Patents

Literature

240 results about "Shape formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

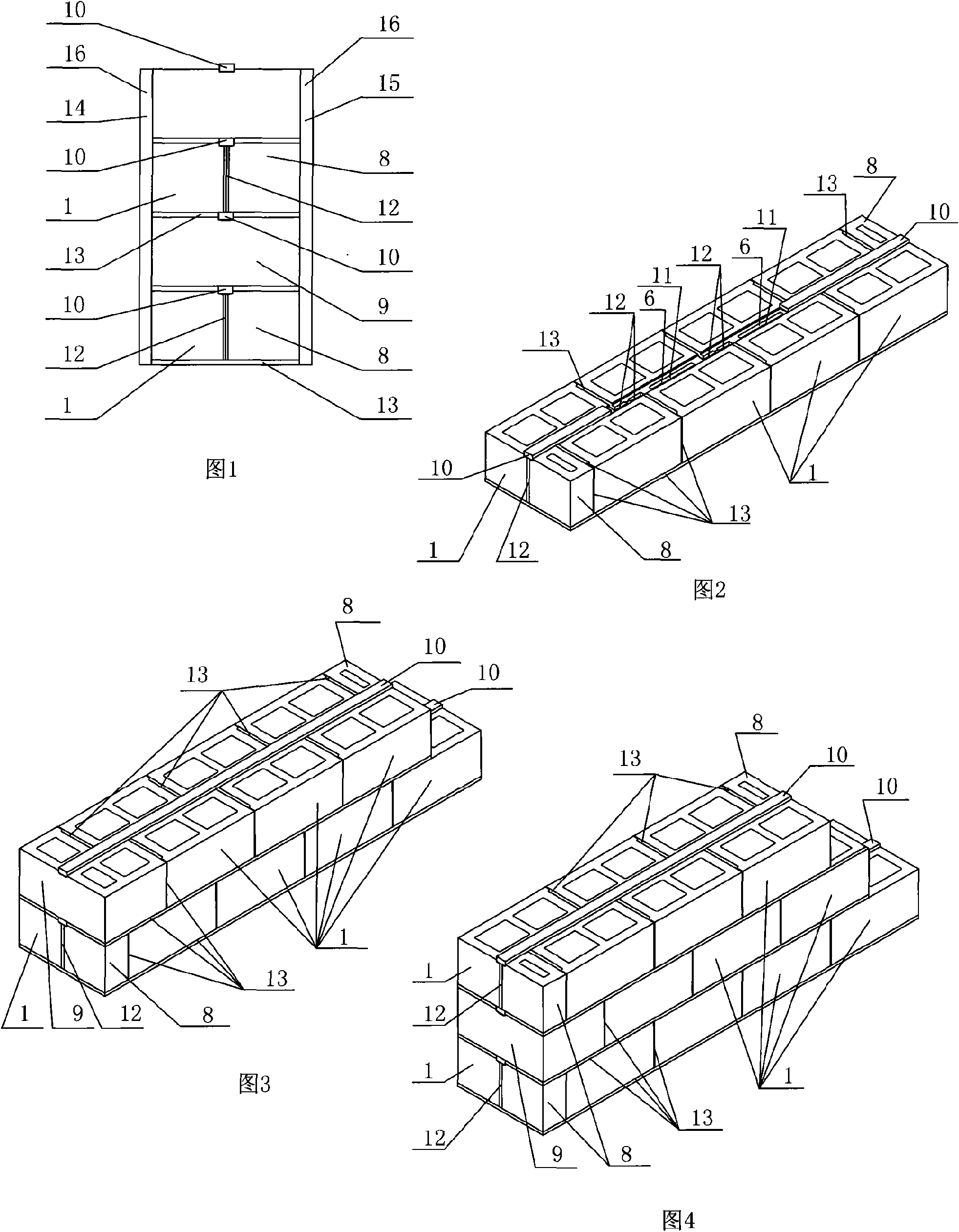

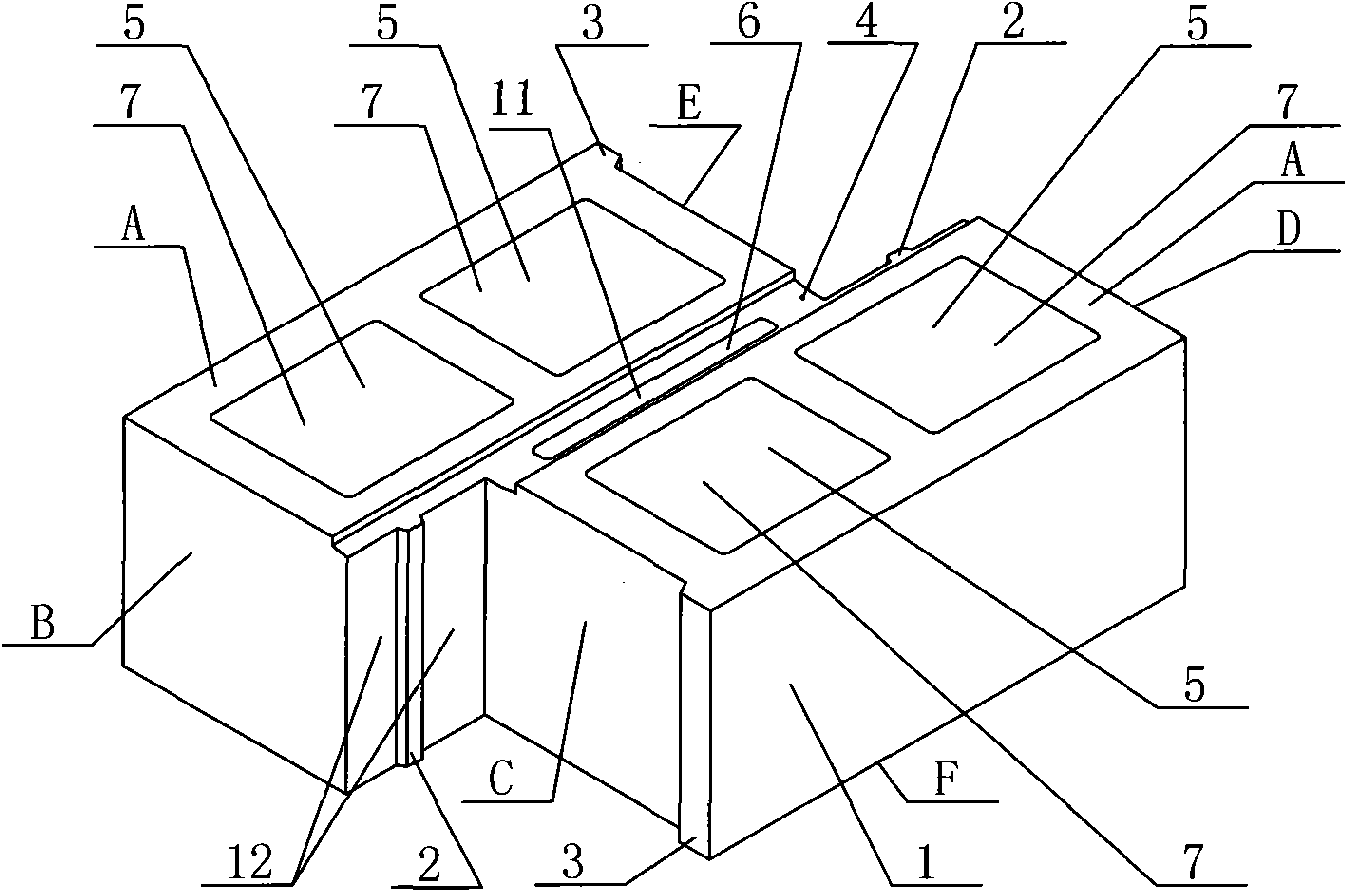

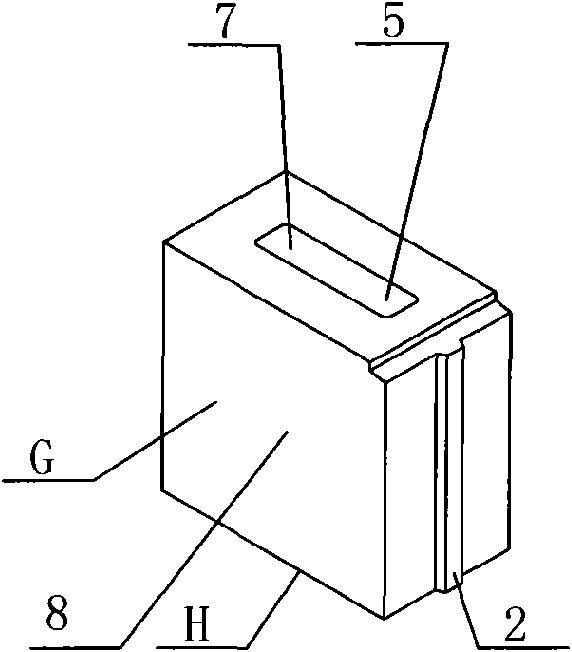

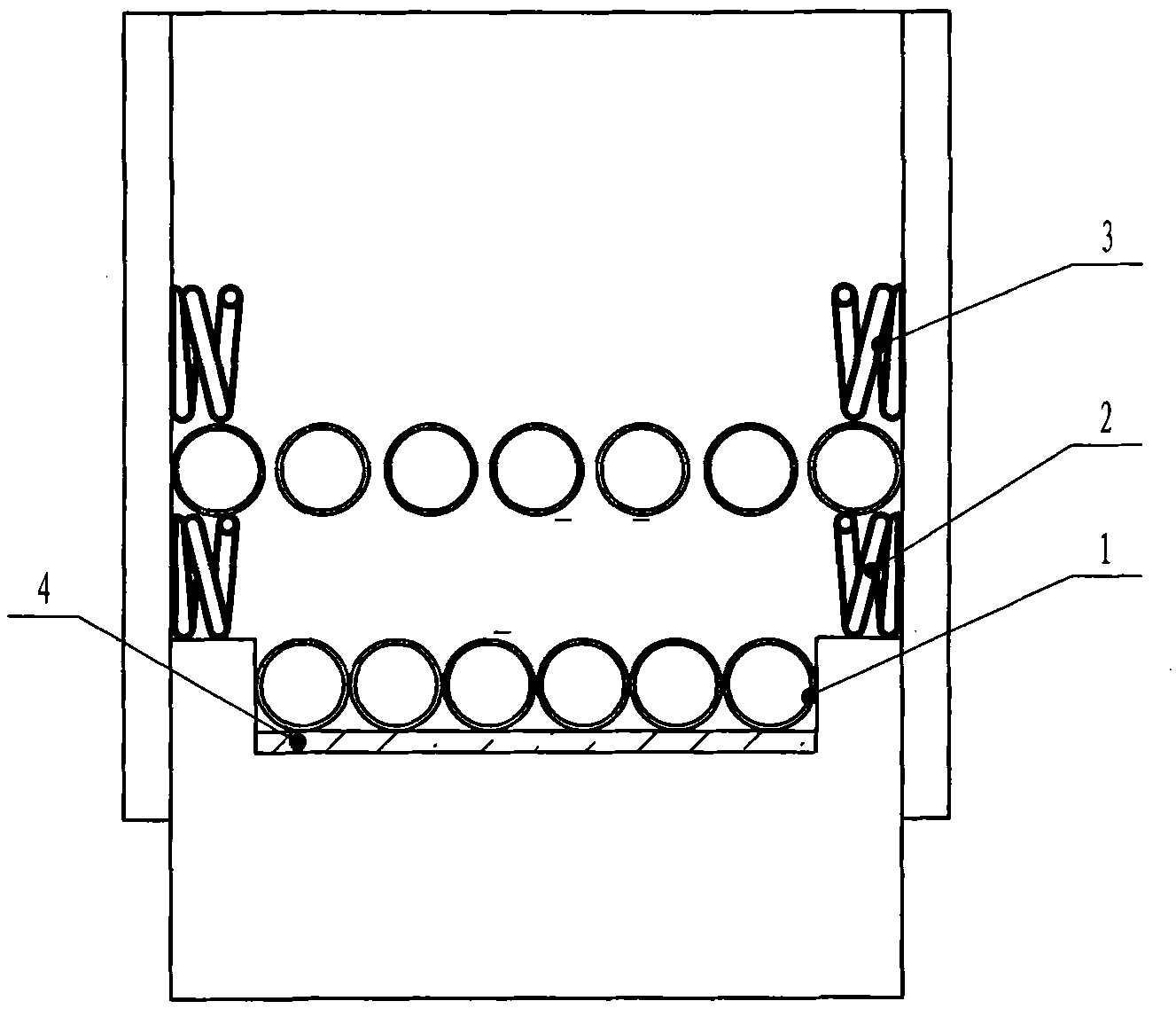

Technical method for building self-insulating and energy-saving wall with Z-shaped energy-saving building blocks

In the invention, the same clad bricks are laid in the forward direction, and a positioning convex platform 2 and a longitudinal positioning convex platform 3 are used for realizing transverse and longitudinal self-locking positioning, thereby naturally ensuring the designed thickness and surface smoothness of the wall, forming a combined still air layer 12 which is 9mm to 10mm wide and vertical to the ground, and further blocking heat bridges in vertical bricklaying seams. The cavity of a 28-30mm-wide groove 4 in the horizontal bricklaying seam between two clad bricks is filled with a broken bridge insulation board 10 which is as wide as the groove and has a thickness of 15mm; the broken bridge insulation board 10 is used for sealing a long-strip groove still air layer 11 and the combined still air layer 12 and cutting off the heat bridges in the horizontal bricklaying seams; the exposed part of broken bridge insulation board with a height of 10mm, is used for controlling the coating thickness of anti-crack masonry mortar 13 to be even and uniform. When the self-insulating and energy-saving wall is built, Z-shaped energy-saving building blocks 1 of the upper clad bricks and the lower bricks are laid in a staggered manner so as to cut off heat bridges in vertical bricklaying seams. The structure of the invention, with a reasonable thickness, can satisfy the requirement of saving 50 percent of energy in various regions, or even higher requiremets without an internal or external insulating layer of walls. Simultaneously, the structure is easy to build and the formation of the block shape effectively ensures the thickness of walls and the smoothness of wall surfaces. The thermal insulation function of the still air layer with a thickness of 10mm to 12mm strengthens the heat insulation effect. The insulation boards (28-30mm wide and 15mm thick) between the two clad bricks is capable of cutting off the heat bridge effects.

Owner:康玉范

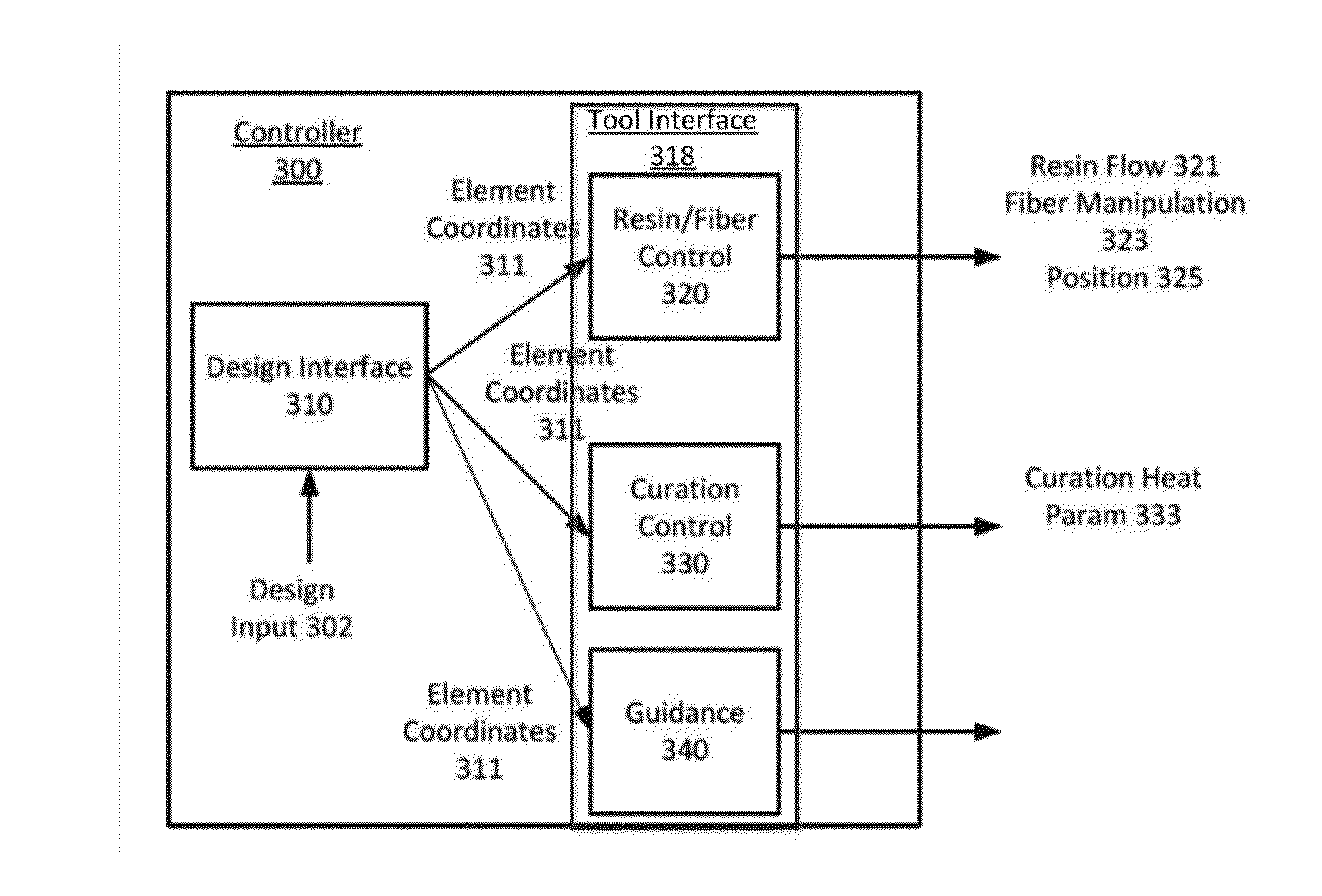

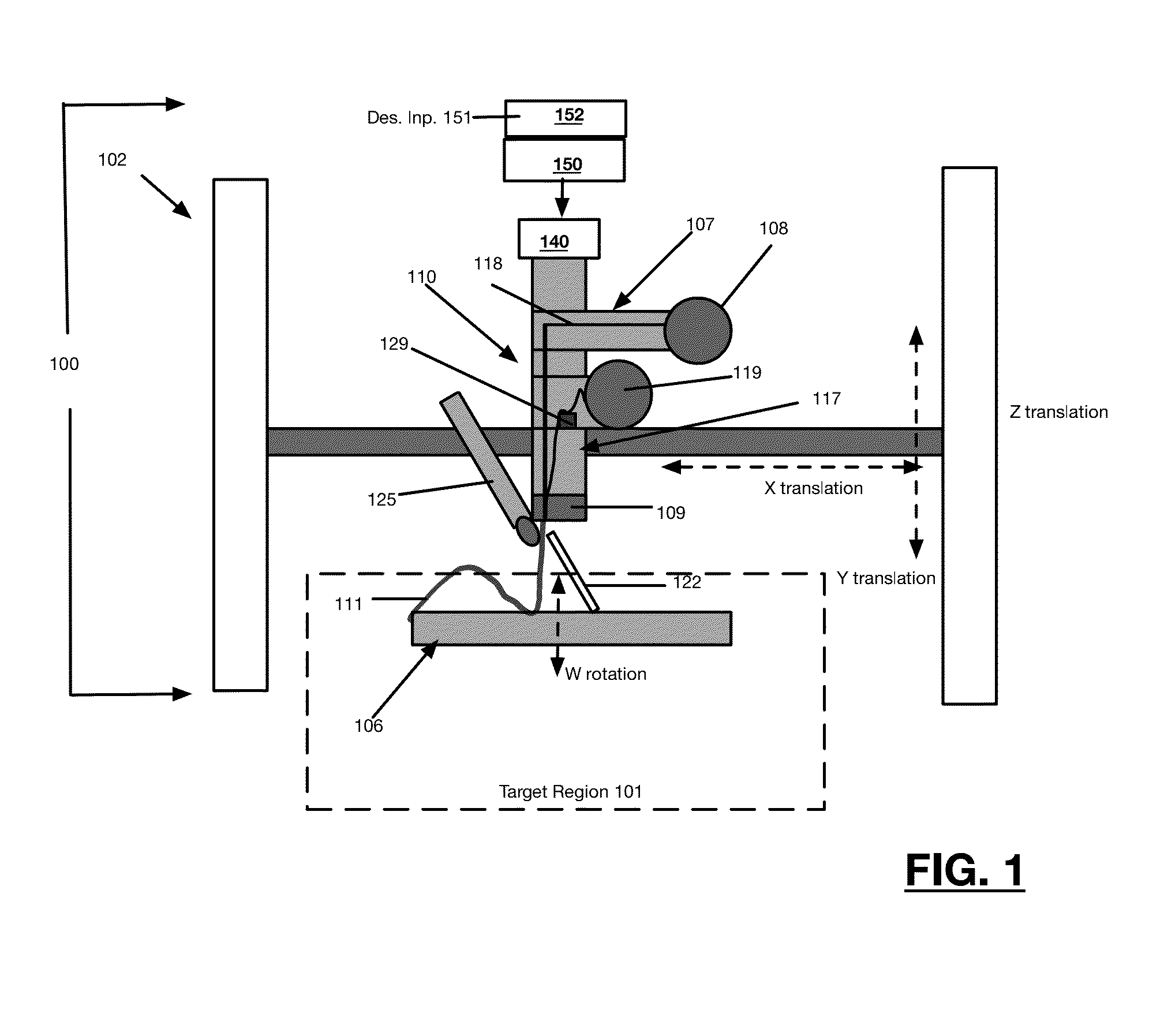

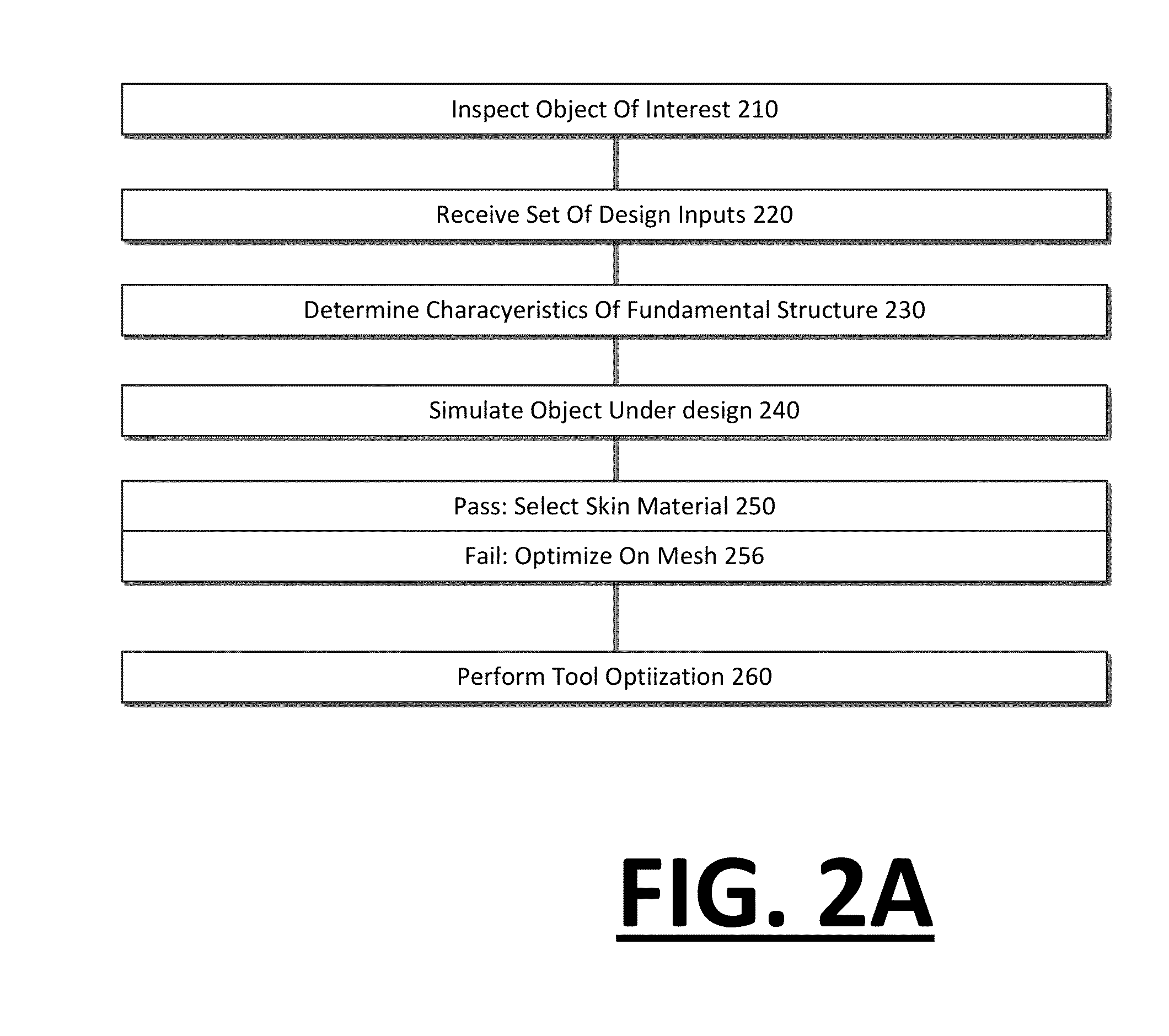

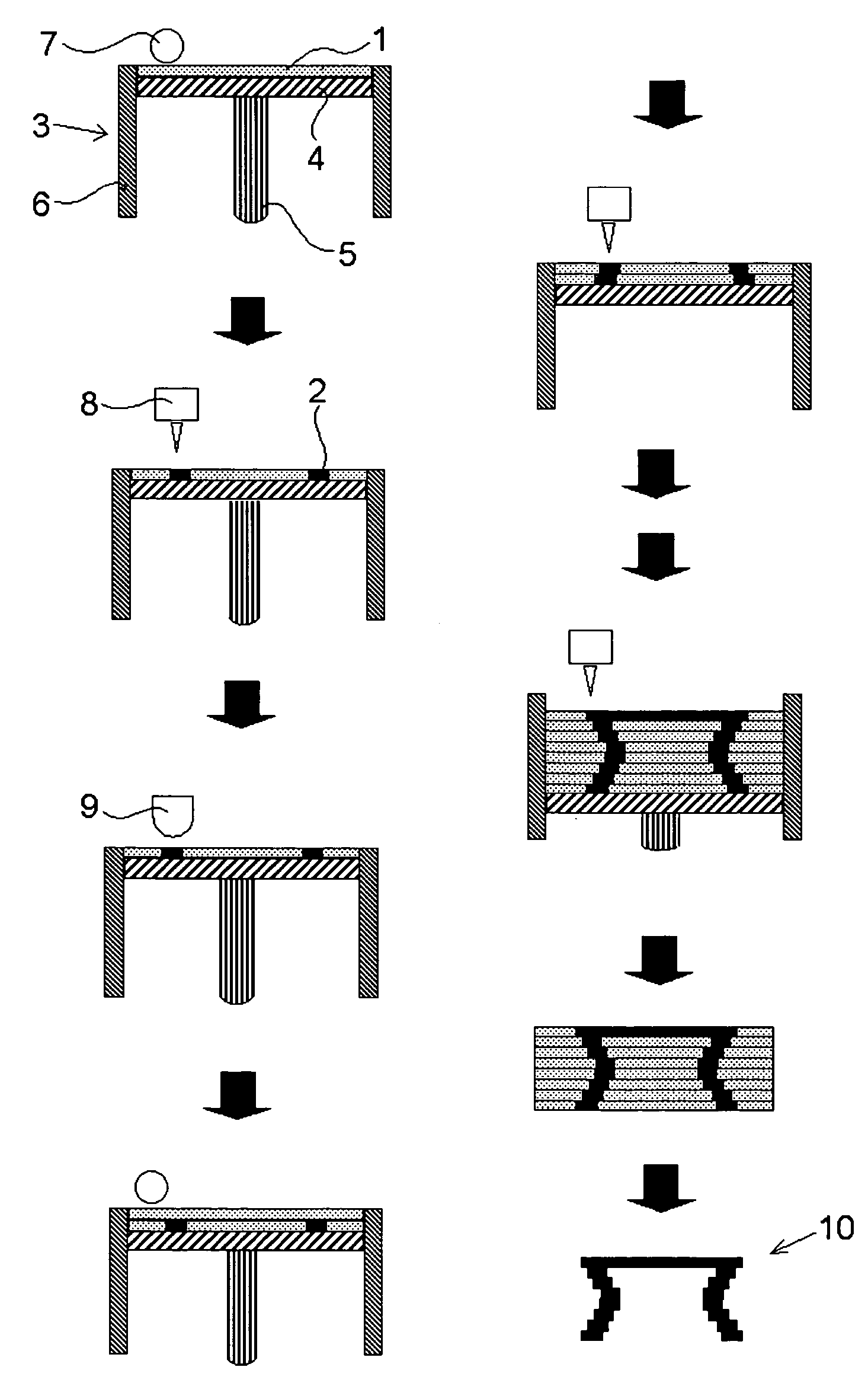

Automated design, simulation, and shape forming process for creating structural elements and designed objects

InactiveUS20160243762A1Additive manufacturing with liquidsPrinted circuit manufactureEngineeringStructuring element

A three-dimensional printer, system and method is provided for individually creating three-dimensional structural elements (individually termed fundamental structures) which are sequentially positioned into formation of a shaped object.

Owner:FLEMING ROBERT J

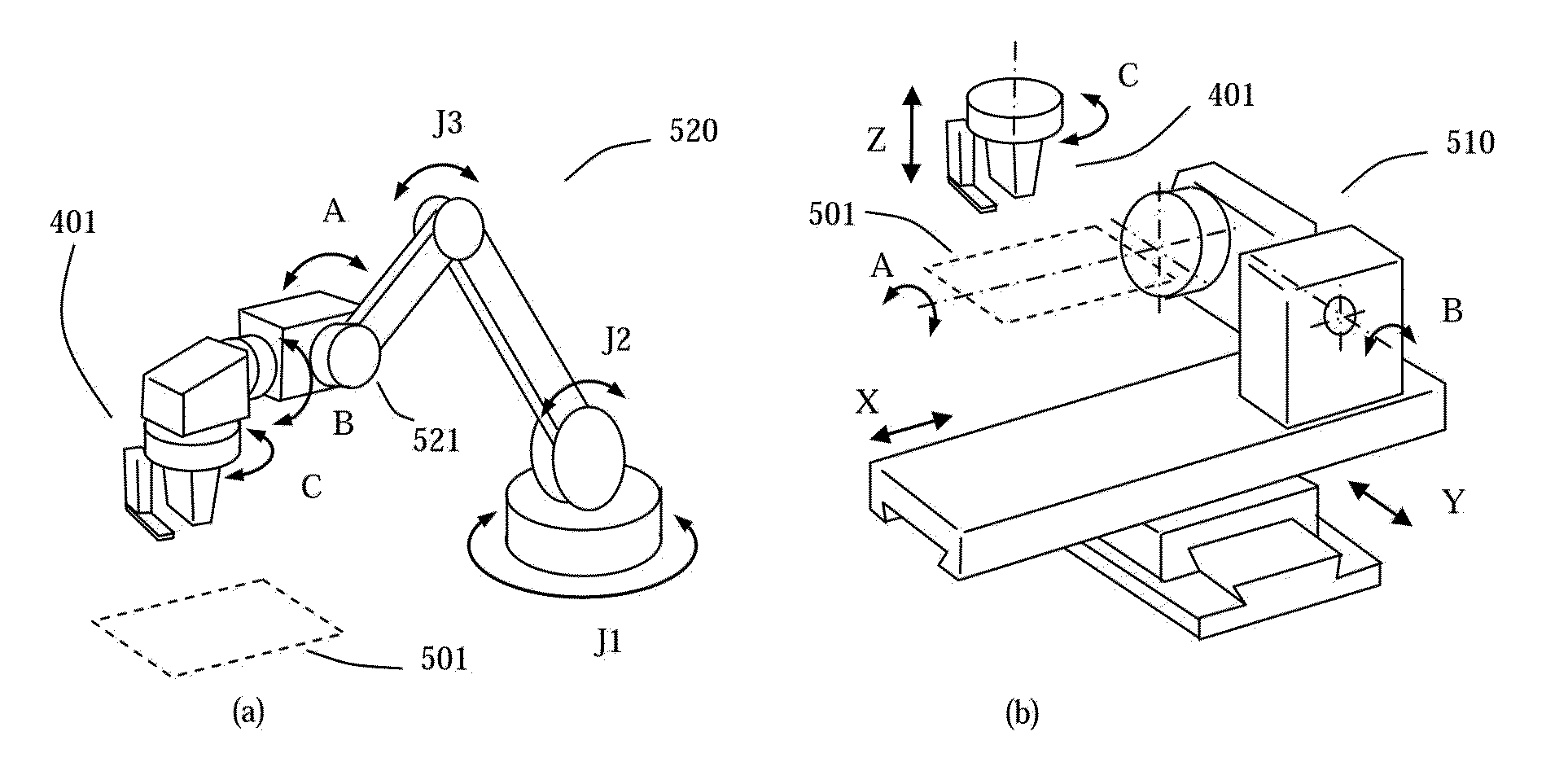

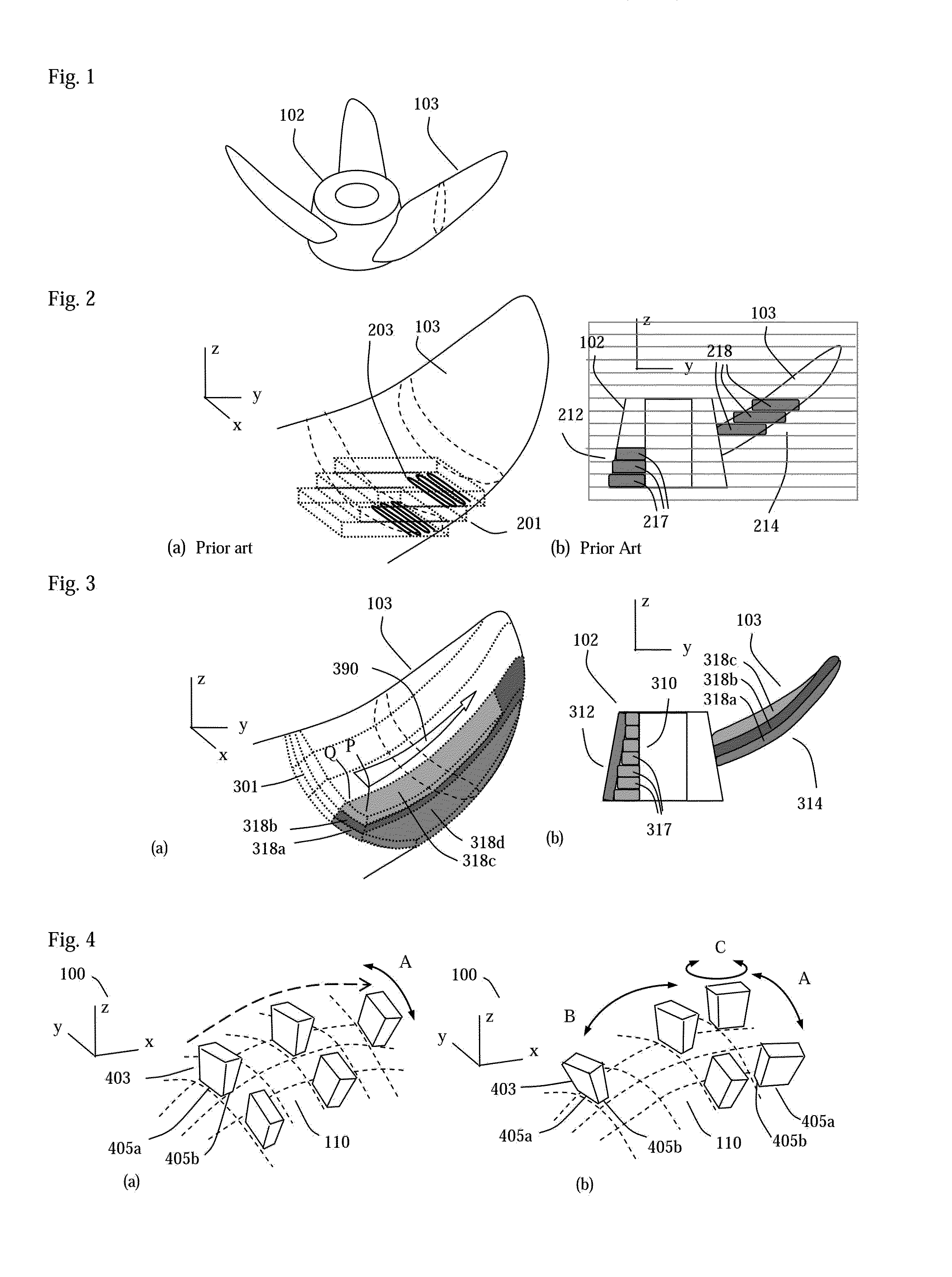

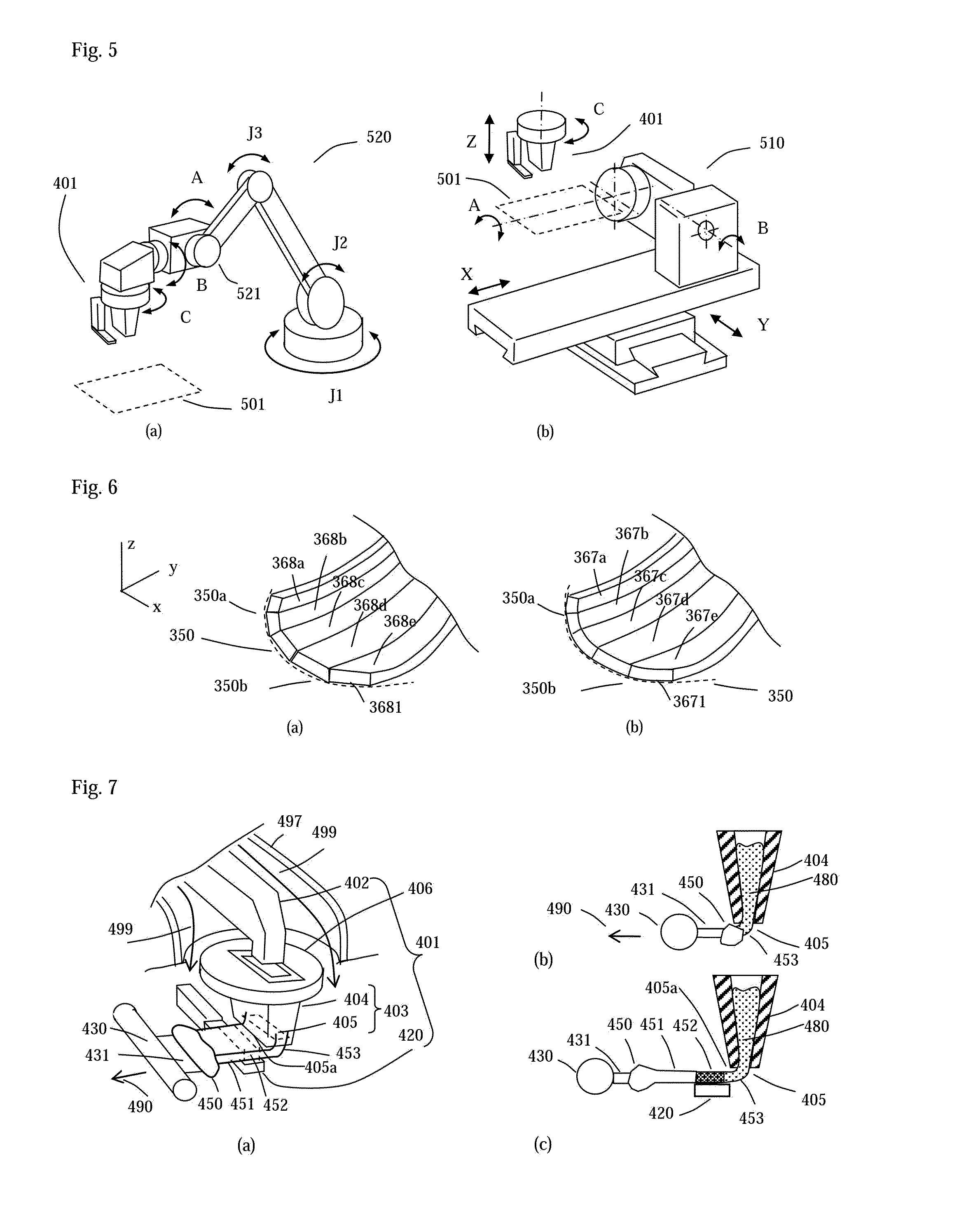

Flexible 3D Freeform Techniques

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

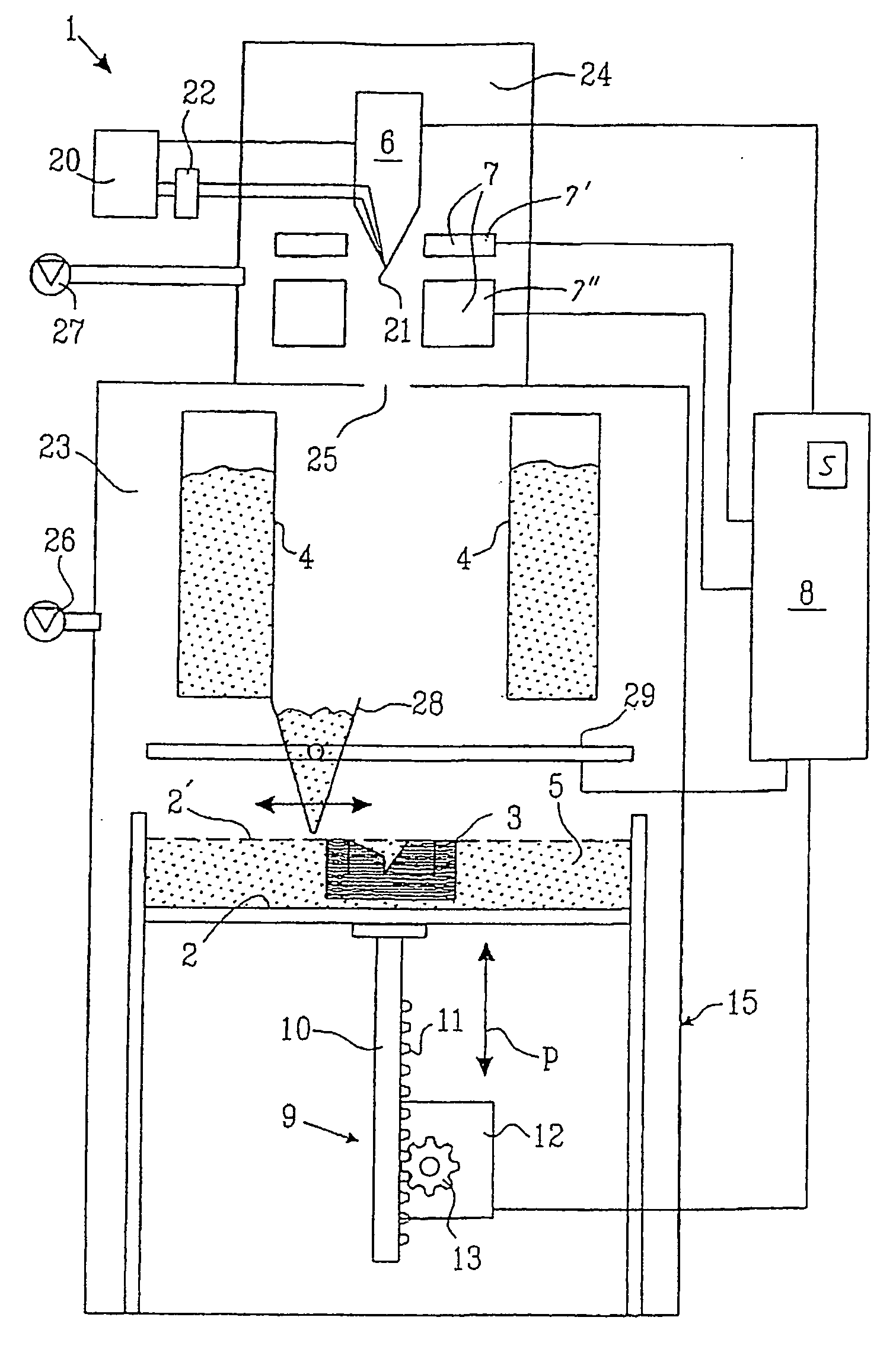

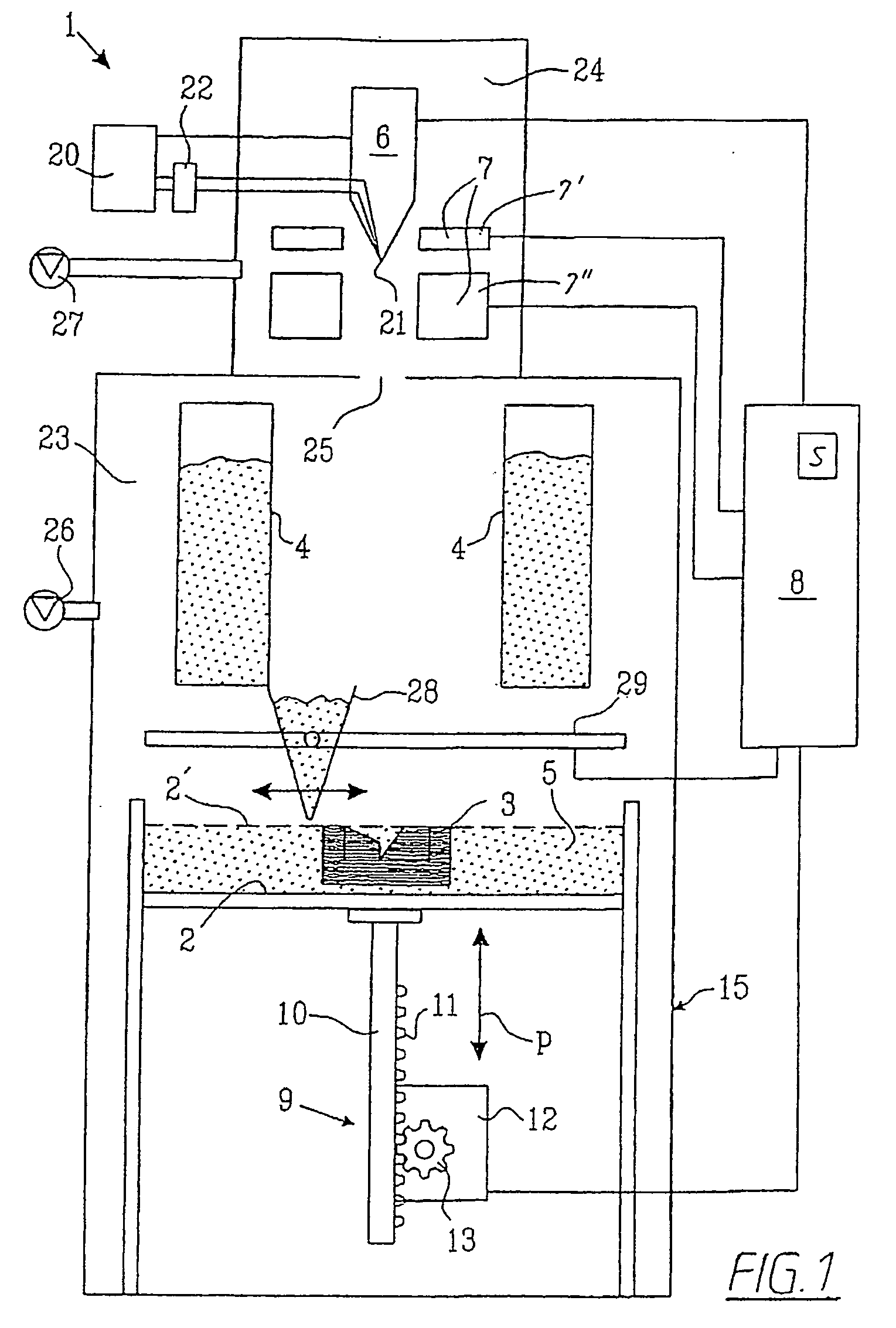

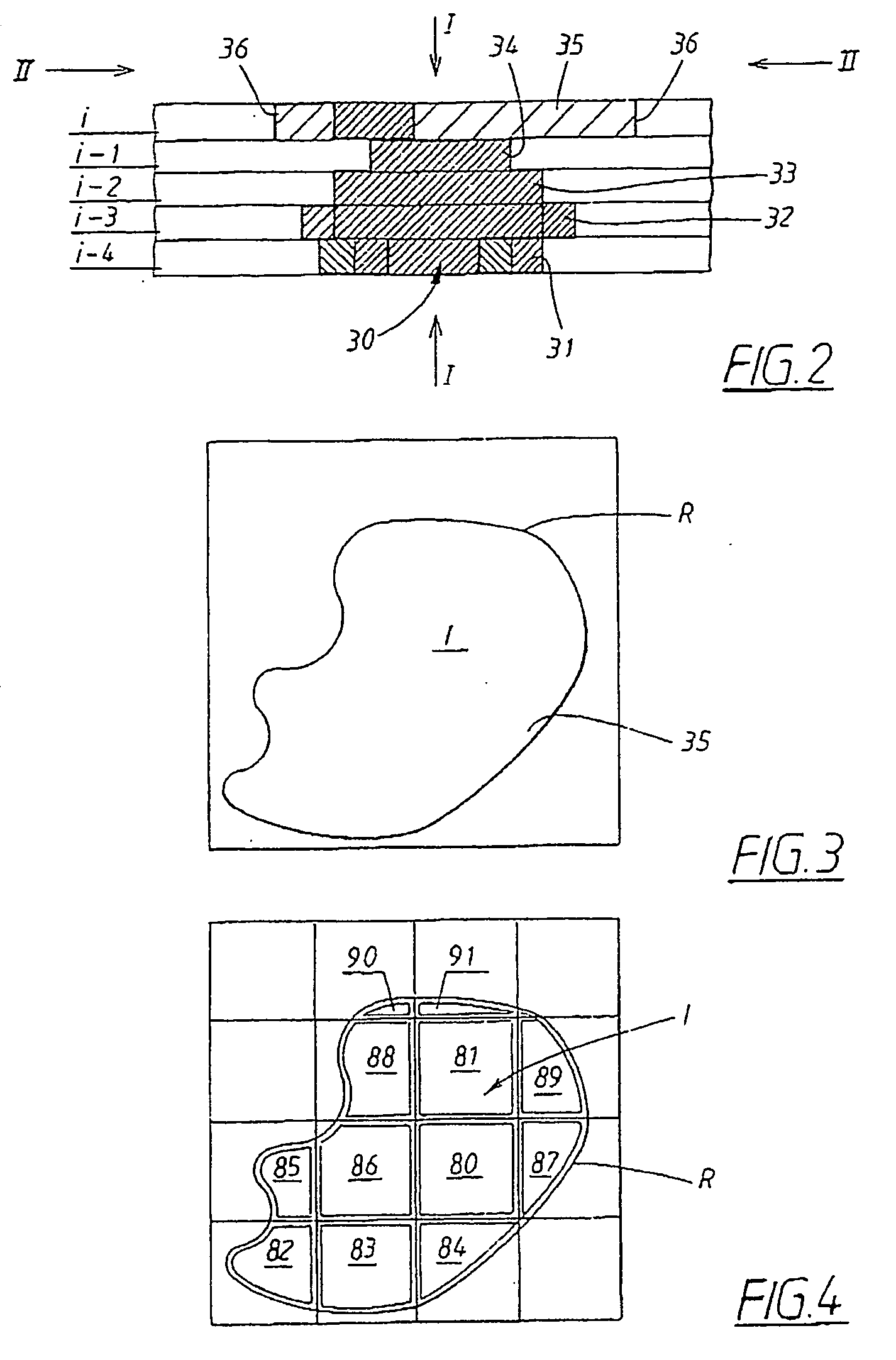

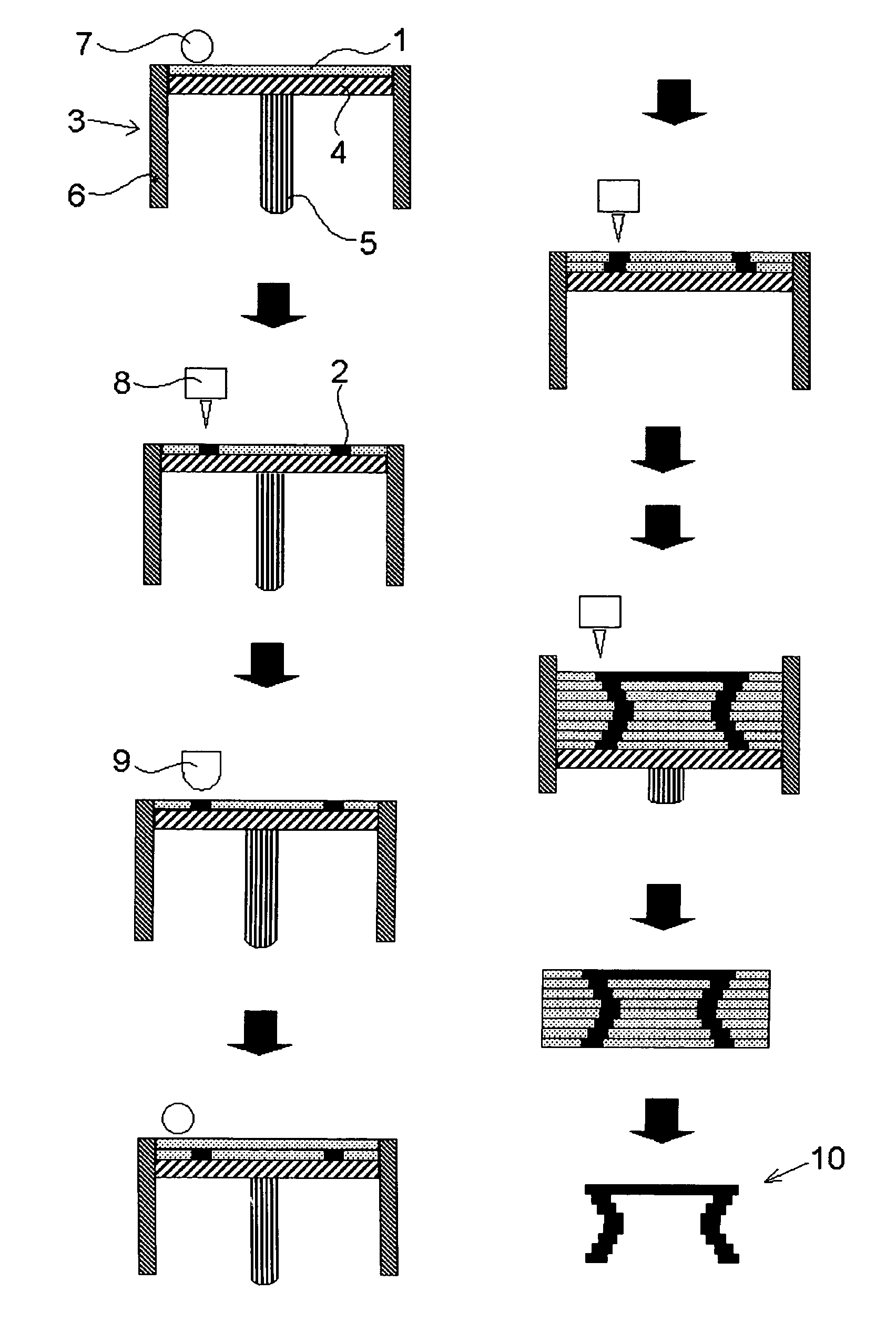

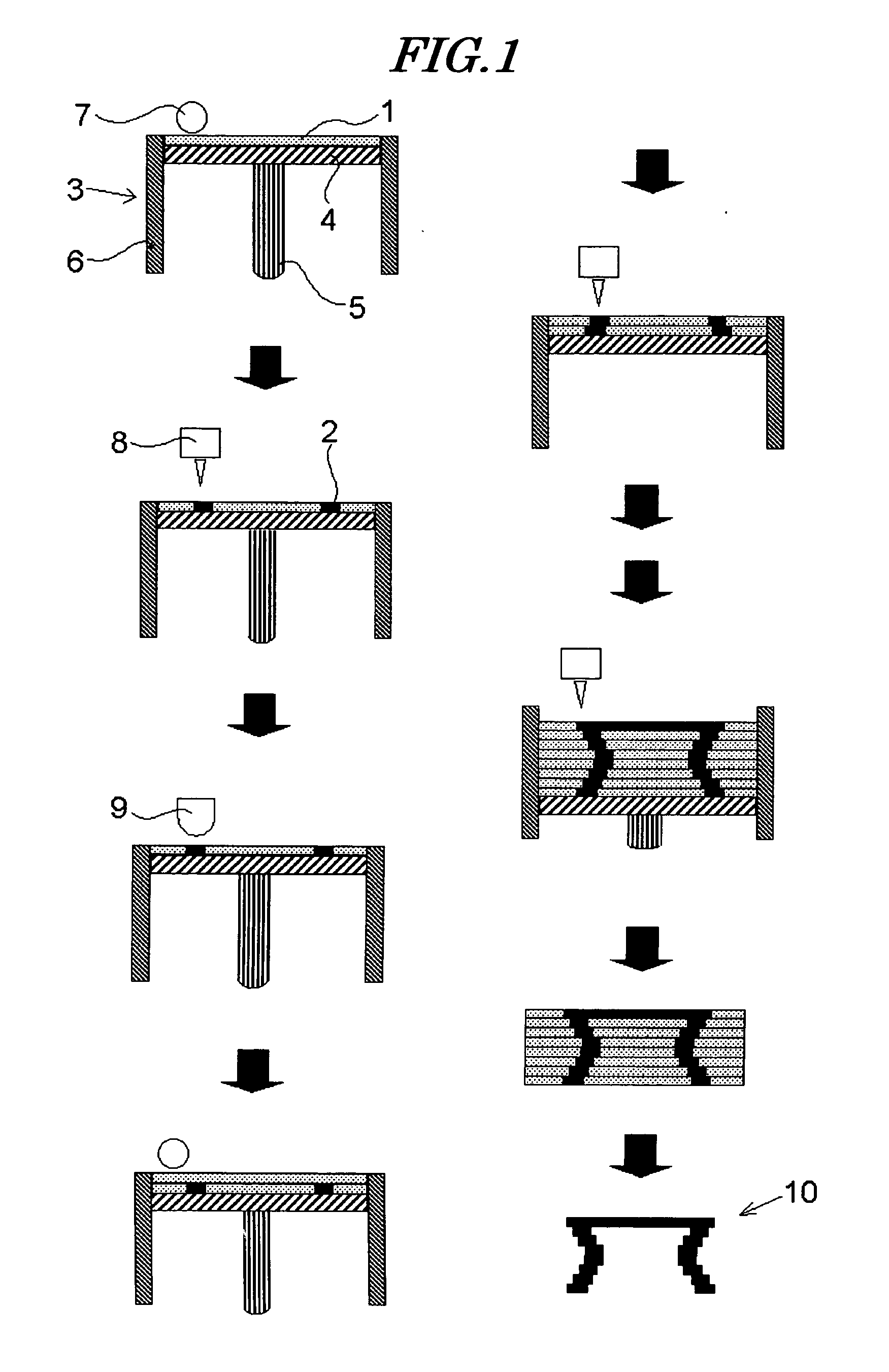

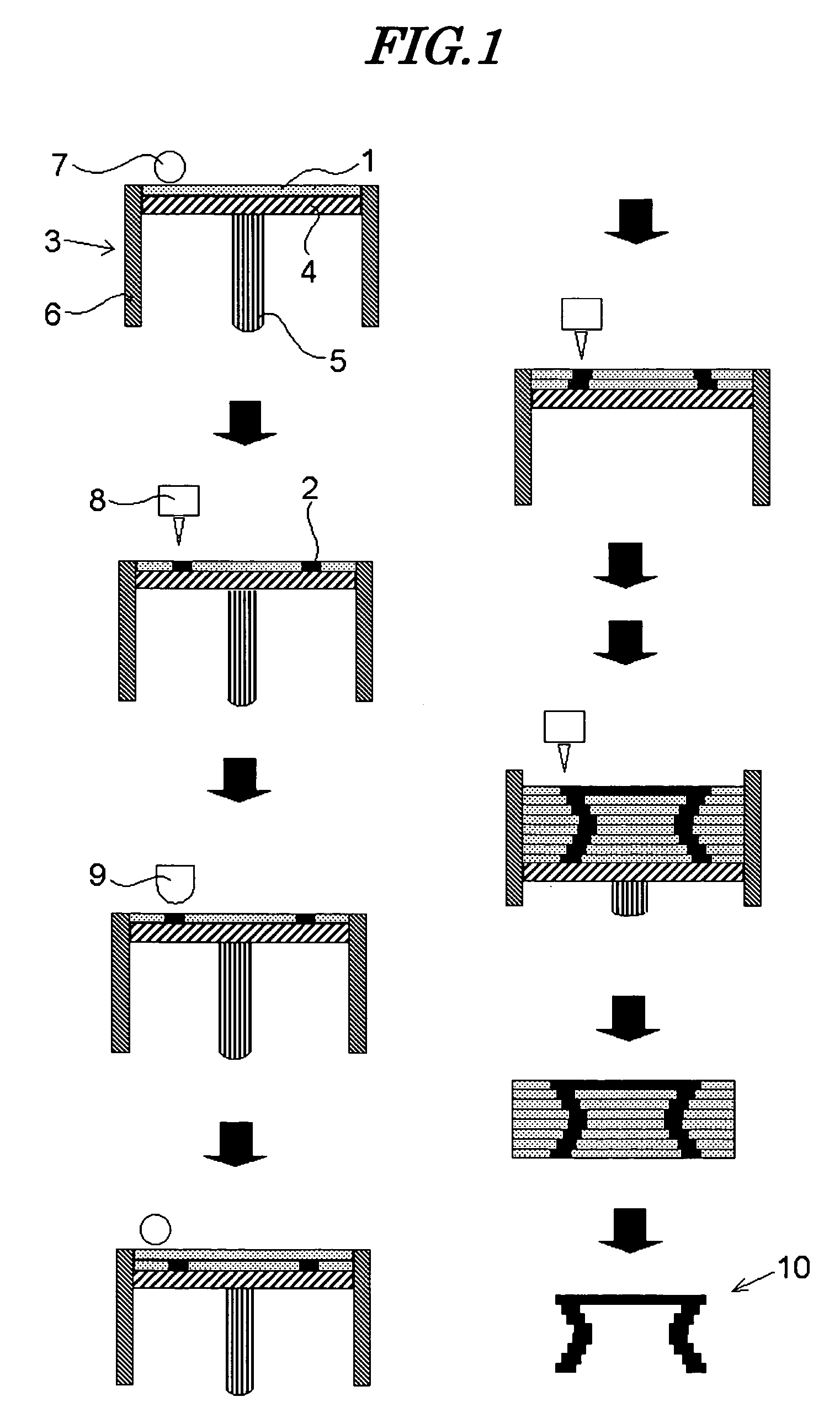

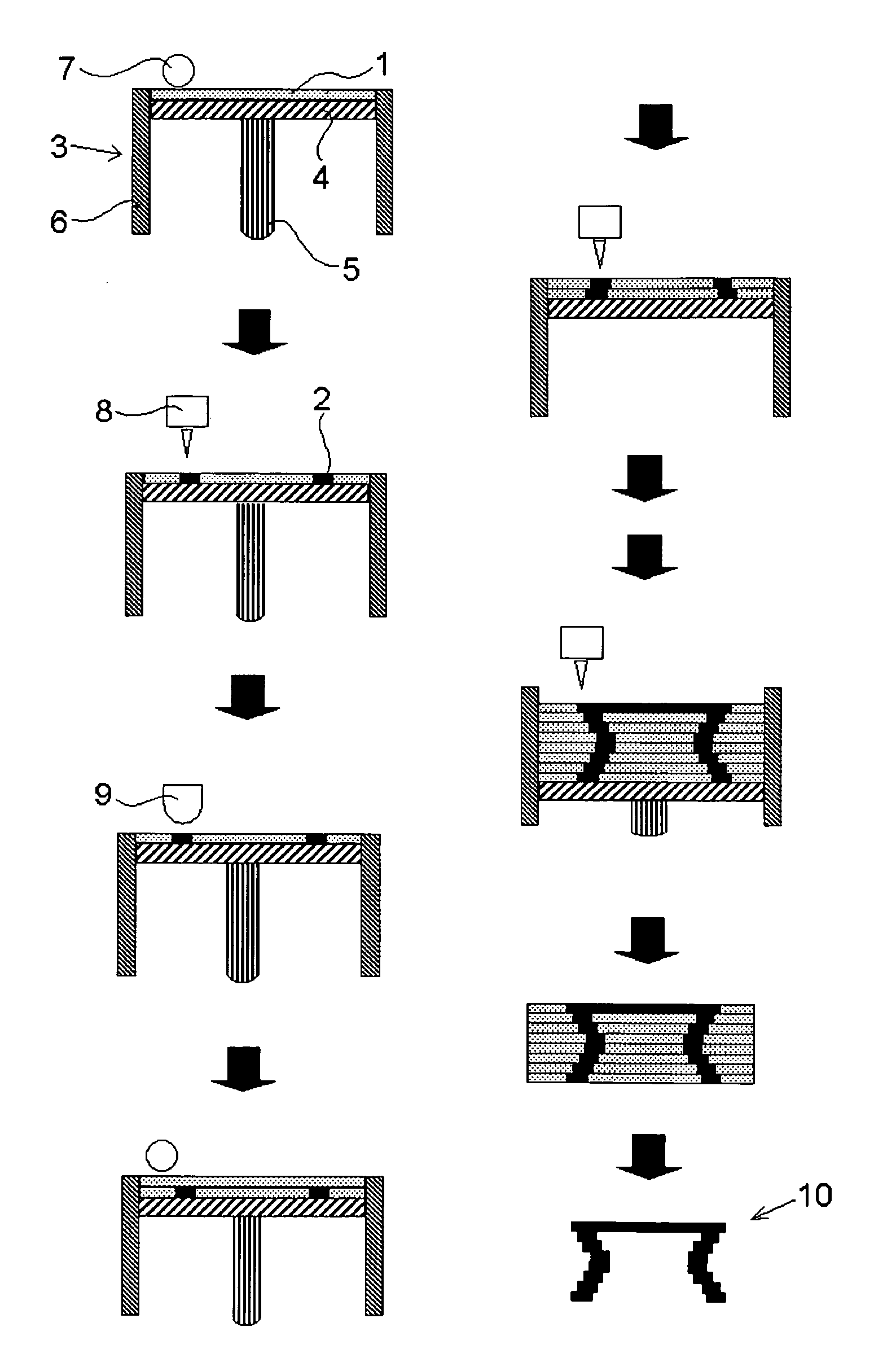

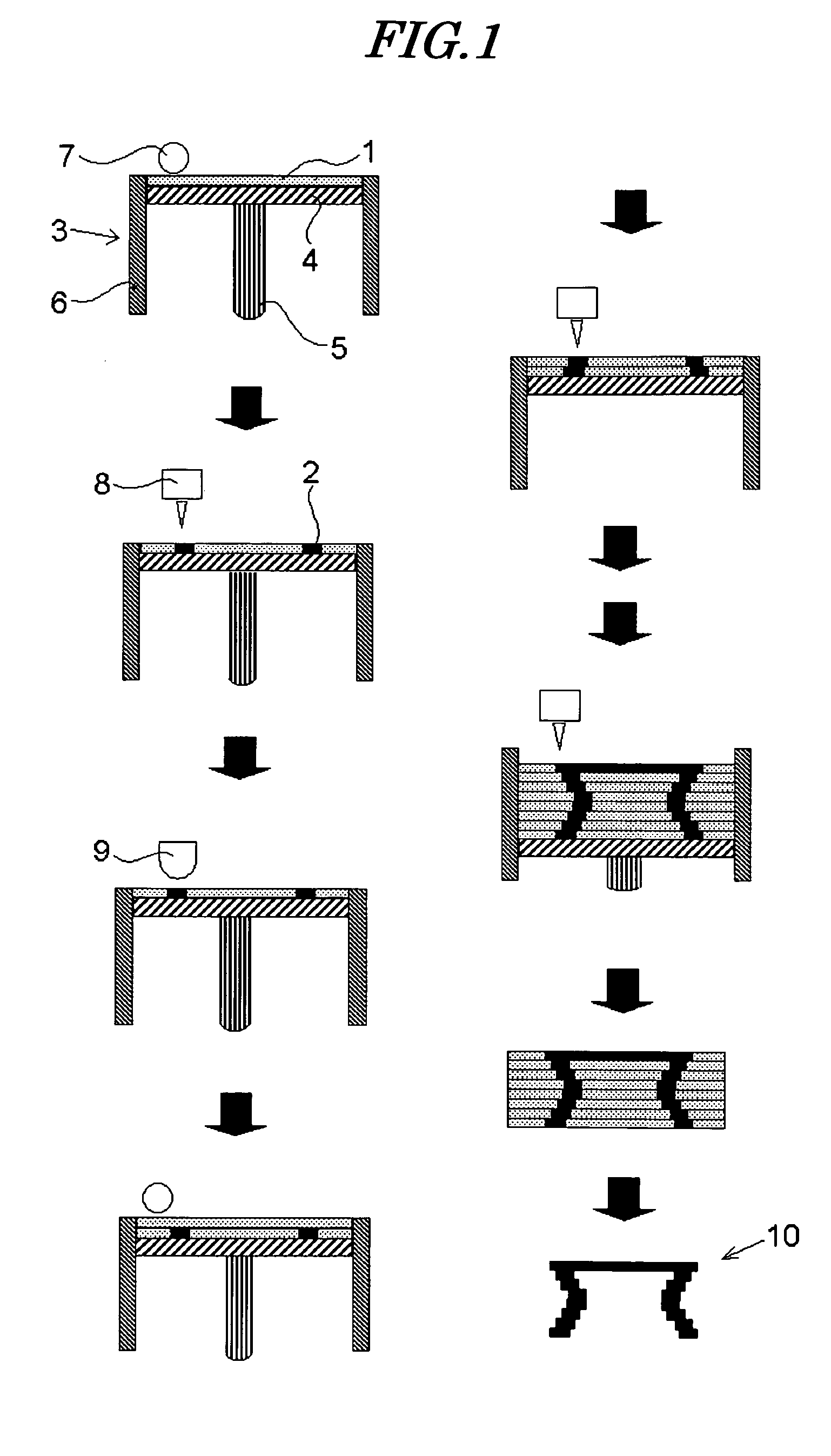

Arrangement and method for producing a three-dimensional product

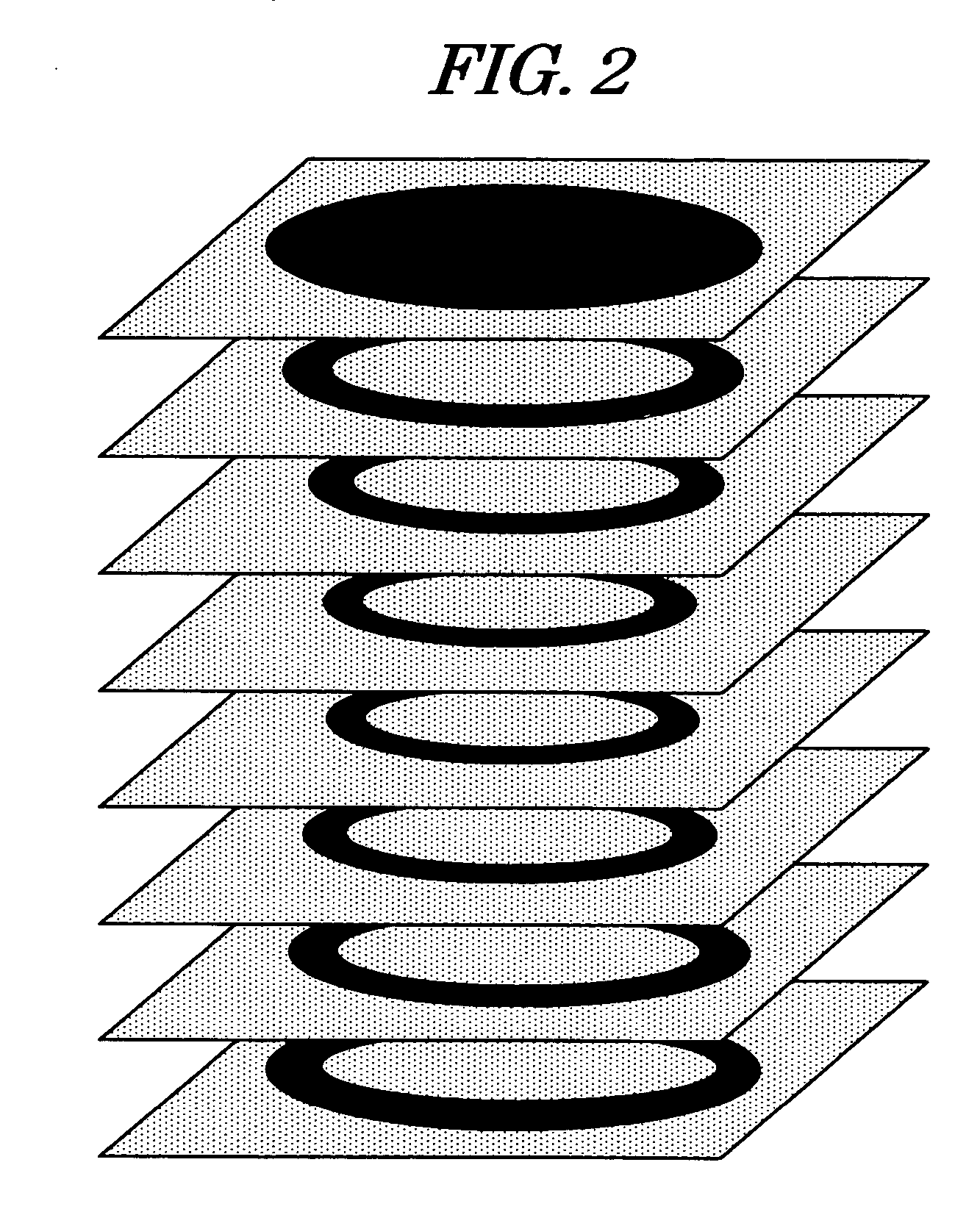

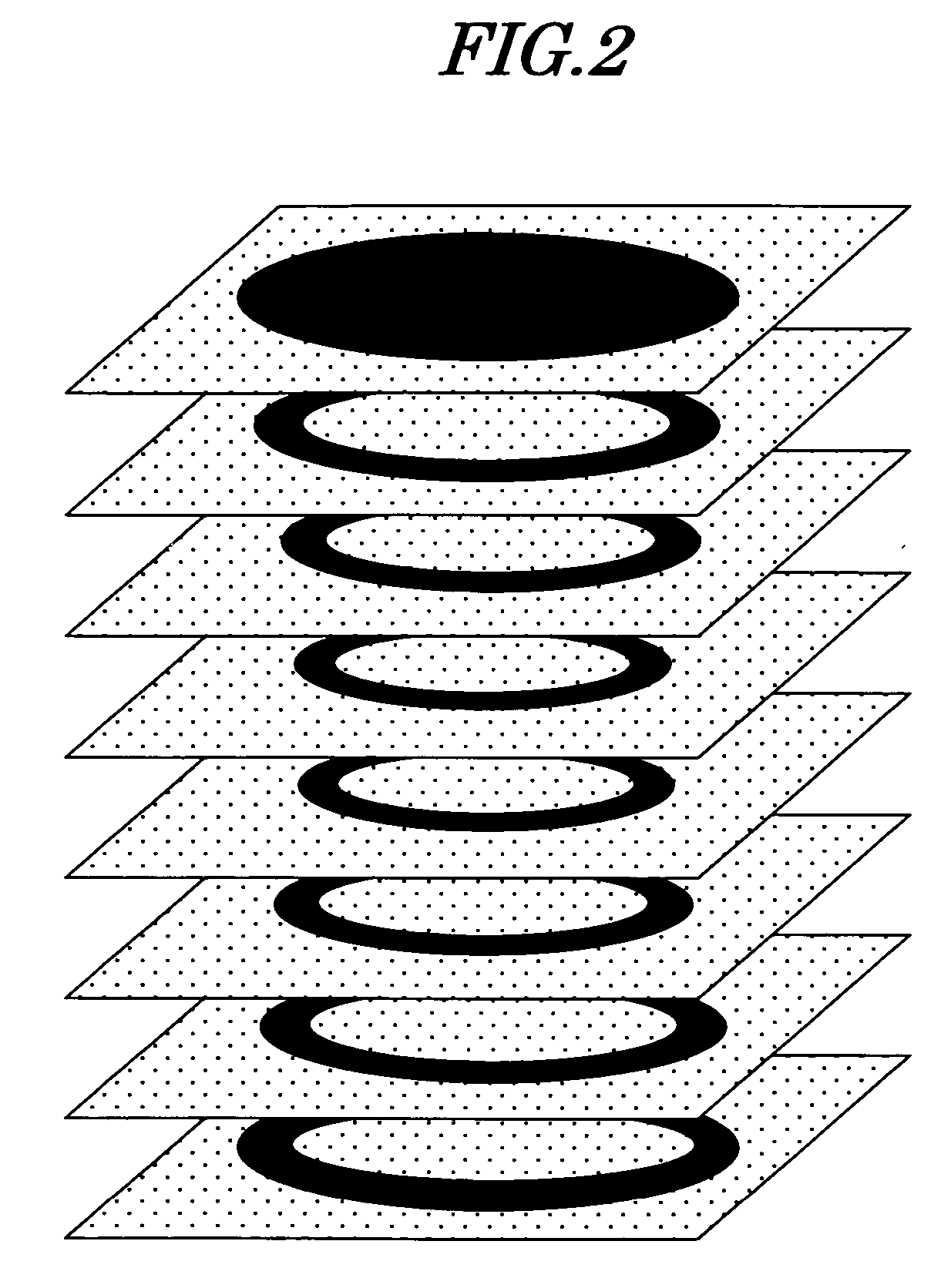

Arrangement for producing a three-dimensional product, which arrangement comprises a work table on which said three-dimensional product is to be built up, a powder dispenser which is arranged so as to distribute a thin layer of powder on the work table for forming a powder bed, a radiation gun for delivering energy to the powder, fusing together of the powder then taking place, means for guiding the beam emitted by the radiation gun over said powder bed for forming a cross section of said three-dimensional product by fusing together parts of said powder bed, and a control computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build up the three-dimensional product, where the control computer is intended to control said means for guiding the radiation gun over the powder bed according to an operating shceme forming a cross section of said three-dimensional body, said three-dimensional product being formed by successive fusing together of successively formed cross sections from by the powder dispenser, and method for procducing three-dimensional product using such an arrangement.

Owner:ARCAM AB

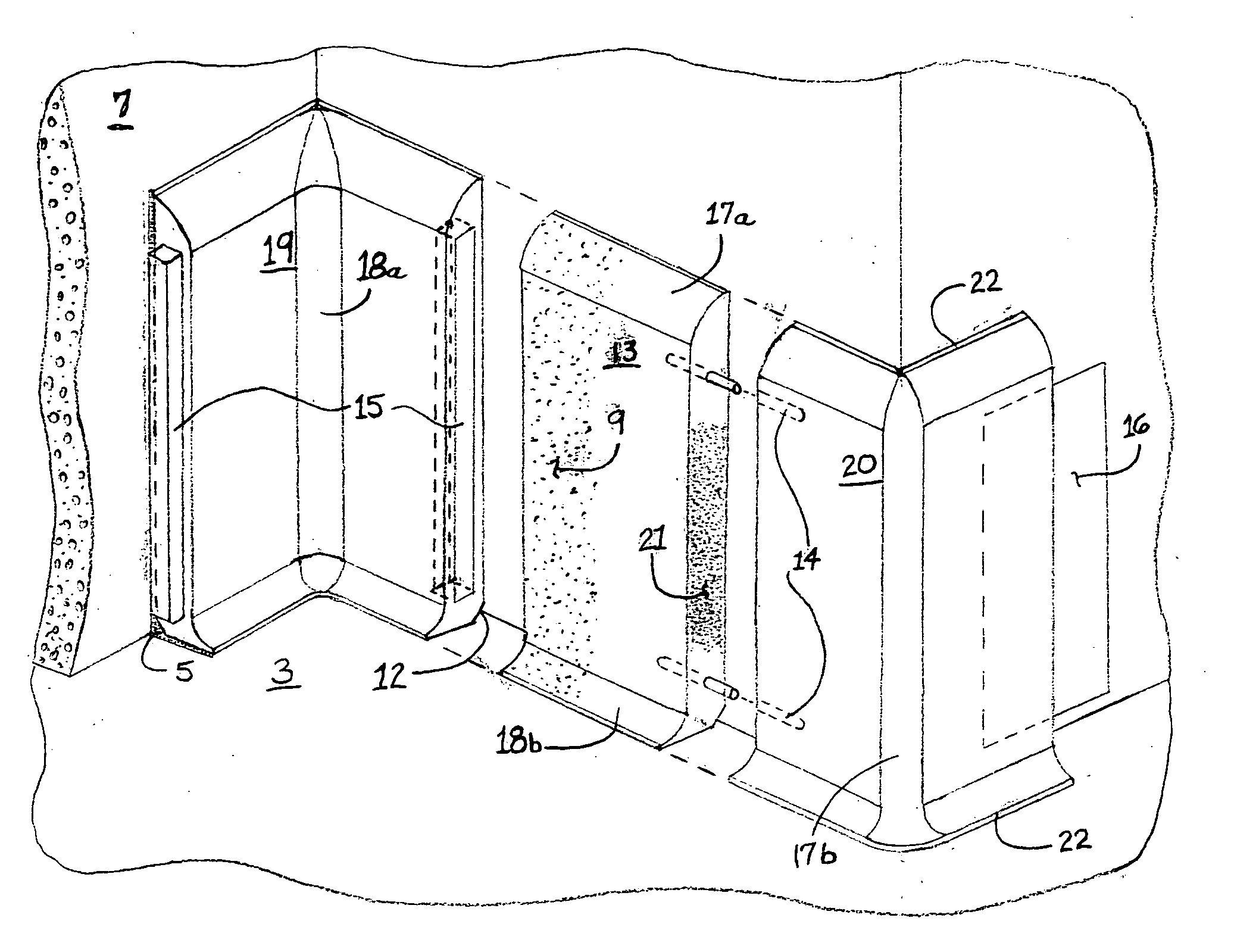

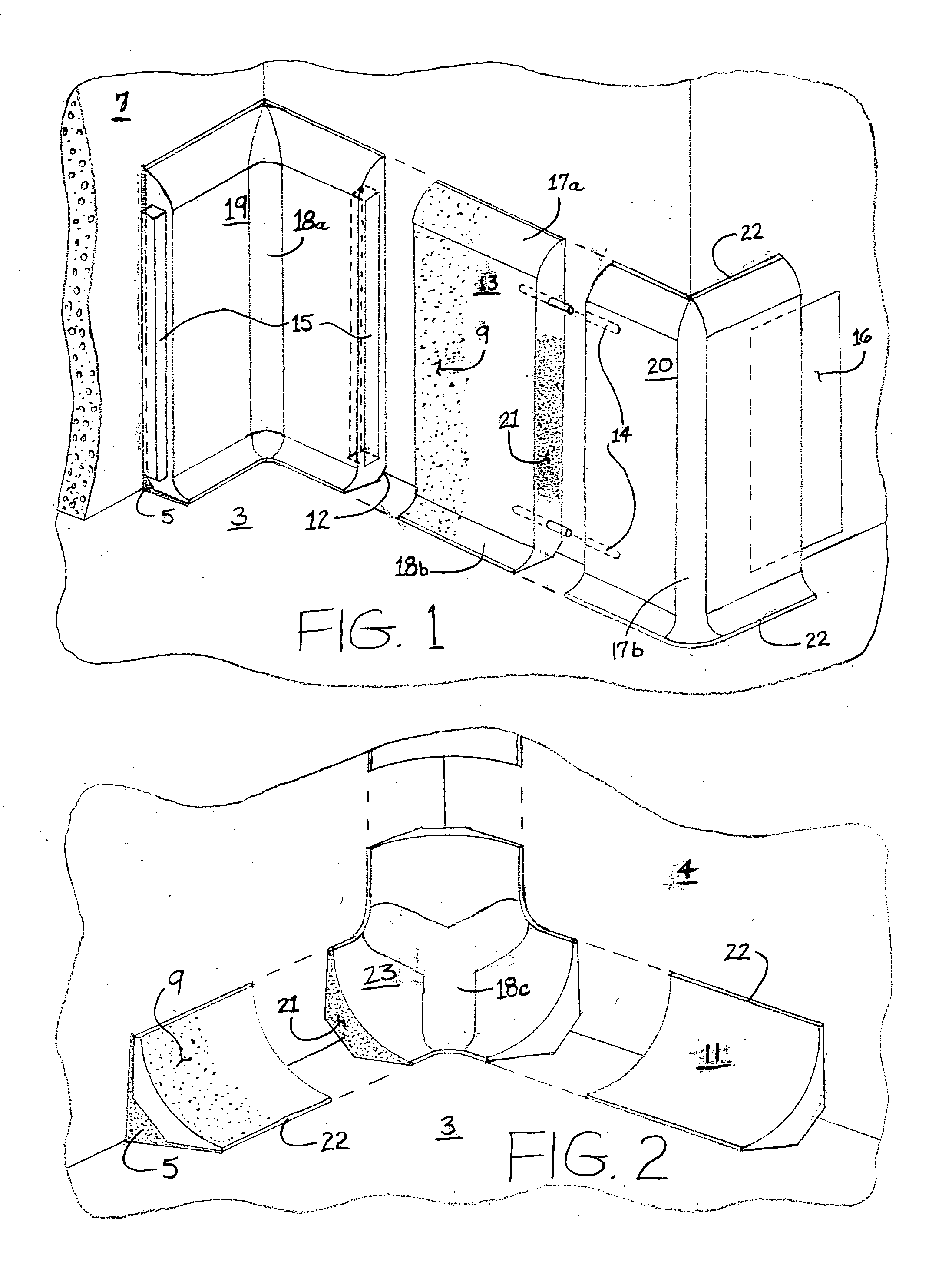

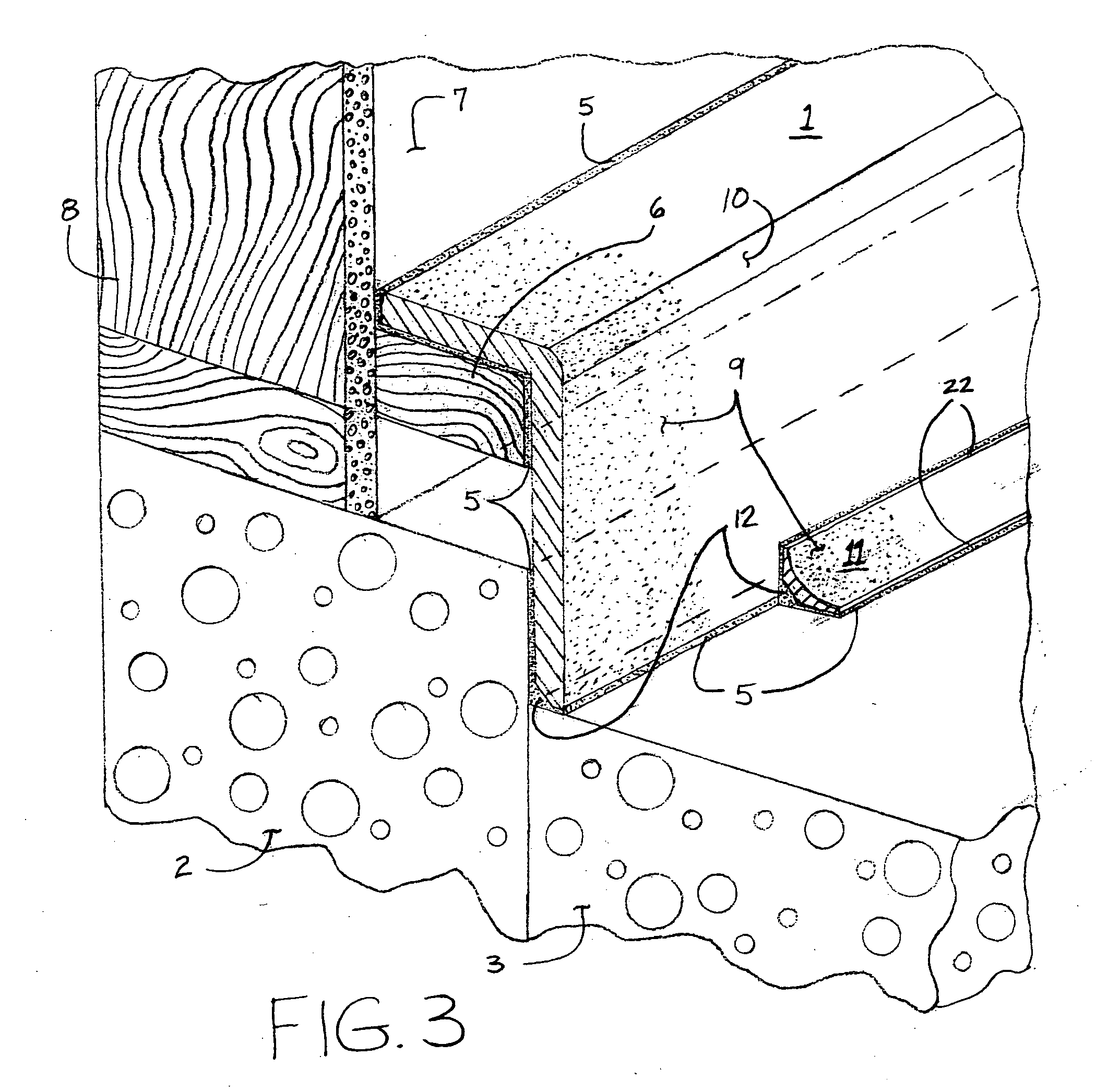

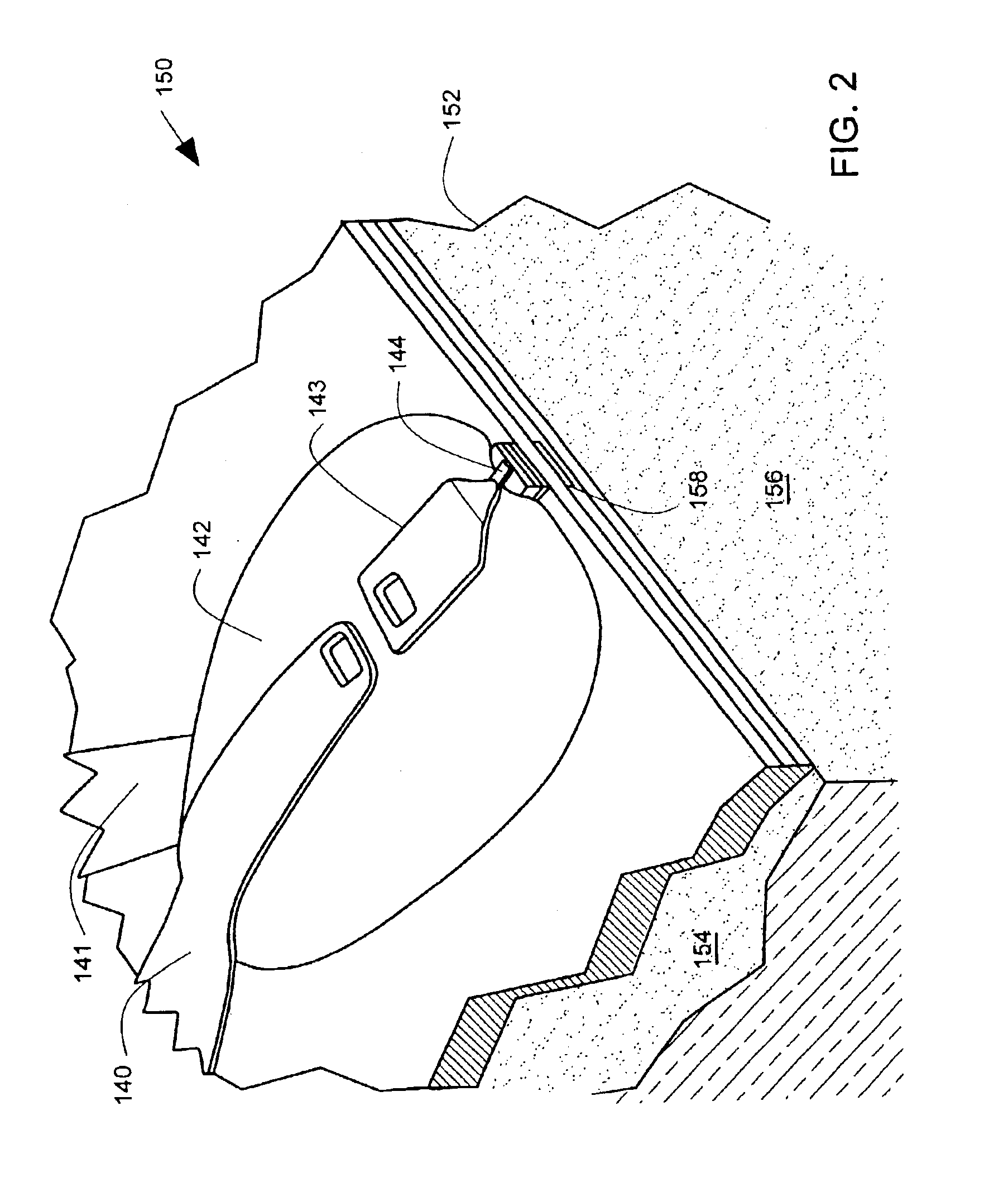

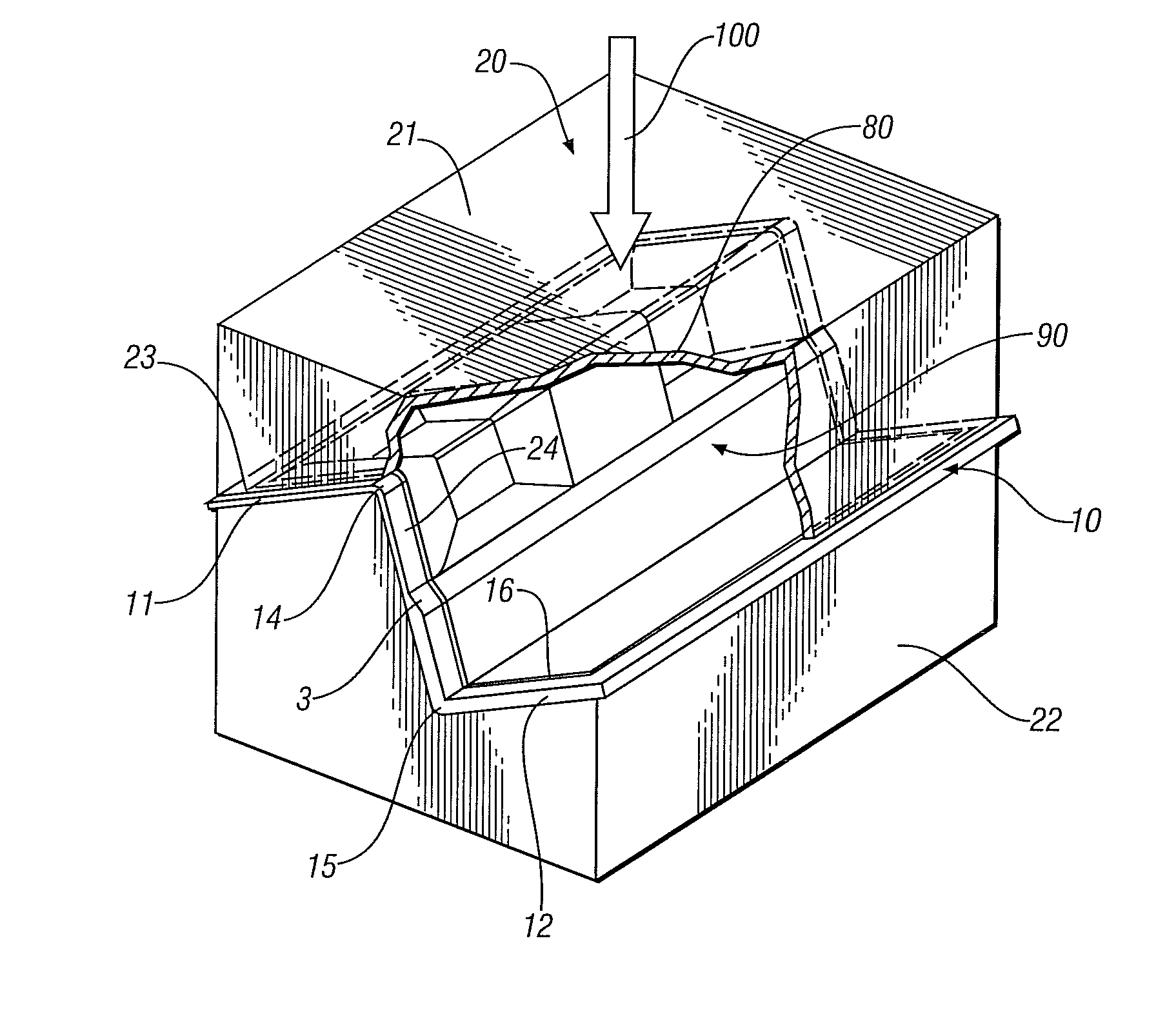

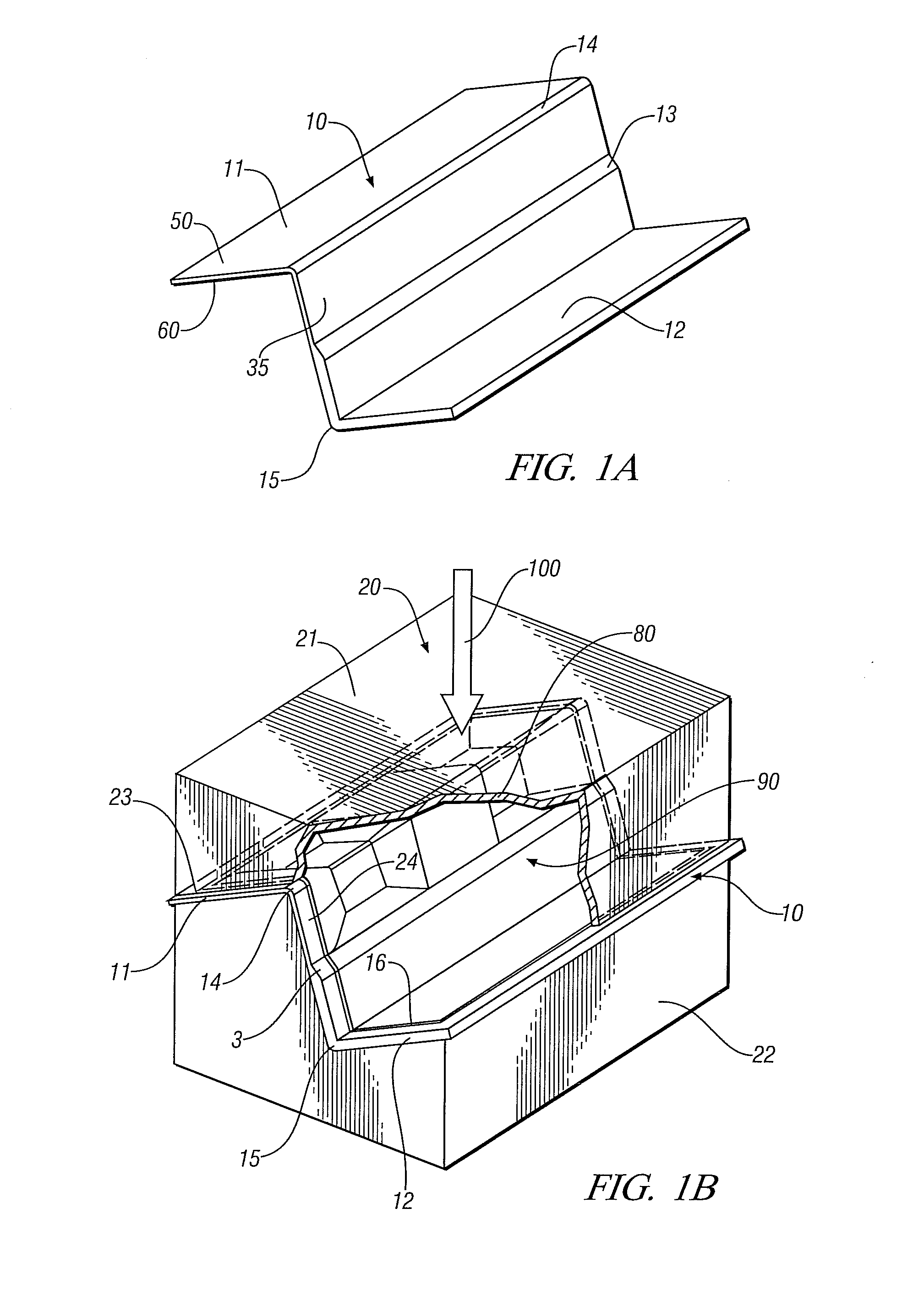

Cove elements and floor coatings and methods for installing

InactiveUS20050011159A1Less-expensive to installSuitable for mass productionWallsMouldsEngineeringShape formation

Described herein is a monolithic flooring system that includes cove elements that are shaped to provide a transition between floor and wall such that a floor coating may be installed over the cove elements and sub-flooring to create a unitary floor-cove covering making for a surface that is more sanitary and easier to clean. Also described are various shaped cove elements that enable creation of a good transition between wall and floor. The cove elements are preferably made of material similar to the sub-floor, for instance a cementitious material. The floor coating is preferably a resinous material.

Owner:STANDAL DOUGLAS J +1

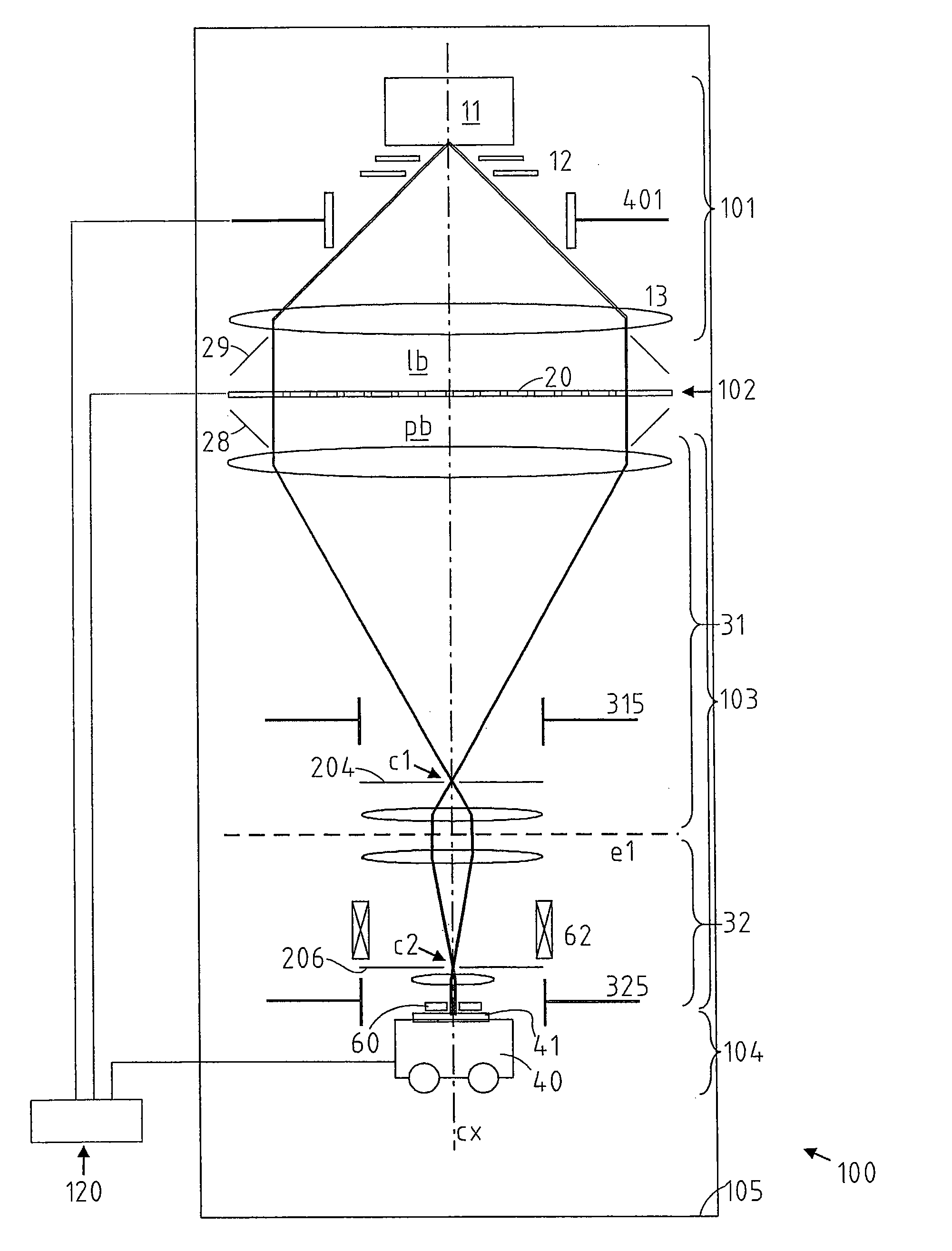

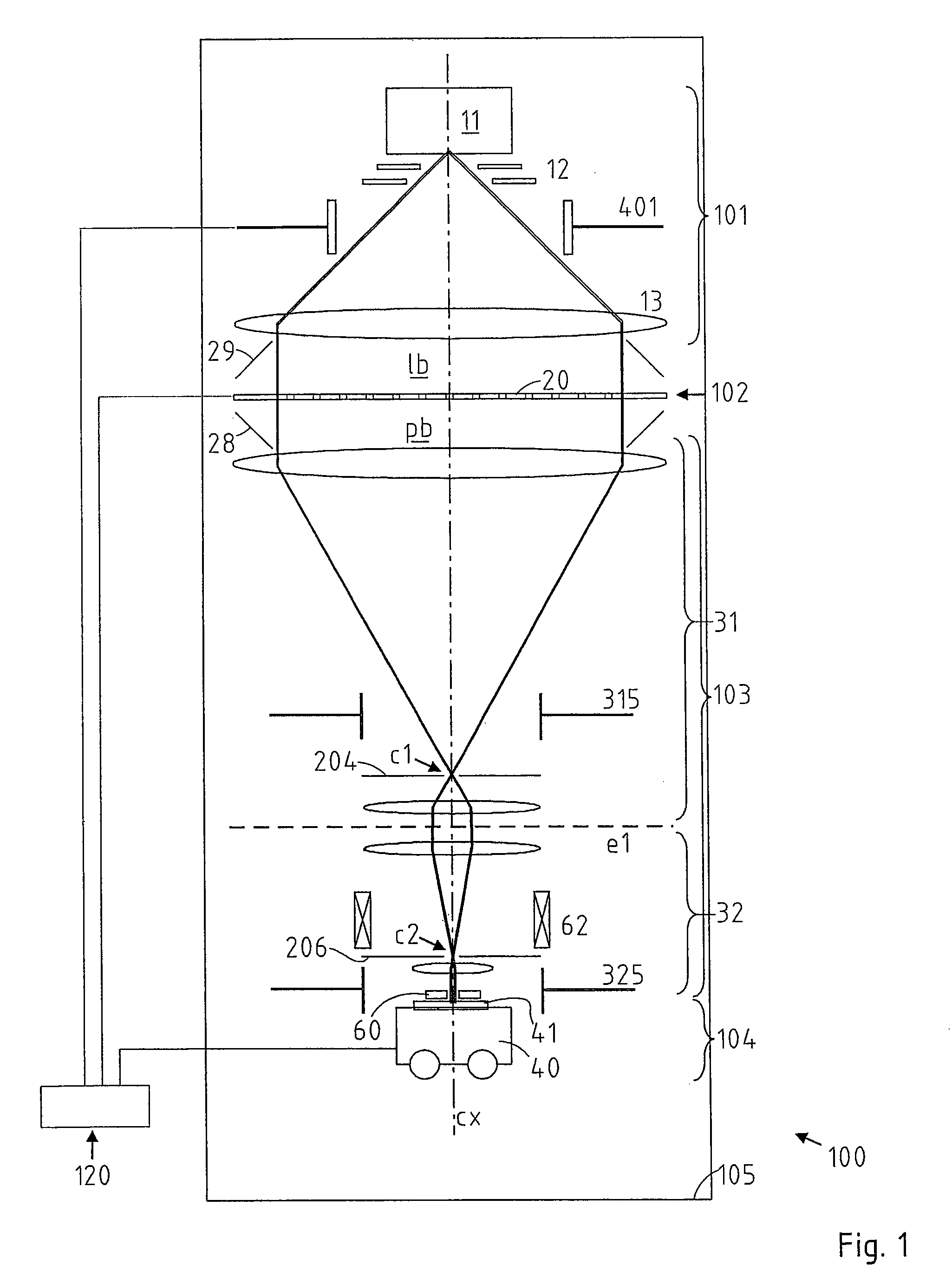

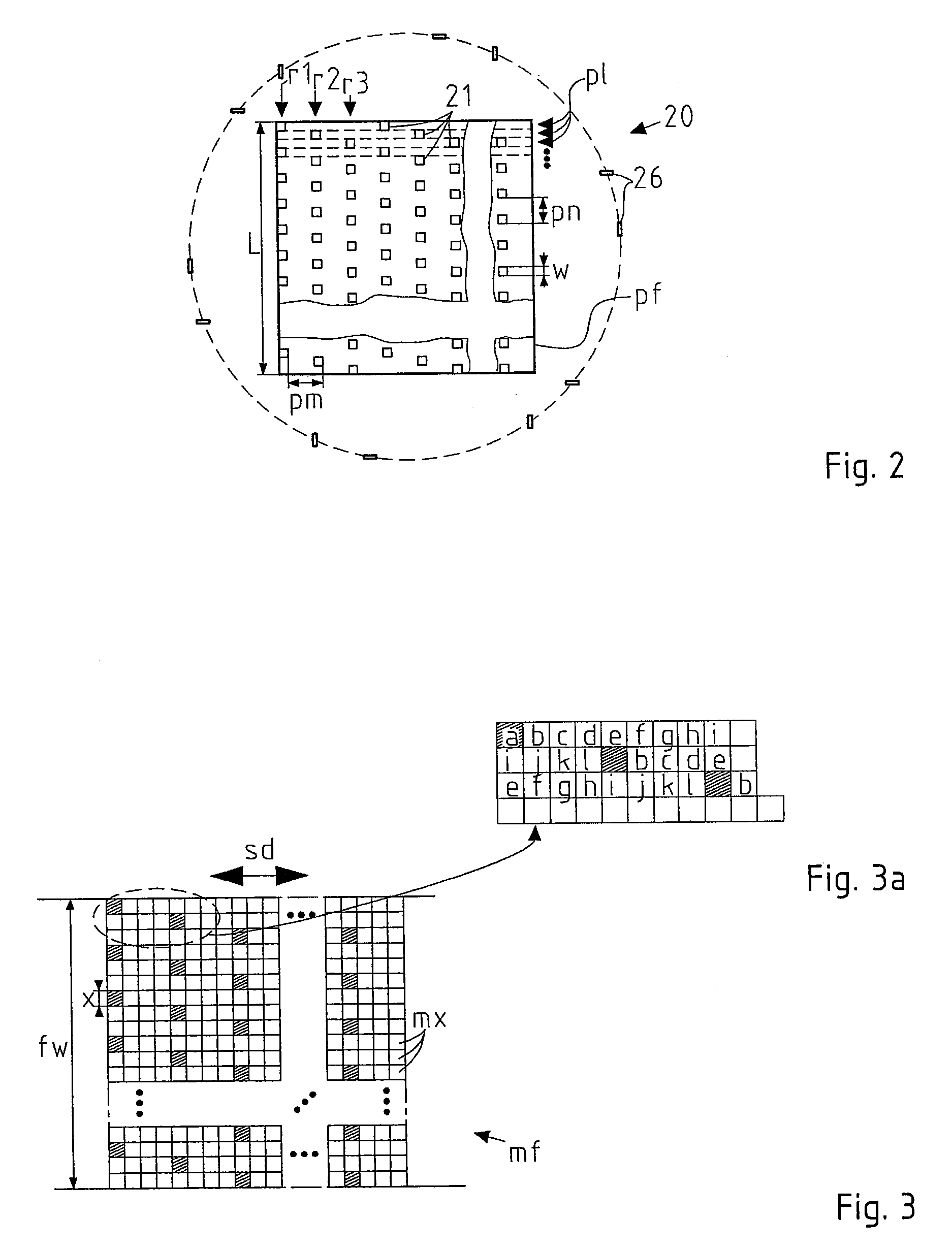

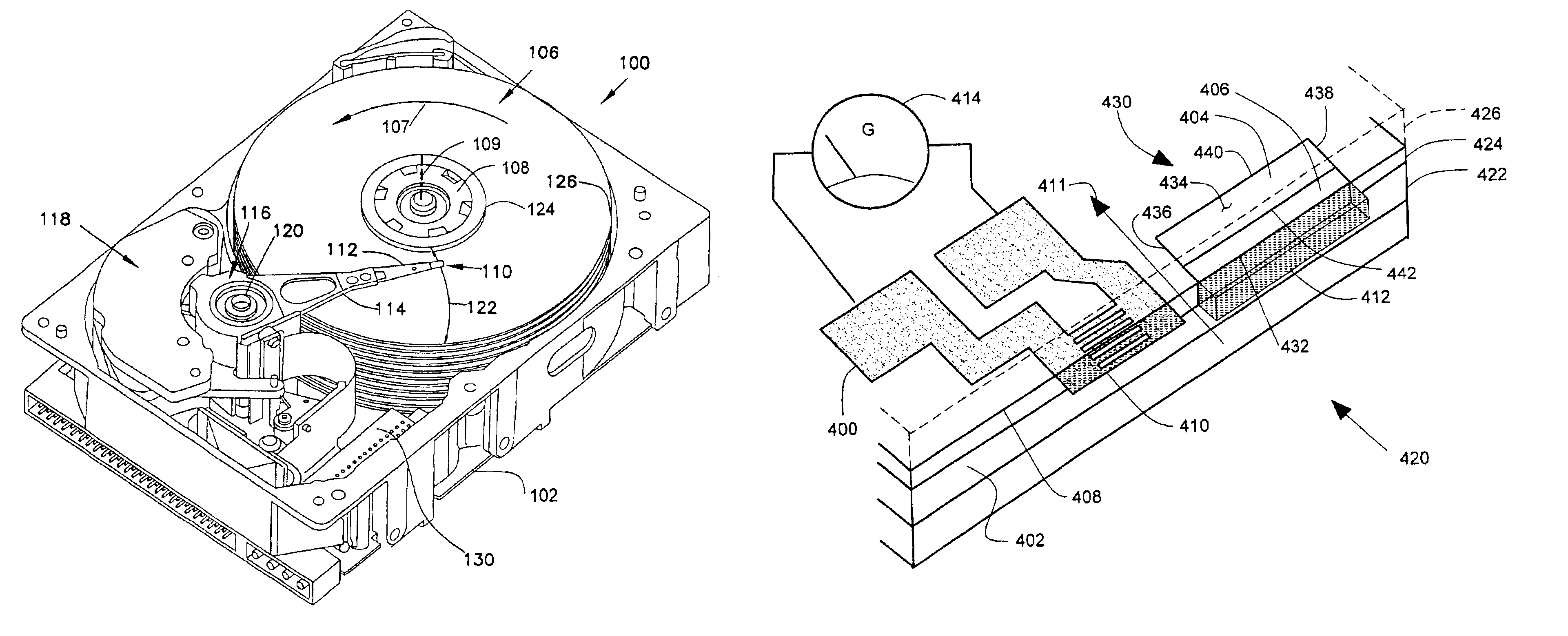

Particle-beam exposure apparatus with overall-modulation of a patterned beam

ActiveUS7781748B2Avoid placement errorsStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsProjection opticsParticle beam

In a charged-particle exposure apparatus for exposure of a target with a beam of electrically charged particles, the illumination system includes a deflector device adapted to vary the direction of incidence of the illuminating beam upon the pattern definition device, the pattern definition device forms the shape of the illuminating beam into a desired pattern, and the projection optics system projects an image of the beam shape defined in the pattern definition device onto the target; the projection optics system includes a blocking aperture device having an opening and being adapted to block passage of beams traversing outside the opening, namely when the deflector device is activated to tilt the beamlet by a sufficient angle from its non-deflected path, e.g., for blanking out during the process of loading a pattern into the pattern definition device.

Owner:IMS NANOFABTION

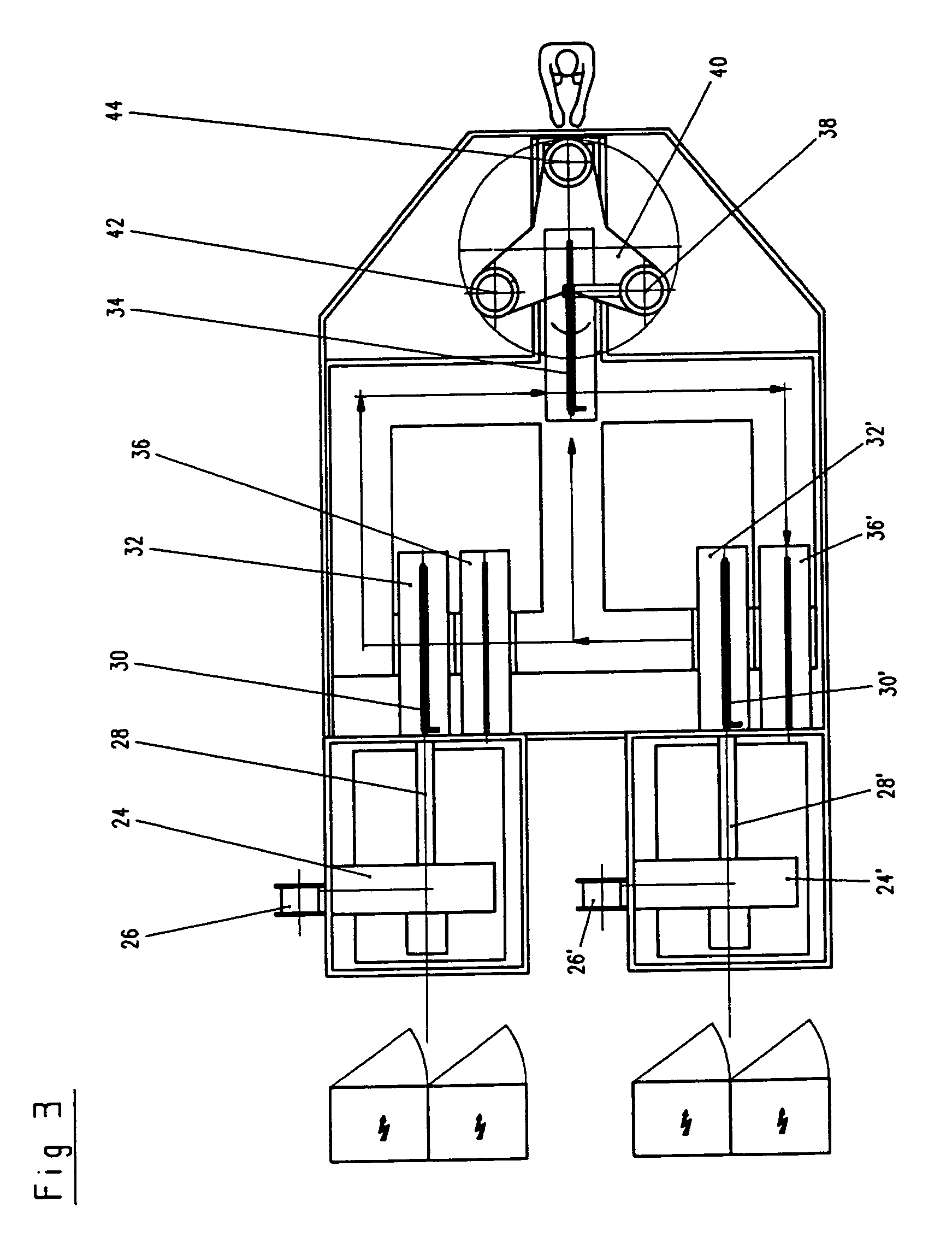

Method of producting three-dimensional model

InactiveUS20070007698A1Improve discharge performanceImprove curing effectNon-woven fabricsAdditive mnaufacturing with solid and fluidViscosityShape formation

The present invention relates to a process for producing a three-dimensional model in which a binder has good discharge properties and curability. The process for producing a three-dimensional model is a process for producing a three-dimensional model that includes a step (layer formation step) of forming above a support a layer of a powder material, the layer having a predetermined thickness, a step (cross-sectional shape formation step) of imagewise bonding the powder material layer by a binder according to sliced cross-sectional data of a modeled object so as to give a cross-sectional shape, and sequentially repeating the above steps, the binder having a viscosity at 25° C. of 5 to 100 mPa·s.

Owner:FUJIFILM CORP +1

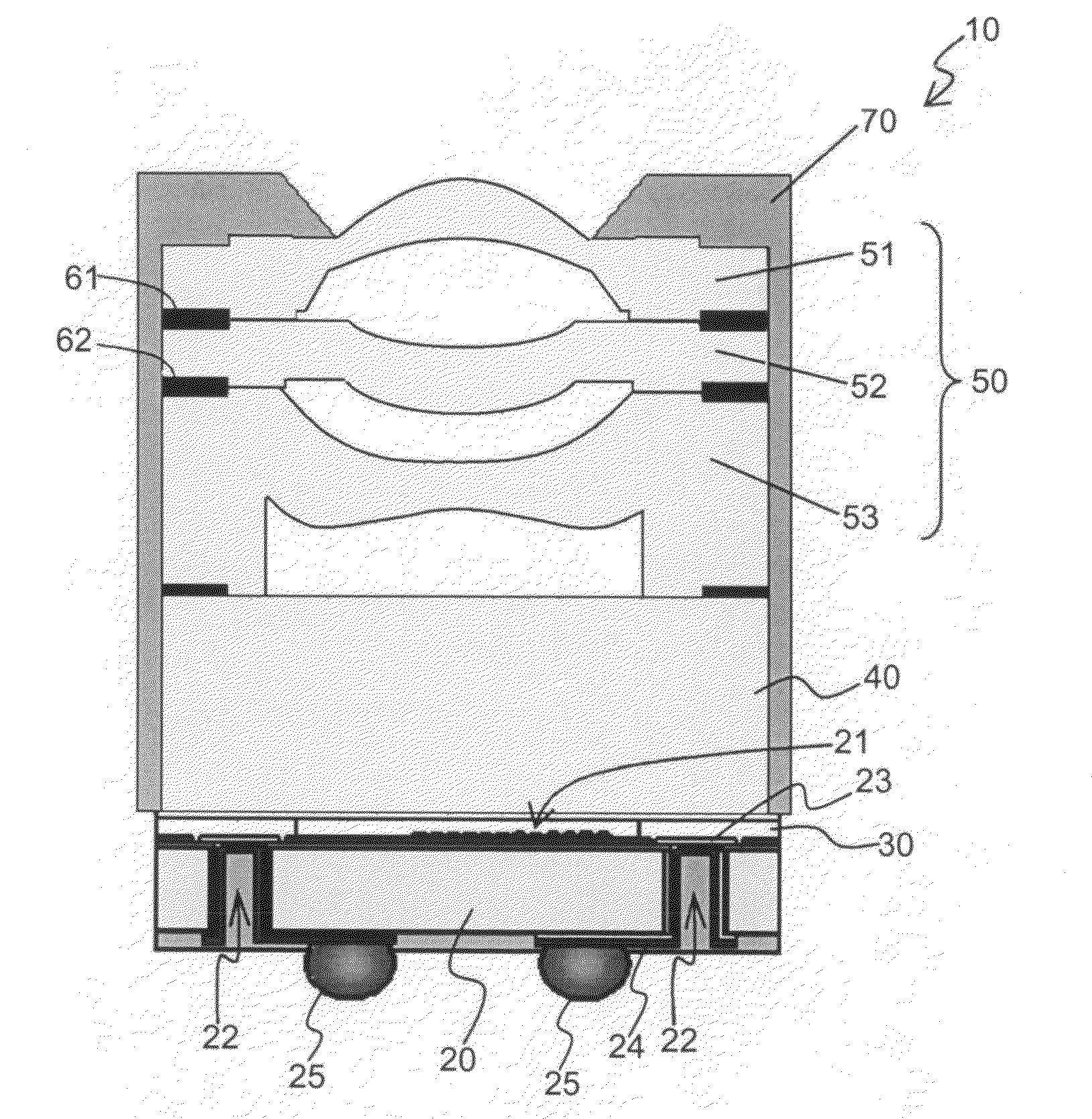

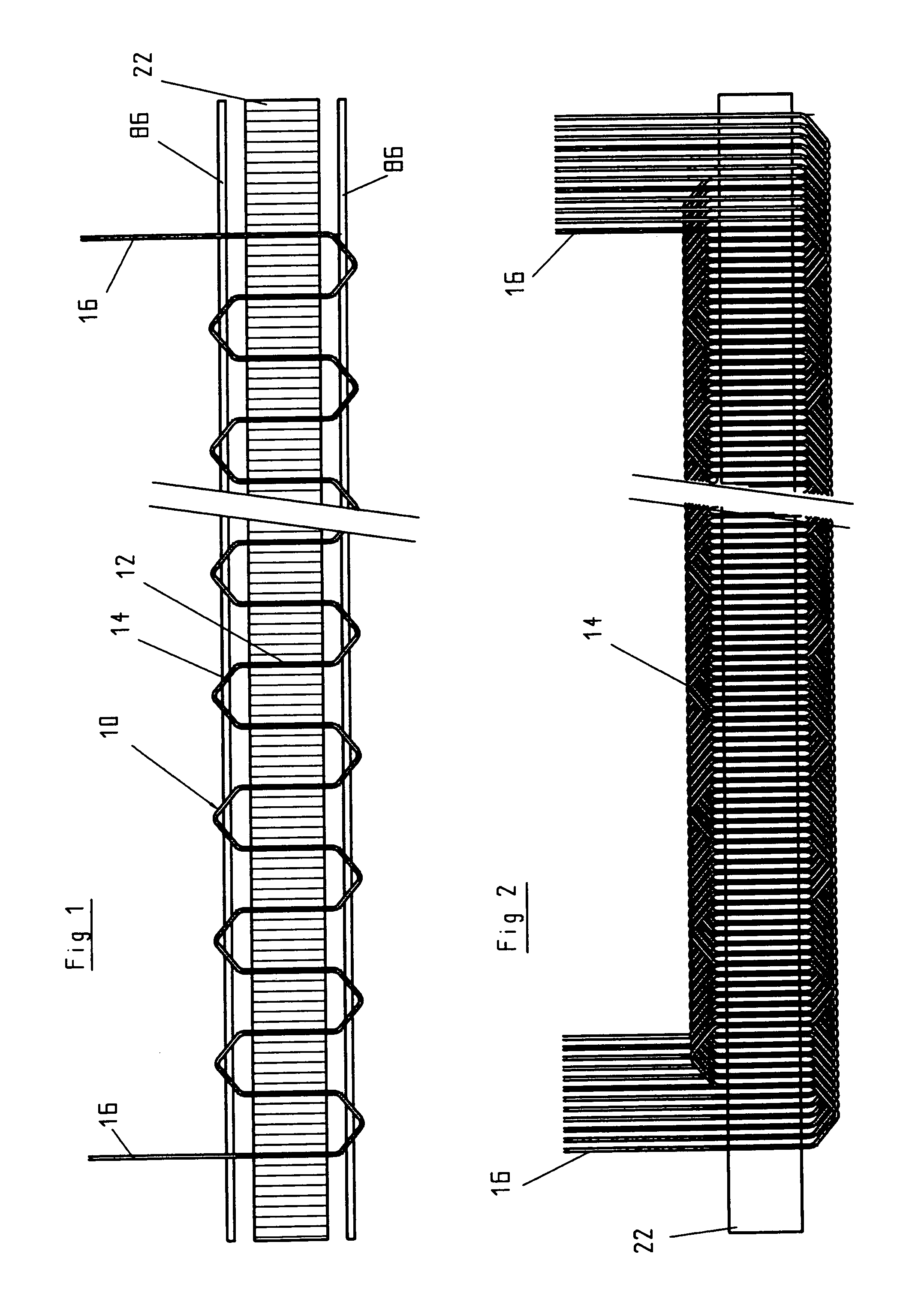

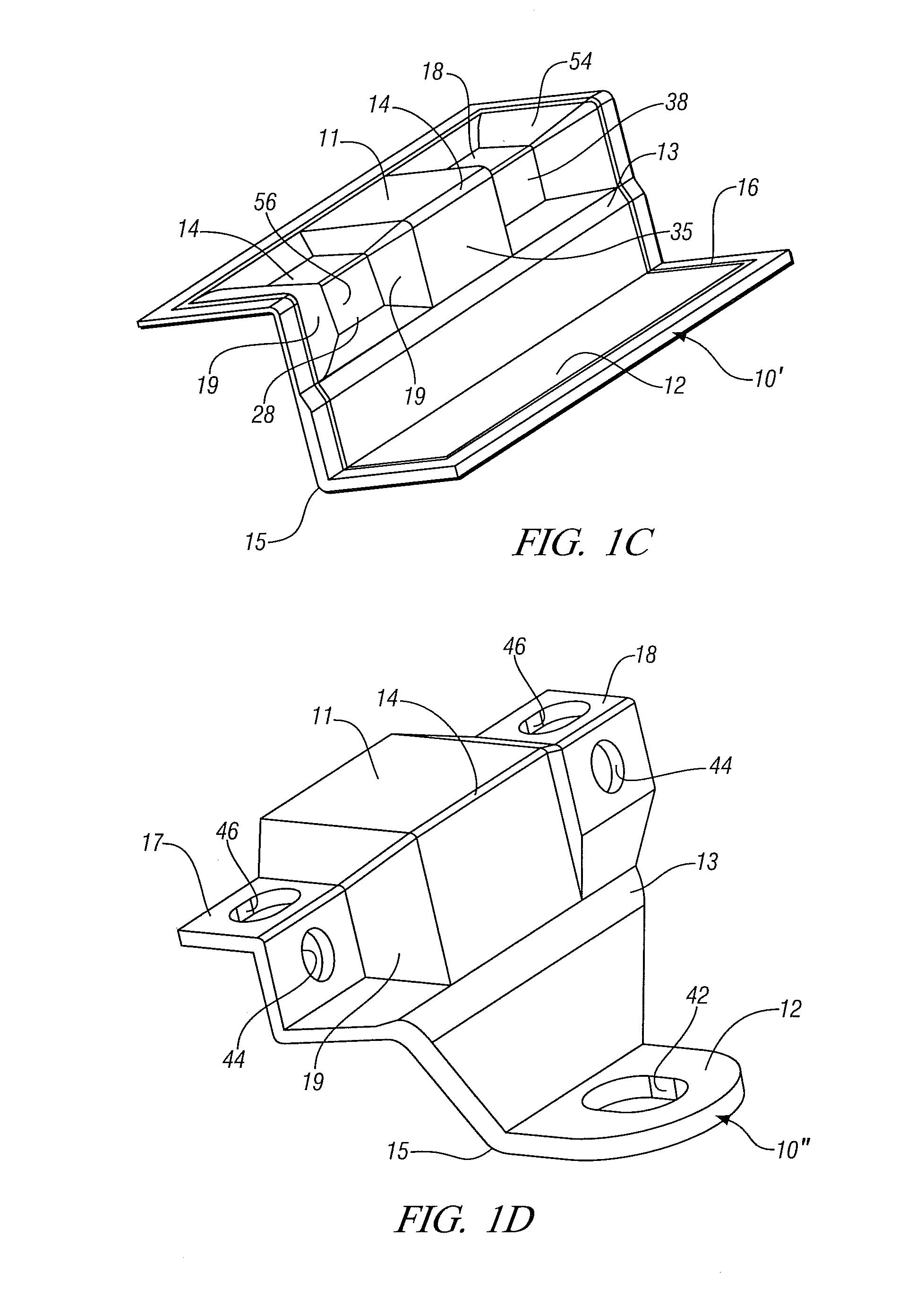

Insulated composite steel member

InactiveUS6158190AEliminate connectionEliminates any thermal shortsStrutsWallsUltimate tensile strengthShape formation

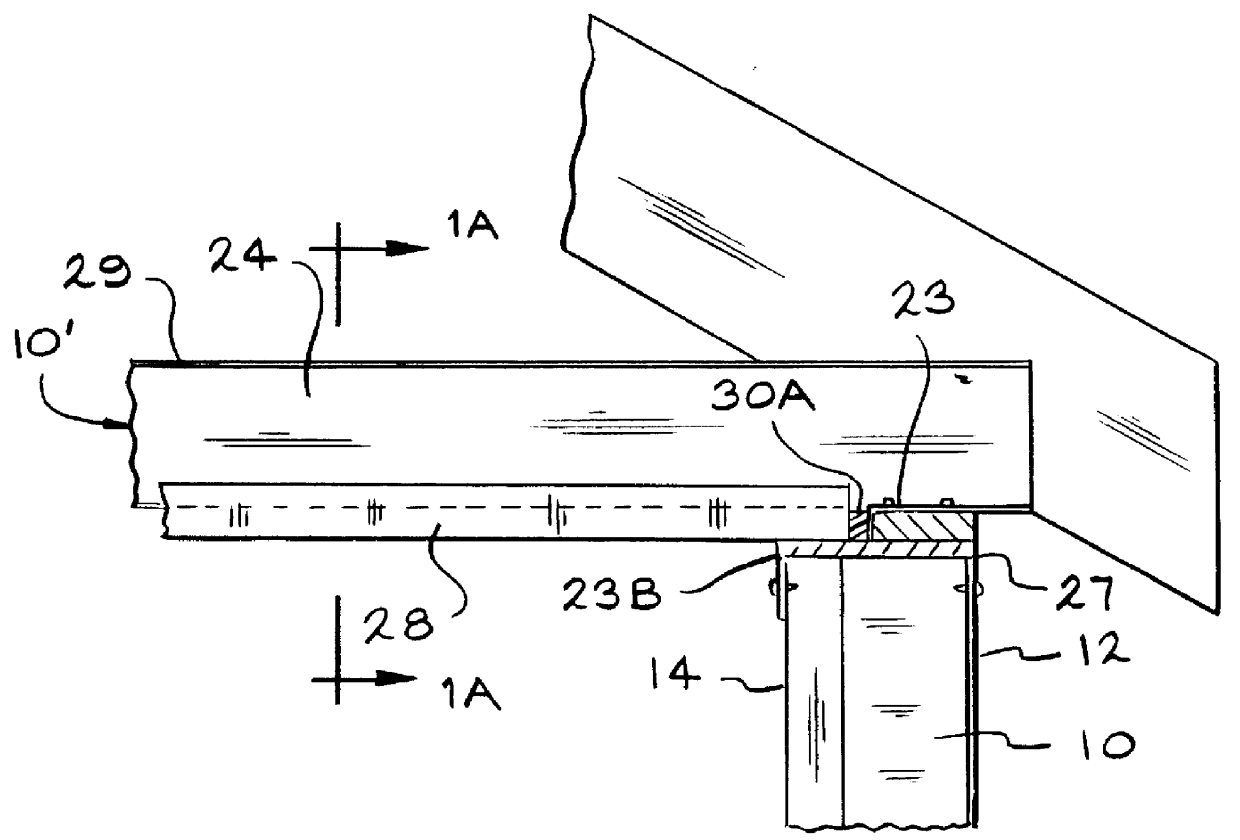

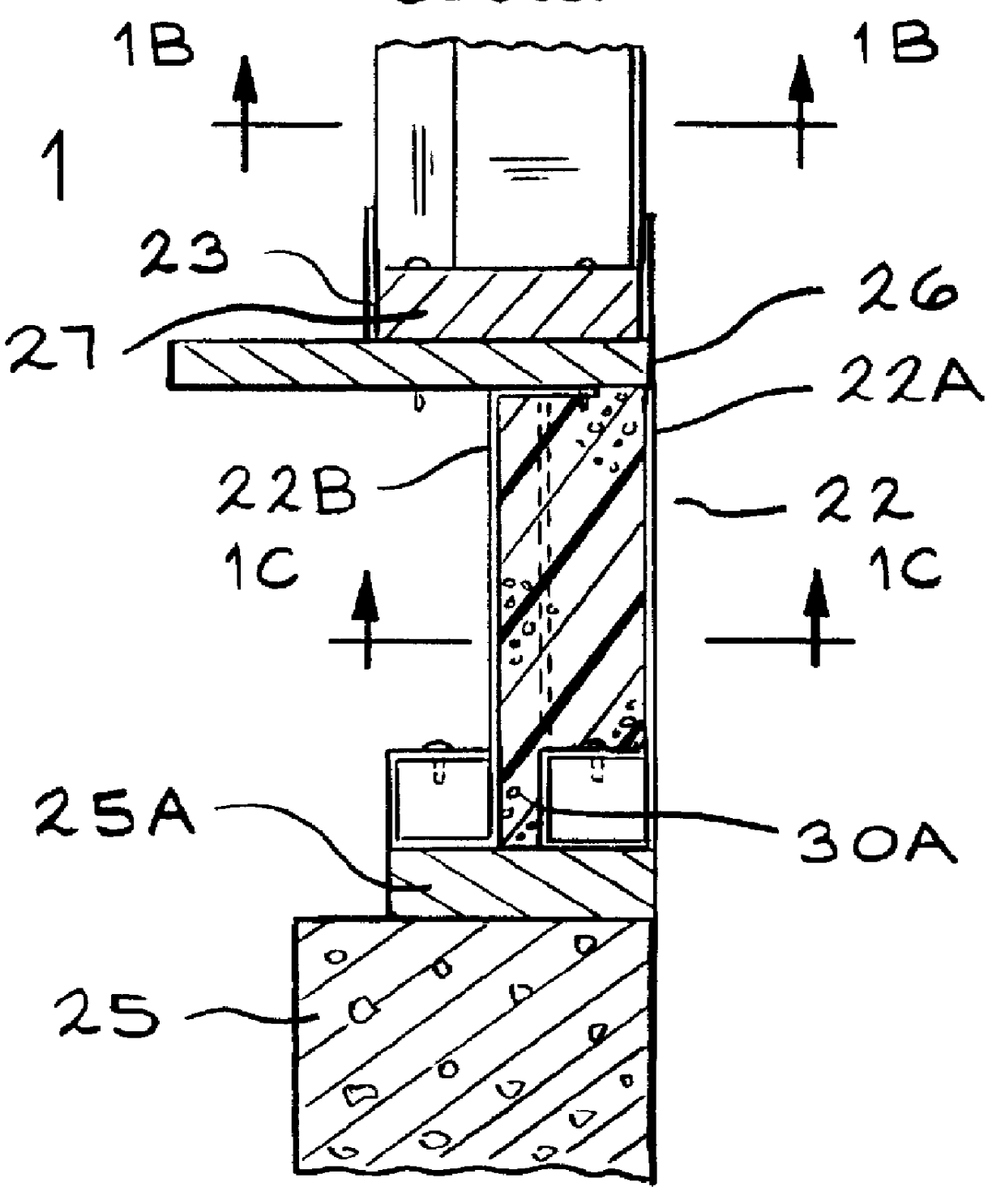

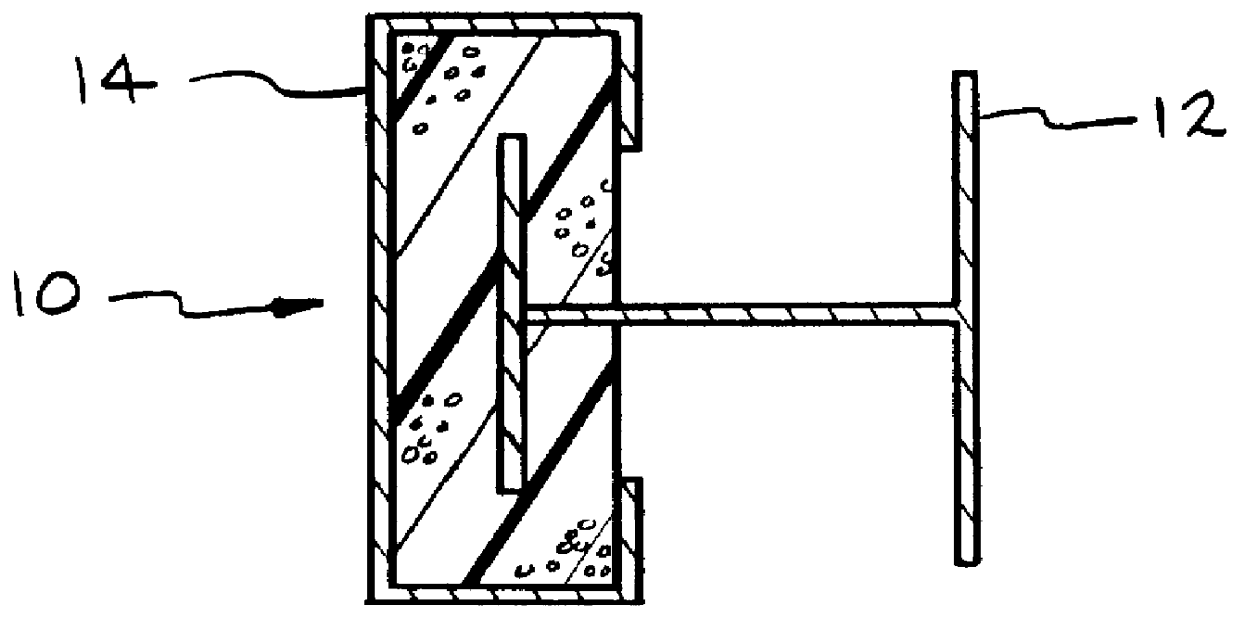

This composite building stud combines two metal shapes, inner and outer, with an insulating material to form a composite structural member having an insulating valve (R-value) greater than a similar metal member normally used as a stud in a residential structure. The composite also has a strength comparable to that of a similar steel member normally used as a stud in a residential structure. One shape encompasses the other shape. The composite structural member eliminates any direct metal connections and thus eliminates any thermal shorts that reduce the overall insulating value (R-value) of the composite member. The shapes, inner and outer, with an insulating material form a composite structural member that has an interlocking shape which holds the insulating material in compression and mechanically couples the inner and outer members.

Owner:EAST OHIO MACHINERY

Process for producing three-dimensional model, and three-dimensional model

InactiveUS7300613B2Low costHigh strengthAdditive manufacturing apparatusCeramic shaping apparatusDimensional modelingShape formation

A process for producing a three-dimensional model is provided. The process includes a step (layer formation step) of forming a layer of a powder material, the layer having a predetermined thickness, a step (cross-sectional shape formation step) of imagewise bonding the powder material layer by a binder according to sliced cross-sectional data of a modeled object so as to give a cross-sectional shape, and sequentially repeating the above steps. The surface gloss of the three-dimensional model obtained when measured at 20° is 20% or more. Furthermore, production equipment used in the above process is provided. Moreover, a three-dimensional model is provided that contains a powder material and a binder and is formed by imagewise curing the binder, the three-dimensional model having a surface gloss when measured at 20° of 20% or more.

Owner:FUJIFILM CORP +1

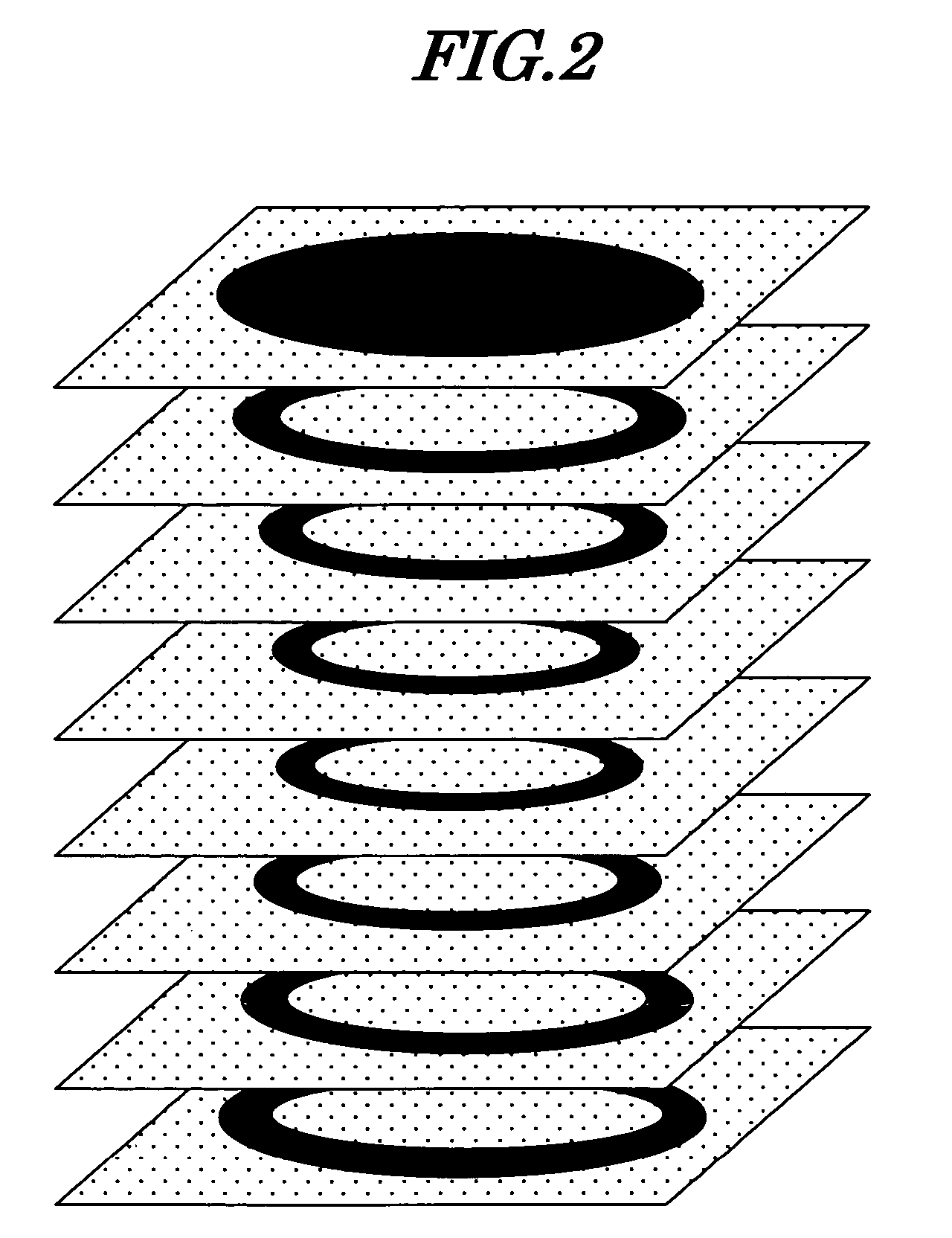

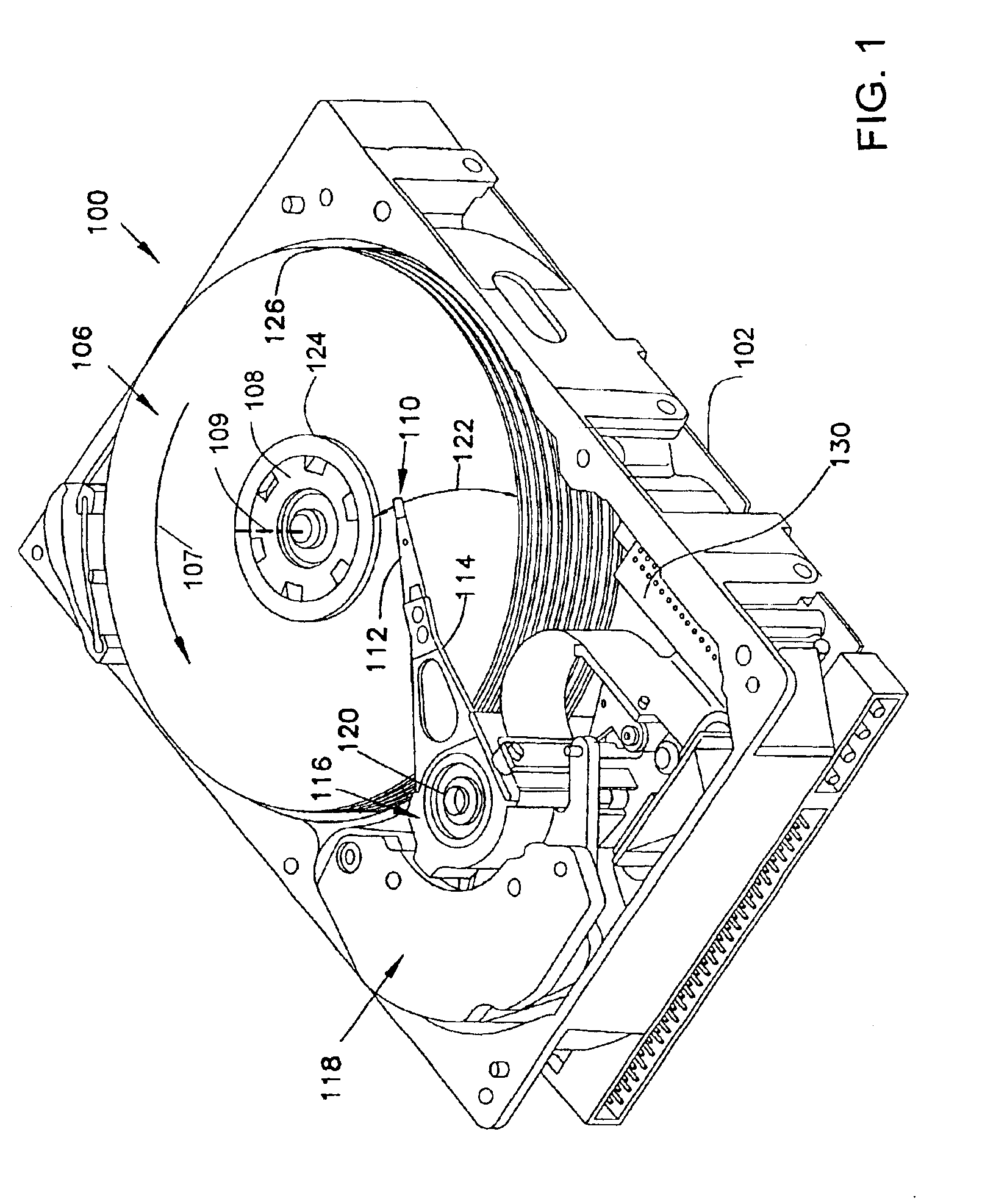

Sensor stripe encapsulation layer in a read/write head

InactiveUS6935923B2Electrical transducersDecorative surface effectsShape formationAir bearing surface

A magnetoresistive read head has read head layers that are shaped to form an air bearing surface and a sensor stripe cavity with an open side at the air bearing surface. A sensor stripe is deposited in the sensor stripe cavity. The sensor stripe has a front surface that is set back from the air bearing surface to define an encapsulation cavity extending from the front surface to the air bearing surface. An encapsulation layer is deposited in the encapsulation cavity. The encapsulation layer encapsulates the front surface.

Owner:SEAGATE TECH LLC

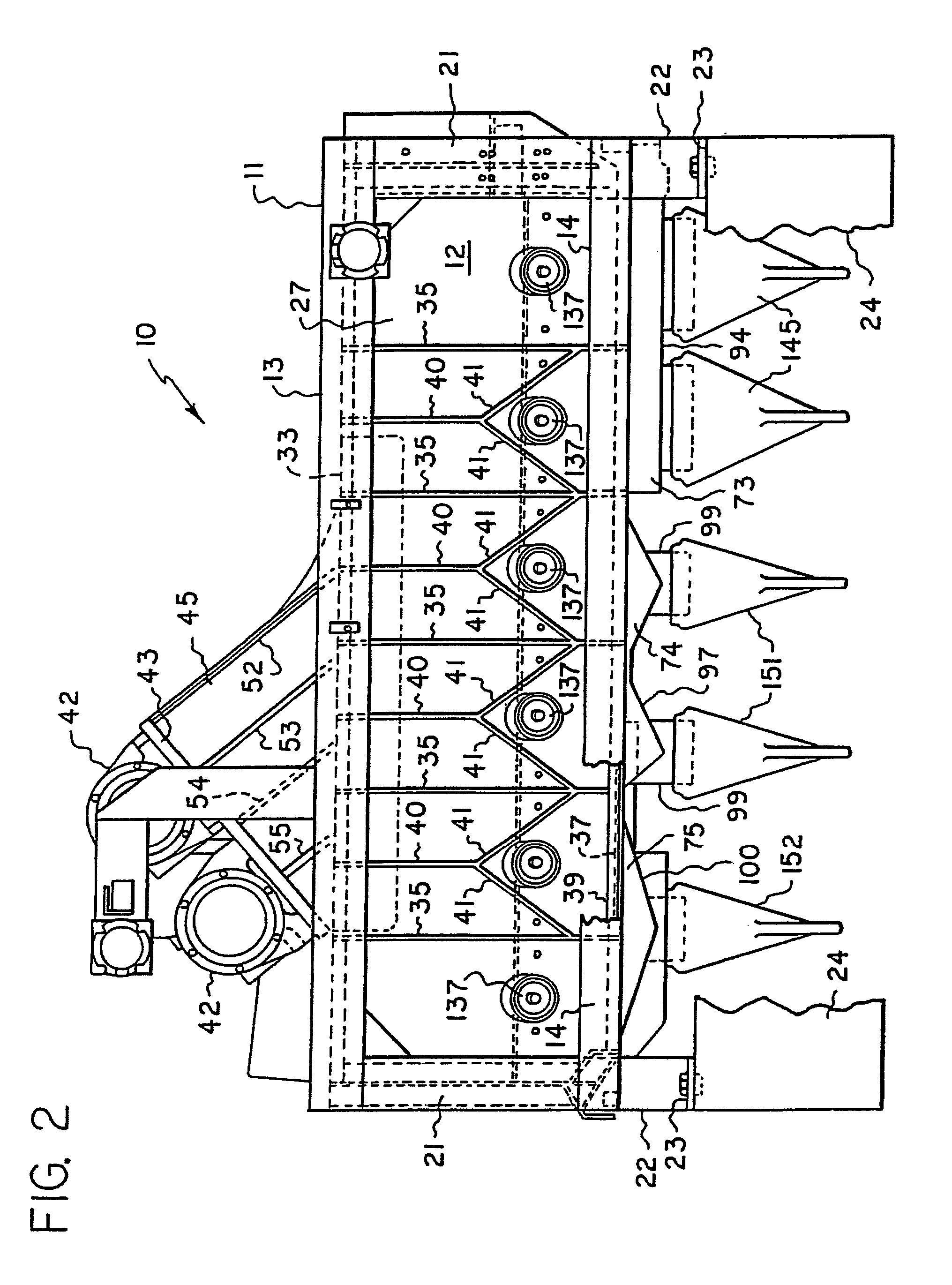

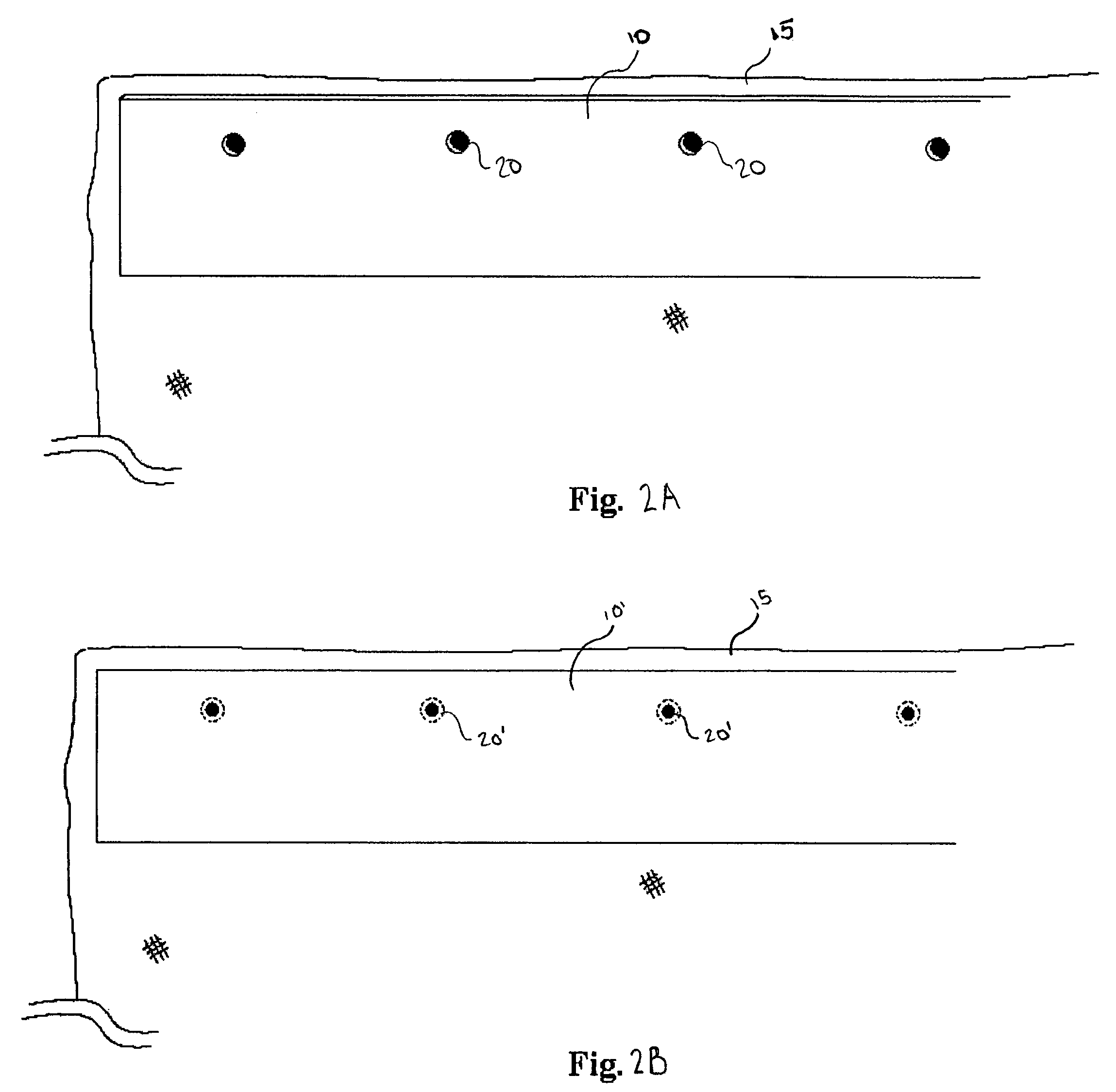

Vibratory screen assembly and method of manufacture

InactiveUS20050133465A1Restricts the passage of airSievingScreeningAtmospheric pressureBiomedical engineering

A screen assembly comprising a support, a screen comprising peaks and troughs, and a coating on at least a portion of a plurality of the peaks. An apparatus for screening material comprising a frame, a motor mounted to the frame, a screen assembly supported by the frame, a chamber beneath the screen assembly adapted to be placed intermittently at less than atmospheric pressure, a screen formed in an undulating shape comprising a plurality of peaks and troughs, and a coating on at least a portion of a plurality of the peaks.

Owner:DERRICK CORP

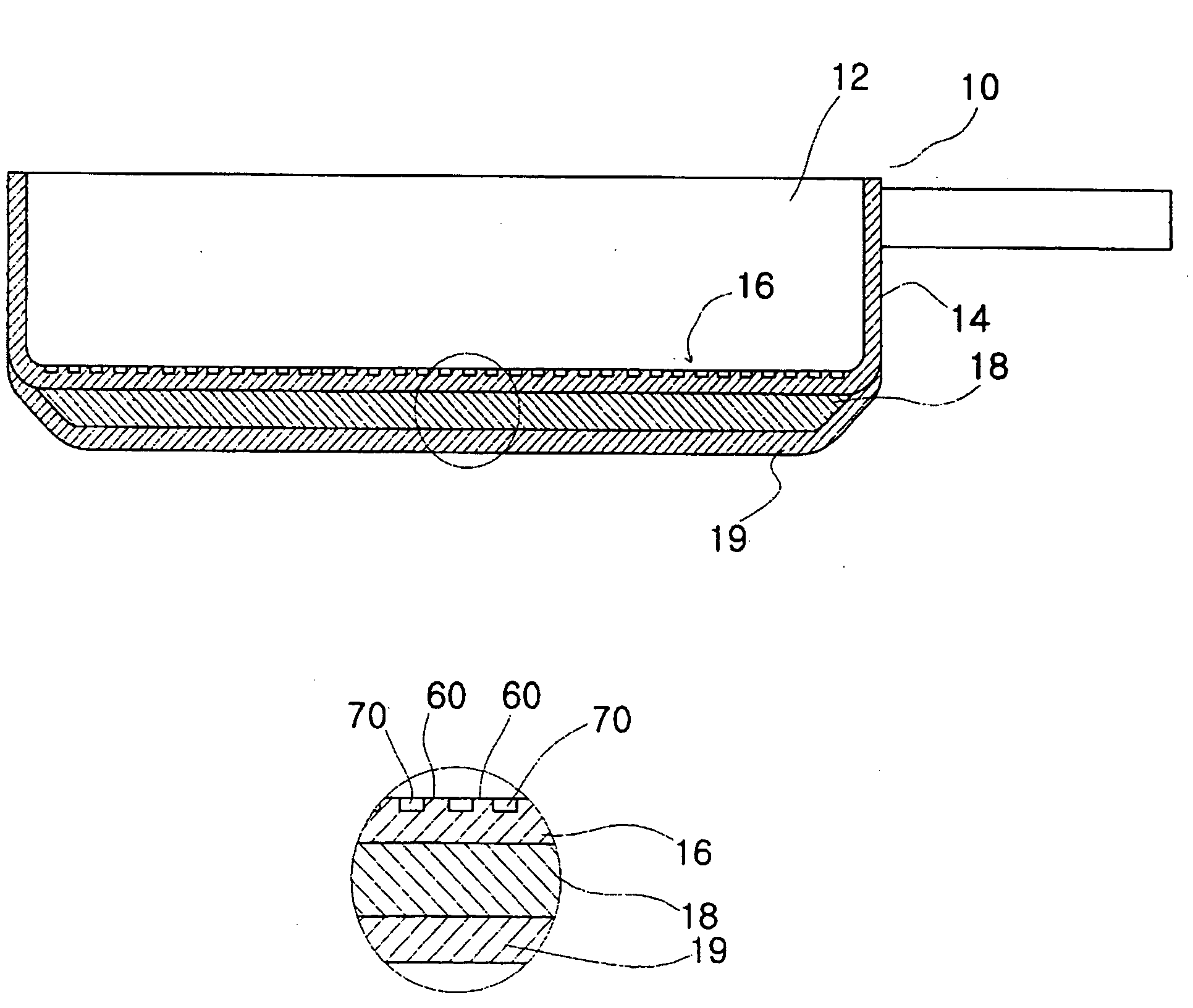

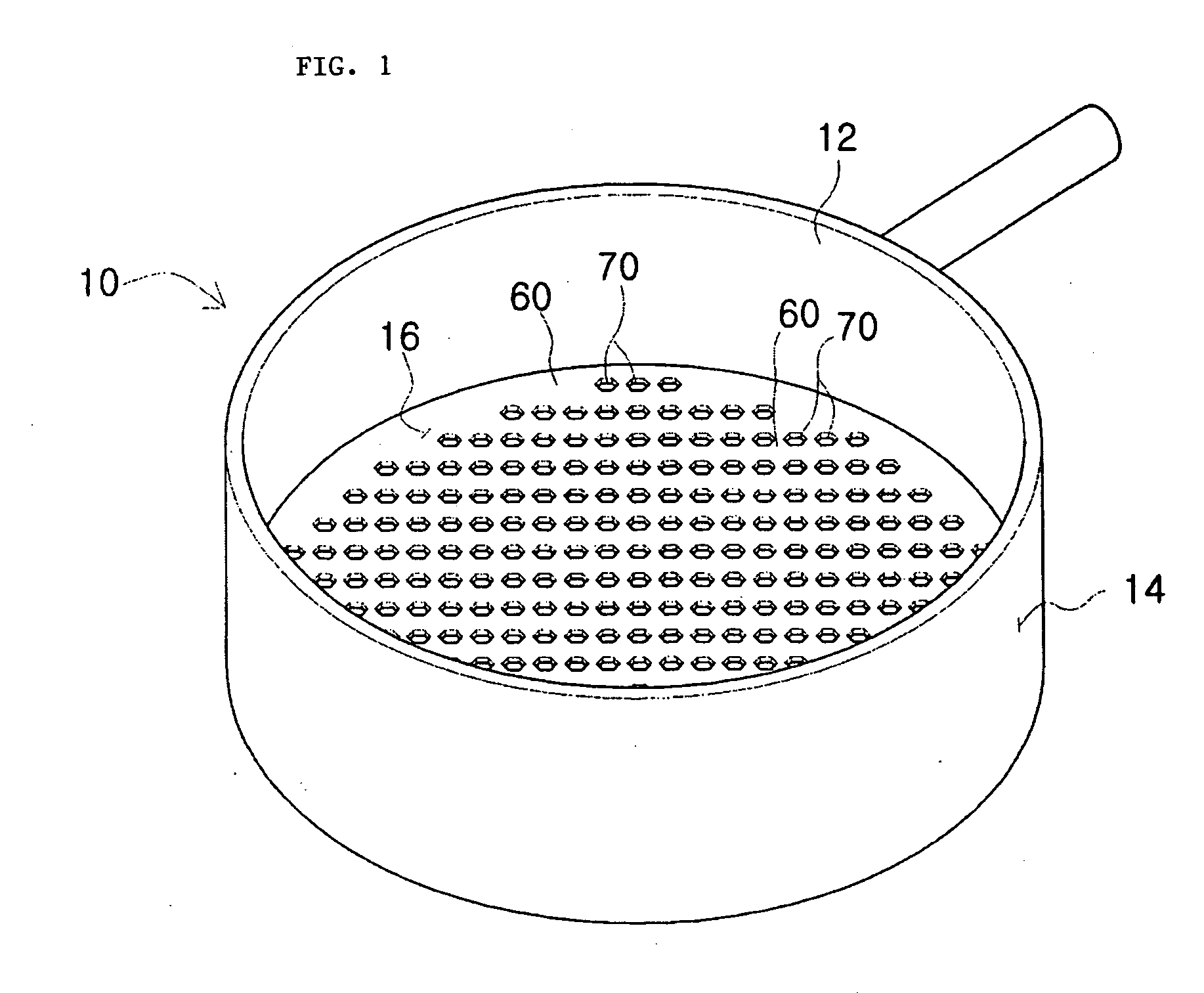

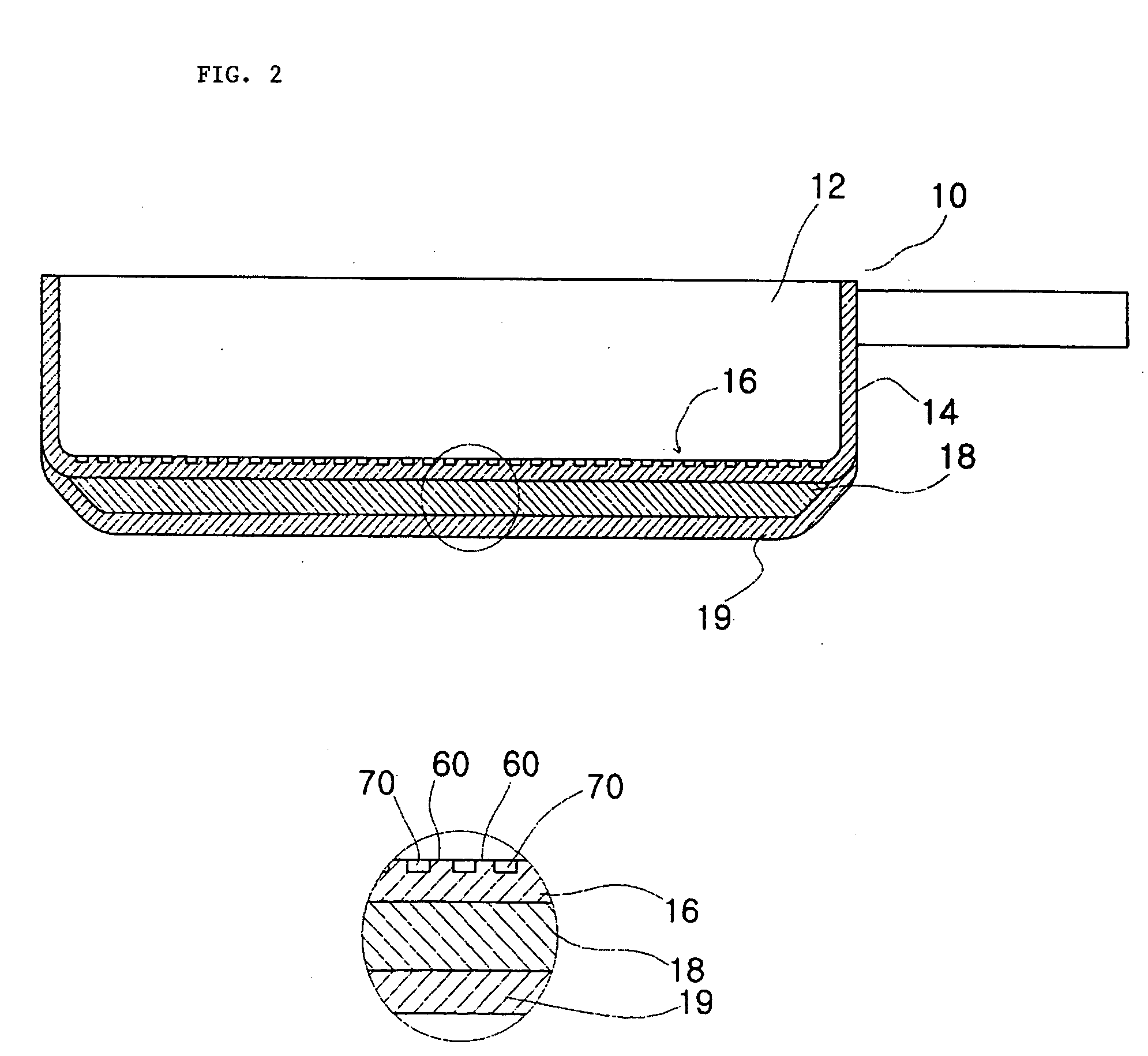

Method for manufacturing cooking vessel

InactiveUS20080083747A1Promote formationHigh strengthMetal rolling stand detailsRefuse receptaclesThin membraneEngineering

Provided is a method for manufacturing a cooking vessel having a bottom on which a plurality of engraving parts and embossing parts are formed in a concavo-convex shape. The method includes attaching a film having through-holes to a cut stainless plate; coating an ink layer on the film, impregnating an ink of the ink layer into the through-holes of the film, peeling off the film, and forming the ink layer; dipping the stainless plate having the ink layer in an erosion solution, and forming the engraving parts, by erosion, on a remnant surface of the stainless plate; and removing the ink layer from the stainless plate, pressing the stainless plate, and forming the vessel body having a housing part therein and having the engraving parts and the embossing parts on the bottom in the concavo-convex shape.

Owner:PARK GEE WOEN

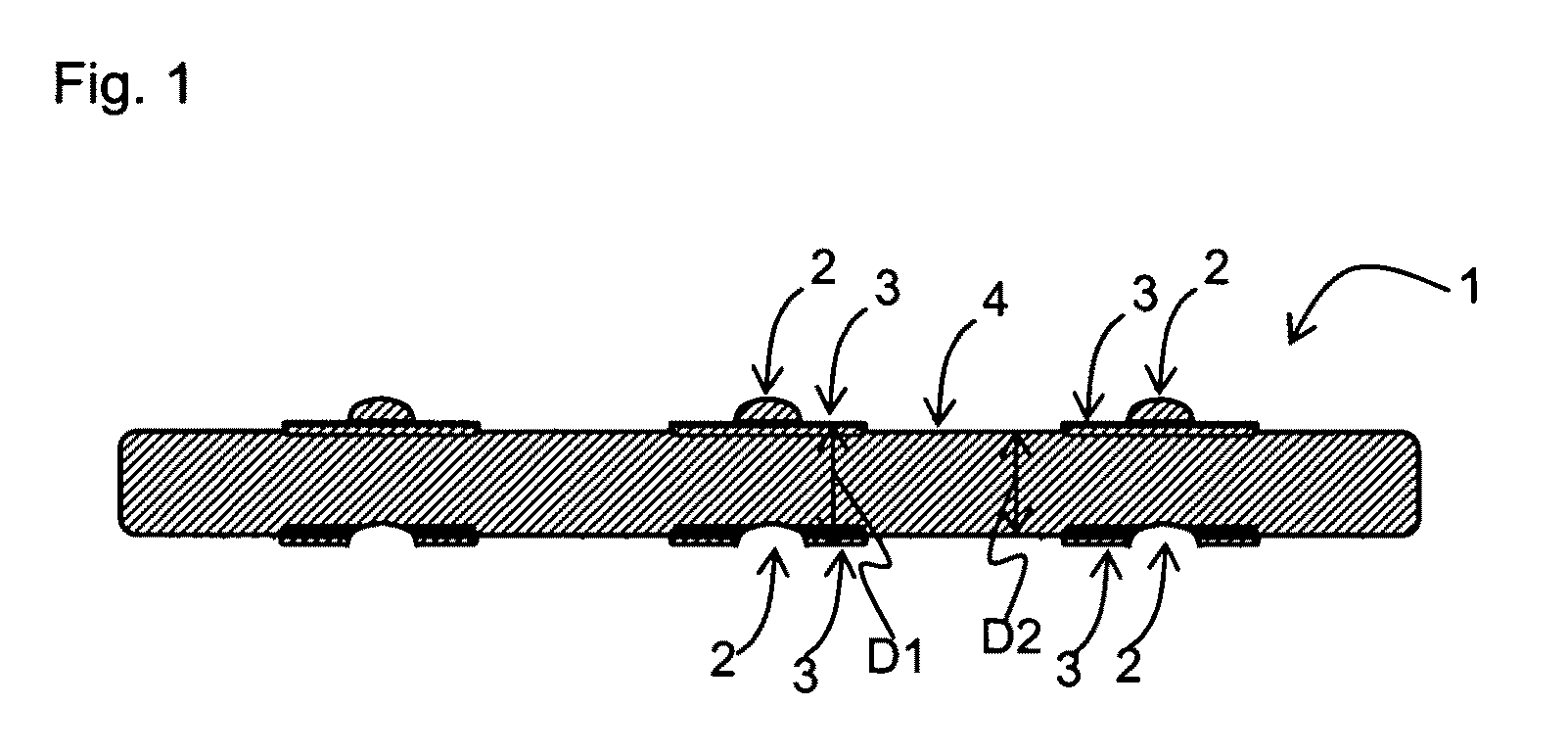

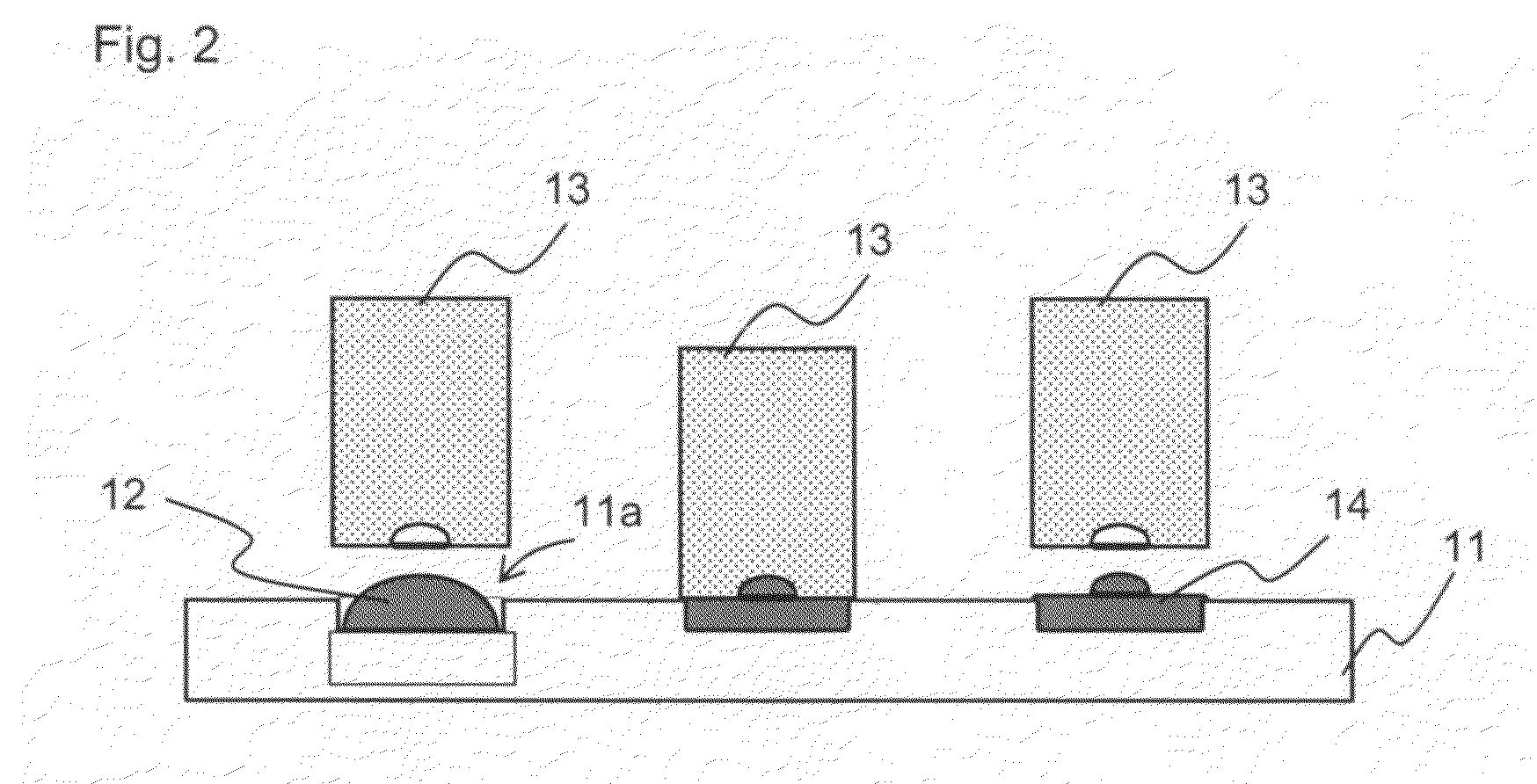

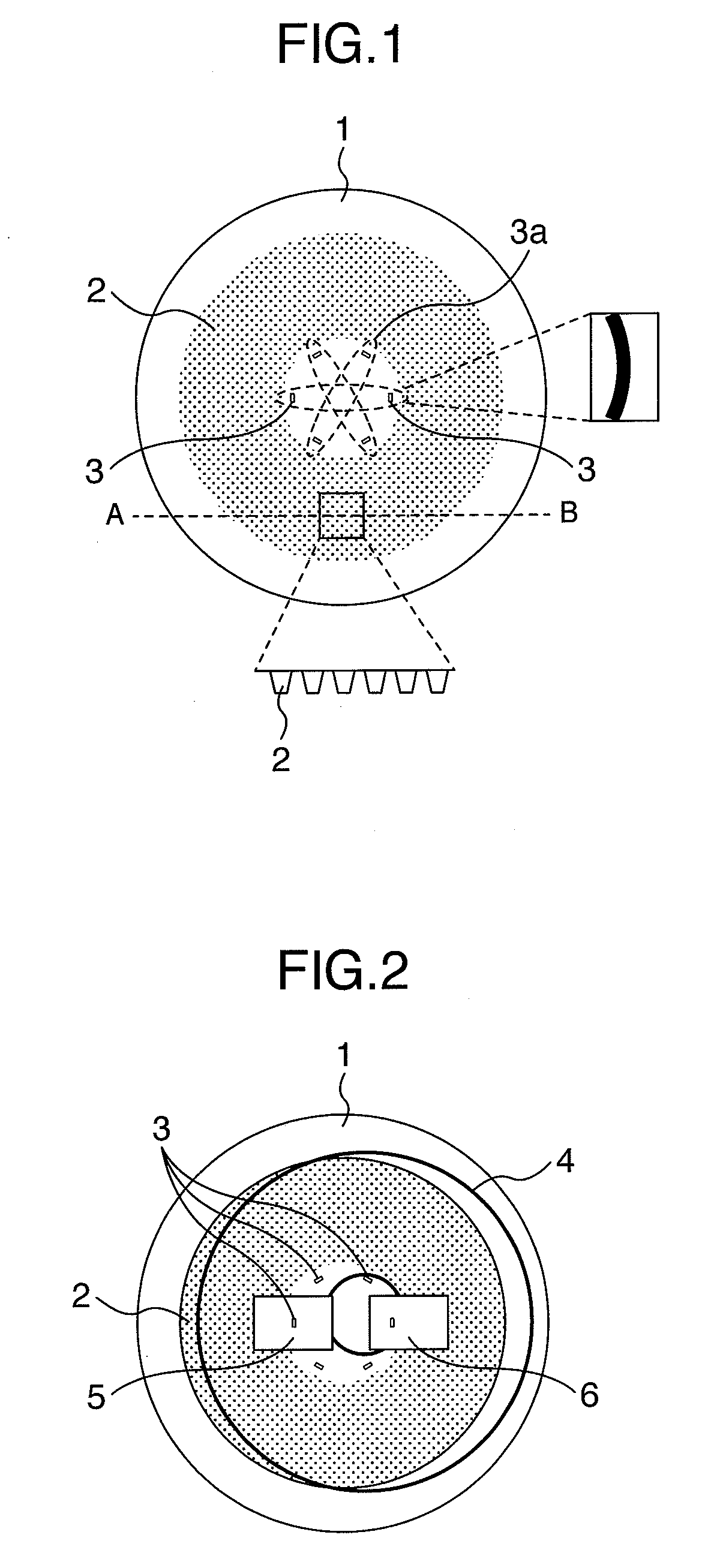

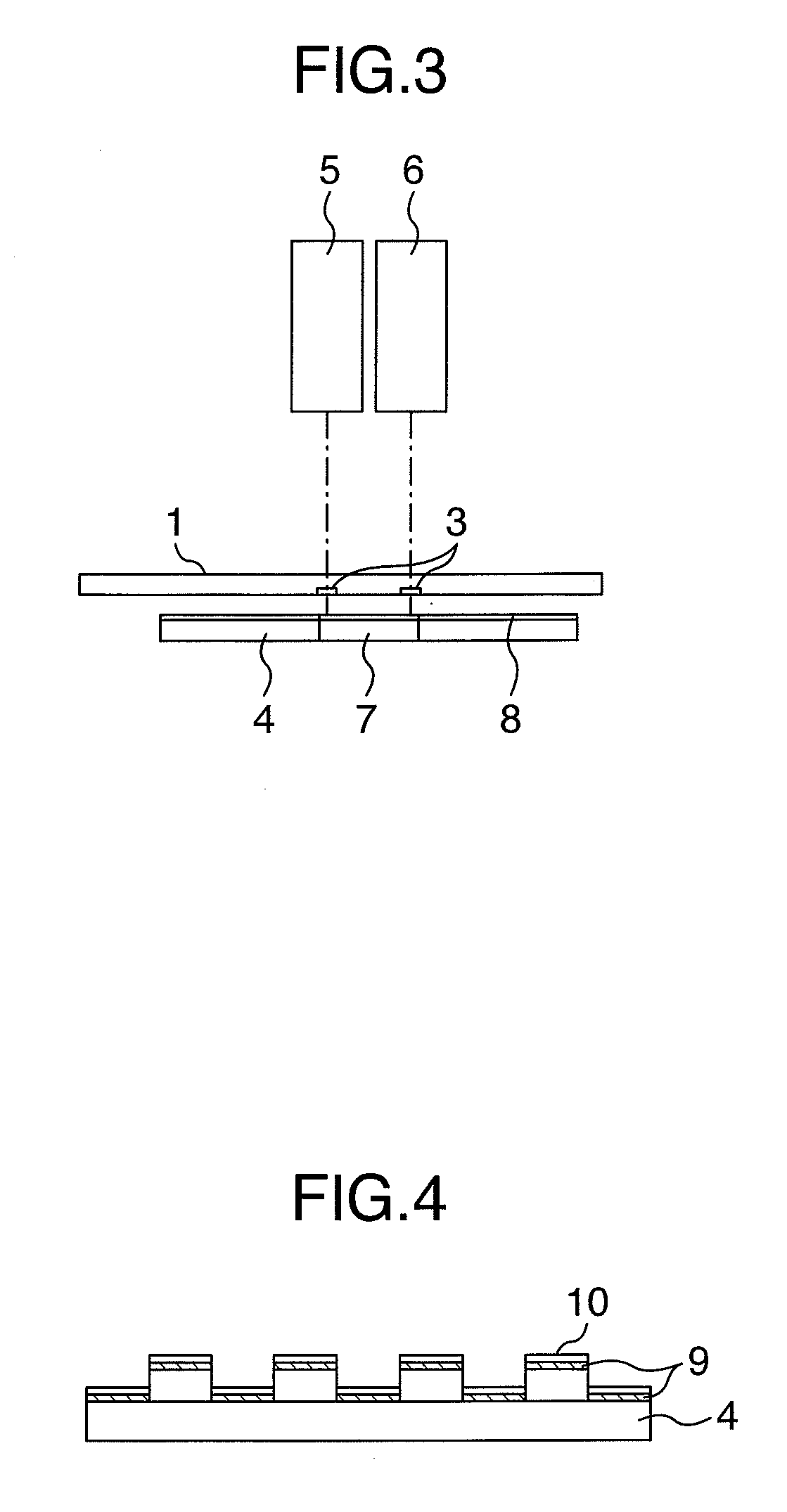

Optical element wafer and method for manufacturing optical element wafer, optical element, optical element module, electronic element wafer module, electronic element module, and electronic information device

InactiveUS20100079642A1Forming accuratelyDifference in levelTelevision system detailsTelevision system scanning detailsComputer moduleEngineering

A method for manufacturing an optical element wafer according to the present invention, in which a plurality of optical elements are arranged in two dimensions, includes: a replica forming step of forming a replica, in which an optical element shape is formed on a front surface side, in each of a plurality of recesses formed in a base; a stamper mold forming step of forming a stamper mold using the optical element shape of the replica; and an optical element wafer forming step of transferring the optical element shape to an optical element material using the stamper mold to form an optical element wafer.

Owner:SHARP KK

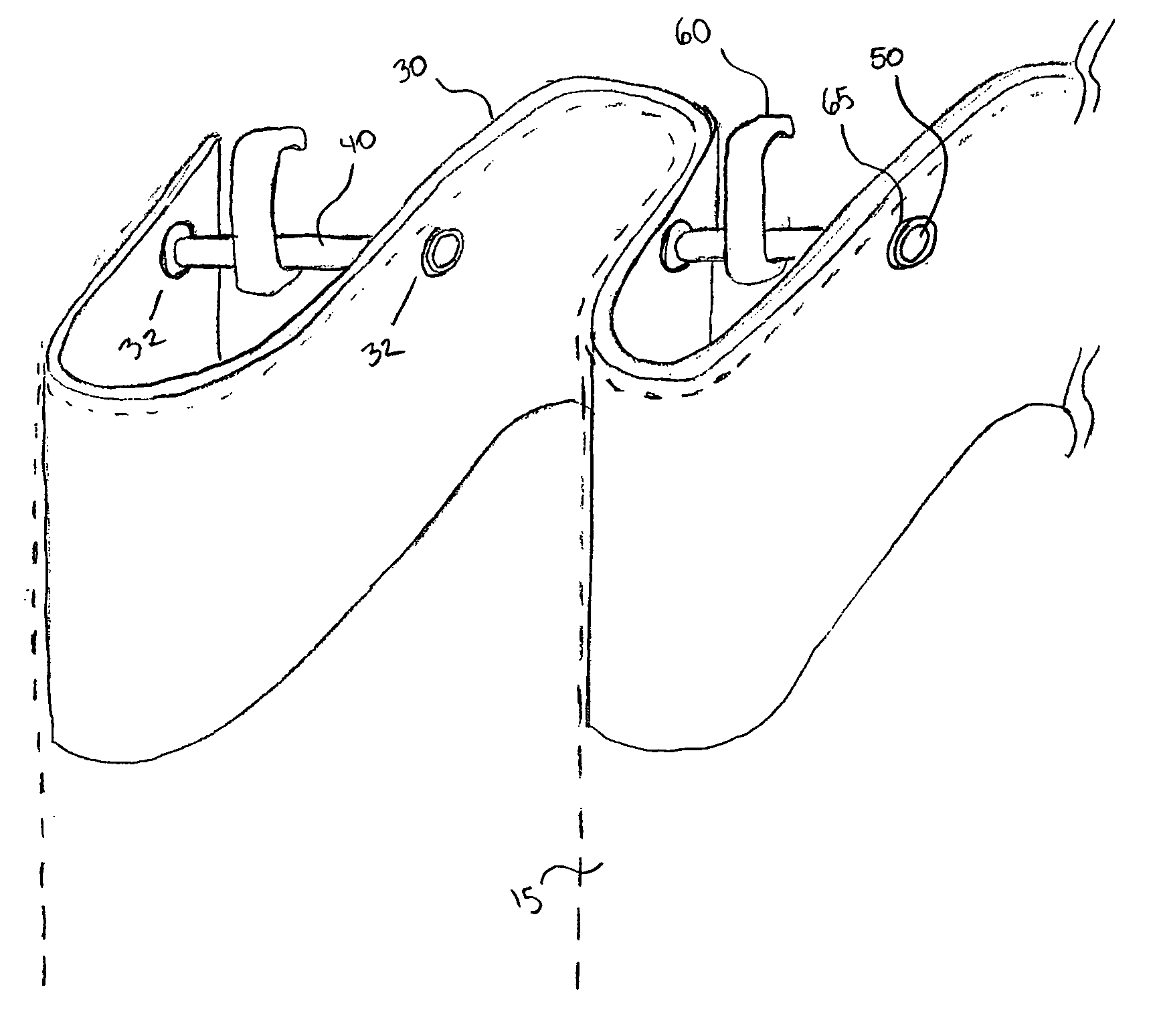

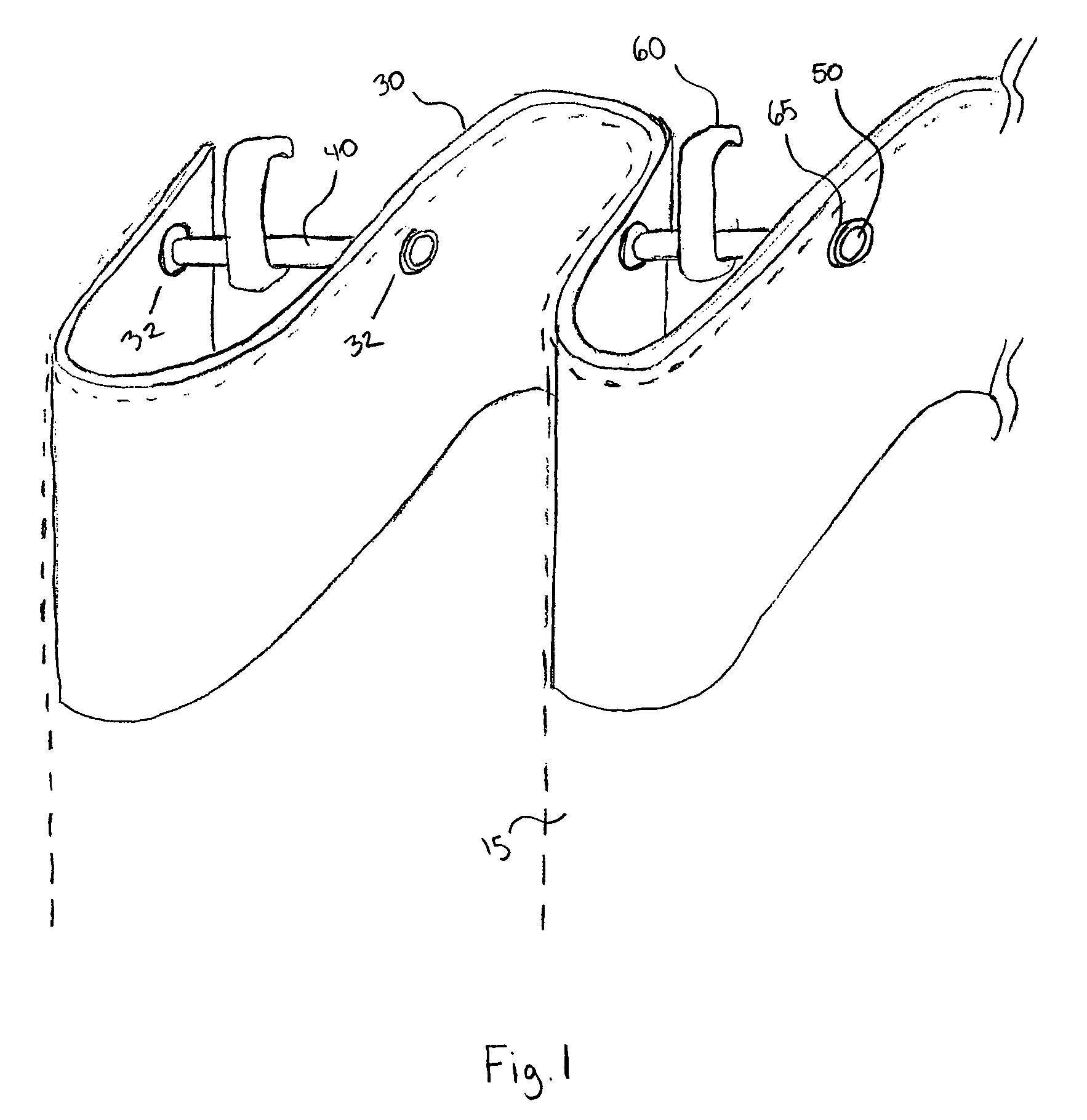

Method and apparatus for producing pleats in curtains and pleated curtains and hanging said curtains using said apparatus

ActiveUS7730931B2Less-time-consuming and labor-intensiveDoor/window protective devicesCurtain suspension devicesEngineeringShape formation

A method and apparatus, for pleating curtains and pleated curtains using the apparatus, are described. The apparatus may be provided as a parts kit which includes a stiffener, pleat-forming members, and fasteners. The stiffener is attached to a curtain and bent into a series of pleat-shaped formations. The pleat-forming members and fasteners are used to hold the stiffener and support the curtain, forming the created pleats in place. The curtain may then be hung on a curtain rod by a separate hanging element which couples the pleat-forming members to a curtain rod. The hanging element may form an integral part of the pleat-forming member.

Owner:STERN MARILYN

Process for producing three-dimensional shaped article

InactiveUS20060290032A1Increase speedHigh transparencyAdditive mnaufacturing with solid and fluidElectric/magnetic/electromagnetic heatingShape formationMaterials science

The present invention relates to a process for producing a three-dimensional model, the process having a high modeling speed and enabling a three-dimensional model having high gloss and transparency to be obtained. The process for producing a three-dimensional model is a process for producing a three-dimensional model that includes a step (layer formation step) of forming above a support a layer containing a powder material, and a step (cross-sectional shape formation step) of imagewise bonding the powder material layer by a binder, (a) the powder material employing a synthetic organic powder, and (b) the binder being cured by actinic radiation.

Owner:FUJIFILM HLDG CORP +1

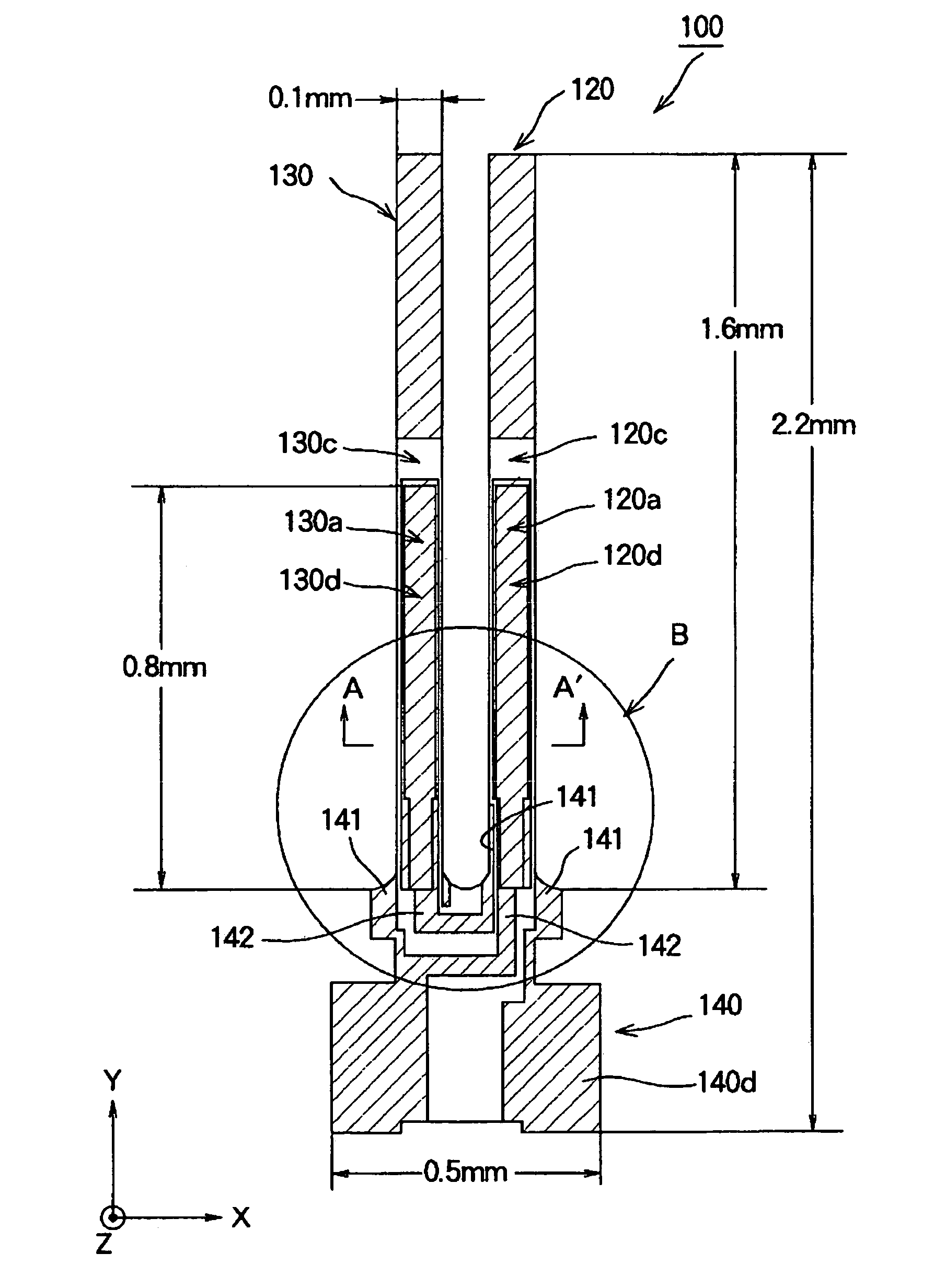

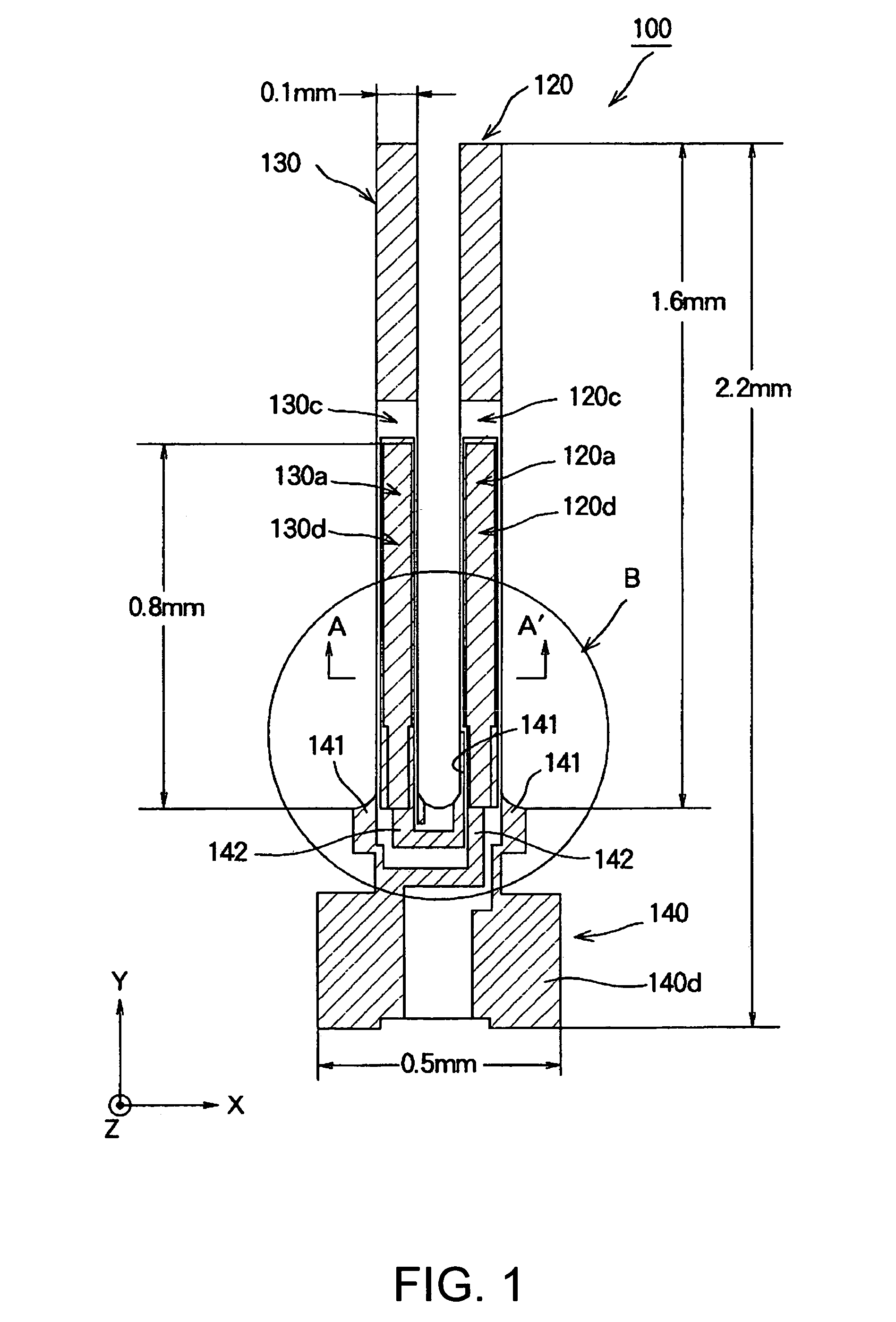

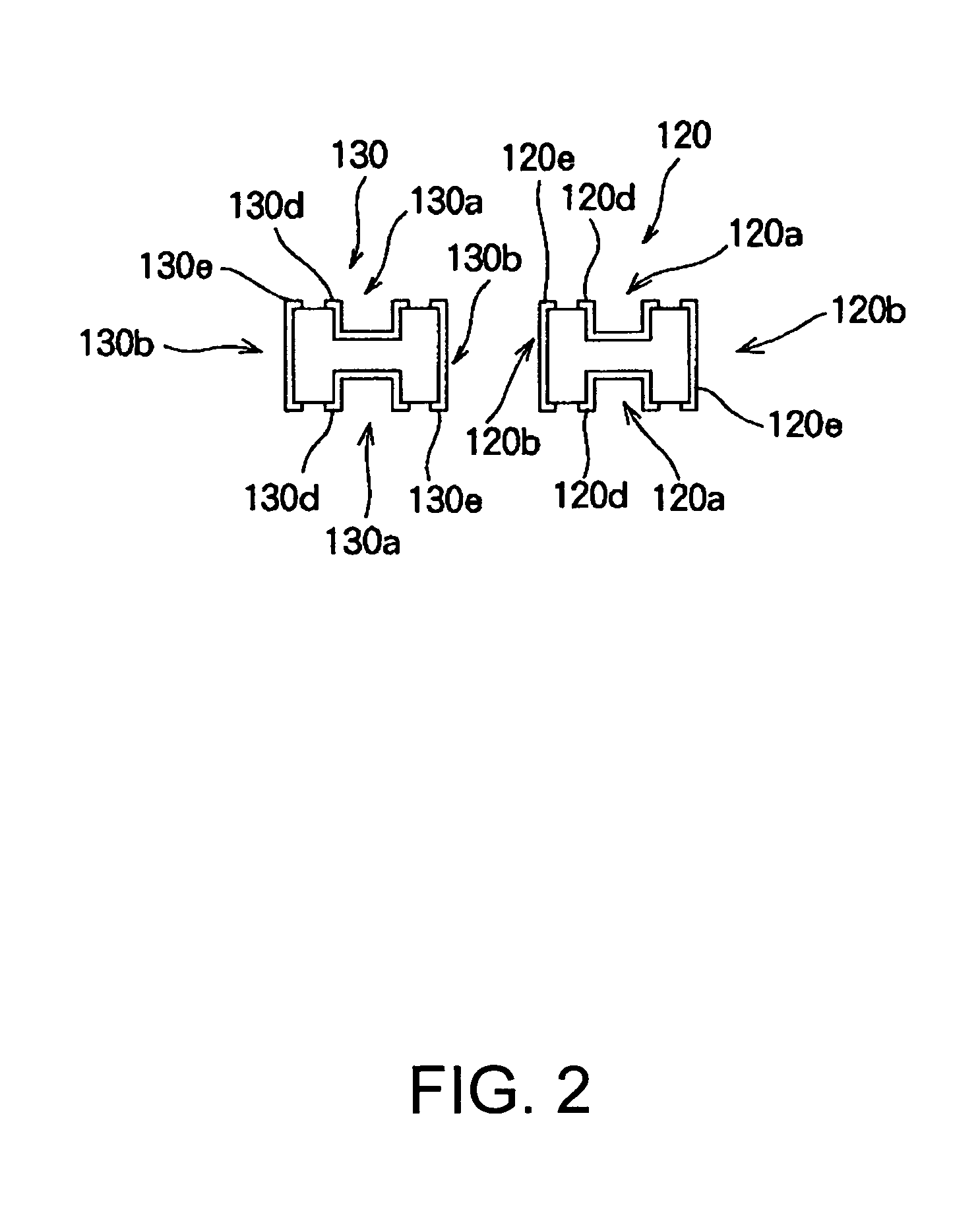

Resonator piece, resonator, oscillator and electronic device

ActiveUS7112915B2Avoid volatilityStable characteristicsImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEngineeringFrequency characteristic

The invention provides a resonator piece, a resonator, an oscillator and an electronic device that can prevent in advance defects from arising in the electrodes and whose frequency characteristics of the resonator piece and CI value are stable. The resonator piece can include a base portion in which a base portion electrode portion is formed, resonating arm portions, groove portions including groove electrode portions, side surface electrode portions, groove electrode-use connection electrode portions, and side surface electrode-use connection electrode portions 141. The width of the base portion side of openings of the groove portions is formed narrower than the width of other portions, with connection electrode disposition portions for disposing the groove electrode-use connection electrode portions or the side surface electrode-use connection electrode portions being formed near the narrowly formed openings of the groove portions, and the shapes of the openings of the groove portions are formed so as to be substantially symmetrical with respect to hypothetical lines disposed along the longitudinal direction at width-direction centers of the groove portions.

Owner:SEIKO EPSON CORP

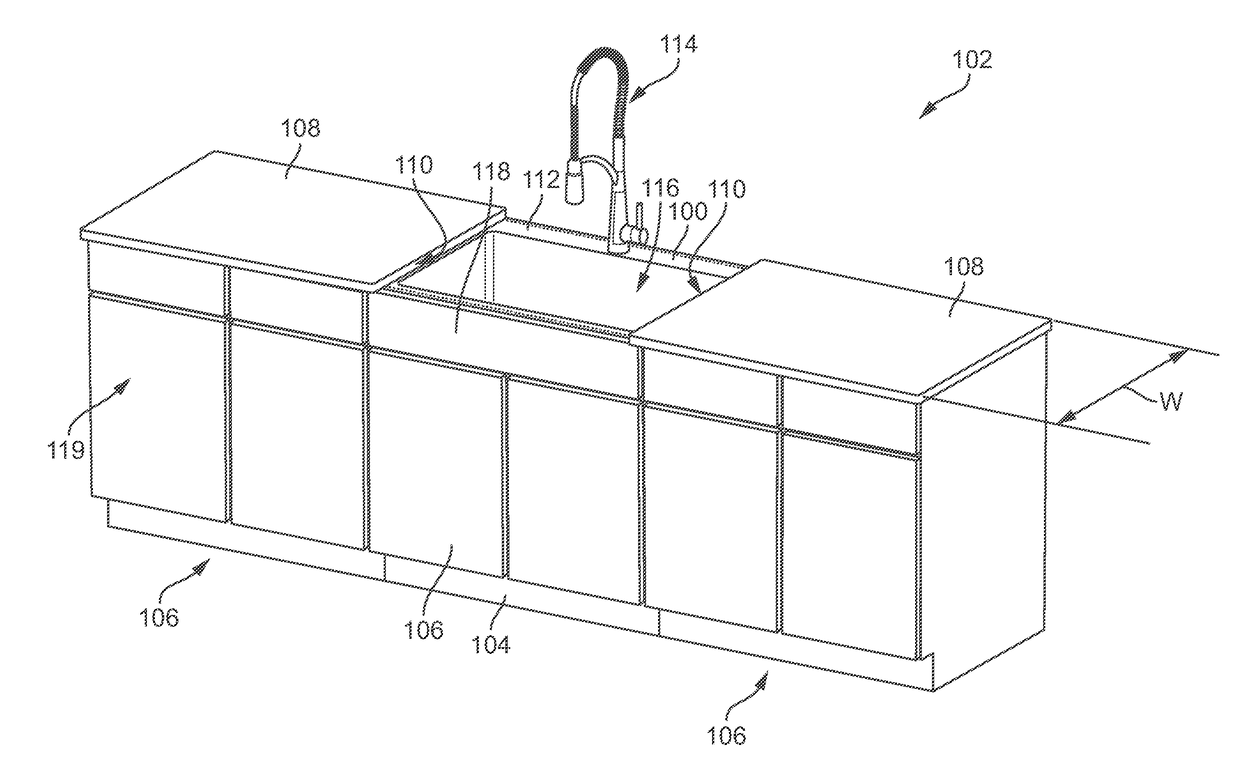

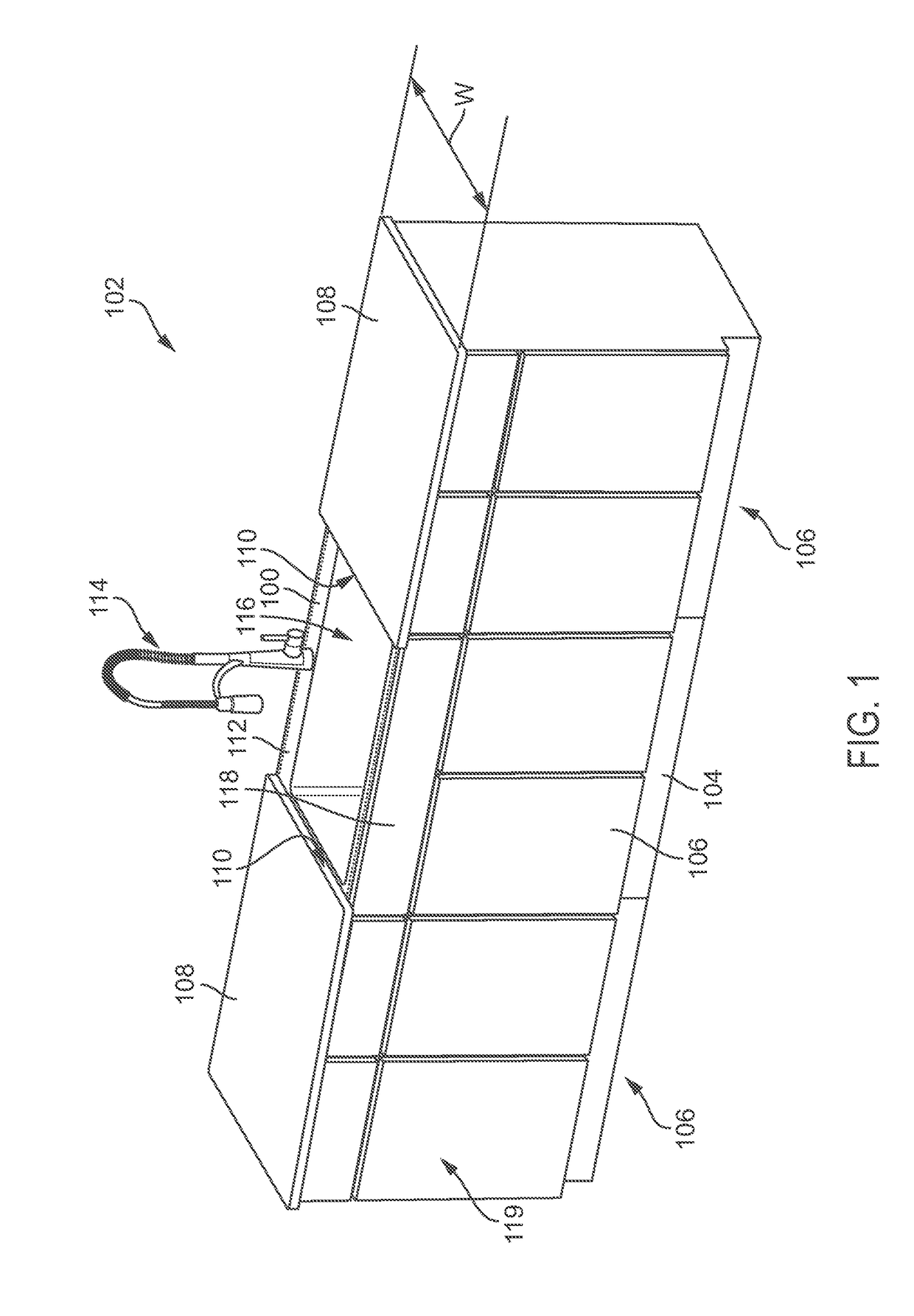

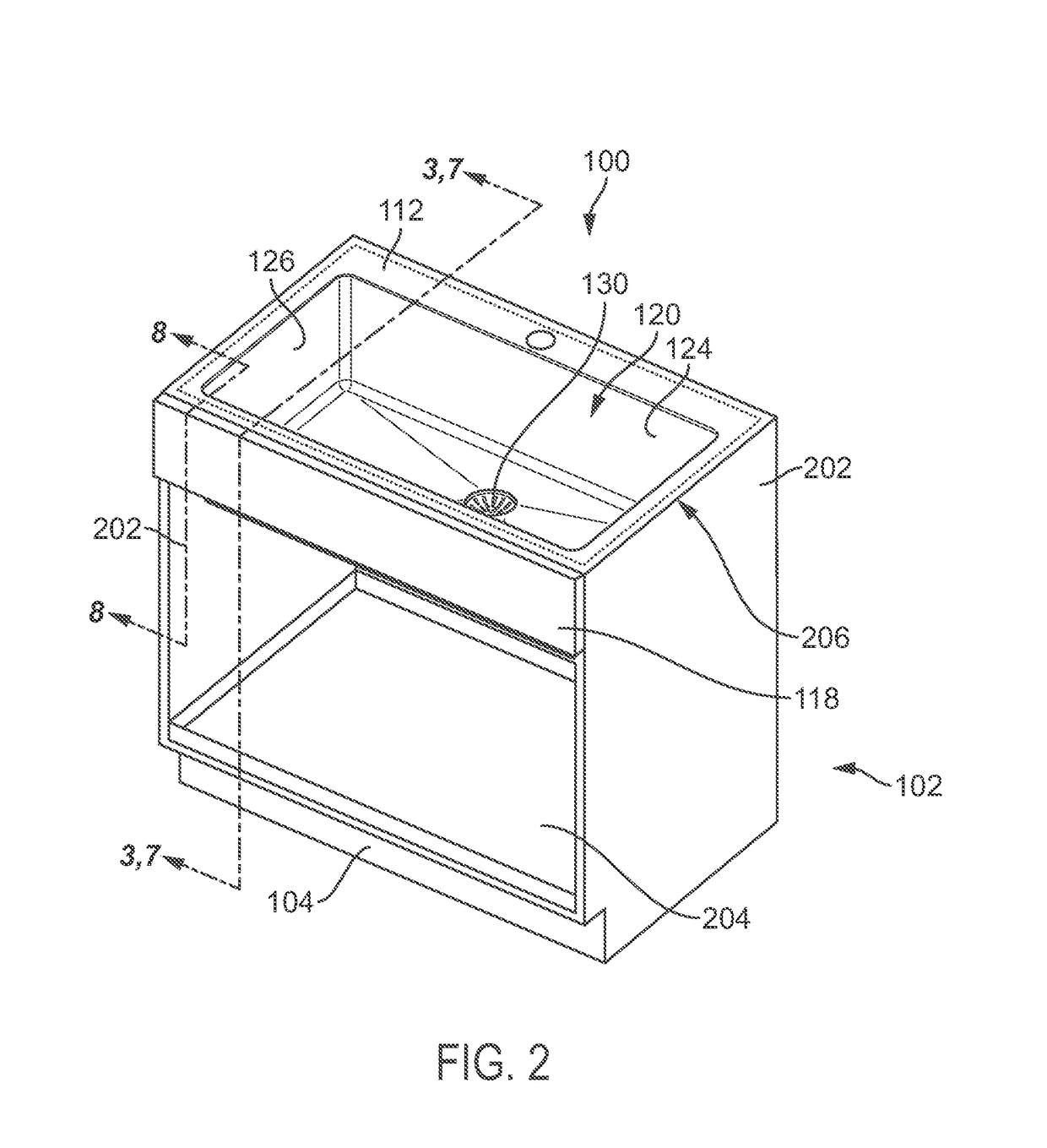

Apron-front sink

A sink includes a basin body having a generally concave shape that forms at least one sink basin, a top flange integrally formed with the basin body, the top flange extending around the at least one sink basin, an apron connected to a front edge of the top flange, a replaceable panel removably connected to the apron, and a fastening system disposed between the apron and the replaceable panel, the fastening system releasably connecting the replaceable panel to the apron.

Owner:ELKAY MFG CO

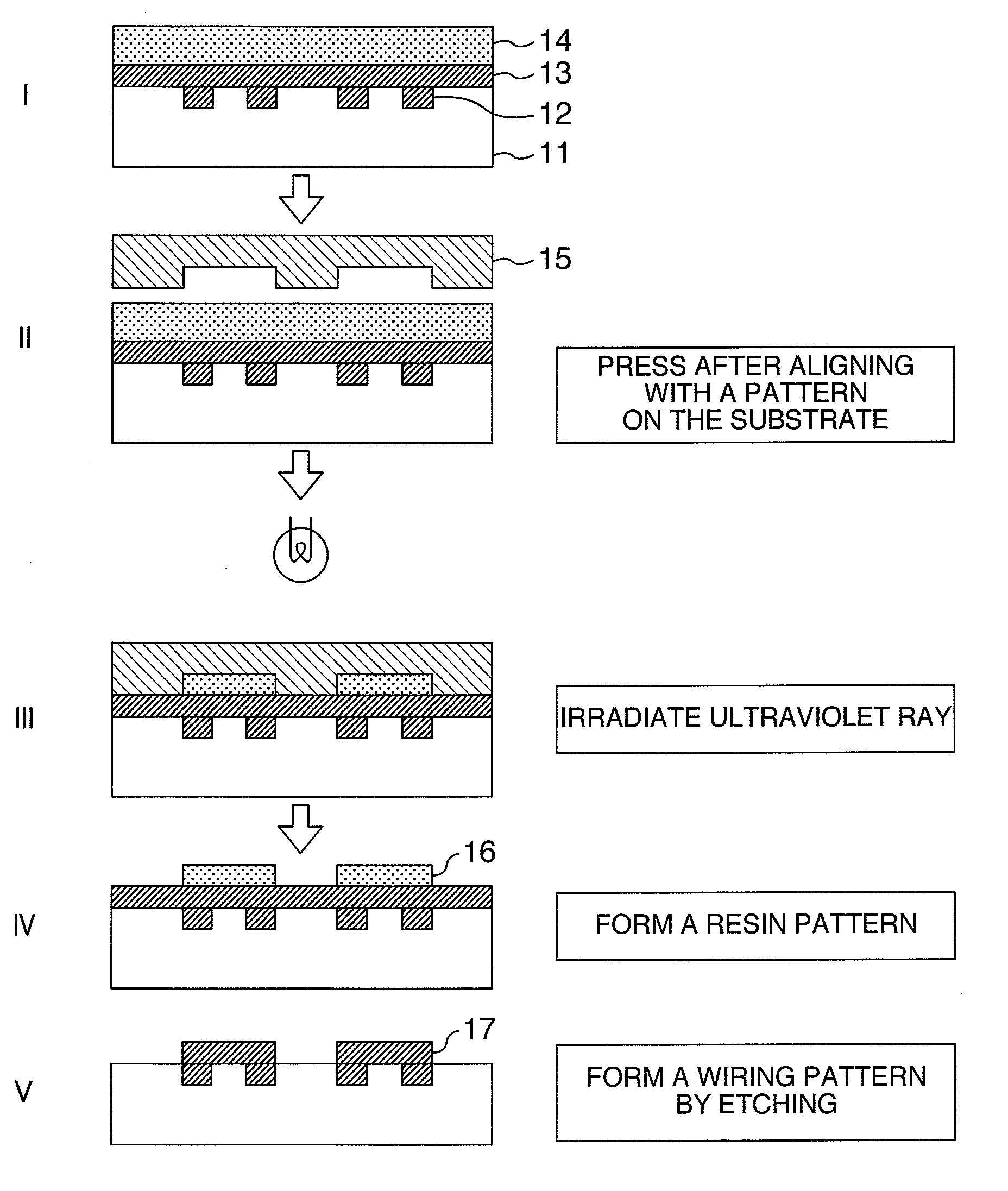

Pattern forming method and its mold

InactiveUS20070164458A1Precise alignmentHigh precision alignmentSemiconductor/solid-state device detailsNanoinformaticsShape formationMaterials science

Owner:HITACHI LTD

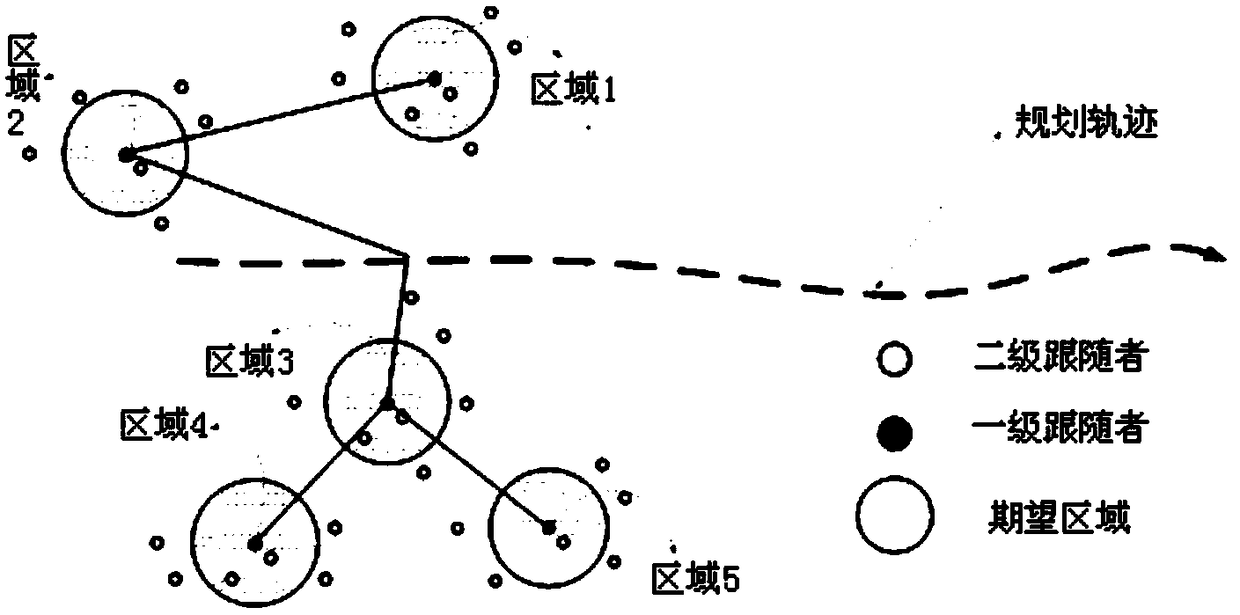

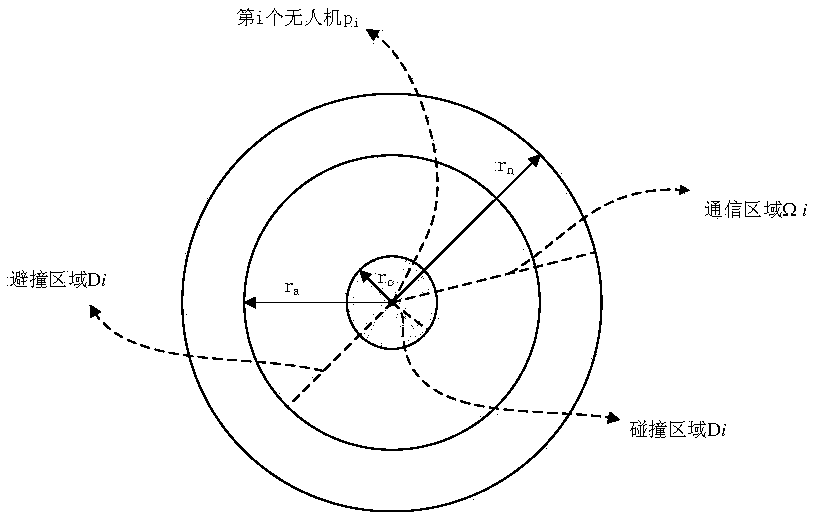

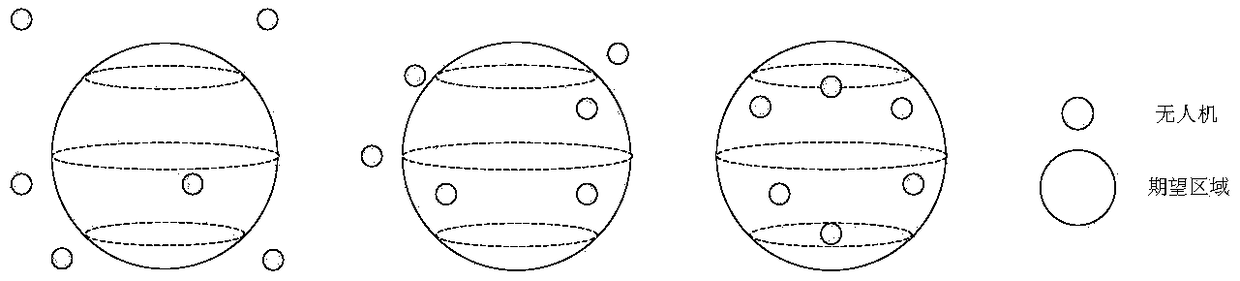

Multi-area classified unmanned aerial vehicle formation route planning method based on distributed control

ActiveCN109508035AHigh precisionImprove efficiencyPosition/course control in three dimensionsCollision detectionPotential field

The invention discloses a multi-area classified unmanned aerial vehicle formation route planning method based on distributed control. The multi-area classified unmanned aerial vehicle formation routeplanning method comprises the steps that unmanned aerial vehicles are distributed into virtual leading vehicles and member vehicles to build an unmanned aerial vehicle multi-area classified control formation network frame; formation is conducted on each area; a constraint function is set, and based on the constraint function, all unmanned aerial vehicles in each area are subjected to formation toform a formation shape corresponding to the constraint function; shape formation is conducted on all the areas; an interarea distance time varying function is set, and a distributed control strategy is adopted to build communication mechanisms between adjacent areas, so that the shape formation of the areas is controlled; by utilizing a collision cone collision detection condition, an obstacle repulsion potential field determination coefficient is designed, the adverse effect on the unmanned aerial vehicle formation generated by the potential field of irrelevant obstacles is eliminated, it isguaranteed that the unmanned aerial vehicles are subjected to formation under the control of a controller, and thus the formation route planning speed is increased; the multi-area classified unmannedaerial vehicle formation route planning method based on distributed control can increase the formation planning speed and achieve multi-area classified formation control of the unmanned aerial vehicles.

Owner:NANJING UNIV OF POSTS & TELECOMM

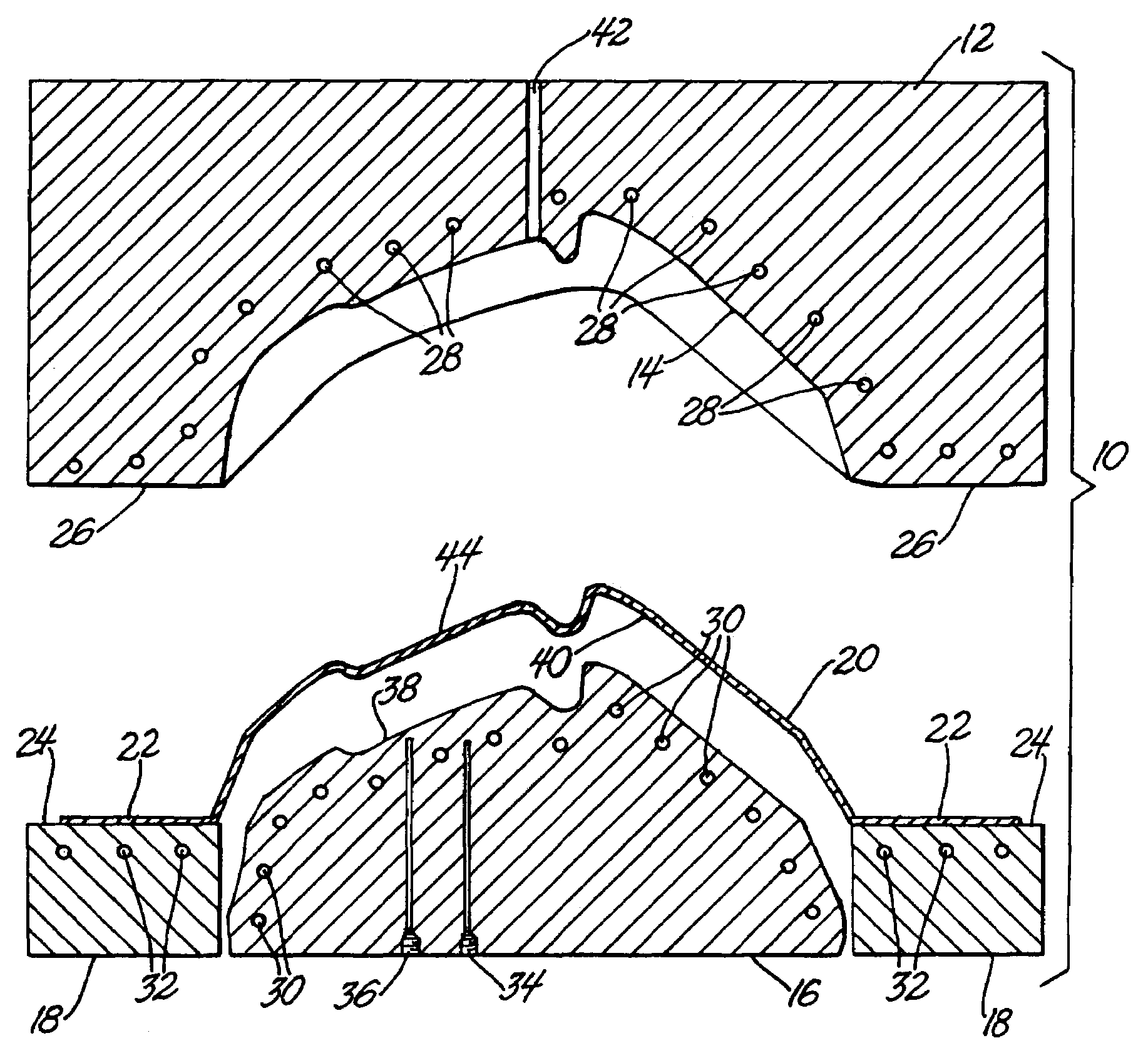

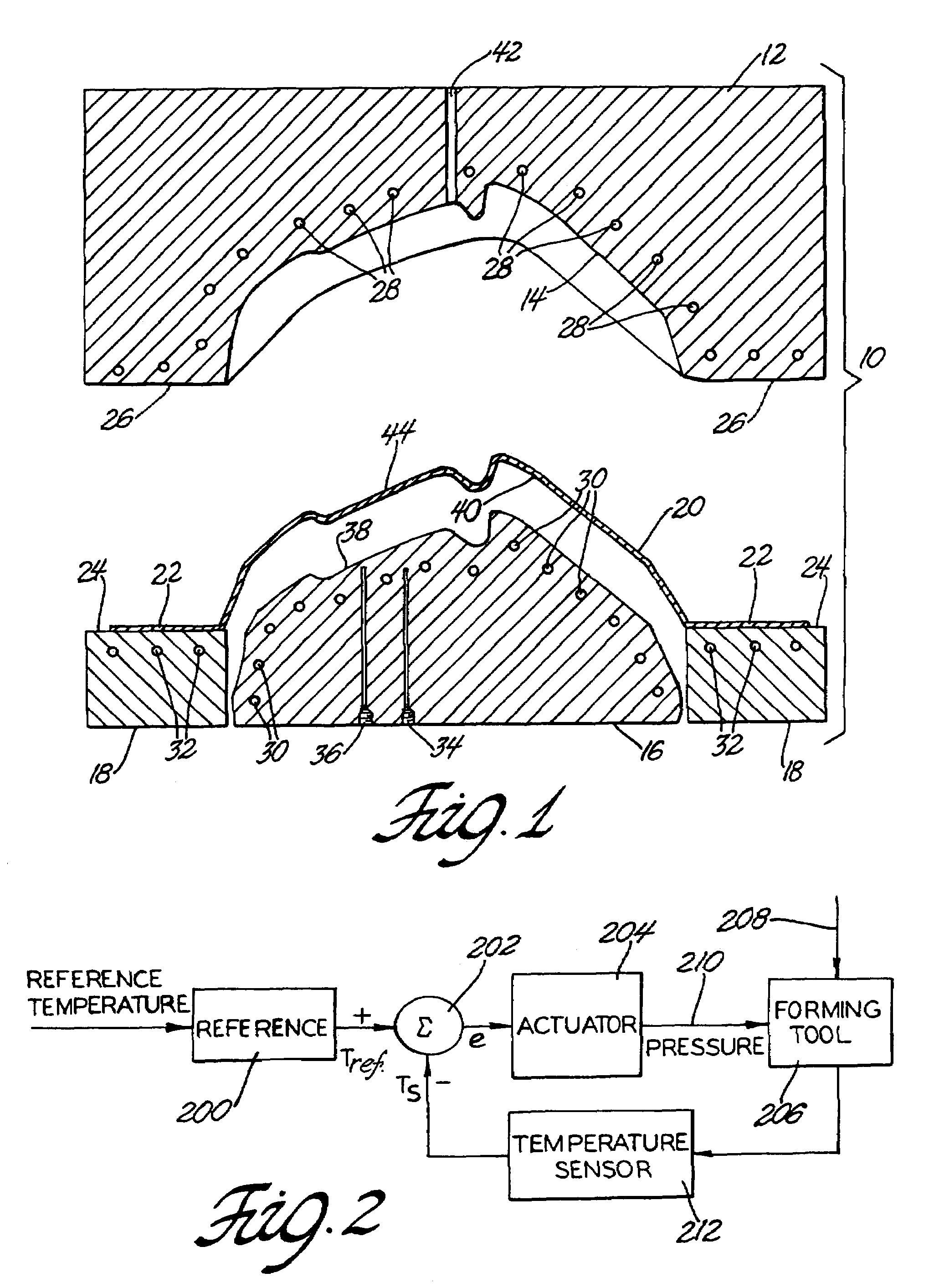

Hot blow forming control method

ActiveUS7112249B2Easy temperature controlRapid and but defect free shapingShaping toolsHeat treatment process controlTime scheduleProduct gas

A sheet material is gripped at its edges and hot blow formed by a pressurized working gas against a forming tool surface. The flow characteristics of the material are determined at increasing gas pressures over a range of temperature relevant to the forming operation. A predetermined pressure / time schedule is determined at a reference temperature for rapid shape formation of good parts on a continual basis. The process is then controlled as parts are thus formed by measuring the forming temperature of the parts and correcting the pressure time schedule, using the determined flow characteristics, for the actual temperature to achieve the desired shape evolution of the parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

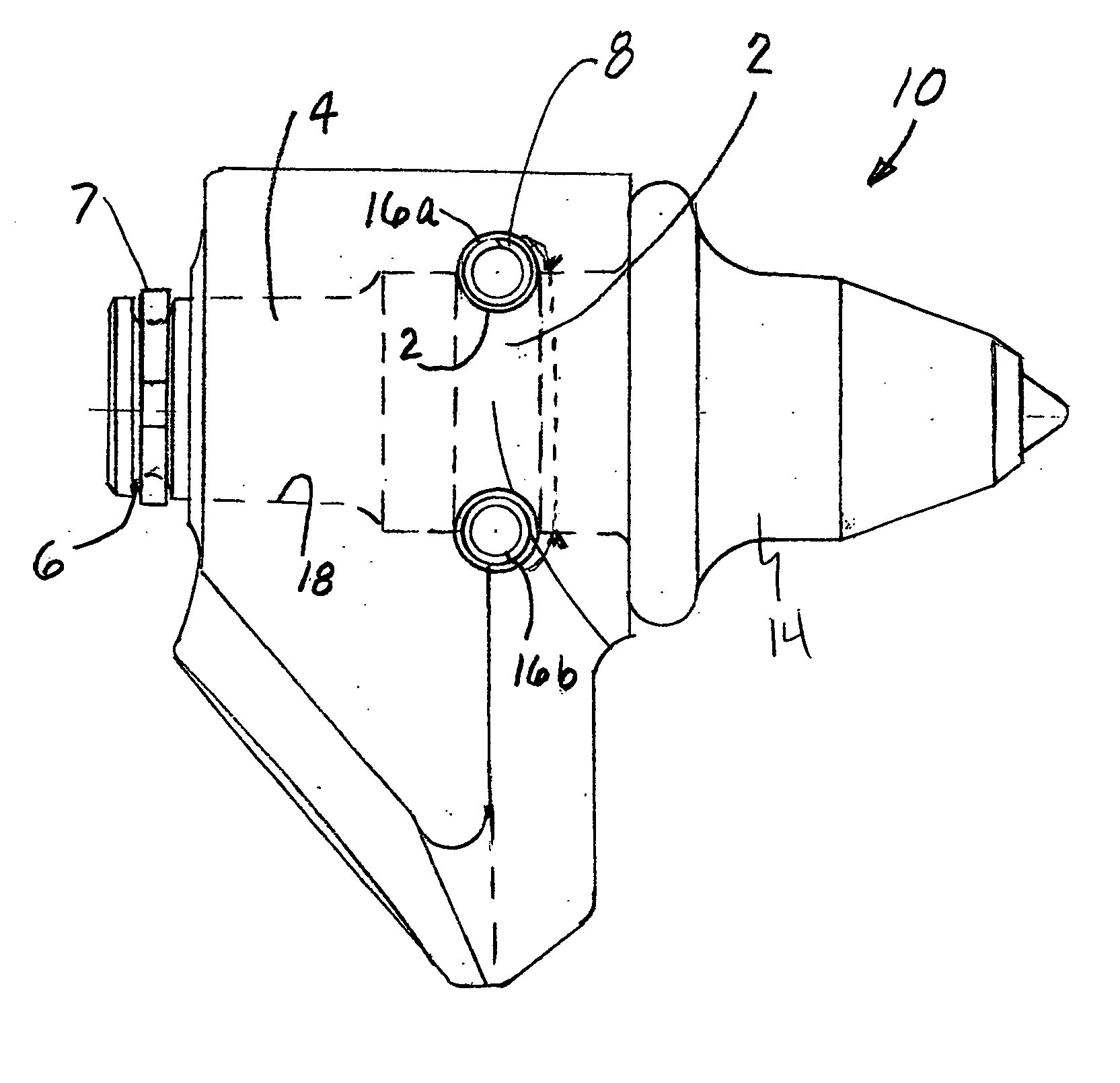

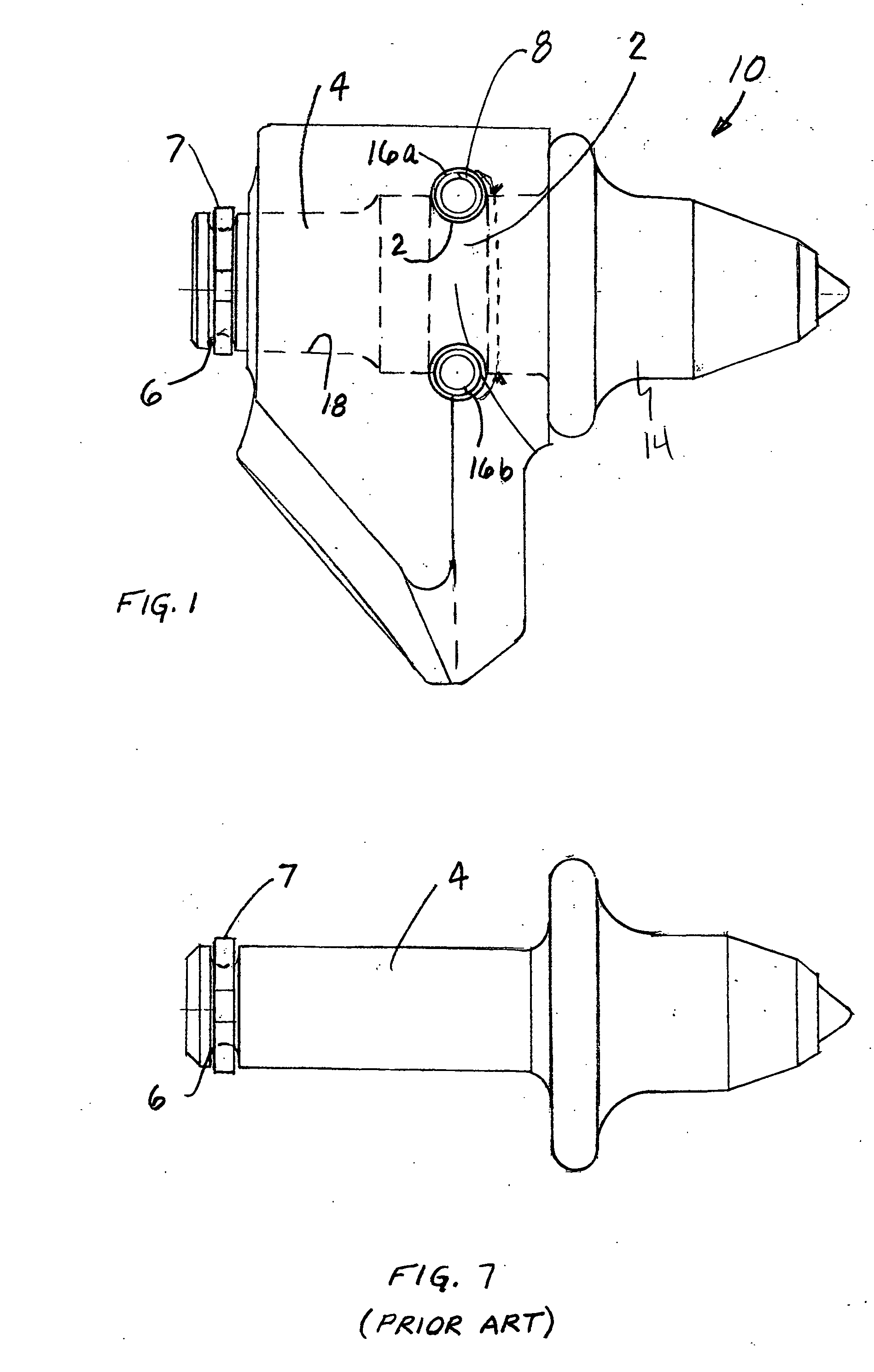

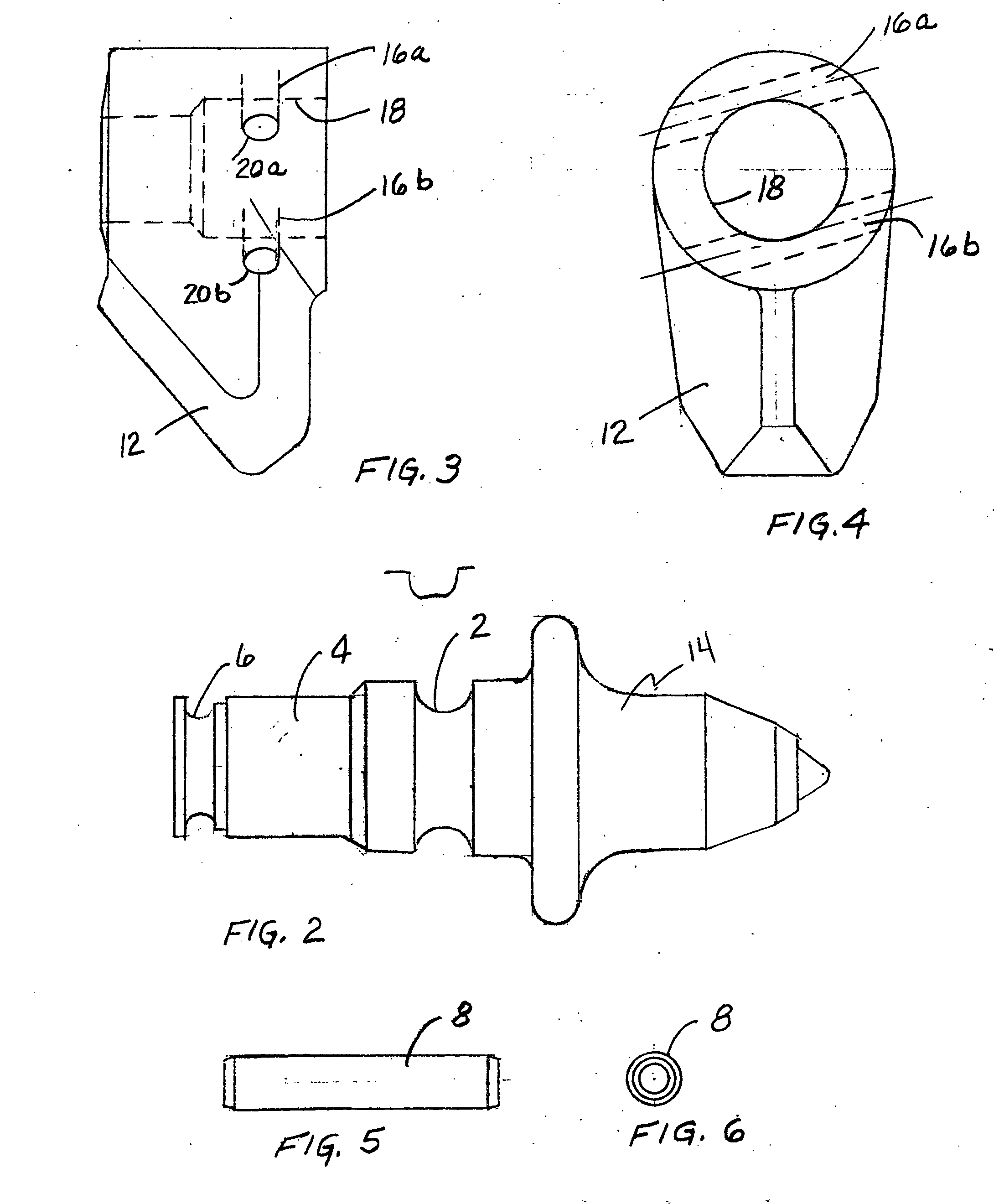

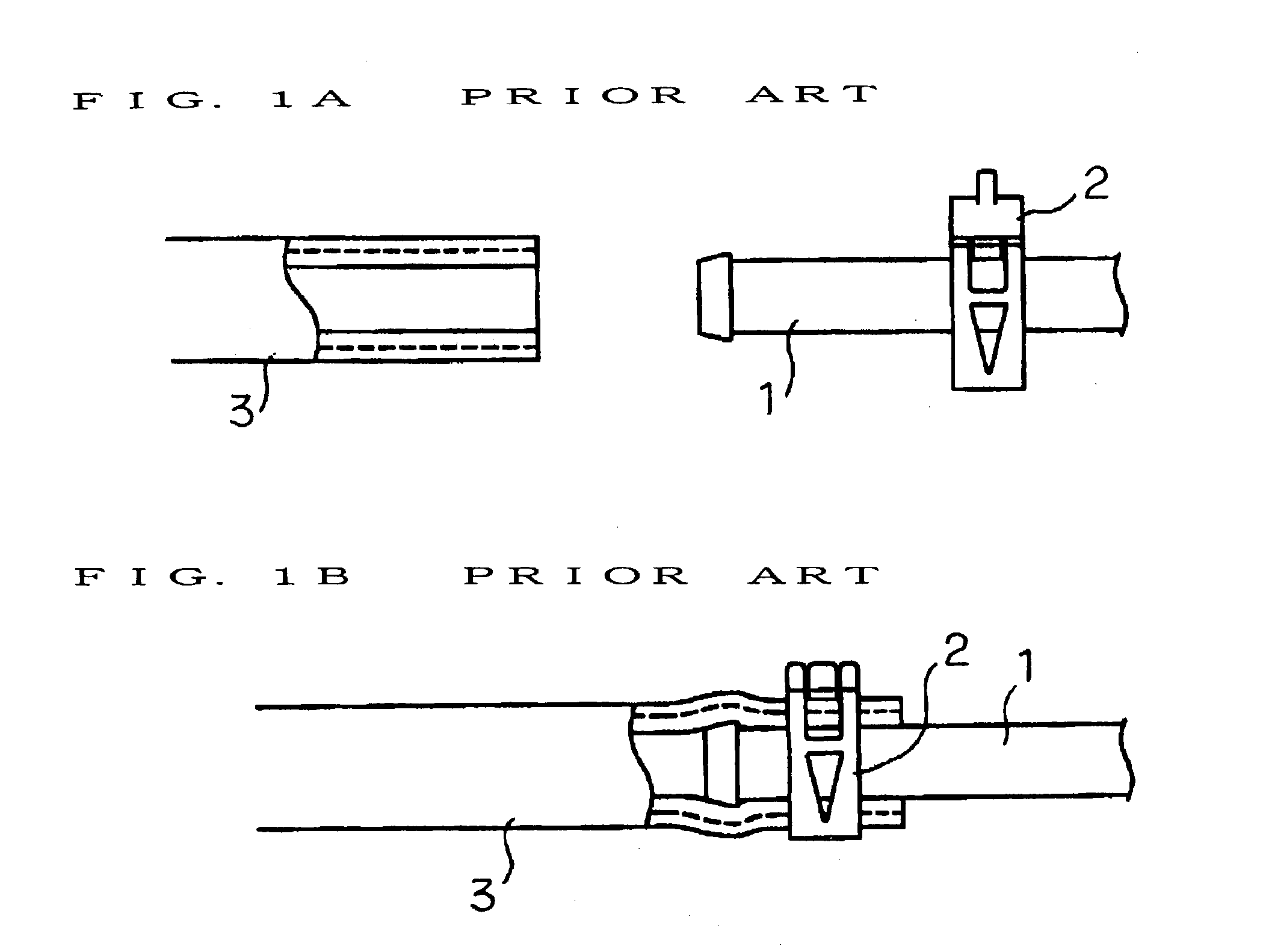

Retaining system for securing a cutting tool to a support block

InactiveUS20050127742A1Easy to disassembleEasy to manufactureSlitting machinesCutting machinesEngineeringMechanical engineering

The present invention provides an improved retaining system for securing a cutting tool to a support block. The retaining system includes at least one groove, having a first predetermined shape, formed in an outer surface of a shank portion of the cutting tool. The groove is formed in a direction transverse to a longitudinal axis of the shank. There is at least one groove, having a second predetermined shape, formed in a surface of a bore formed through an axis of the support block for receiving the shank portion of the cutting tool. The at least one groove formed in the outer surface of the shank portion of the cutting tool is radially opposed to the at least one groove formed in the surface of the bore formed through the axis of the support block when the shank portion is inserted into the bore of the support block. The final essential element of the retaining system is at least one pin member engageable with each of at least one groove formed in the outer surface of such shank portion of the cutting tool and the at least one groove formed in the surface of the bore formed through the axis of the support block for securing the cutting tool to the support block.

Owner:RIVER CITY MFG

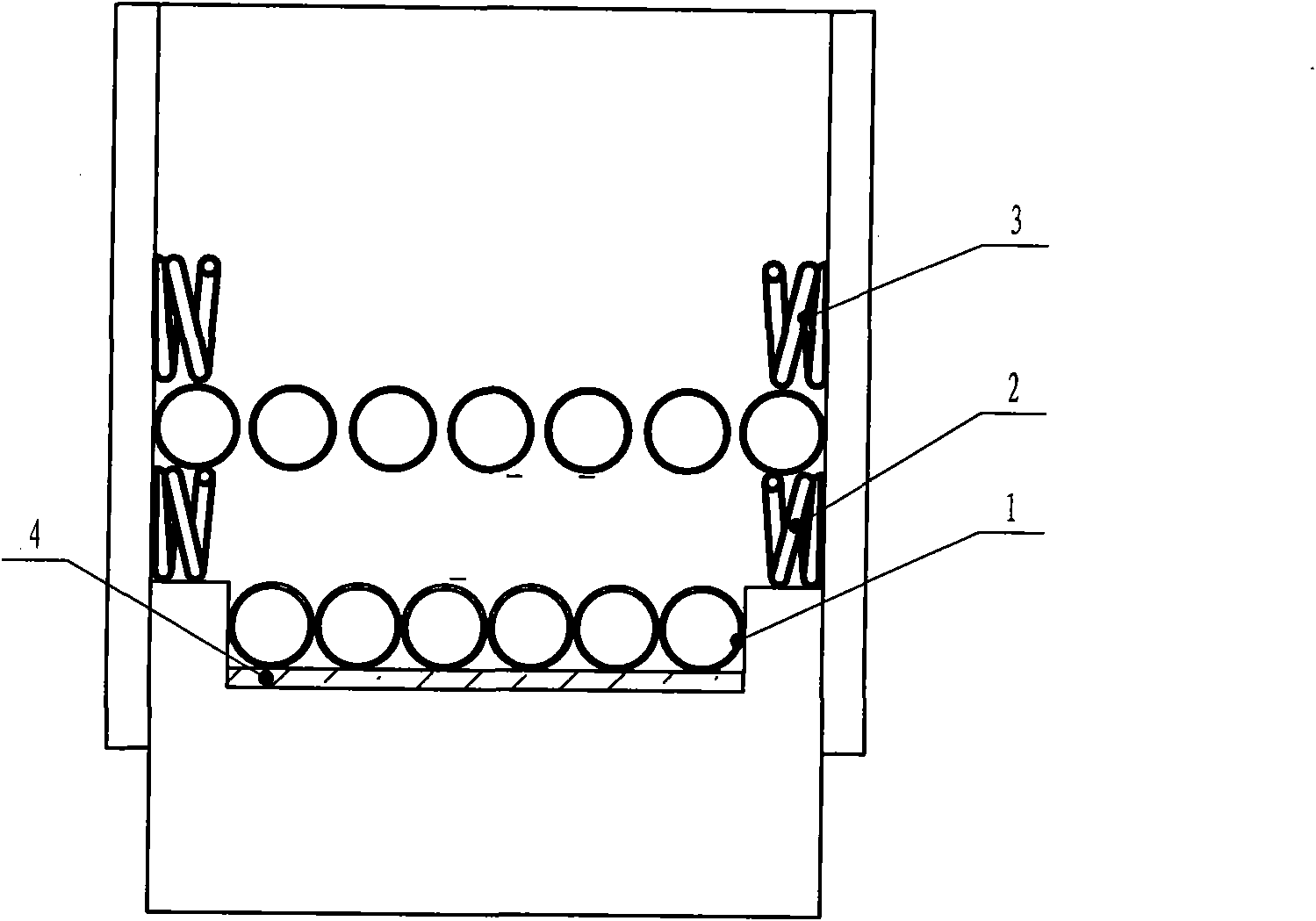

Method for plugging dummy bar head

InactiveCN101890487AGuaranteed StrengthHelps control flow directionMolten steelUltimate tensile strength

The invention belongs to the field of stainless steel billet continuous casting production, and in particular relates to a method for plugging a dummy bar head. The method comprises the following steps of: 1, plugging a gap between the dummy bar head and a crystallizer by using an asbest rope; 2, spreading nail scraps with thickness of 10 to 15mm over the upper part of the dummy bar head and the copper pipe corner part of the crystallizer; 3, putting a first layer of springs on the bottommost layer in a groove of the dummy bar head in a direction perpendicular to the copper pipe of the crystallizer; 4, overlaying a second layer of springs on the groove, wherein the second layer of springs are crossed with the first layer of springs; 5, putting a third layer of springs which are parallel to the first layer of springs; and 6, putting a fourth layer of springs which are parallel to the second layer of springs. The method can guarantee the strength of cold materials and prevent partial collapse; meanwhile, a molten steel flowing channel is formed by using shape of the spring to help to control molten steel flowing direction. The method has the advantages of uniformly cooling a billet head and avoiding accidents of decoupling at the start and bleeding out in gating practice along with good molten steel filling state in the dummy bar head.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

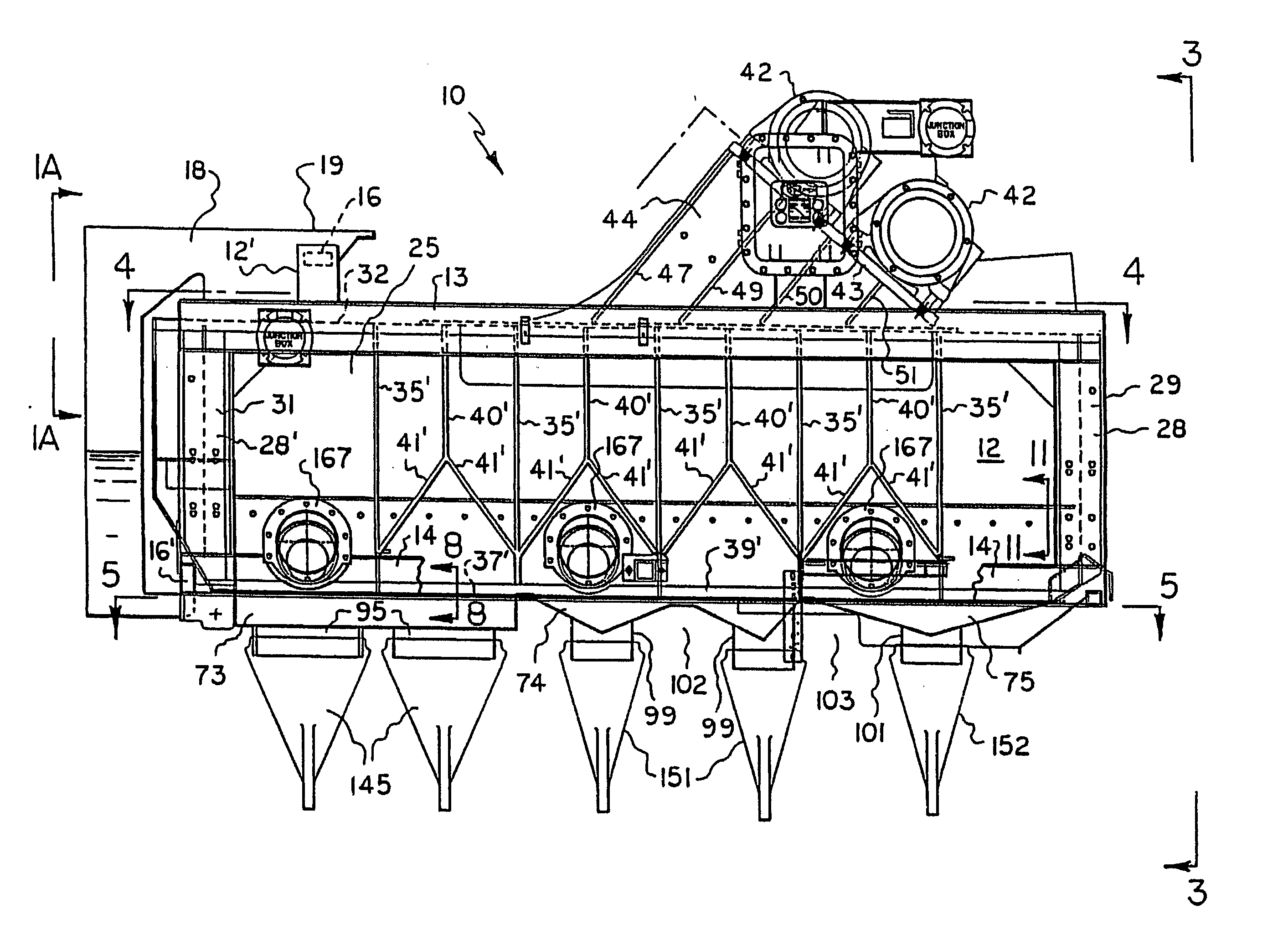

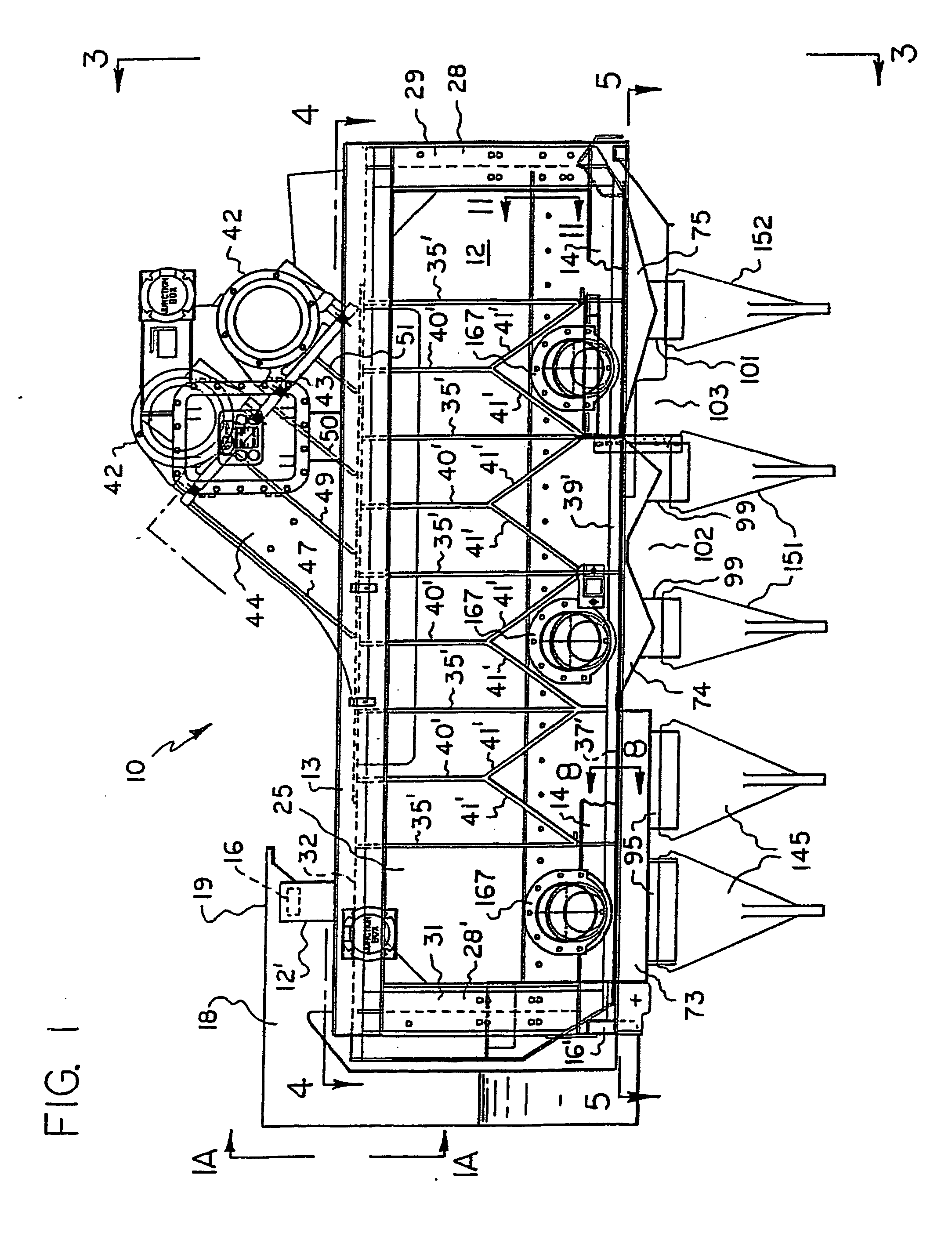

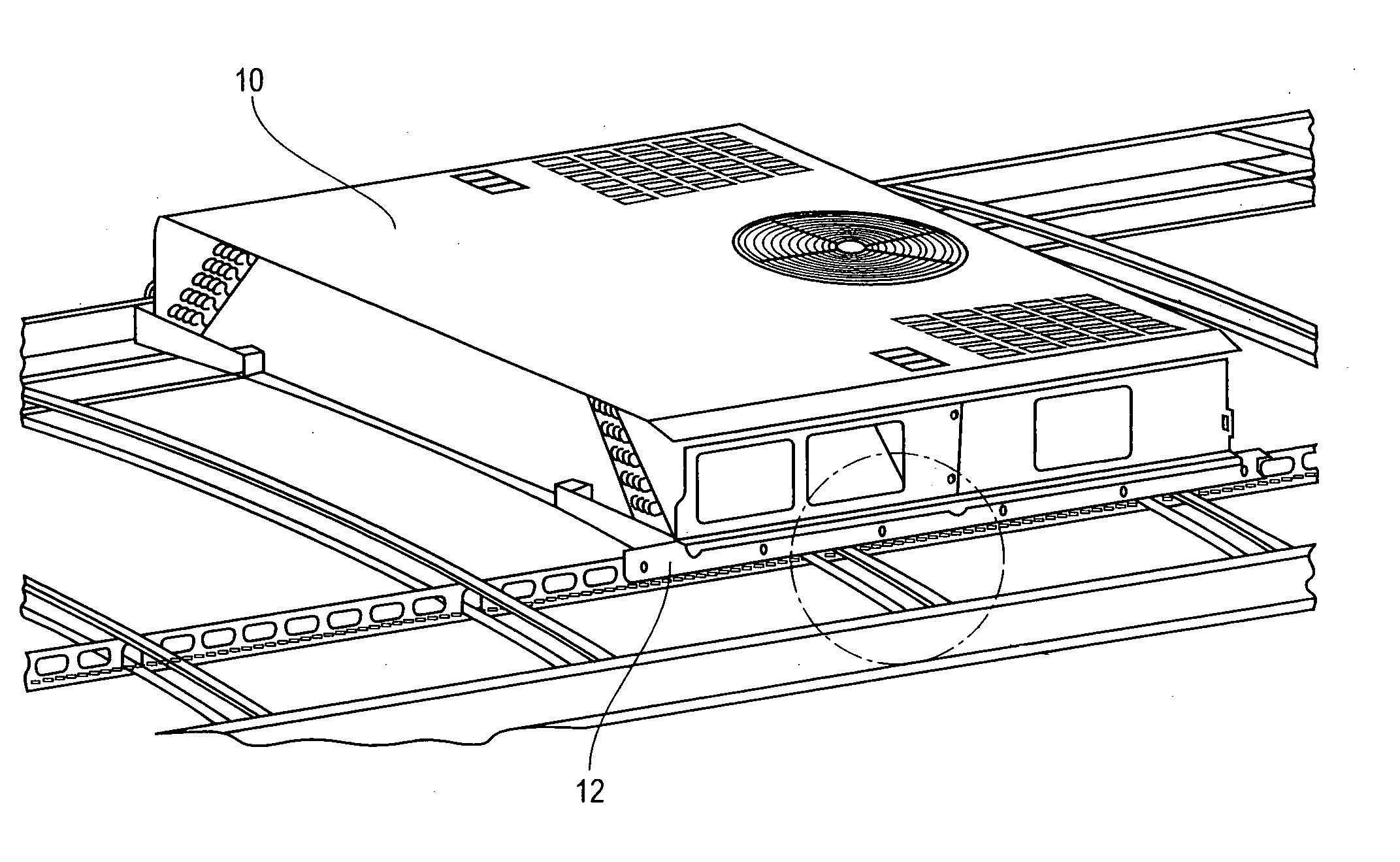

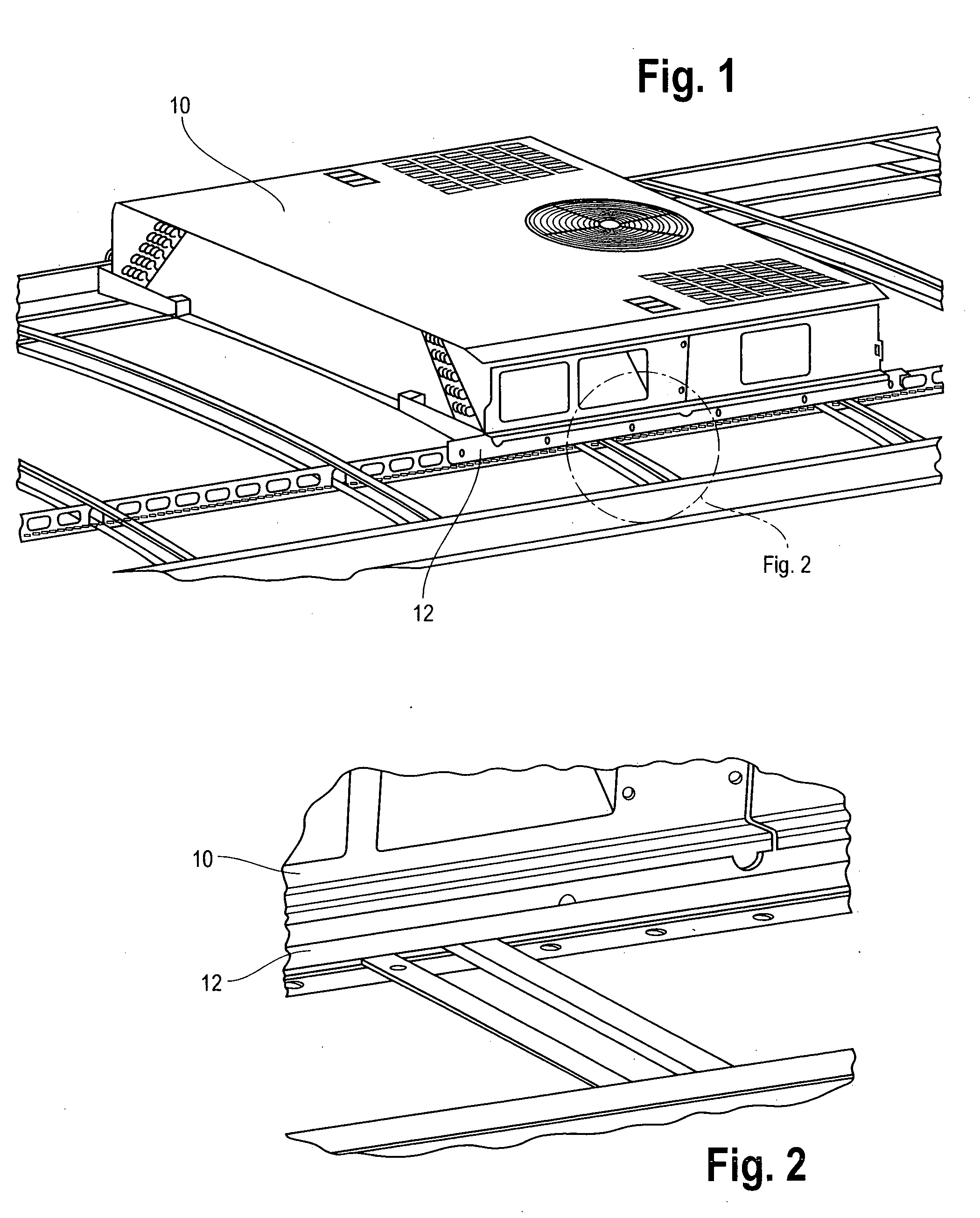

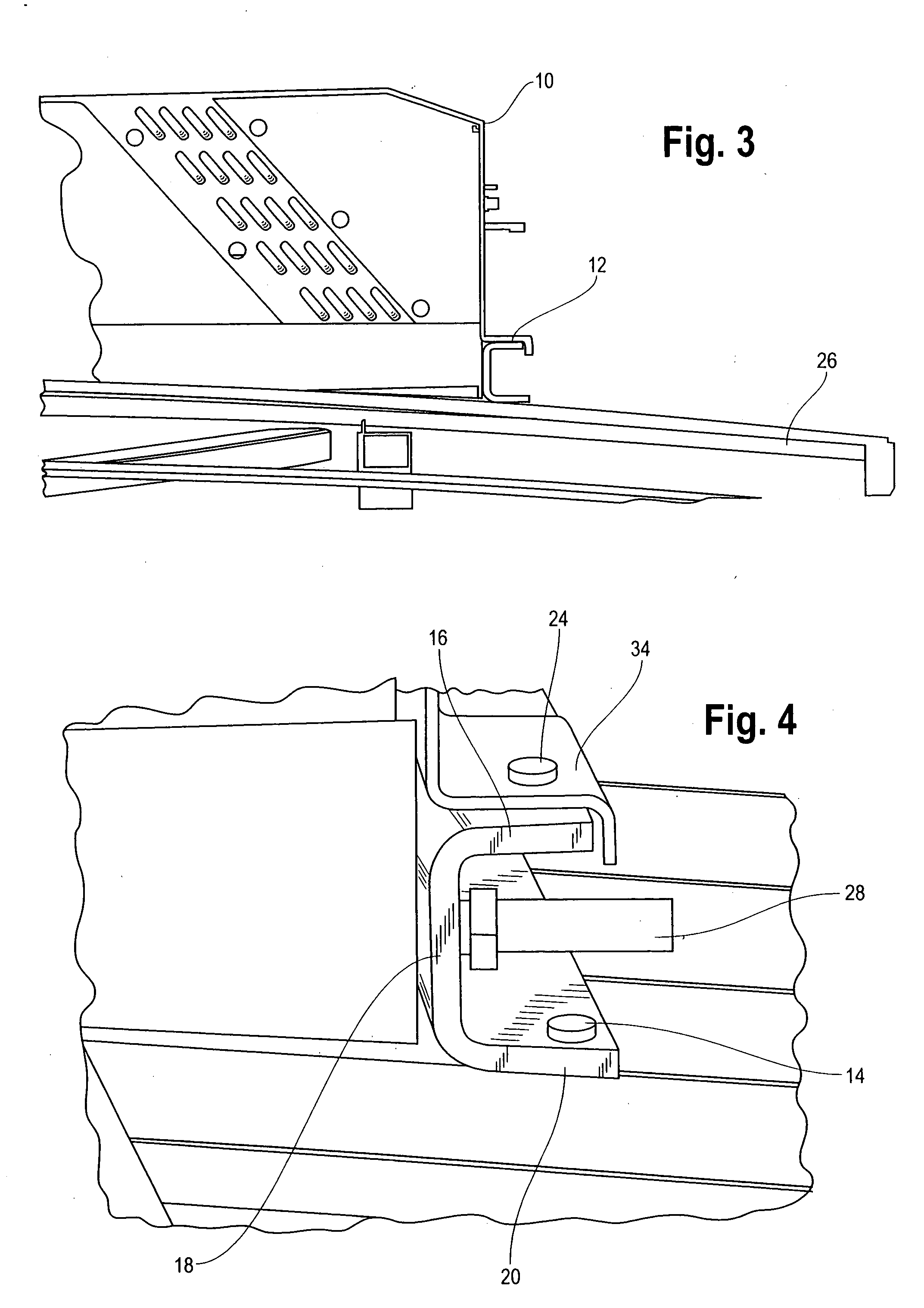

Modular rooftop air conditioning system mounting arrangement

InactiveUS20060059932A1Avoid insufficient lengthEasy to disassembleAir-treating devicesVehicle heating/cooling devicesModularityAir conditioning

A system and method for mounting one or more air conditioning modules to the roof of a bus is disclosed. The system and method includes standardized, modular air conditioning modules which are capable of fitting a wide variety of bus geometries, and are attached to the bus roof by a set of rails which are fastened to the roof, the rails having flanges and a length which are tailored to the bus roof configuration so as to provide a standardized alignment by capturing the roof rail in a channel shaped formation.

Owner:MOBILE CLIMATE CONTROL YORK CORP

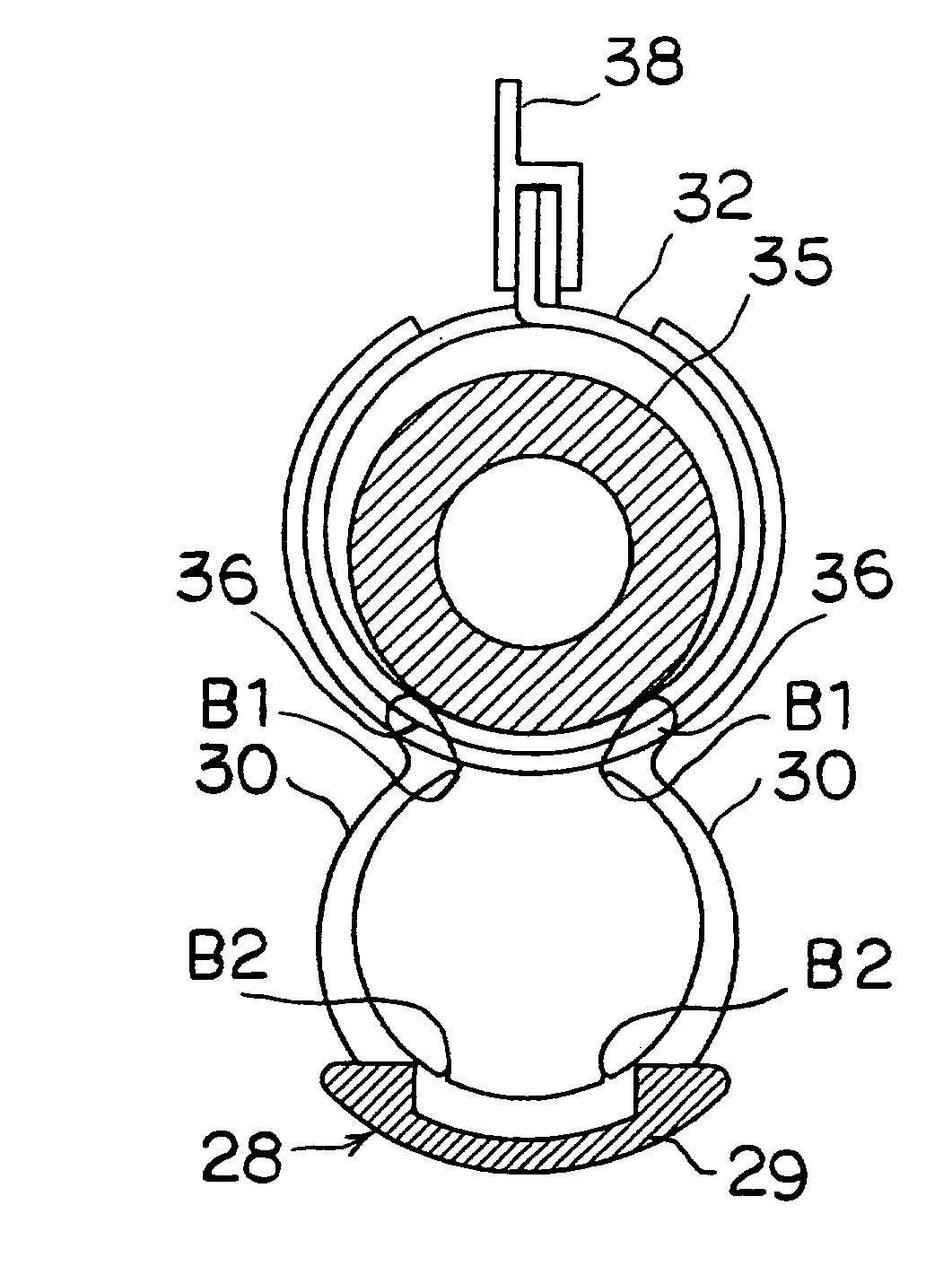

Clamp holder

InactiveUS7093808B2Easy to packAvoid damageSnap fastenersPipe supportsEngineeringMechanical engineering

In a holder having a holder base and holding arms and used for holding a hose clamp in position, the holder base is so constructed as to be capable of being positioned on the outer periphery of an annular hose clamp and a pair of holding arms protrude from each of a pair of opposite lateral edges of the holder base. Each pair of holding arms are so shaped as to define a pair of opposed arcs extending along a circumference A having a diameter somewhat smaller than the outside diameter of a hose. Each holding arm has a sharp projection B1 formed on its inner peripheral surface at its distal end and directed substantially toward the center of the circumference A, or more inwardly than it. The clamp holder facilitates the preliminary holding of a hose clamp in position on a hose without damaging the hose, and without slipping off the hose or being displaced easily.

Owner:SUMITOMO RIKO CO LTD

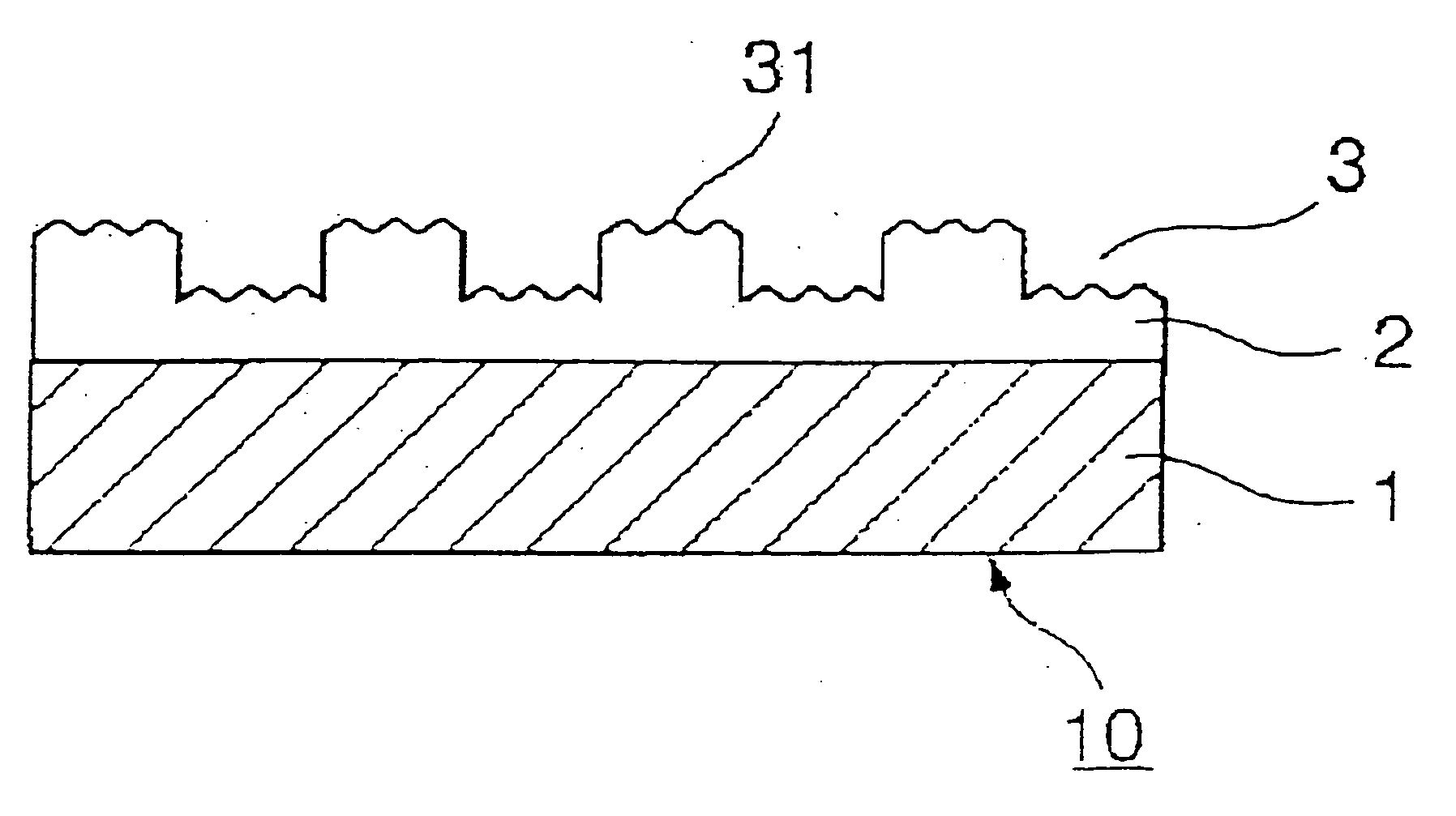

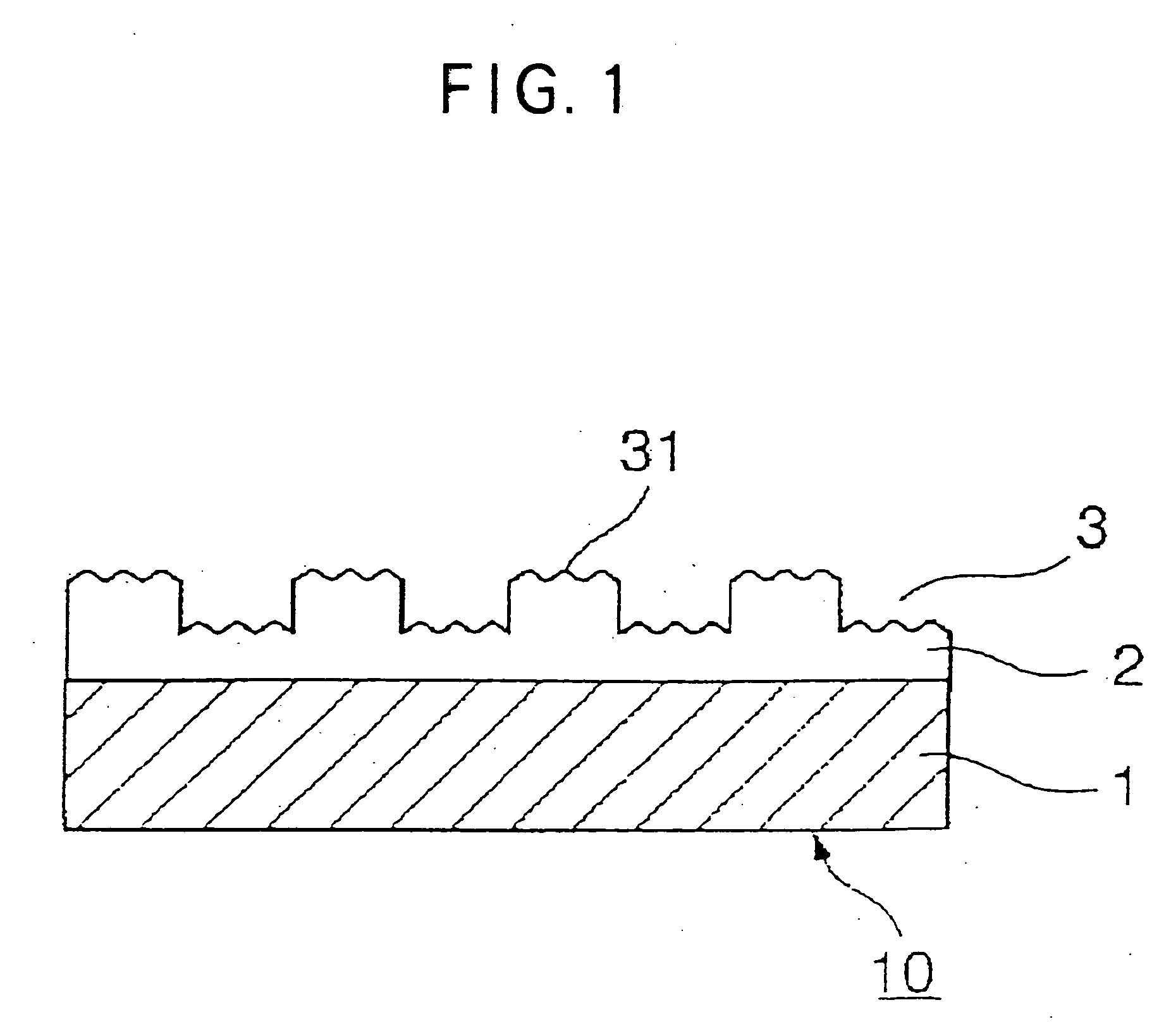

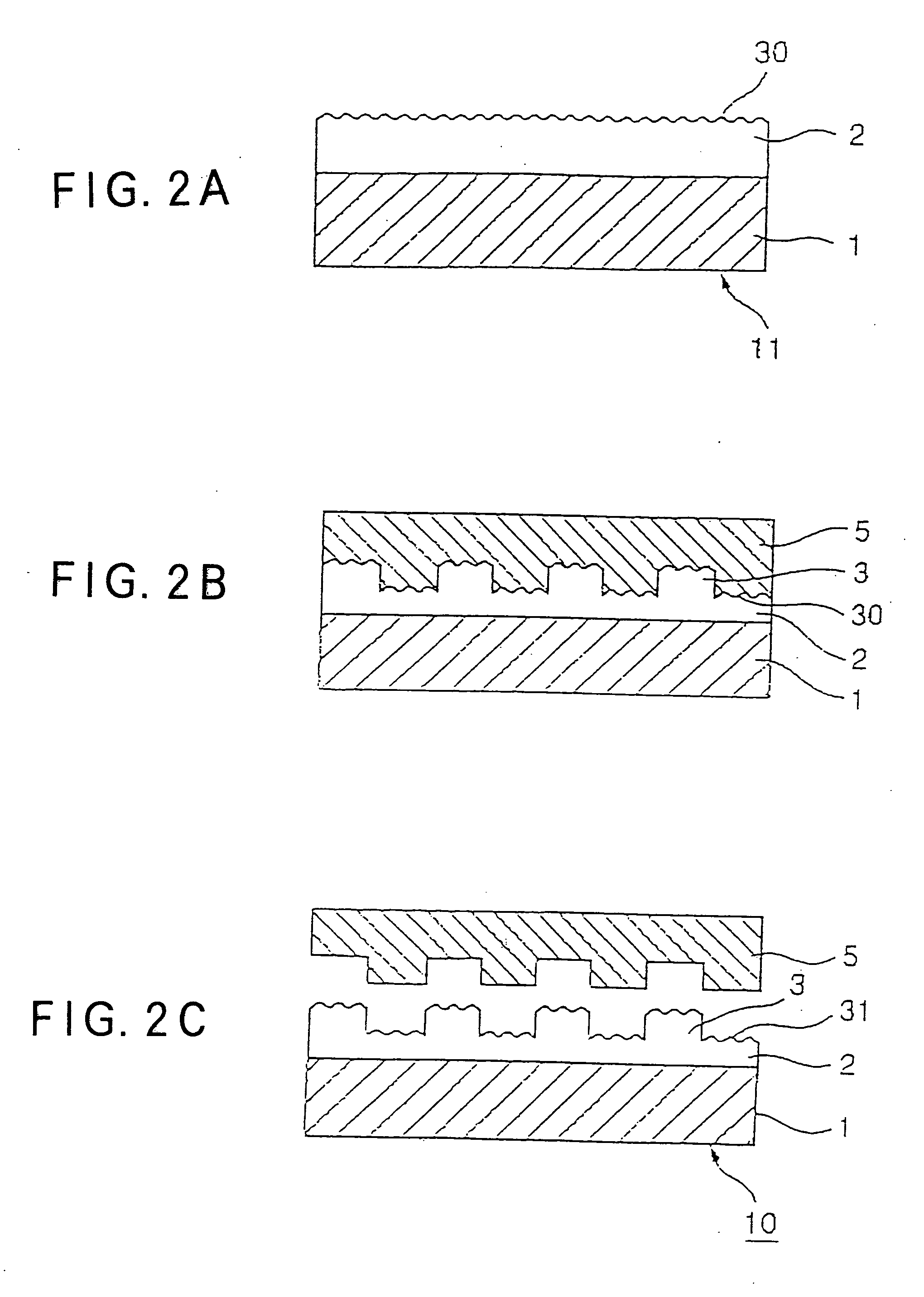

Shaped sheet and method for producing the same

InactiveUS20050089671A1Increase production capacitySynthetic resin layered productsTraffic signalsProduction rateShape formation

An object of the present invention is to fairly reproduce the irregular surface of a shaped sheet for a cast resin film and a production method having high productivity. In order to attain the above object, the present invention provides a shaped sheet provided with a releasable resin layer having a transfer pattern formed of an irregular shape on one side of a substrate sheet 1, wherein a flat portion of the transfer pattern is formed of an fine irregular surface having an arithmetic average roughness Ra of 30.0 to 1.5 μm.

Owner:DAI NIPPON PRINTING CO LTD

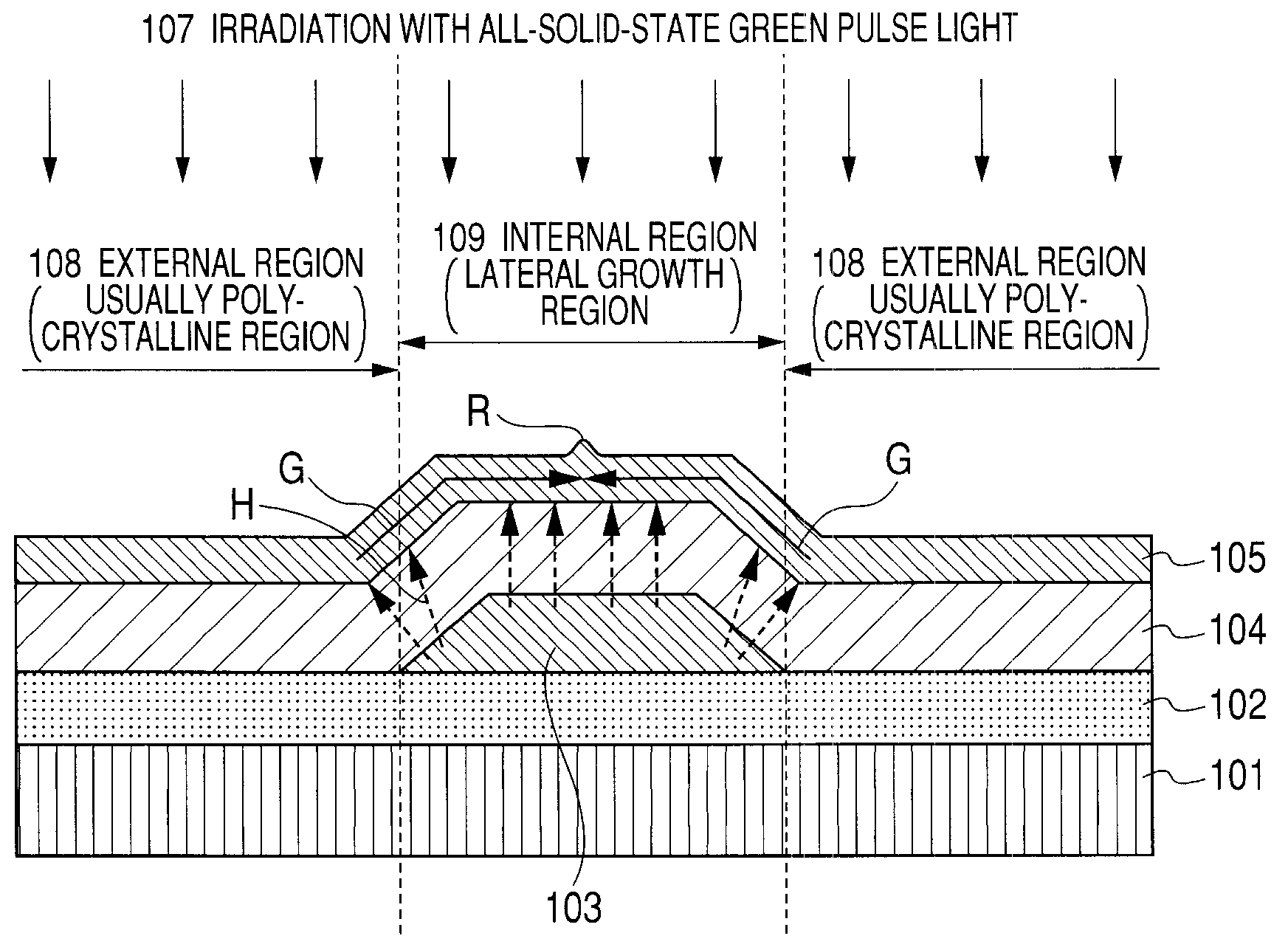

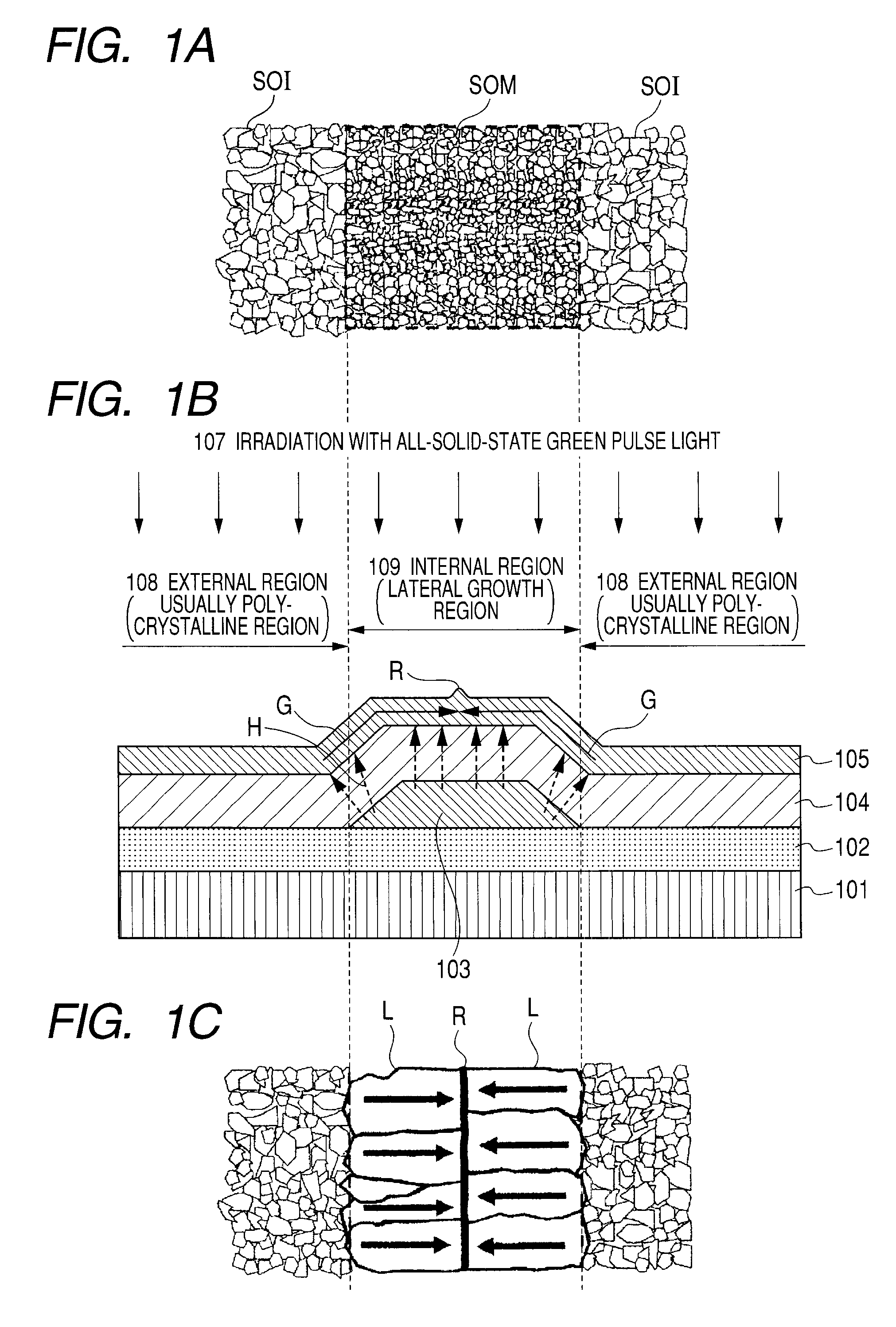

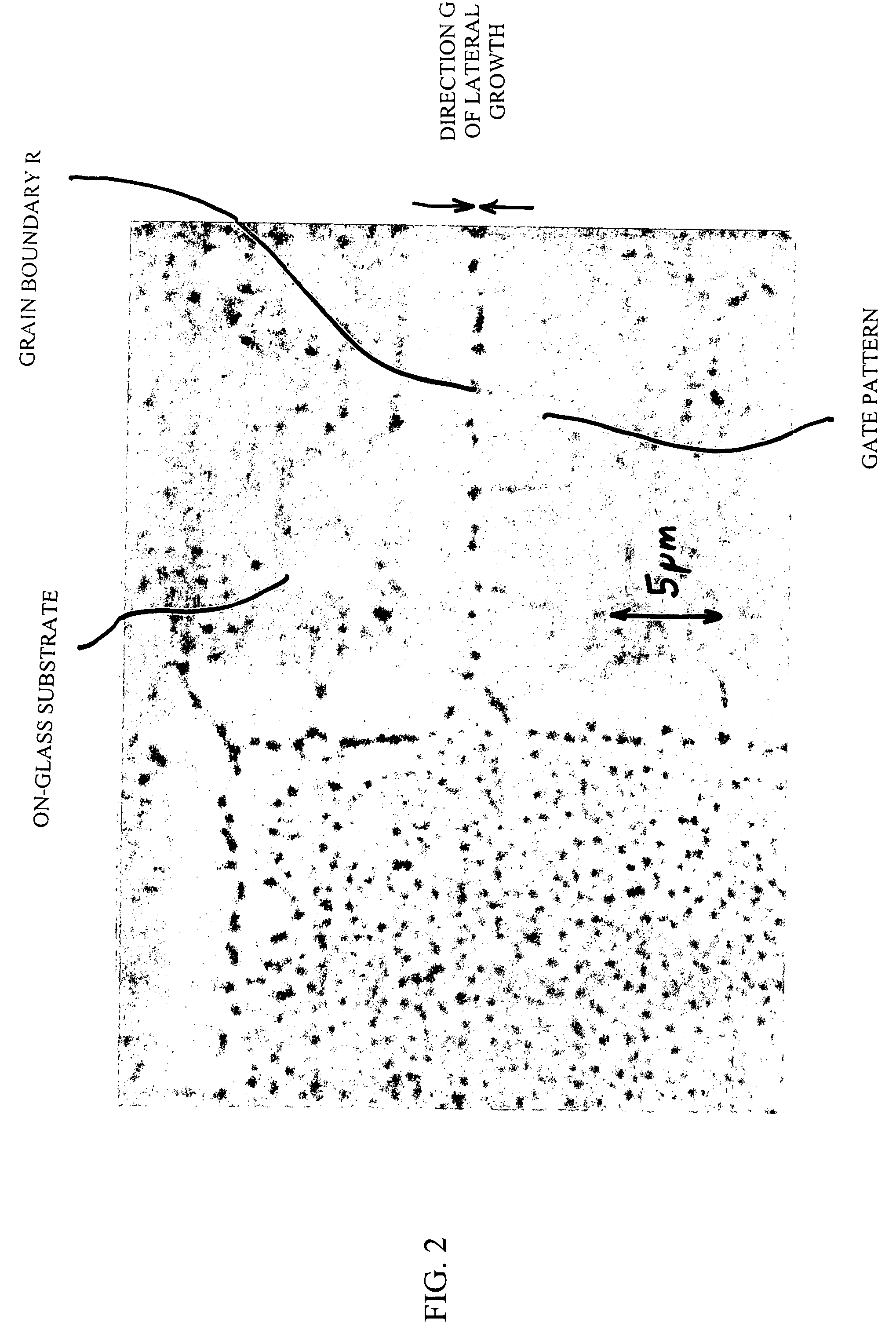

Thin film semiconductor device, method of manufacturing the same and display

InactiveUS20070290200A1Improve featuresExcellent characteristicsTransistorSolid-state devicesDisplay deviceLight reflection

A method of manufacturing a thin film semiconductor device is disclosed. The method includes the steps of: forming a light reflection and absorption layer for reflecting and absorbing light on a substrate; patterning the light reflection and absorption layer in a prescribed shape; forming an insulating film covering the patterned light reflection and absorption layer; forming a semiconductor thin film containing a polycrystalline grain on the insulating film; and laser annealing the semiconductor thin film by irradiating pulse oscillated laser light to crystallize the semiconductor thin film. The laser annealing step includes a heating process, and a cooling process.

Owner:SONY CORP

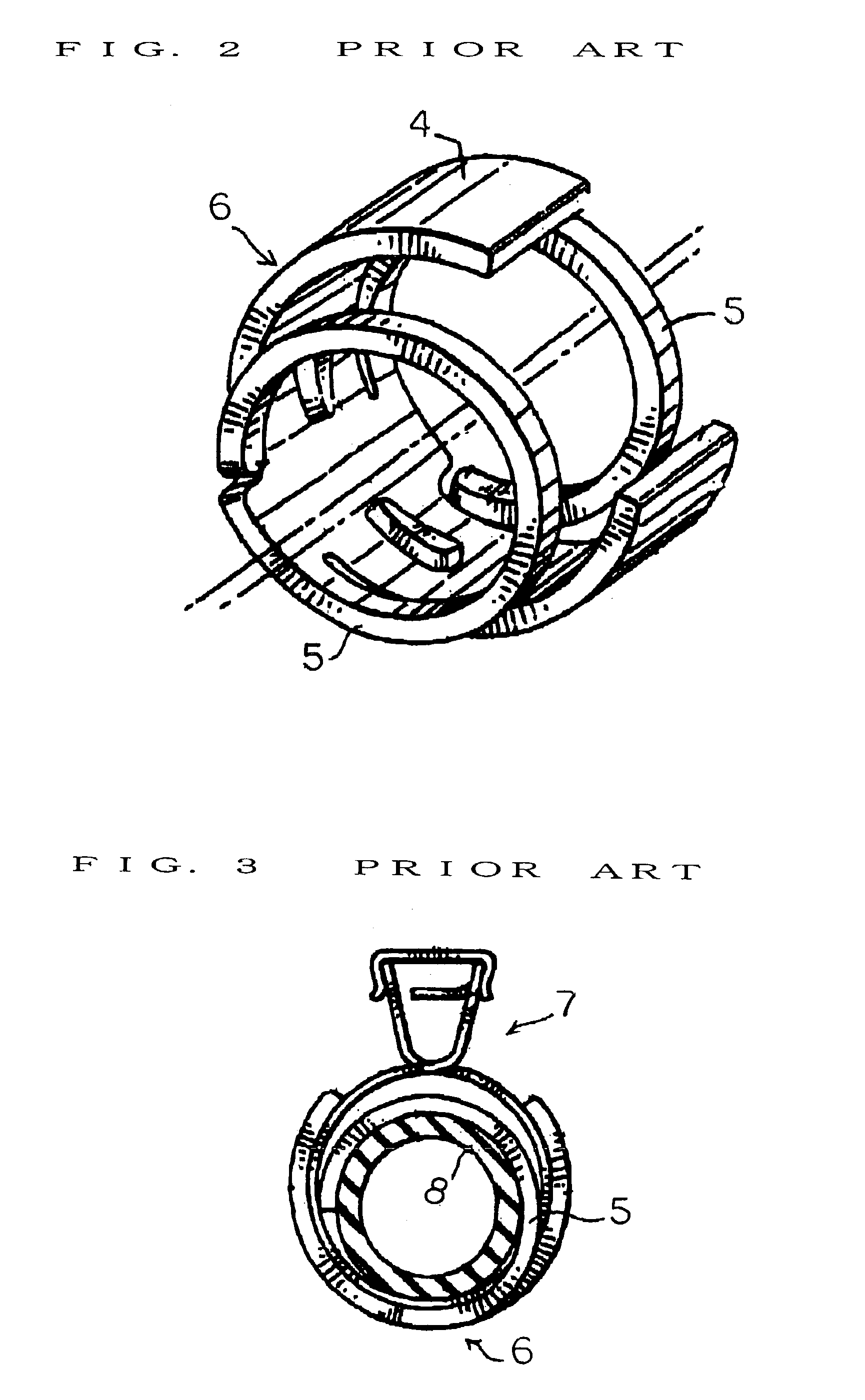

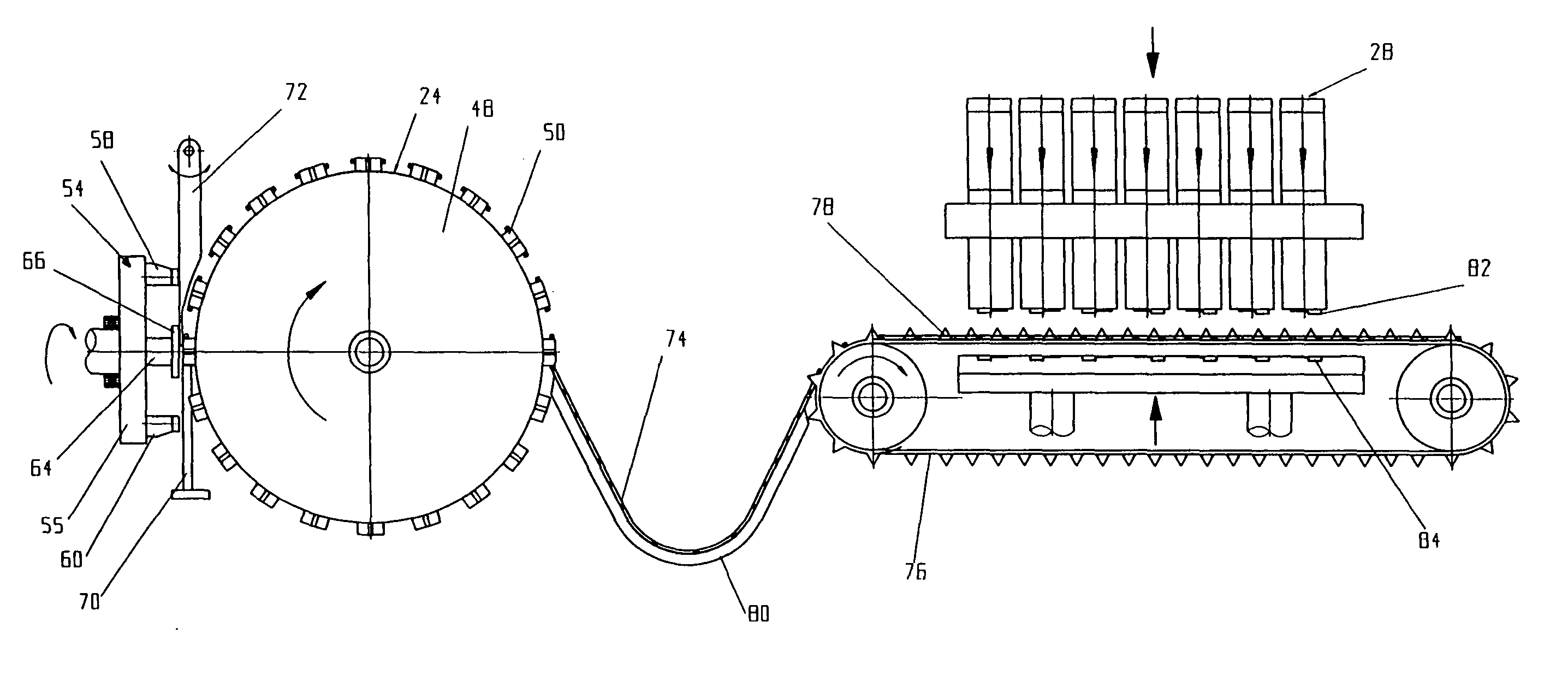

Apparatus for forming wave windings for rotor and stator lamination packets of electrical machines

InactiveUS7185414B2Manufacturing stator/rotor bodiesEmbedding prefabricated windingsWave shapeEngineering

An apparatus in which wave windings with a defined number of waves are cut from a continuously formed wave winding band. In forming with a wire guide, the wave winding band is laid in alternation around the outer side faces of forming protrusions, offset from one another on the circumference of two disks. The two disks can be driven to rotate. In the angular range in which the wave winding band is driven on the circumference of the disks or roller, the spacing between one forming protrusion of one row and the next forming protrusion in the other row is increased by such an amount that the outer side faces of the forming protrusions form the winding heads of the wave windings. The wave windings cut from the wave winding band are introduced into radially outwardly open slots of a lamination packet or a rotorlike transfer tool.

Owner:ELMOTEC STATOMAT VERTRIEBS

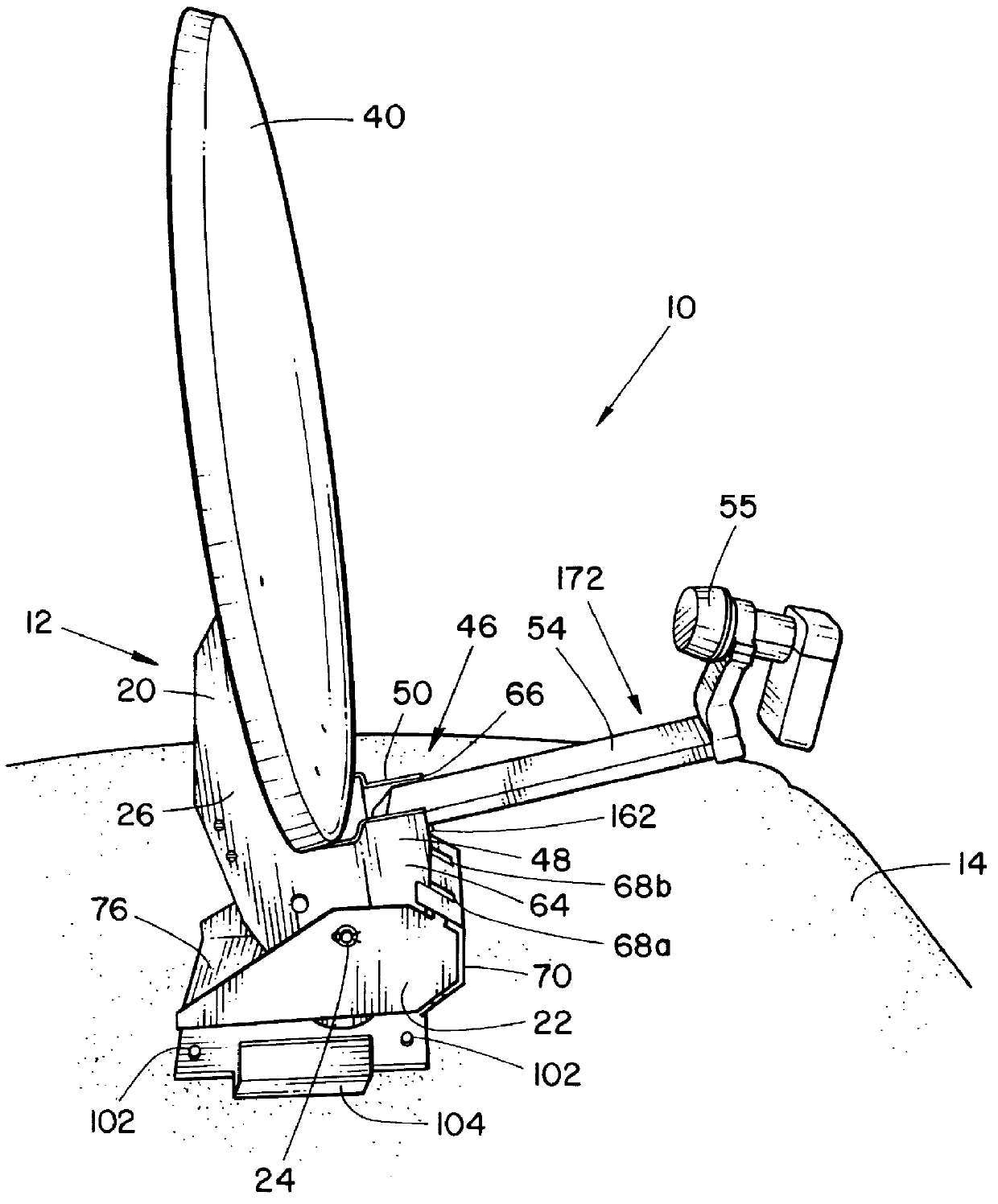

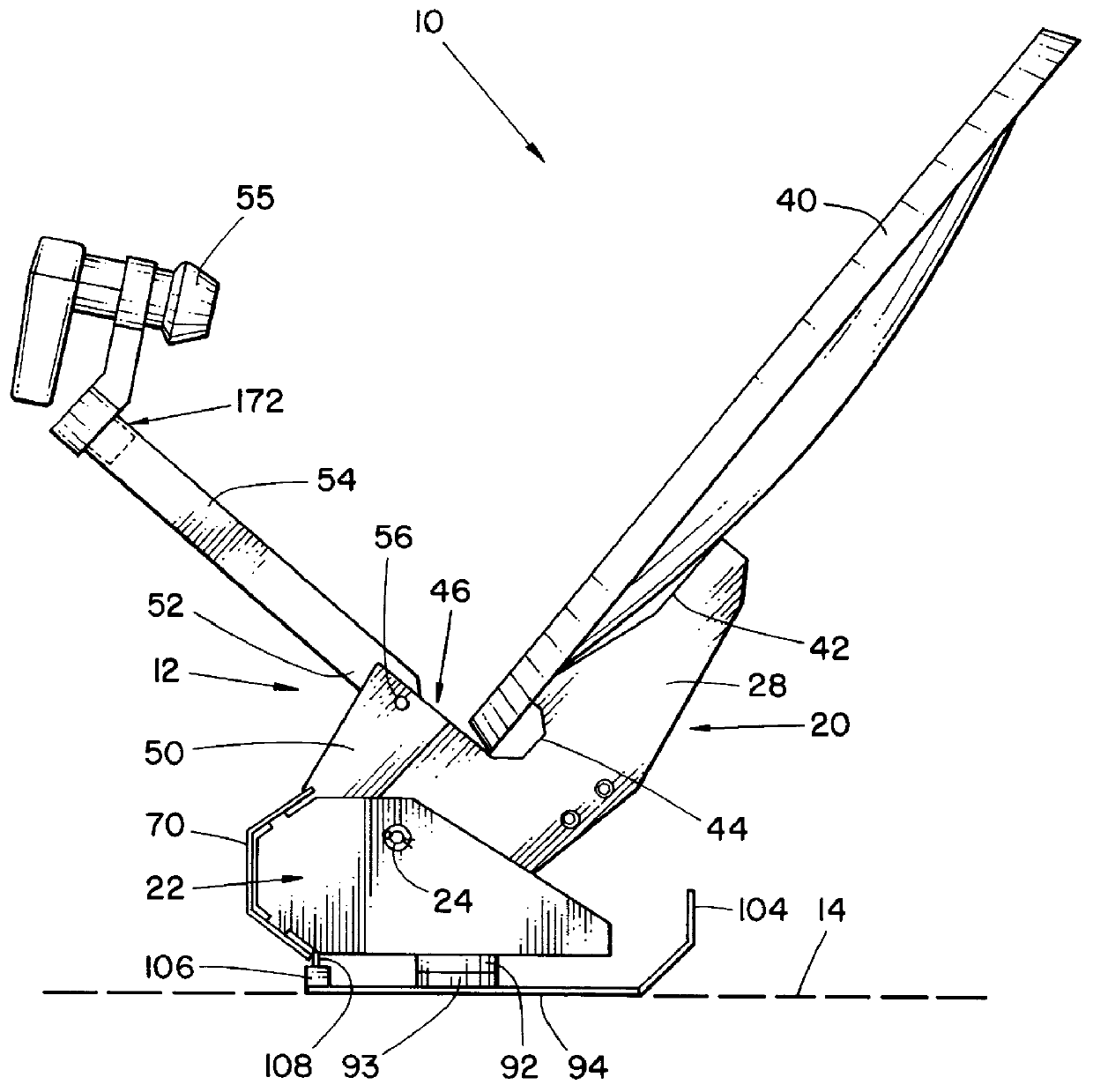

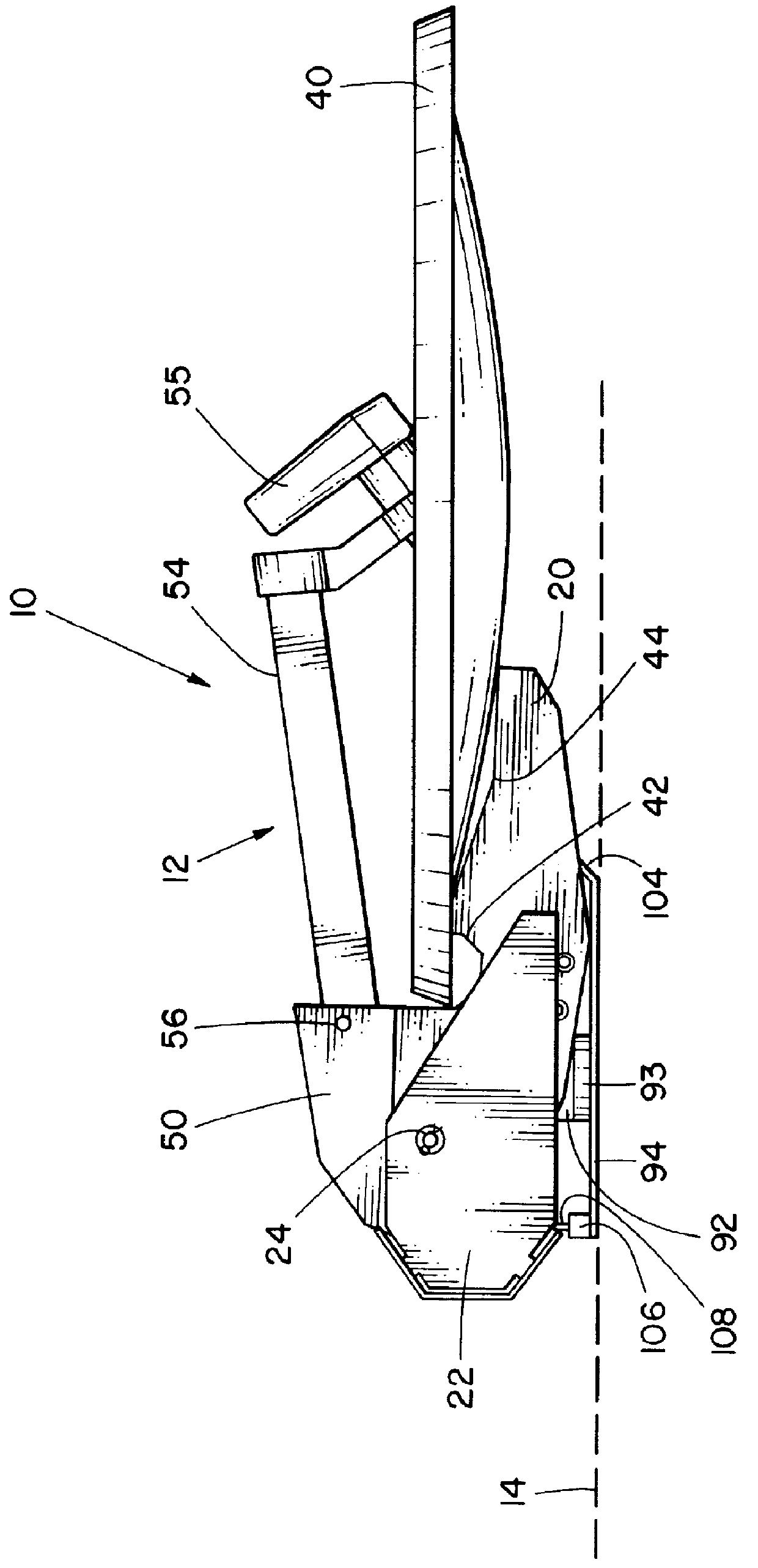

RV mounting for a satellite dish

InactiveUS6124836AFor signal receptionEliminate errorsCollapsable antennas meansAntenna supports/mountingsMechanical engineeringShape formation

In a collapsible roof mounting for orienting a satellite dish system from below, an upper channel-shaped formation arranged to present a dish-shaped component adjacent one end and an arm formation for the feed horn intermediately thereof and nestable within and interconnected to a lower channel-shaped formation adjacent the other end for swinging movement thereabove, a tubular shaft formation supporting the lower channel-shaped formation centrally thereof from below for rotation about a substantially upright axis, a displaceable linkage including a worm gear interconnected to the upper channel-shaped formation and a worm extending axially of the tubular shaft formation for swinging the upper channel-shaped formation upwardly from the nested disposition and reversely, a handle formation for the tubular shaft formation below the roof for imparting rotation thereto and a crank for the worm located below the handle formation for imparting displacement to the worm and worm gear.

Owner:ROGERS JOHN STEPHEN

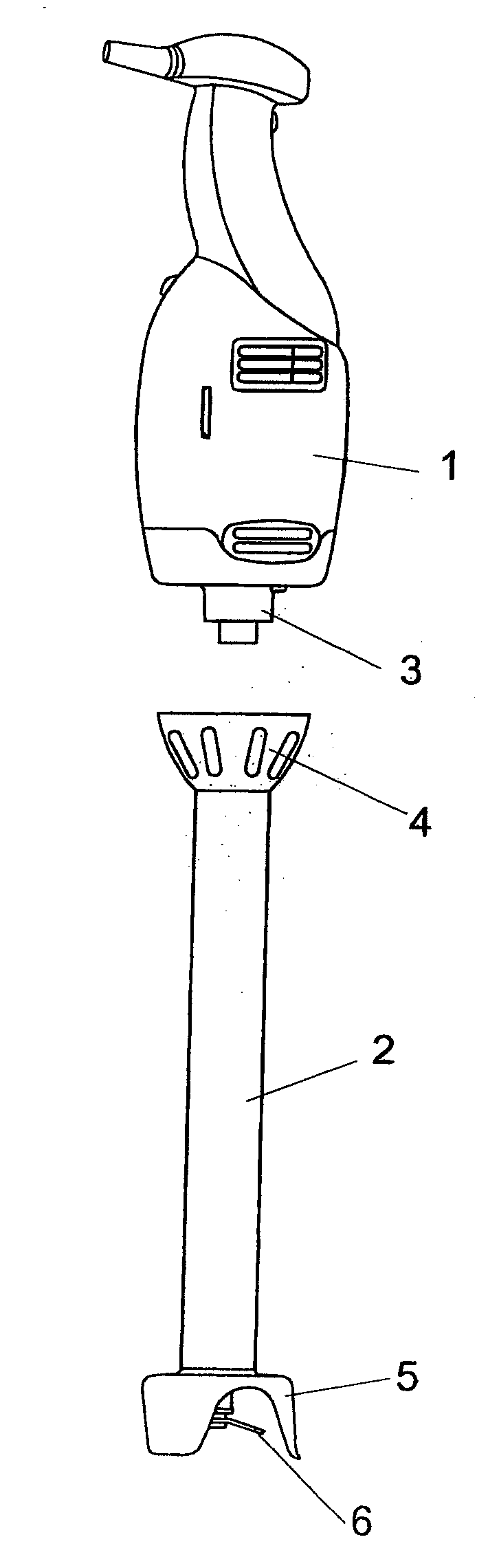

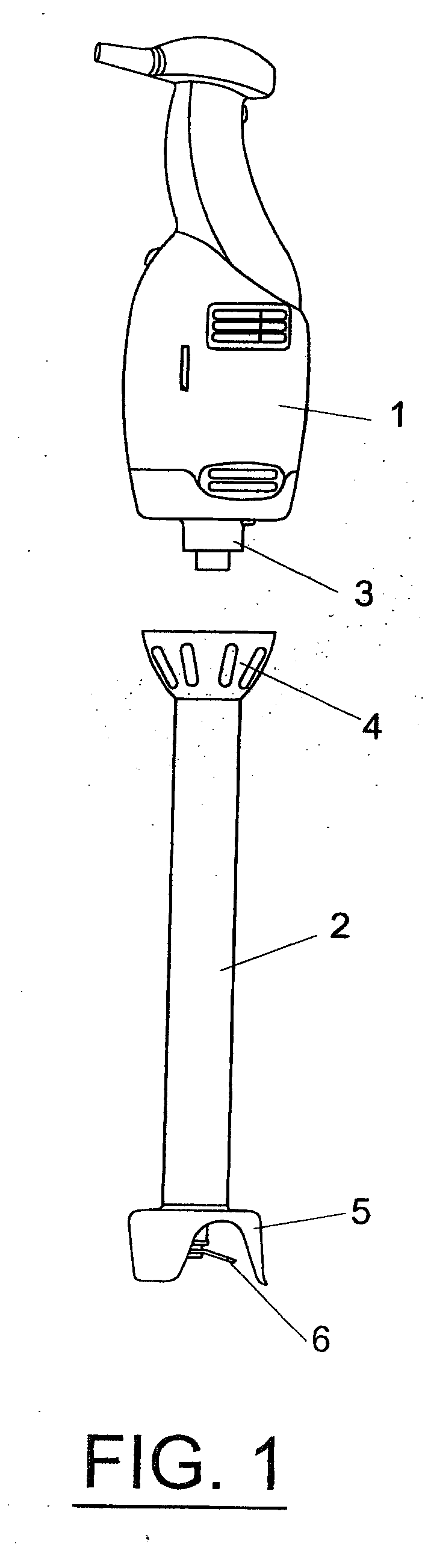

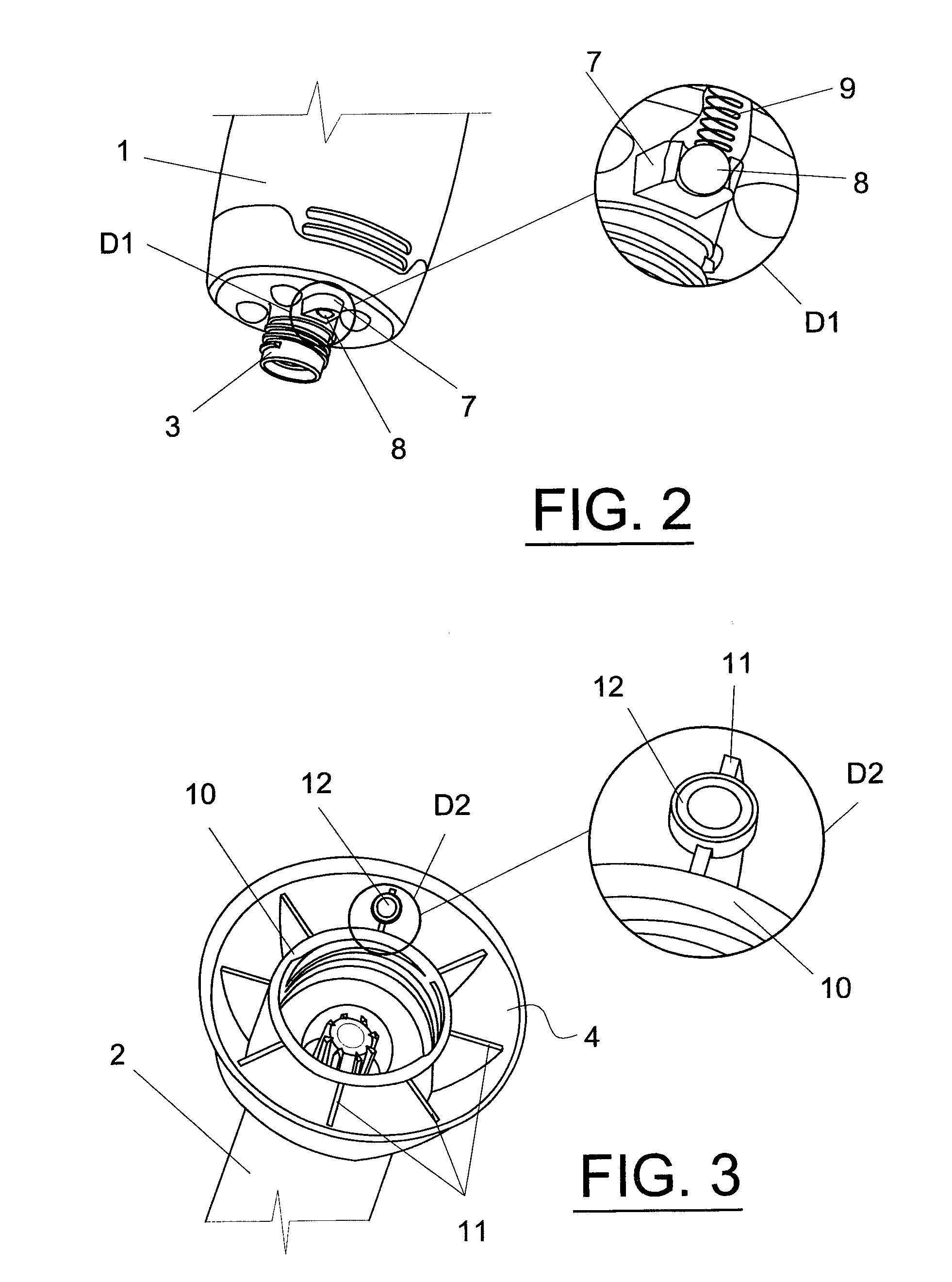

Releasable Coupling Device Between a Tool Shank and a Motor Assembly in Hand-Held Blenders

The invention discloses a fast and reliable coupling device between a tool shank and a motor assembly of a hand-held blender, which can be released by the user. The motor assembly is of the type that has a cylindrical nozzle centrally positioned on the base by which it couples to the tool shank, the outer side of which has a threaded portion, whilst the tool shank has an internally threaded nut that is complementary to the nozzle, the base of the motor assembly also including a formation that projects outwards, with a hole through which a retaining ball projects, pushed by a spring, whilst radial partitions project from the outer wall of the coupling nut of the tool shank towards the inner face of the coupling bell, one of these partitions having on its upper edge a cup-shaped formation that is of suitable dimensions to admit and house said ball when aligned with it during the coupling operation between said tool shank and motor assembly.

Owner:SAMMIC

Forming of complex shapes in aluminum and magnesium alloy workpieces

A billet of an aluminum alloy or magnesium alloy is formed by a combination of forming operations into a desired article of complex, but open shape. In a first step a billet is heated and extruded to form an extruded workpiece profile having at least first and second sections of different thicknesses. The extruded workpiece may be shaped so that the respective sections are at an angle to each other. The extruded workpiece is then further formed against a forming surface so that the shape of least one of the sections is further formed toward the shape of the article. The methods are suitable for efficient manufacture of many like complex shapes such as brackets and reinforcement members, and even container pans for computers and other electronic devices.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com