Patents

Literature

69results about "Vacuum and blow machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible 3D Freeform Techniques

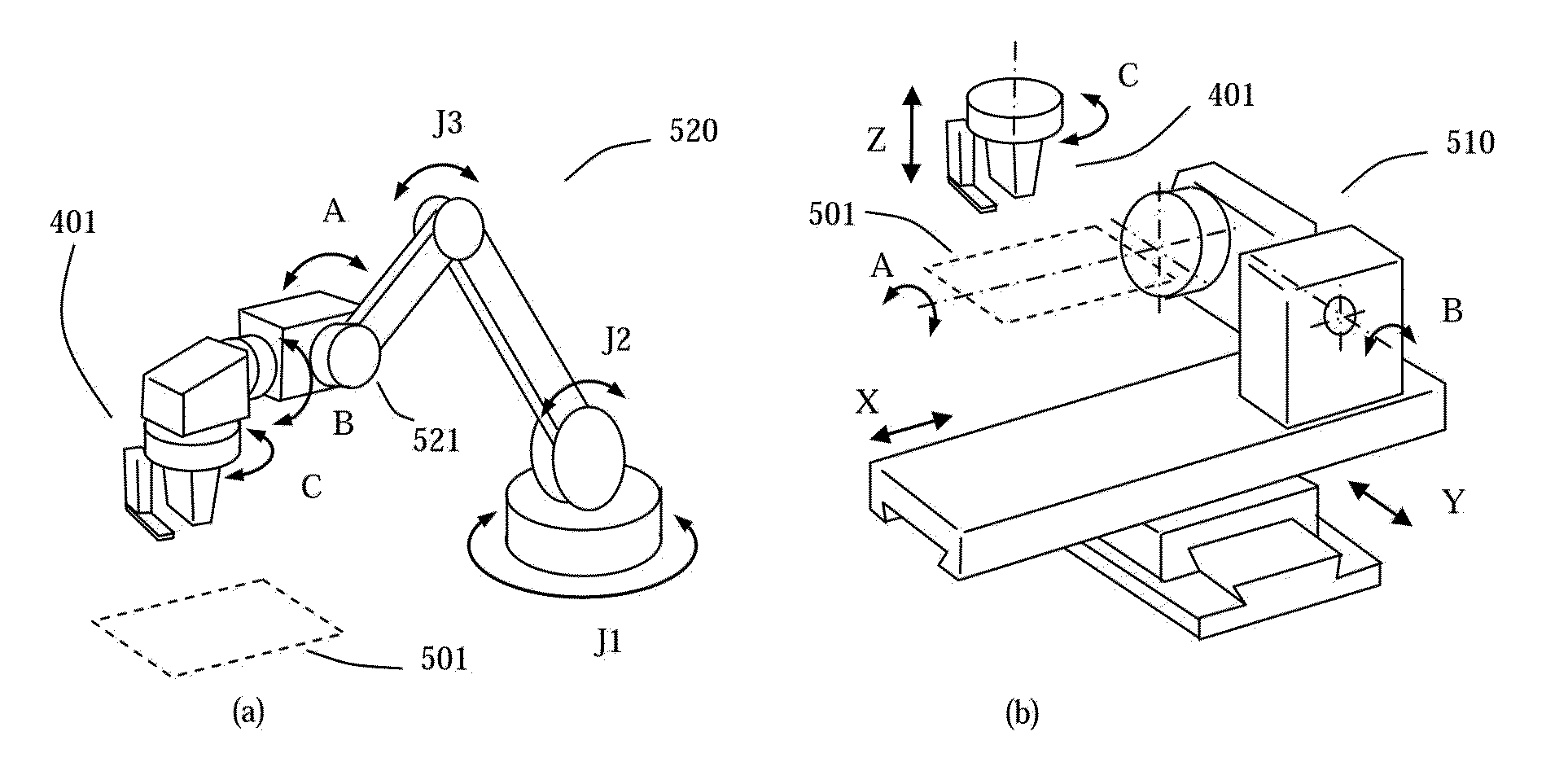

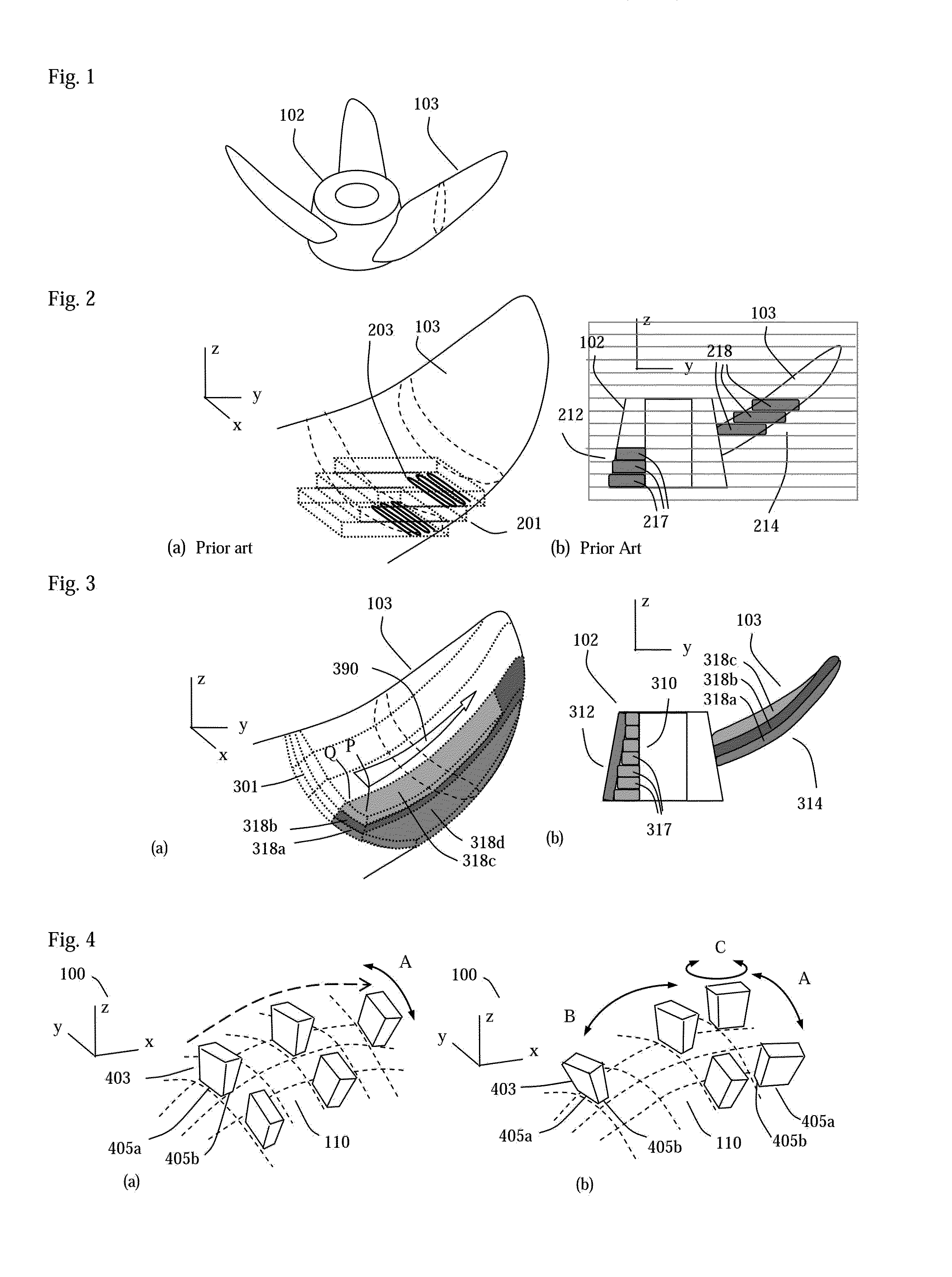

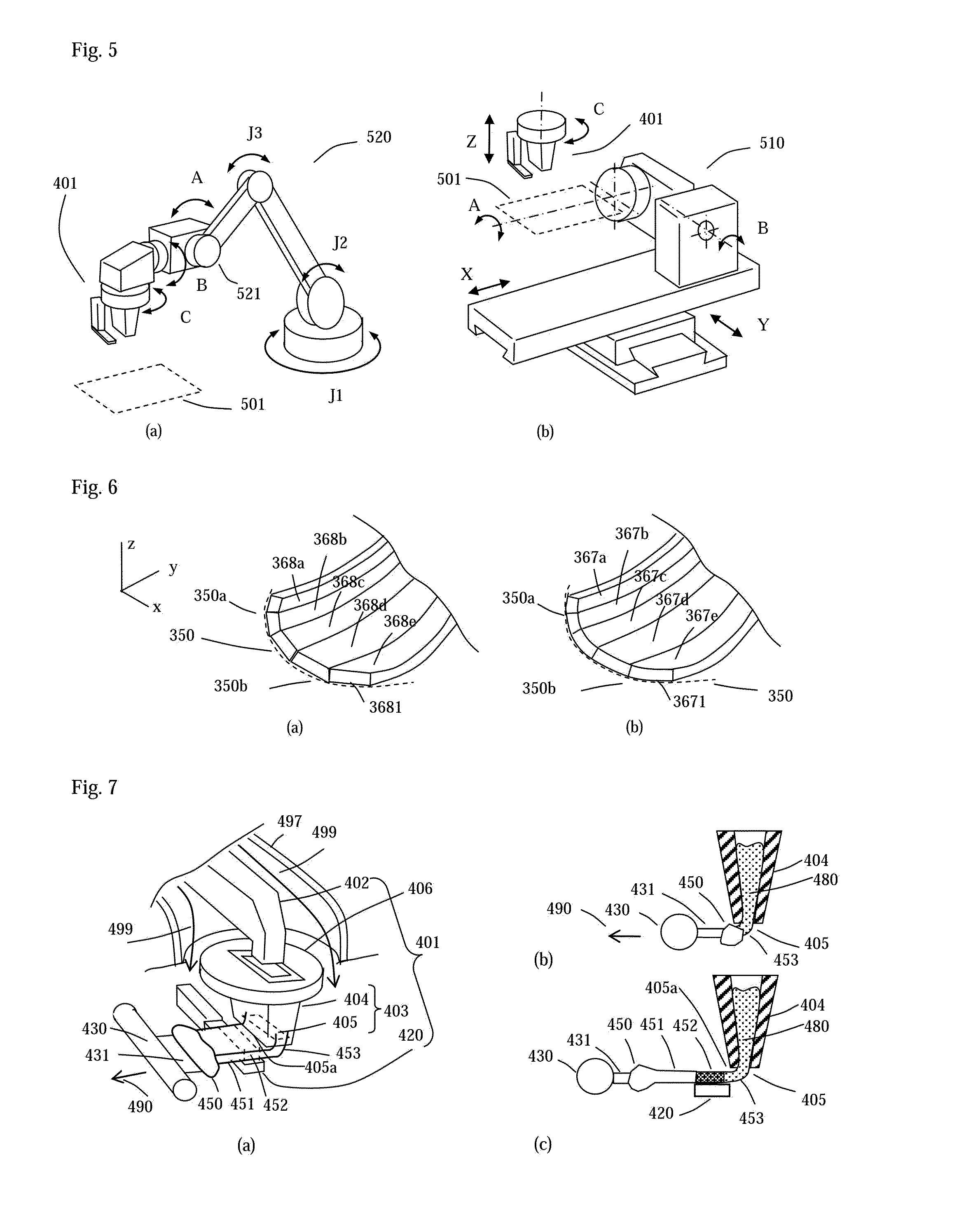

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

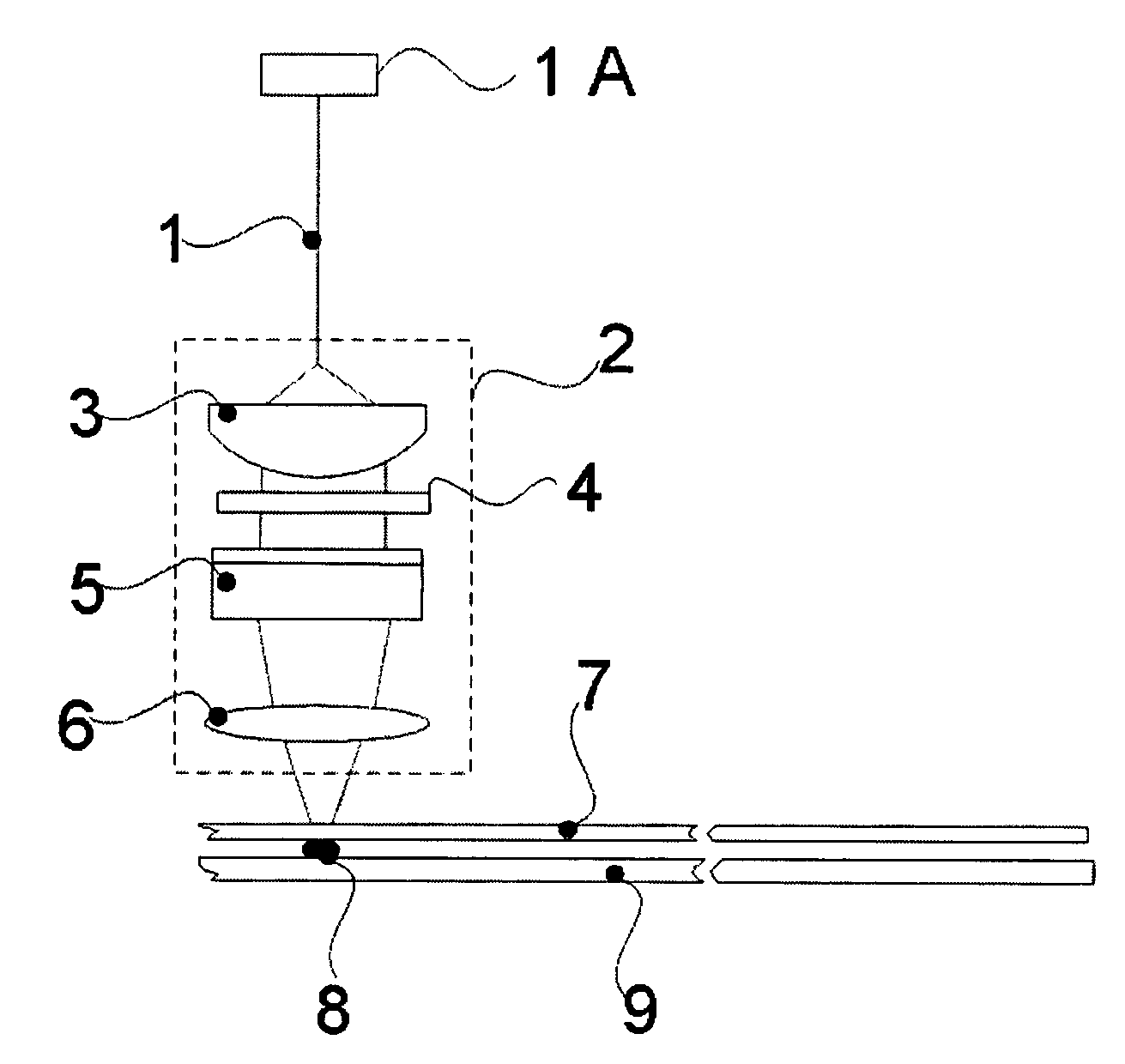

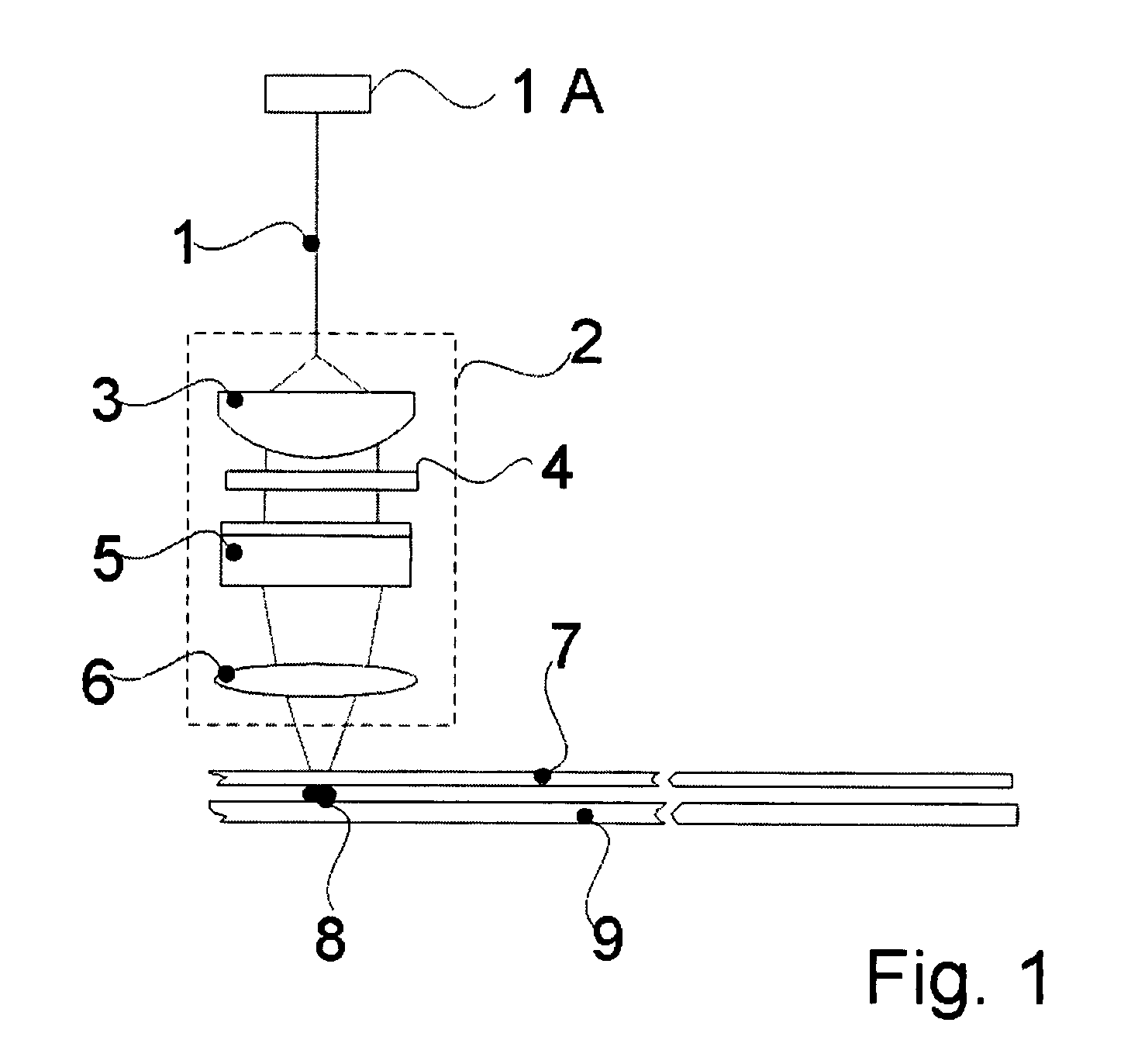

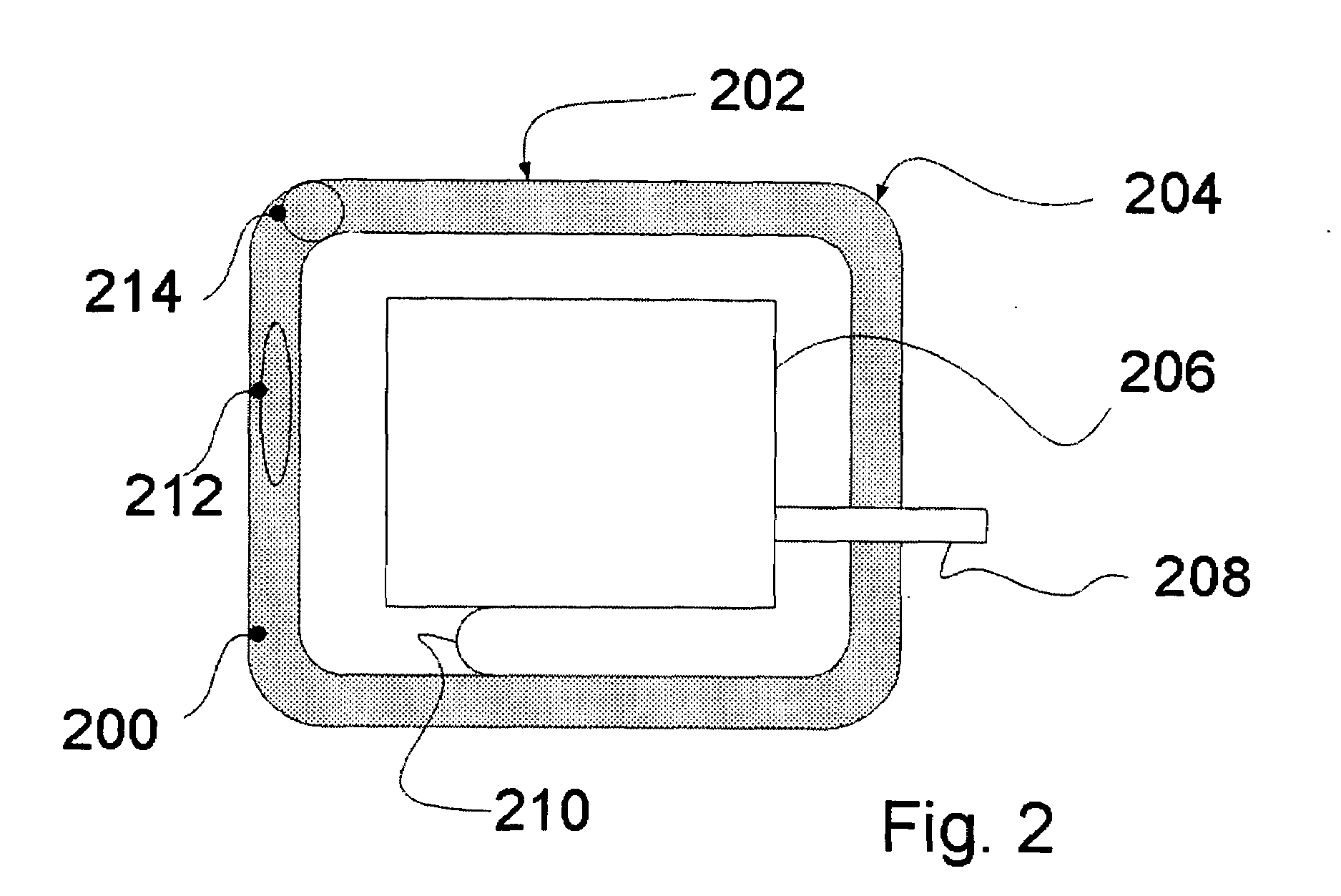

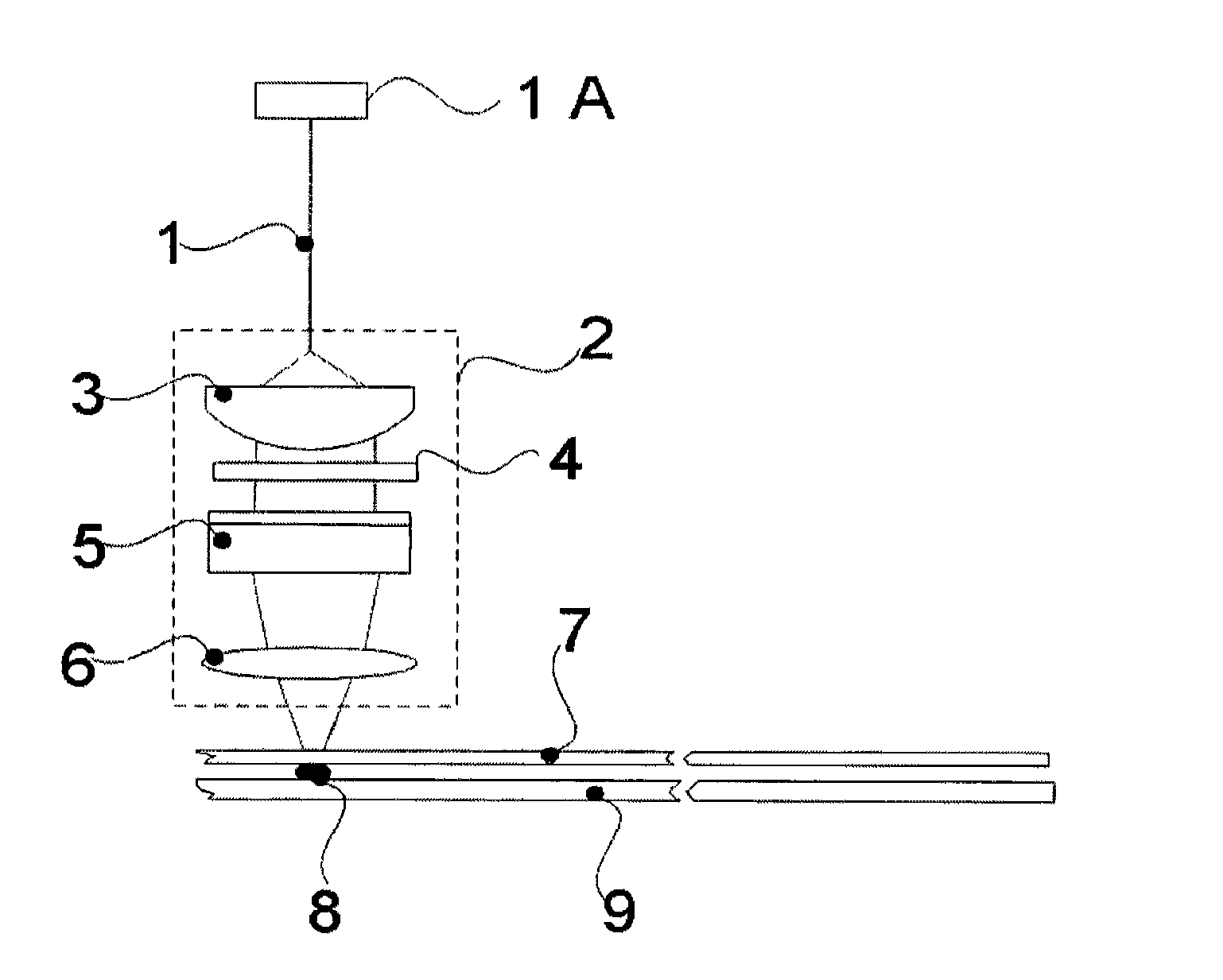

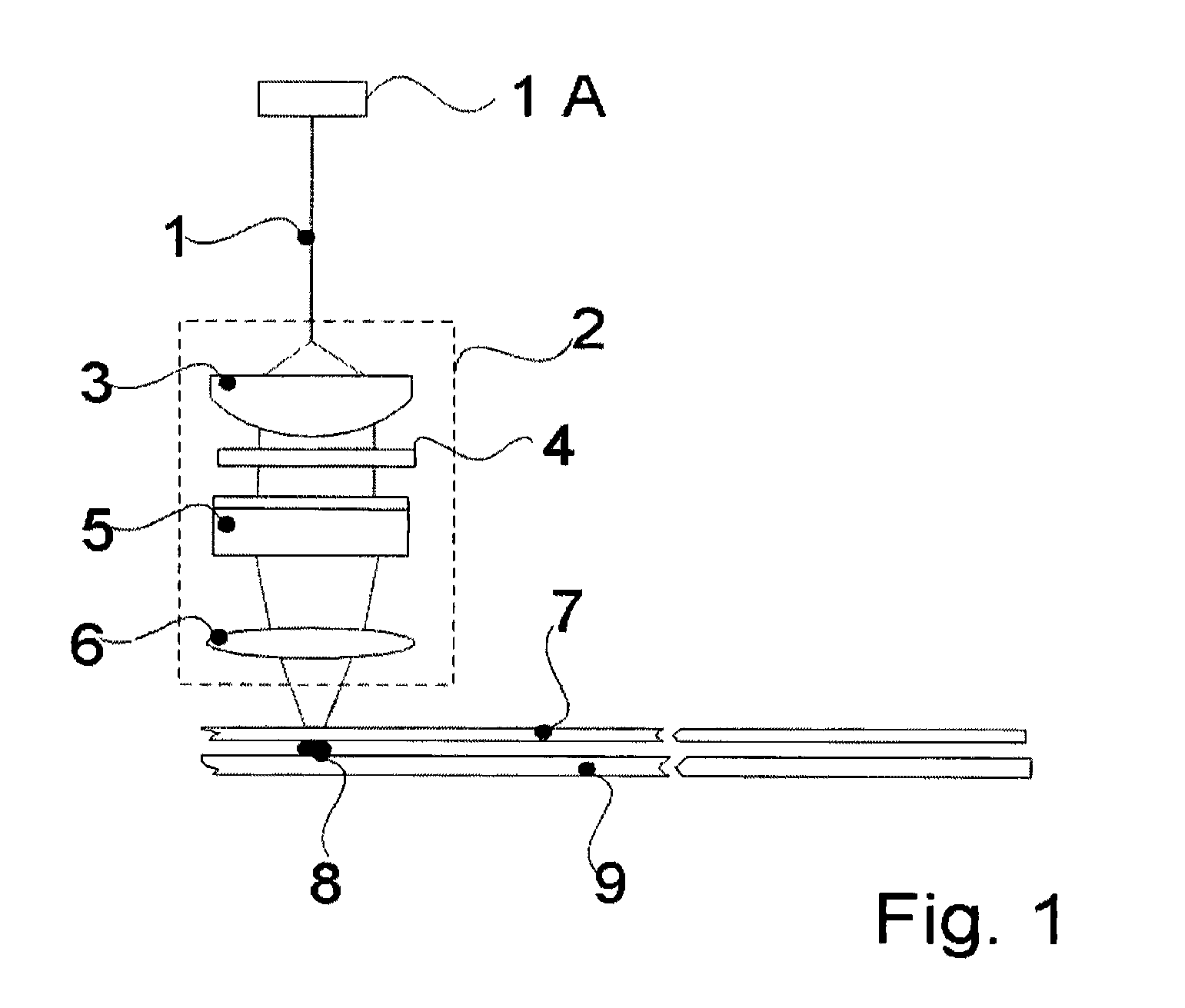

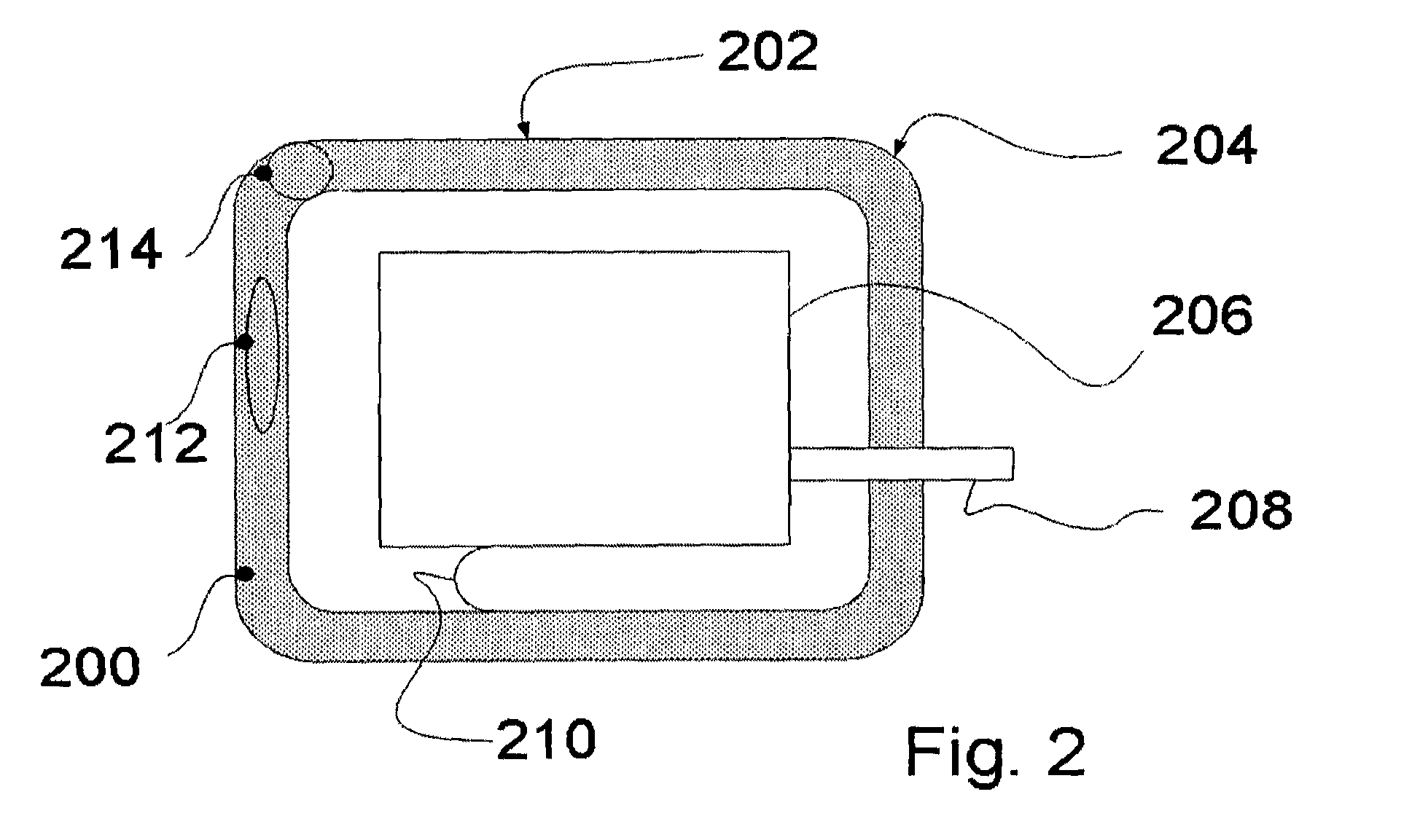

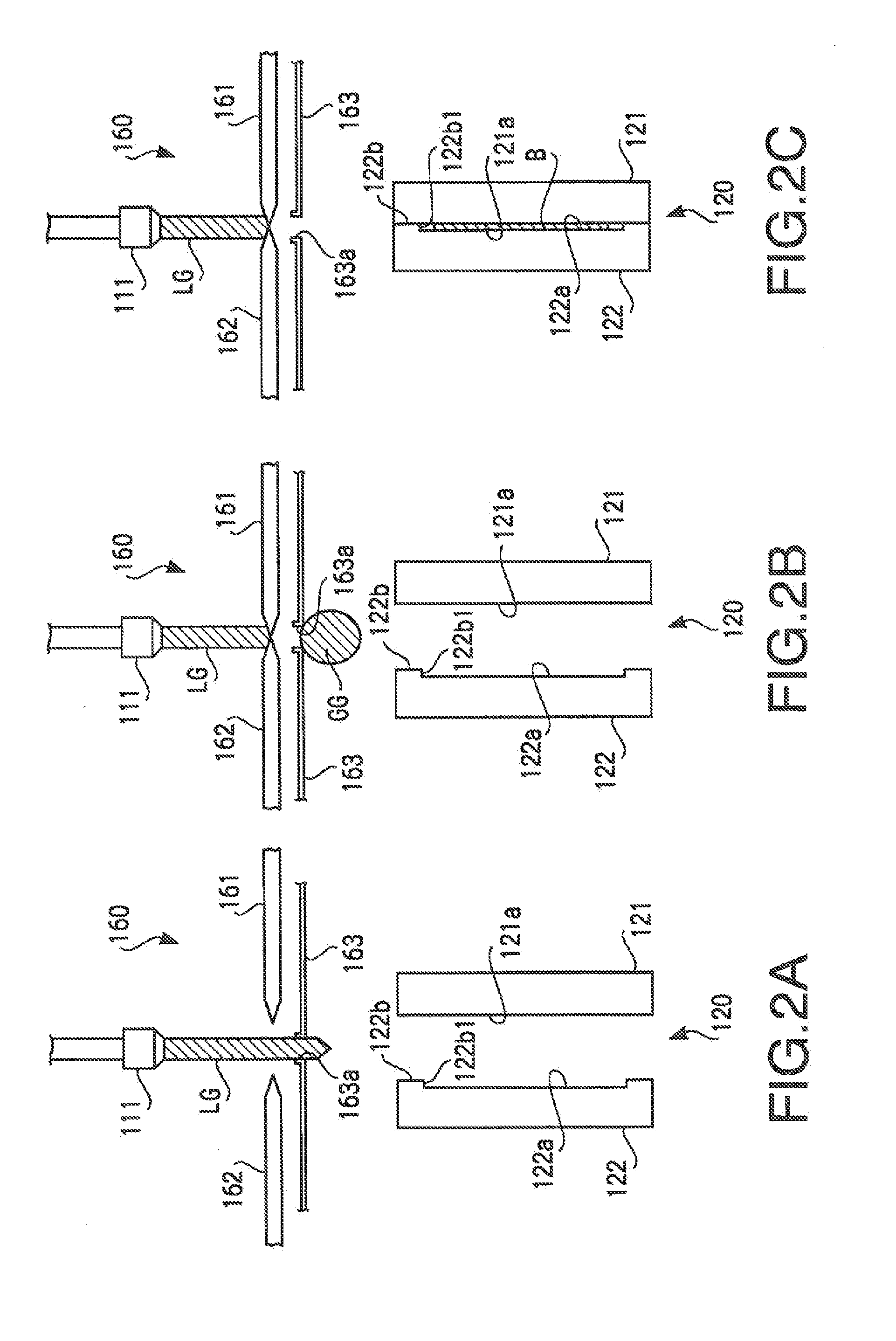

Method and apparatus for frit sealing with a variable laser beam

InactiveUS20090086325A1Uniform temperature distributionImprove overall utilizationDiffusing elementsElectroluminescent light sourcesFritLight beam

A beam shaper is implemented to seal an OLED. The beam shaper comprises a first and second lens and a beam shaper. Changing the relative position of the first, second lens and beam shaper relative to each other enables the beam shaper to generate laser beams with different shapes and intensity profiles.

Owner:CORNING INC

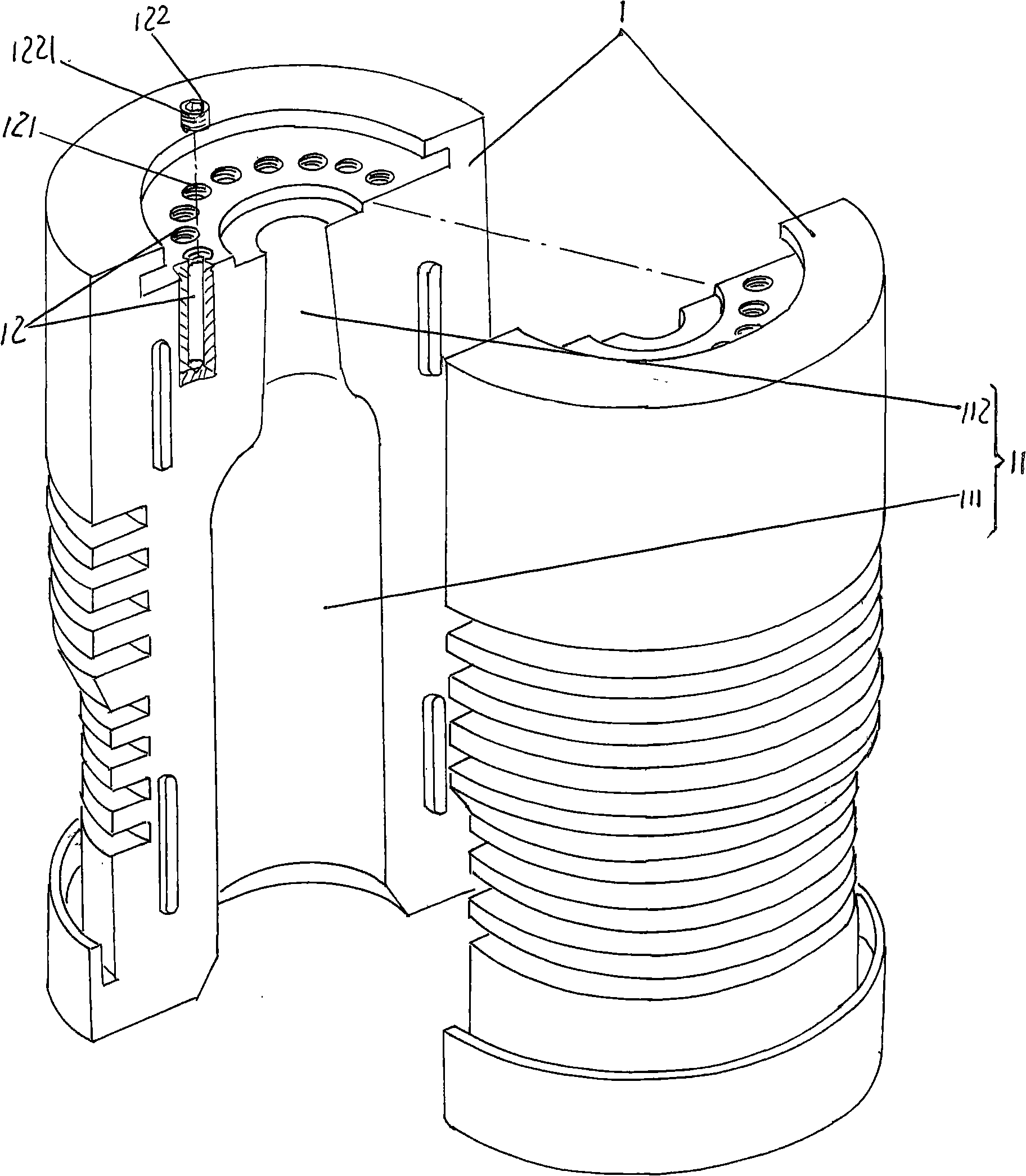

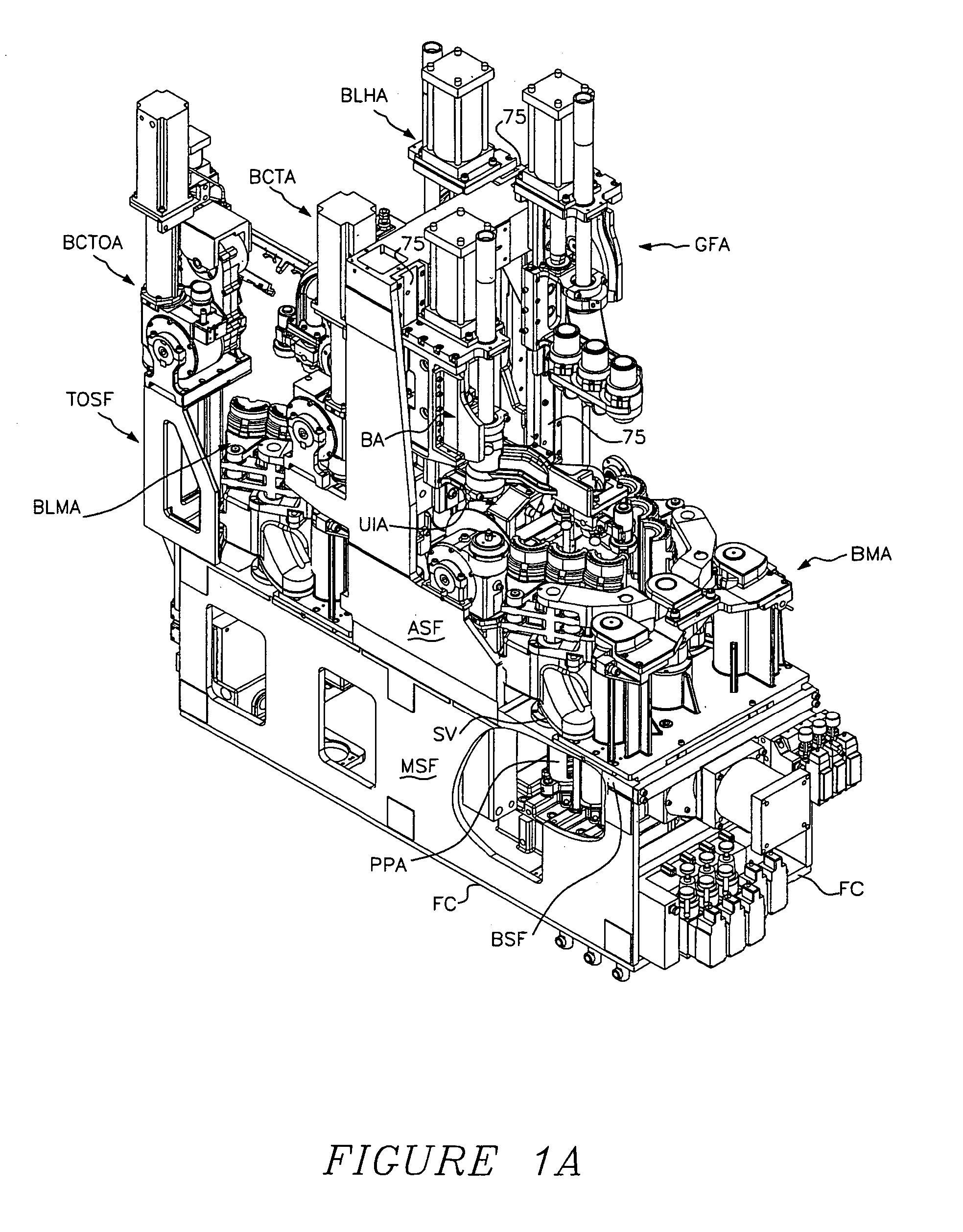

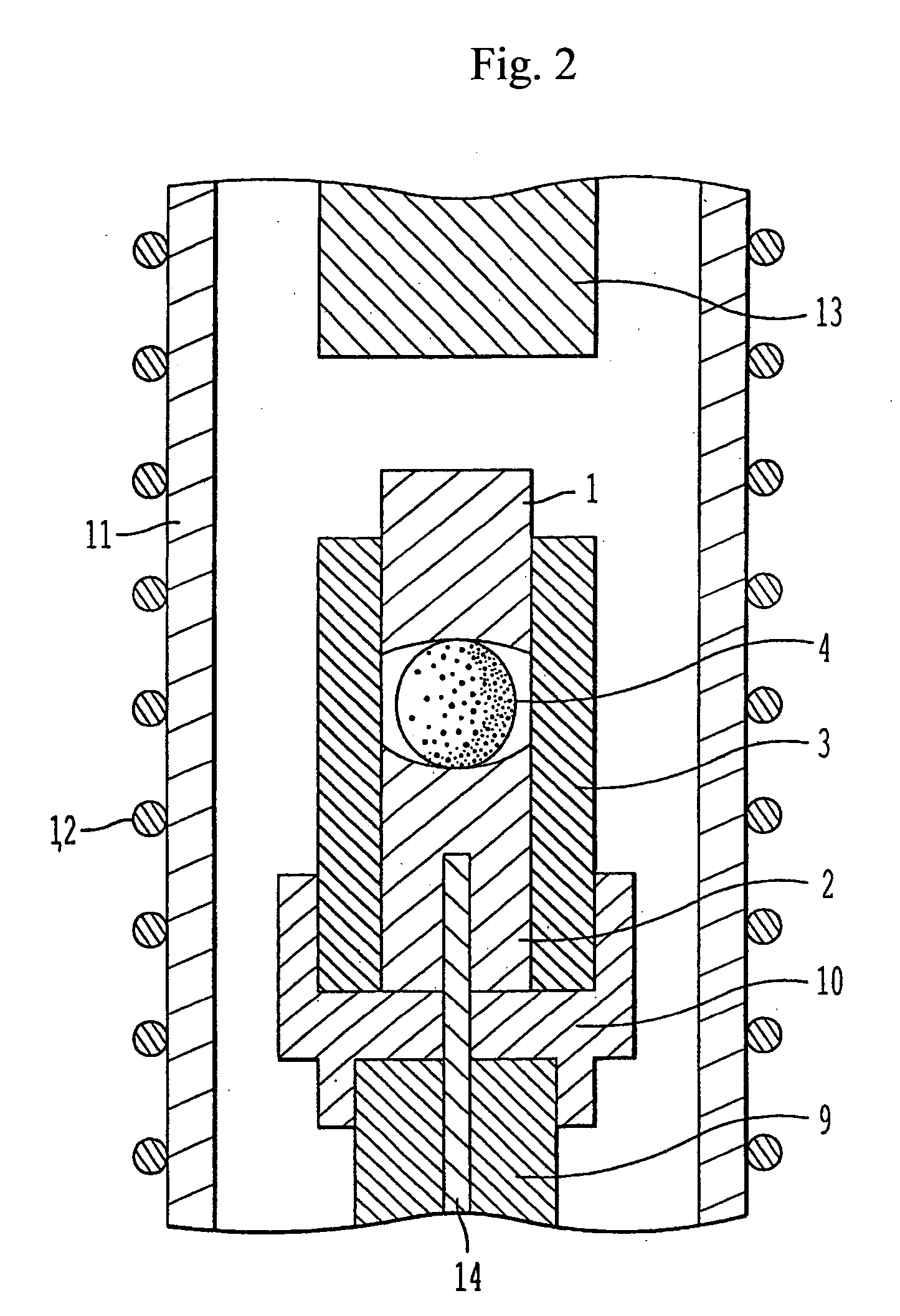

Mould for making glass container

ActiveCN101298355AIncrease temperatureEvenly distributedVacuum and blow machinesGlass containerMaterials science

The invention provides a mold for producing a glass container and belongs to the technical field of mold. The mold includes a pair of half bottle molds that are opposite to each other, a bottle die cavity is composed of a bottle body cavity and a bottleneck cavity and is formed on the inner wall of each of the half bottle molds. The mold is characterized in that heat-insulating holes are regularly distributed around the bottleneck cavity at the upper part of the half bottle mold, so the temperature around the bottleneck cavity can be improved, which is helpful to lead the materials to distribute evenly during the two blowing processes and can guarantee that the wall thickness of the bottleneck is uniform.

Owner:CHANGSHU WEIHENG MOLD MFG

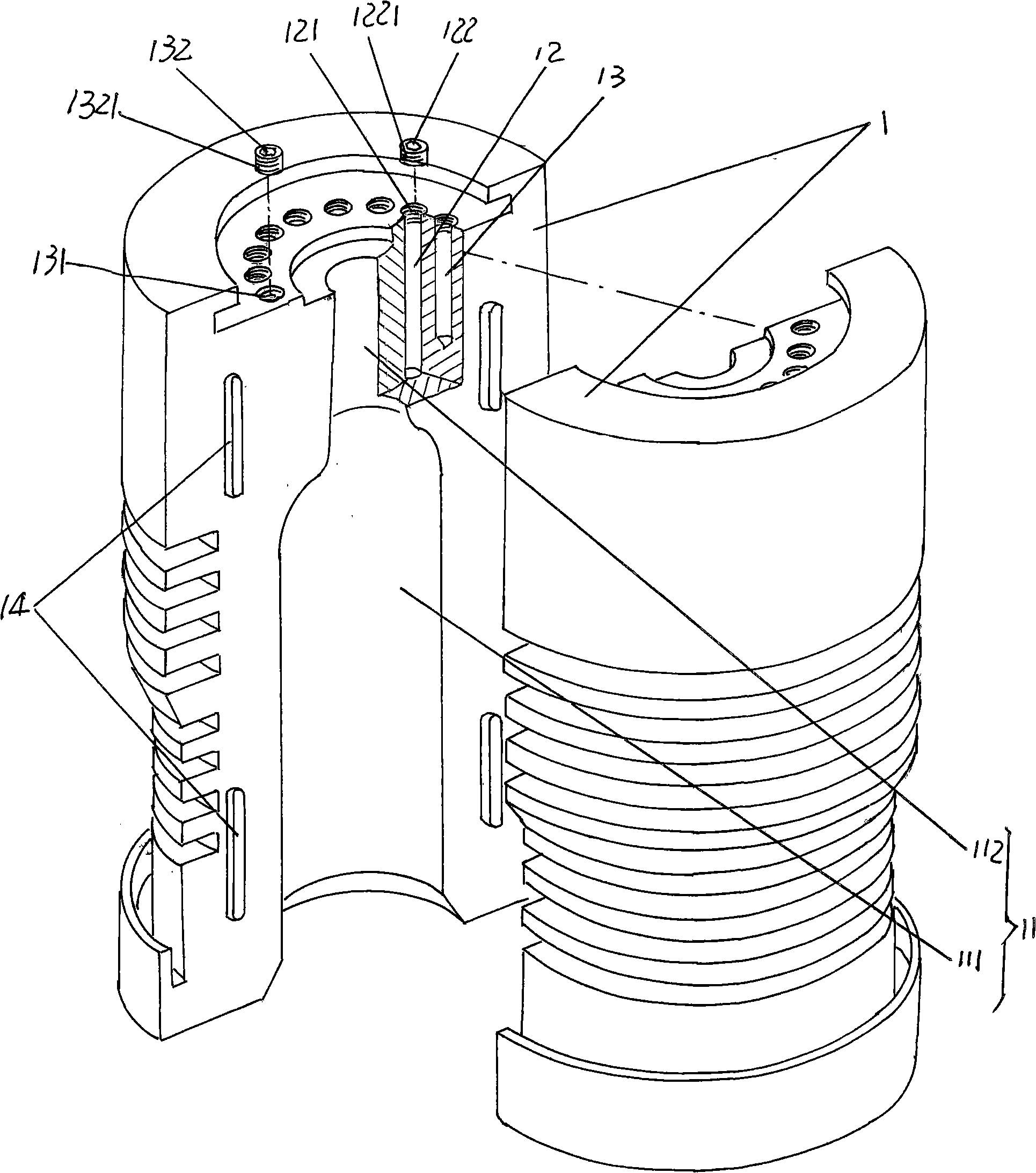

Mould for making glass container

ActiveCN101298356AIncrease temperatureEvenly distributedVacuum and blow machinesBottleMaterials science

The invention provides a mold for producing a glass container and belongs to the technical field of mold. The mold includes a pair of half bottle molds that are opposite to each other, and a bottle die cavity is formed in the inner wall of each half bottle mold and is composed of a bottle body cavity and a bottleneck cavity. The mold is characterized in that a first heat-insulating hole and a second heat-insulating hole are alternatively distributed around the bottleneck cavity at the upper part of the half bottle mold, wherein, the depth of the two heat-insulating holes is different. The mold has the advantages that the temperature around the bottleneck cavity can be improved as the first heat-insulating hole and the second heat-insulating hole are arranged at the upper part of the half bottle mold and are corresponding to the surrounding of the bottleneck cavity, which is helpful to lead the materials to distribute evenly during the two blowing process and can guarantee that the wall thickness of the bottleneck is uniform.

Owner:CHANGSHU WEIHENG MOLD MFG

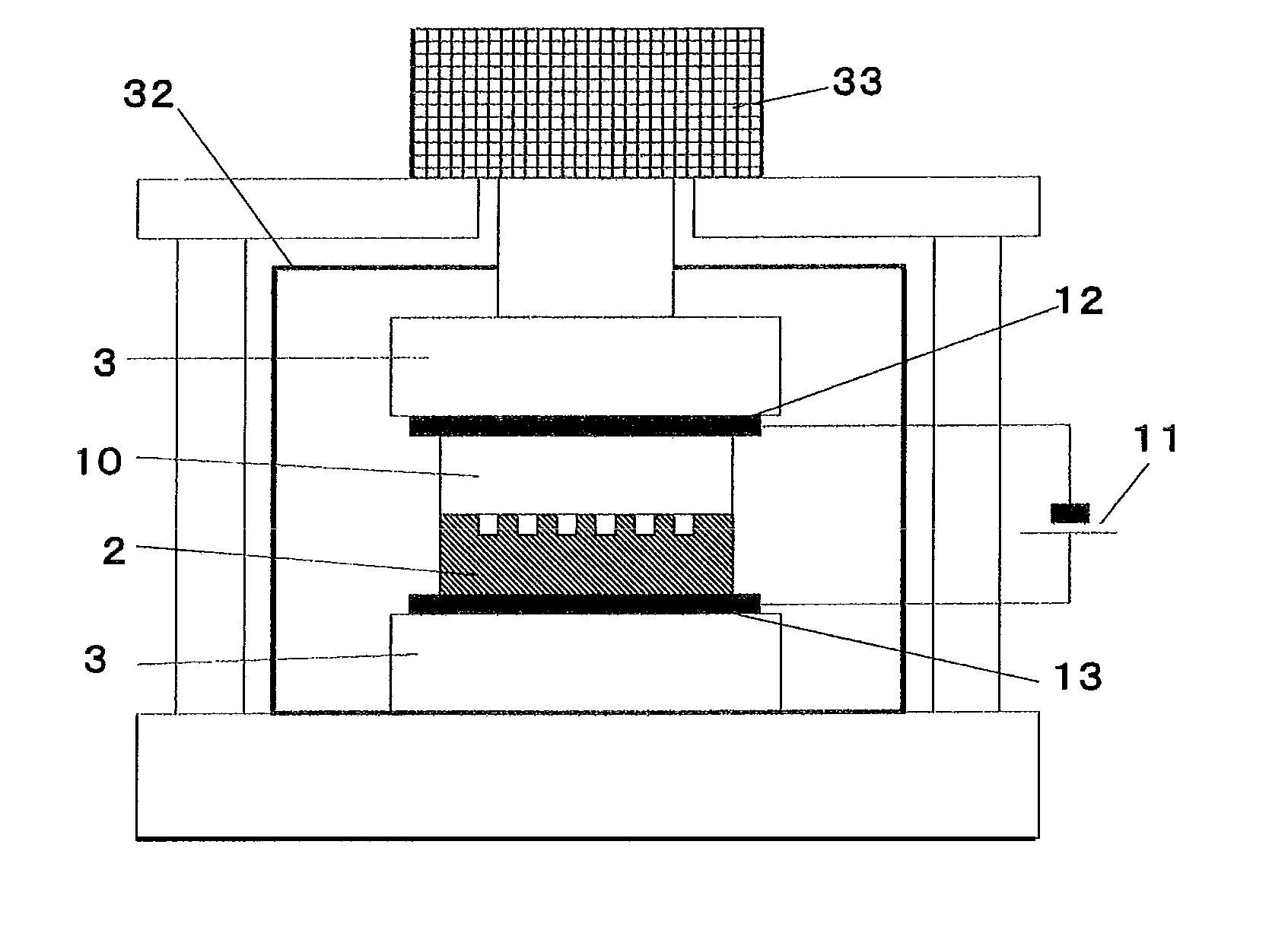

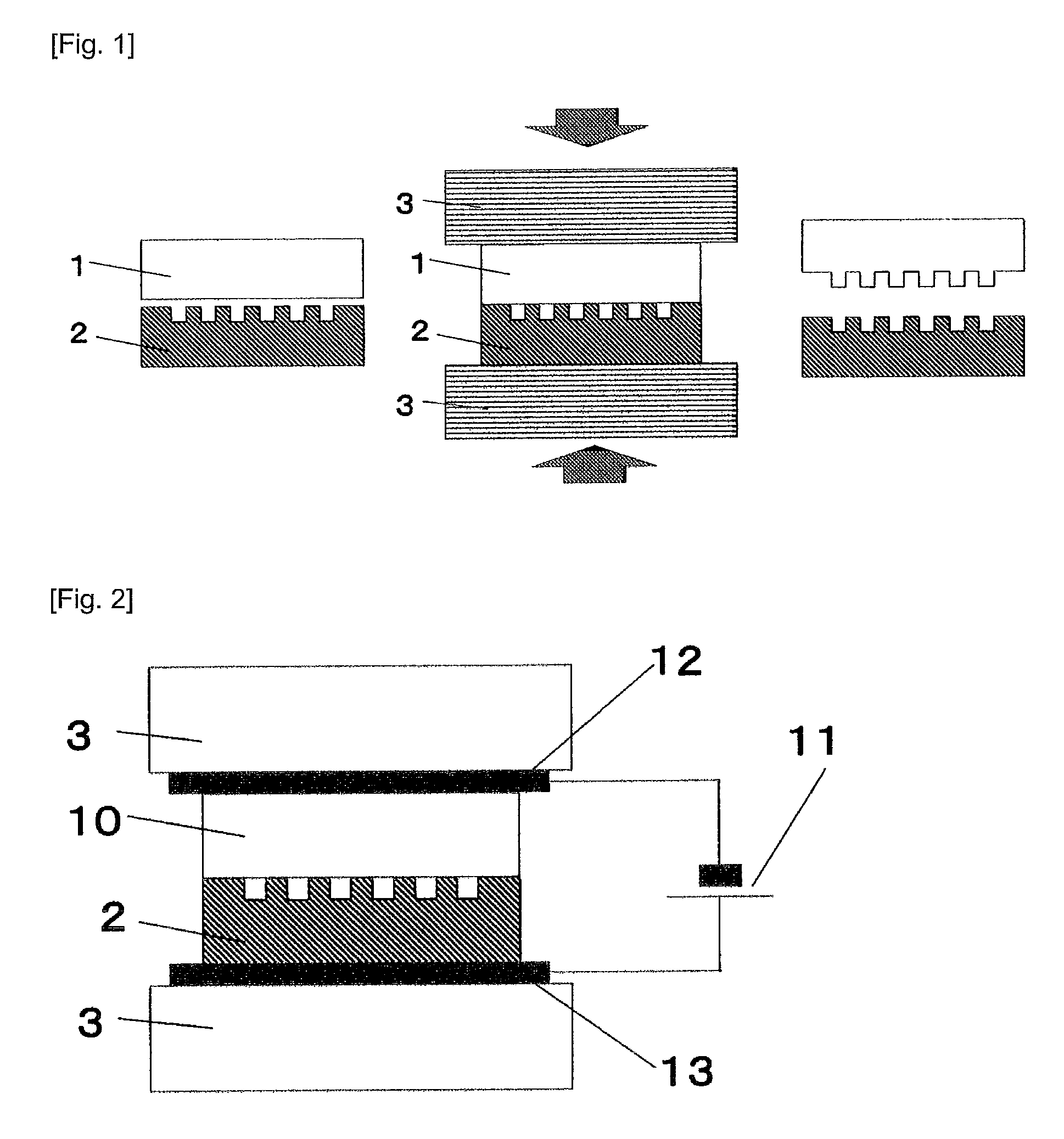

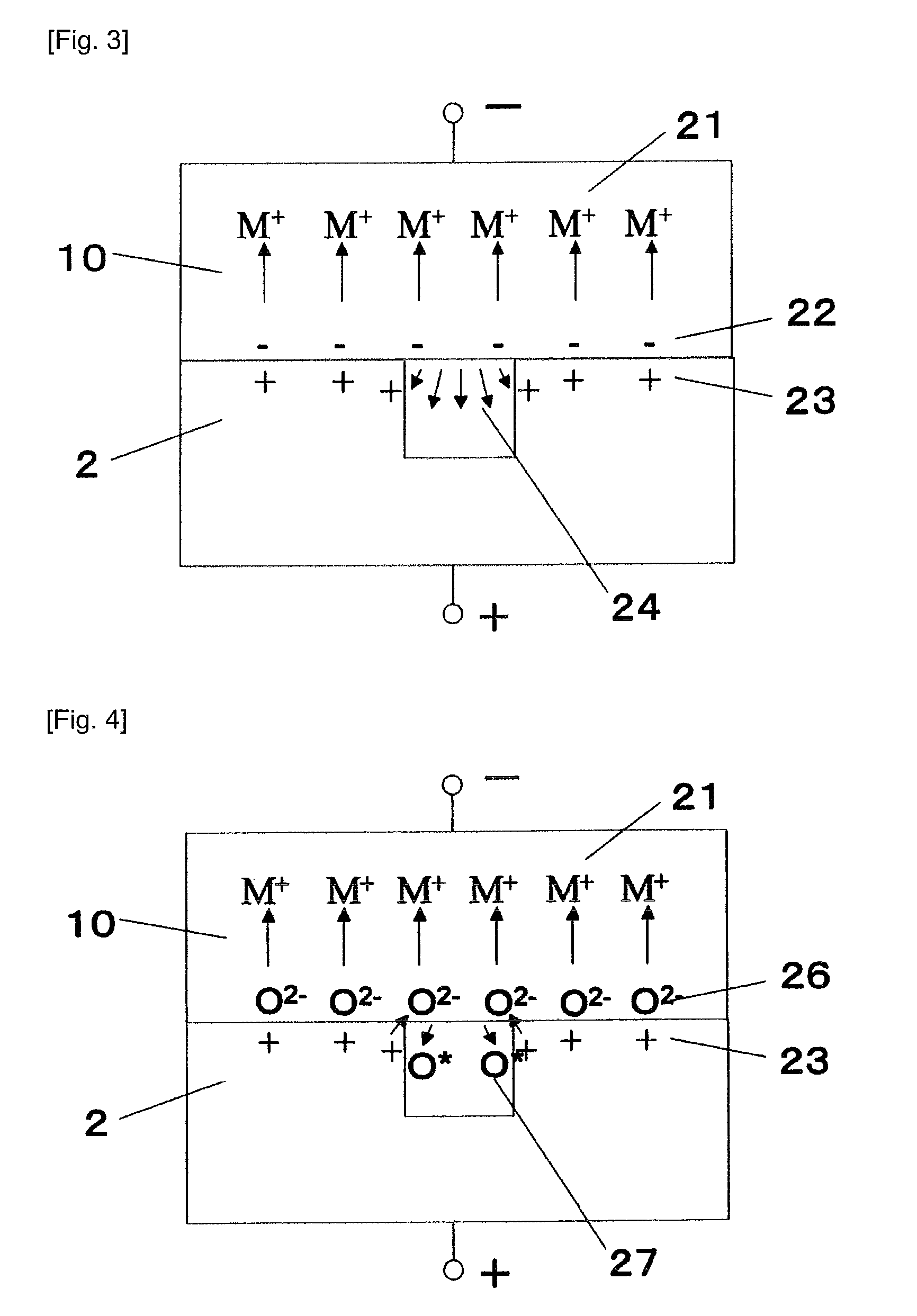

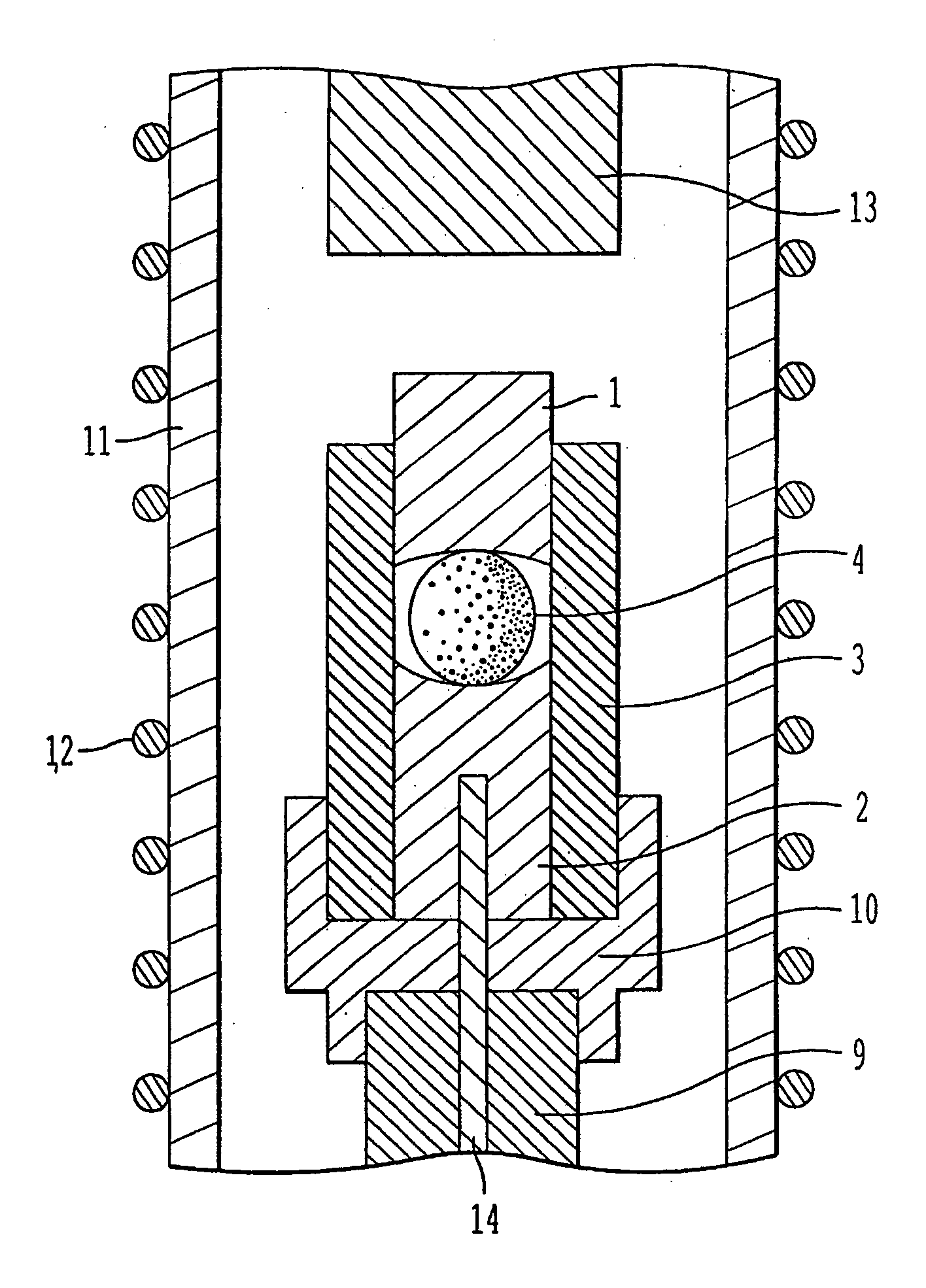

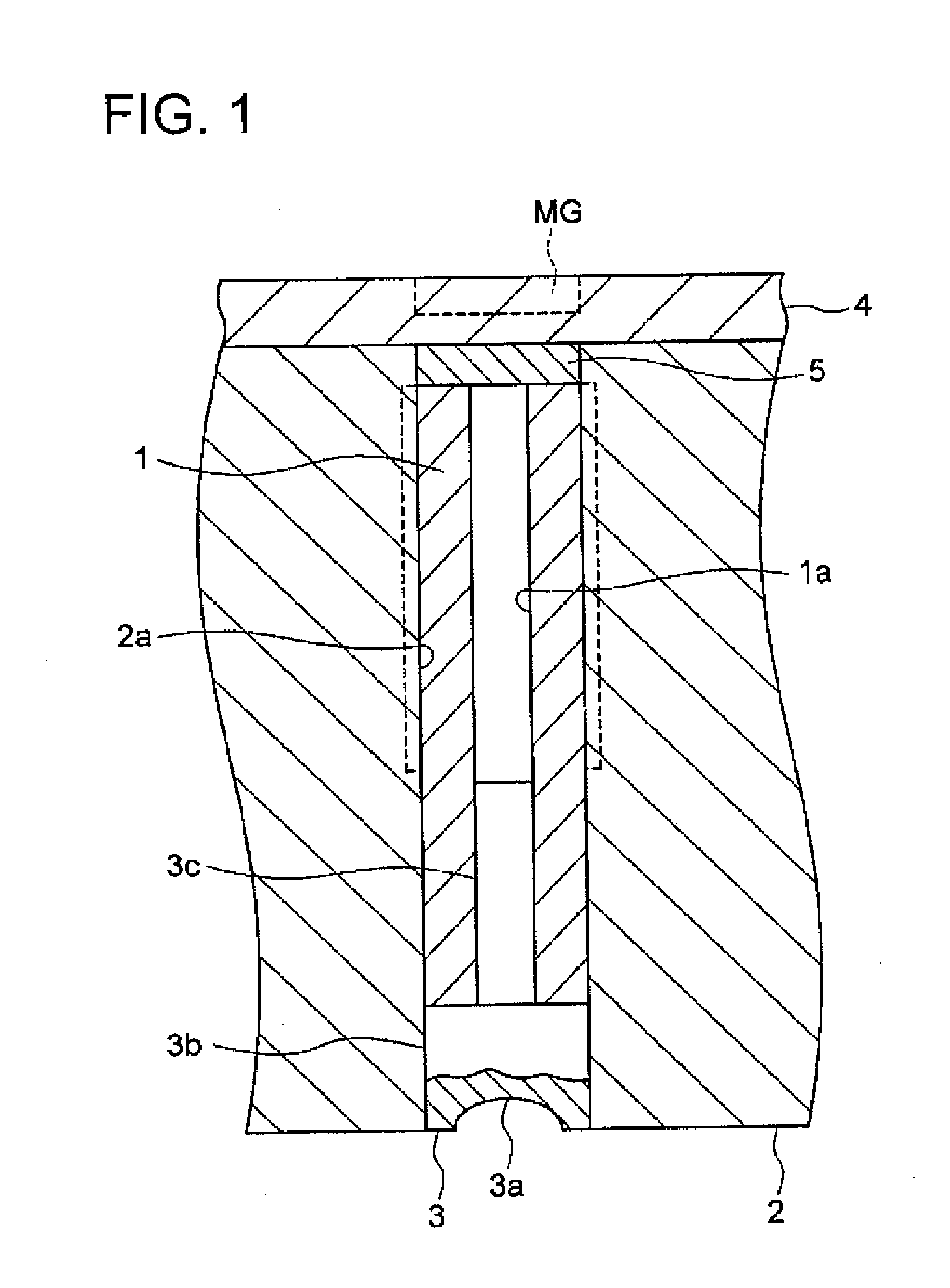

Method of molding glass parts and molding apparatus

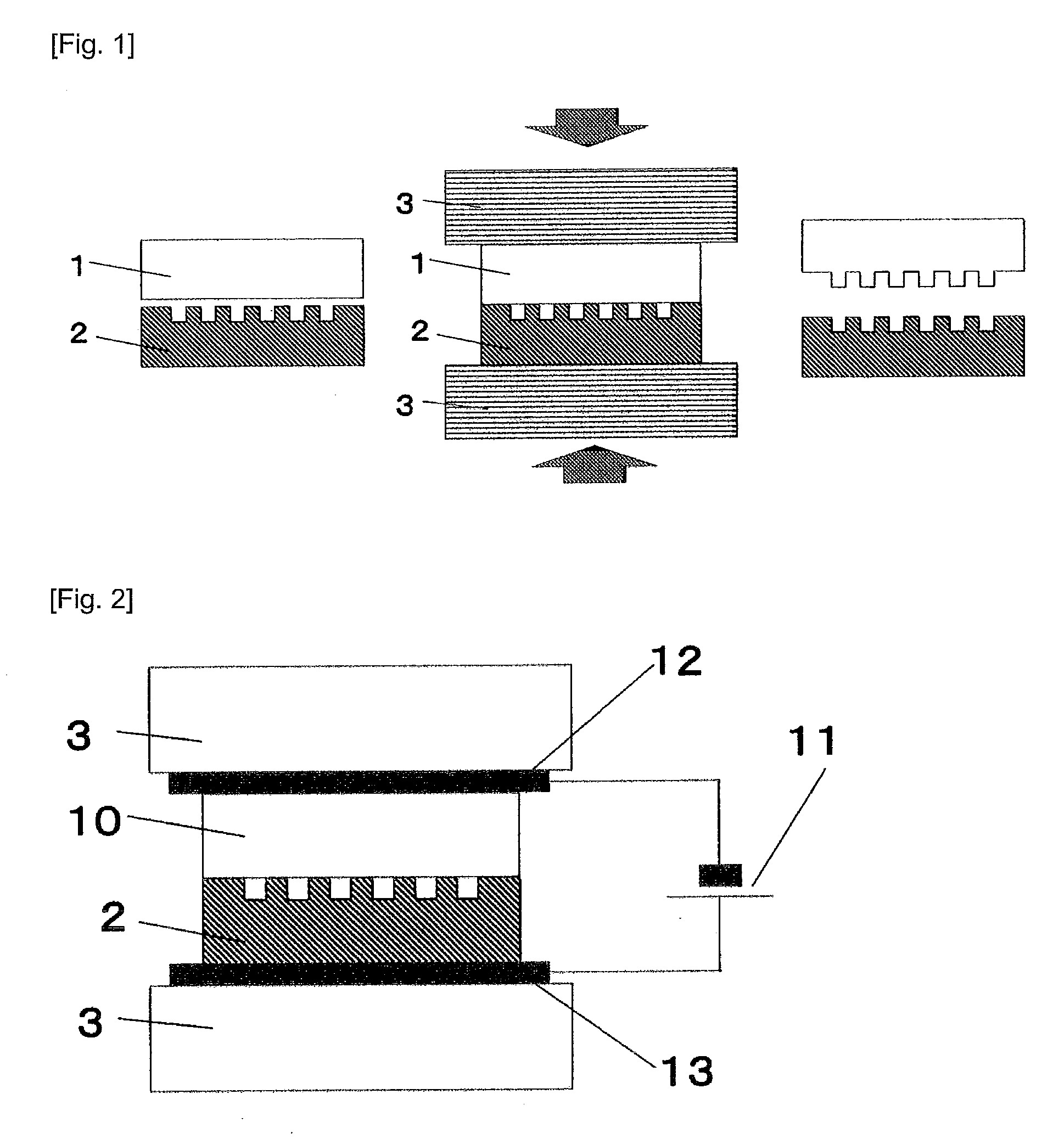

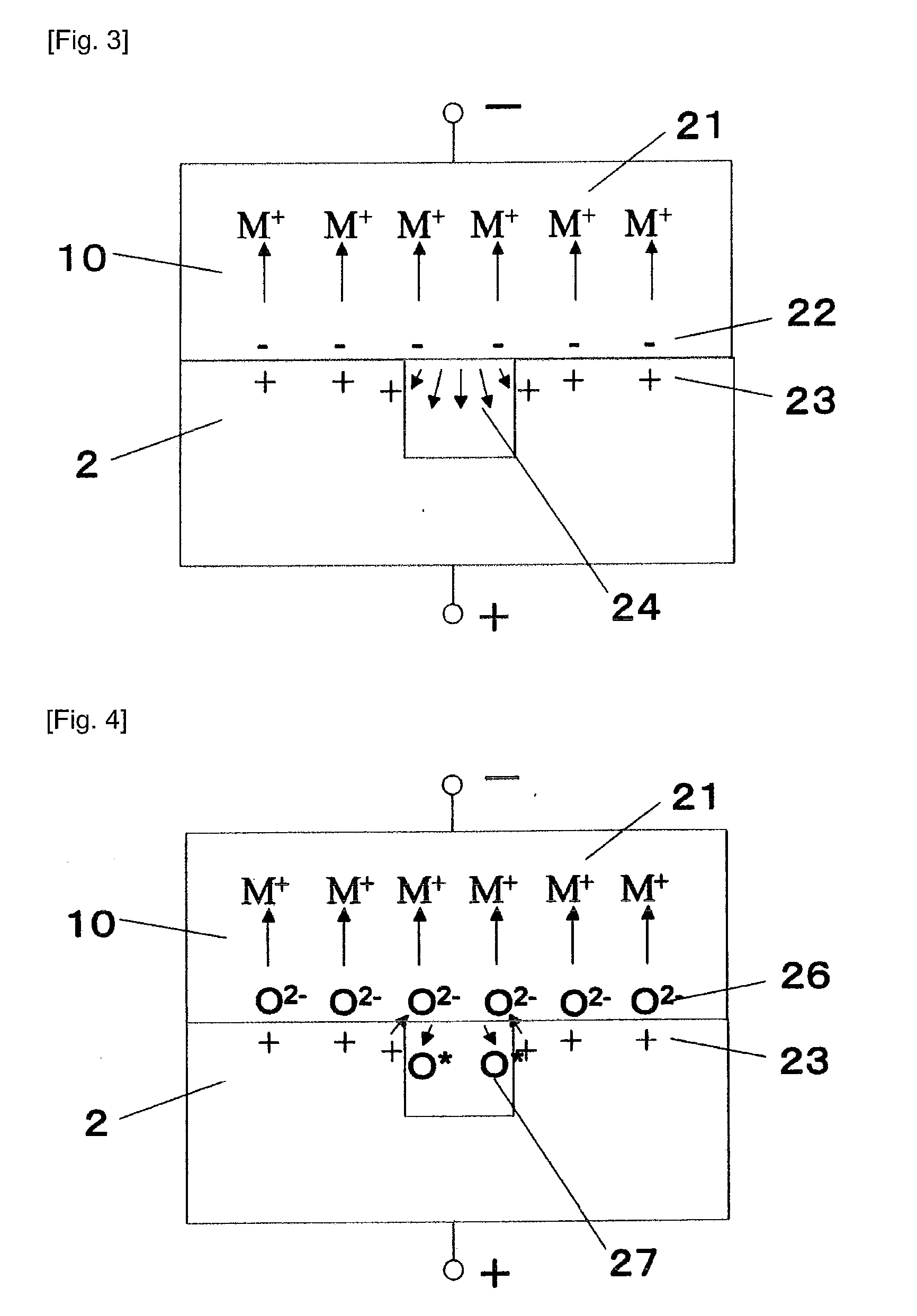

InactiveUS8099982B2Reduced size and costSmall sizeElectric discharge heatingGlass drawing apparatusShell moldingAlkali metal

A molding apparatus of a glass material according to the present invention is characterized by containing means for holding a glass material and a molding die in contact with each other, means for heating the glass material and the molding die, and means for applying a voltage across the glass material and the molding die, in which press-molding is performed by electrostatic attraction acting between a surface of the glass material and a surface of the molding die. Further, a molded product of a glass material according to the present invention is characterized by including an alkali metal as a component, in which a concentration of the alkali metal is lowered in vicinity of a surface to be molded as compared with that of a glass base material.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method of molding glass parts, molding apparatus, and molded product of glass material

InactiveUS20100112341A1Good effectElectric discharge heatingGlass drawing apparatusShell moldingMetal

In order to solve problems involved in micromolding of a glass, according to the present invention, there can be provided a technology for enabling molding of a glass without applying a large load.A molding apparatus of a glass material according to the present invention is characterized by containing means for holding a glass material and a molding die in contact with each other, means for heating the glass material and the molding die, and means for applying a voltage across the glass material and the molding die, in which press-molding is performed by electrostatic attraction acting between a surface of the glass material and a surface of the molding die. Further, a molded product of a glass material according to the present invention is characterized by including an alkali metal as a component, in which a concentration of the alkali metal is lowered in vicinity of a surface to be molded as compared with that of a glass base material.

Owner:NAT INST OF ADVANCED IND SCI & TECH

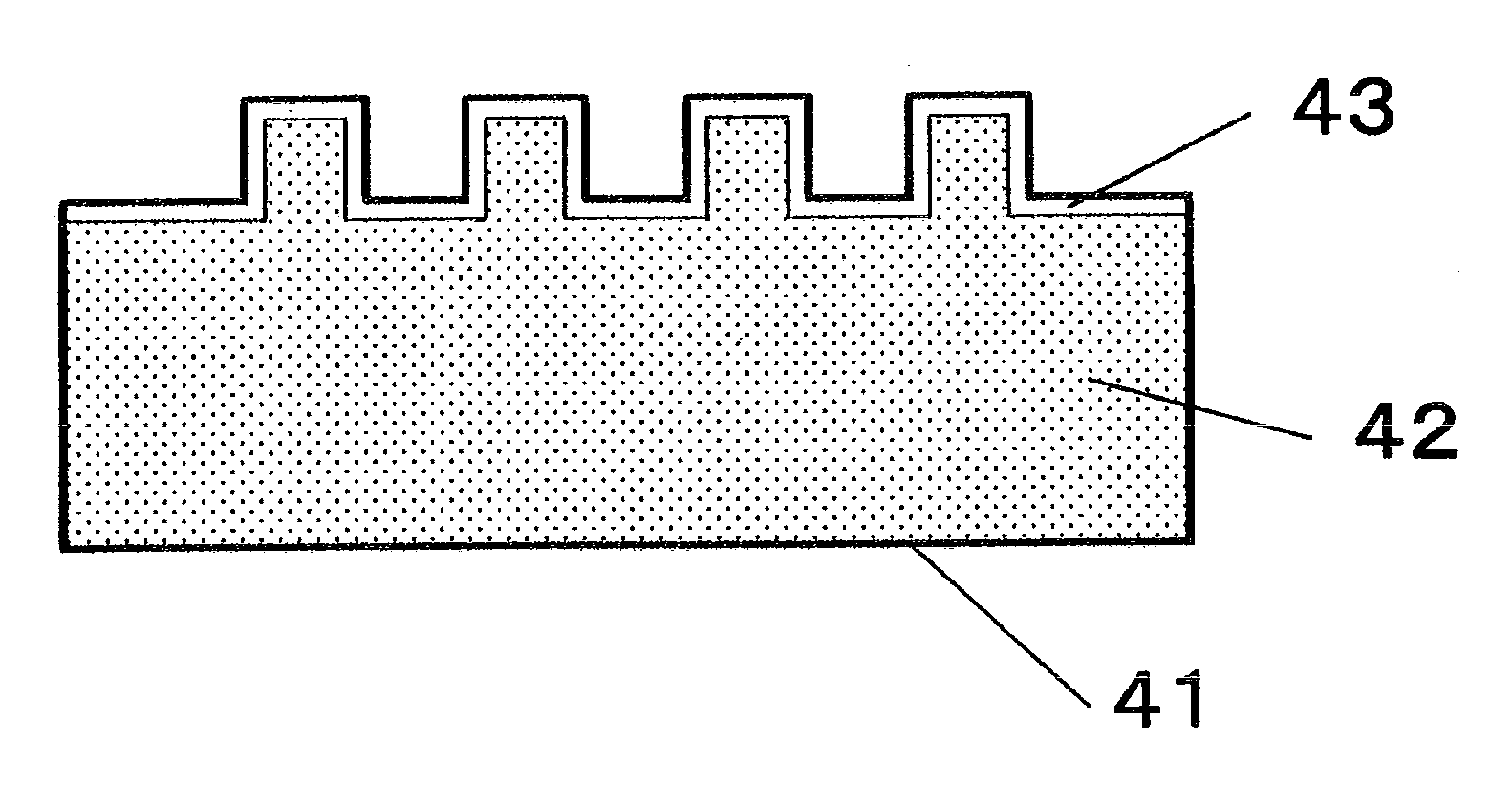

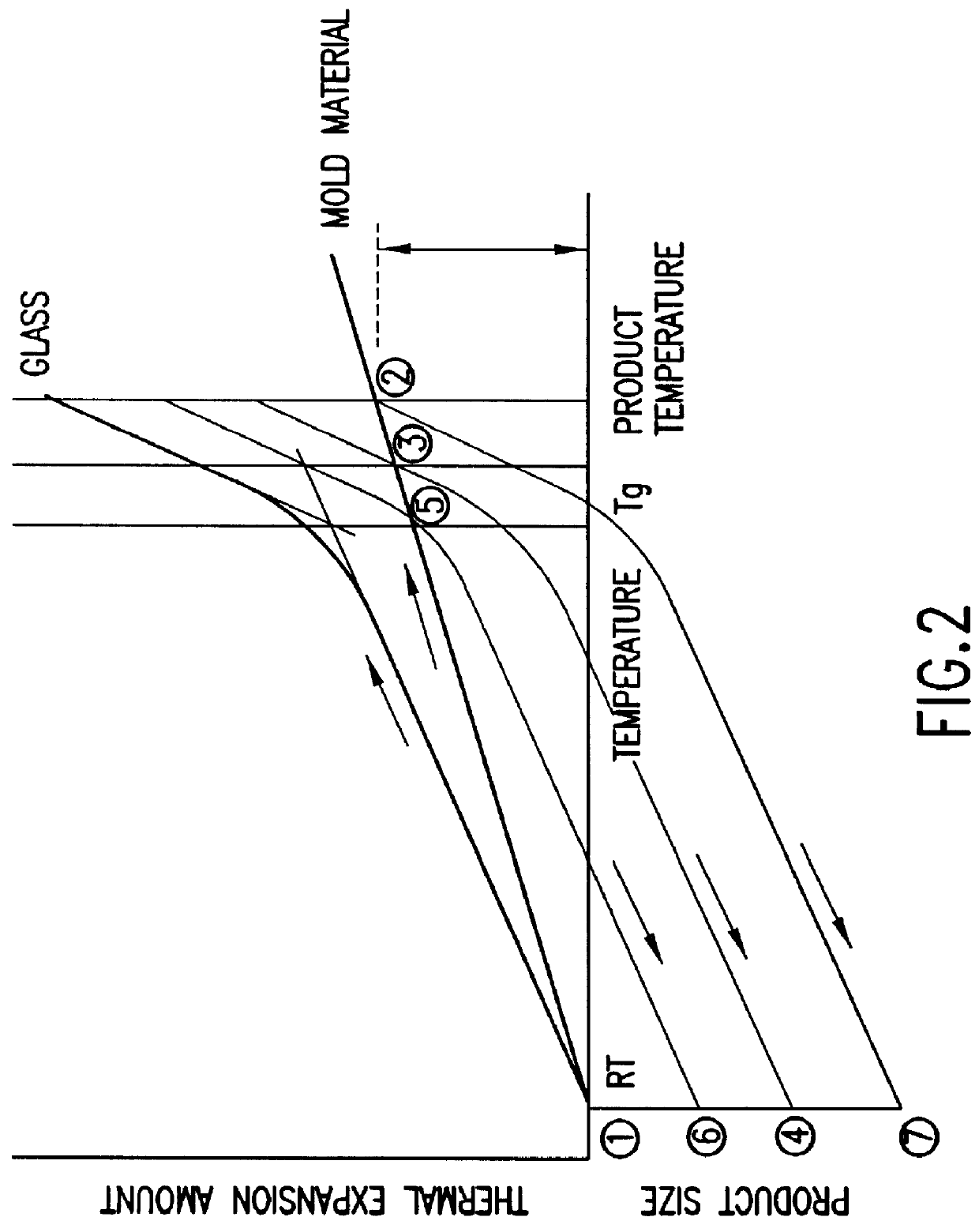

Manufacturing method for glass molded products

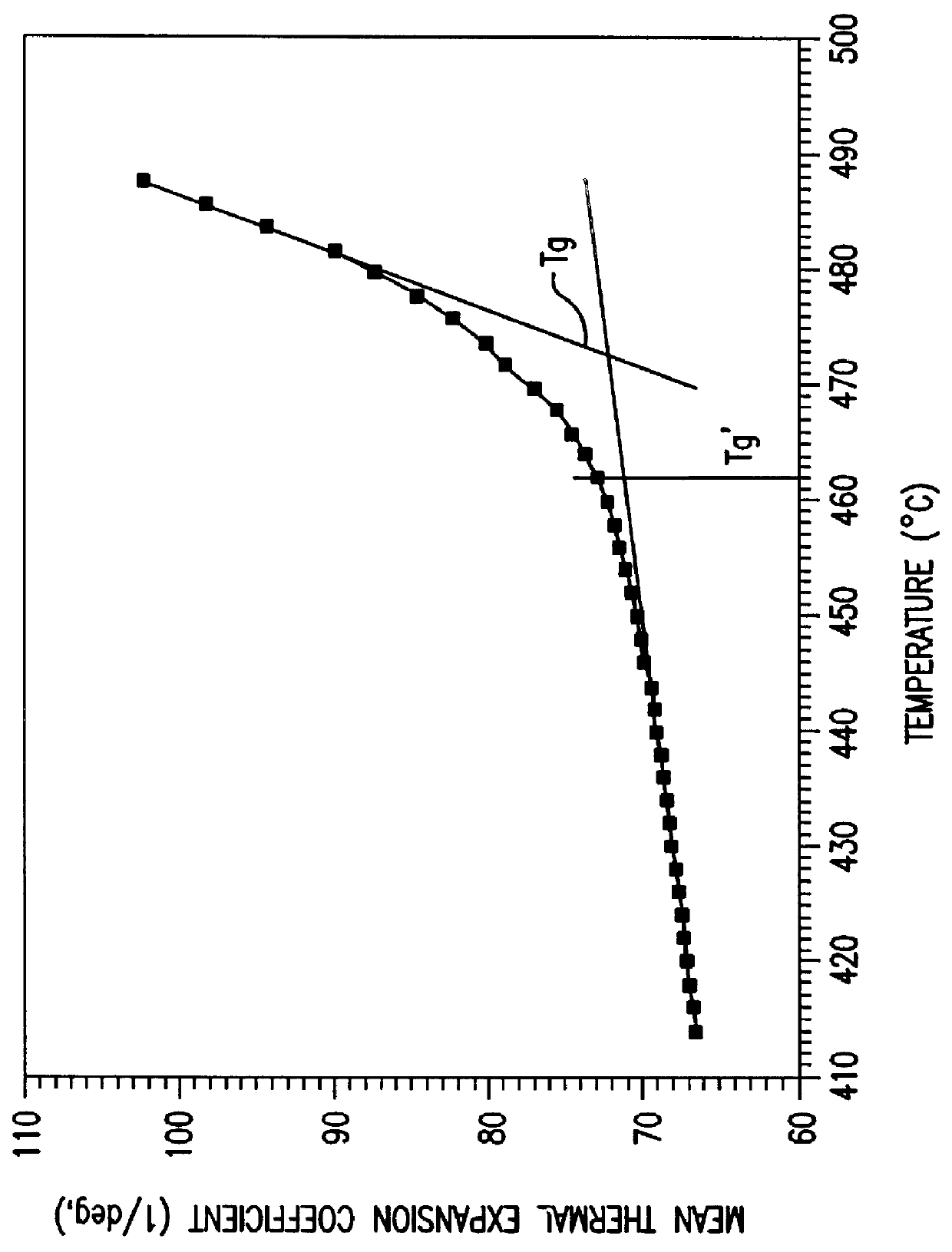

In a method for molding glass products having a fine structure as of an optical fiber holder with a high size precision, a mold used for the molding has the fine structure in a size such that a size difference occurring when the glass product is cooled down to a room temperature where at the end of molding with a pressure a size of the fine structure of the mold for glass product and a size of a fine structure of the glass product formed by transfer of the fine structure of the mold are the same as one another is so adjusted that a size of the fine structure of the completed glass product falls within a permissive size precision range. The mold may has a size satisfying, as a size of a fine structure at a room temperature, a formula [1+( alpha g- alpha m)x DELTA T+ alpha g'x DELTA T']xSg, wherein Sg denotes a size of a fine structure of thc glass product at the room temperature; alpha g denotes a mean thermal expansion coefficient of the glass to be molded in a temperature range from the room temperature to the glass transition temperature of the glass to be molded; alpha m denotes a mean thermal expansion coefficient of the mold in a temperature range from the room temperature to the glass transition temperature of thc glass to be molded; DELTA T denotes a difference between the room temperature and the glass transition temperature of the glass to be molded; DELTA T' denotes a difference between a temperature at which the mold's pressure exerted to the glass product is released and the glass transition temperature, in a case where the mold's pressure exerted to the glass product is released at a temperature higher than the glass transition temperature after pressing the mold with a high pressure; and alpha g' is a thermal expansion coefficient of the glass to be molded at a mean temperature of summation of the glass sag temperature and the glass transition temperature.

Owner:HOYA CORP +1

Vibration Damping Mechanism And Electronic Device Having The Damping Mechanism

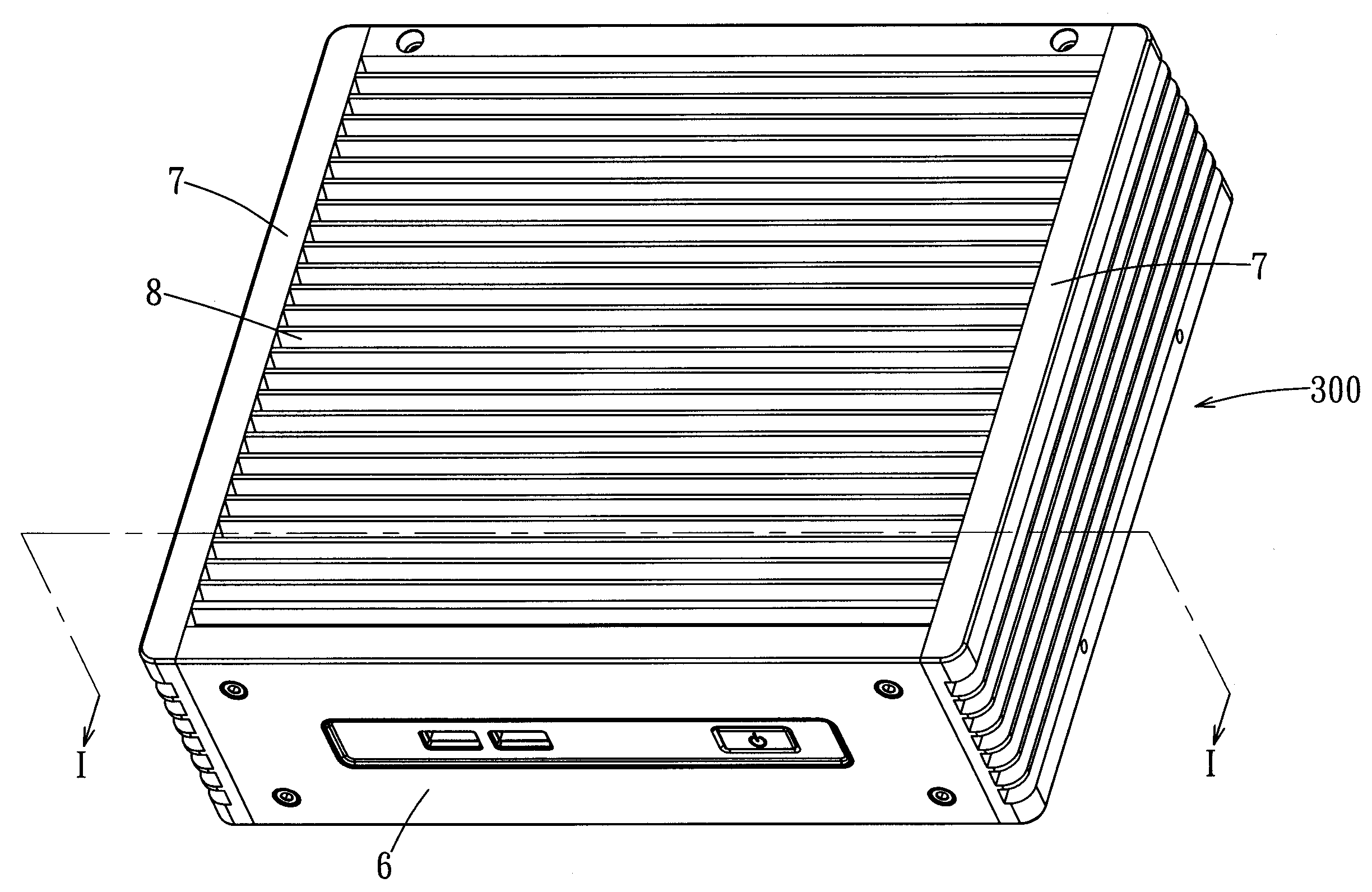

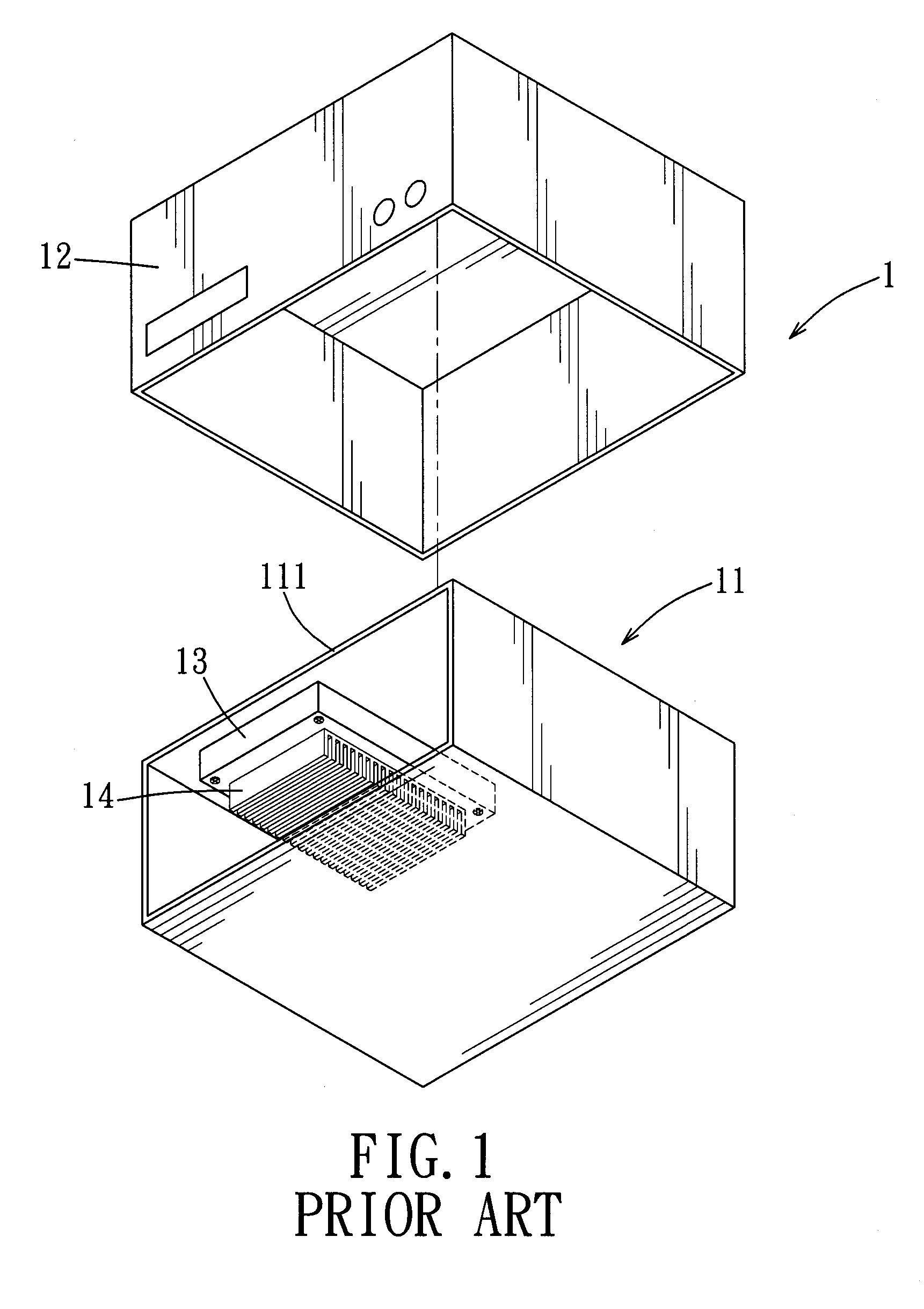

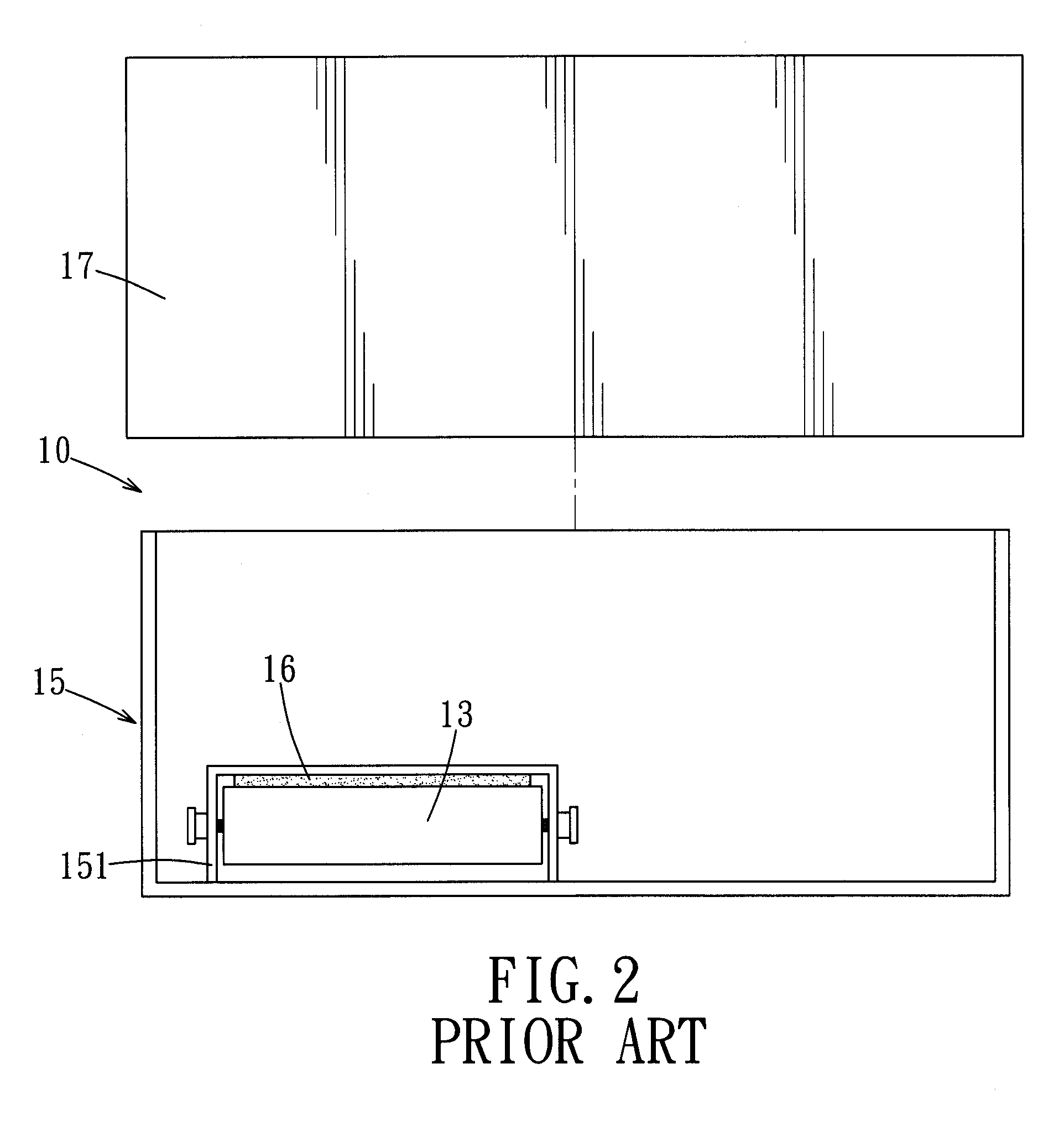

InactiveUS20090195976A1Increase contact areaImprove heat transfer efficiencyPortable framesDomestic cooling apparatusEngineeringHeat transfer efficiency

A vibration damping mechanism includes a frame, cushioning members, a heat sink, and fastening members. The frame has a base plate and supporting arms disposed on the base plate. Each cushioning member is disposed on a respective one of the supporting arms, and has a through hole. The heat sink supports a hard disk thereon such that the hard disk lies flat against and is secured on the heat sink, and has a plurality of fastening holes. Each fastening member extends through the respective through hole and threadedly engages the respective fastening hole such that the heat sink is suspended on the supporting arms and abuts against the cushioning members. Thus, the area of contact between the heat sink and the hard disk is increased to enhance the heat transfer efficiency, and the cushioning members provide the heat sink and the hard disk with a cushioning effect.

Owner:AOPEN

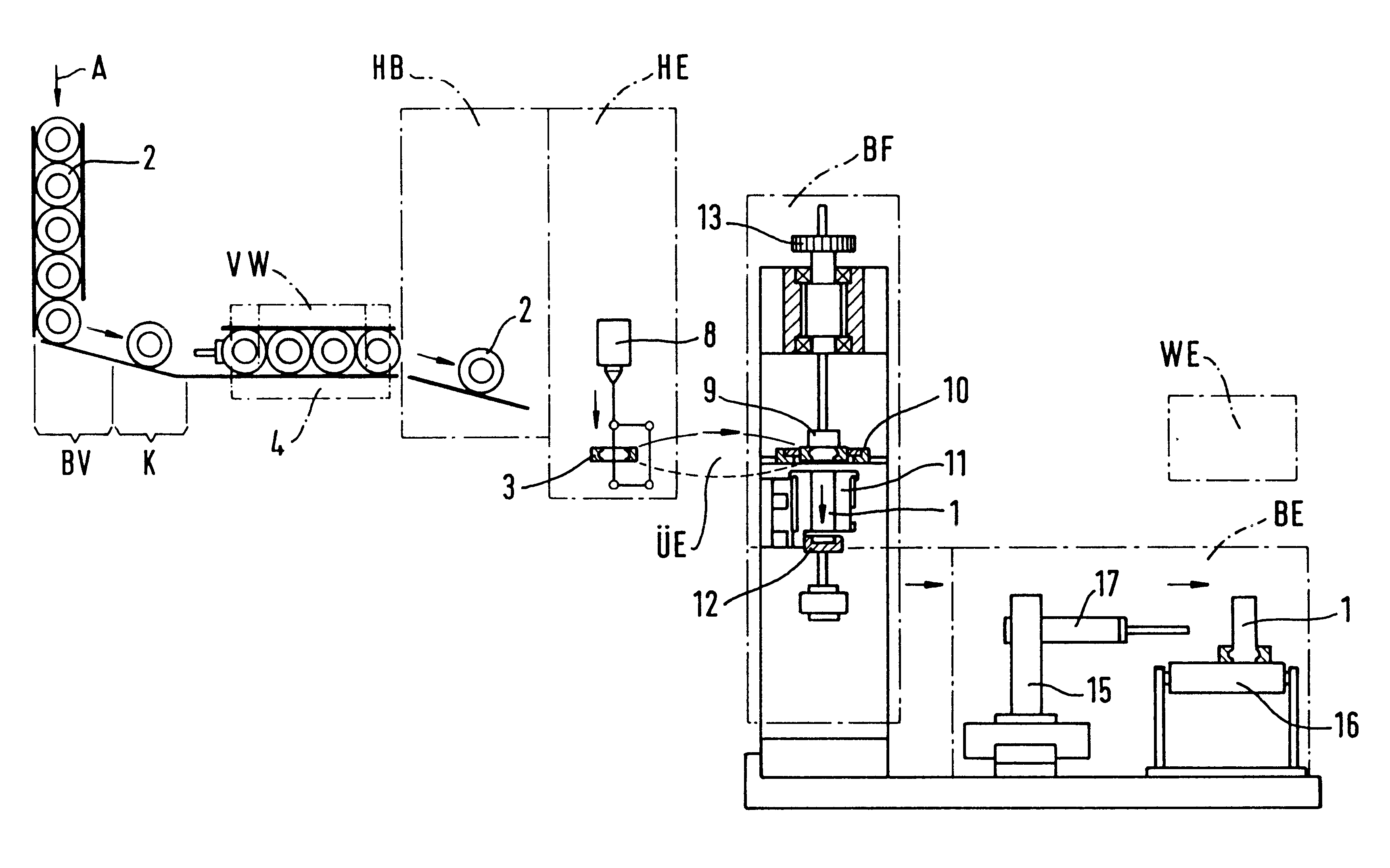

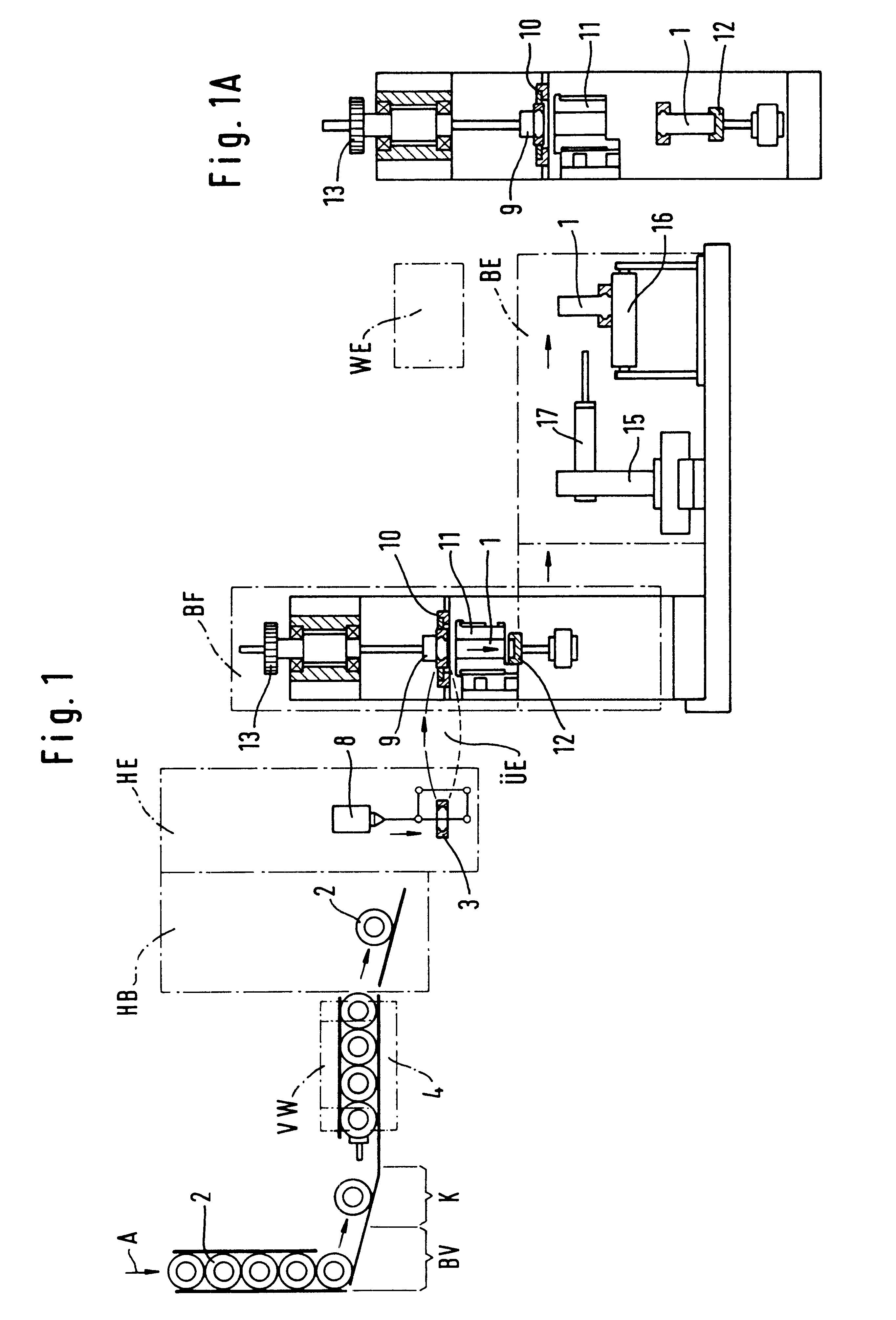

Method for producing glass goblets, tumblers and similar hollow glasses, and corresponding device for carrying out said method

InactiveUS6497119B1Cheap productionInexpensive productionBlowing machine gearingsGlass drawing apparatusBlow moldingEngineering

A device and process for forming hollow glassware comprising producing solid glass blanks in a manufacturing line, storing the blanks, feeding the blanks to a manufacturing line for forming hollow glassware, preheating the blanks during the feeding step, supplying the preheated blanks to a heating stage, heating to form solid plastically deformable glass globs, transferring the glass gobs to a blow molding stage and blow molding the glass gobs supported by a bottom lifter in a blow mold.

Owner:SCHOTT ZWIESEL

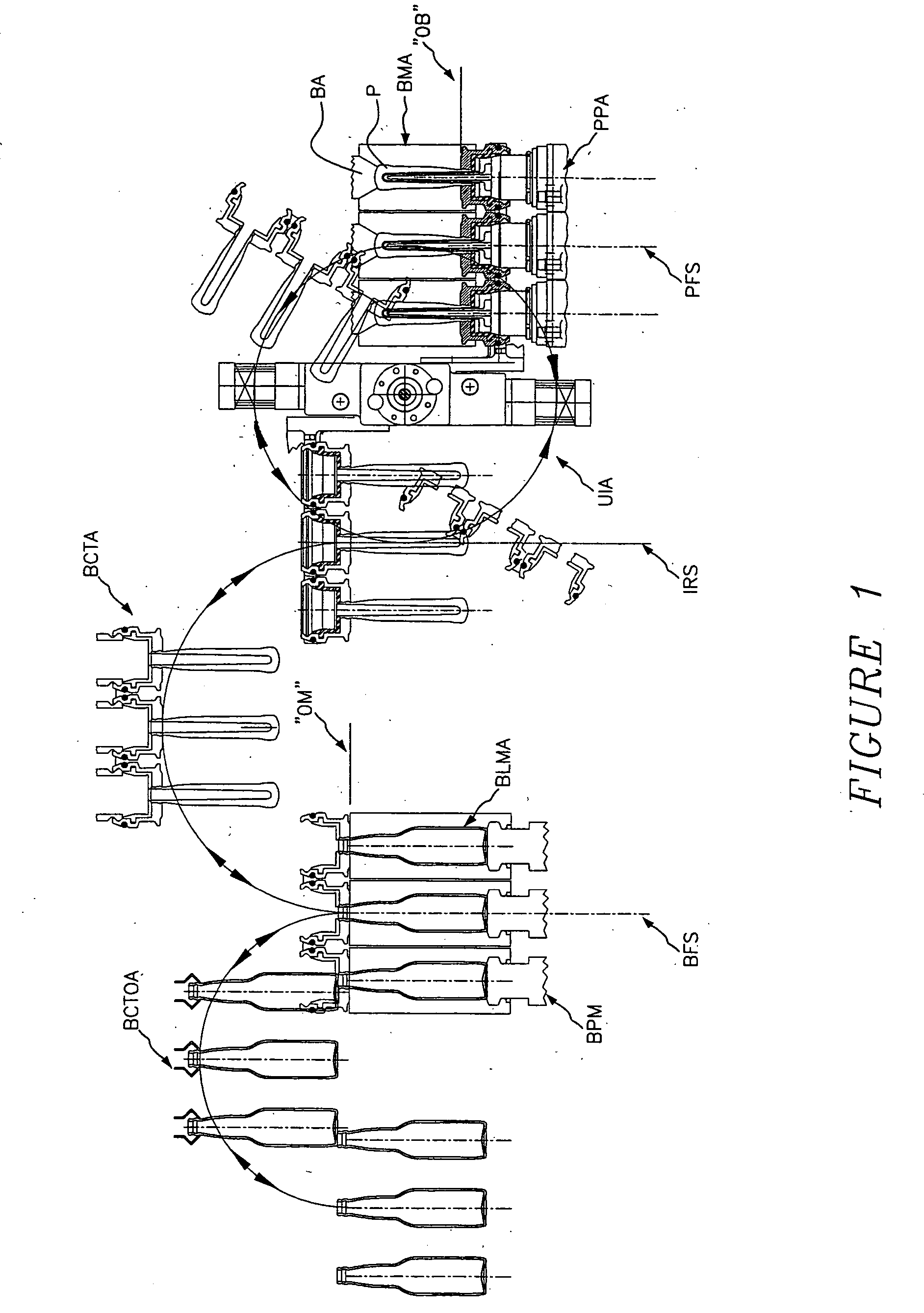

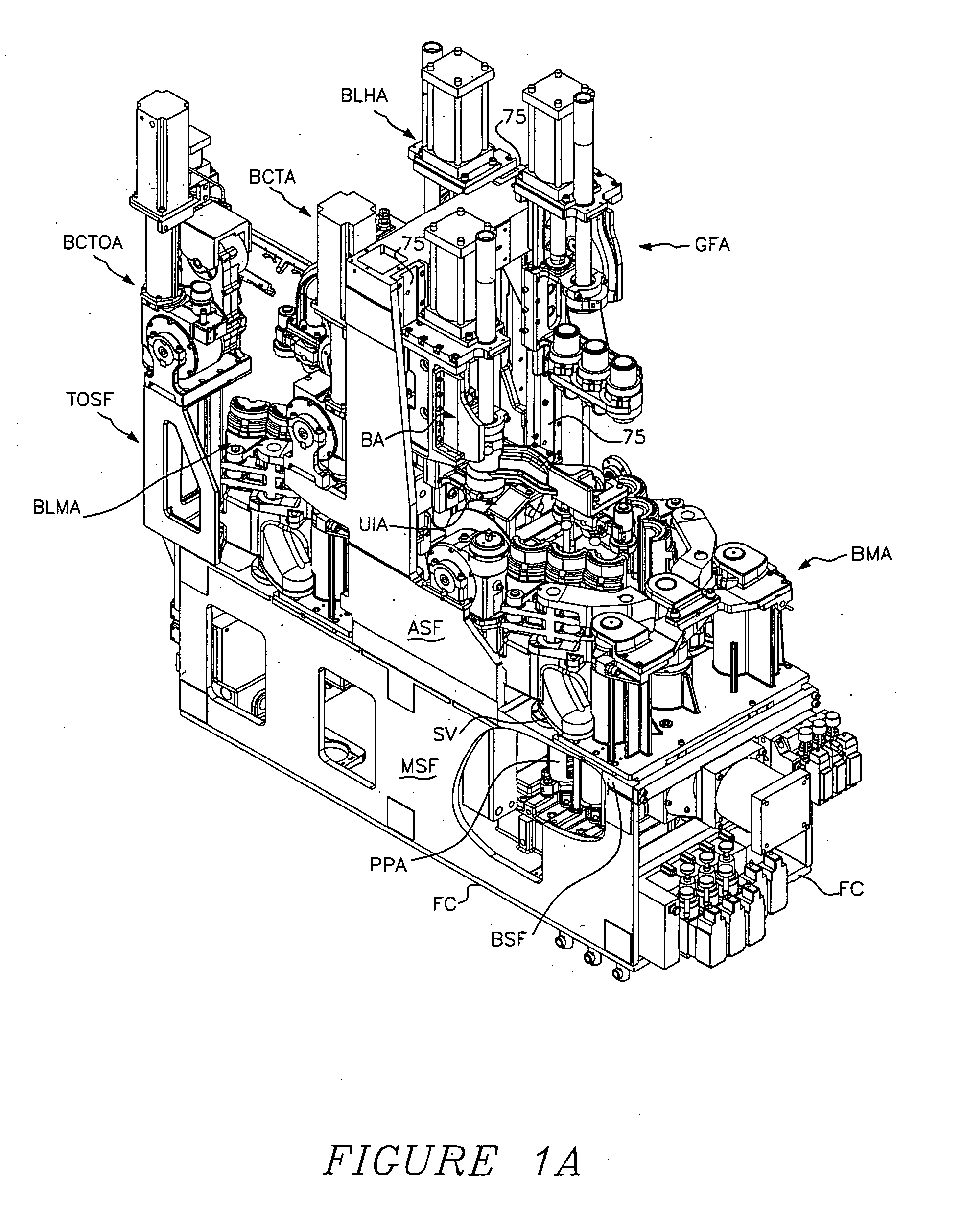

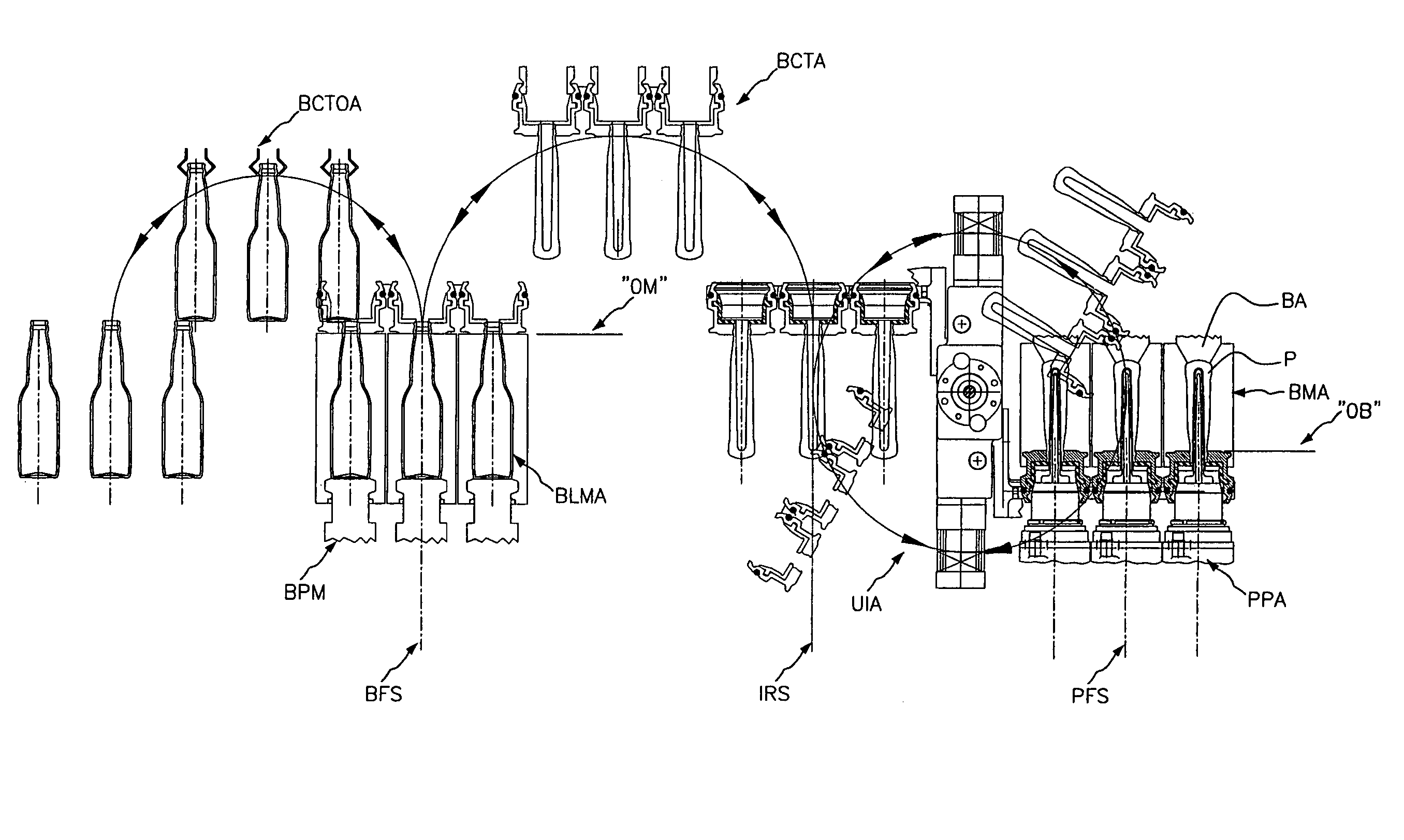

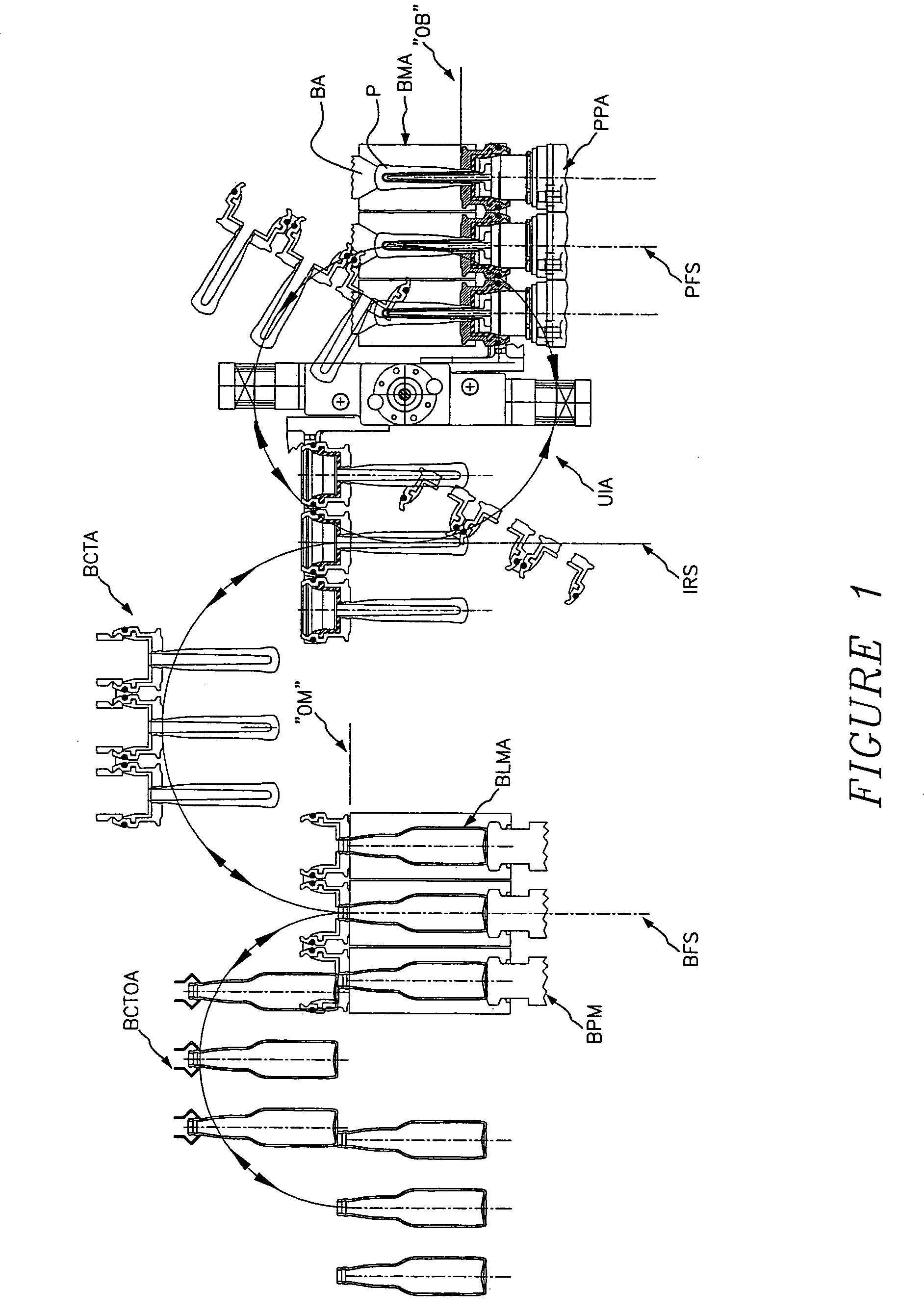

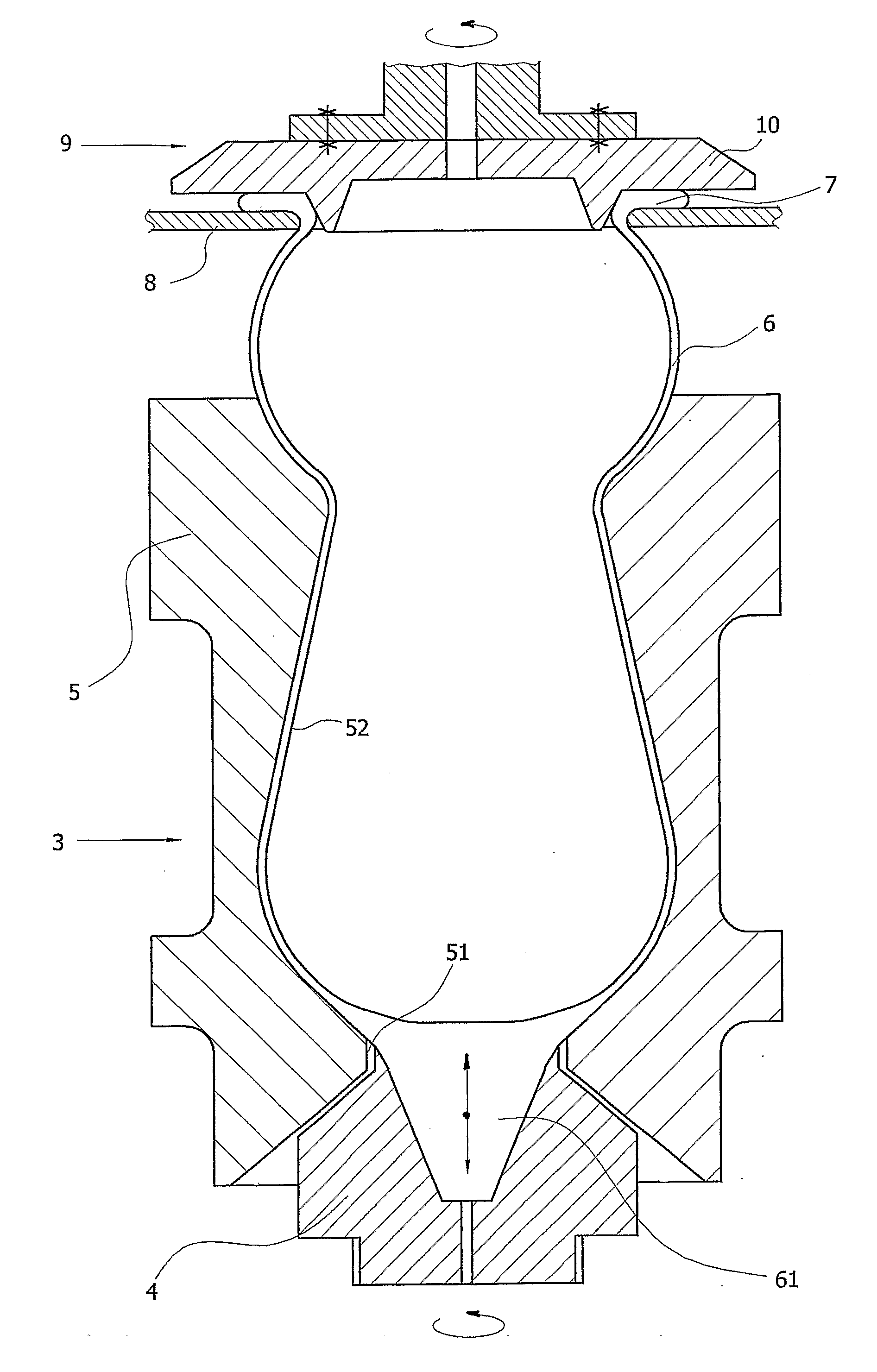

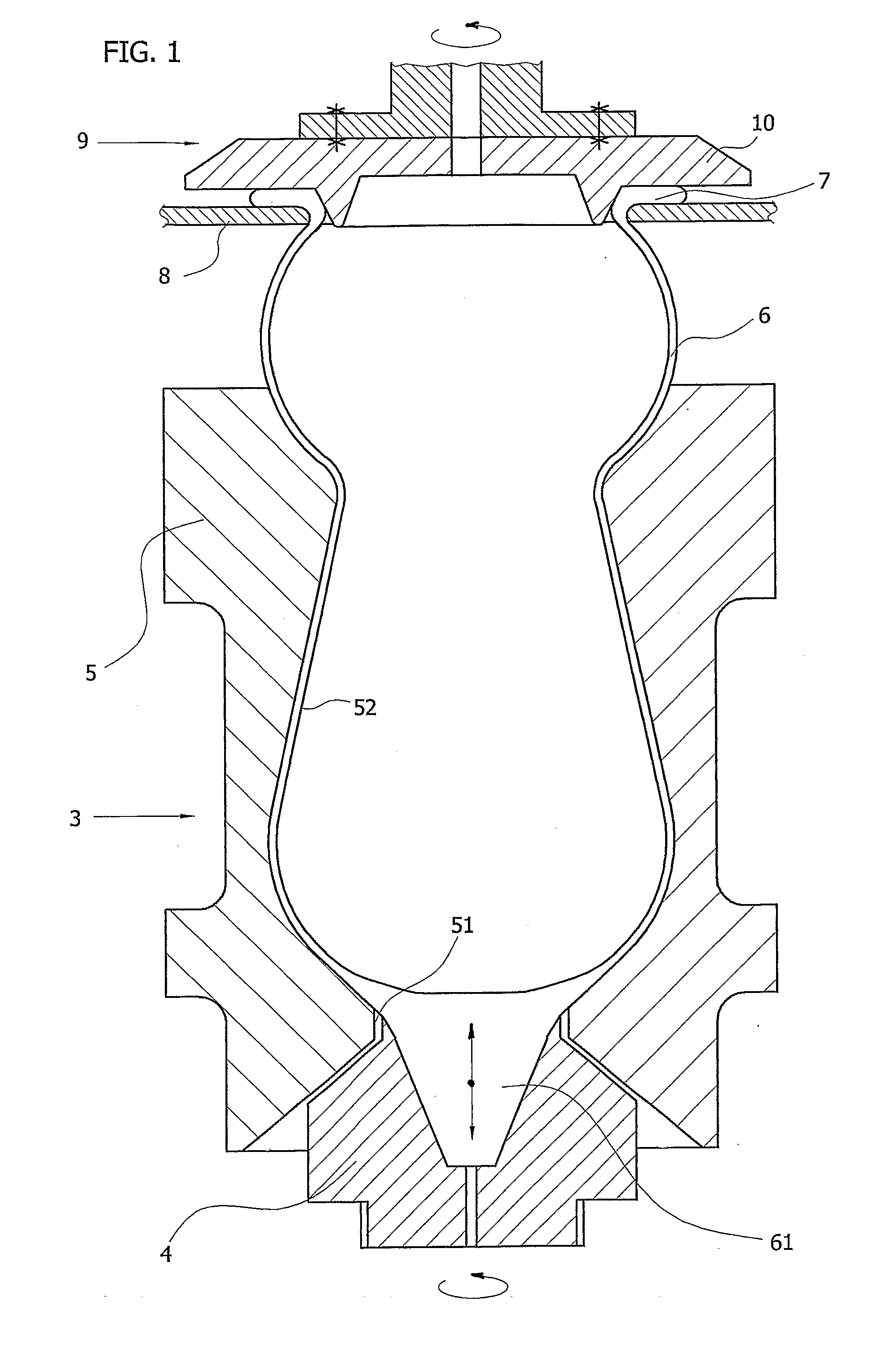

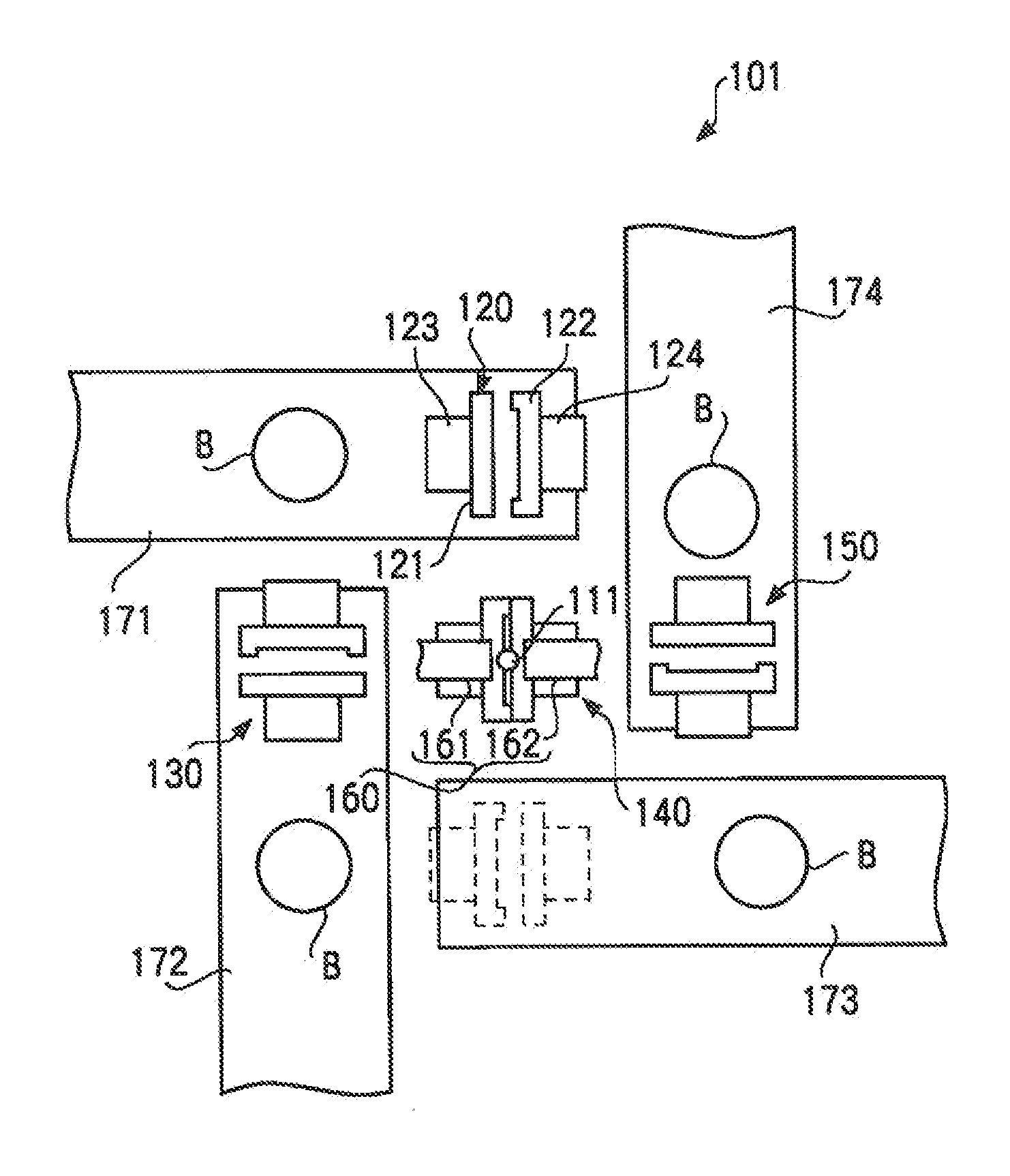

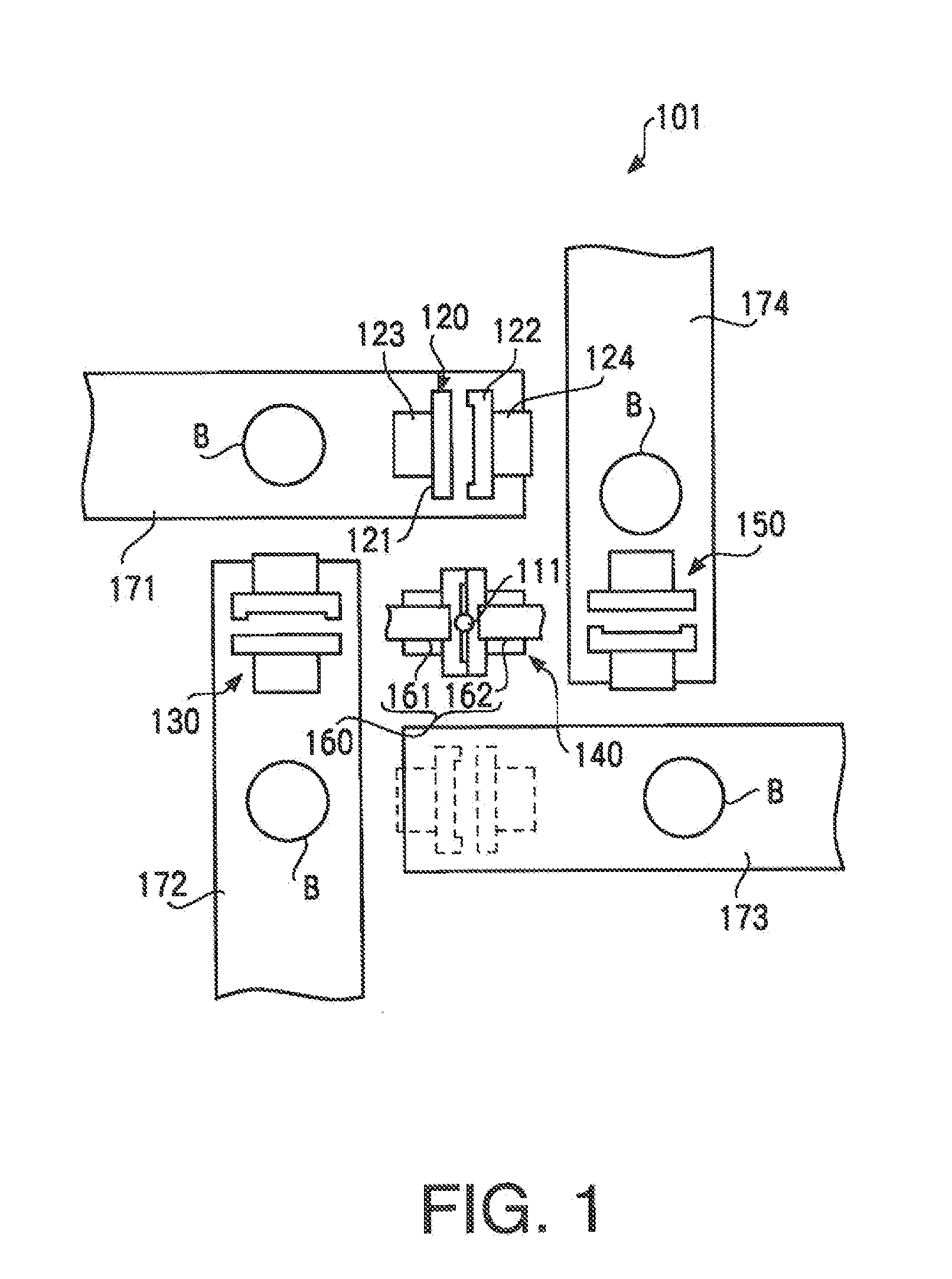

Method and a machine for the production of hollow glassware articles

InactiveUS20050235697A1Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusMolding machineGlass vessel

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO SAB DE CV

Optical glass

The invention relates to optical glasses intended for the application fields of imaging, sensors, microscopy, medical technology, digital projection, photolithography, laser technology, wafer / chip technology, and for telecommunication, optical communication engineering and optics / lighting in the automotive sector, having a refractive index of 1.60≦nd≦1.80 and / or an Abbe number of 30≦νd≦40 with a pronounced short flint character, good chemical stability, excellent crystallization stability, good solarization stability and the following composition (in wt. % based on oxide):SiO219-45B2O3 3-7.5Nb2O525-31K2O2-8TiO20.1-2 ZrO2 6-10Ta2O50.5-8.

Owner:SCHOTT AG

Method for packing nickel base alloy into glass mold cavity adopting silicon-copper alloy as base metal matrix

The invention relates to a method for packing a nickel base alloy into a glass mold cavity adopting silicon-copper alloy as a base metal matrix, which belongs to the technical field of glass mold cavity processing. The method comprises the steps of mold cavity preprocessing, preheating, pre-welding treatment, welding, annealing and finish machining. The method has the advantages that the nickel bas alloy can be reliably combined with the glass mold cavity adopting the silicon copper alloy as the base metal matrix, the characteristics of the copper alloy and the nickel base alloy are fully utilized to meet the requirements of high machine speed and long service life to the mold expected by glass product manufacturers, the method is simple, the cost is low, and the industrialized production requirement can be satisfied.

Owner:ORI MOLD TECH SUZHOU

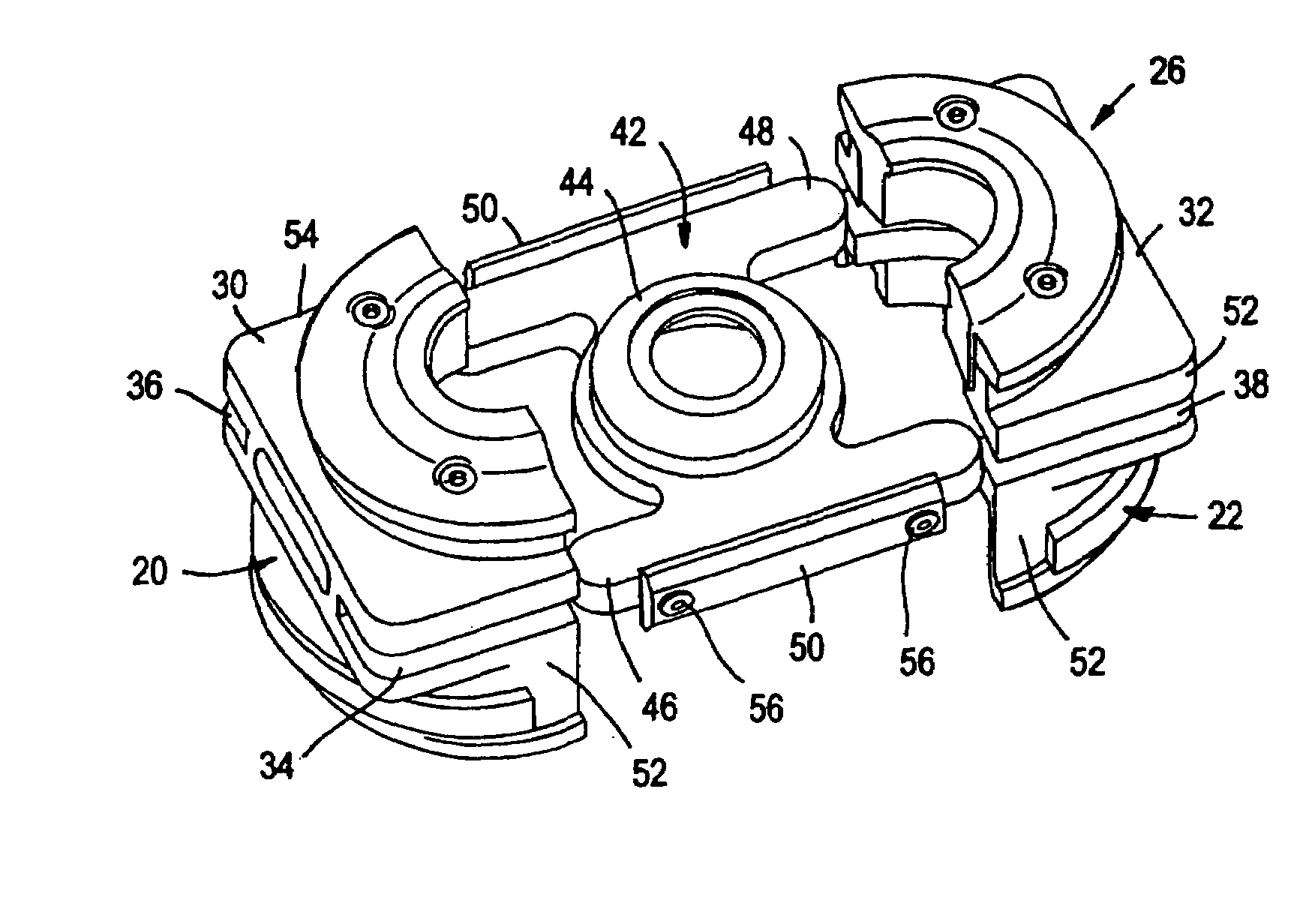

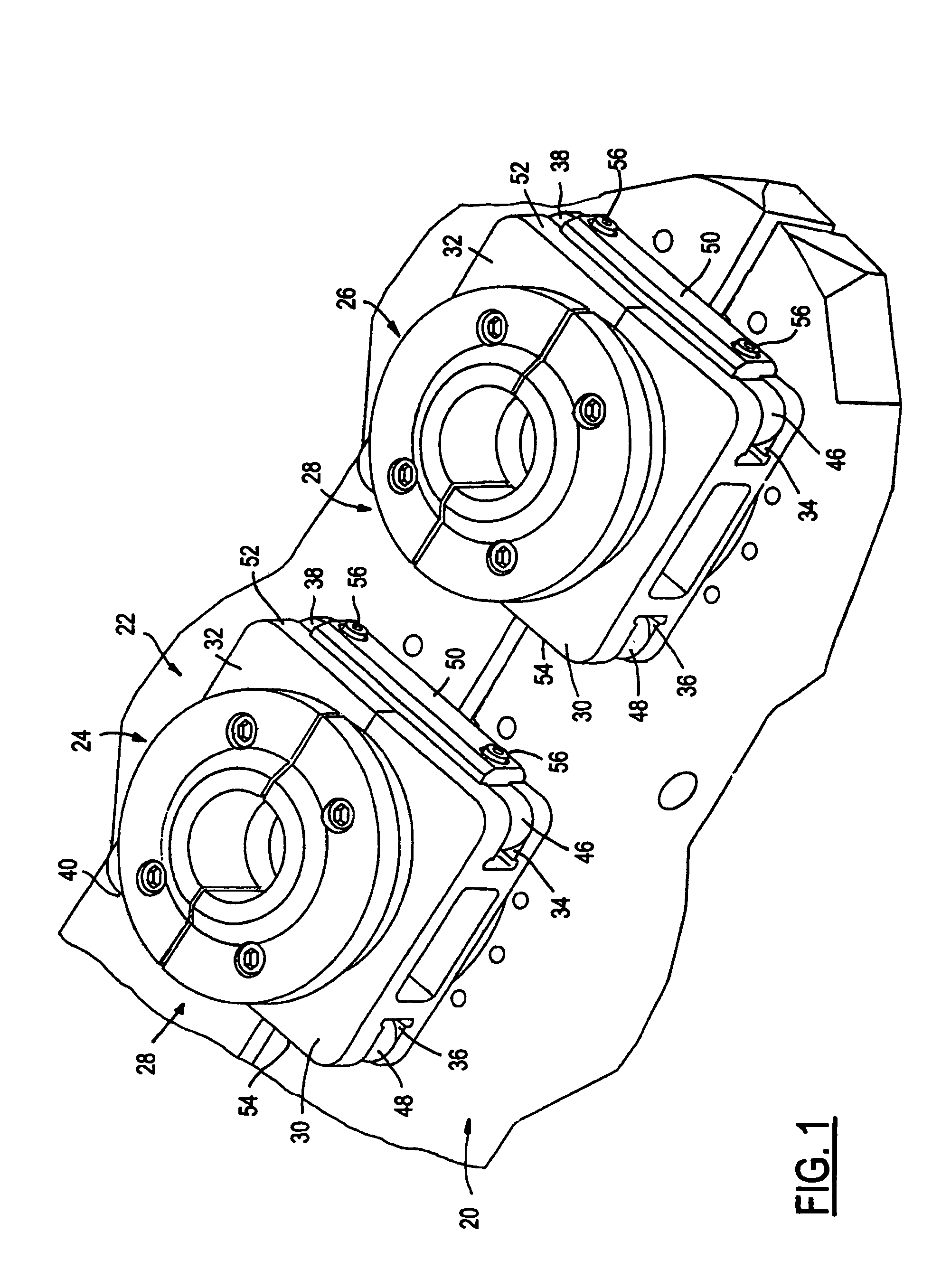

Neck ring guide for glassware making machine

A neck ring guide for aligning neck ring sections in a glassware forming machine has a center body and a pair of spaced parallel runners coupled to the center body for receipt in guide slots in the neck ring sections. Keepers on the outboard sides of the runners retain the runners in the guide slots. Instead of keepers, the runners may be retained in the guide slots by roll pins on the neck ring sections engaged in retainer slots in the runners.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

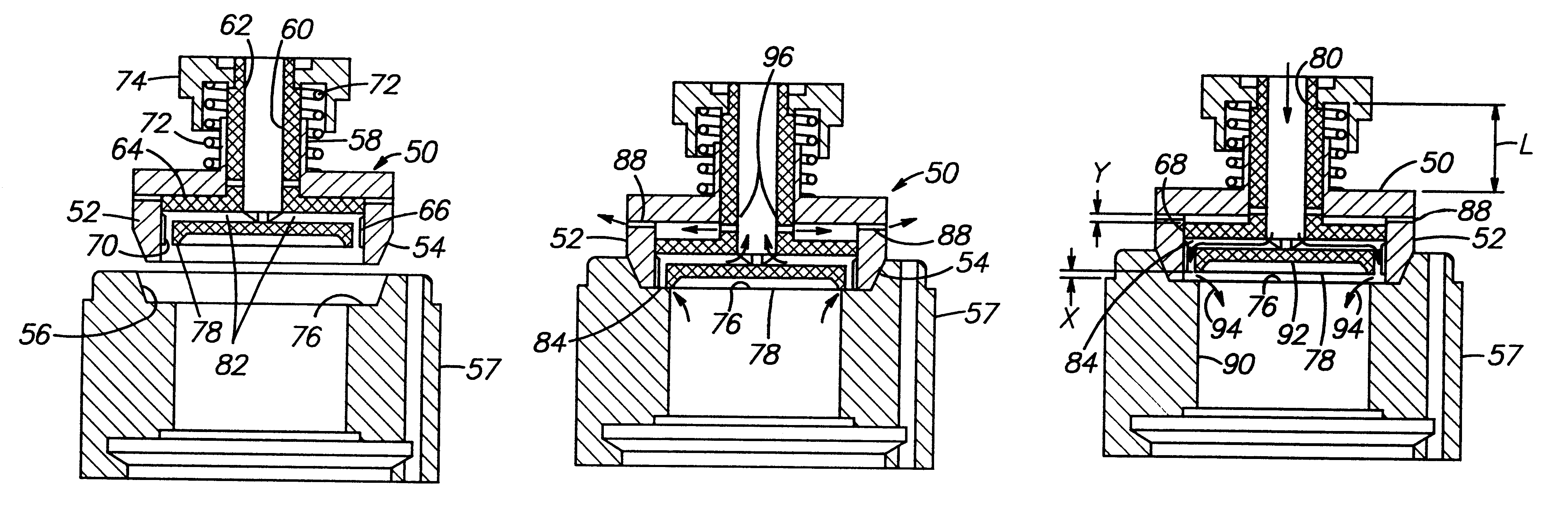

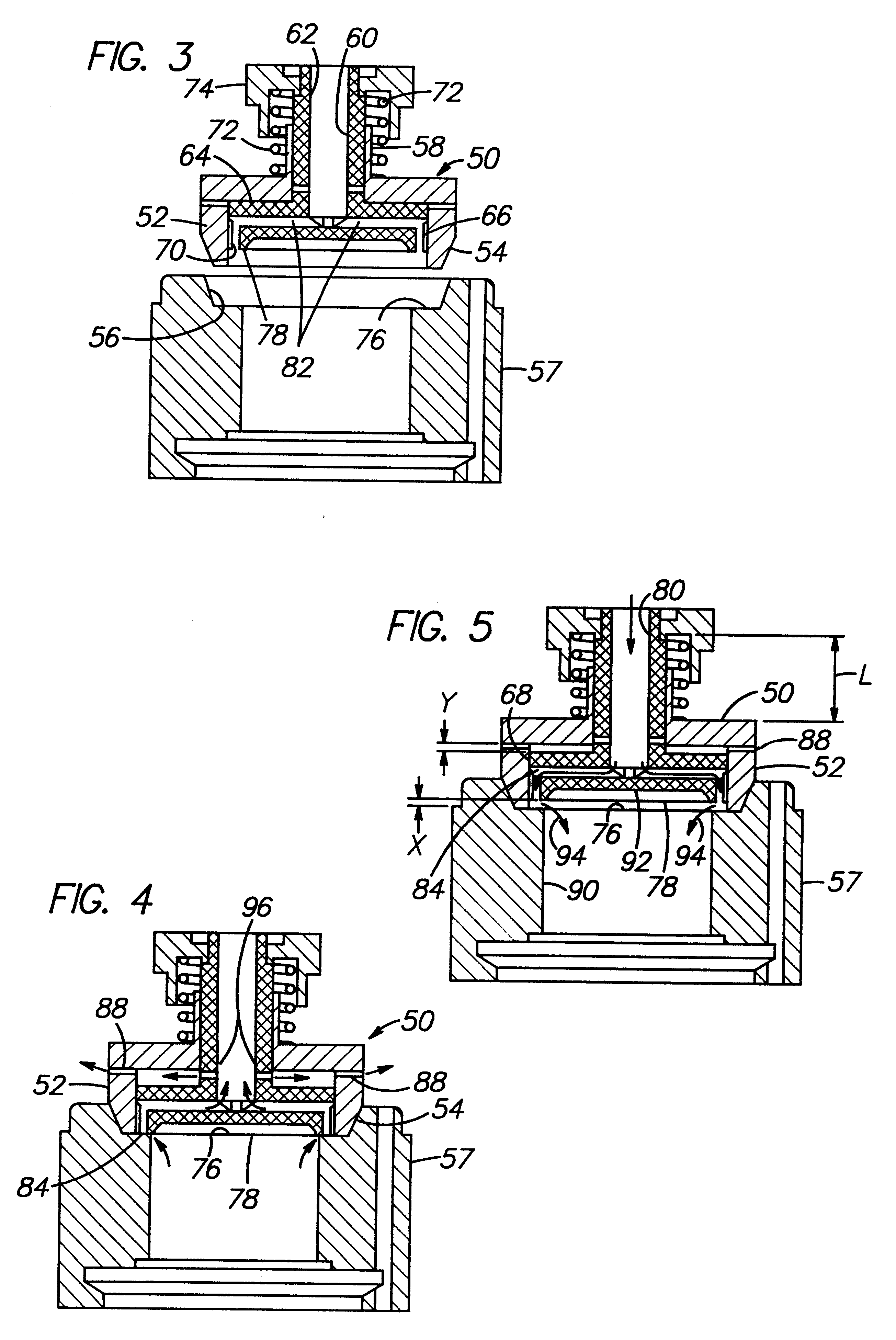

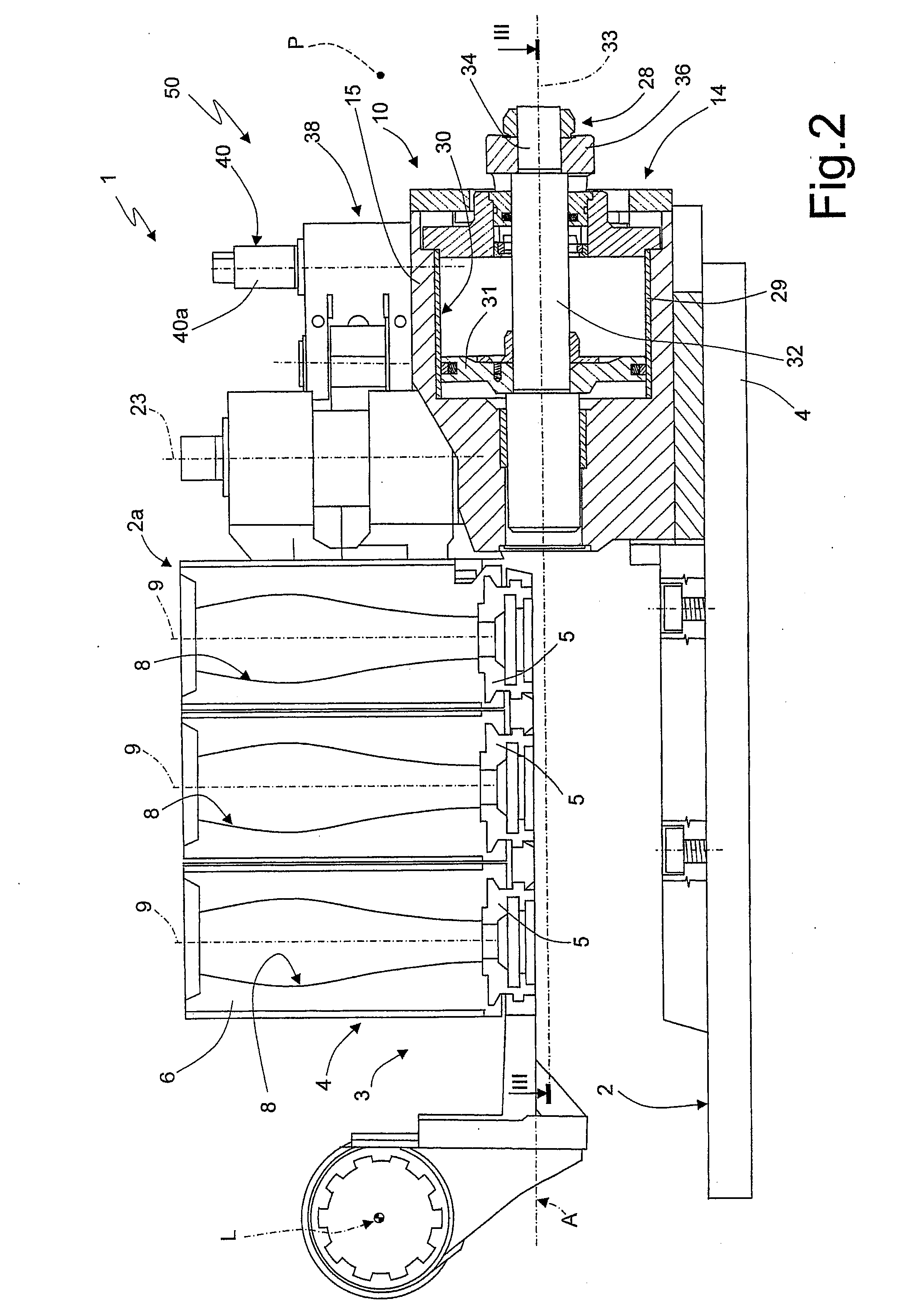

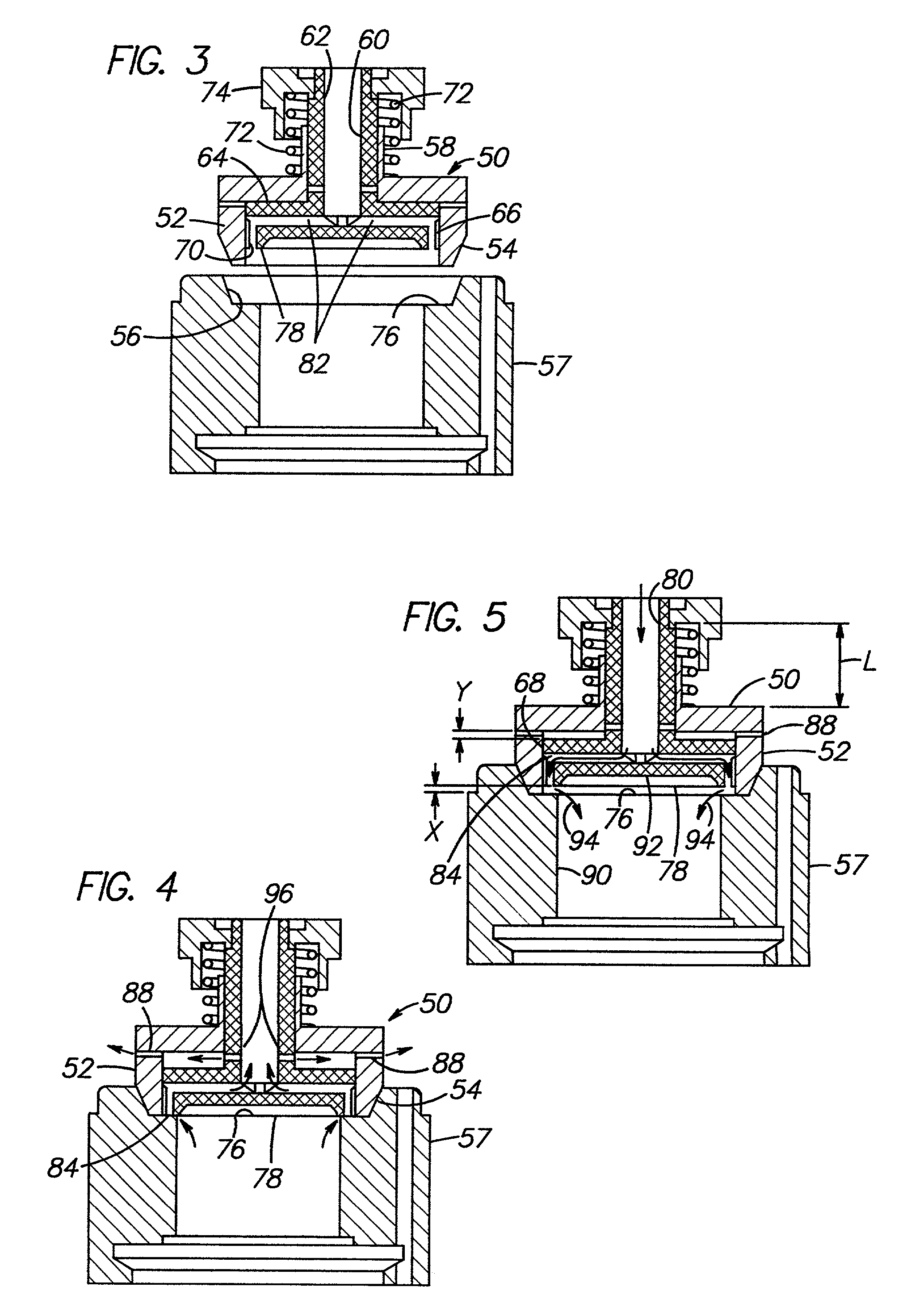

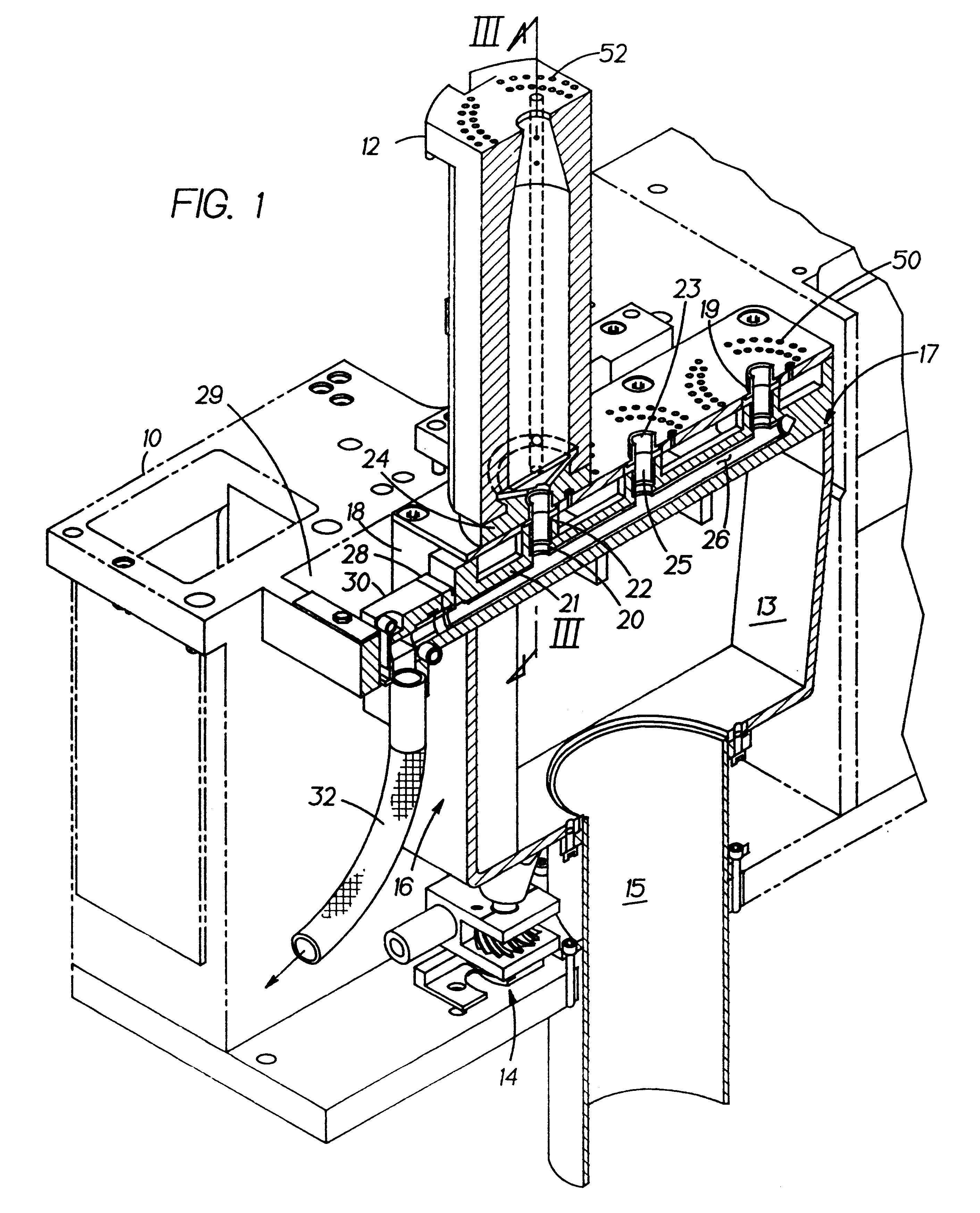

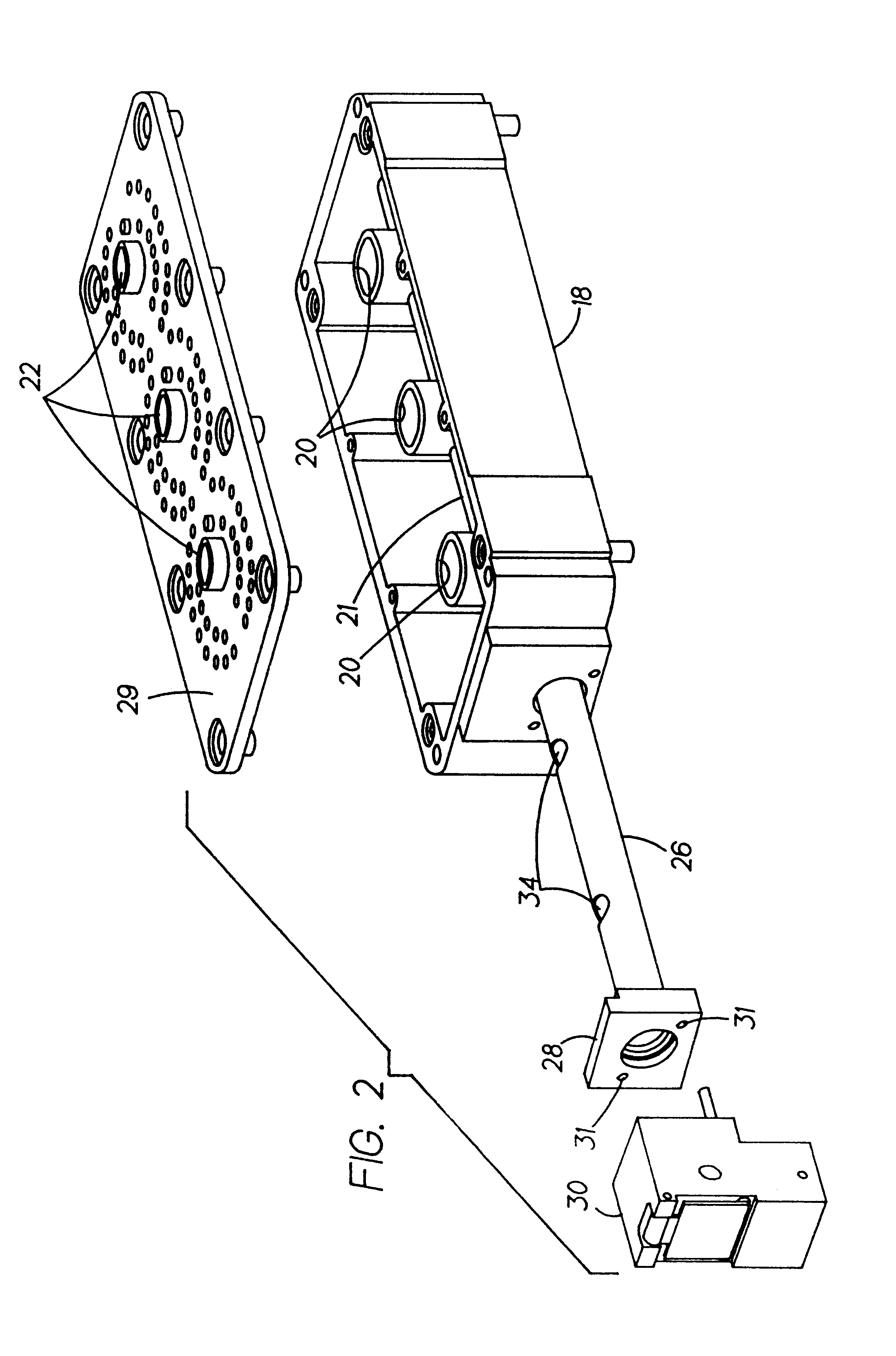

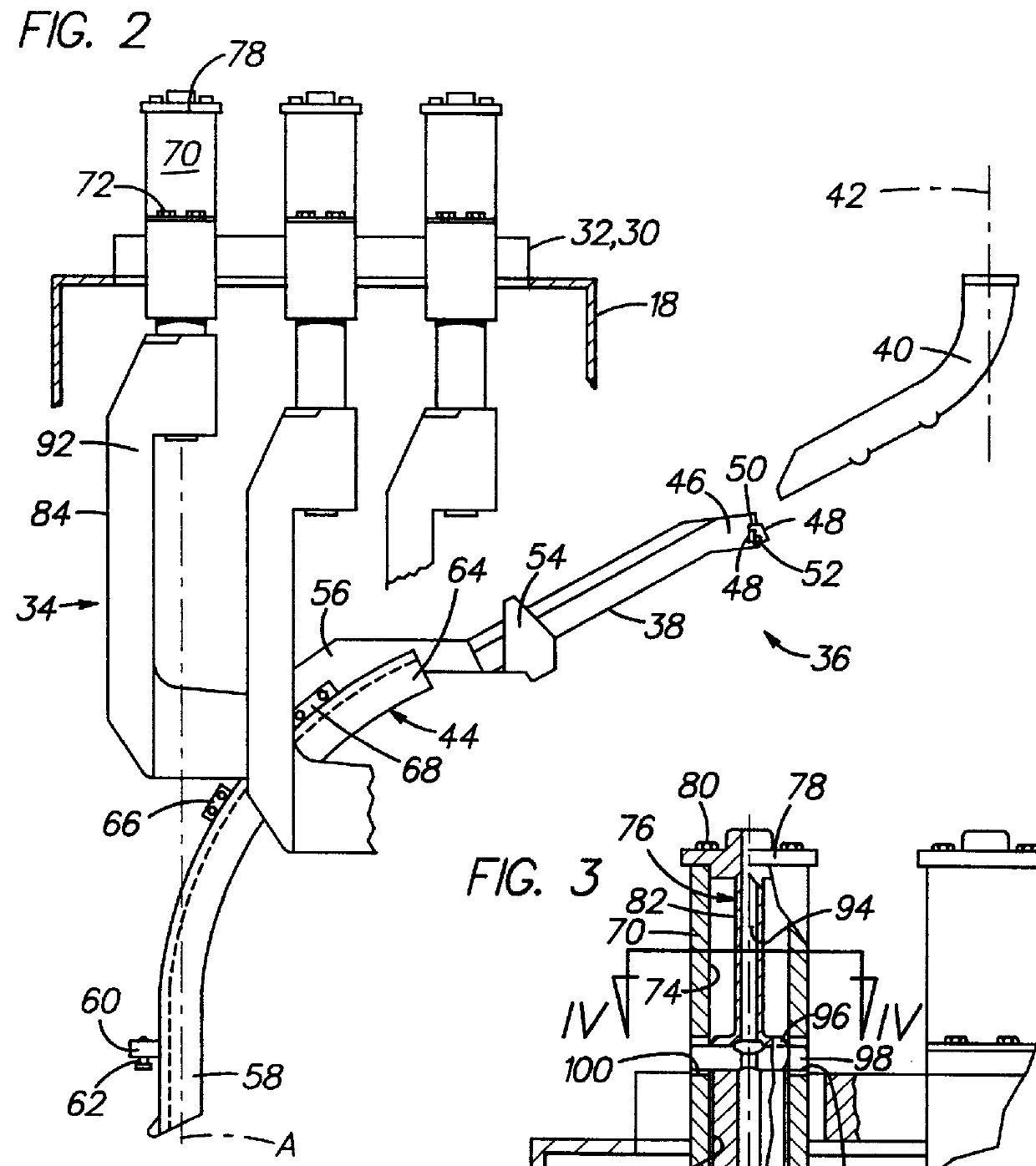

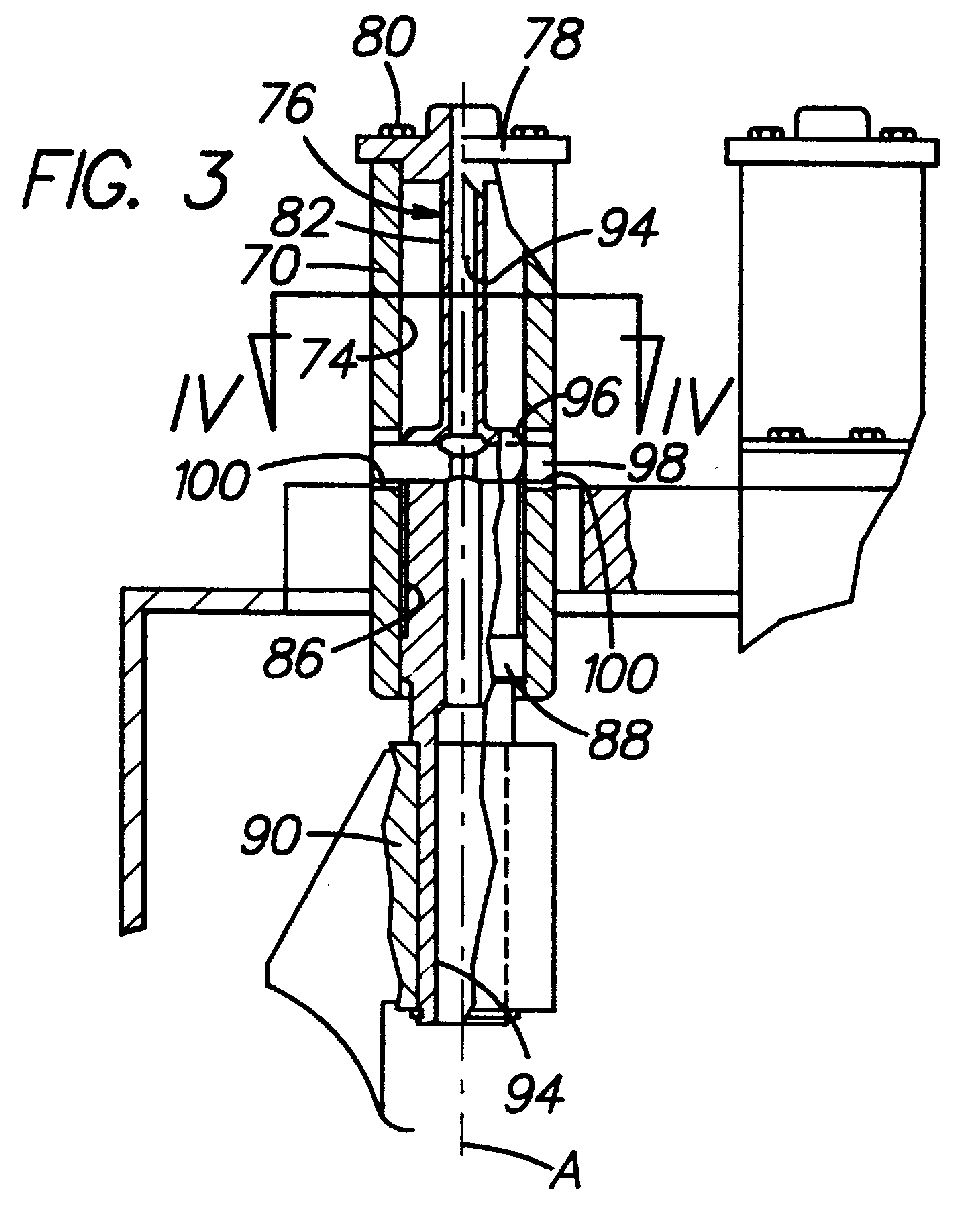

Baffle mechanism for I.S. machine

An I.S. machine has a blankmold which is open at the top and includes inner and outer annular top sealing surfaces. Associated with the blankmold is a baffle including a body having a cup shaped portion closed with a vertical cylindrical bore open at the bottom, an annular bottom sealing surface for sealingly engaging the blankmold outer annular top sealing surface, and a top having a hole. A tubular sleeve communicates with the hole and extends vertically upwardly from the top of the body. A piston has a cylindrical head including a top surface, a cylindrical sealing surface and an annular bottom sealing surface having a plurality of radial notch means across the bottom thereof. A tubular rod extends vertically upwardly from the top surface for slidable displacement in the tubular sleeve, and a collar is secured to the top of the rod. A spring located between the collar and the cup shaped portion urges the cylindrical head vertically upwardly to a position whereat the cylindrical head top surface engages the top of the cup shaped portion. The collar is pneumatically displaced vertically downwardly at a high pressure to bring the cup shaped portion annular surface into sealing engagement with the blankmold outer annular sealing surface. The pressure is then reduced so that a predetermined distance separates the cylindrical head annular bottom sealing surface and the blankmold inner annular sealing surface so that settle air can be introduced into the mold, and then the pressure is again raised to the high pressure for parison formation.

Owner:EMHART GLASS SA

Method and apparatus for frit sealing with a variable laser beam

InactiveUS8247730B2Increase speedImprove sealingDiffusing elementsElectroluminescent light sourcesFritLight beam

Owner:CORNING INC

Method and a machine for the production of hollow glassware articles

InactiveUS7024887B2Reduction in forming cycle time of machineQuality improvementGlass drawing apparatusGlass forming apparatusEngineeringNeck rings

A method and a machine for the production of hollow glassware articles, by the blow-and-blow, press-and-blow, press-and-blow paste mold and direct-press processes in a glassware forming machine including single or multiple machine sections each having single or multiple-cavity, comprising: forming a parison in an inverted orientation, into a blank mold and a first transferable and open-able neck ring mold held by an inverting apparatus having a first and a second diametrically opposed arms, each arm holding a transferable and open-able neck ring mold; inverting the parison held by the first transferable and open-able neck ring mold, by rotating the first arm 180° to an upright orientation at an intermediate station, while the second arm with a second transferable and open-able neck ring mold is simultaneously placed at the parison forming station; transferring the first transferable and open-able neck ring mold holding the parison in an upright orientation, from the intermediate station, to a blow mold station, by a transference apparatus; releasing the first parison into a blow mold, and turning back the first transferable and open-able neck ring mold empty to the first arm of the inverting apparatus, at the intermediate station to be placed again at the parison forming station by rotating the first arm additional 180°, completing a 360° turn, while the second arm reaches to the intermediate station; blowing the parison into a blow mold to form a finished article; and transferring the finished article in an upright orientation, once the blow mold is opened, by a take out apparatus, to place it at a dead plate or at a carrying conveyor.

Owner:VITRO

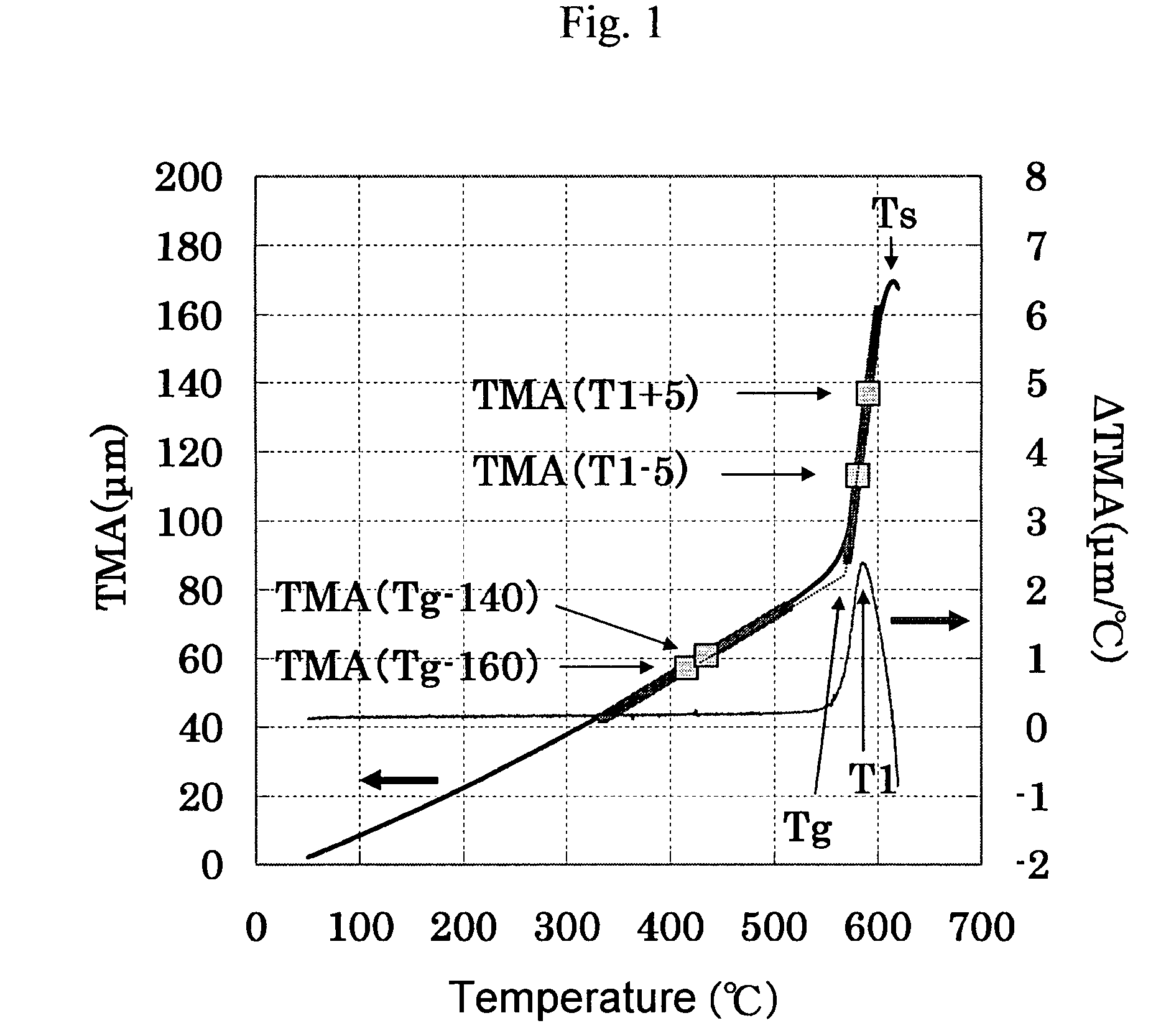

Optical glass, preform for precision press molding and method of manufacturing thereof, optical element and method of manufacturing thereof

InactiveUS20070247721A1ManufacturingImprove productivityGlass drawing apparatusGlass forming apparatusRefractive indexGlass transition

The present invention relates to an optical glass having a refractive index (nd) of greater than or equal to 1.65 and an Abbé number (ν (nu)d) of greater than or equal to 50 for use in precision press molding. The glass exhibits that a ratio α (alpha)1 / α (alpha)2 is less than 17 when temperature denoting maximum value of differential in amount of elongation of glass relative to temperature differential DELTAT (where DELTAT denotes a constant value of 1° C. or less) over a temperature range from glass transition temperature (Tg) to sag temperature (Ts) is denoted as T1, average coefficient of linear expansion over a range from T1-5° C. to T1+5° C. is denoted as alpha1, and average coefficient of linear expansion over a range from the glass transition temperature (Tg)−160° C. to the glass transition temperature (Tg)−140° C. is denoted as alpha2.

Owner:HOYA CORP

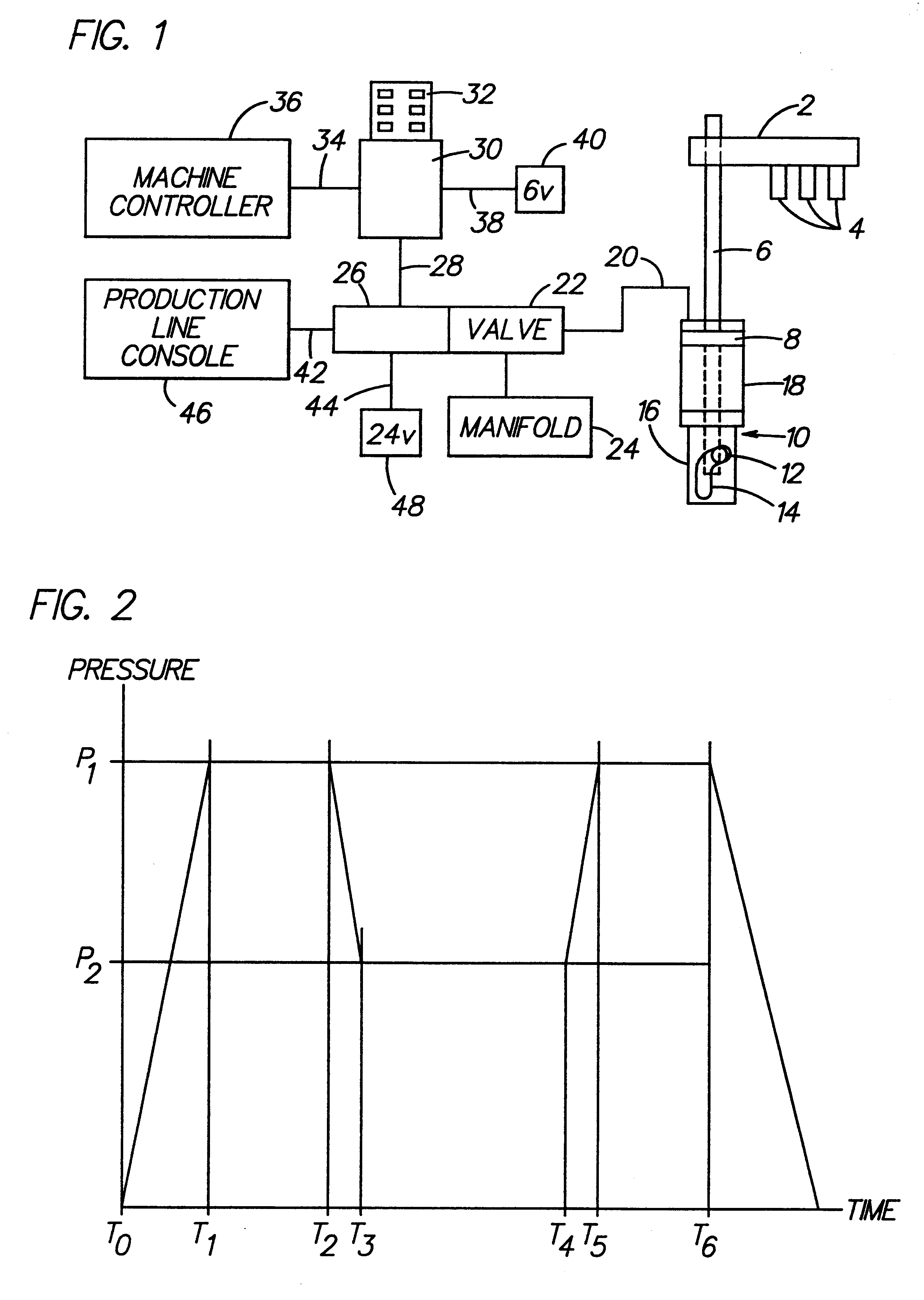

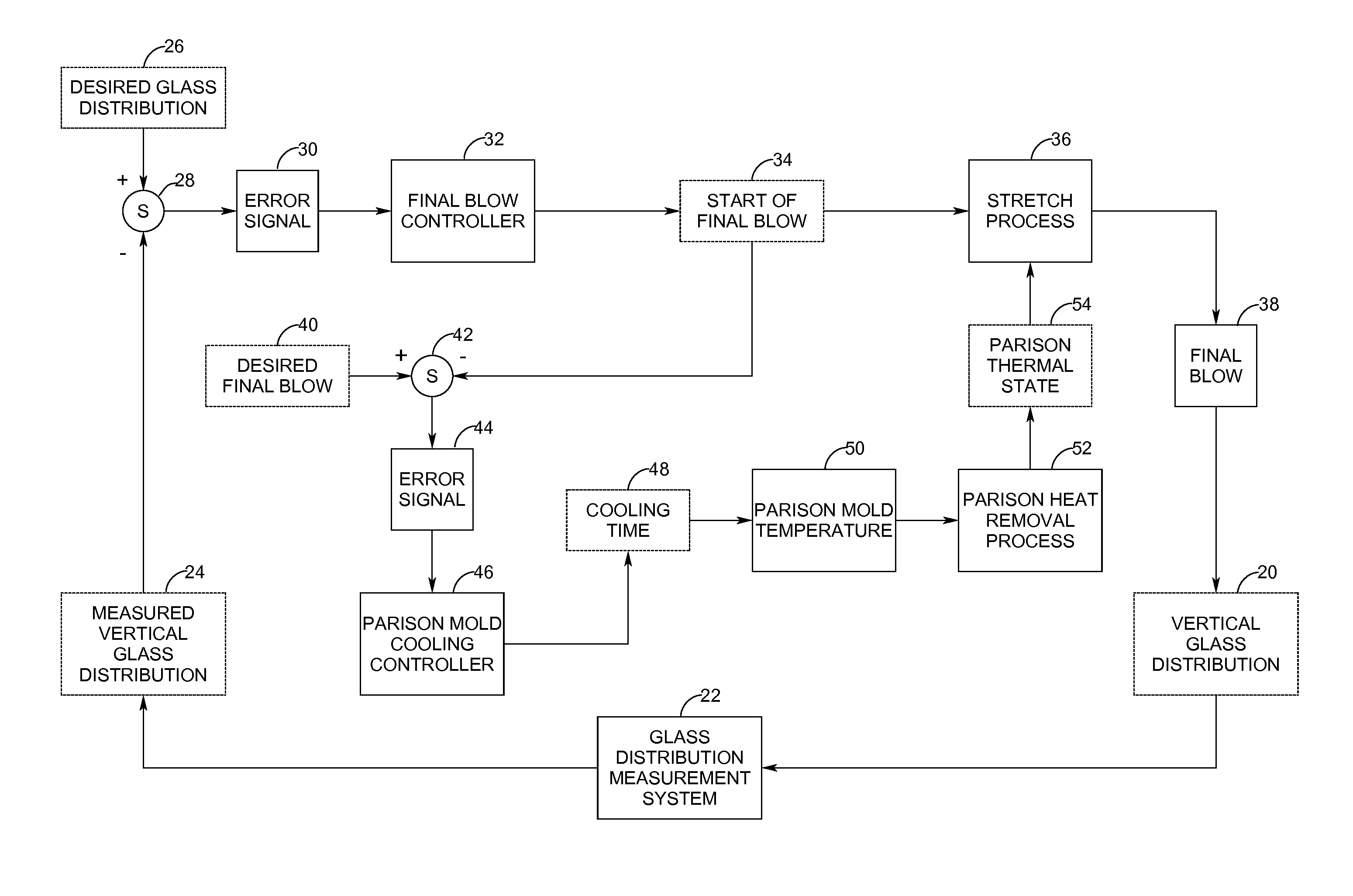

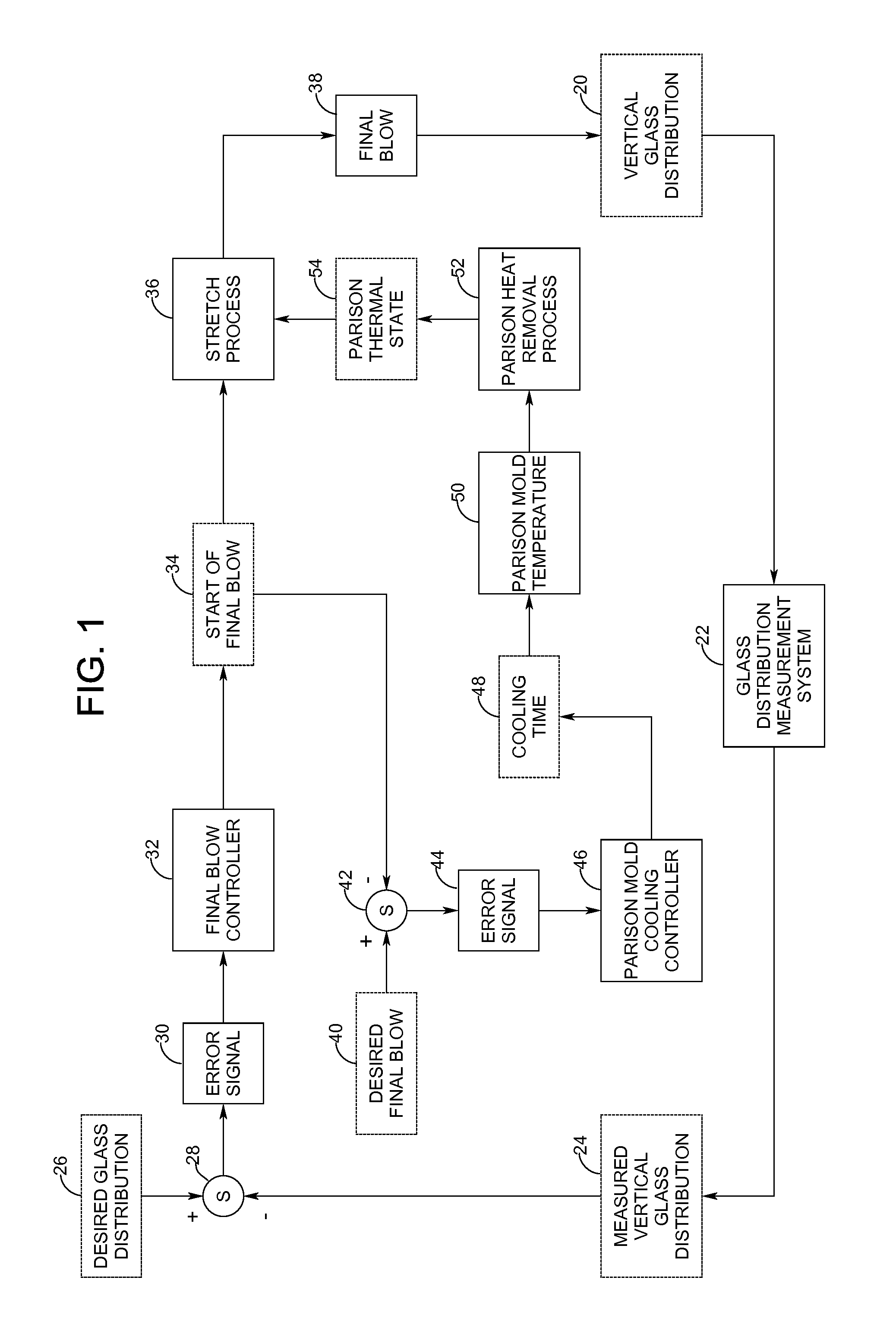

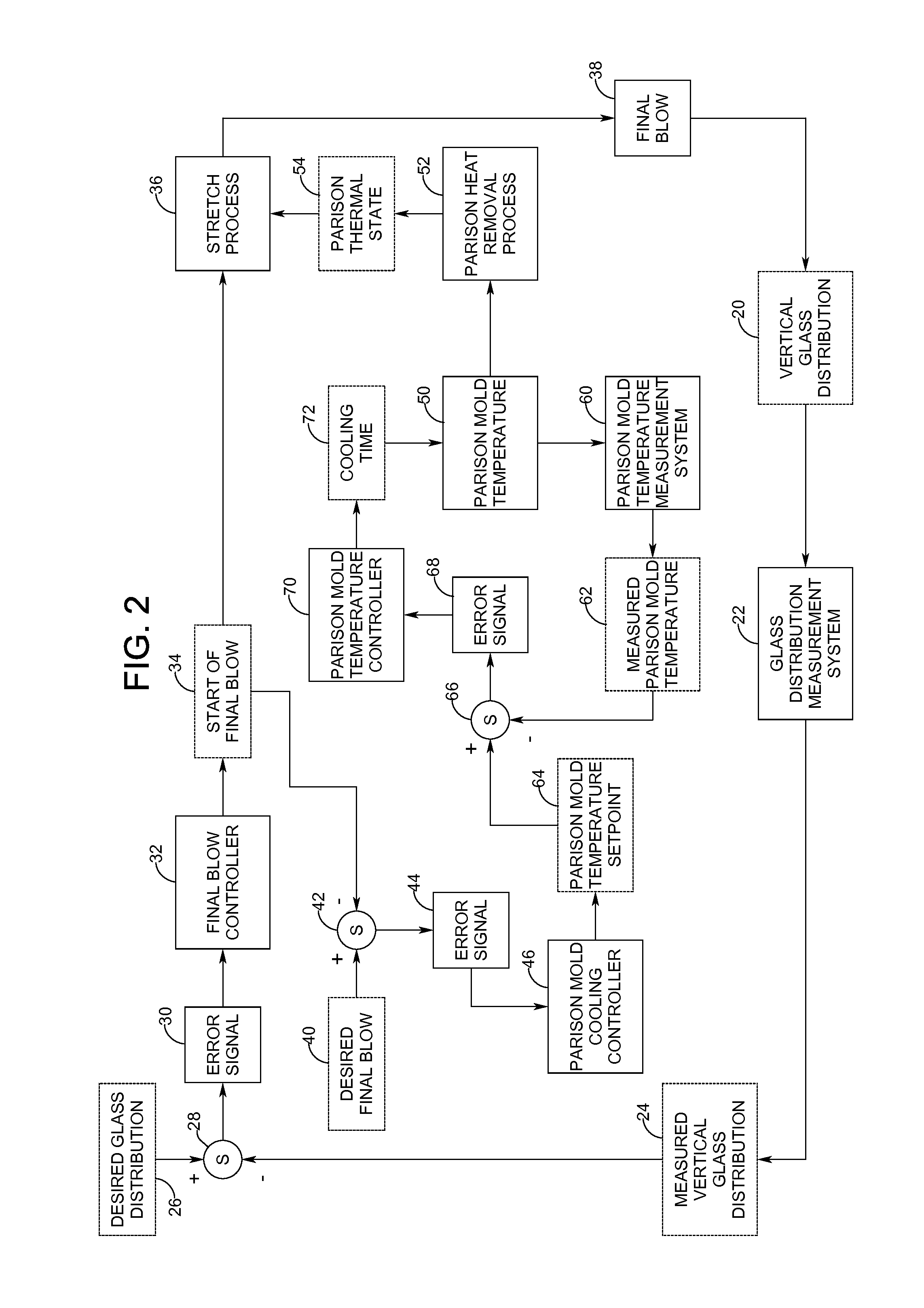

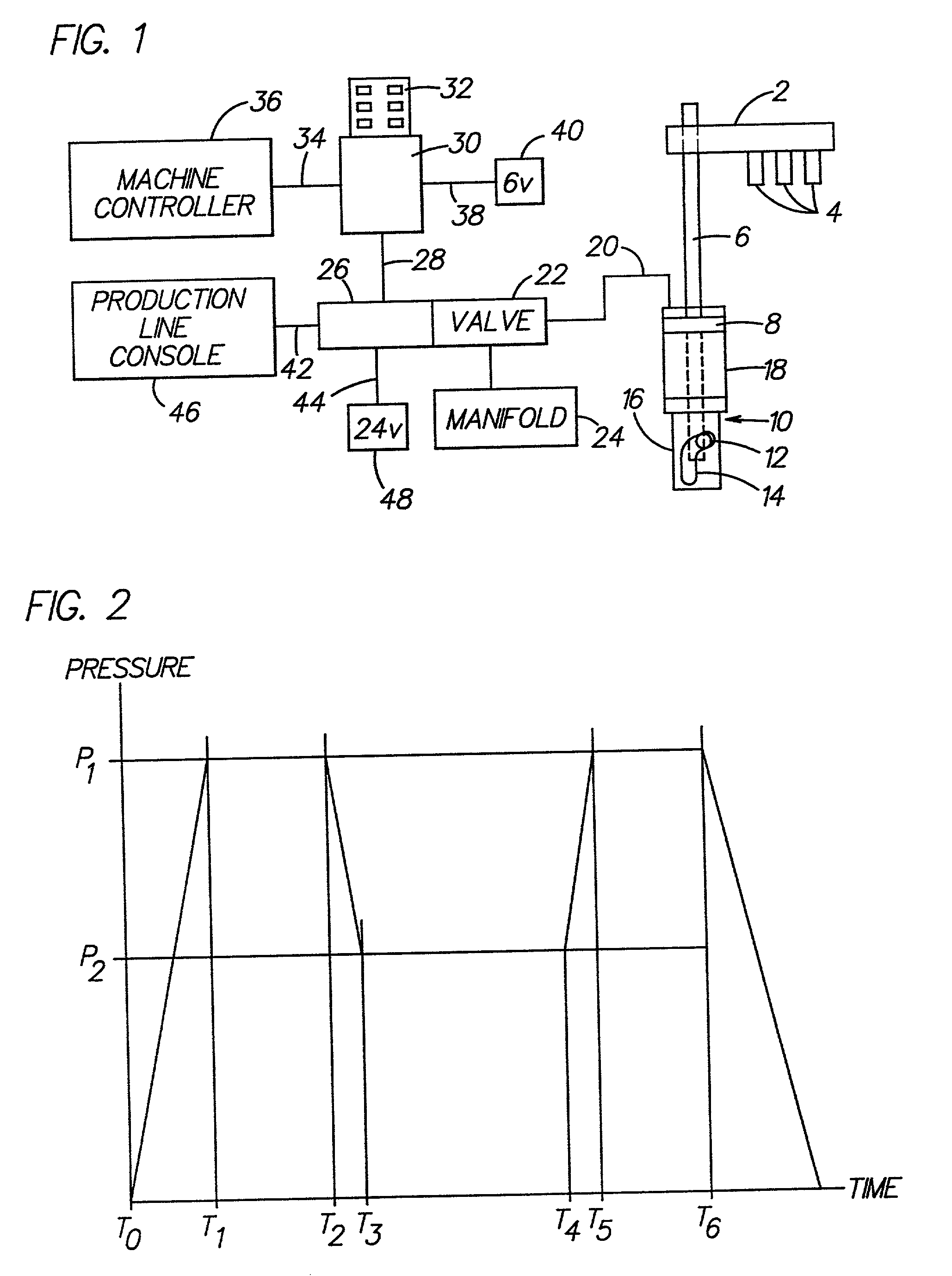

Vertical Glass Distribution Habituating Control System and Method

ActiveUS20120174628A1Quick controlReduce stretchProgramme controlBlowing machine gearingsControl systemEngineering

A system and method for automatically adjusting I.S. machine timing to maintain desired vertical glass distribution to improve process yield and quality while reducing dependence on operator skill. Deficiencies in the vertical glass distribution are rapidly addressed by automatically varying the start of final blow to allow more or less stretching of the parison, and more fundamentally addressed by adjusting the cooling of the parison mold. The cooling time of the parison mold may be adjusted by using final blow timing error correction or by also using parison mold temperature error correction.

Owner:EMHART GLASS SA

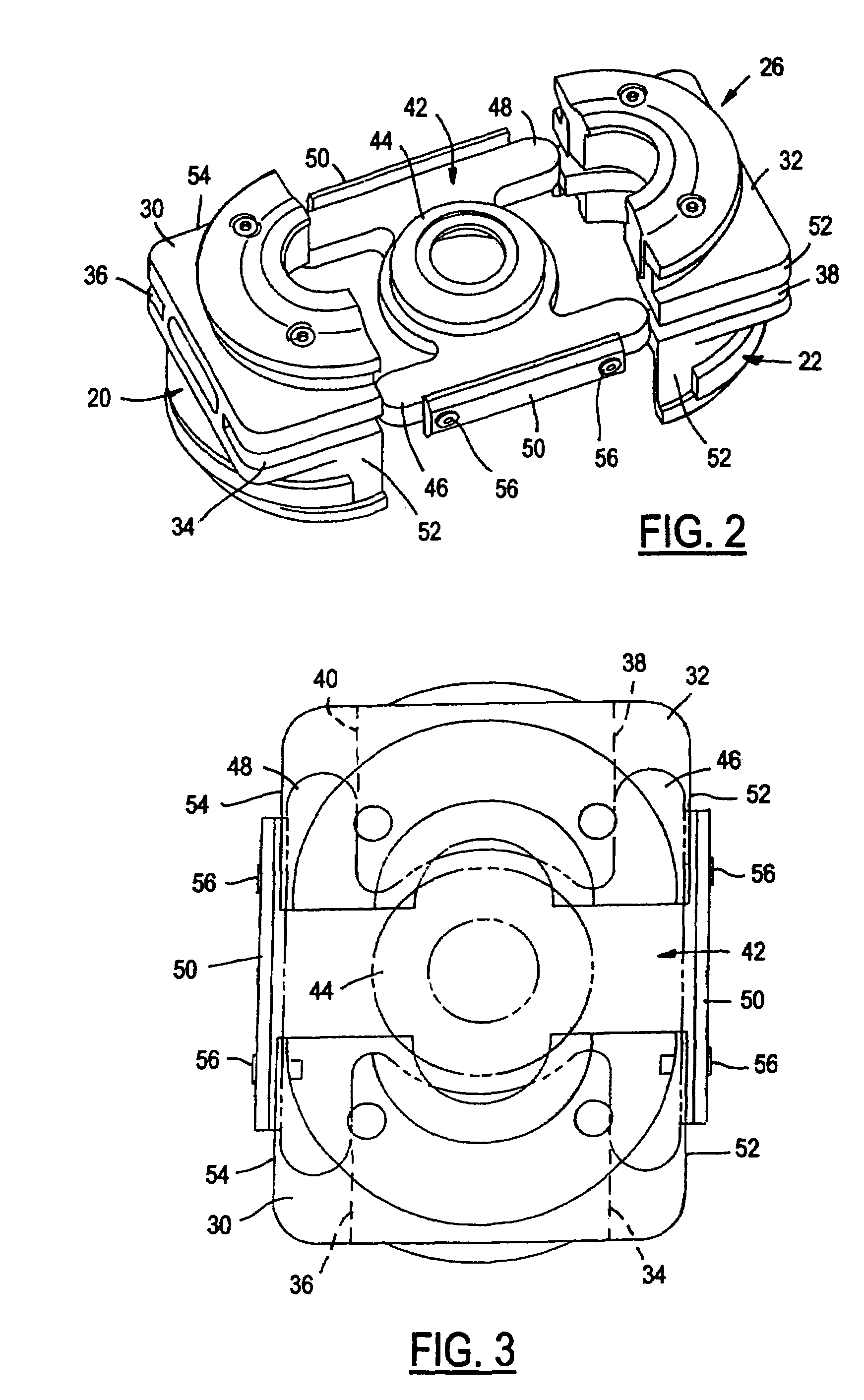

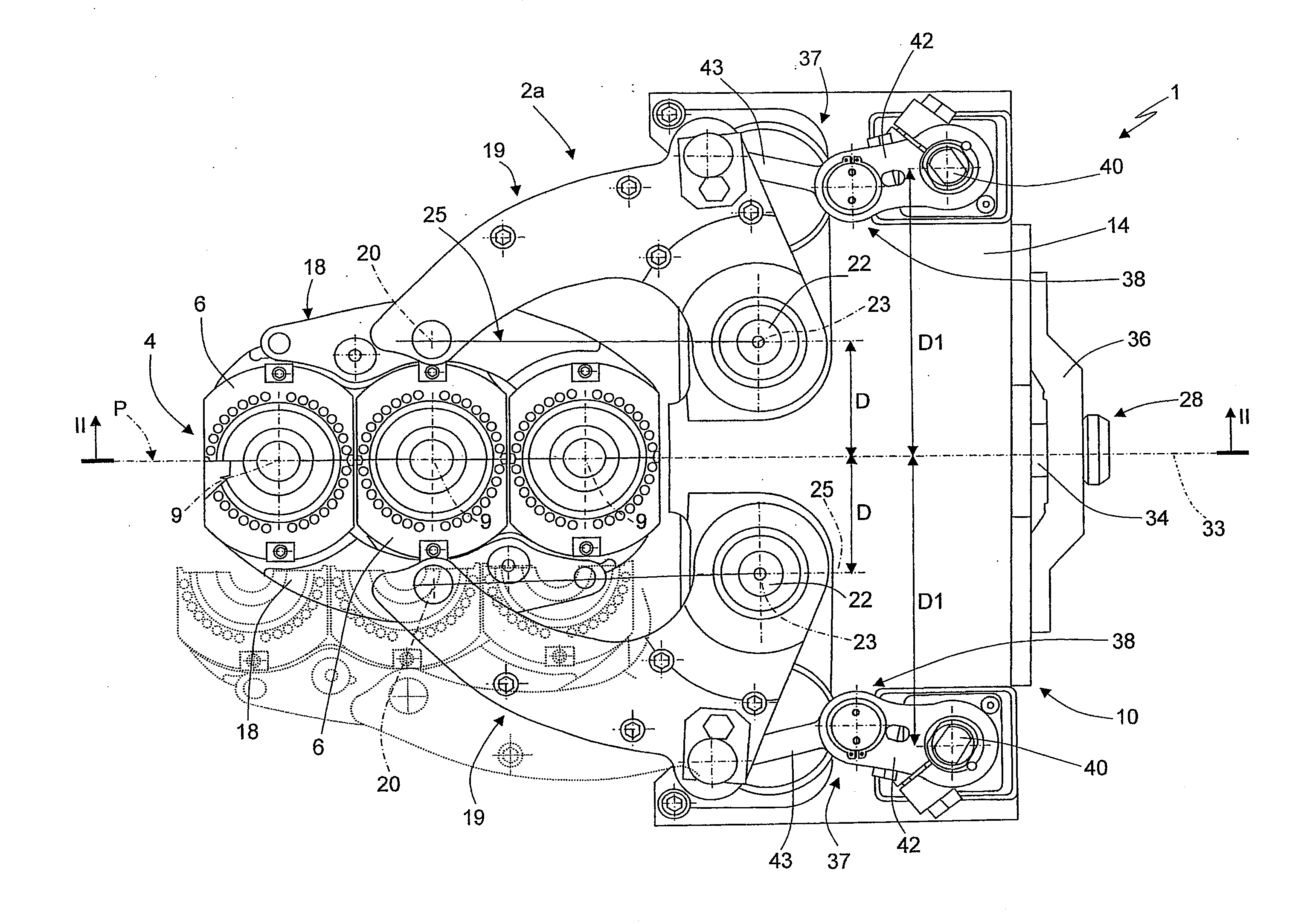

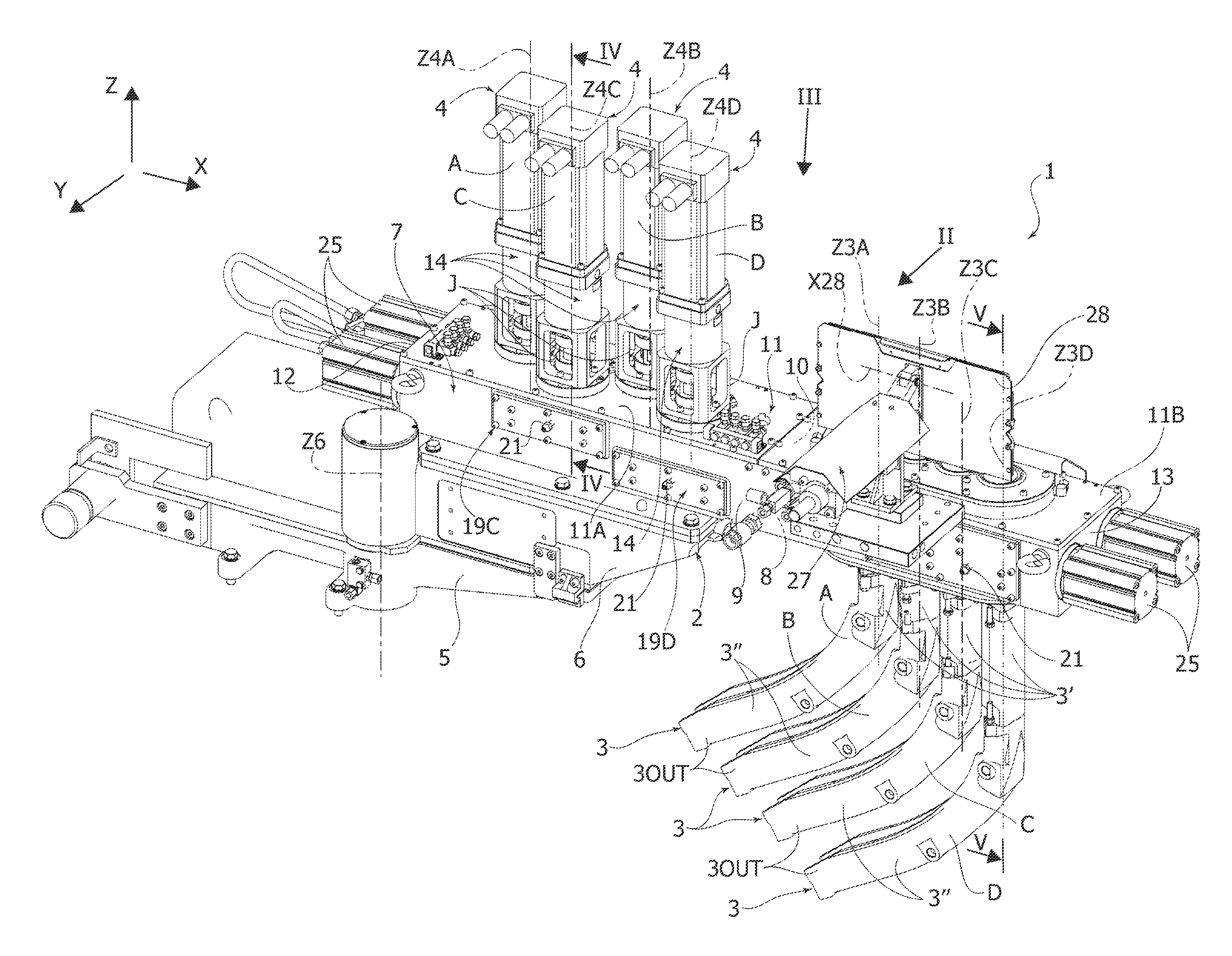

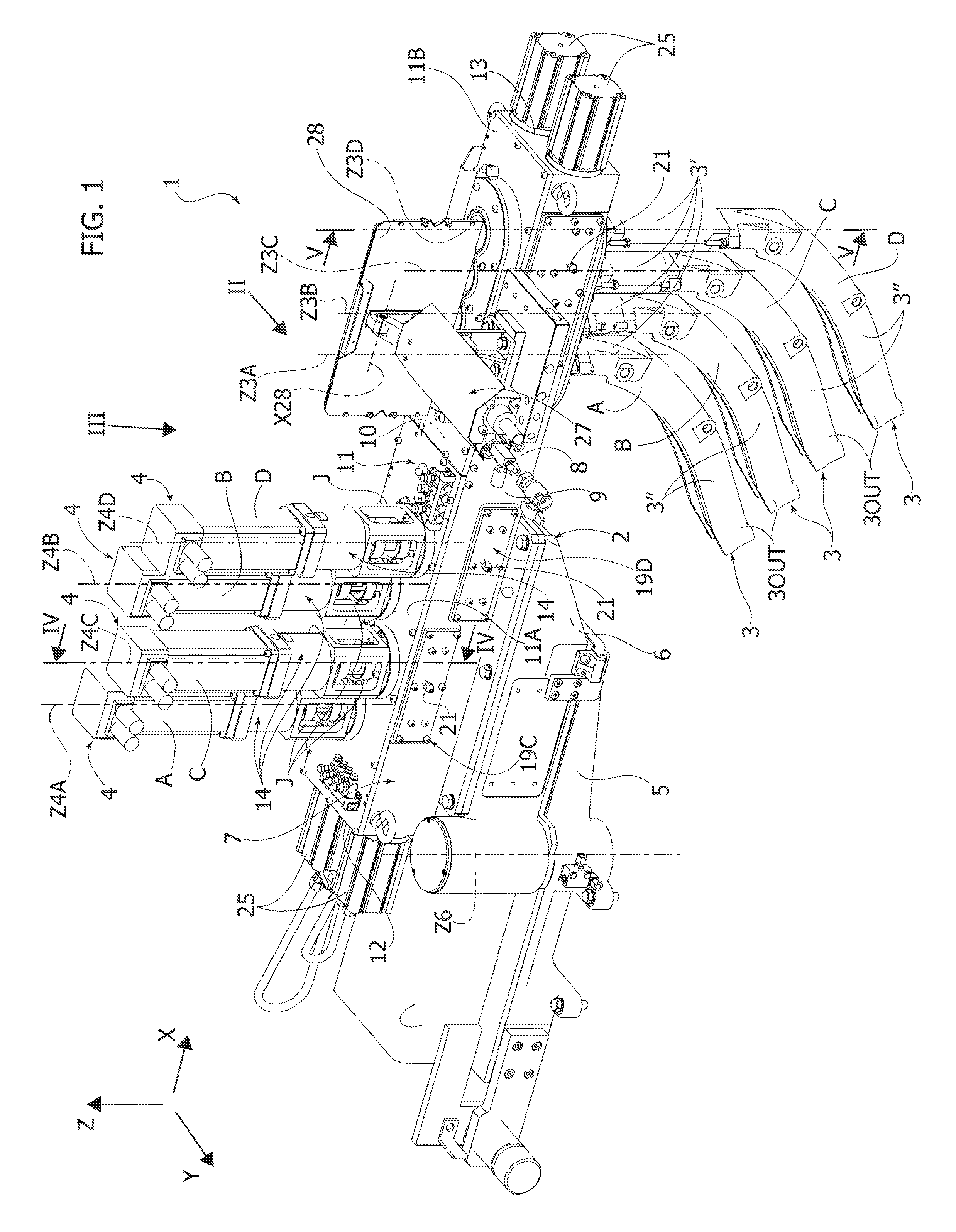

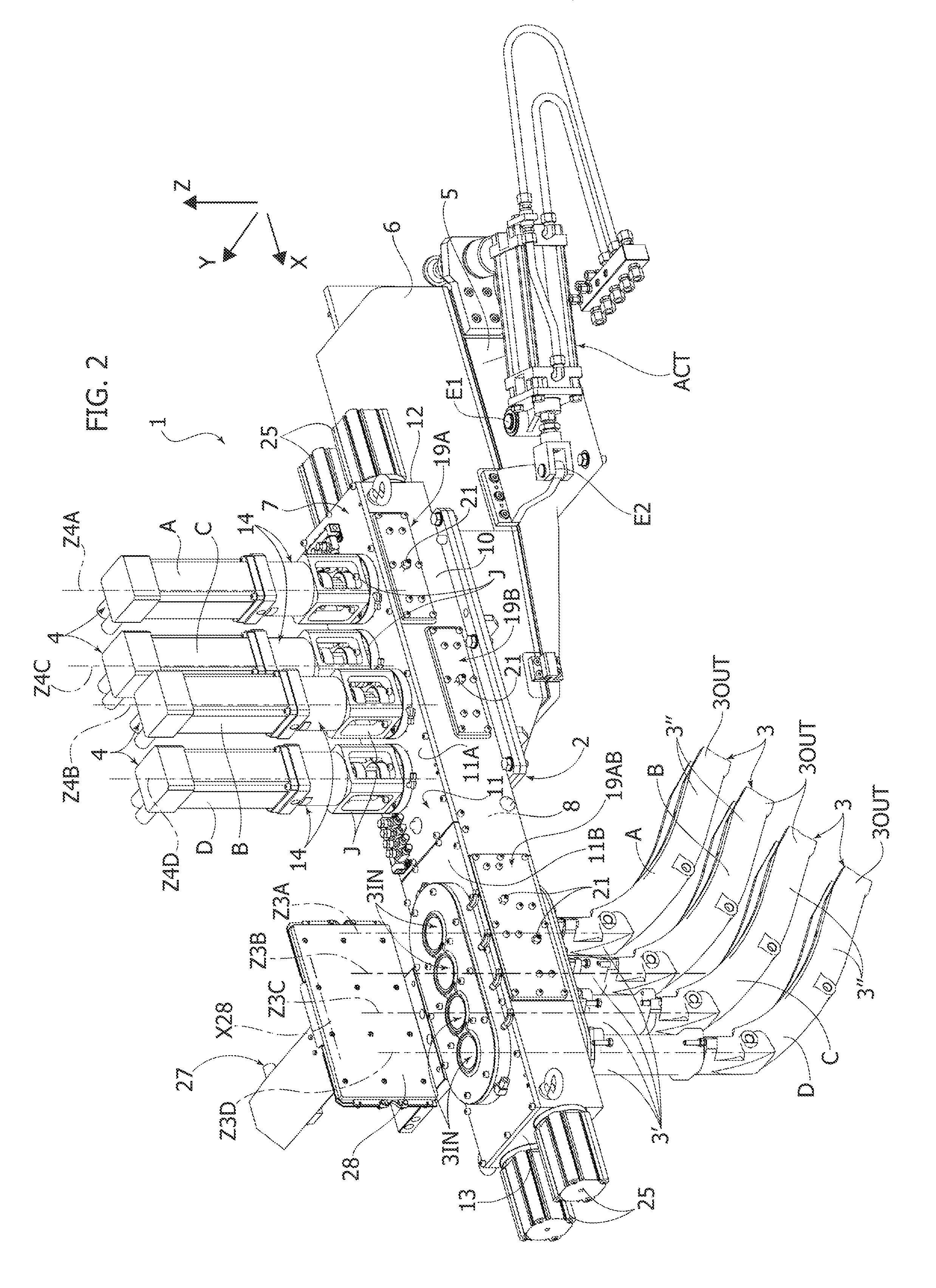

Glassware forming machine molds opening/closing device

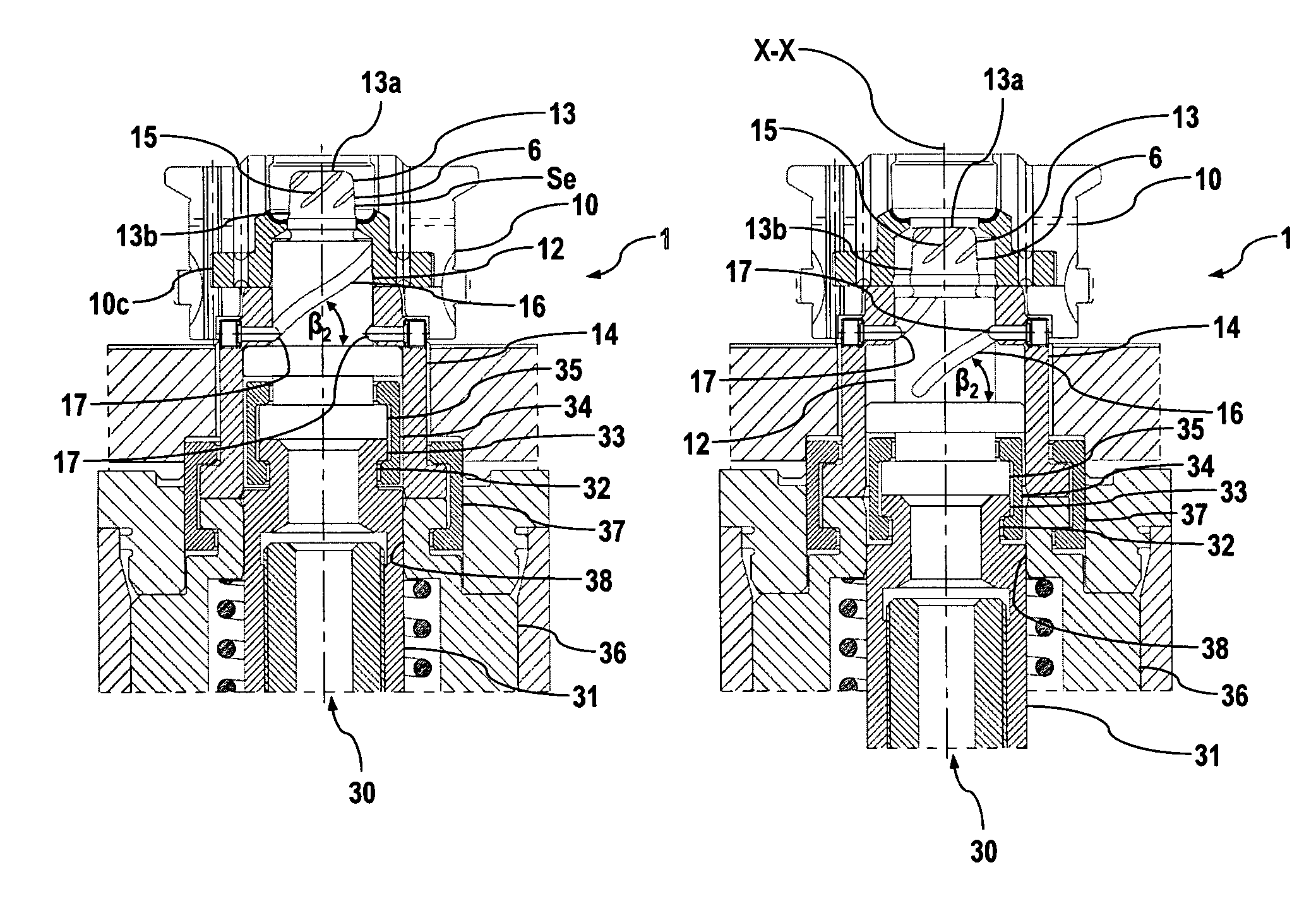

ActiveUS20080209951A1Efficient and reliable and compactBlowing machine gearingsGlass drawing apparatusLongitudinal planeMolding machine

A mold of a glassware forming machine has a longitudinal plane of symmetry, and two half-molds movable between a closed position and an open extraction position by a powered mold opening / closing device, which has a fixed fastening and supporting structure, two mold-holders, and, for each mold-holder, a respective supporting and actuating arm hinged to the relative mold-holder to rotate about a movable hinge axis, and to the fixed structure to rotate about a fixed hinge axis; the fixed hinge axes being located on opposite sides of the plane of symmetry, and at such a distance from the plane of symmetry that, when the half-molds are in the closed position, the line intersecting the fixed axis and movable axis of each arm extends substantially parallel to the plane of symmetry.

Owner:BOTTERO SPA

Baffle mechanism for I.S. machine

An I.S. machine has a blankmold which is open at the top and includes inner and outer annular top sealing surfaces. Associated with the blankmold is a baffle including a body having a cup shaped portion closed with a vertical cylindrical bore open at the bottom, an annular bottom sealing surface for sealingly engaging the blankmold outer annular top sealing surface, and a top having a hole. A tubular sleeve communicates with the hole and extends vertically upwardly from the top of the body. A piston has a cylindrical head including a top surface, a cylindrical sealing surface and an annular bottom sealing surface having a plurality of radial notch means across the bottom thereof. A tubular rod extends vertically upwardly from the top surface for slidable displacement in the tubular sleeve, and a collar is secured to the top of the rod. A spring located between the collar and the cup shaped portion urges the cylindrical head vertically upwardly to a position whereat the cylindrical head top surface engages the top of the cup shaped portion. The collar is pneumatically displaced vertically downwardly at a high pressure to bring the cup shaped portion annular surface into sealing engagement with the blankmold outer annular sealing surface. The pressure is then reduced so that a predetermined distance separates the cylindrical head annular bottom sealing surface and the blankmold inner annular sealing surface so that settle air can be introduced into the mold, and then the pressure is again raised to the high pressure for parison formation.

Owner:EMHART GLASS SA

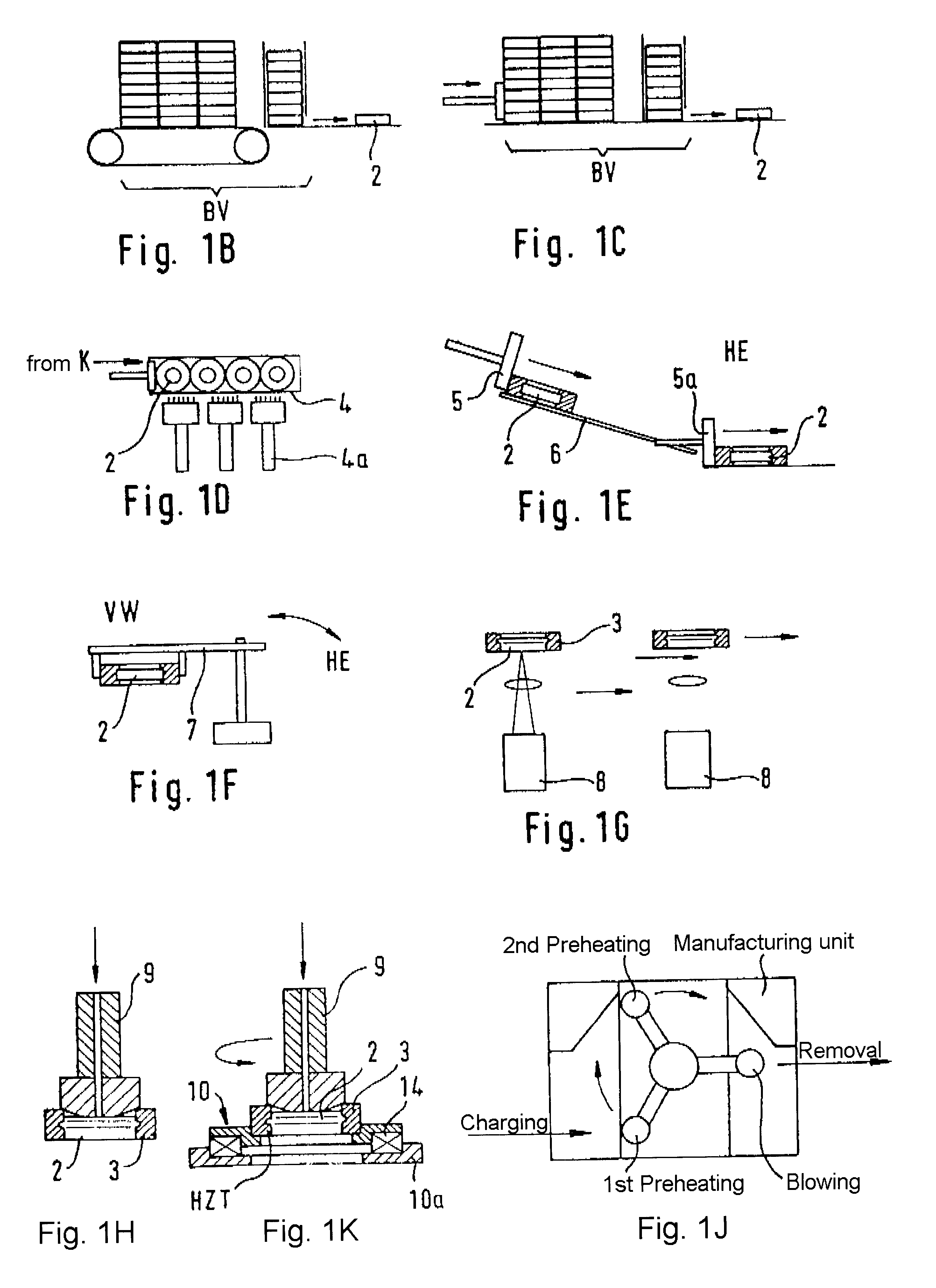

Method of Manufacture of Glass Flasks with Stem and Apparatus for Performing of this Method

InactiveUS20080256982A1OptimizationGlass pressing apparatusBlow machinesEngineeringMechanical engineering

Owner:OLIVOTTO GLASS TECH

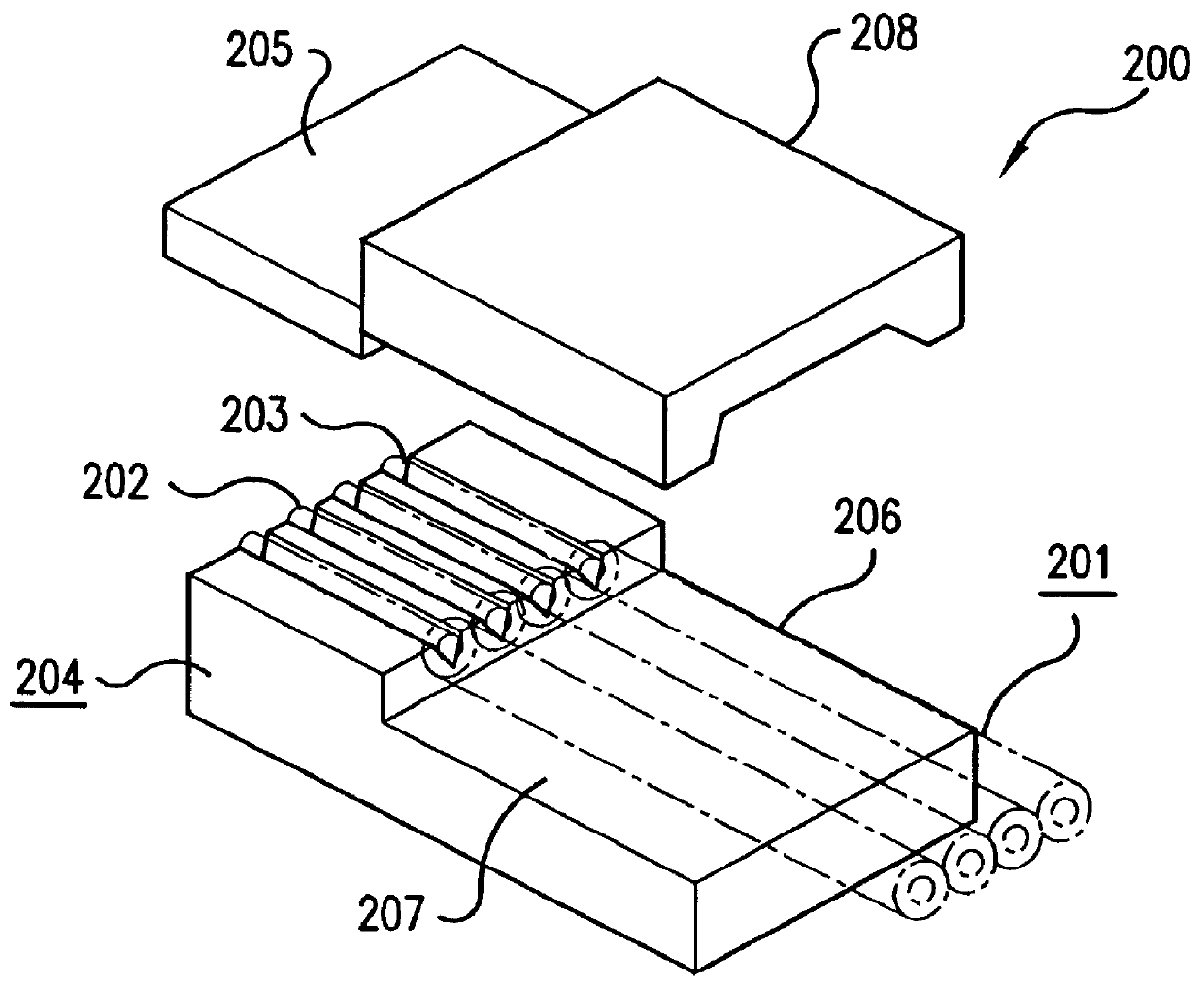

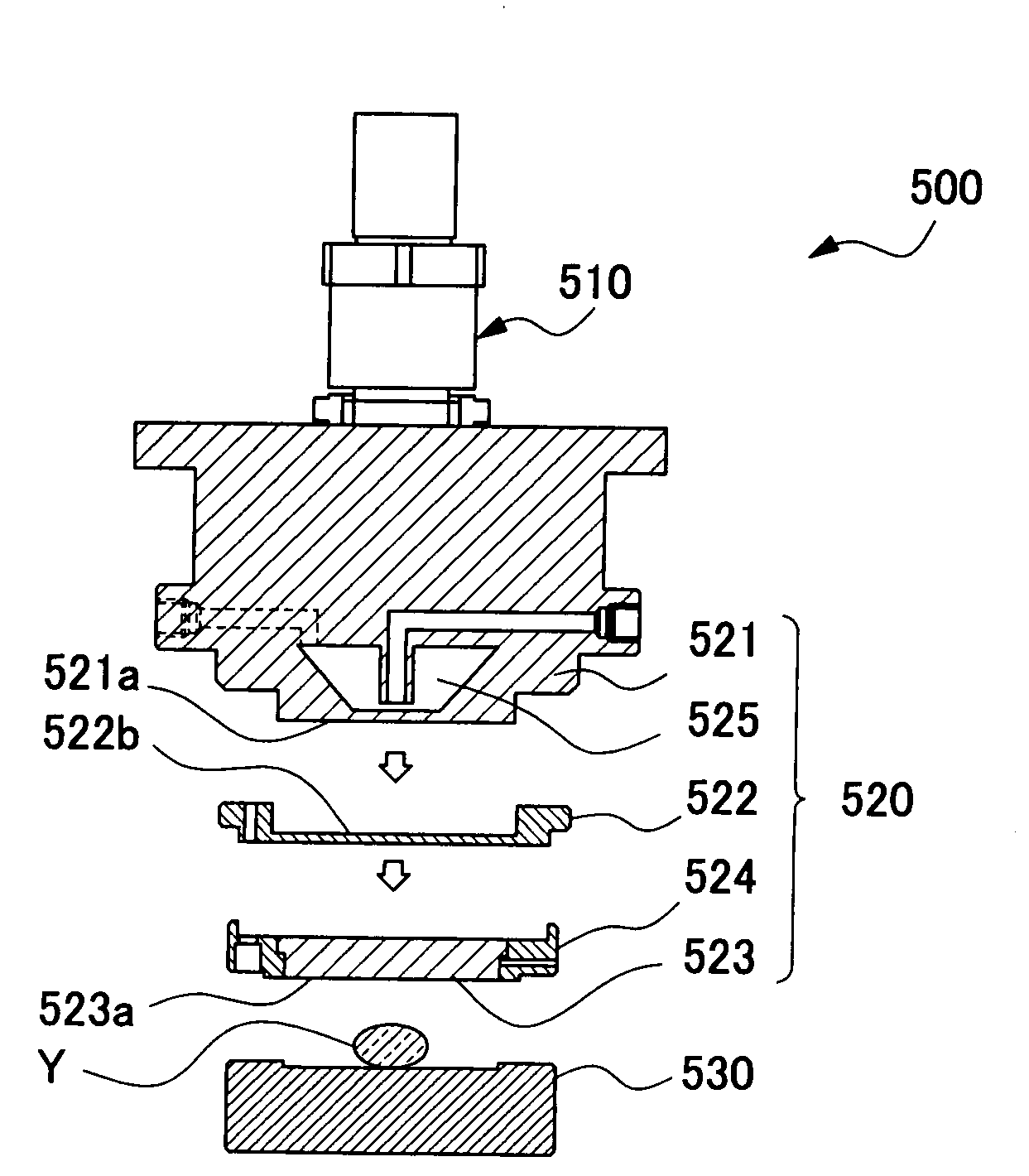

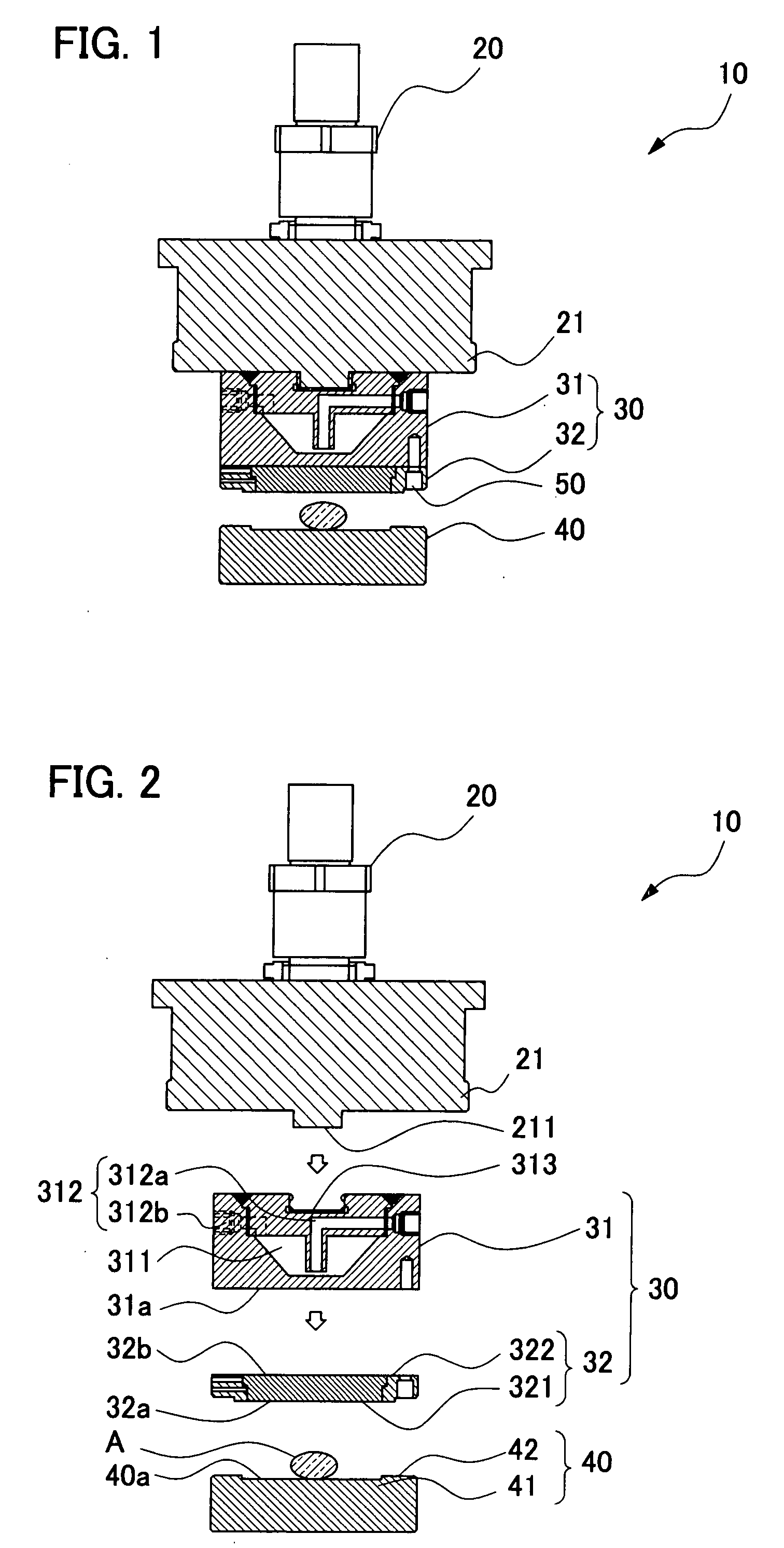

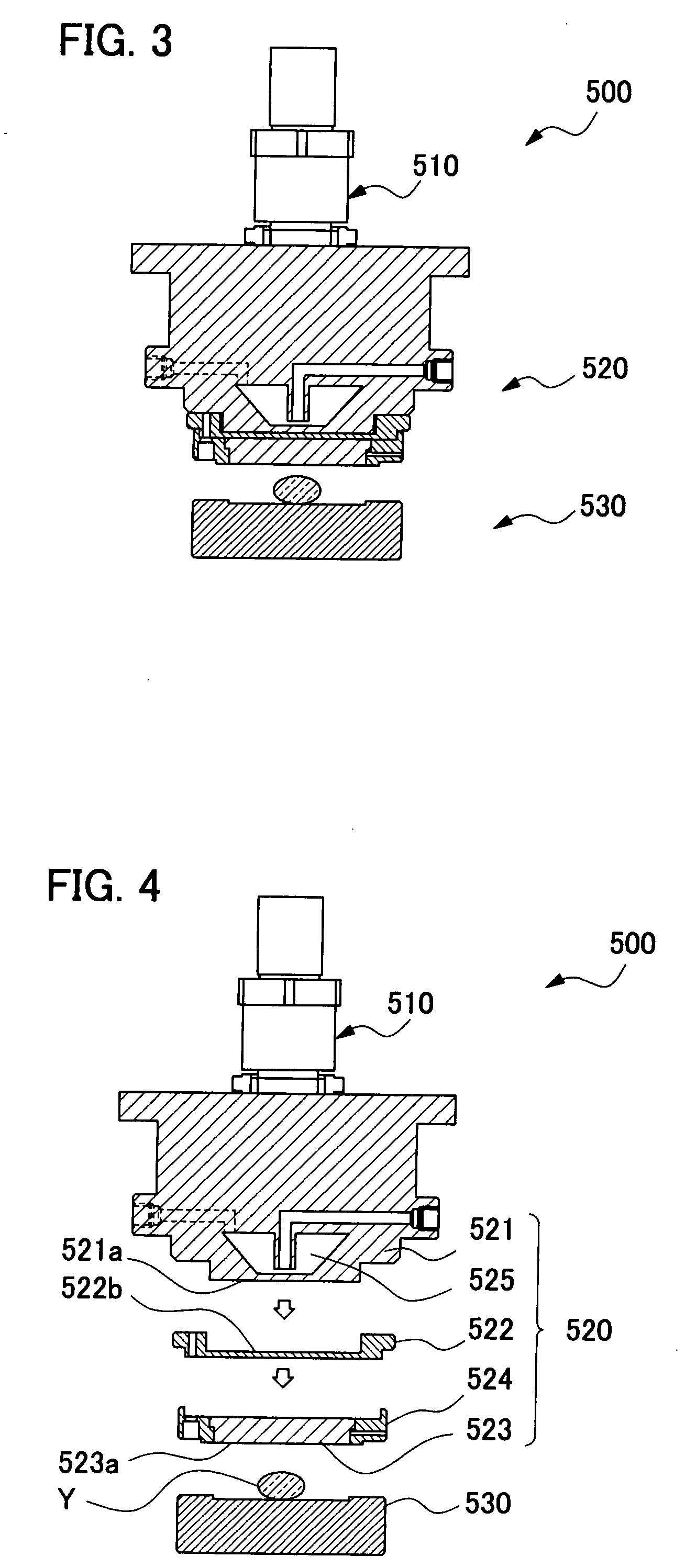

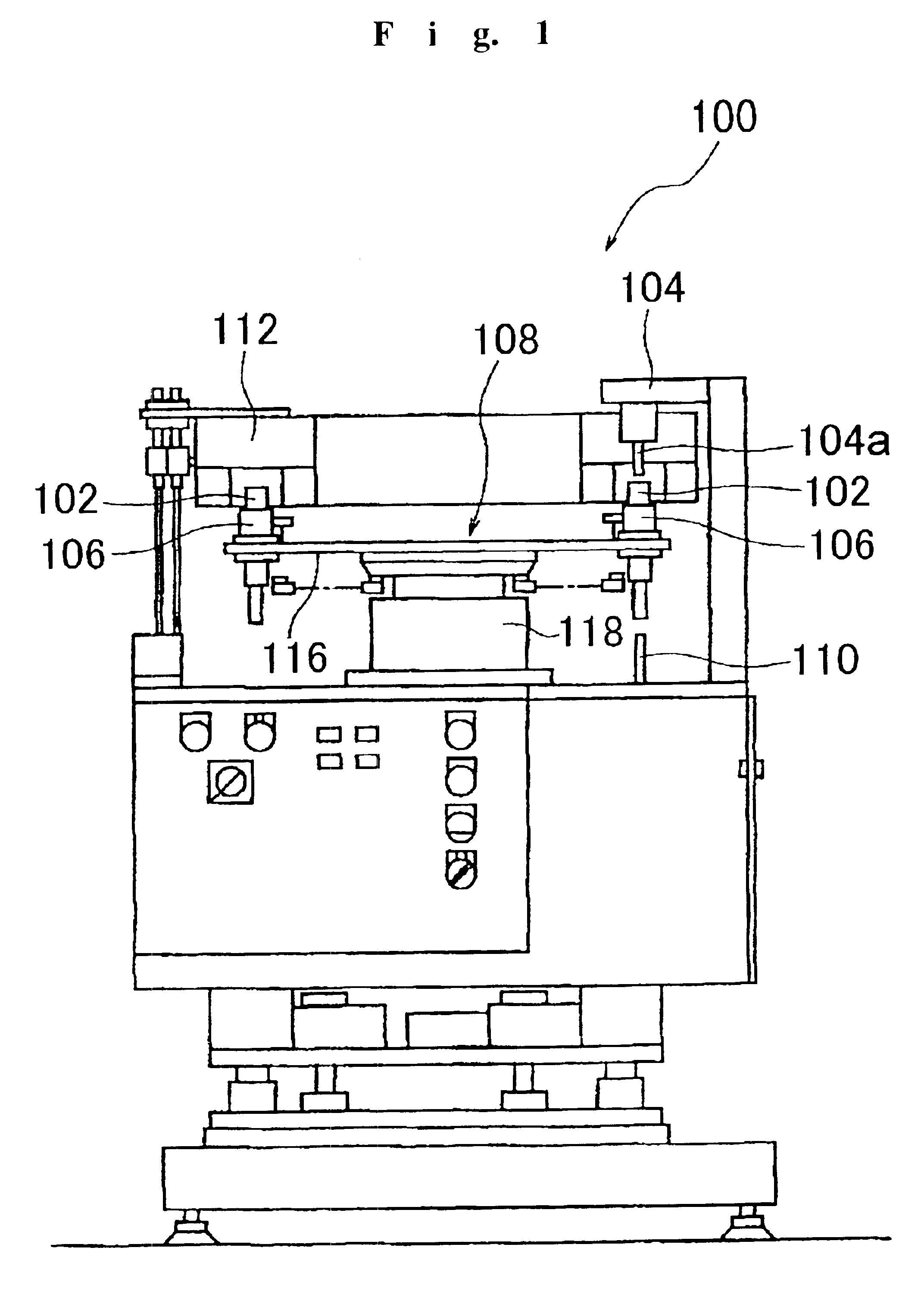

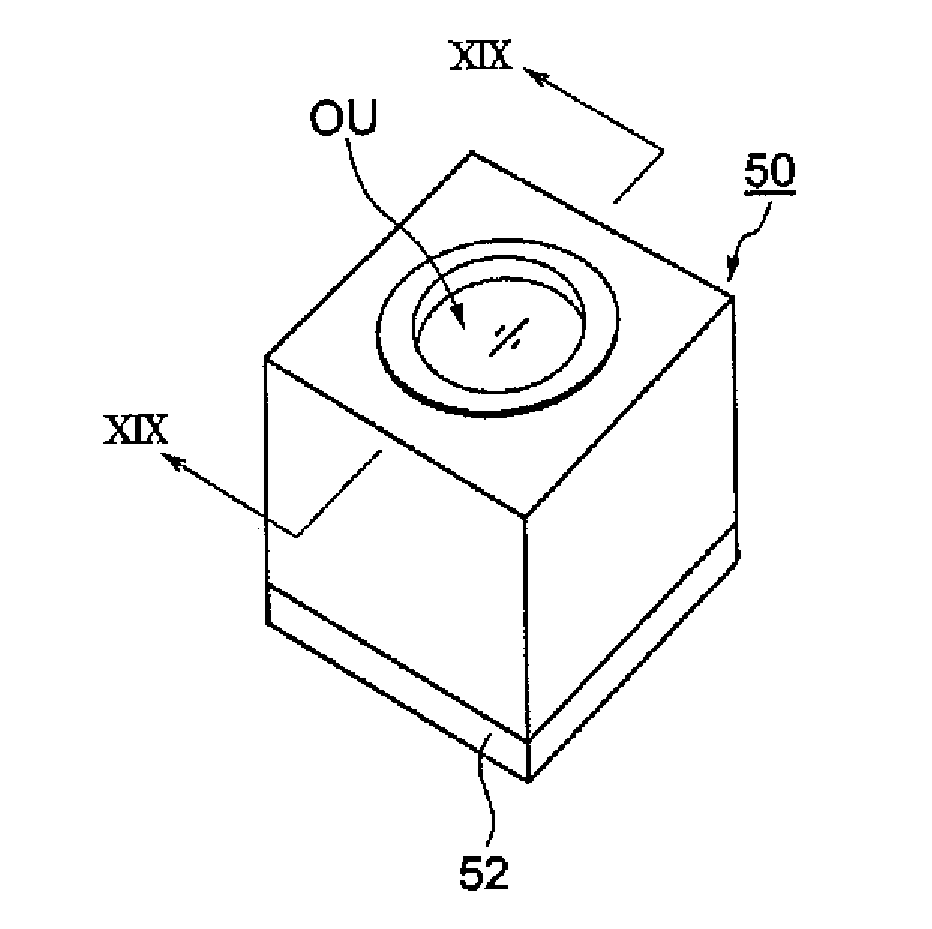

Glass forming apparatus and glass forming method

InactiveUS20070234760A1High economicalHigh productGlass drawing apparatusGlass transportation apparatusSurface roughnessEngineering

A glass forming apparatus and a glass forming method of high economical merit and high production efficiency are provided. More specifically, the glass forming apparatus has dies, in which at least one die is divided into a heat exchange unit and a press unit, and in the glass forming apparatus and glass forming method, the plane precision is improved in the contact dividing surfaces of the heat exchange unit and the press unit.A glass forming apparatus includes a die having a press surface for pressing a glass material, in which the die has a plurality of dies, and at least one die is divided into a heat exchange unit and a press unit. Preferably, the surface precision of at least one part of each dividing surface in contact with the heat exchange unit and the press unit has a flatness (PV) of 500 μm or less, and the plane precision of at least one part of the dividing surface has a surface roughness (Ra) of 100 μm or less.

Owner:OHARA

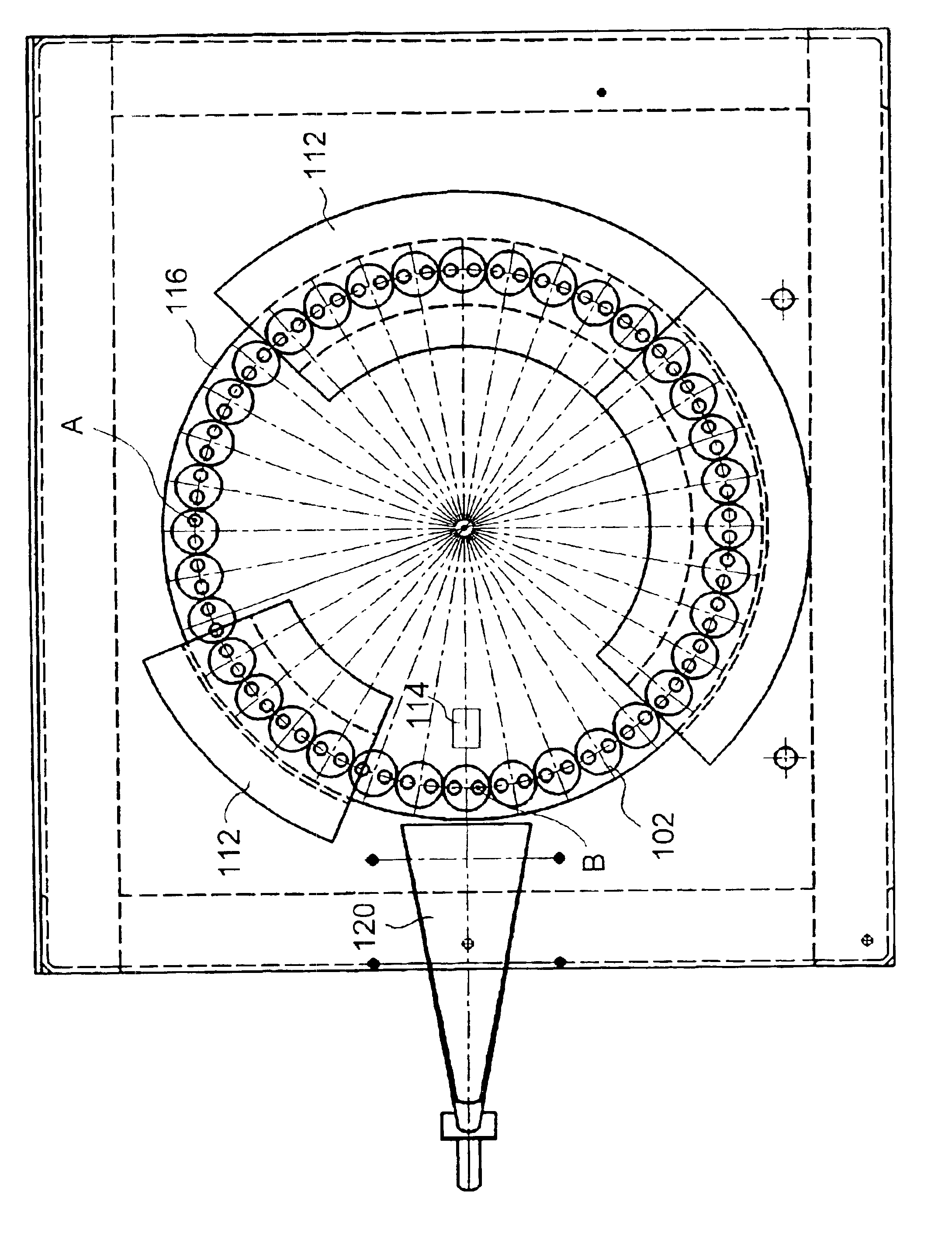

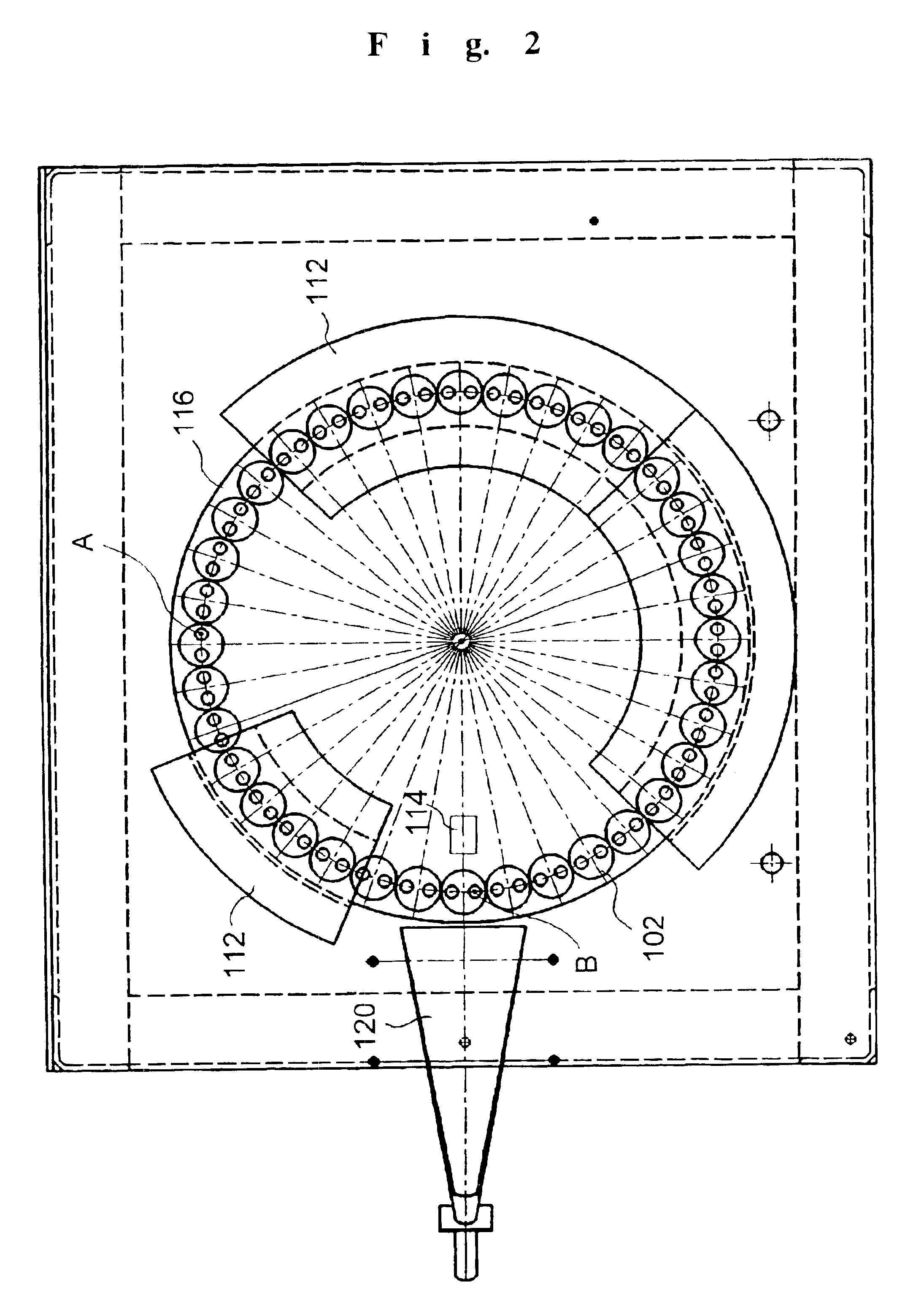

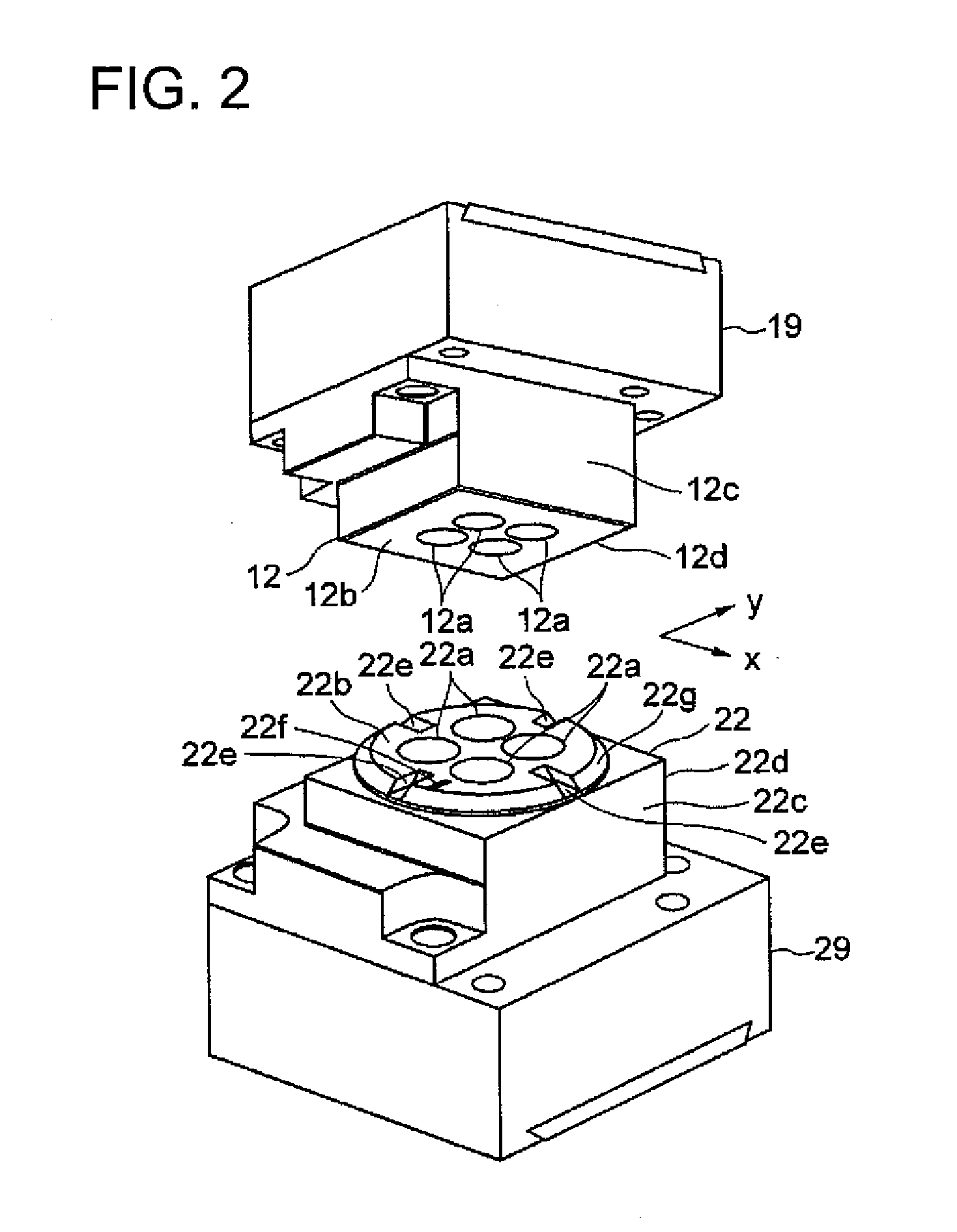

Method of manufacturing glass gobs molded glass articles, and optical elements

Methods and a device of manufacturing glass gobs with good productivity without defects in appearance from a glass melt. Glass gobs are manufactured from glass melt gobs by molding and cooling glass melt gobs in glass gob molding parts that are intermittently rotated. In one method, single intermittent rotation period of said glass gob molding part is in a range of 0.1 to 0.25 second, and the single intermittent rotation distance of said glass gob molding part is 0.8-7 cm. The device for molding glass gobs from a continuously flowing glass melt has a turntable intermittently rotated around a rotation axis and glass gob molding molds positioned on said turntable. The glass gob molding mold has multiple glass gob molding parts that receive glass melt on the upper surface thereof and mold the glass melt into glass gobs. The glass gob molding mold is positioned on a turntable so that said glass gob molding parts are disposed at equal intervals around a circumference centered on the rotation axis of the turntable.

Owner:HOYA CORP

Method of producing glass blank for substrate of information recording medium, substrate for information recording medium, and information recording medium; and manufacturing apparatus for glass blank for substrate of information recording medium

InactiveUS20120204601A1High surface flatnessImprove surface roughnessBlowing machine gearingsGlass furnace apparatusMolten glassRecording media

A method of manufacturing a glass blank for a substrate for an information recording medium, the method including steps of: cutting out a gob of a glass material from a molten glass material by cutting the molten glass material discharged from a glass material outlet at a predetermined timing; causing the gob of the glass material to fall downwardly; pinching and pressing the gob of the glass material by a press unit having a pair of molds, the molds' surfaces facing to each other being press surfaces which are planes without an unevenness, so as to contact the falling gob of the glass material only to the press surfaces; and forming a circular flat plate-shaped glass blank having a target flatness as a glass substrate for a magnetic disk such that a ratio between a diameter and a thickness of the glass blank is within a range of from 50:1 to 150:1, from the gob of the glass material.

Owner:HOYA CORP

Method for Manufacturing Lens Unit, Imaging Device, Method for Manufacturing Mold, Mold For Molding, and Method for Molding Glass Lens Array

InactiveUS20120300320A1Accurately and readily mass-producingGlass drawing apparatusGlass forming apparatusOptical axisOptoelectronics

A method for manufacturing a lens unit including the steps of: forming a first lens array, having plural first lens sections and first reference surfaces formed in a predetermined arrangement, via glass forming by arranging a glass material between a first assembled molds and by clamping the molds; forming a second lens array, having plural second lens sections and second reference surfaces formed in a predetermined arrangement, via glass forming by arranging a glass material between a second assembled molds and by clamping the molds; forming a third lens array by stacking and bonding the first and second lens arrays so that an optical axis of each lens section of the first and second lens arrays coincide, by using the first and second reference surfaces; and cutting the third lens array into each lens unit which includes at least each one of the first and the second lens sections.

Owner:KONICA MINOLTA OPTO

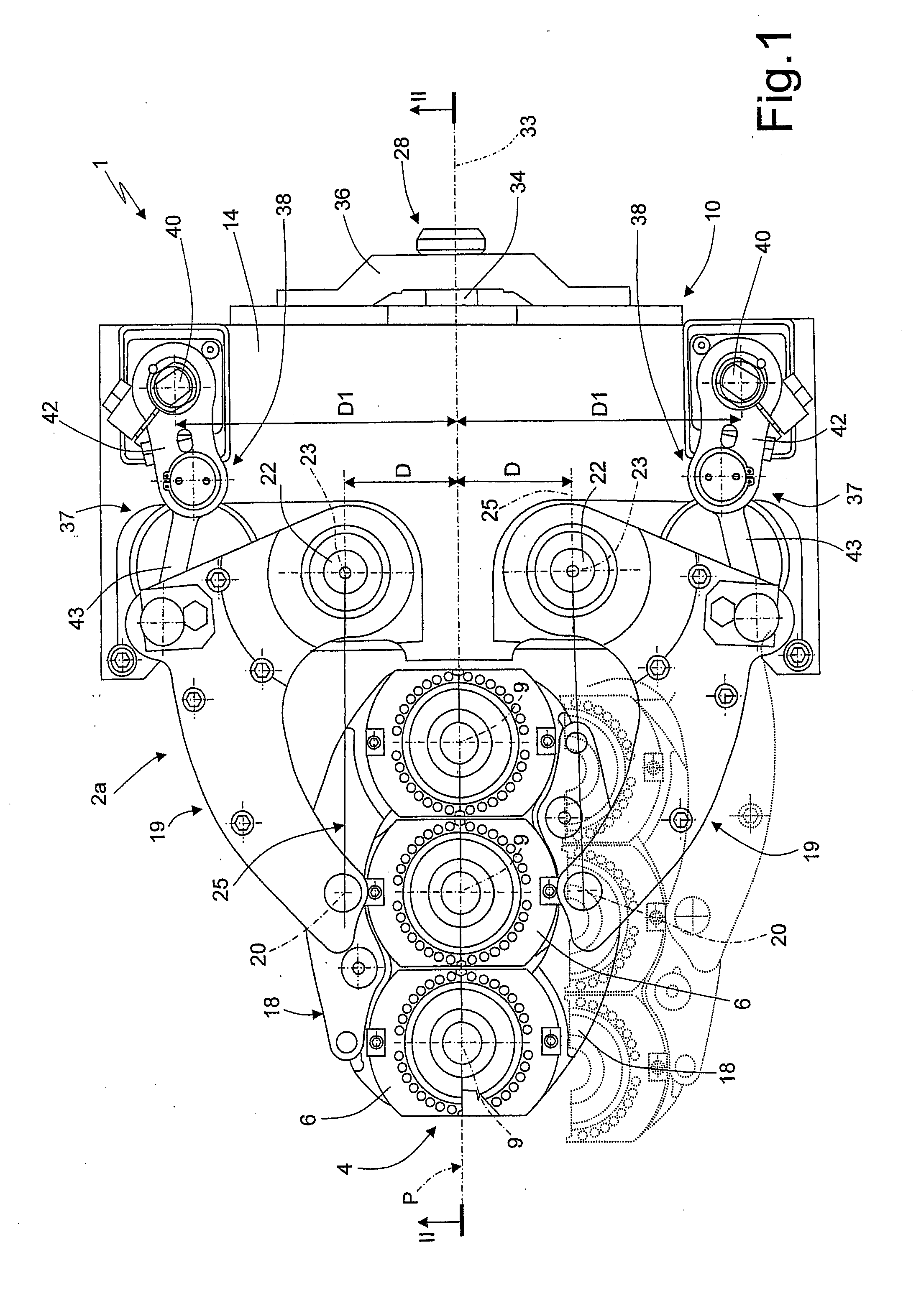

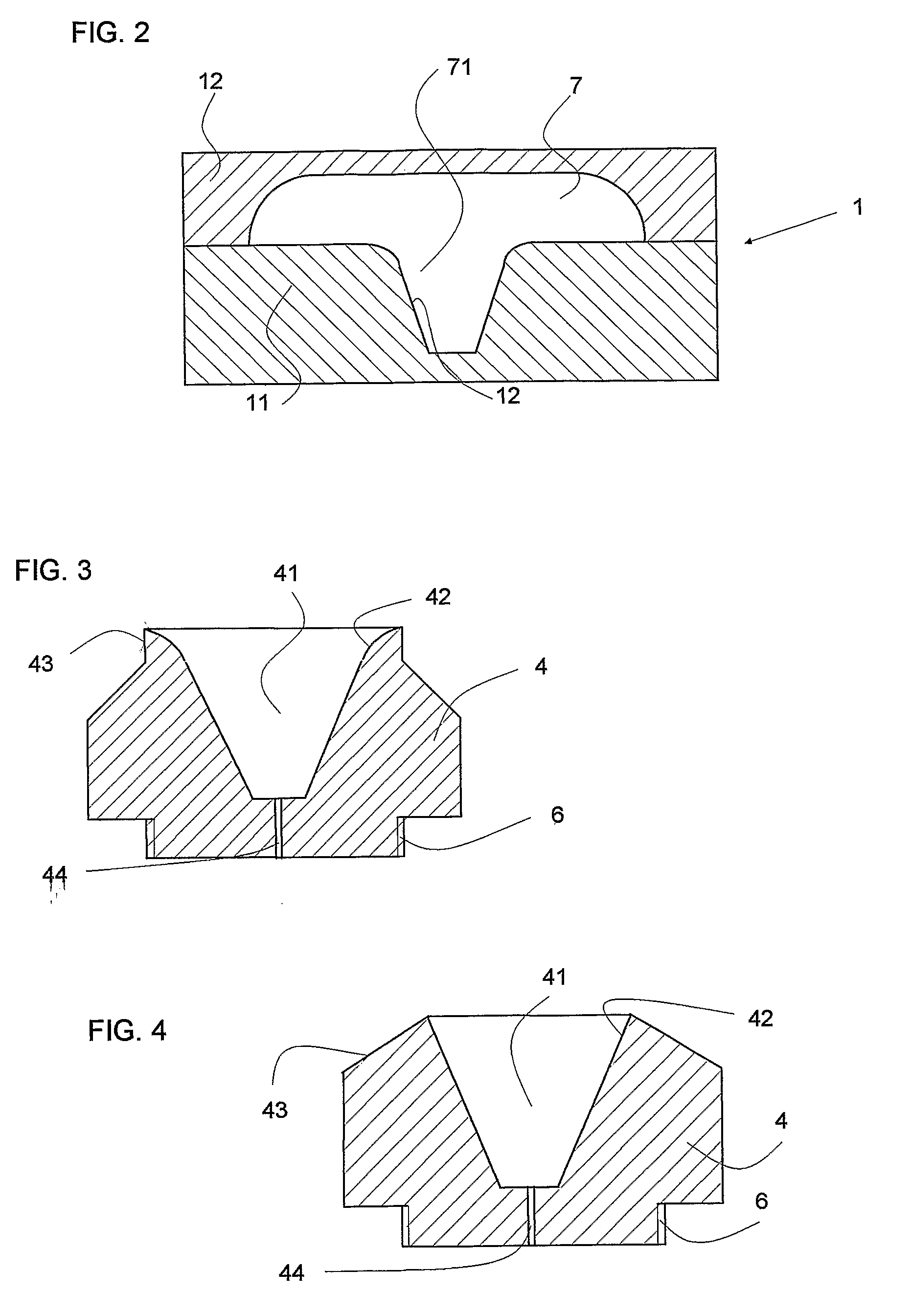

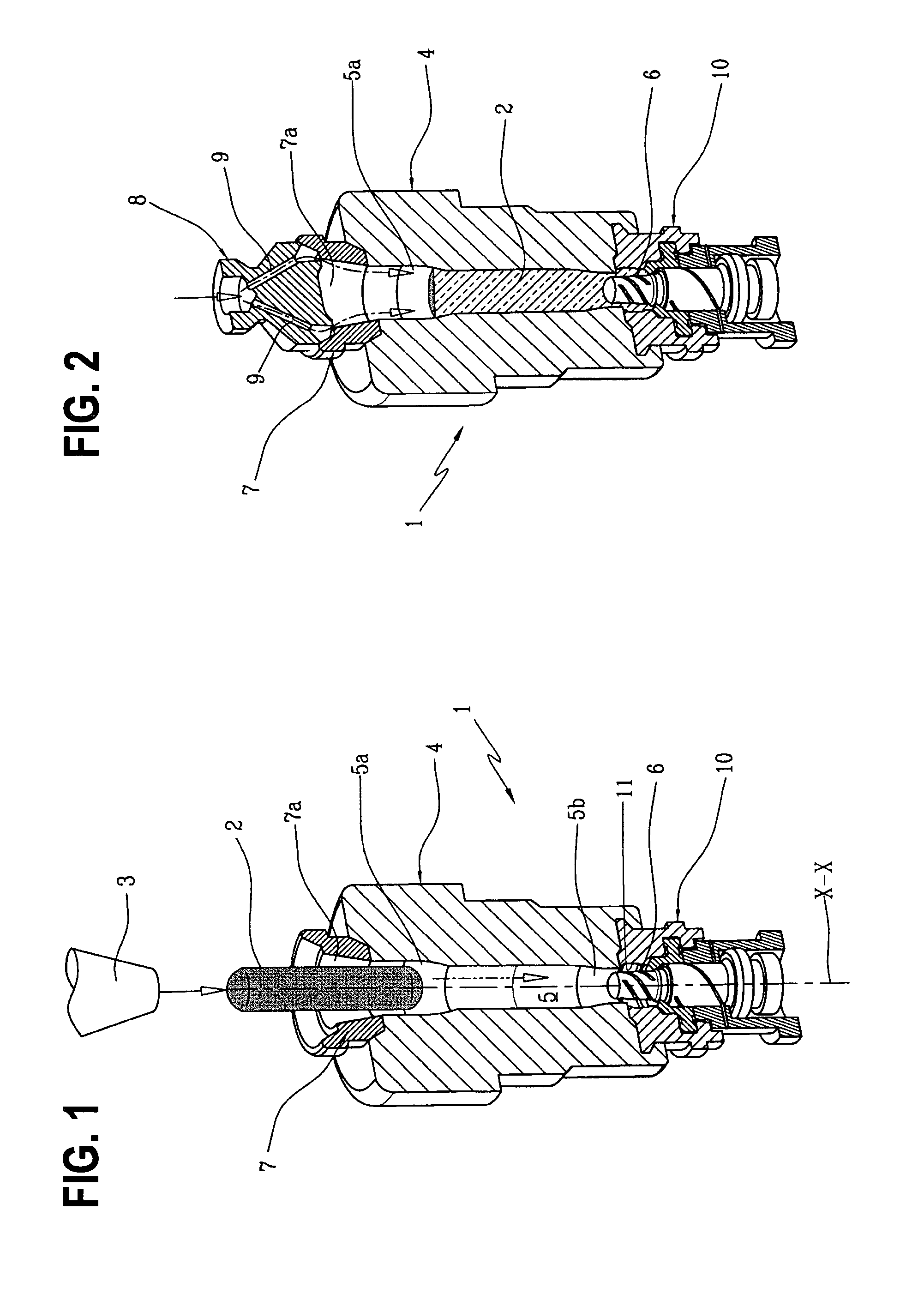

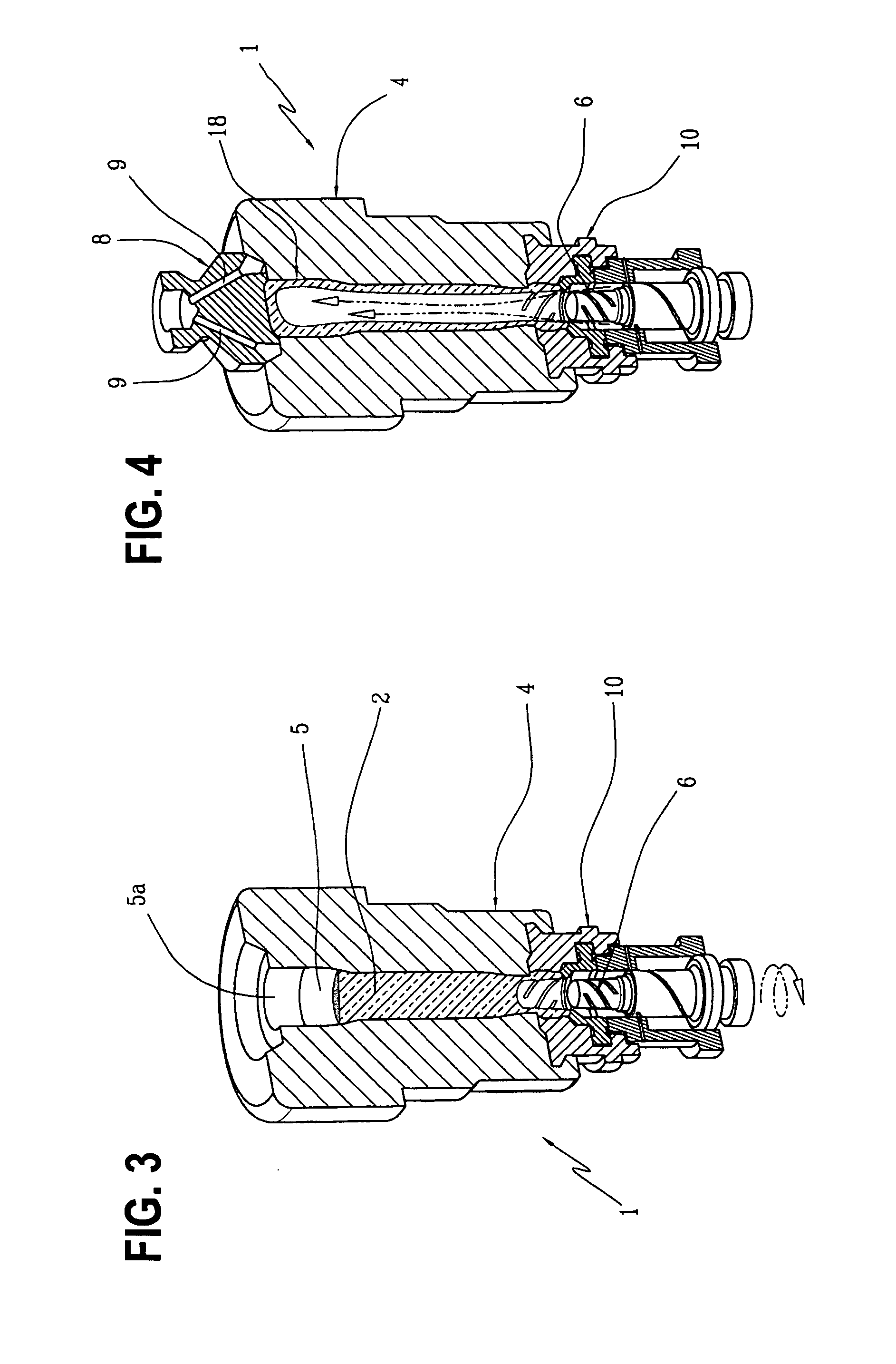

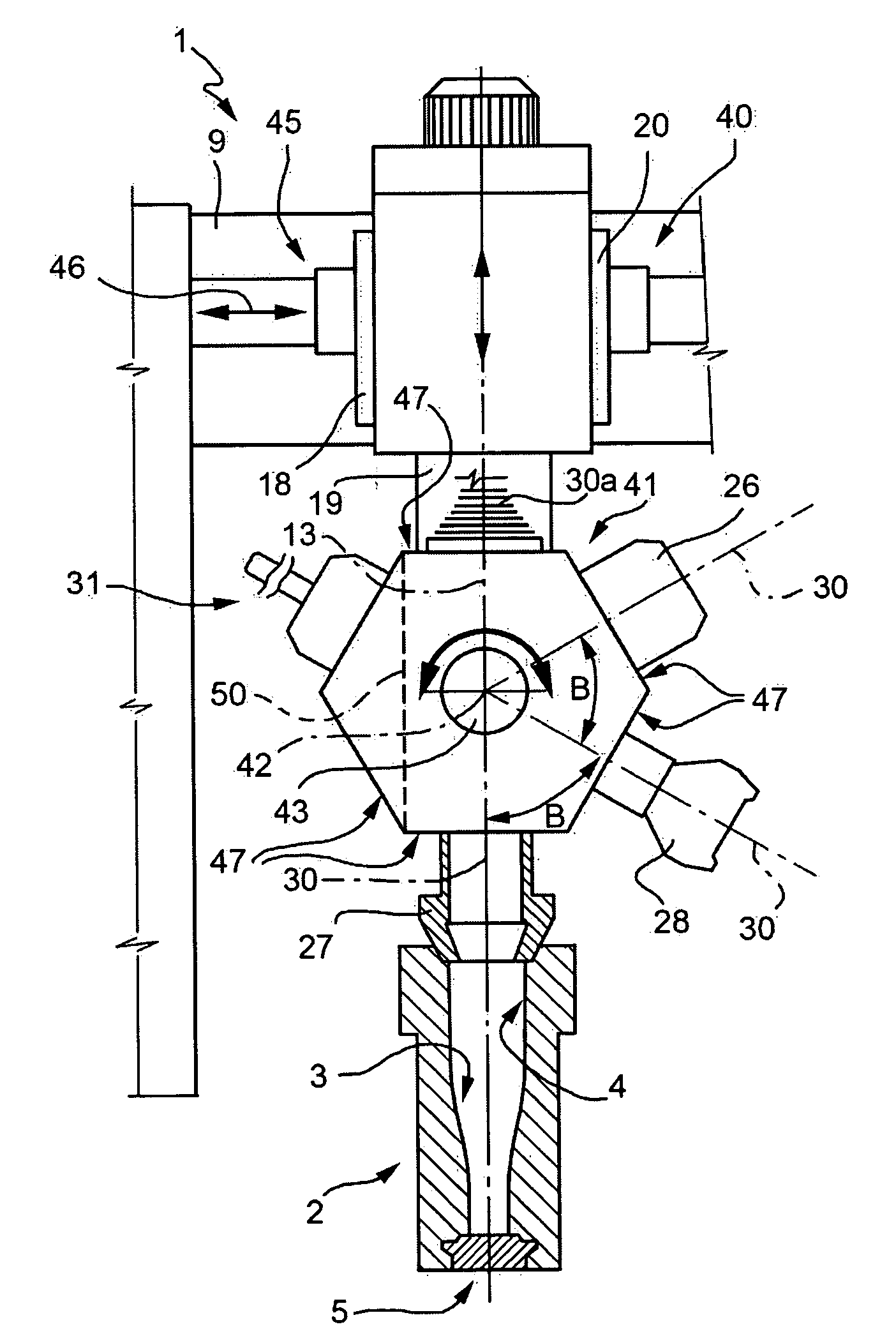

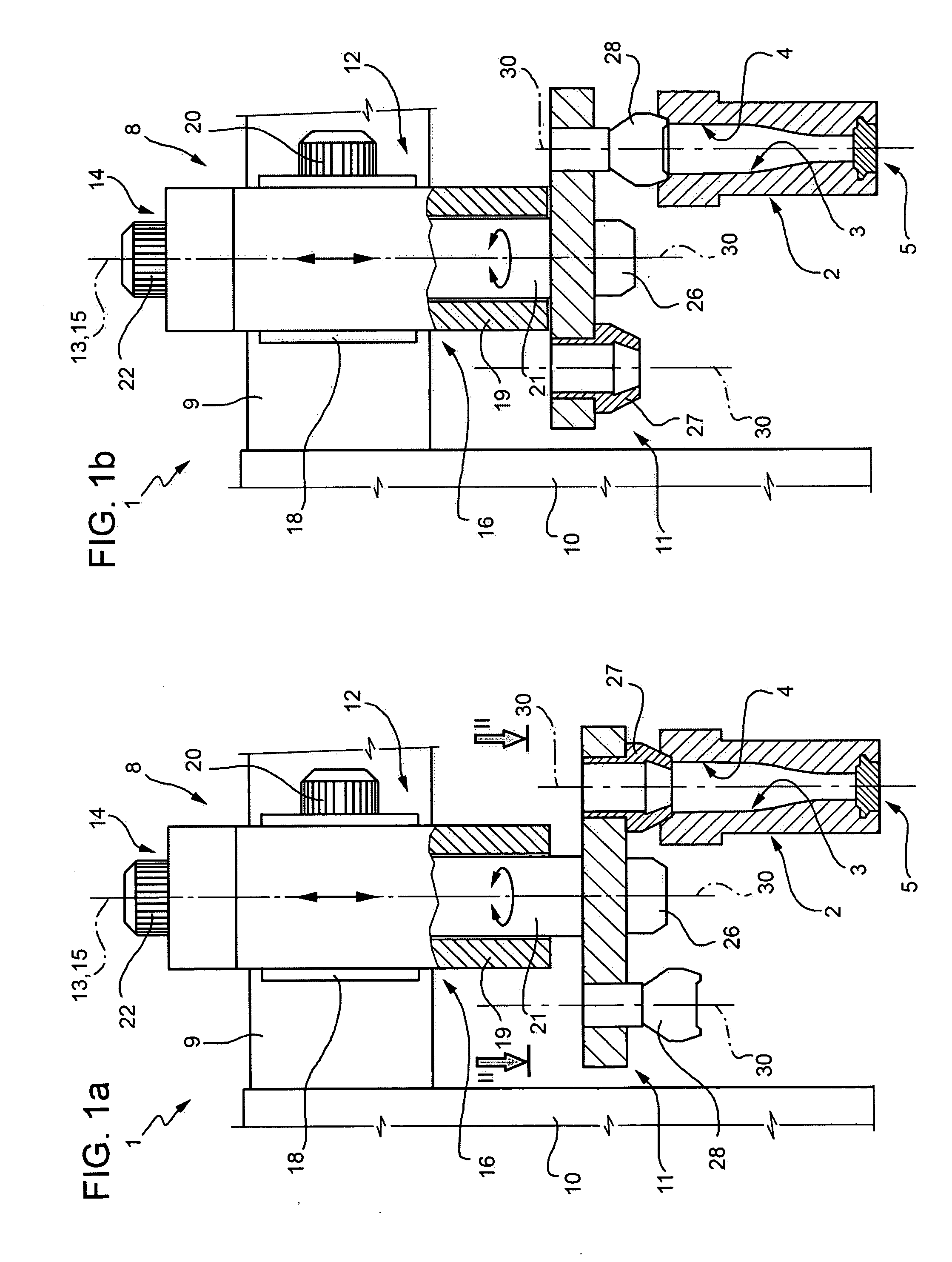

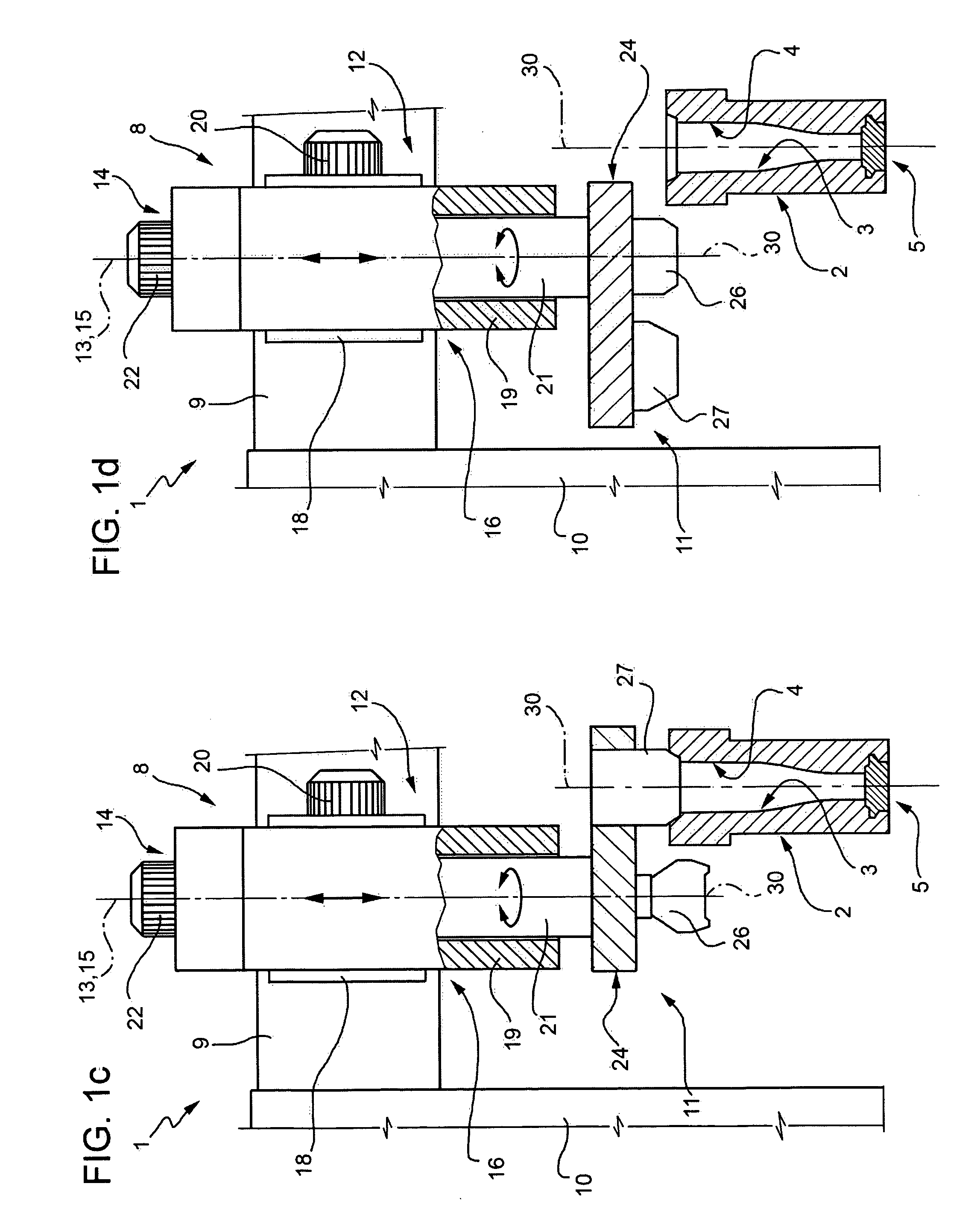

Process and equipment for the fabrication of glass containers with internally threaded neck

ActiveUS20130299444A1Easy to controlSimilar performanceBottlesGlass pressing apparatusEngineeringBottle

The present invention relates to a process and equipment for the fabrication of glass containers with internally threaded neck and such containers. The plunger (6) is from the glass leaving an imprint corresponding to the mouth (M) of a bottle, wherein the plunger has at least one helical groove (15) in its outside surface. During the extraction, the plunger is rotated around a longitudinal axis (X-X) performing a roto-translational motion to unscrew the plunger out of the partially solidified glass, leaving an internal thread in the mouth (M) of the bottle. The roto-translational motion for the extraction of the plunger is generated by: a linear actuator (30) acting on the plunger (6), thereby effecting a linear movement of the plunger (6) along said longitudinal axis (X-X), a guide body (14) wherein the plunger (6) is moved relative to the guide body (14) along said longitudinal axis (X-X), and a helical guide (16, 17) coaxial to the longitudinal axis (X-X) and being provided between said guide body (14) and said plunger (6) and transforming said linear movement effected by said linear actuator (30) on said plunger (6) into said roto-translational motion of said plunger (6).

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Vacuum system for an I.S. machine

A vacuum system is disclosed for opposed engaged pairs of blow mold halves on a section of an I.S. machine. The system includes a bottom housing which is open at the top and closed by a top plate assembly including a top plate having a vertical opening for each of the opposed pairs of blow mold halves and an annular manifold support portion below the top plate. A vacuum manifold which has a cylindrical inlet conduit and a vertical outlet conduit beneath each of the top plate vertical openings is supported by the annular mold support portion. A vacuum tube slides into the cylindrical inlet conduit and is mounted on the annular manifold portion. The vacuum tube has a hole for communicating with each of the vacuum manifold vertical outlets.

Owner:EMHART GLASS SA

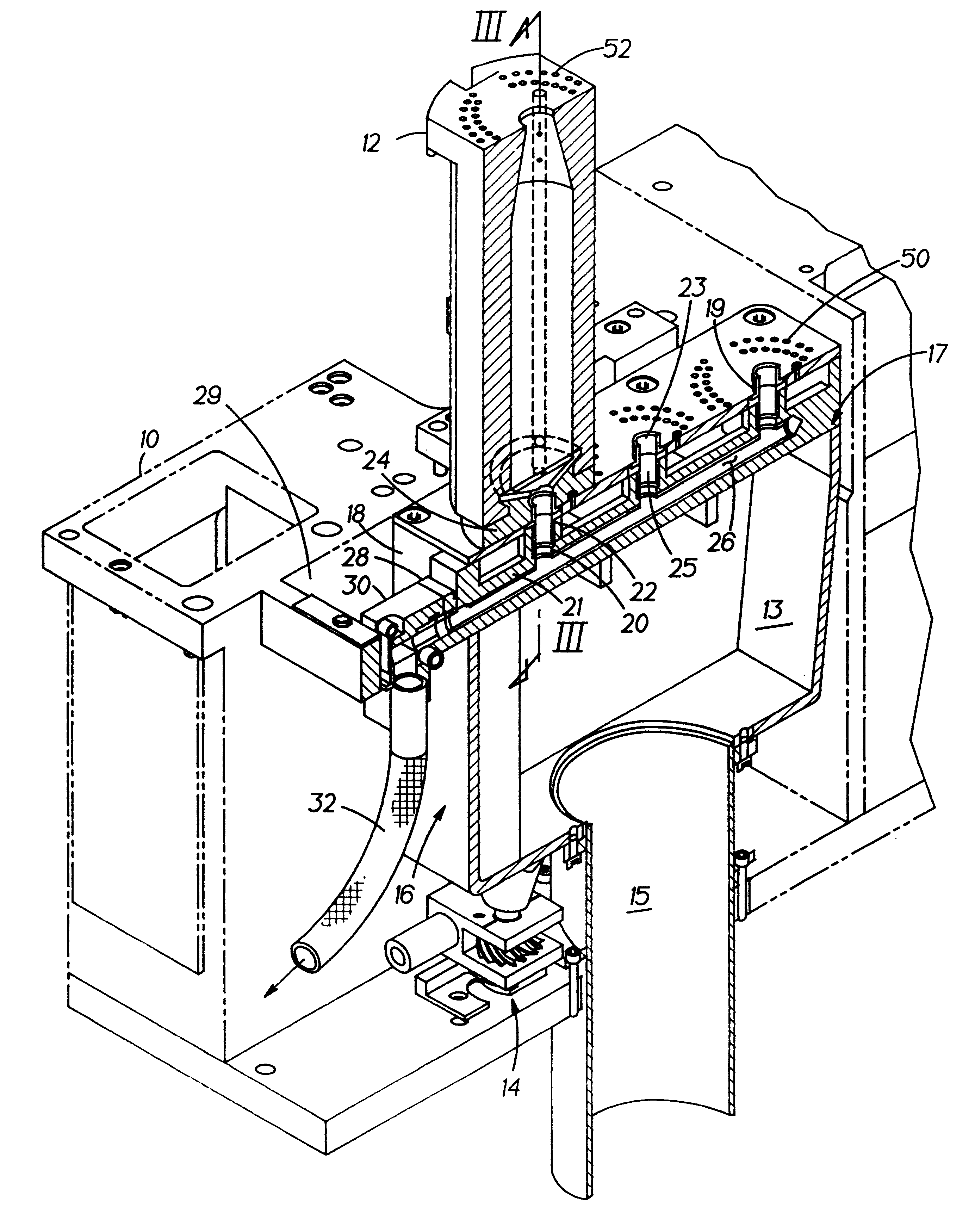

Multifunctional group for a glass items forming machine

ActiveUS20100018254A1Low costGlass pressing apparatusPress and blow machinesMolding machineFunnel shape

A rough mold of a machine for forming glass items is provided with a multifunctional group, which has a common support head; a handling device for moving the common head along a first handling axis; and a further handling device for rotating the common head about a second handling axis. The common head being fitted with a mold closing member for sealing the top opening of the rough mold, and at least one further operating member selectable from a funnel-shaped member for guiding at least one glass gob into the rough mold, a blowing member for blowing pressurized air into the rough mold, and one or more members for treating the inner surface of the rough mold.

Owner:BOTTERO SPA

Dispenser for gobs of molten glass for for hollow-glass forming machines

A dispenser of gobs of molten glass for a hollow-glass forming machine includes a supporting frame and a plurality of distributor scoops carried by the supporting frame and mounted oscillating about corresponding axes of rotation. Each distributor scoop is configured for conveying a gob of molten glass to corresponding parison moulds of a hollow-glass forming machine. The dispenser includes a plurality of motors configured for operating the plurality of distributor scoops about the corresponding axes of rotation. In addition, each motor of the plurality is operatively connected for operation to at least one scoop of the plurality of distributor scoops.

Owner:BDF IND

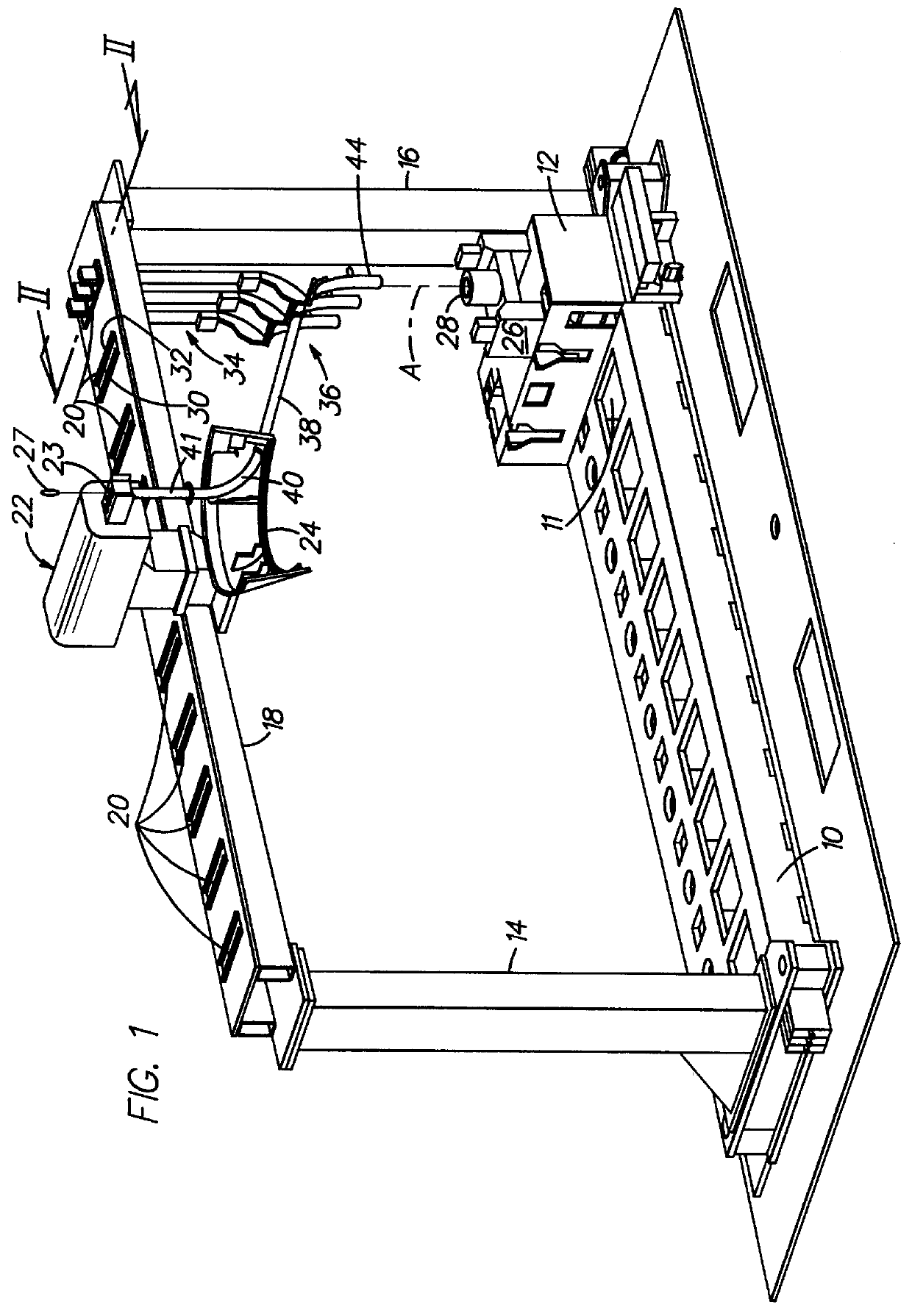

I.S. machine

InactiveUS6032492AProcess economyCheap constructionConfectioneryGlass pressing apparatusMolding machineEngineering

An I.S. glass forming machine is disclosed which has a plurality of individual sections each having a parison mold including a cavity having a first vertical axis. There is a trough assembly for each of the mold cavities which includes a deflector defining a second vertical axis. A horizontal beam supported by vertical uprights extends over the individual sections. The horizontal beam has a plurality of vertical openings corresponding to the number of individual sections of the machine which are in substantial alignment with the vertical axis of corresponding parison mold cavities. A corresponding plurality of hangers each defining a third vertical axis. The hangers are secured within the vertical openings with the third vertical axis coincident with the first vertical axis of a corresponding parison mold cavity and the trough assemblies are supported on a corresponding hanger with the third vertical axis of the hanger coincident with the second vertical axis of the supported deflector.

Owner:EMHART GLASS SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com