Mould for making glass container

A glass container and mold technology, applied in the field of molds for making glass containers, can solve the problems of inconsistency, uneven distribution of material and liquid, and inability to guarantee the overall quality of the bottle, and achieve the effect of ensuring consistent wall thickness and uniform distribution of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

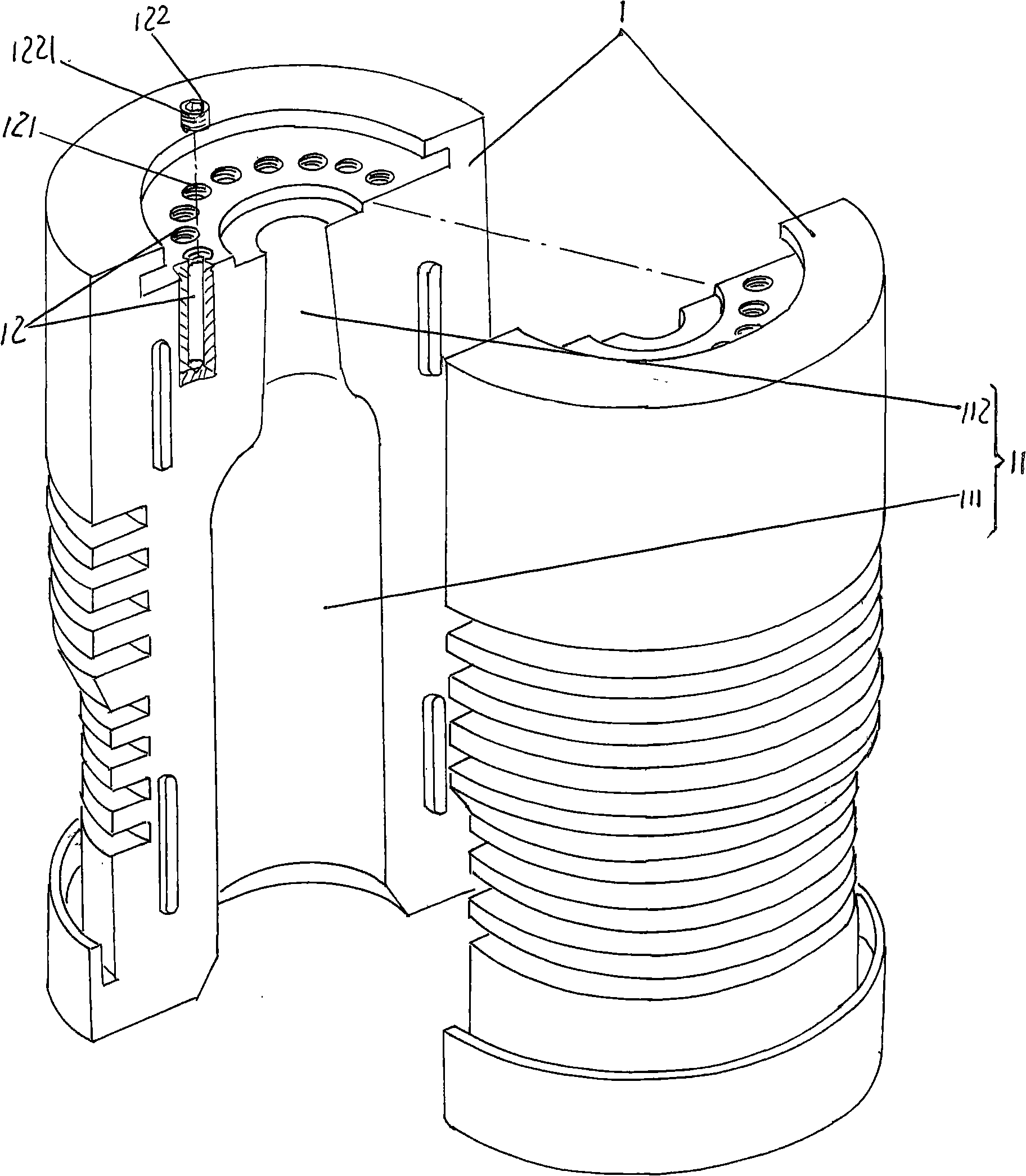

[0016] Please refer to the attached drawing, which shows a pair of bottle half-molds 1 opposite to each other with the same shape and structure for making beer bottles, and a bottle mold for forming beer bottles is processed at the center of the inner wall of each bottle half-mold 1 Cavity 11, the bottle mold cavity 11 includes a lower bottle body cavity 111 and an upper bottle neck cavity 112, wherein the height of the bottle neck cavity 112 is 60 mm. On the top of a pair of bottle half-moulds 1 and around the bottle neck cavity 112, a group of heat preservation holes 12 with a diameter of 4 mm and a depth of 60 mm are provided at a distance of 10 mm, and each heat preservation hole 12 is equipped with a hole cover 122. In addition, internal threads 121 are processed at the openings of each heat preservation hole 12, and external threads 1221 are processed on the hole cover 122. Through the cooperation of internal and external threads 121, 1221, the hole cover 122 can be relia...

Embodiment 2

[0019] Figure slightly, only change the spacing between the insulation holes 12 to 12mm, the diameter to 5mm and the depth to 50mm, the height of the bottle neck cavity 112 of the bottle mold cavity 11 to 50mm, and the tenon protrusion 13 to a cylinder or a cylinder. Cylindrical pin, mortise cavity is changed into circular hole, all the other are all the same as the description to embodiment 1.

Embodiment 3

[0021] The figure is omitted, only the spacing between the insulation holes 12 is changed to 13.5mm, the diameter is changed to 5.8mm and the depth is changed to 55mm, the height of the bottleneck cavity 112 of the bottle mold cavity 11 is changed to 55mm, and all the others are the same as those of embodiment 1 describe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com