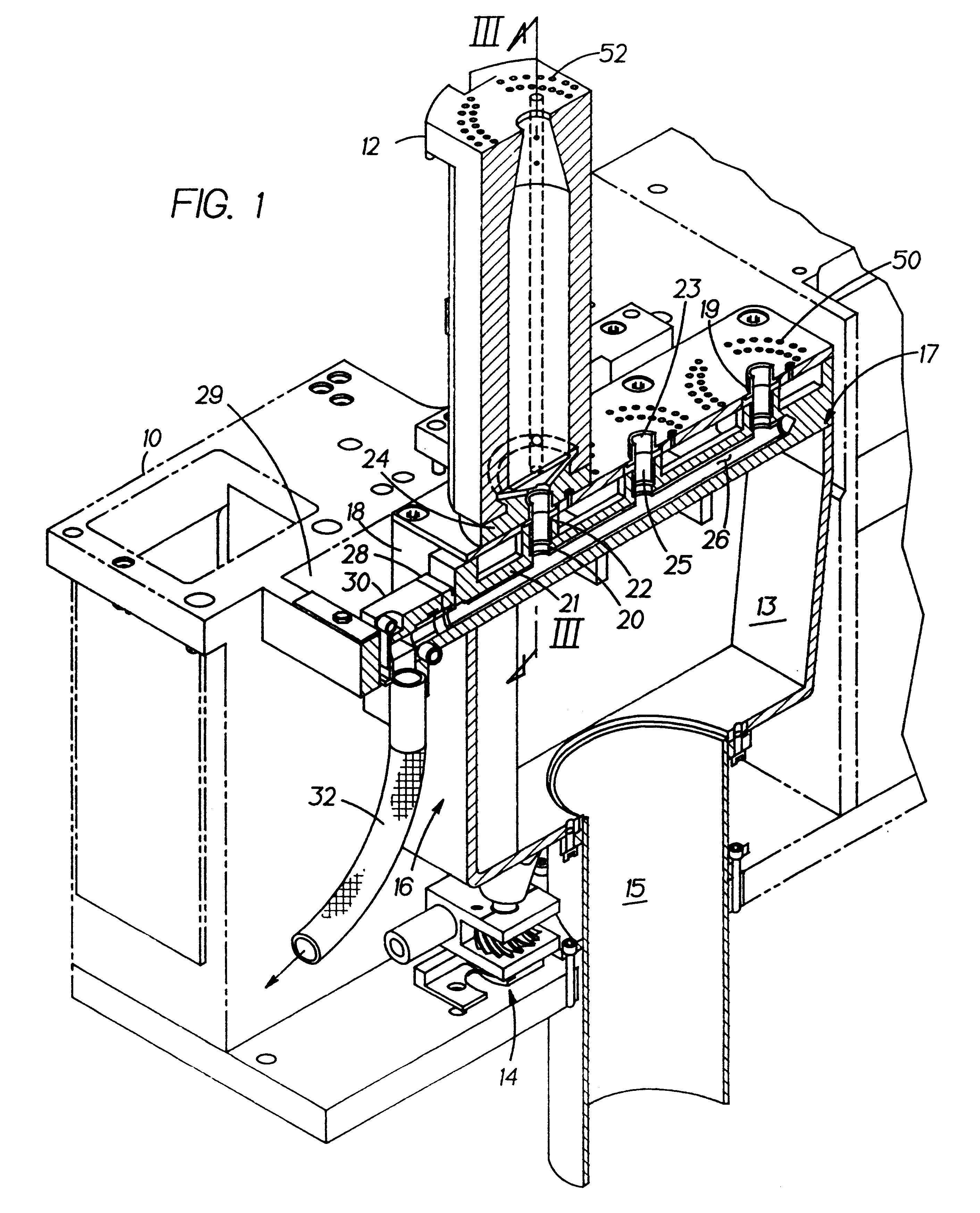

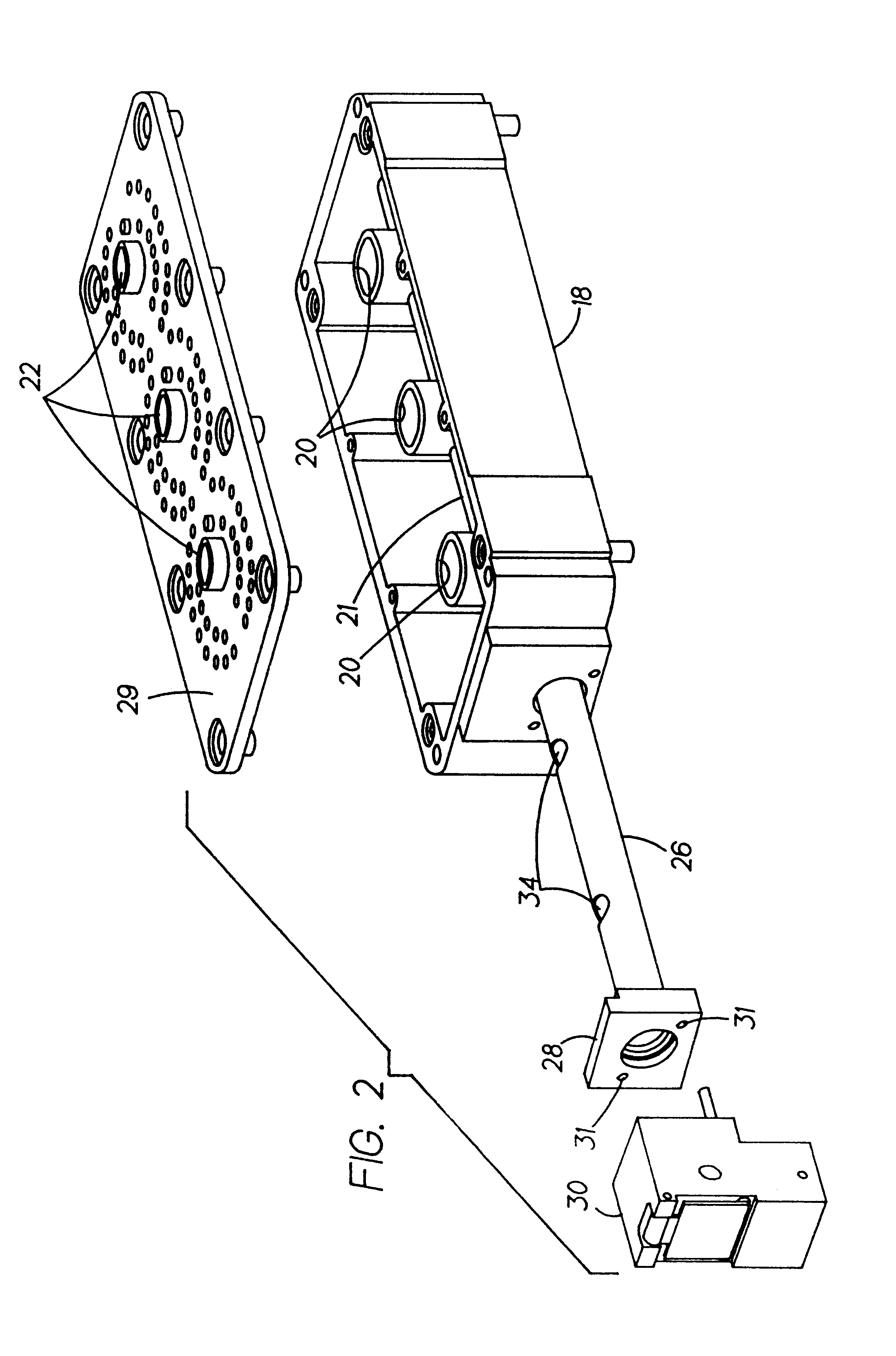

Glassware forming machine mold cooling apparatus and method

InactiveUS20060179884A1Smooth inlet angleGlass drawing apparatusGlass transportation apparatusVertical planeSpherical bearing

In a blank mold side of an I.S. glass container forming machine, mold cooling air flows from a fixed source through a supply conduit to a plenum that underlies and oscillates with a mold-carrying arm. Cooling air from the source flows upwardly through the supply conduit and then into a hollow member that has an inlet portion telescopically received in an outlet of the supply conduit. The hollow member, which is capable of oscillating motion in a horizontal plane with respect to the supply conduit, has a horizontally-facing outlet with an annular part-spherical bearing surface, and an annular part-spherical bearing is positioned in the part-spherical bearing surface for pivoting motion in a vertical plane of the part-spherical bearing with respect to the hollow member. A cooling air inlet tube has an inlet end telescopically received in the part-spherical bearing. The outlet end of the cooling air inlet tube is non-telescopically received in a part-spherical bearing surface of the plenum. In a blow mold side of an I.S. glass container forming machine, cooling air flows from a fixed source through a supply conduit to a plenum that underlies and oscillates with a mold-carrying arm without any substantial change in the direction of air flow therethrough. A cooling air inlet tube having an outer element, an inner element telescopically positioned within the outer element and a spring to resiliently bias the inner element and the outer element away from one another is provided to accommodate changes in distance between the source and the plenum that occur because of oscillating motion of the mold-carrying arm.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

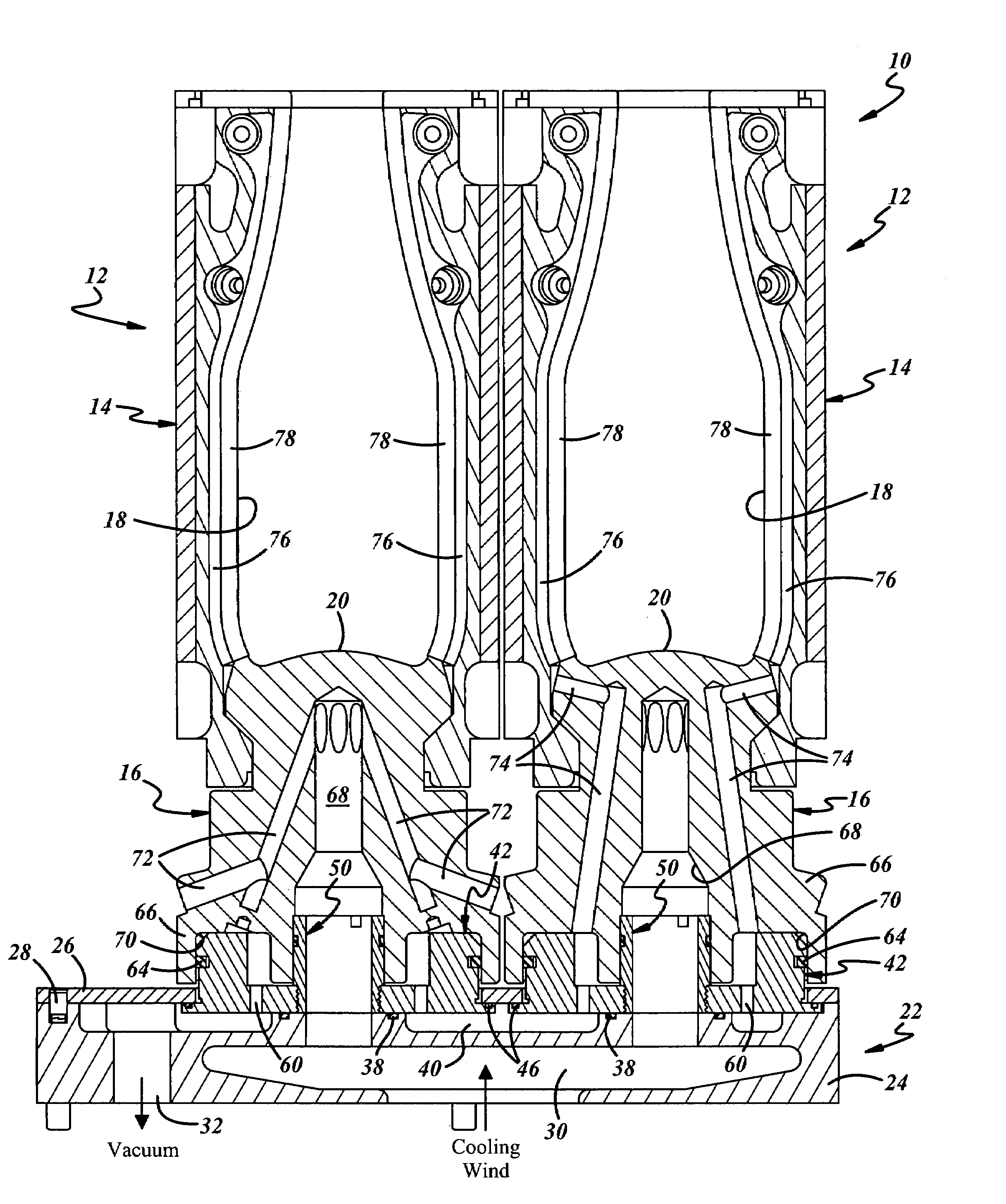

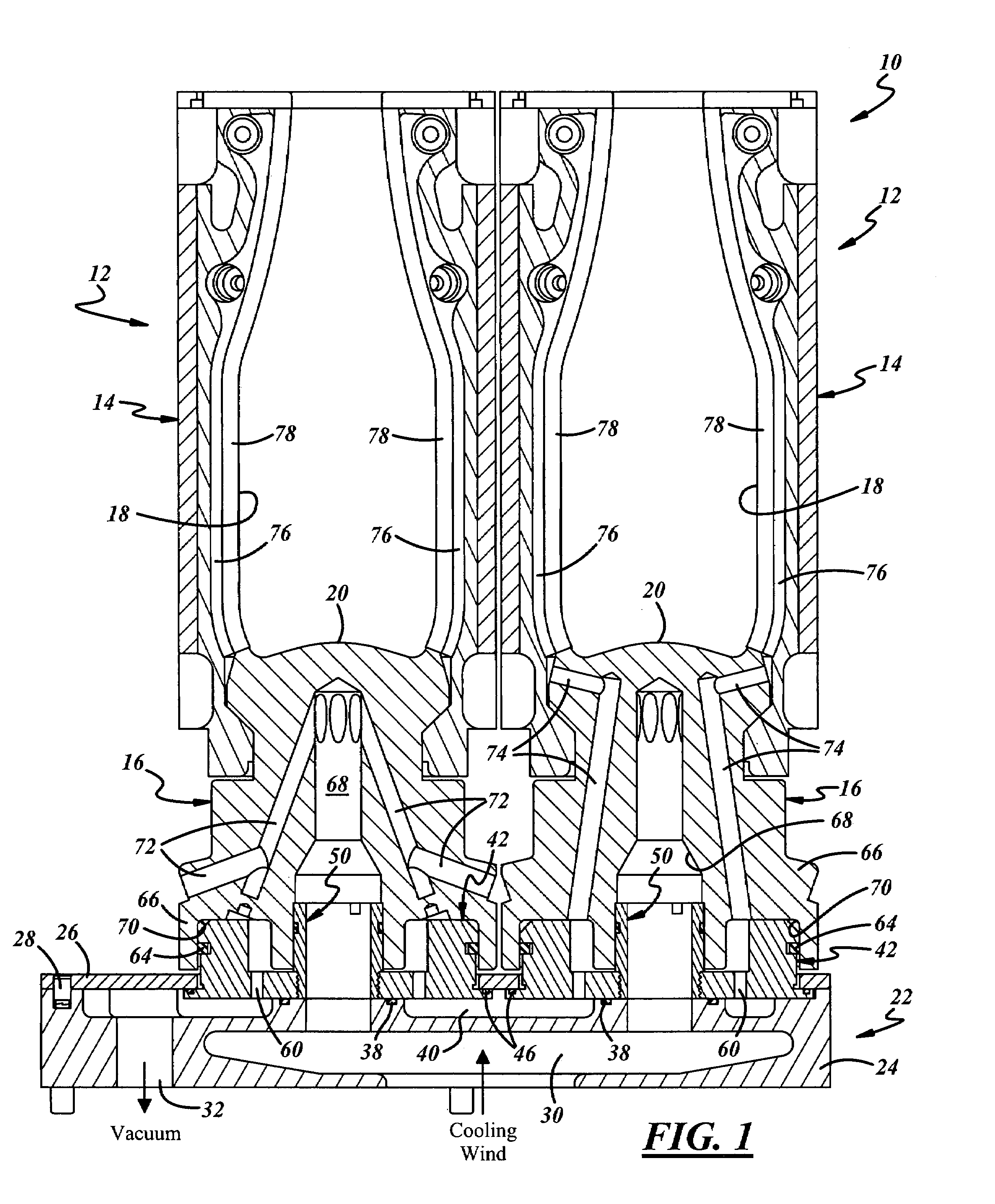

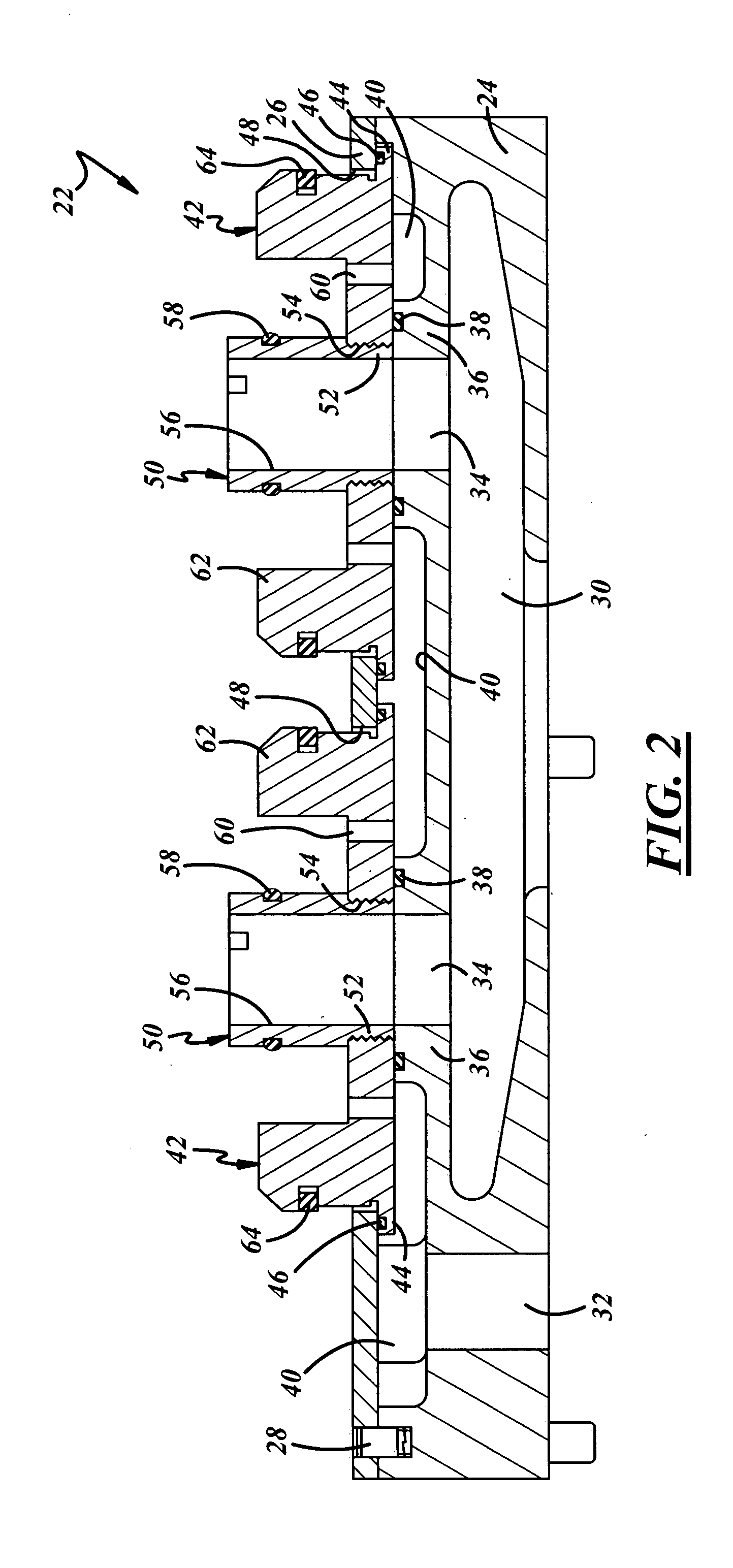

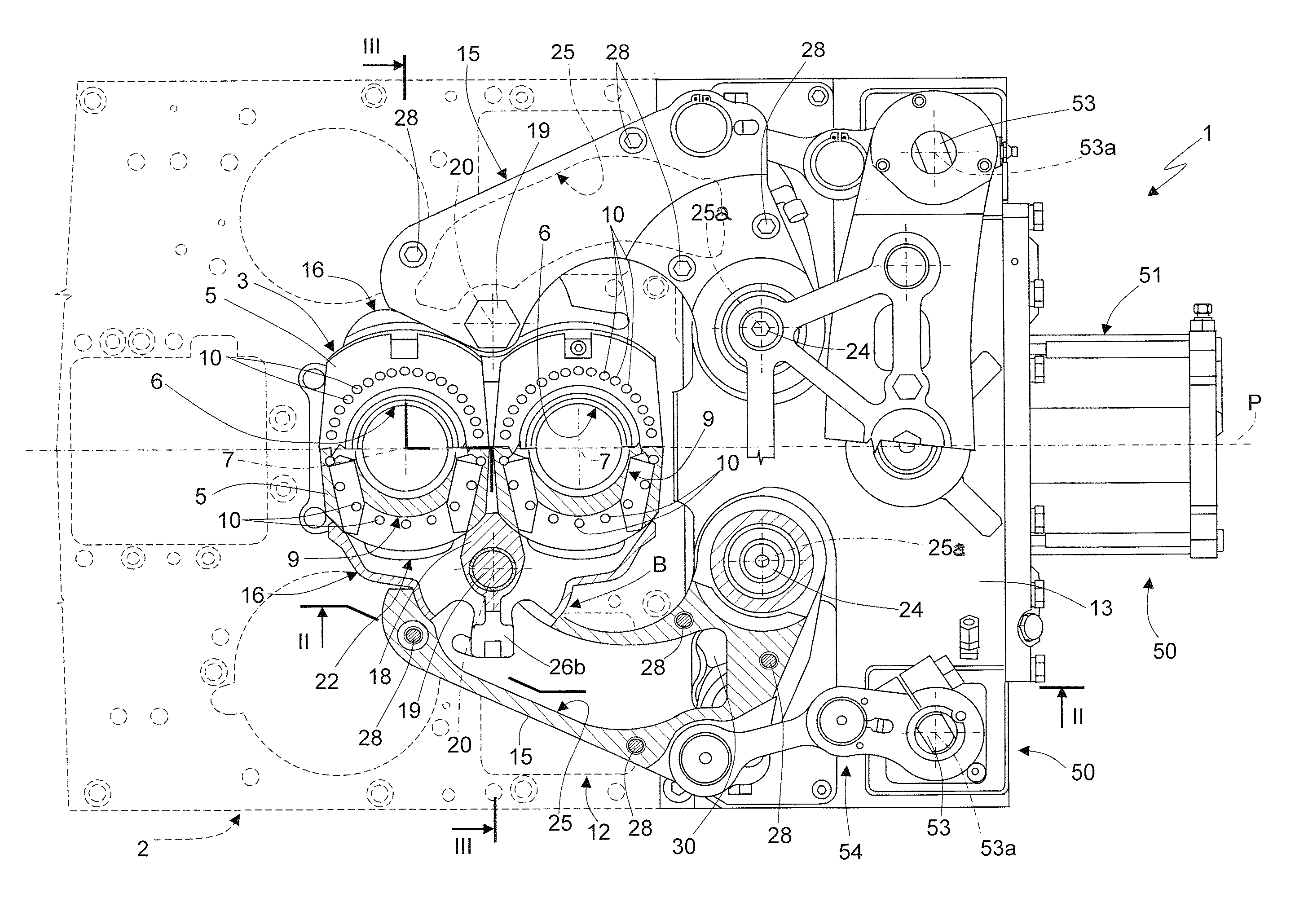

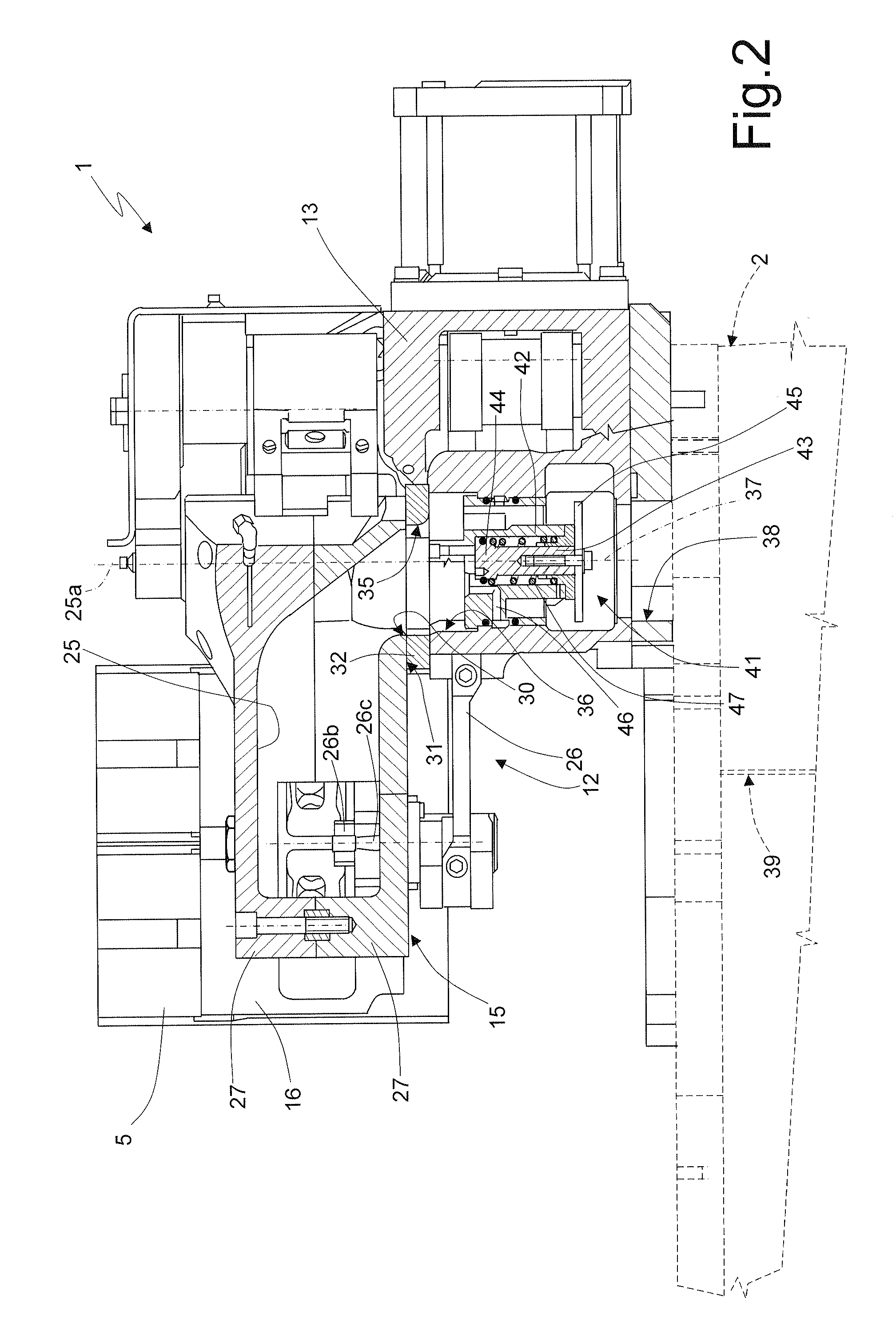

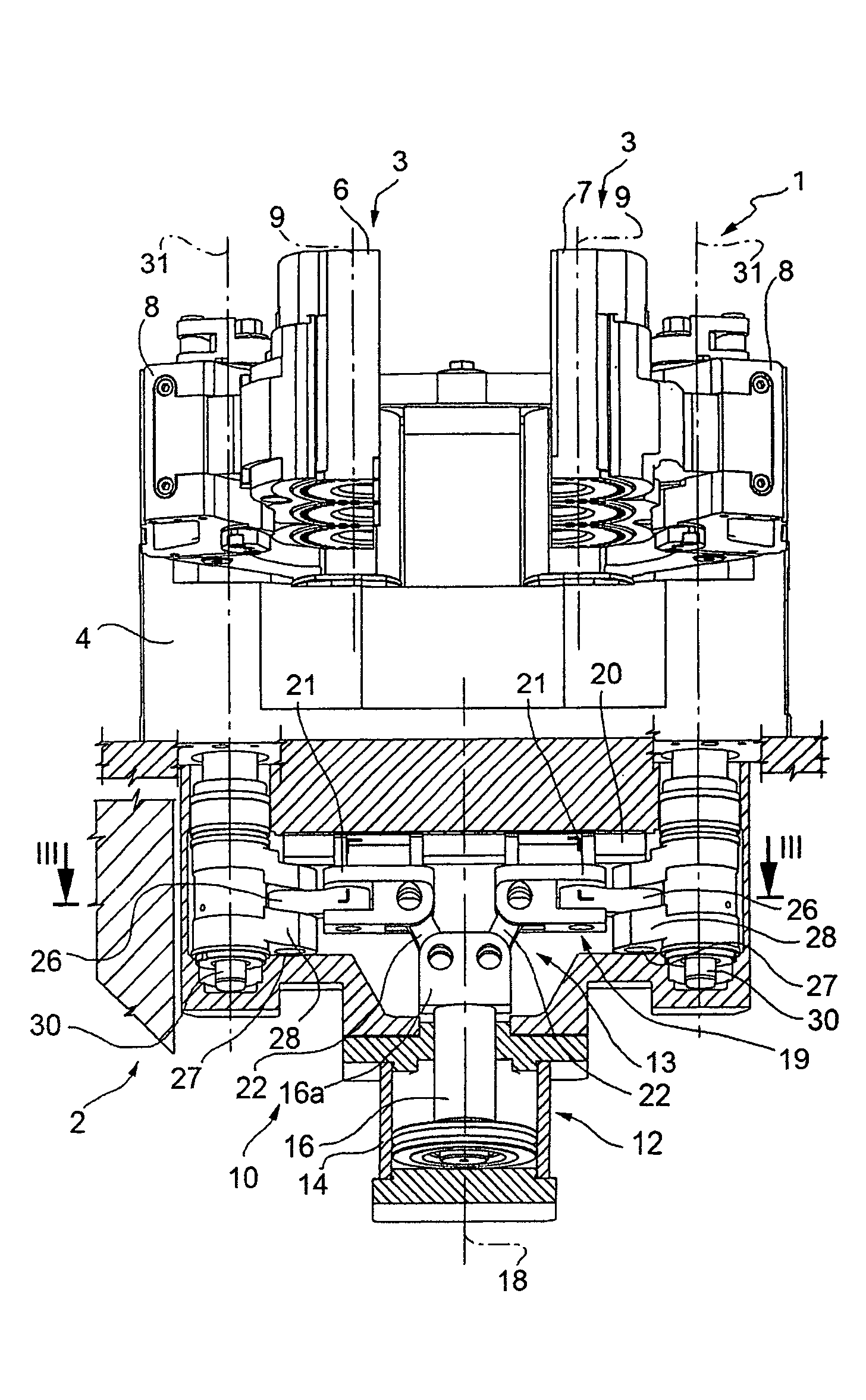

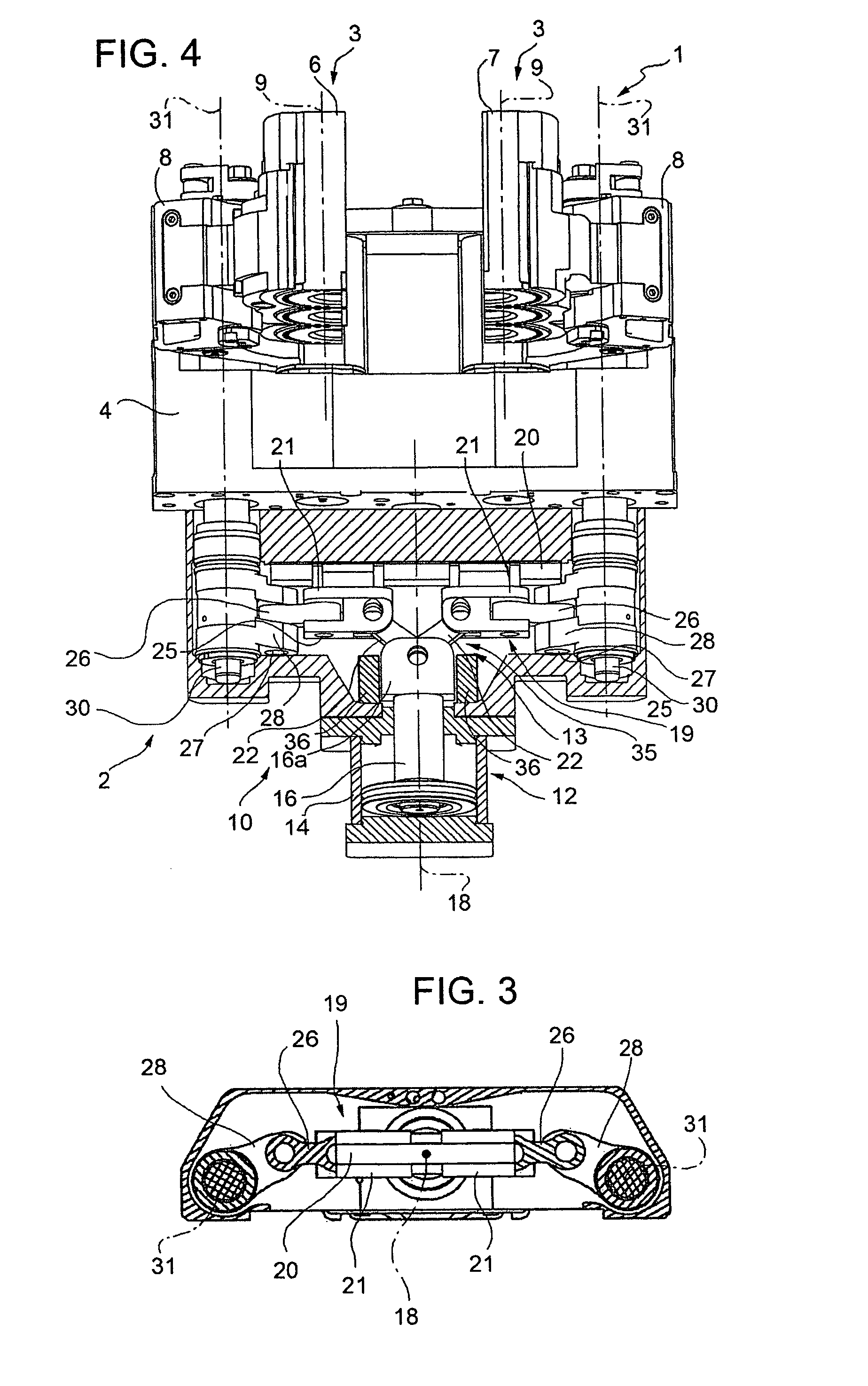

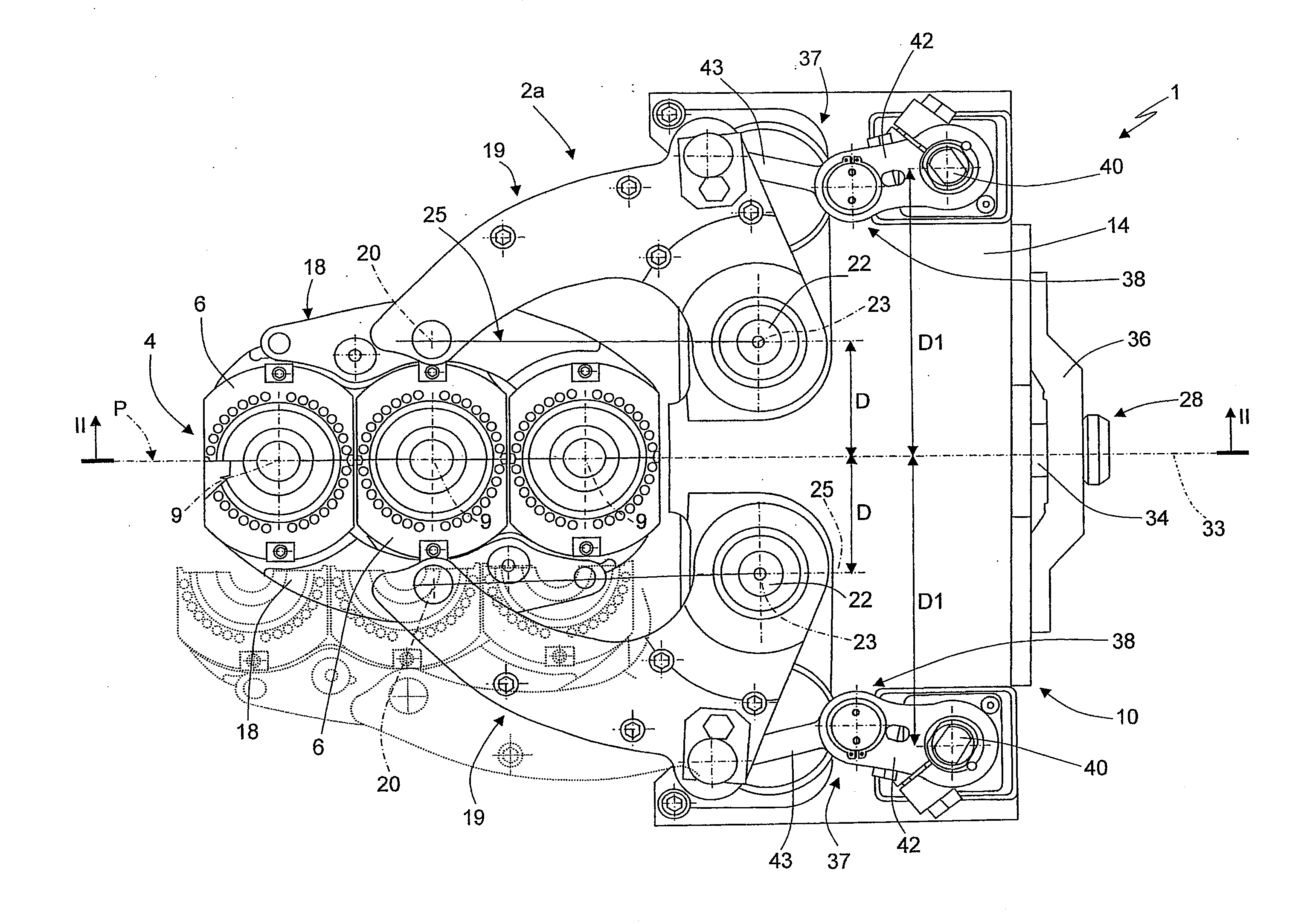

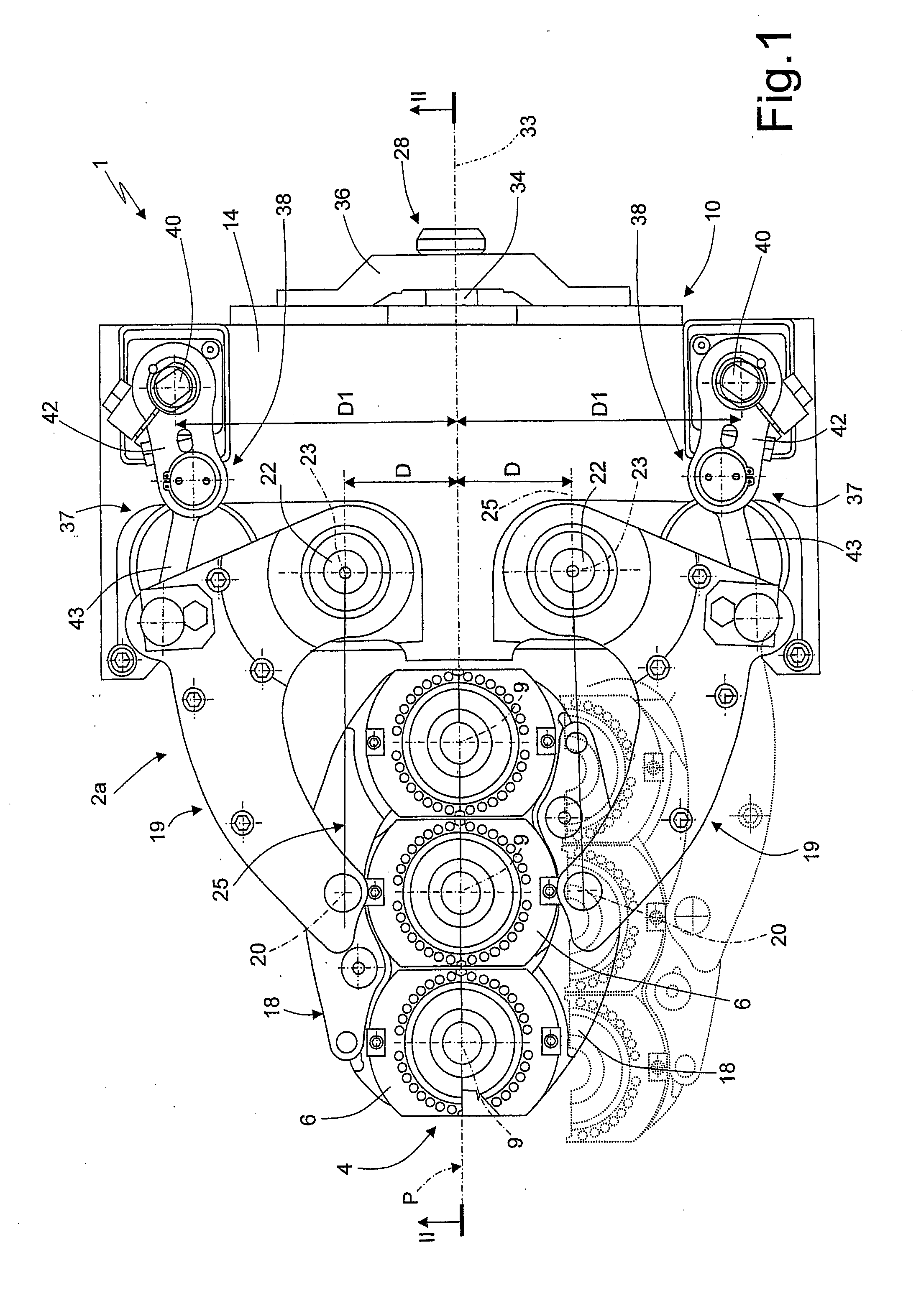

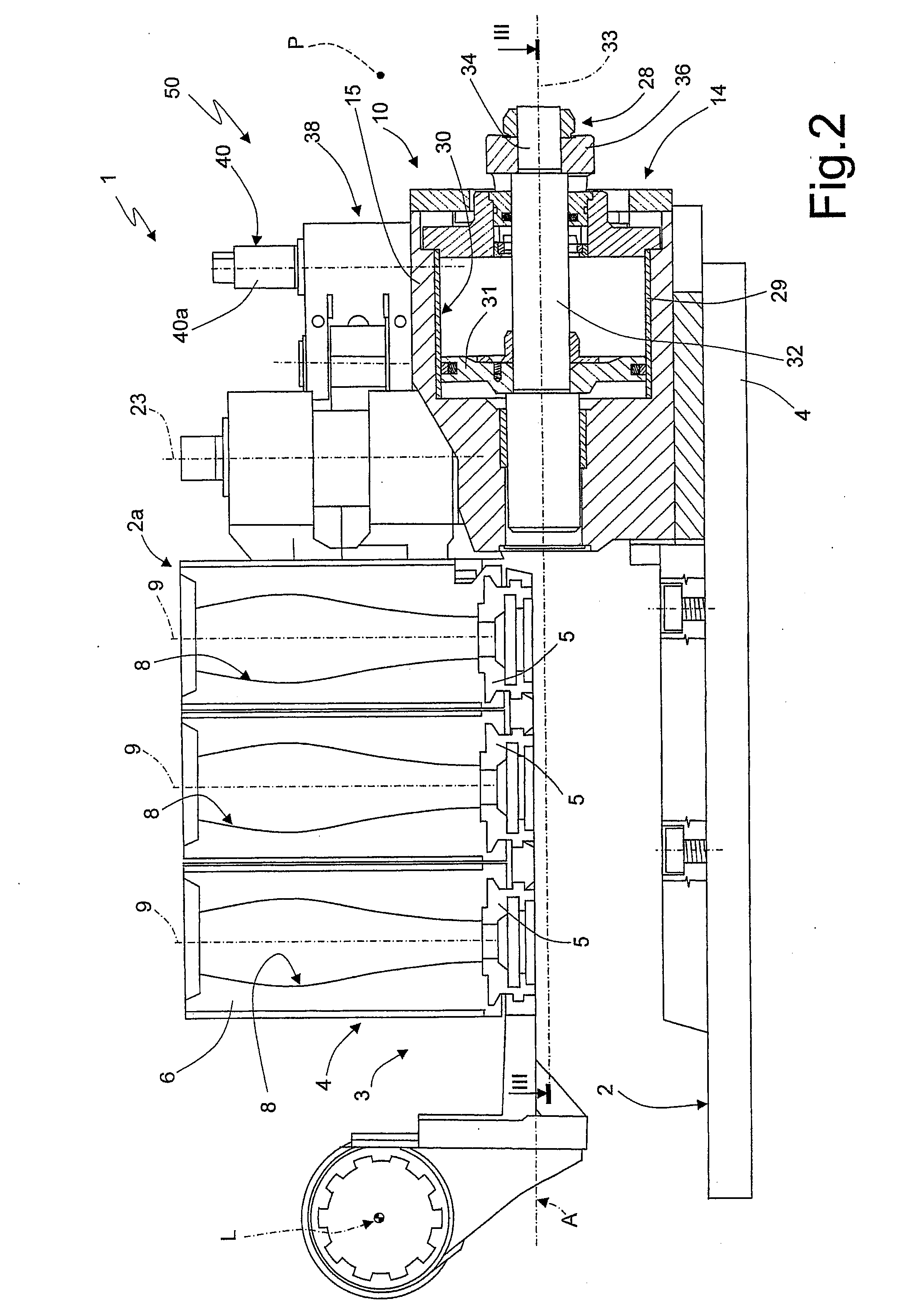

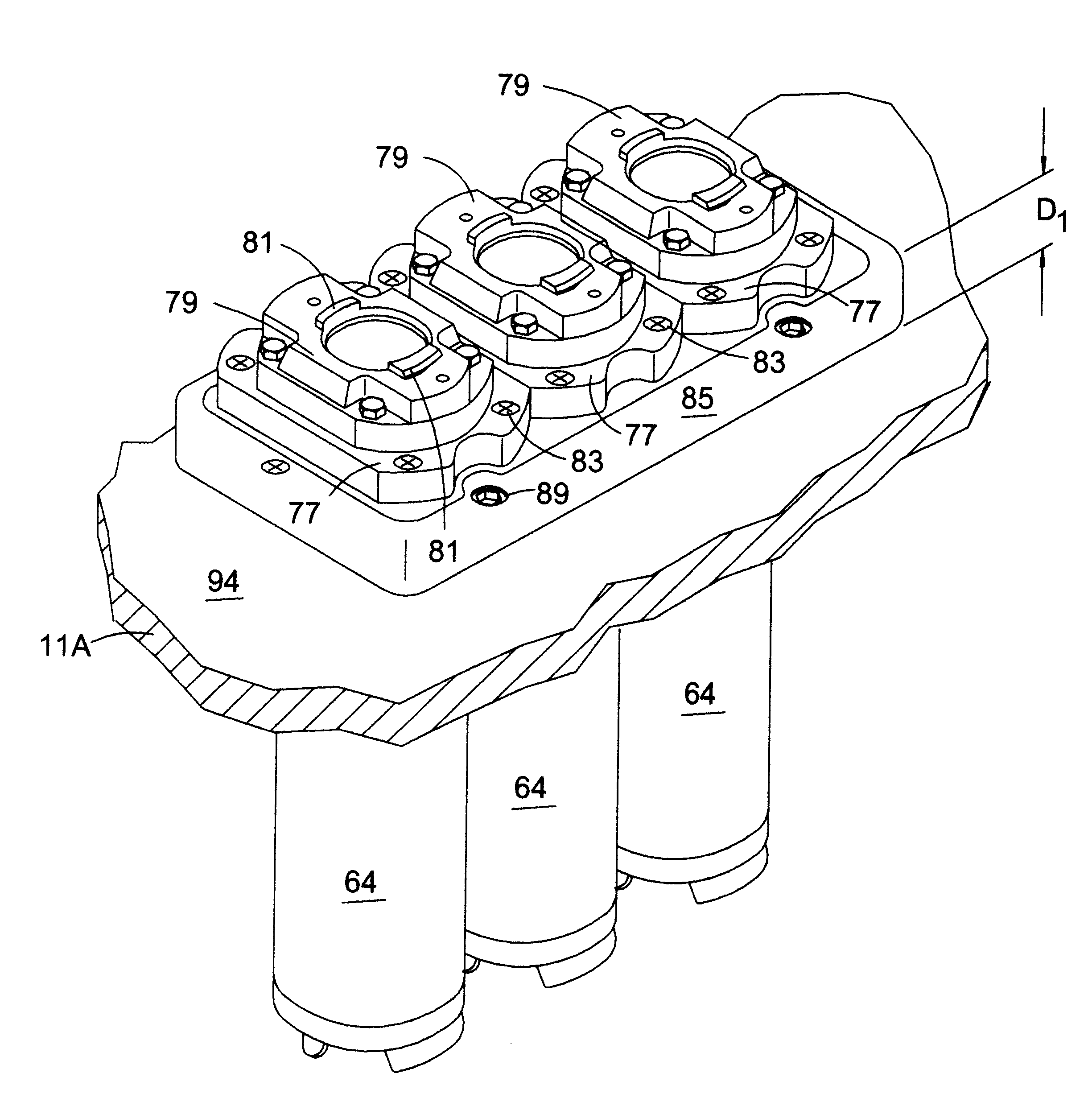

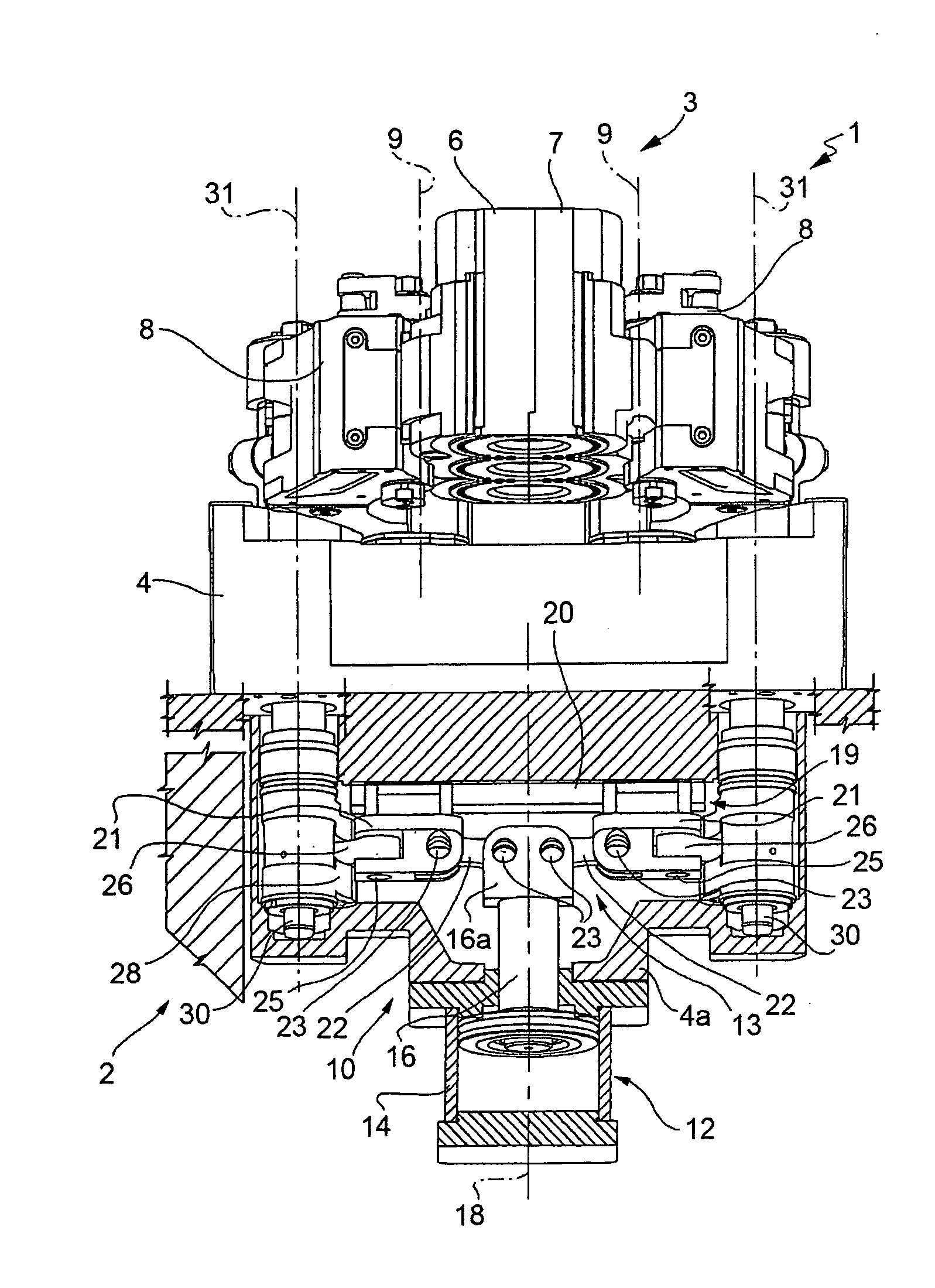

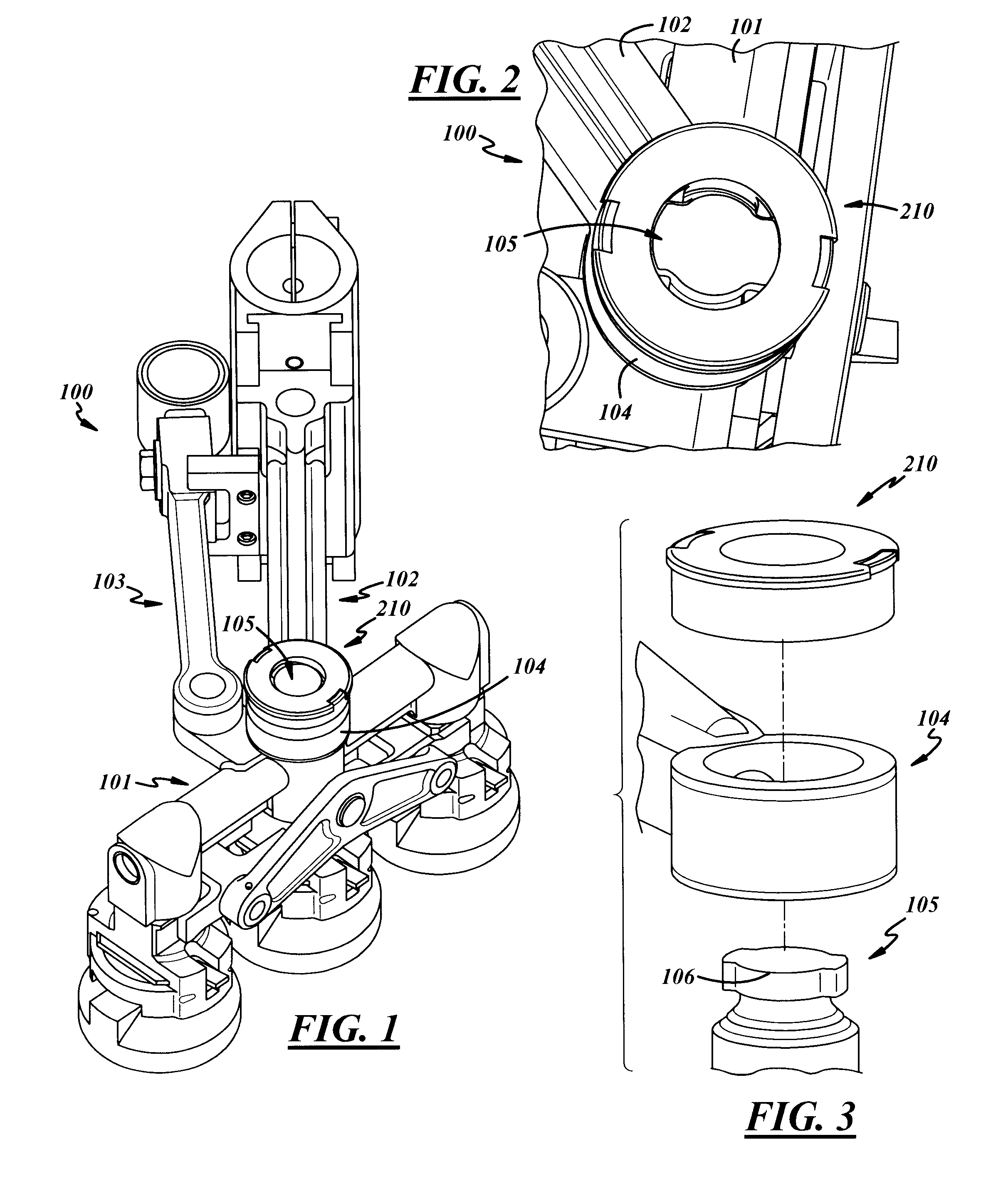

Mold actuating and cooling assembly for a glassware molding machine

ActiveUS20090025429A1Straightforward and low-costImprove efficiencyGlass furnace apparatusGlass drawing apparatusMolding machineEngineering

In a glassware molding machine, the half-molds of a mold are moved between an open position and a closed position and cooled by an actuating and cooling assembly having a fixed supporting structure and, for each half-mold, a respective supporting and actuating arm fitted to the relative half-mold and hinged to the fixed supporting structure to rotate about a fixed hinge axis; each supporting arm internally defining a chamber communicating with a ring of cooling conduits formed through the half-molds, and the chamber having an inlet formed through an outer lateral wall of the supporting arm to receive cooling air from a compressed-air tank of the machine.

Owner:BOTTERO SPA

Method and a machine for the production of hollow glassware articles

InactiveUS7024887B2Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusEngineeringNeck rings

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO

Aligning fixture for mold opening and closing mechanism

InactiveUS6085552AImproved mold openImproved close mechanismBlowing machine gearingsGlass pressing apparatusTransducerEngineering

A mold opening and closing mechanism includes an aligning mechanism which has a horizontal mounting plate including a number of vertical openings for the number of molds, that is supported by a pair of spaced vertical uprights secured to the section frame top surface. A plurality of aligning cylinders are located in the vertical openings in the horizontal mounting plate and move parallel with the mold holder motion. Each cylinder includes surfaces configured to mate with the clamping surfaces of the mold holders. The axis of one of the aligning cylinders is held but not clamped at the theoretical centerline so it can move to the actual centerline when the mold holders are located at the advanced clamped closed position. A position transducer is mounted parallel with the mold holder motion to sense movement of the axis of one of the aligning cylinders and a computer receiving positional data from the transducer compares the theoretical centerline with the actual centerline determined from the data and defines a displacement offset for the displacement program to align the mold holders to the theoretical centerline.

Owner:EMHART GLASS SA

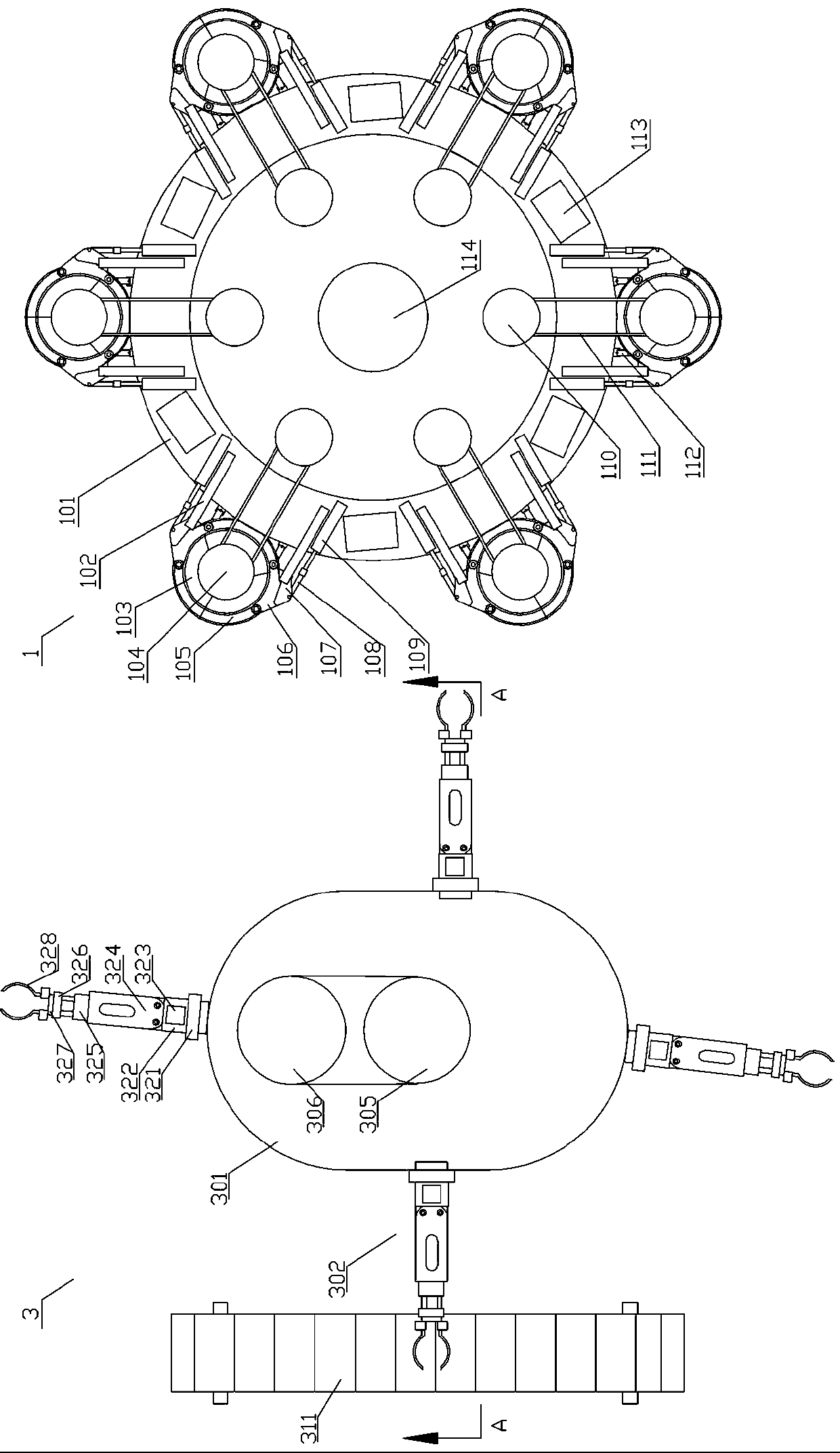

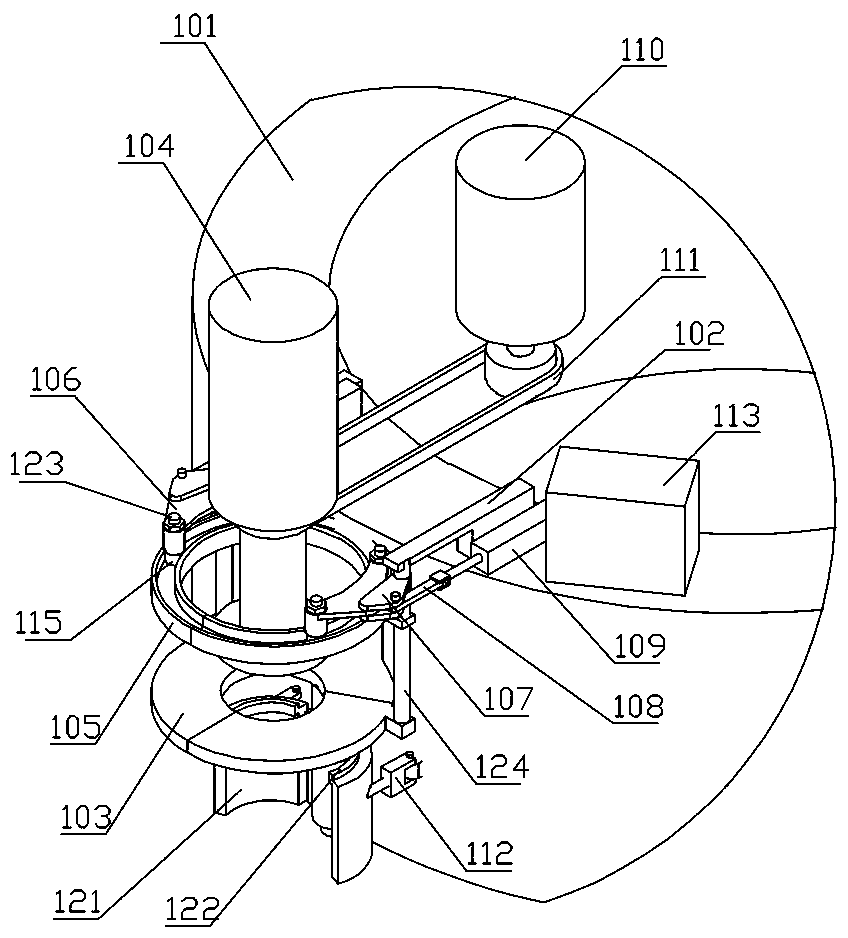

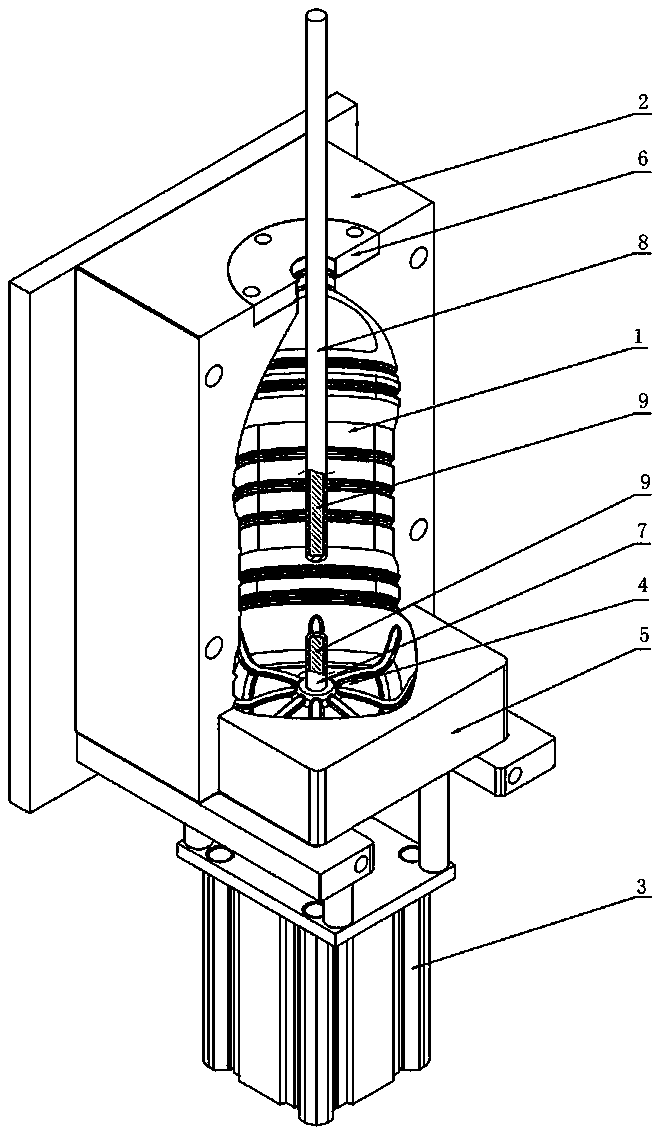

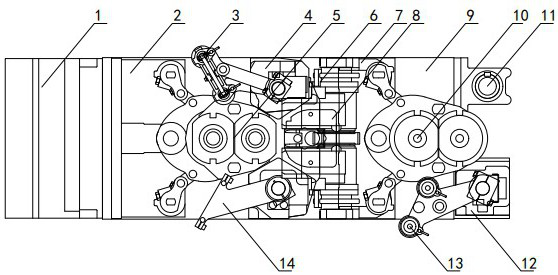

Automatic production system of high borosilicate glass kettle

PendingCN107902874AImprove efficiencyIncrease productivityBlowing mouldsRolling-element bearingMechanical drive

The invention provides an automatic production system of a high borosilicate glass kettle. The automatic production system comprises blower molding equipment, a molding mold and a discharging device,wherein the blower molding equipment comprises an annular rack; the annular rack is provided with at least three blowers; each blower comprises a glass blank clamping plate and connecting column sleeves are arranged at two sides of each glass blank clamping plate; an annular sliding channel is arranged above each glass blank clamping plate and a rolling bearing is arranged in each annular slidingchannel; each rolling bearing is mechanically driven through an air cylinder to open the corresponding glass blank clamping plate; an openable mold hanging plate with an arc-shaped bulge is arranged below each glass blank clamping plate; each mold hanging plate is pushed through the air cylinder; the molding mold comprises a kettle wall mold and a kettle bottom mod; one circle of L-shaped reversedhooks are arranged on an outer wall surface of the kettle wall mold and are matched with the arc-shaped bulges; the discharging device comprises discharging equipment; a conveyor belt is arranged ona side face of the discharging equipment; at least three mechanical arms are uniformly distributed on the discharging equipment. The automatic production system of the high borosilicate glass kettle is high in automation degree and high in production efficiency and influences on quality in a product transportation process are not caused.

Owner:HUBEI RUIXIN HEALTH CARE PROD SCI & TECH CO LTD

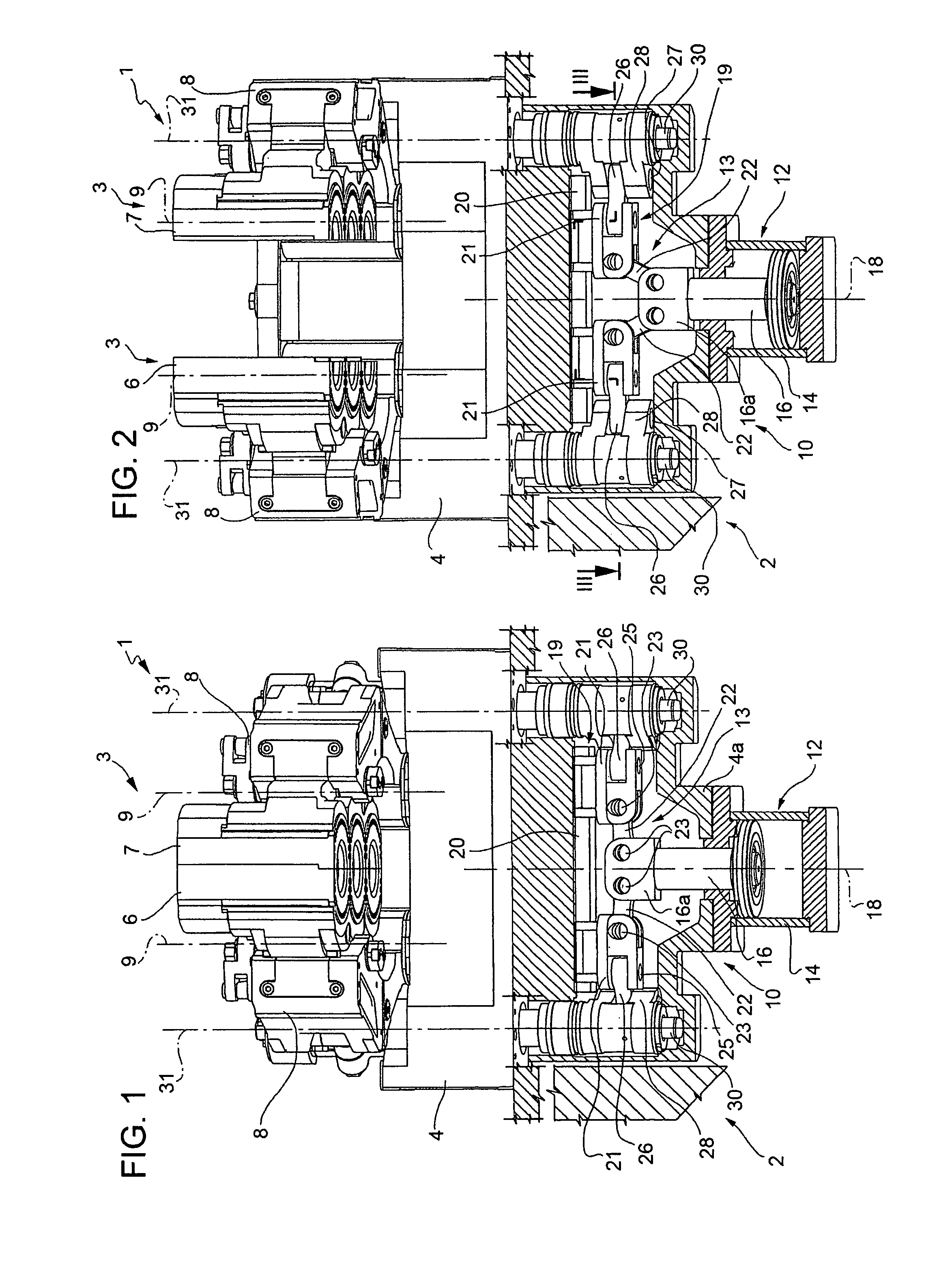

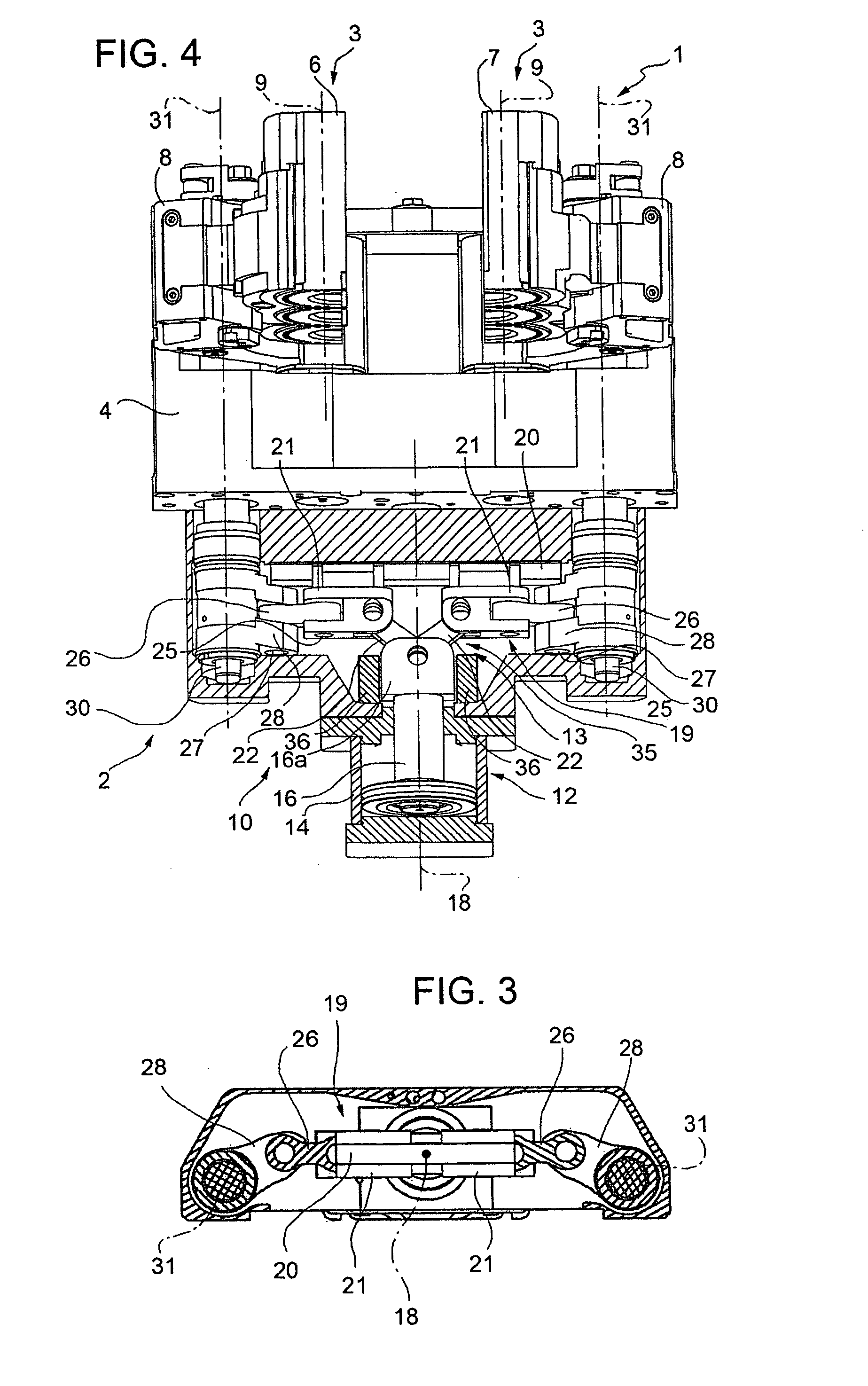

Molds opening/closing group of a forming glass machine items

In a machine for forming glass items, a mold having two half-molds movable between a closed forming position and an open extraction position by a mold opening / closing group is provided. The mold includes two handling arms, each connected to a respective half-mold, which are rotated about respective fixed hinge axes by a single linear actuator. The mobile member translates in a direction parallel to the fixed hinge axes, and is connected to the handling arms by a mechanical transmission having a respective guide-and-slide assembly for each handling arm.

Owner:BOTTERO SPA

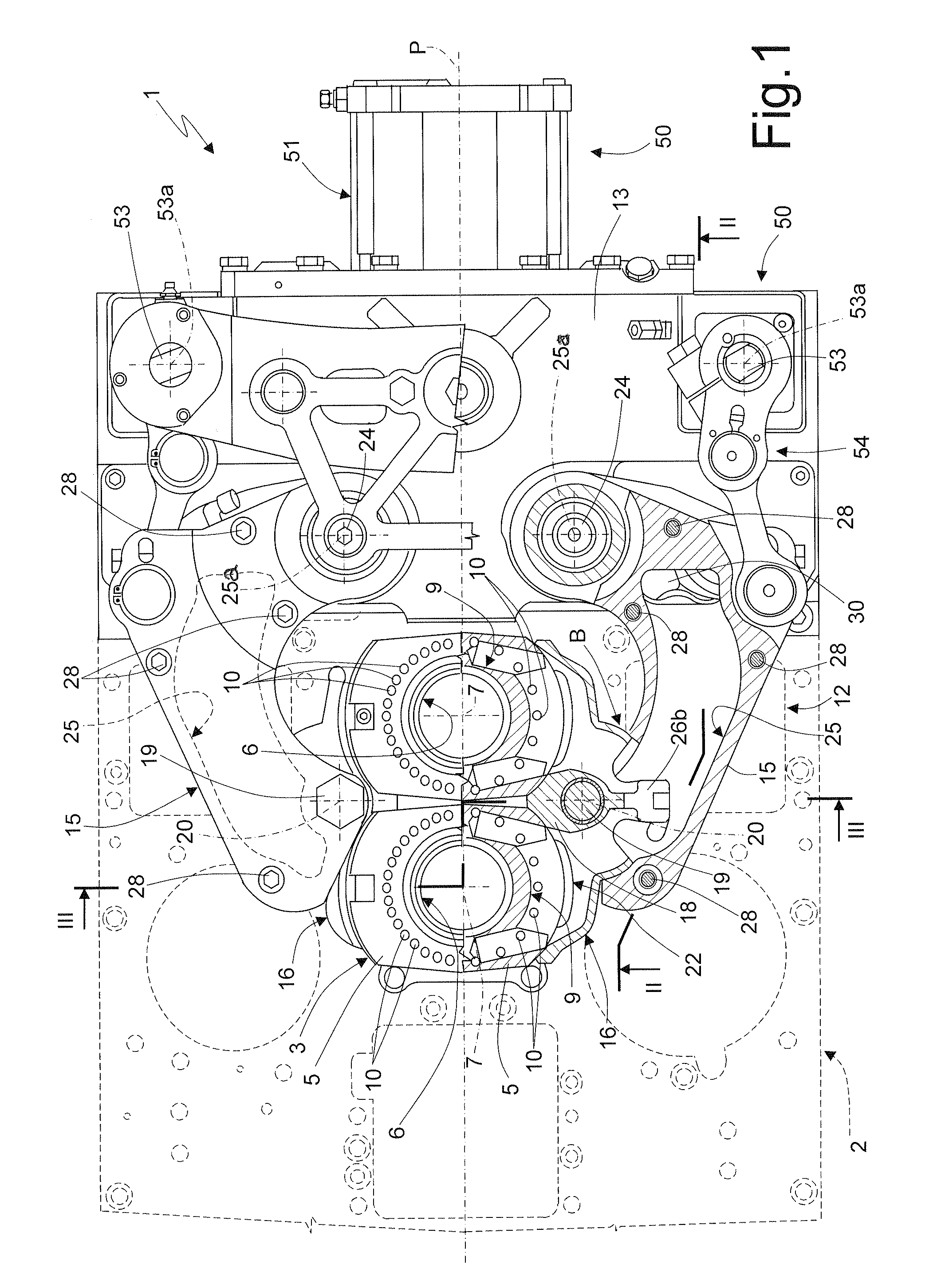

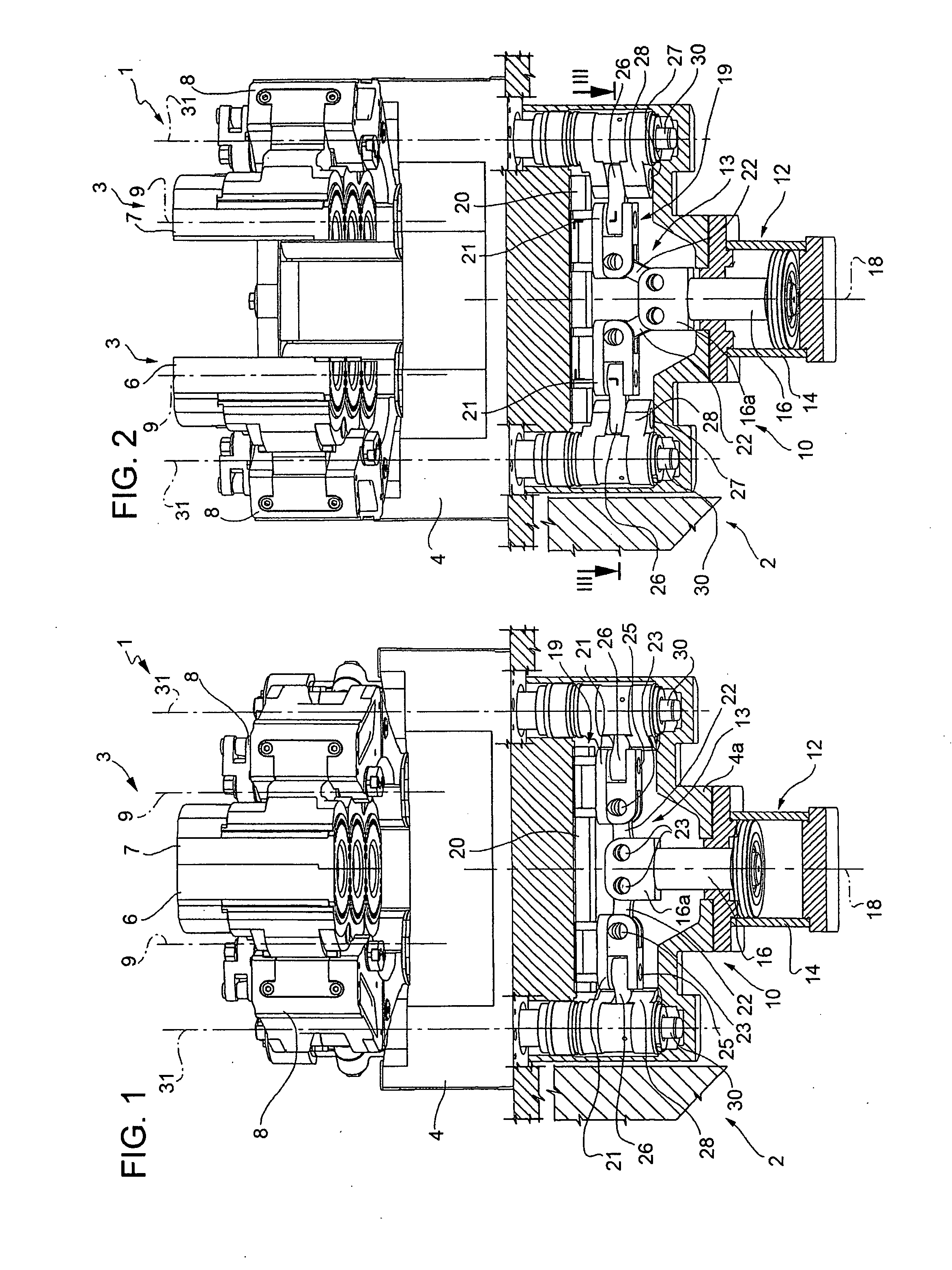

Glassware forming machine molds opening/closing device

ActiveUS20080209951A1Efficient and reliable and compactBlowing machine gearingsGlass drawing apparatusLongitudinal planeMolding machine

A mold of a glassware forming machine has a longitudinal plane of symmetry, and two half-molds movable between a closed position and an open extraction position by a powered mold opening / closing device, which has a fixed fastening and supporting structure, two mold-holders, and, for each mold-holder, a respective supporting and actuating arm hinged to the relative mold-holder to rotate about a movable hinge axis, and to the fixed structure to rotate about a fixed hinge axis; the fixed hinge axes being located on opposite sides of the plane of symmetry, and at such a distance from the plane of symmetry that, when the half-molds are in the closed position, the line intersecting the fixed axis and movable axis of each arm extends substantially parallel to the plane of symmetry.

Owner:BOTTERO SPA

Baffle mechanism for I.S. machine

An I.S. machine has a blankmold which is open at the top and includes inner and outer annular top sealing surfaces. Associated with the blankmold is a baffle including a body having a cup shaped portion closed with a vertical cylindrical bore open at the bottom, an annular bottom sealing surface for sealingly engaging the blankmold outer annular top sealing surface, and a top having a hole. A tubular sleeve communicates with the hole and extends vertically upwardly from the top of the body. A piston has a cylindrical head including a top surface, a cylindrical sealing surface and an annular bottom sealing surface having a plurality of radial notch means across the bottom thereof. A tubular rod extends vertically upwardly from the top surface for slidable displacement in the tubular sleeve, and a collar is secured to the top of the rod. A spring located between the collar and the cup shaped portion urges the cylindrical head vertically upwardly to a position whereat the cylindrical head top surface engages the top of the cup shaped portion. The collar is pneumatically displaced vertically downwardly at a high pressure to bring the cup shaped portion annular surface into sealing engagement with the blankmold outer annular sealing surface. The pressure is then reduced so that a predetermined distance separates the cylindrical head annular bottom sealing surface and the blankmold inner annular sealing surface so that settle air can be introduced into the mold, and then the pressure is again raised to the high pressure for parison formation.

Owner:EMHART GLASS SA

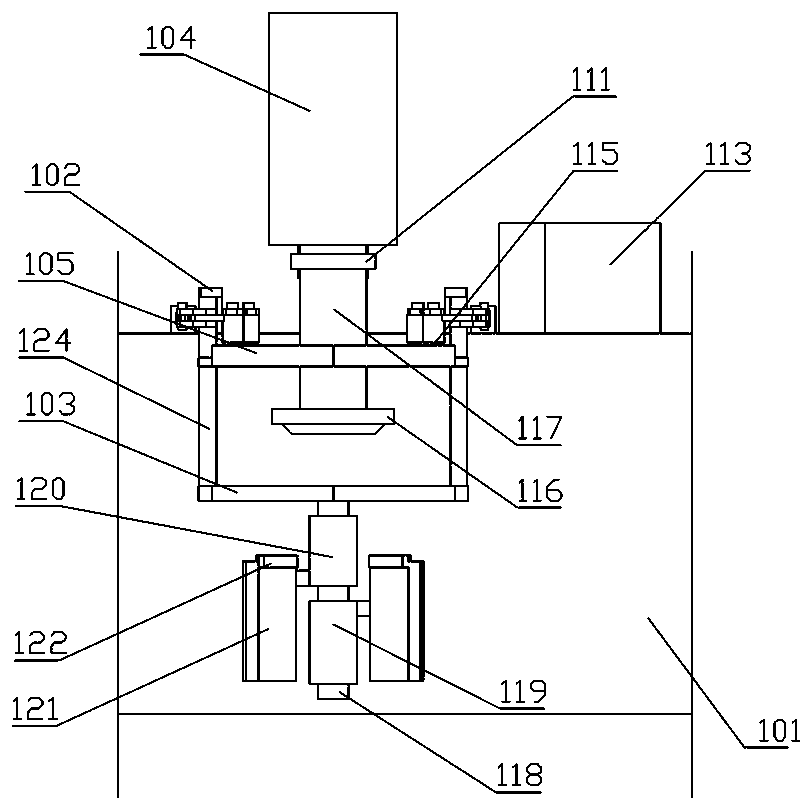

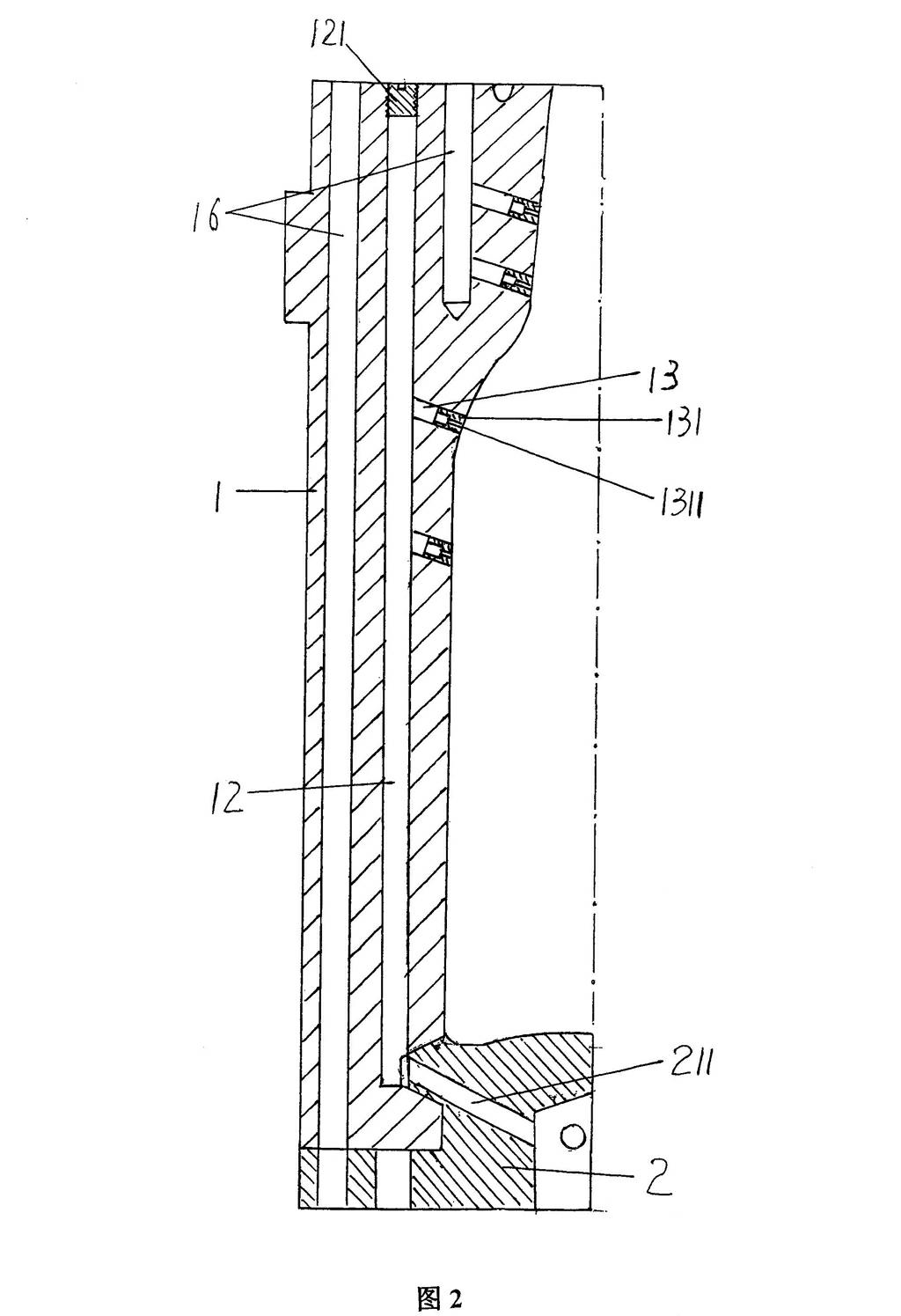

Mould for manufacturing bottle and jar glass containers

The invention discloses a mould for manufacturing bottle and jar glass containers, belonging to the technical field of glass moulds. The mould comprises a pair of bottle semi-moulds and a bottle bottom mould, wherein each bottle semi-mould is provided with a bottle semi-mould cavity and a group of axial exhaust holes; and the bottle bottom mould is matched with the bottoms of the bottle semi-moulds and is provided with a matching boss for being matched with a matching groove of the bottle bottom mould. The mould is characterized in that the group of axial exhaust holes are communicated with the matching groove of the bottle bottom mould; the top of each axial exhaust hole is provided with a screw plug for ensuring that the axial exhaust hole is isolated from the outside; an aspirating connecting cavity is formed at the center of the bottle bottom mould and the side opposite to the bottle semi-moulds; and the matching boss is provided with aspirating holes communicated with the matching groove of the bottle bottom mould and the aspirating connecting cavity, the amount of the aspirating holes is equal to that of the exhaust holes, and each aspirating hole corresponds to one of the axial exhaust holes. The mould has the advantages that neck and shoulder parts can be ideally cooled, and the thickness uniformity of the neck and shoulder parts of the glass containers can be guaranteed.

Owner:CHANGSHU JIANHUA MOLD TECH

Blow molding mold and method equipped with heating stretching system

PendingCN110303664AFully stretchedUniform wall thicknessBlowing machine gearingsBlow headsBlow moldingBottle

The invention discloses a blow molding mold equipped with a heating stretching system. The blow molding mold equipped with the heating stretching system comprises a front mold and a rear mold which form a mold cavity in an encircling mode, a bottom mold located at the bottom of the mold cavity, a bottom mold plate used for installing the bottom mold and a stretching rod stretched from the top of the mold cavity into the mold cavity, wherein a bearing mechanism is arranged in the mold cavity, the bearing mechanism comprises a bearing rod and a drive mechanism which drives the bearing rod to stretch into the middle of the mold cavity, and heating elements are arranged in the stretching rod and / or the bearing rod. According to the blow molding mold equipped with the heating stretching system,the heating elements are arranged in the stretching rod and / or the bearing rod, and when a bottle is blown, temperature of the stretching rod and the bearing rod is approximate to temperature of a bottle blank, situations of early cooling and the like cannot occur, and materials at the bottom of the bottle blank are fully stretched, uniformly distributed at the bottom of the bottle, and cooled and shaped well. Due to the fact that the materials are fully stretched, not only is inner stress at the bottom of the bottle reduced, but also a bursting probability is reduced.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

Narrow Neck Glass Container with Integral Embossments and Method of Manufacture

A narrow neck glass container includes a container body and a container neck finish. The container neck finish has an external closure attachment diameter of not more than 36 mm, and the container body has at least one internal embossment of predetermined geometry. The at least one internal embossment preferably comprises a plurality of internal embossments in a geometric pattern.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

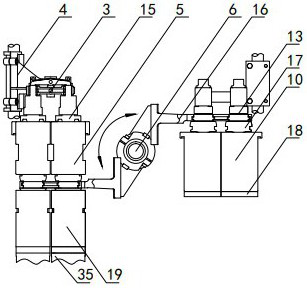

High borosilicate glass bottle making machine and fast blowing method production process

ActiveCN114105448AIncrease productivityAvoid Yield DefectsBlow headsBlow machinesProcess engineeringBottle

The invention discloses a high borosilicate glass bottle making machine and a fast blowing method production process, and belongs to the technical field of glass instruments. Which comprises a prototype side and a forming side, a prototype mold (5) and a forming mold (10) are arranged on the prototype side and the forming side respectively, an air flapping mechanism (4) and a reverse blowing mechanism are arranged on the prototype side, and a forward blowing mechanism (12) is arranged on the forming side, and is characterized in that an air flapping head (15) directly butted with the prototype mold (10) is arranged in the air flapping mechanism (4); a flapping opening in the bottom of the flapping head (15) is opened or closed along with flapping airflow; and a core mechanism is arranged at the top of the reverse blowing mechanism and comprises a plurality of layers of cores which are sleeved inside and outside. According to the high borosilicate glass bottle making machine and the fast blowing method production process, air is directly flapped after the air flapping head is in butt joint with the prototype mold, the process steps are reduced, meanwhile, the core mechanism with multiple layers of cores is arranged, reverse blowing failure is avoided, and the high borosilicate glass bottle making machine and the fast blowing method production process are particularly suitable for production of high borosilicate glass bottles and have the advantages of being high in efficiency and high in yield.

Owner:SHANDONG JIAFENG GLASS MACHINERY

Die for manufacturing glass container

InactiveCN101885576ASpeed up coolingMeet production requirementsBlowing mouldsWine bottleBody cavity

The invention relates to a die for manufacturing a glass container, and belongs to the technical field of glass dies. The die comprises a pair of bottle half-dies which have the same shapes and are arranged opposite to each other, wherein a bottle die cavity formed by a bottle body cavity and a bottleneck cavity commonly is formed on the inner wall of each bottle half-die. The die is characterized in that: heat transfer post holes are formed on upper parts of the pair of bottle half-dies and side faces surrounding the bottleneck cavities at intervals, and a heat transfer post is arranged in each heat transfer post hole. In the technical scheme, a group of heat transfer post holes are formed on the upper parts of the pair of bottle half-dies and the side faces surrounding the bottleneck cavities at intervals, and the heat transfer post is arranged in each heat transfer post hole, so the cooling speed at bottleneck shoulders can be accelerated. When bottle pincers take formed glass bottles out of the bottle die cavities of the pair of bottle half-dies, the glass bottles are not deformed, so the production requirements of demanding high-quality wine bottles can be met.

Owner:CHANGSHU JIANHUA MOLD TECH

I. S. machine

An I.S. Machine for making glass bottles, having a plurality of sections, each having a blank station for forming a parison. Each section has a section frame having a top surface, and a plunger mechanism including at least one plunger canister having a lower cylinder and an upper flange. A horizontal mounting plate having a top surface and vertical openings for receiving the lower cylinder of each of the plunger canisters is fixedly secured on the top surface of the section frame. The section frame top surface has vertical openings for receiving the lower cylinders of each of the plunger canisters and the flange of the plunger mechanism is secured to the top surface of the mounting plate.

Owner:EMHART GLASS SA

Finishing mold for shaping a glass item, for example such as a glass bottle

InactiveUS20130047675A1Glass pressing apparatusBlowing mouldsBottleElectrical and Electronics engineering

Owner:POCHET DU COURVAL

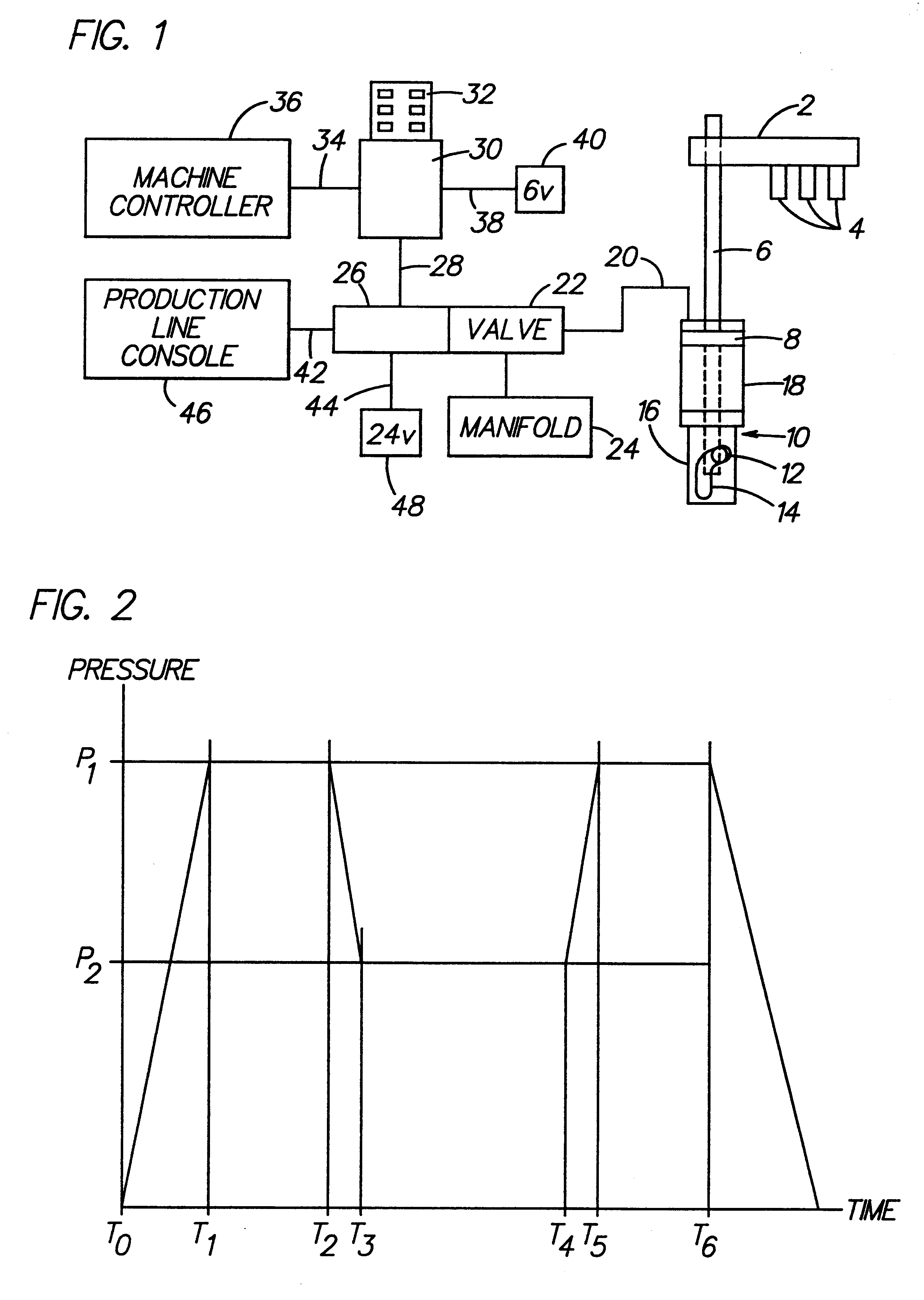

Vacuum system for an I.S. machine

A vacuum system is disclosed for opposed engaged pairs of blow mold halves on a section of an I.S. machine. The system includes a bottom housing which is open at the top and closed by a top plate assembly including a top plate having a vertical opening for each of the opposed pairs of blow mold halves and an annular manifold support portion below the top plate. A vacuum manifold which has a cylindrical inlet conduit and a vertical outlet conduit beneath each of the top plate vertical openings is supported by the annular mold support portion. A vacuum tube slides into the cylindrical inlet conduit and is mounted on the annular manifold portion. The vacuum tube has a hole for communicating with each of the vacuum manifold vertical outlets.

Owner:EMHART GLASS SA

Molds opening/closing group of a forming glass machine items

In a machine for forming glass items, a mold having two half-molds movable between a closed forming position and an open extraction position by a mold opening / closing group is provided. The mold includes two handling arms, each connected to a respective half-mold, which are rotated about respective fixed hinge axes by a single linear actuator. The mobile member translates in a direction parallel to the fixed hinge axes, and is connected to the handling arms by a mechanical transmission having a respective guide-and-slide assembly for each handling arm.

Owner:BOTTERO SPA

Method for fabricating bottle molds

InactiveUS6837297B1Promotes local meltingEnhance mechanical interlockingBlowing mouldsBottleMachining

The method allows fabricating a bottle mold having dissimilar metal inserts embedded in regions where the bottle mold is most subject to attack by hot glass, and has a glass contact surface with refined grain size. To fabricate the bottle mold, rough castings are made by pouring cast-iron into a composite mold having dissimilar metal insert blanks fixably positioned therein. The dissimilar metal insert blanks become embedded in the cast-iron matrix to form rough dissimilar metal inserts in the rough casting. The composite mold has regions formed by metal chills that are partially embedded in a sand mix. The chills and the exposed surfaces of the rough dissimilar metal inserts define a cavity surface of the rough casting, which is subsequently machined to provide the glass contact surface of the bottle mold. The chills refine the grain size of the cast iron at the glass contact surface.

Owner:KELLY MACHINE & FOUNDRY

Threadless nut

A glassware forming machine baffle arm assembly that includes a quick-connect / disconnect arrangement mounting a baffle manifold on a baffle arm. The arrangement includes a baffle arm having an aperture, and a baffle manifold having a segment extending through said aperture and permitting rotation of said baffle manifold with respect to said baffle arm. The arrangement also includes a threadless nut, and a bayonet connection between said threadless nut and said baffle manifold segment.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Primary mold

InactiveCN104140193AIncrease productivityImprove product qualityBlowing mouldsGlass productionBottle

The invention relates to a primary mold. A cavity is formed in the primary mold. A hopper-shaped feeding cavity is formed in an opening in the upper end of the primary mold. The feeding cavity is communicated with the cavity. The lower portion of the primary mold is a bottle forming portion. The cavity is arranged in the bottle forming portion. The upper portion of the primary mold is a feeding portion. The feeding cavity is arranged in the feeding portion. The bottle forming portion and the feeding portion are integrally formed. The bottom of the feeding cavity is communicated with the top of the cavity. Compared with the prior art, the hopper-shaped feeding cavity is directly formed in the opening in the upper end of the primary mold, and the primary mold and the feeding cavity are integrally formed, so that time consumed when a hopper arm drives a hopper to reach the opening in the upper end of the primary mold and the hopper arm drives the hopper to be reset in the prior art is saved, hopper displacement and reset actions are reduced, and glass bottle production efficiency is improved on the same condition.

Owner:DEQING CAIFU GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com