Patents

Literature

197 results about "Neck rings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neck rings, or neck-rings, are any form of stiff jewellery worn as an ornament around the neck of an individual, as opposed to a loose necklace. Many cultures and periods have made neck rings, with both males and females wearing them at various times.

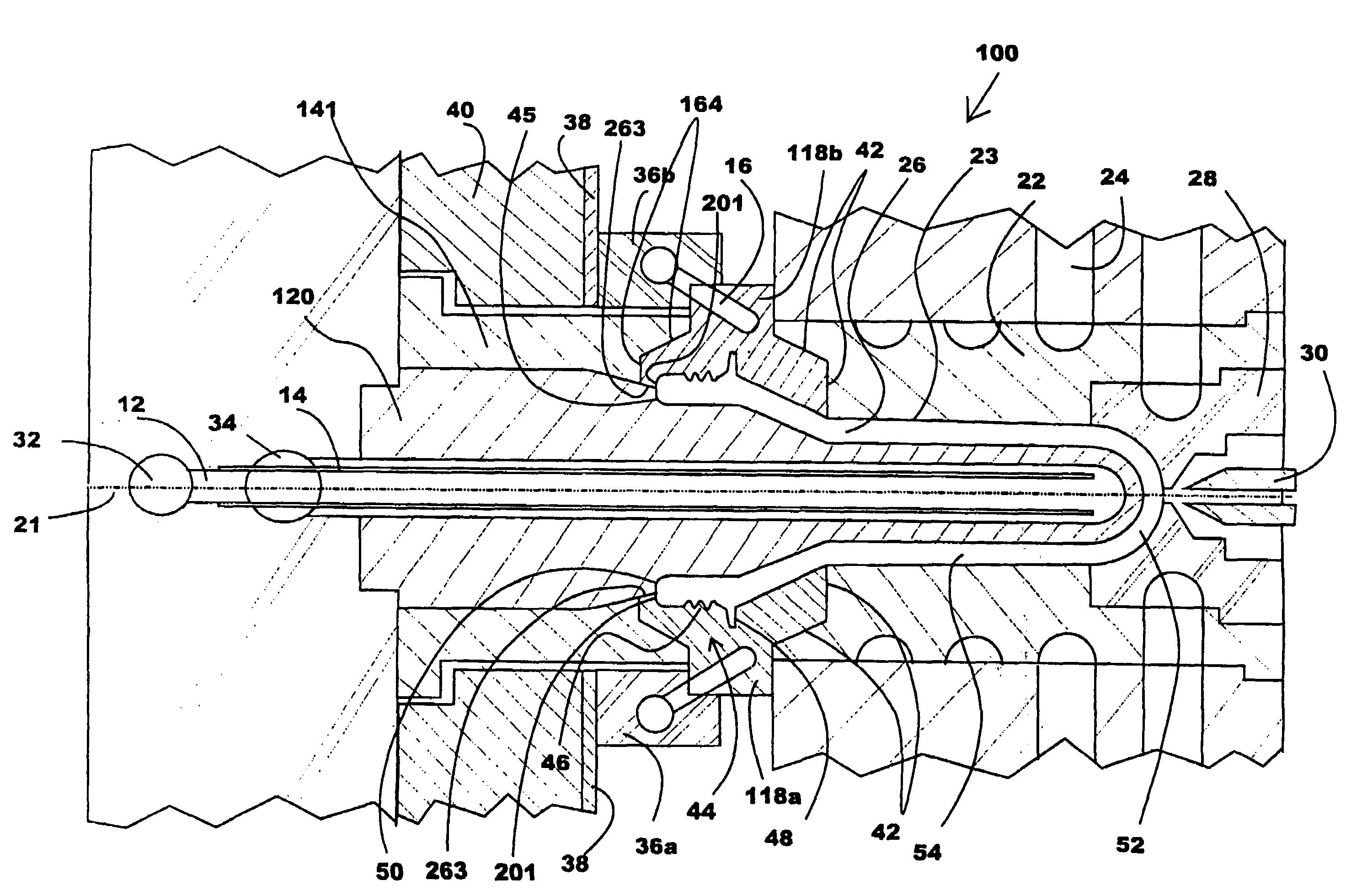

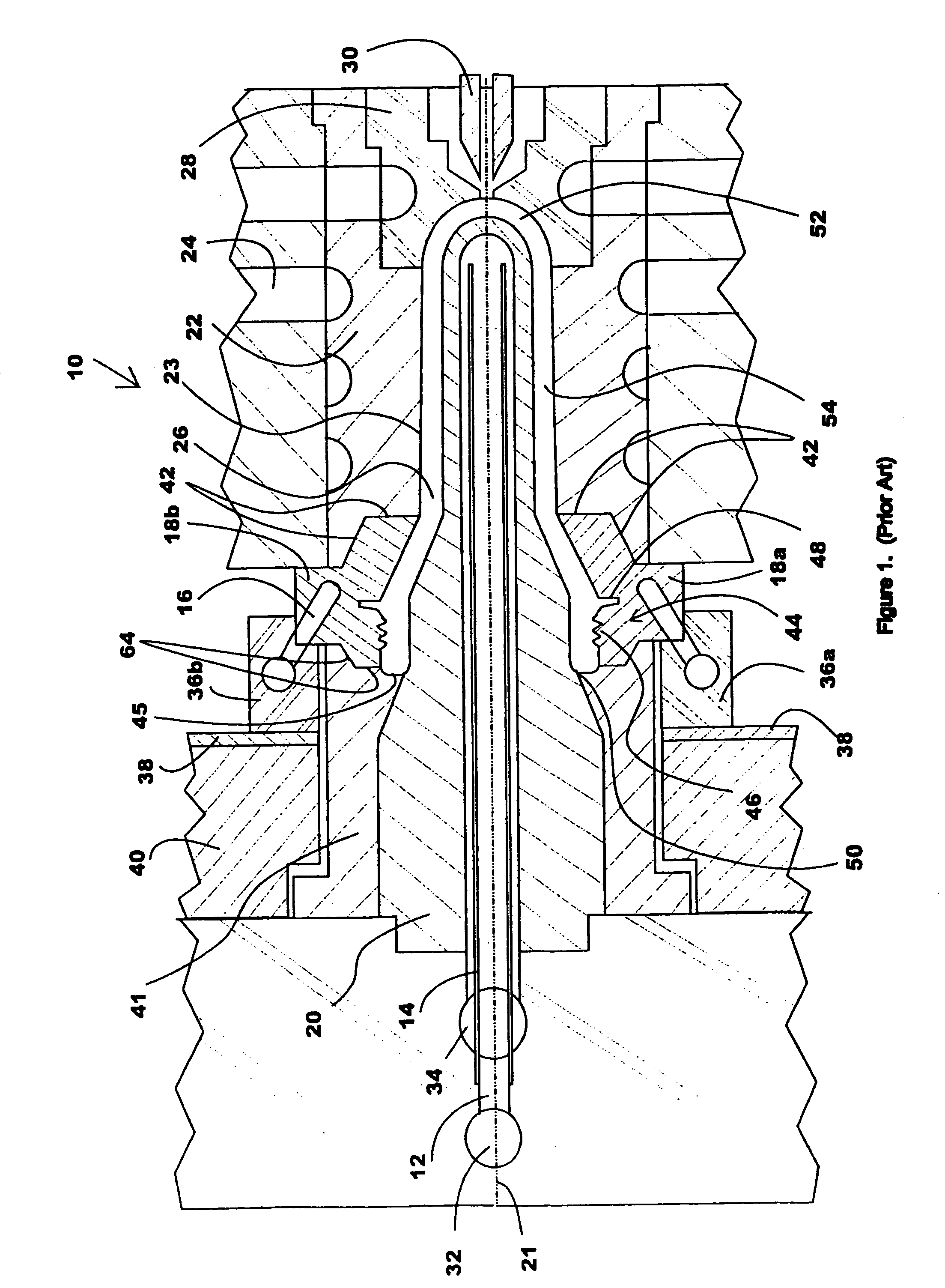

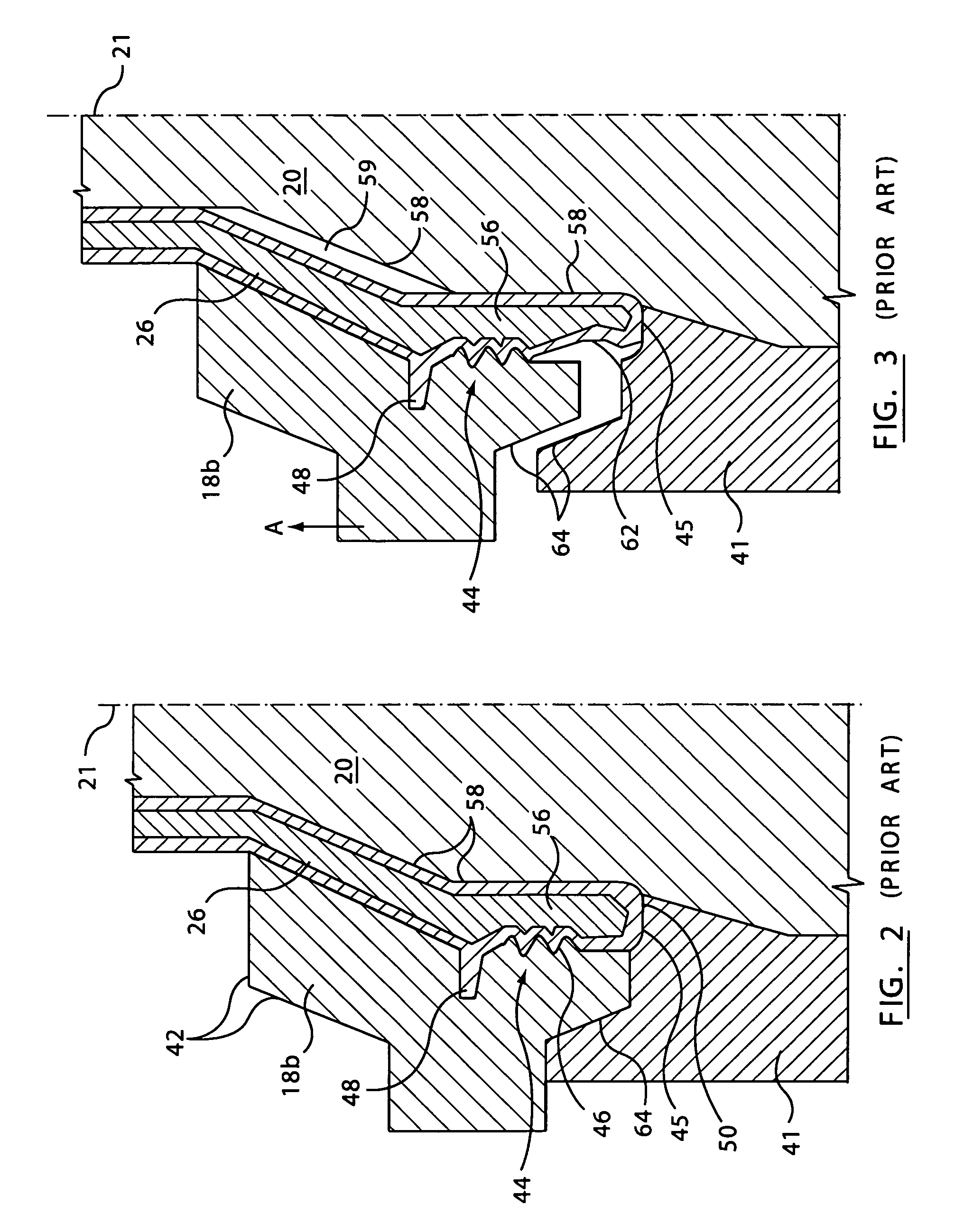

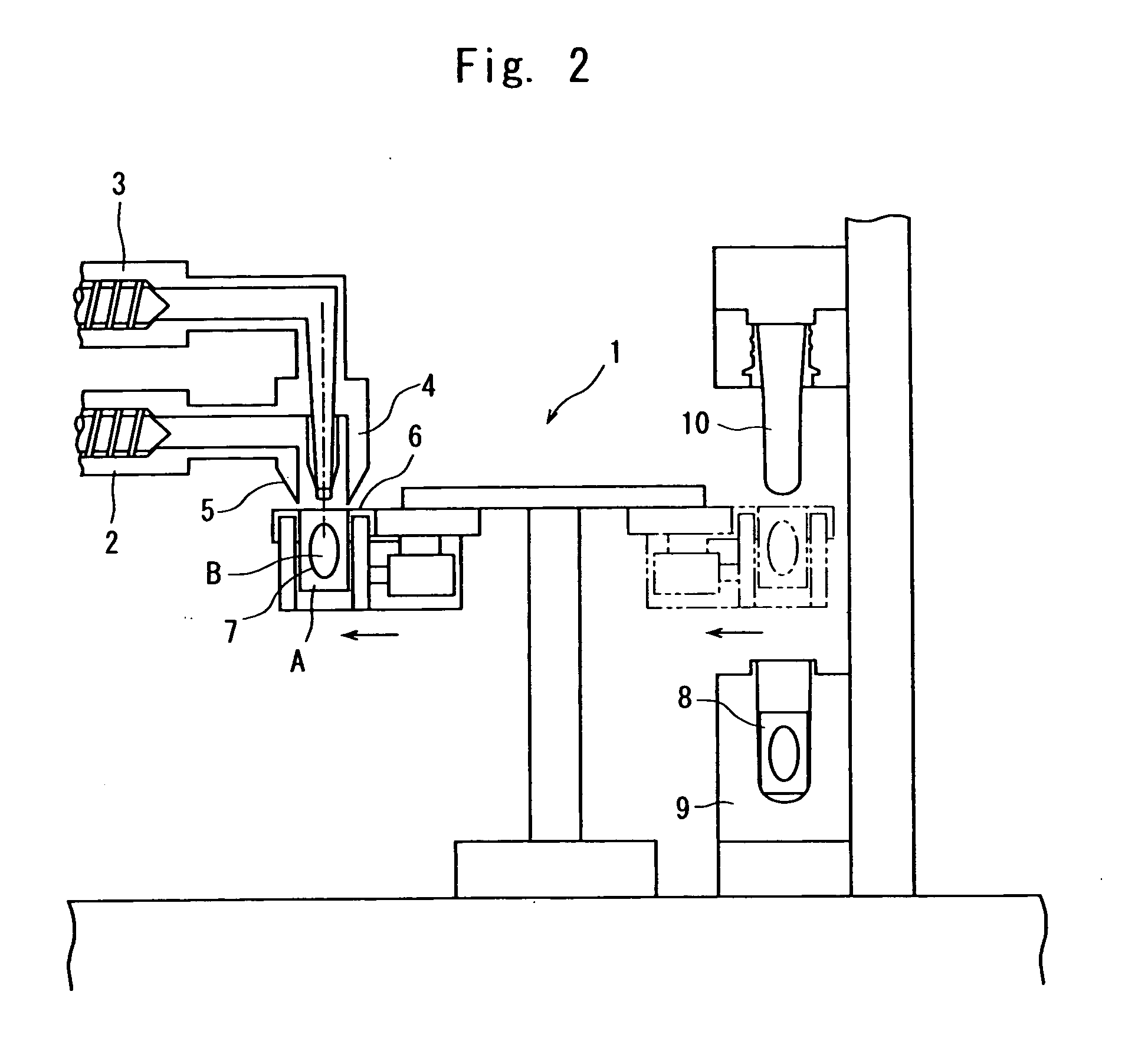

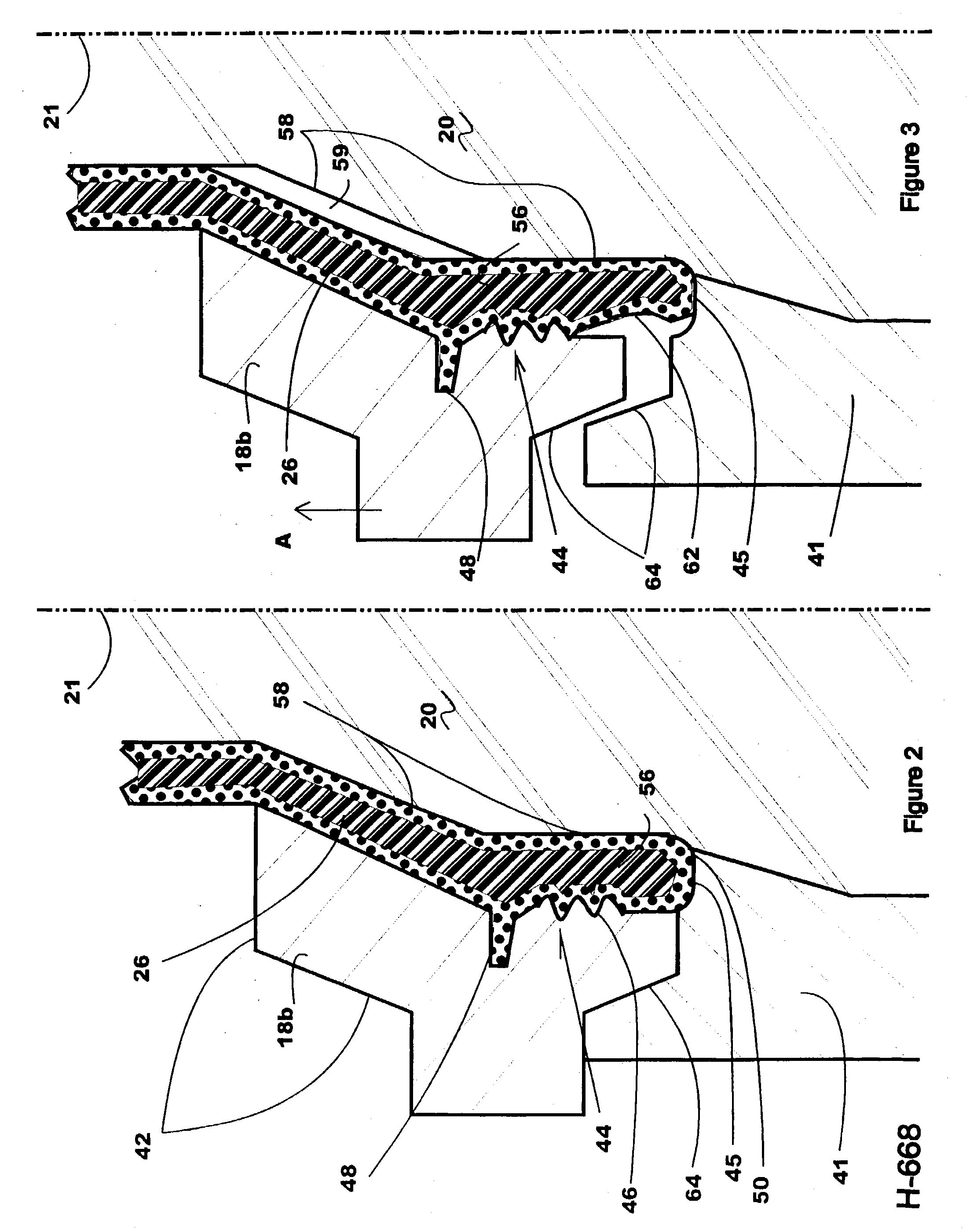

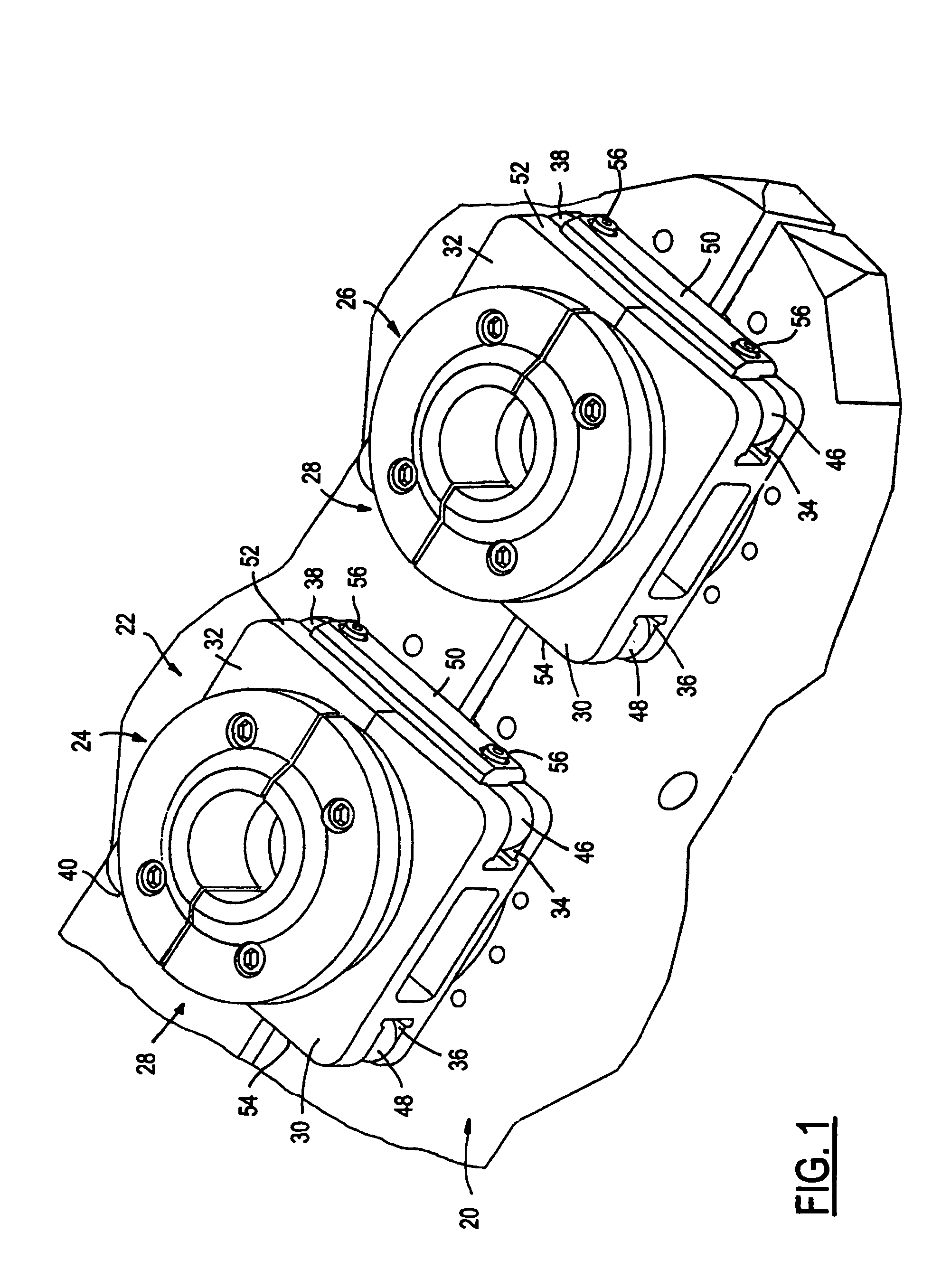

Apparatus and method for removing a molded article from a mold

InactiveUS6989124B2Improve cooling effectShorten cycle timeDischarging arrangementMouldsAcute angleShell molding

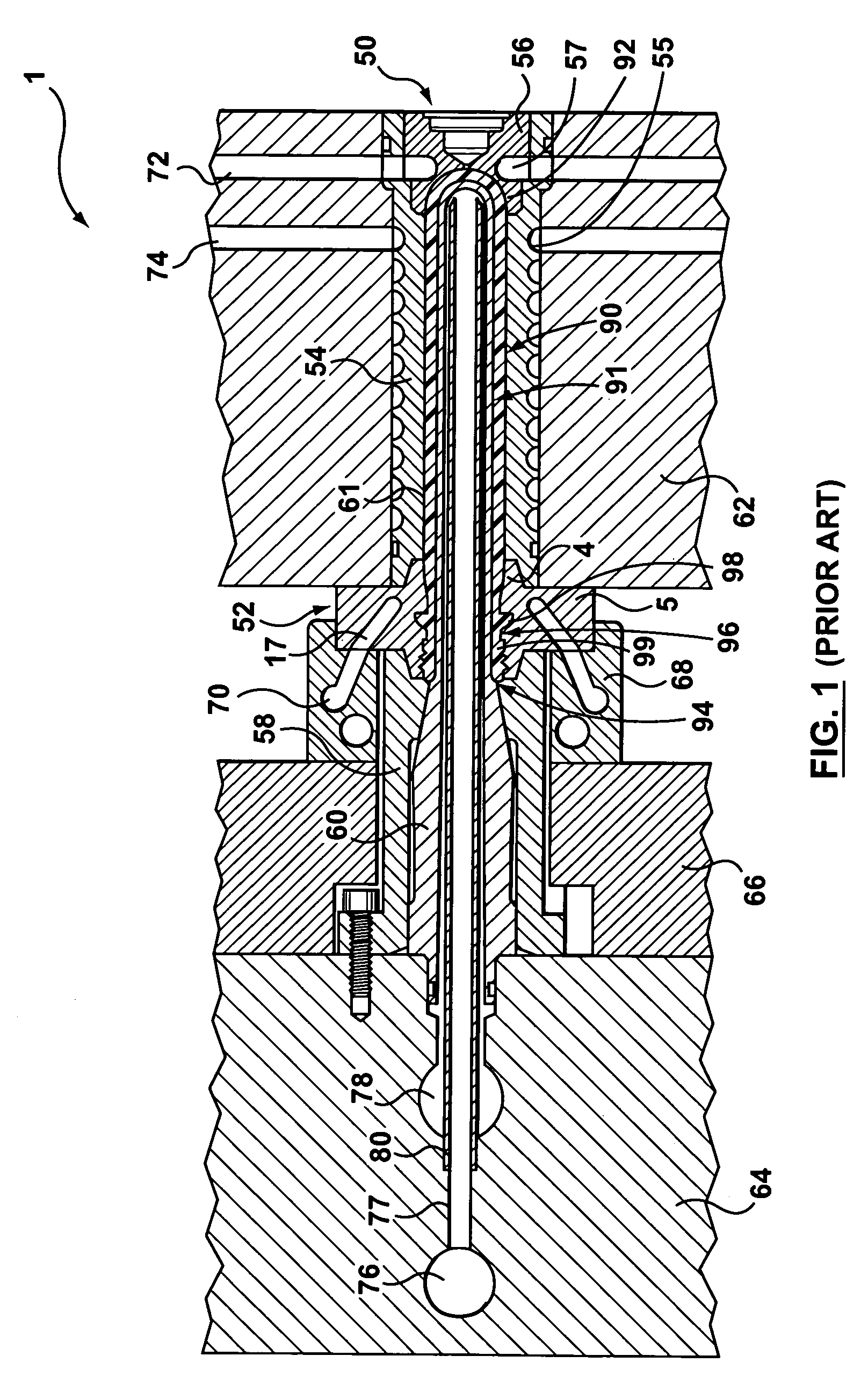

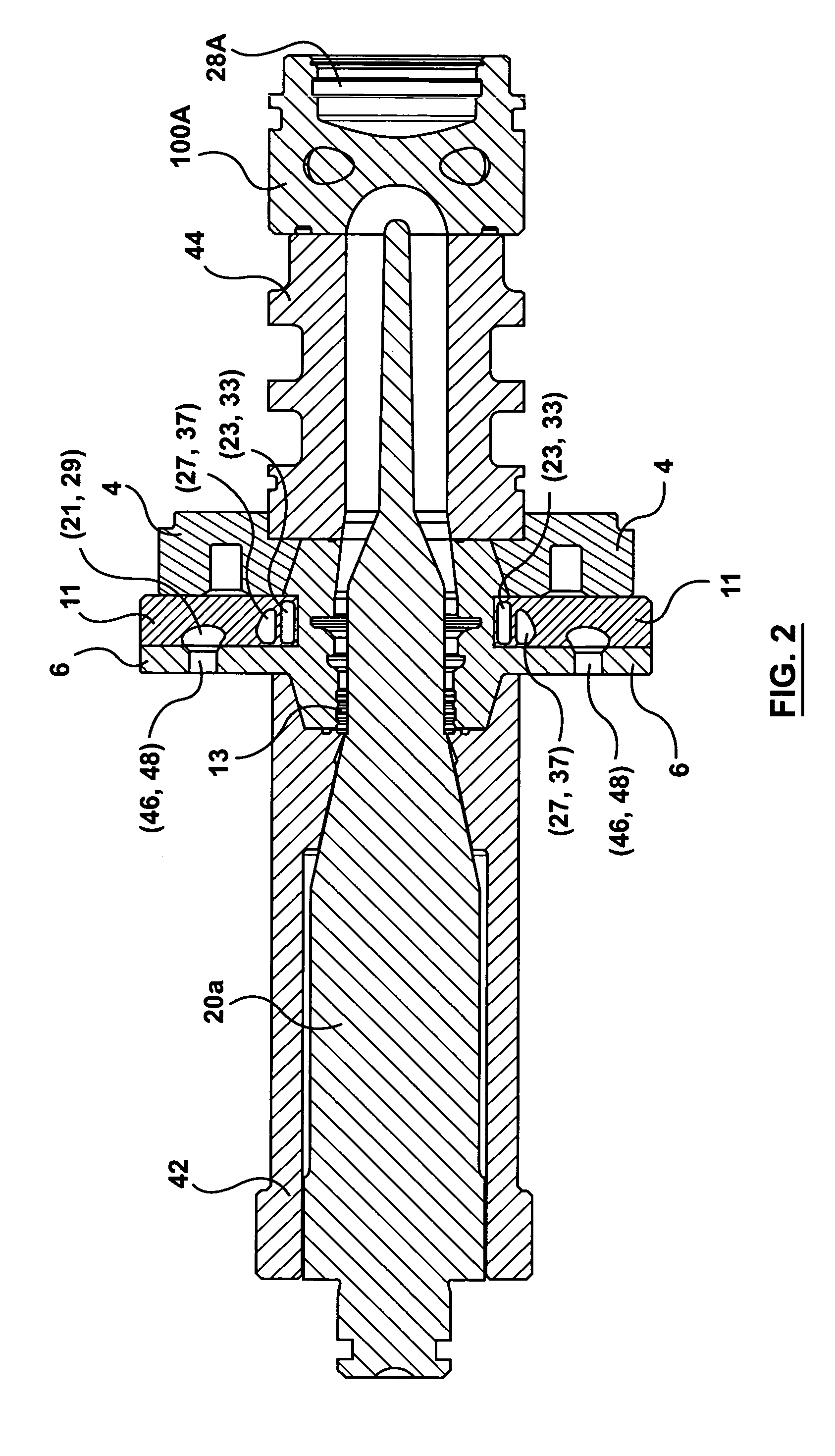

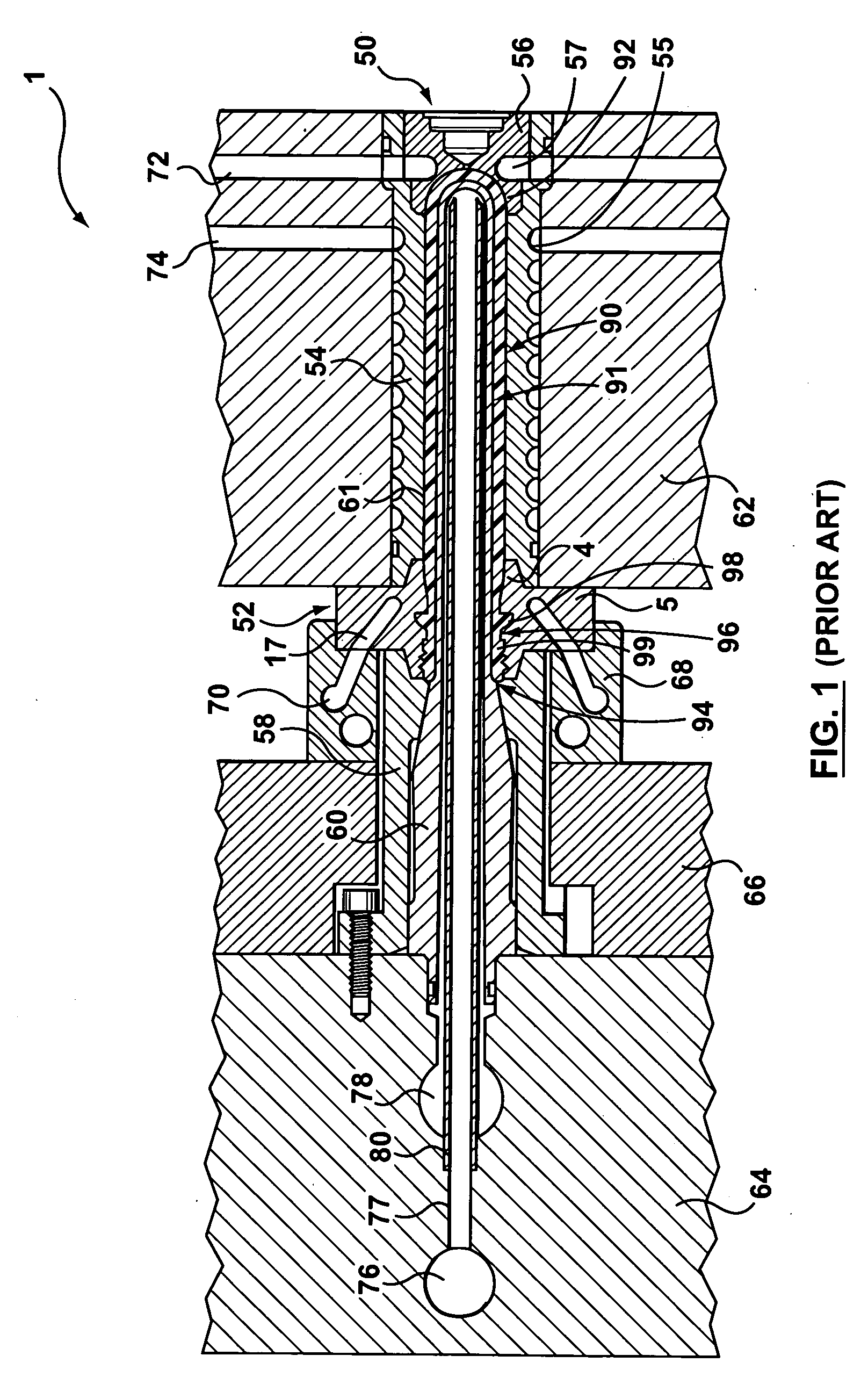

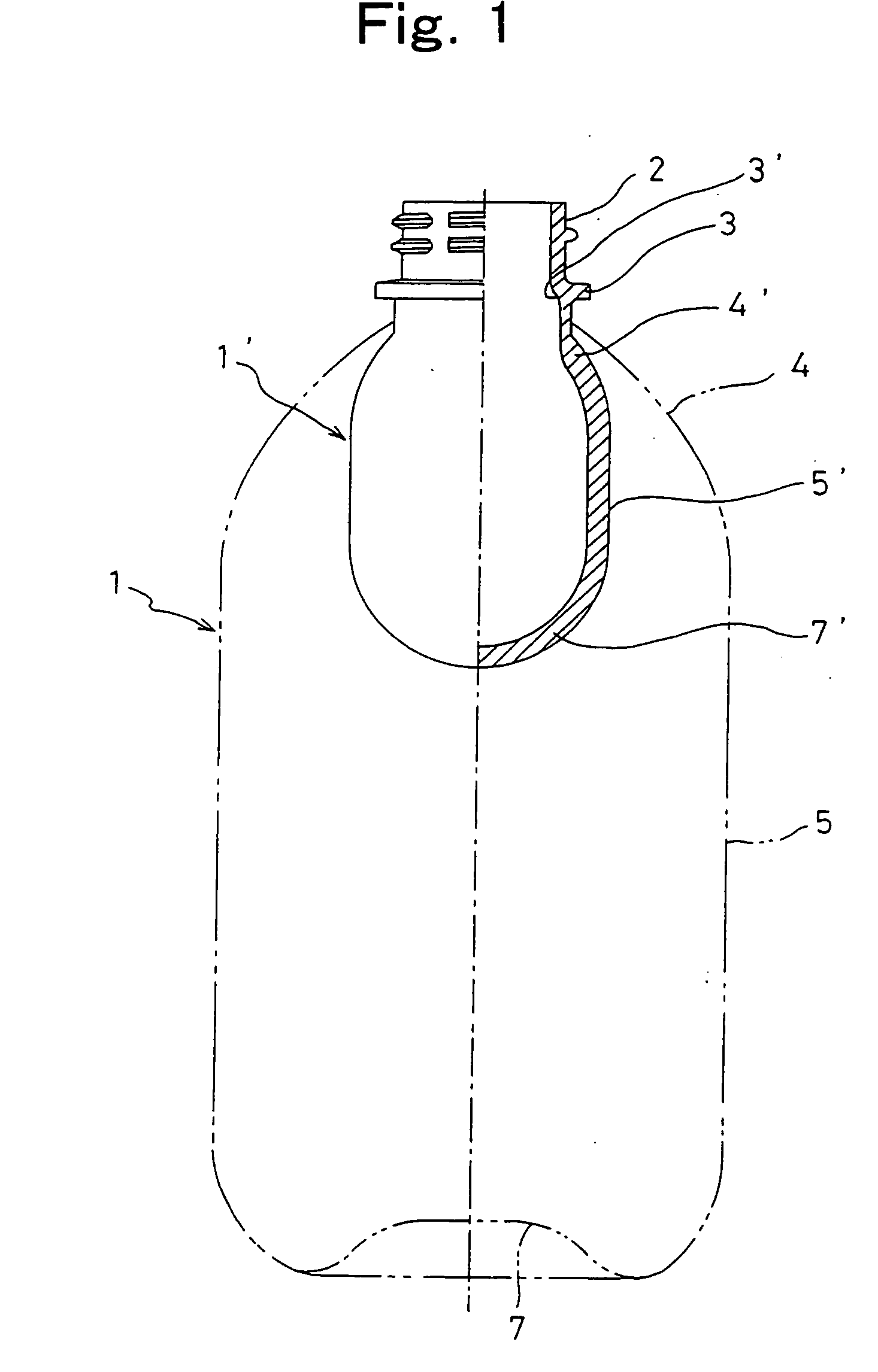

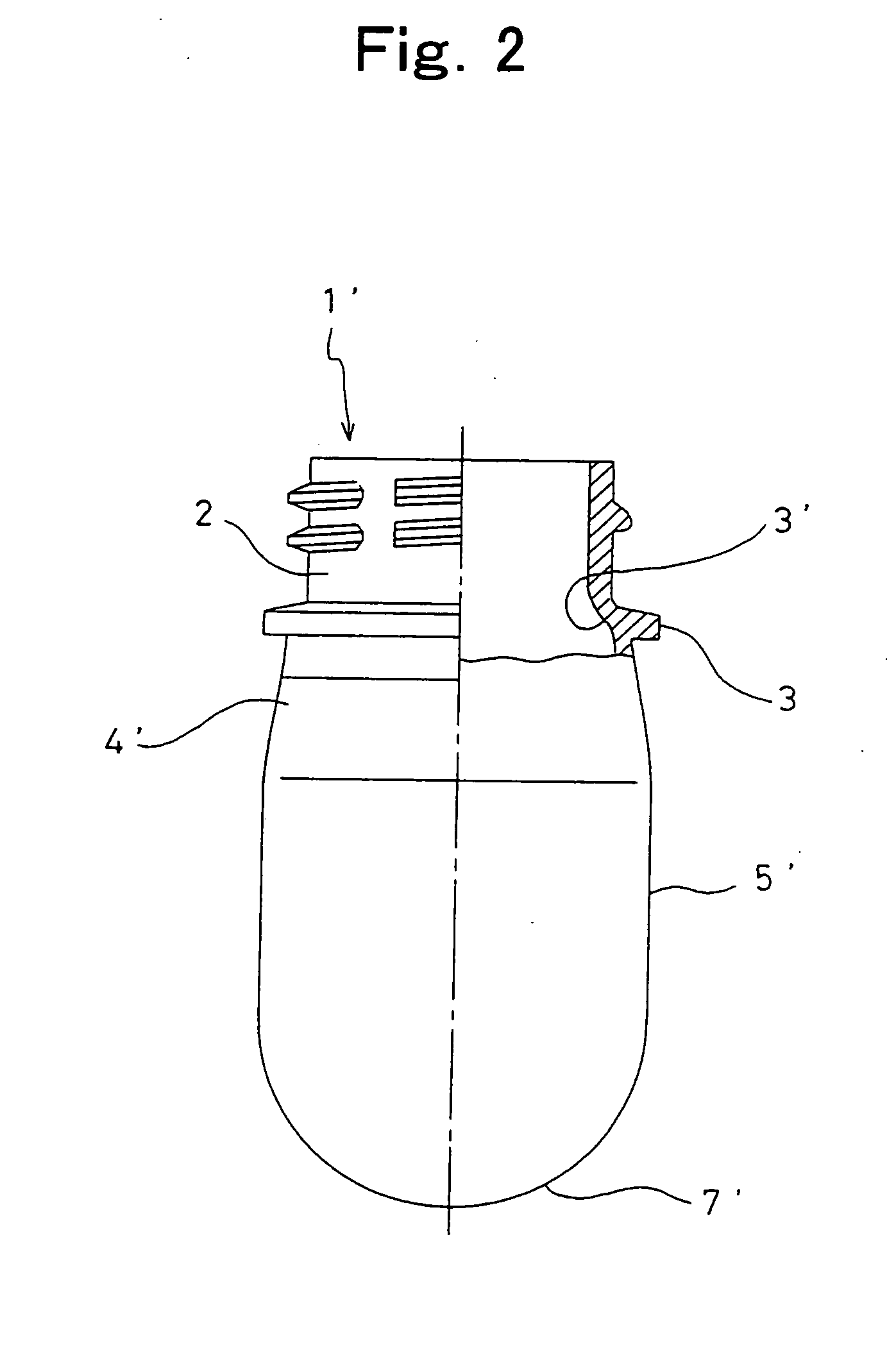

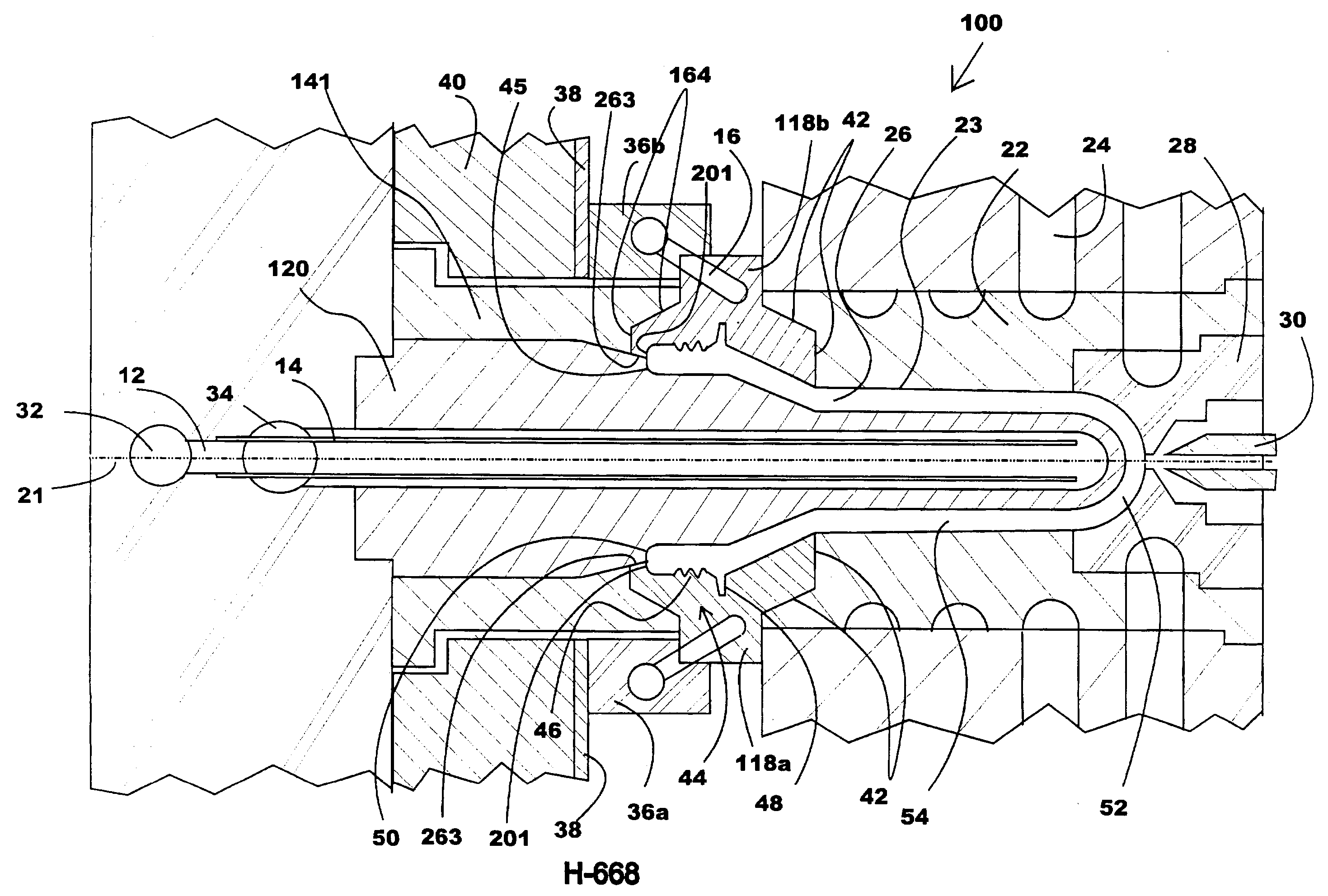

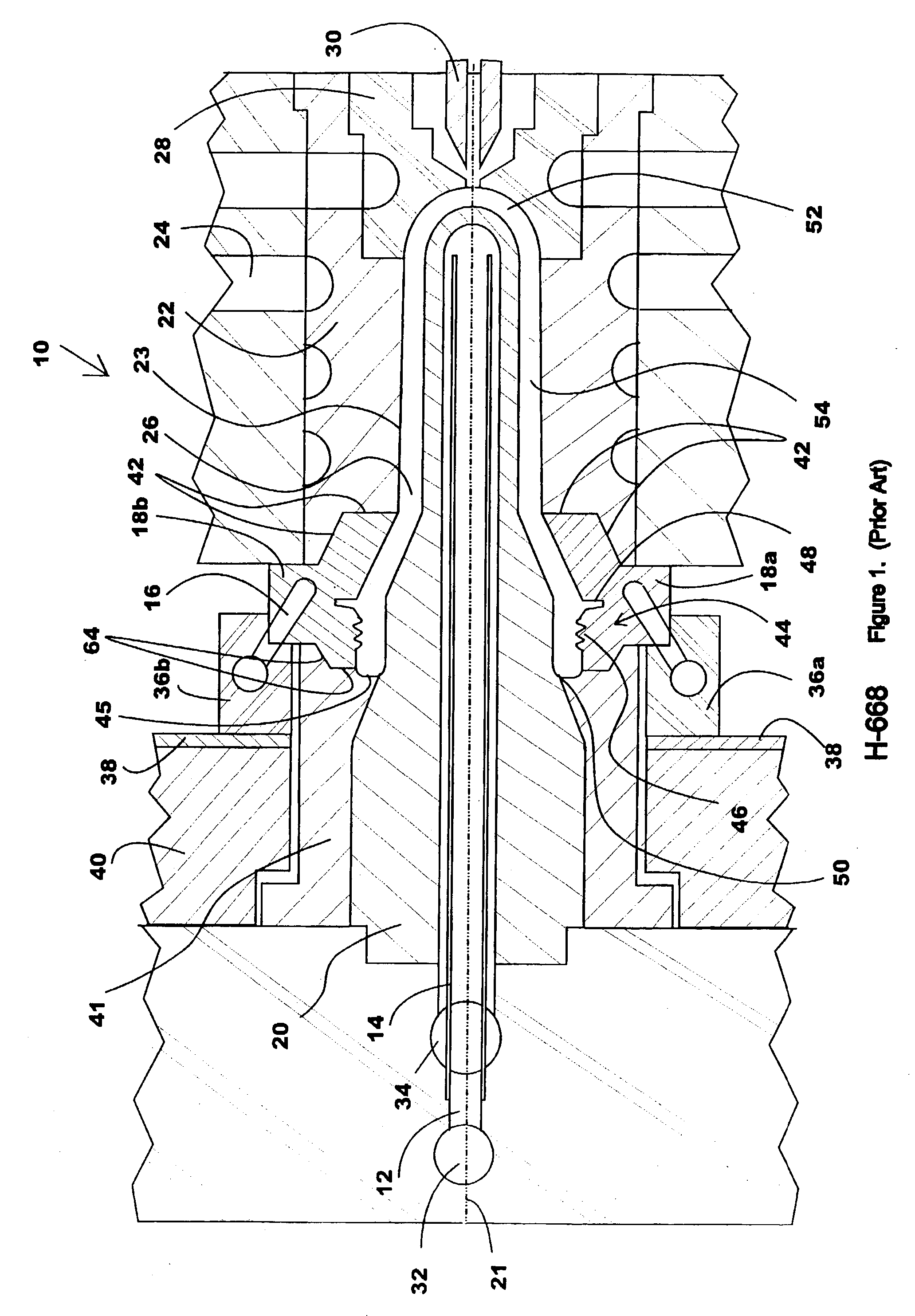

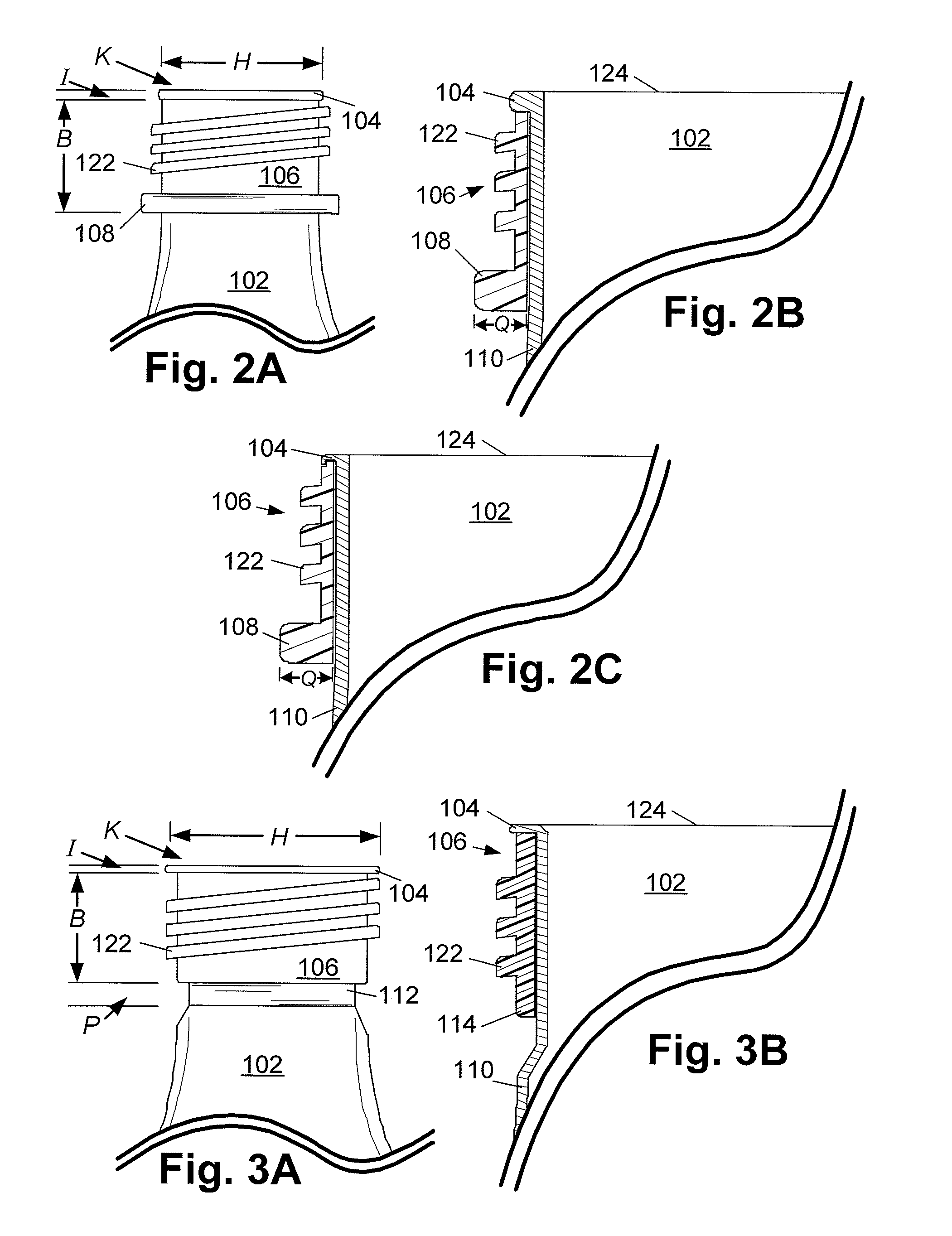

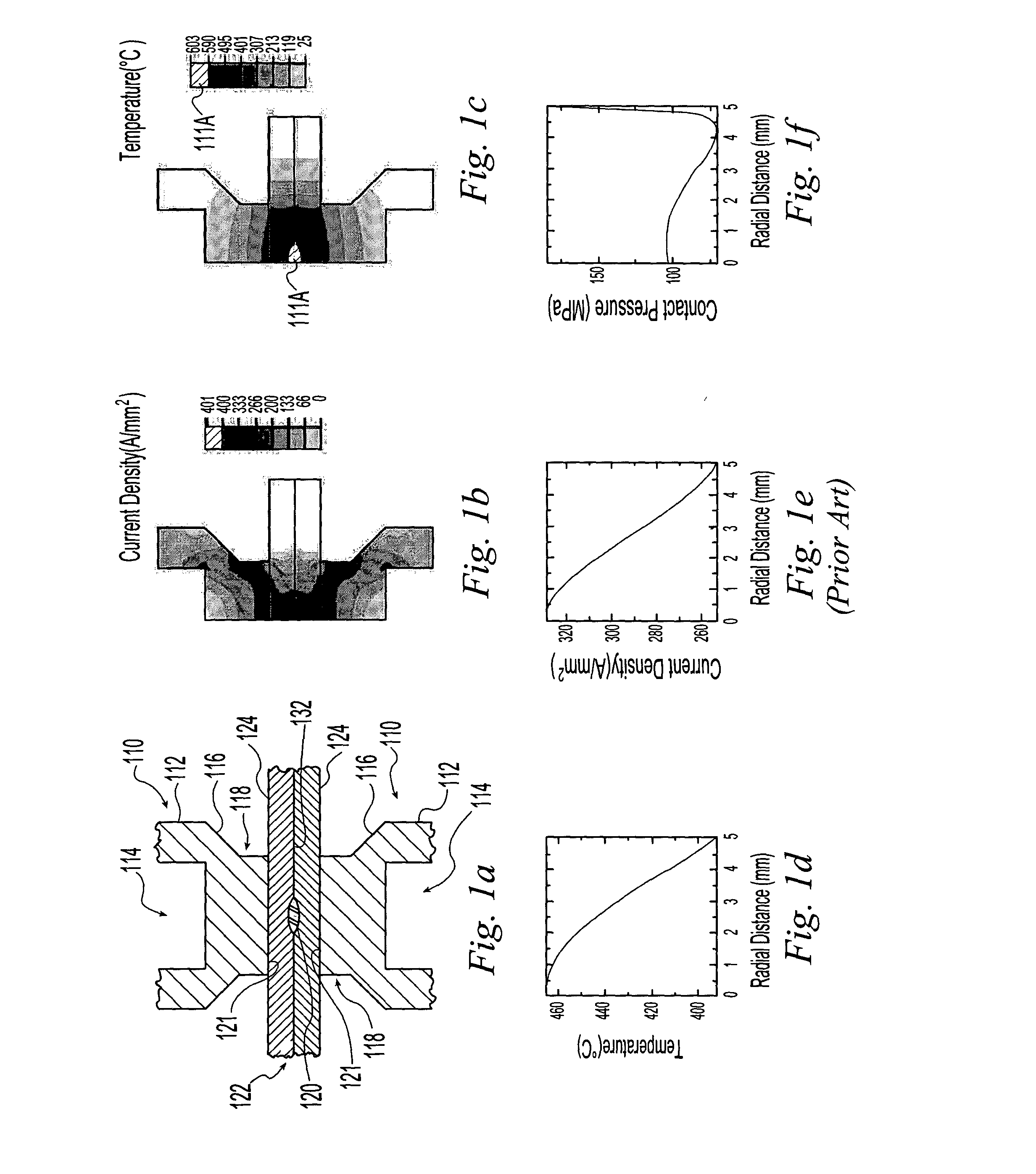

Injection molding method and apparatus for ejecting a molded plastic article from a mold. A lifting structure and / or step is provided with a lifting portion which is configured to contact substantially one half of an end of the molded plastic article along a line substantially perpendicular to the lifting direction. Since the molded plastic article is lifted by its end, the article does not have to be solidified at its interior, thus allowing earlier removal of the article from the mold, reducing cycle time. A tapered surface forms an acute angle with respect to the lifting portion to form a tight seal with the mold, preventing leakage. Preferably, the neck ring engages only an outer circumferential portion of the molded plastic article during a majority of a mold opening stroke.

Owner:HUSKY INJECTION MOLDING SYST LTD

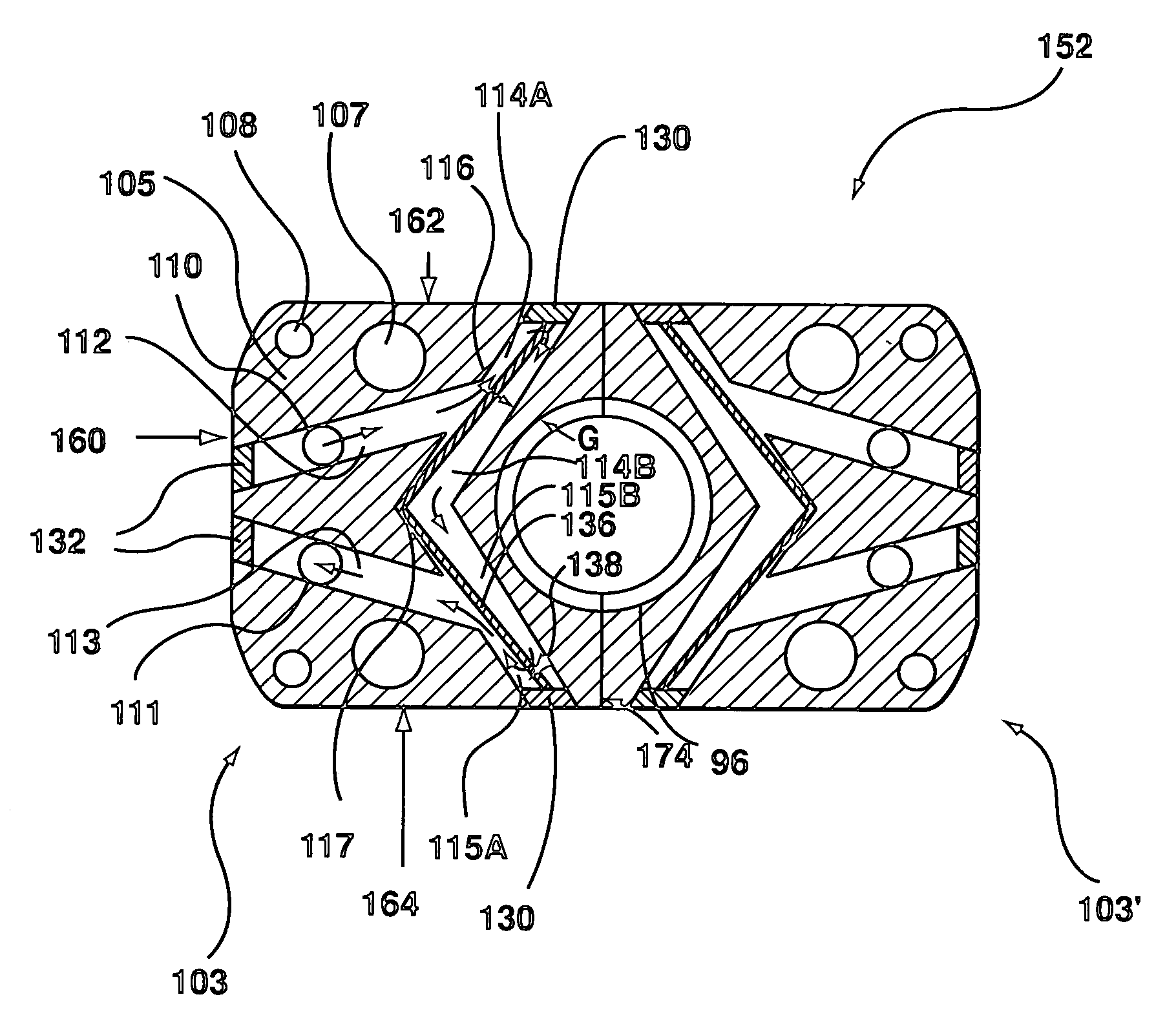

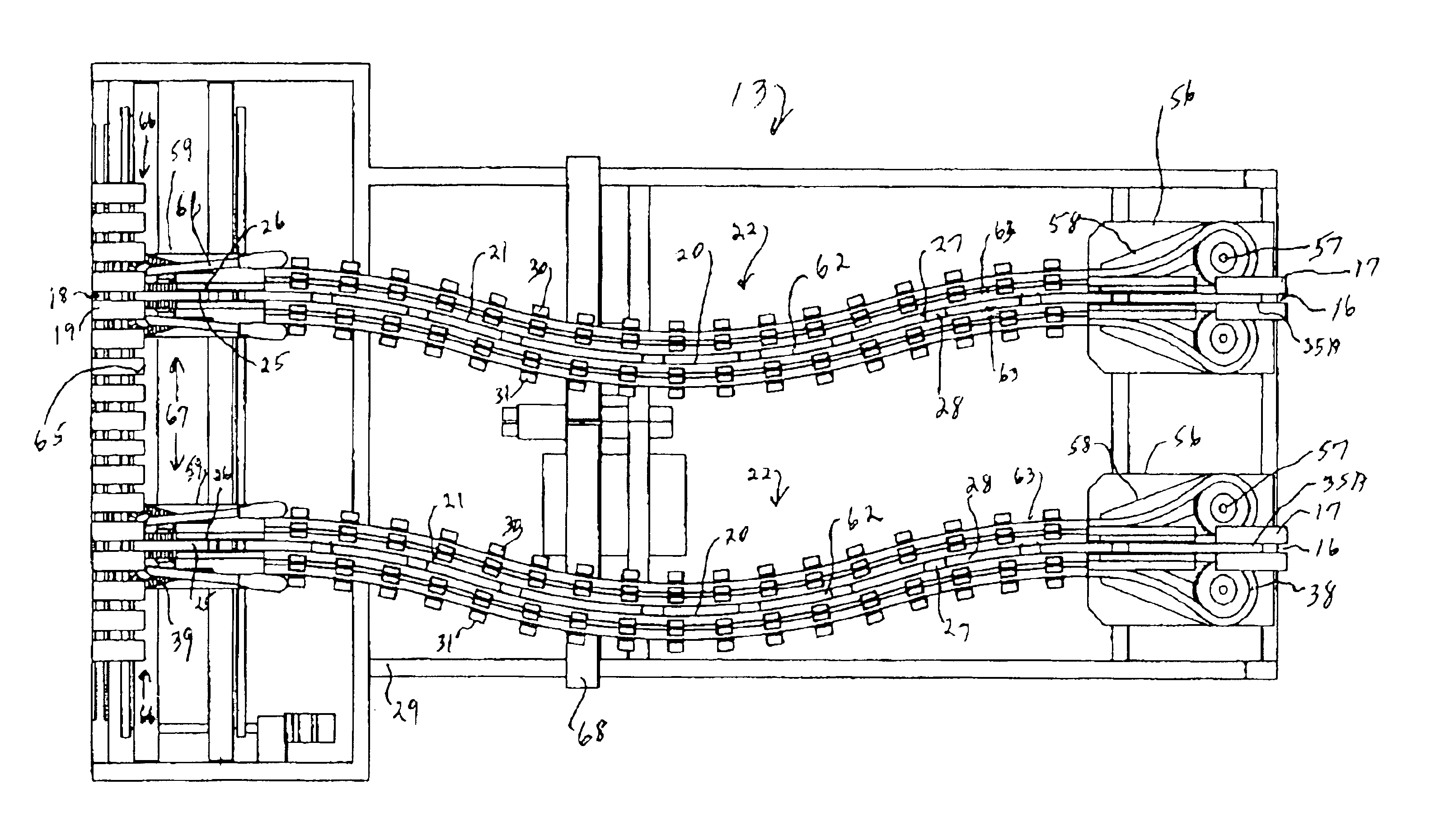

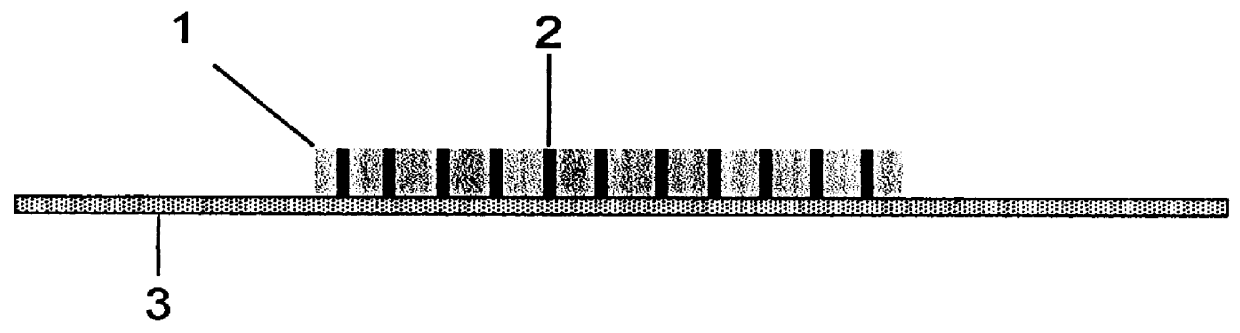

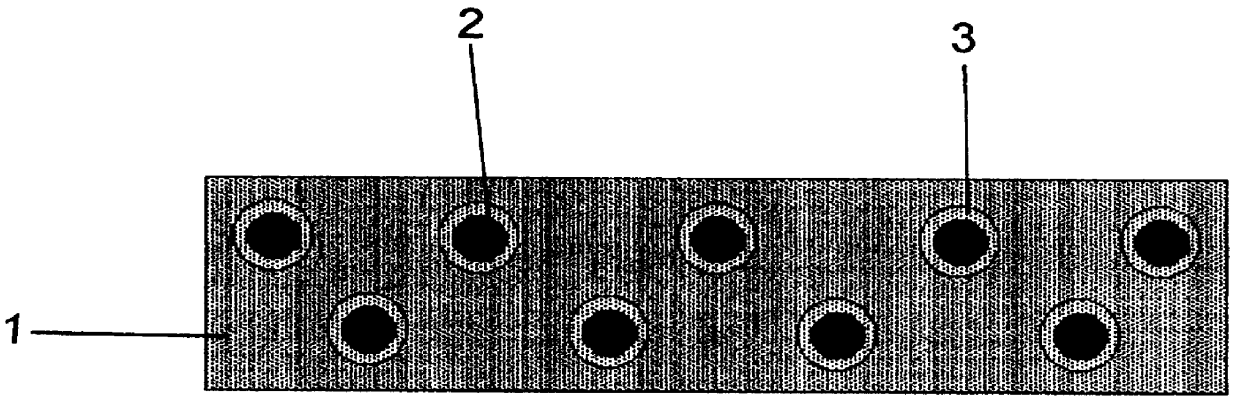

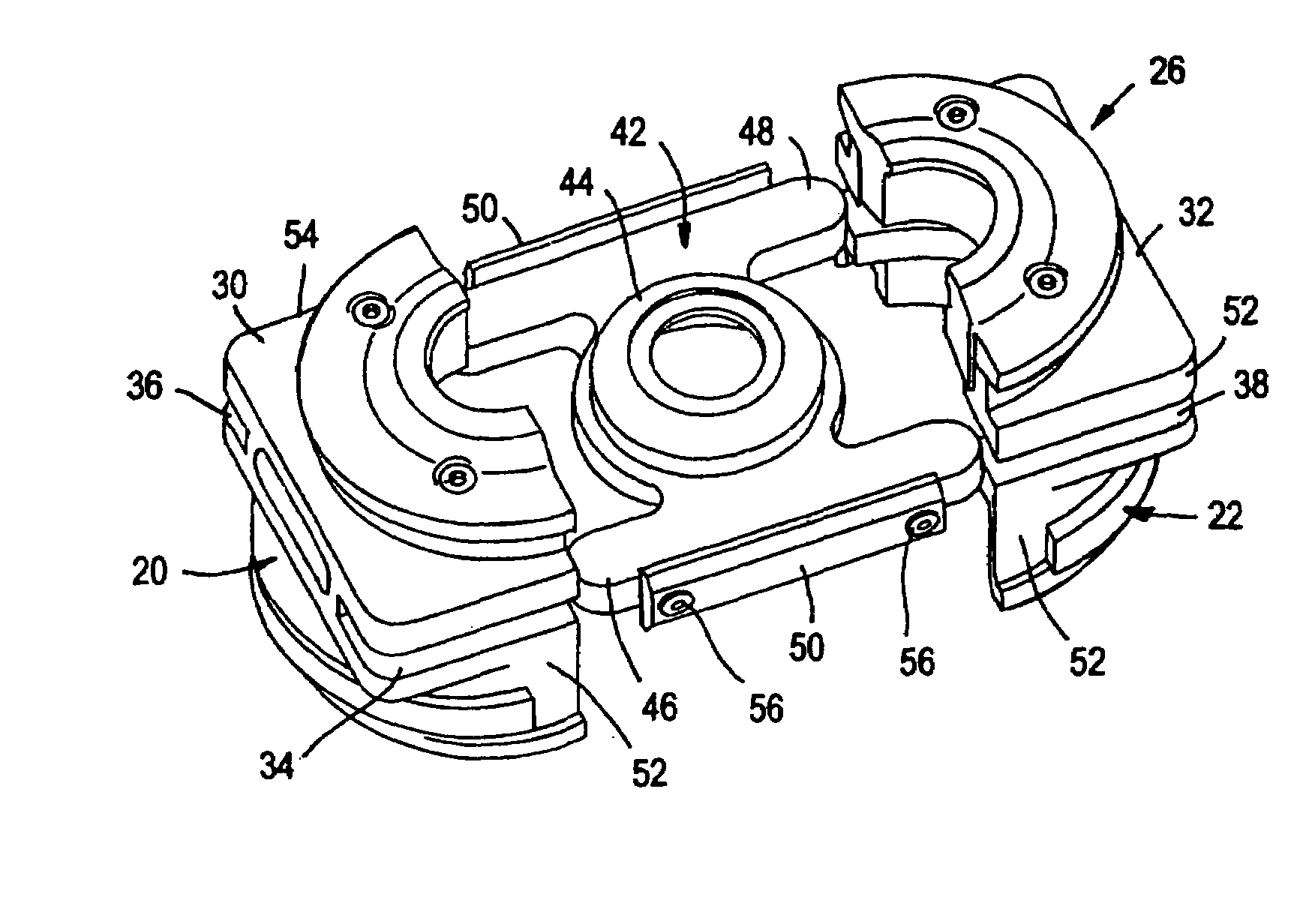

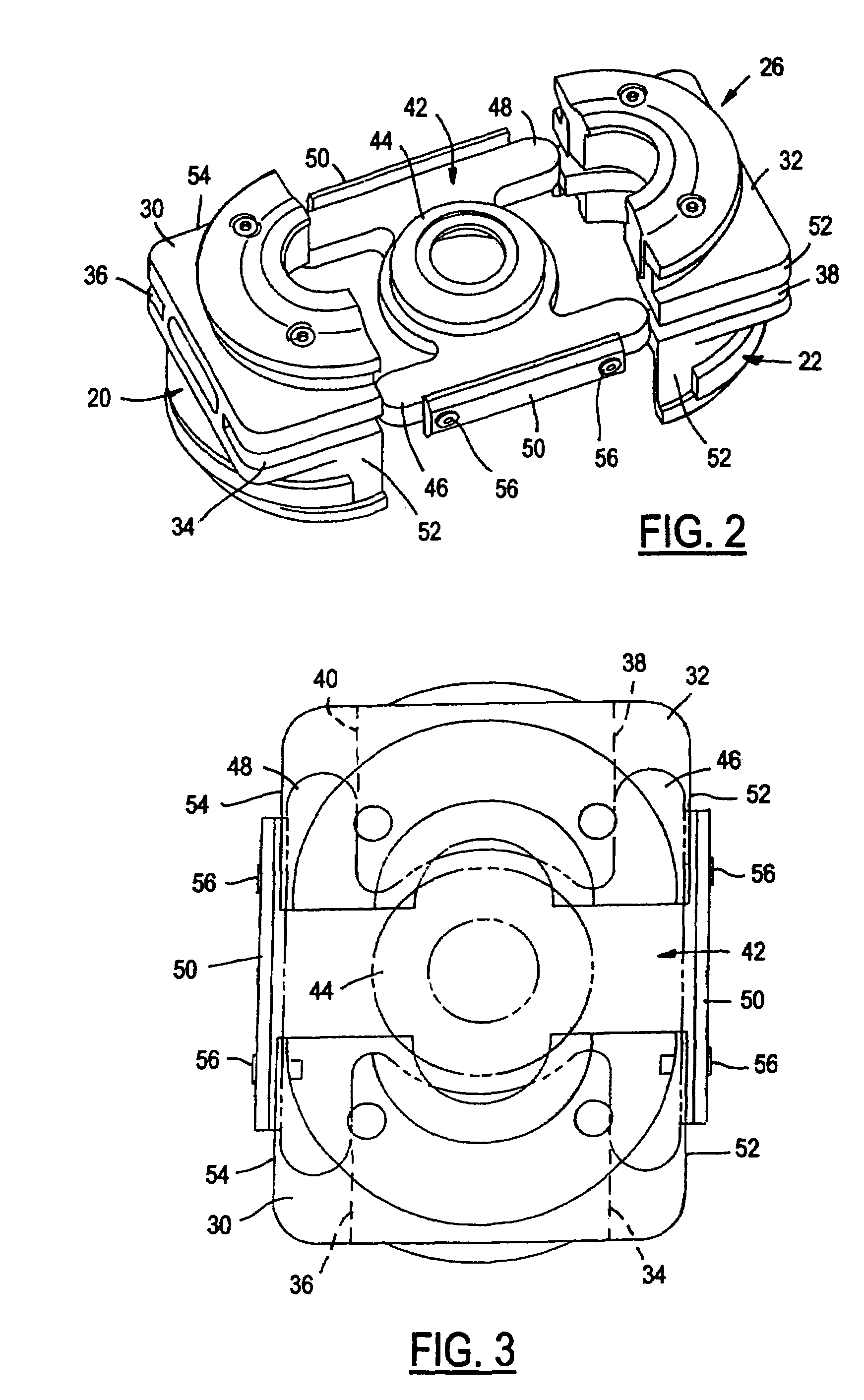

Mold split insert

InactiveUS7377767B2Reduce decreaseSimple and economical to manufactureCeramic shaping apparatusFood shapingShell moldingEngineering

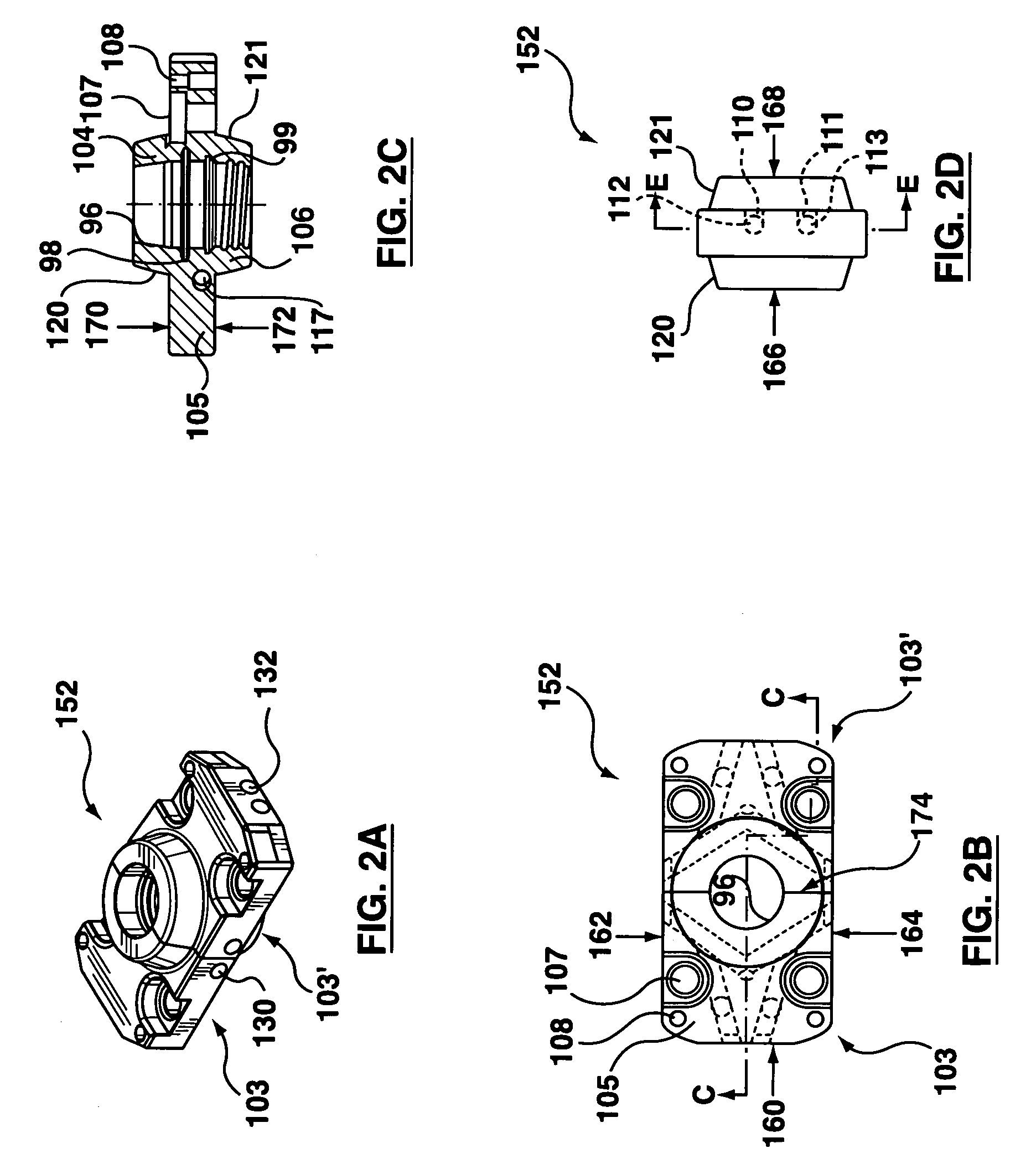

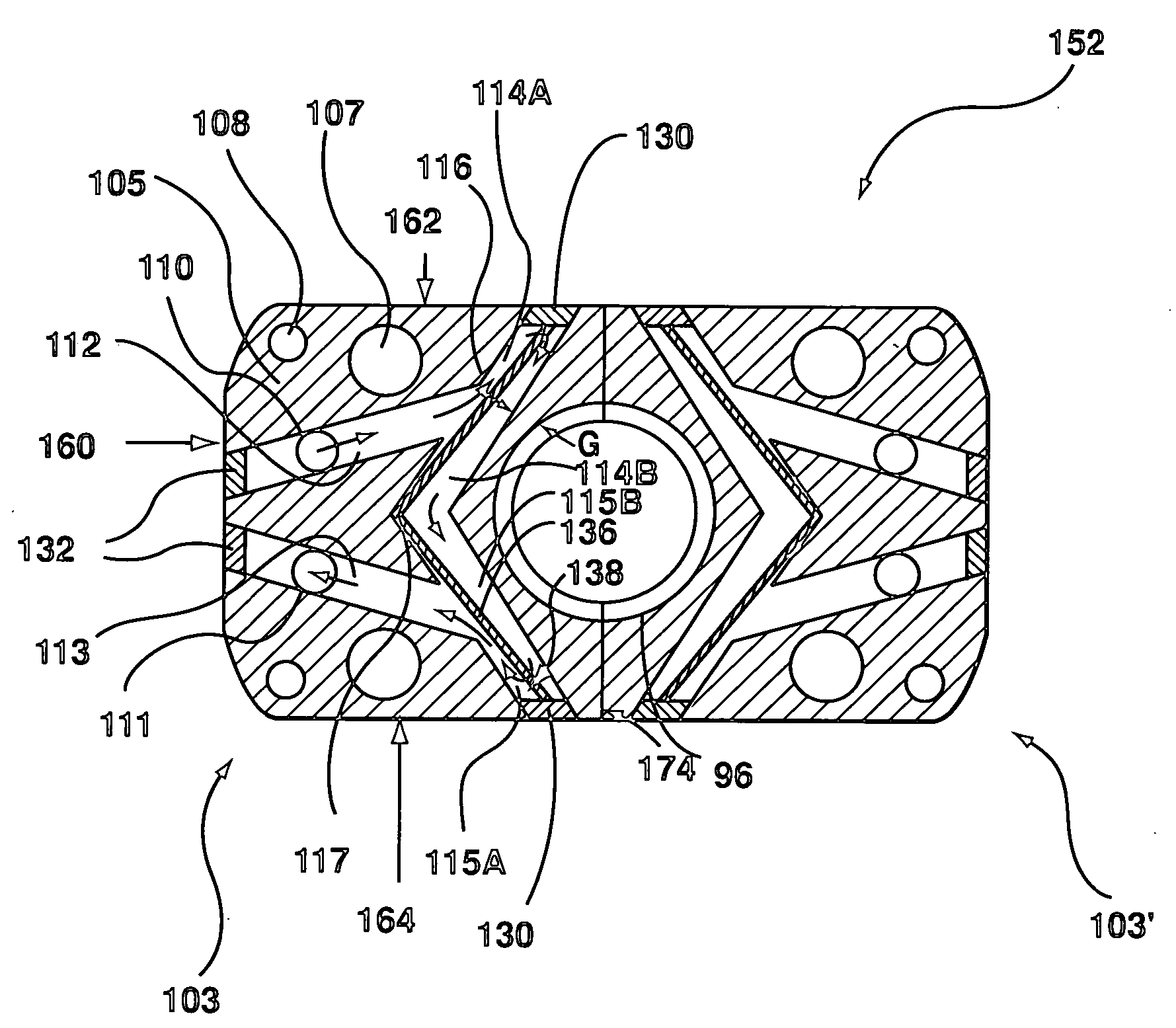

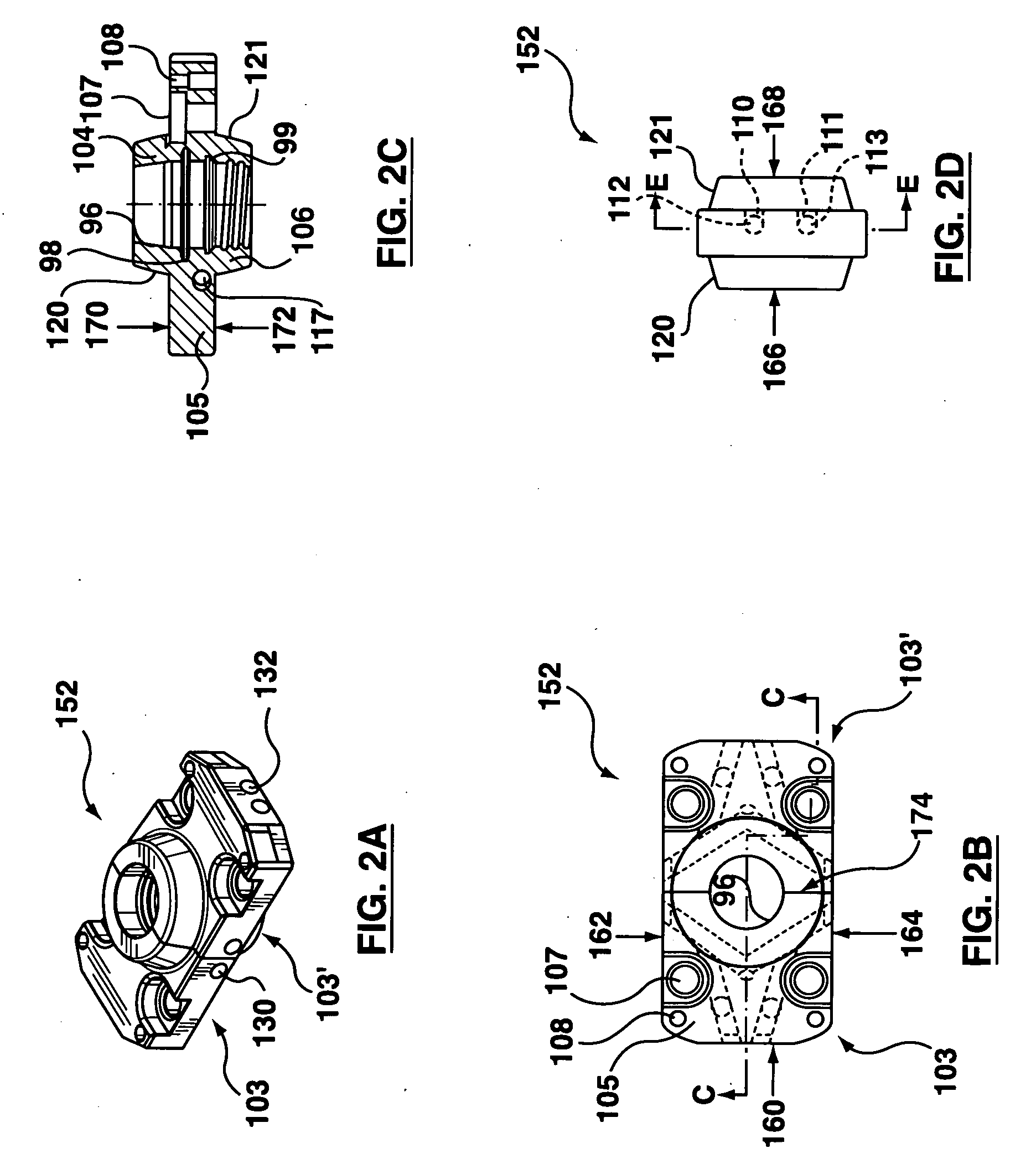

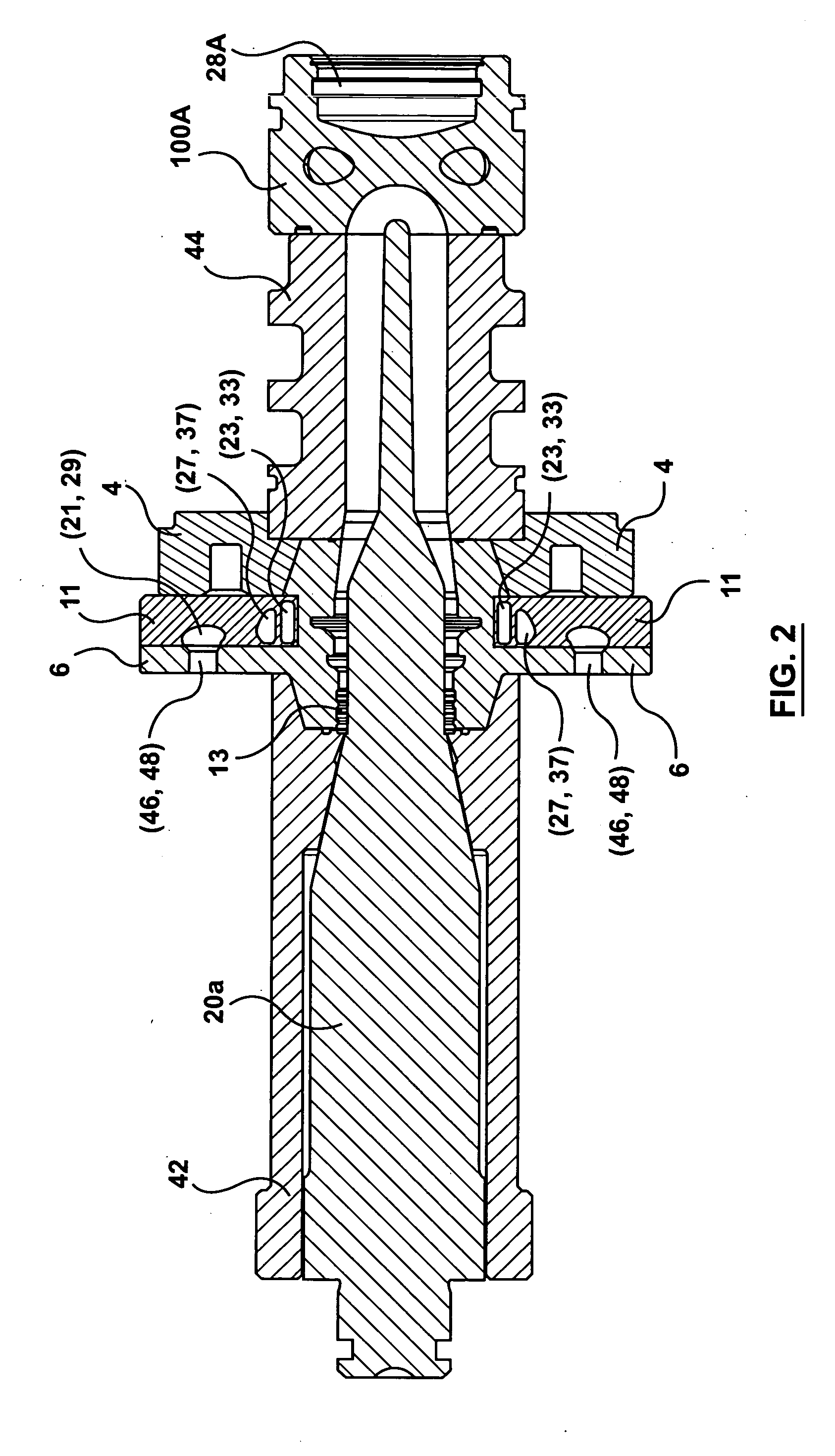

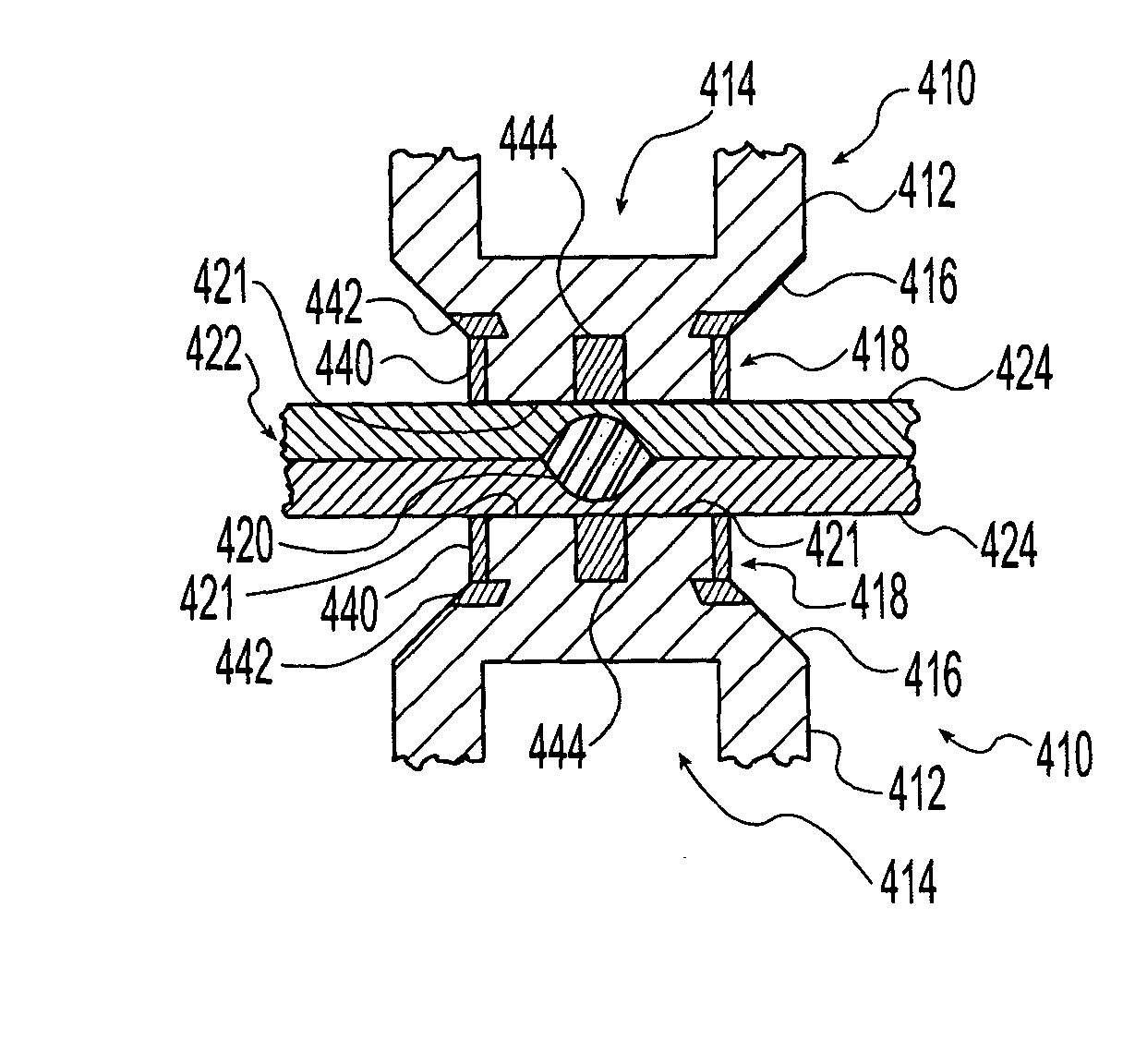

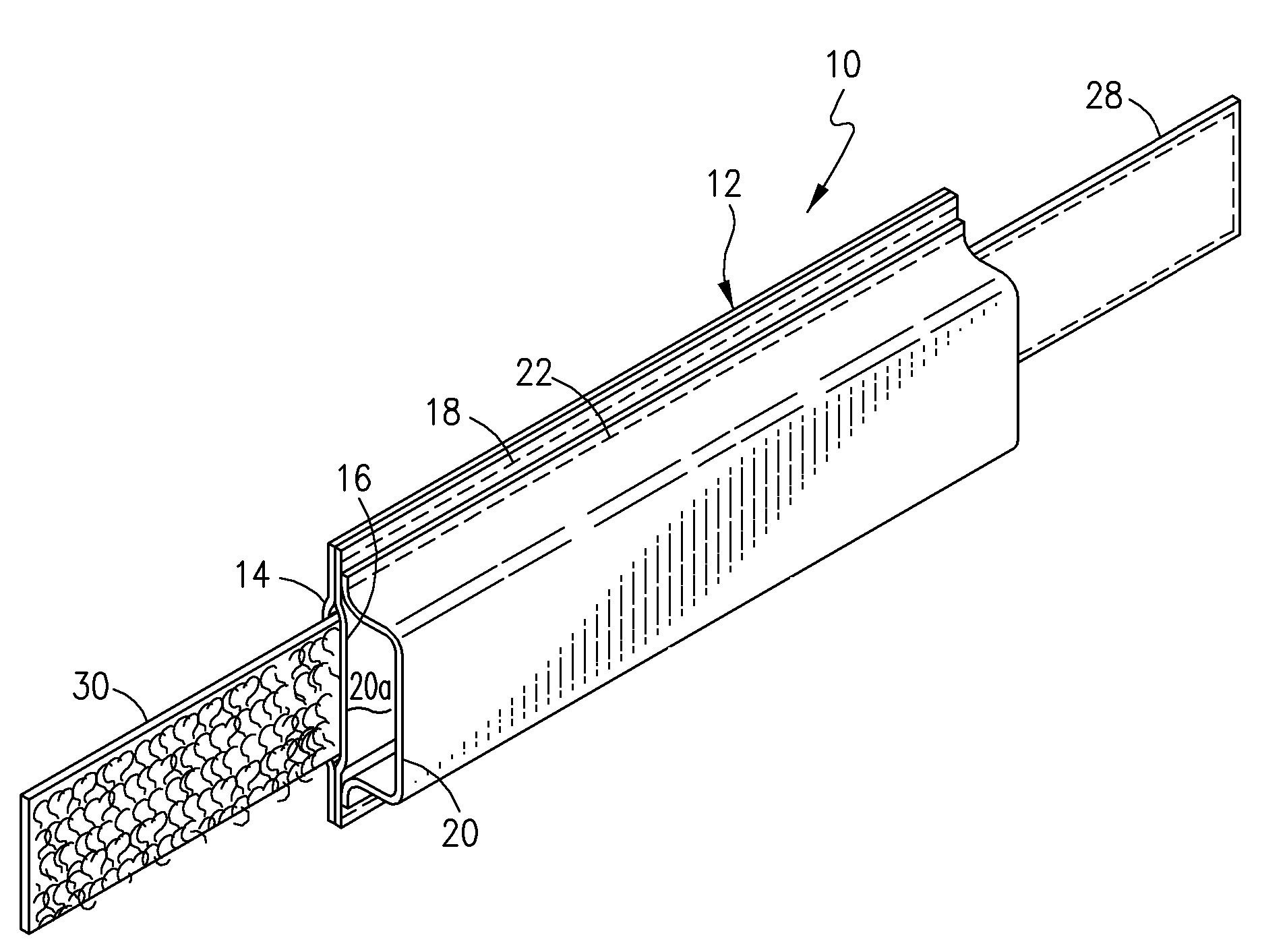

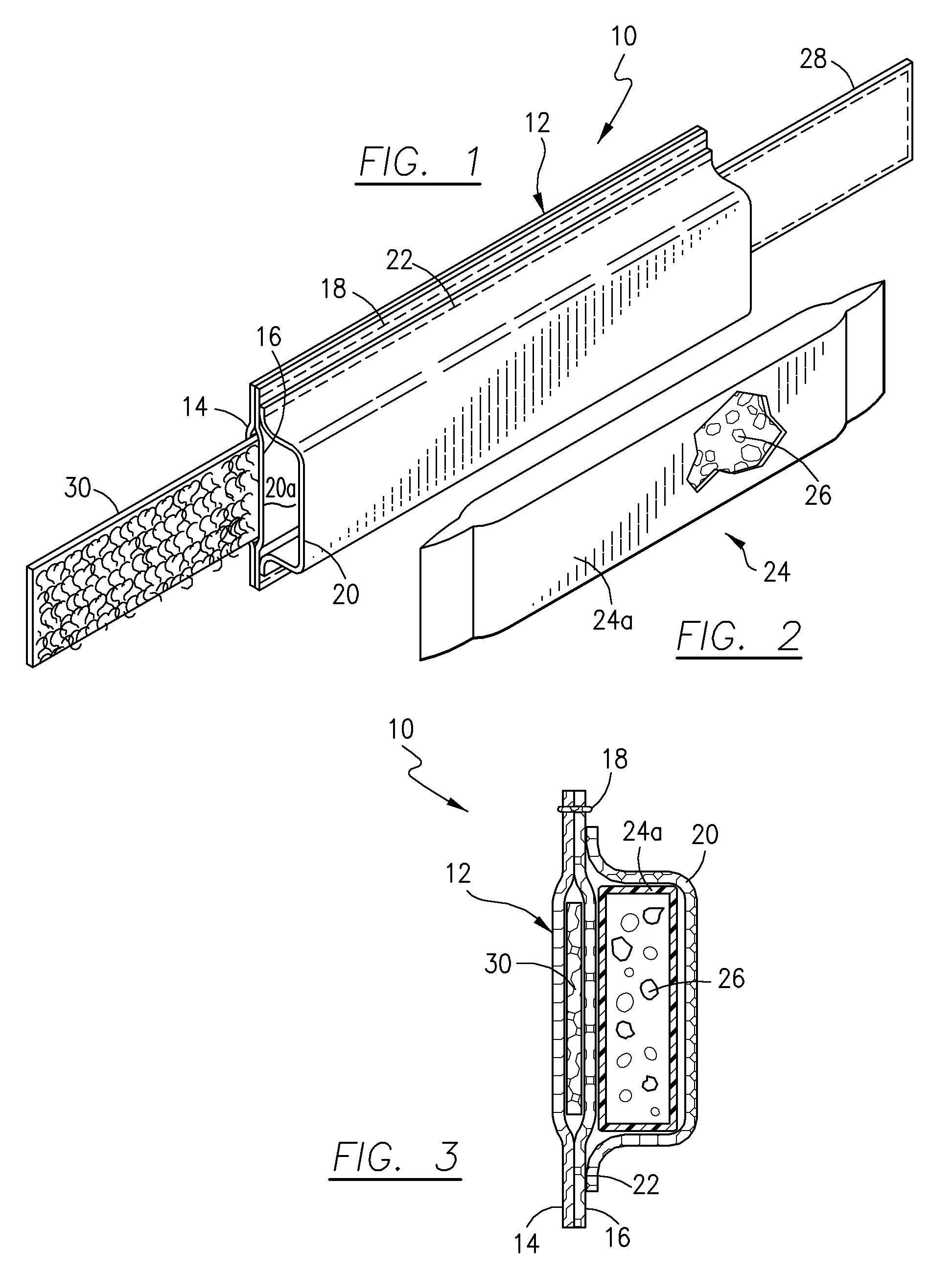

A mold split insert for use in a molding stack assembly, and in particular a preform mold neck ring insert for use in an injection molding stack assembly for making bottle mold preforms. The split insert comprises a body with a molding surface configured thereon. The split insert also includes a coolant channel configured in the body with a partition arranged therein. The partition dividing a portion of the coolant channel into a first and a second branch. A transfer coolant channel is configured between the branches.

Owner:HUSKY INJECTION MOLDING SYST LTD

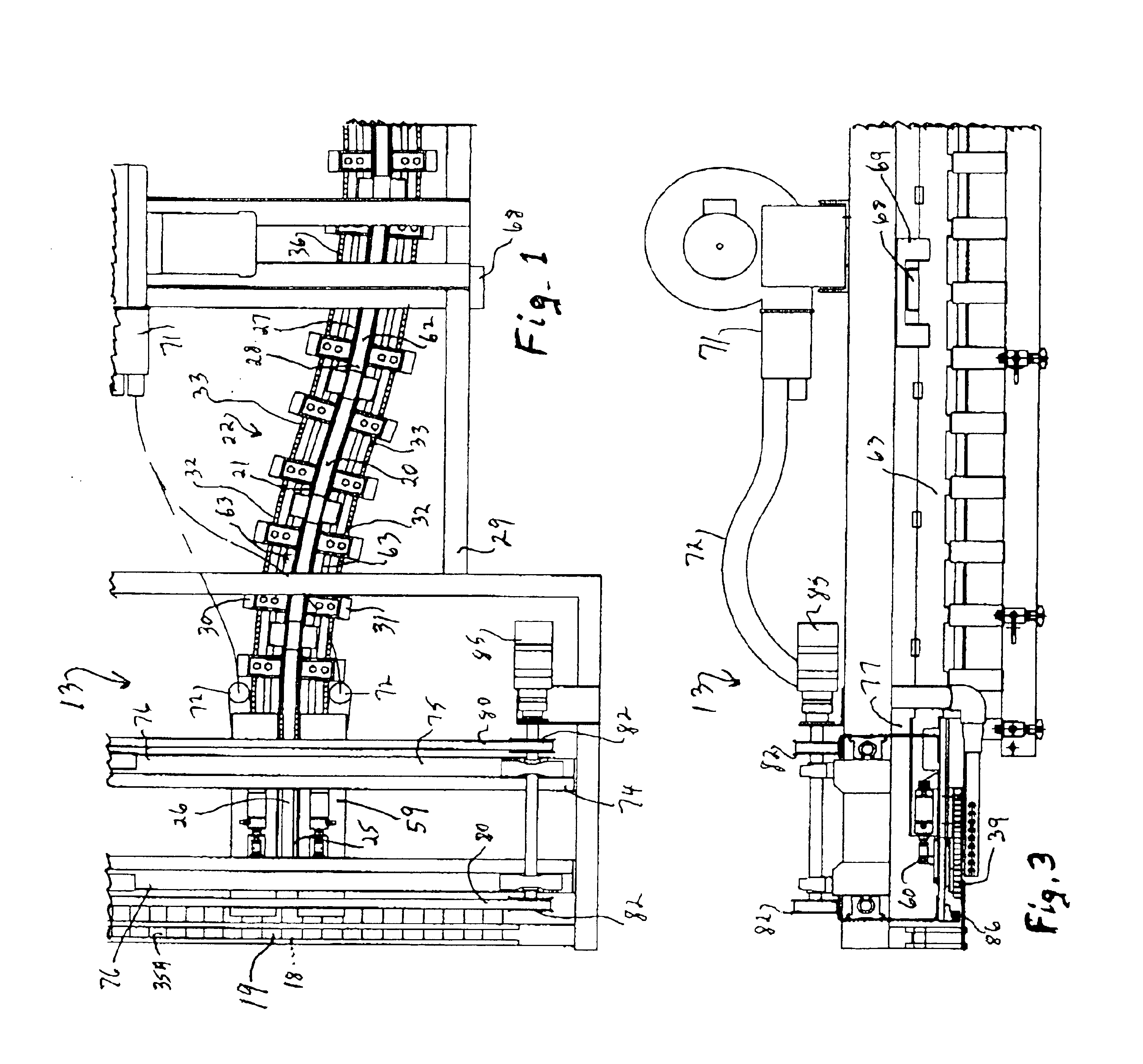

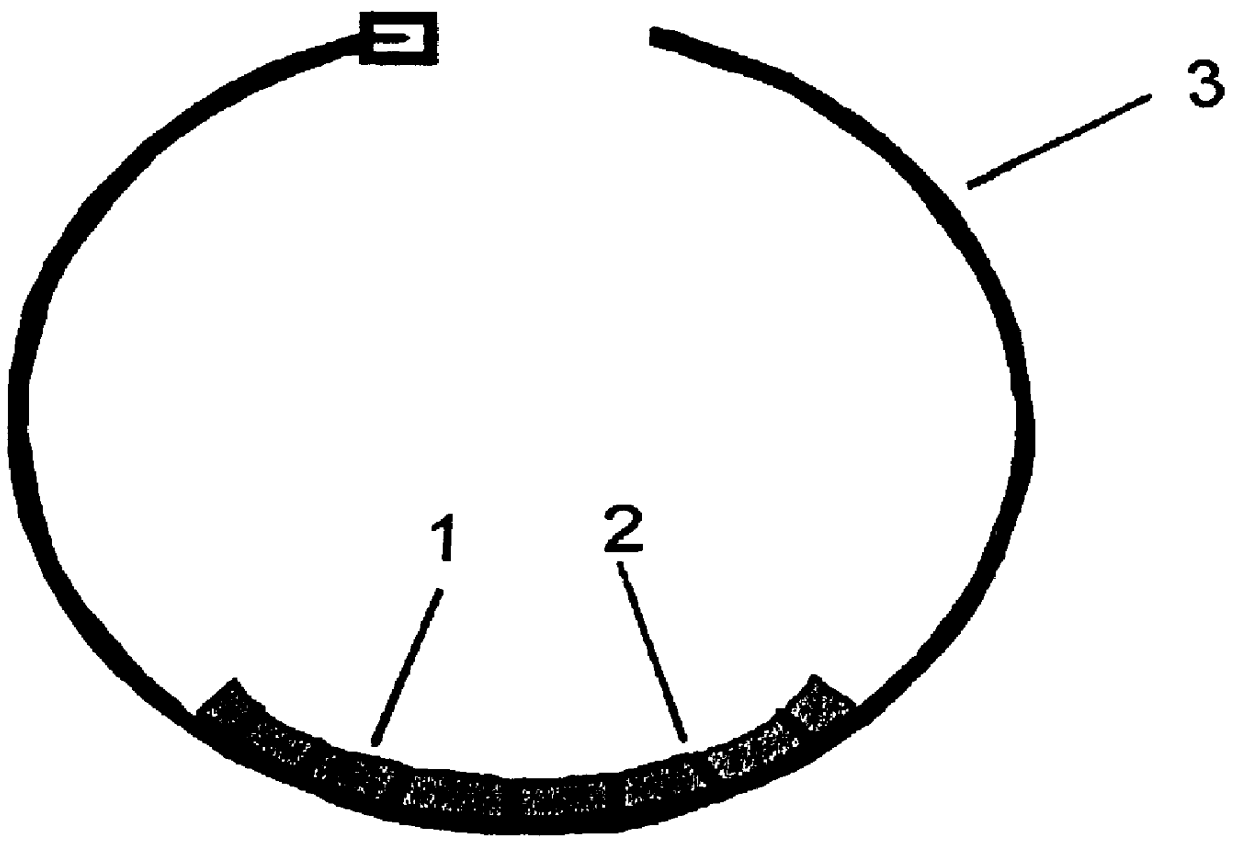

Cooling circuit for cooling neck ring of preforms

InactiveUS7234930B2Easy to changeControlled cooling of the preform neck ringAdditive manufacturing apparatusFood shapingNeck ringsCooling channel

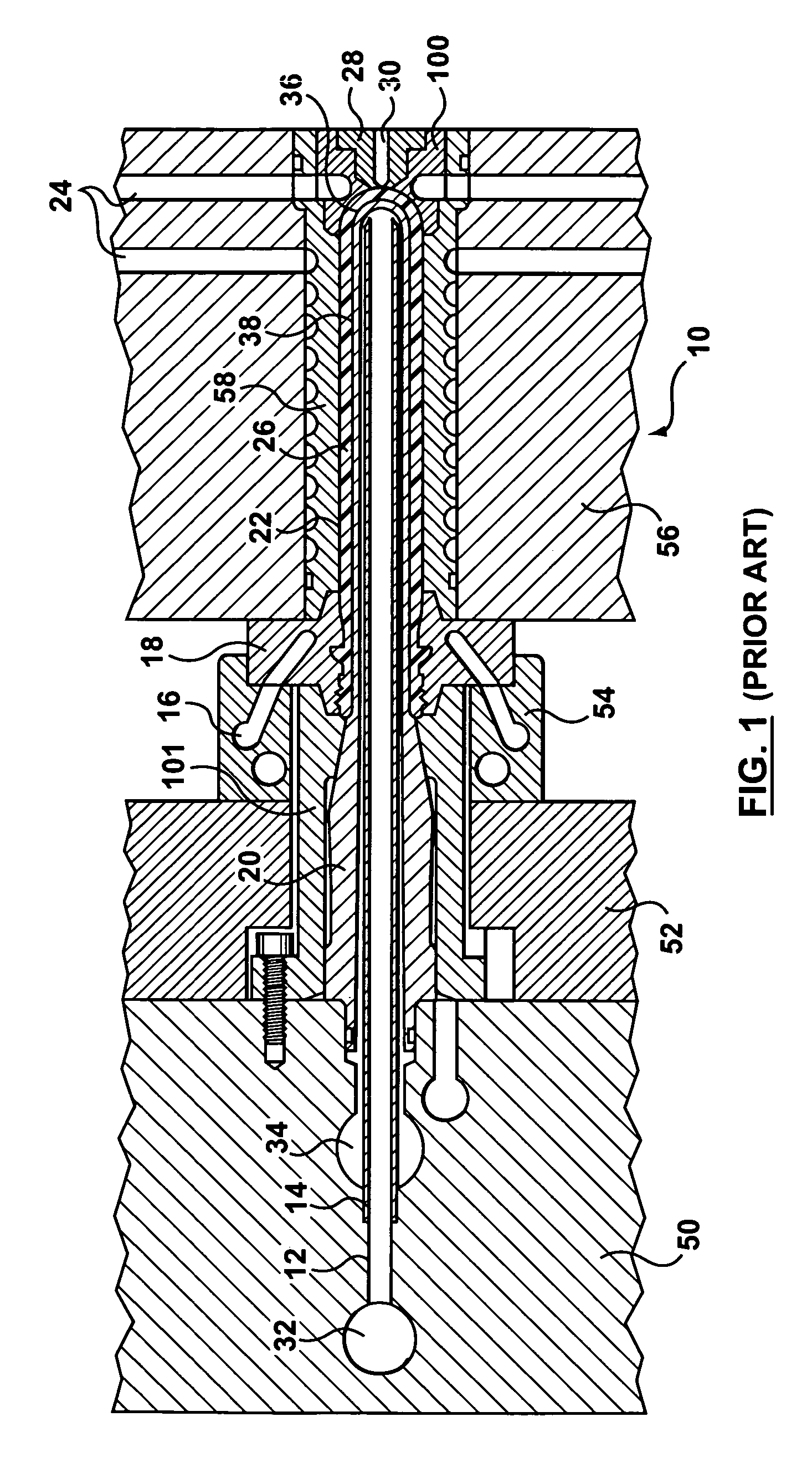

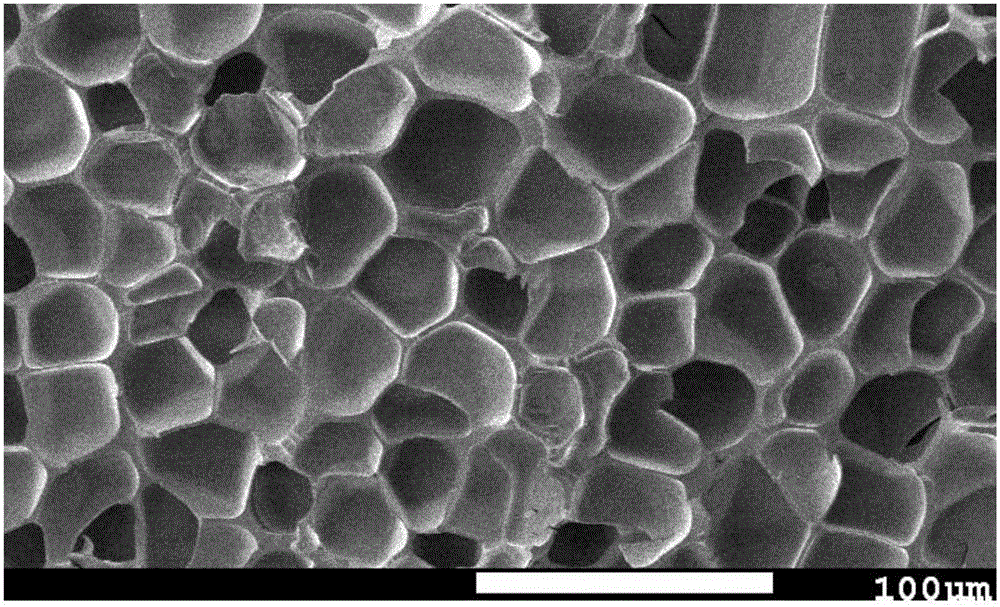

A cooling circuit for a neck ring of a preform is conformed to the surface of the neck ring by providing a neck ring in two parts. The first part supports the neck ring and provides strength and durability to the neck ring insert. The second part is formed of porous steel impregnated with highly thermally conductive metal and includes a cooling channel that provides substantially uniform cooling around the neck ring of the preform.

Owner:HUSKY INJECTION MOLDING SYST LTD

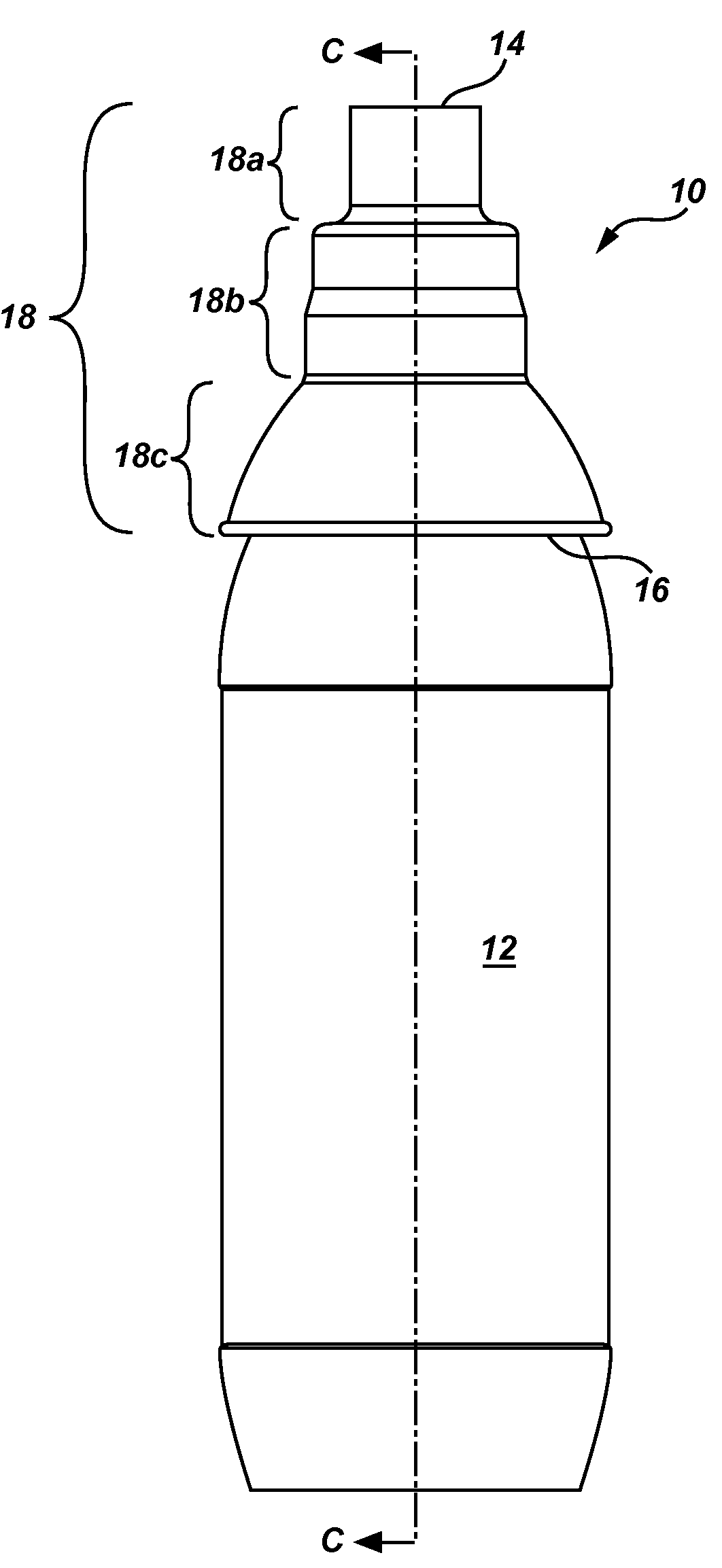

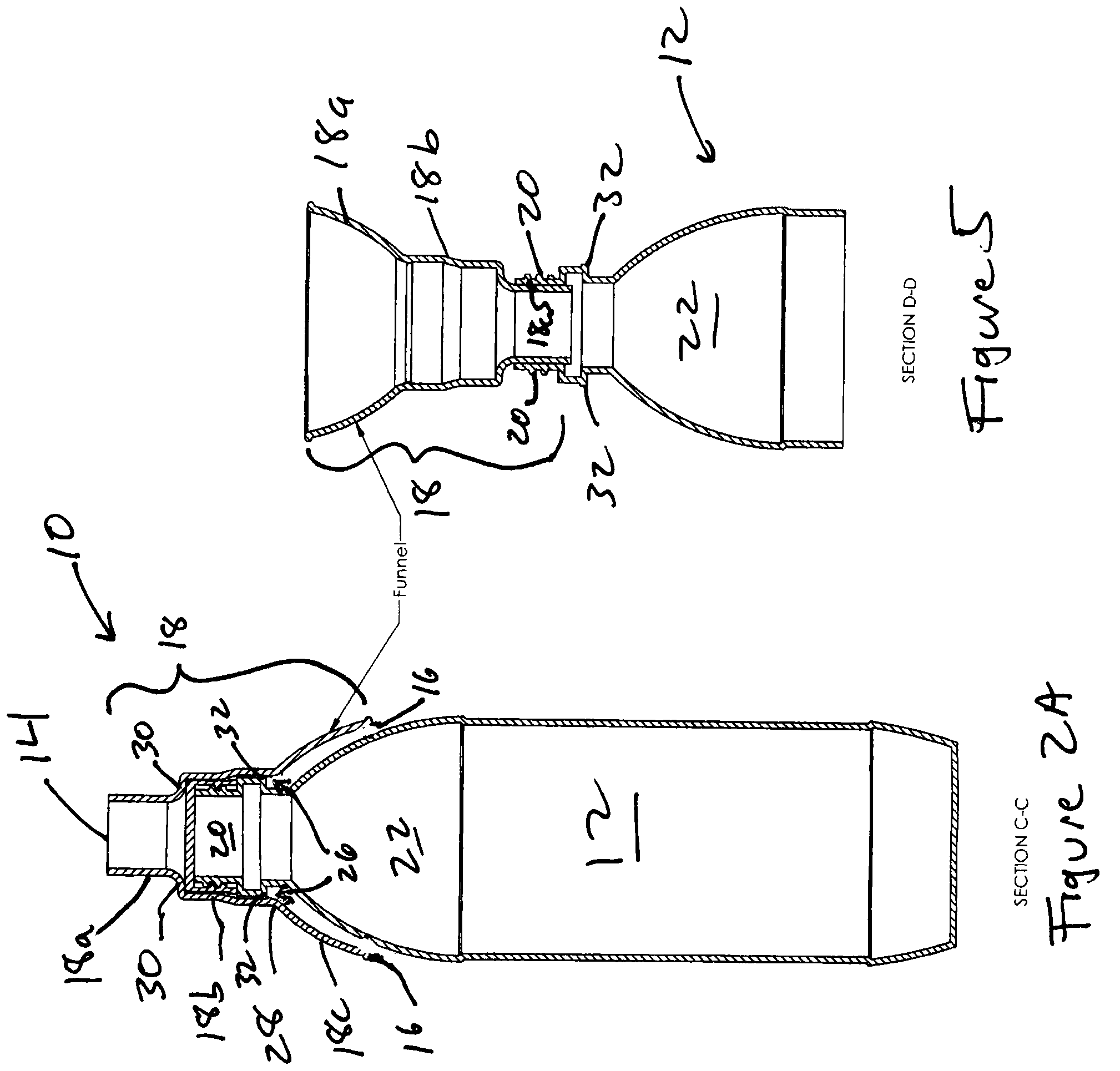

Detachable Funnel For Water Bottles

A detachable funnel apparatus for use with a container has an open wide end, an open narrow end, and sidewalls connecting the open wide end to the open narrow end whereby materials poured into the open end pass through the sidewalls and out the open narrow end when the detachable funnel apparatus is coupled to the container. The funnel is configured to removably affix to the container when stored by a coupling mechanism on the inside of the funnel such as a ring snap to create a snap connection between the funnel and a neck ring on the container or threads to connect to the threads on the container normally used by the cap of the container.

Owner:SAYAGE LARRY

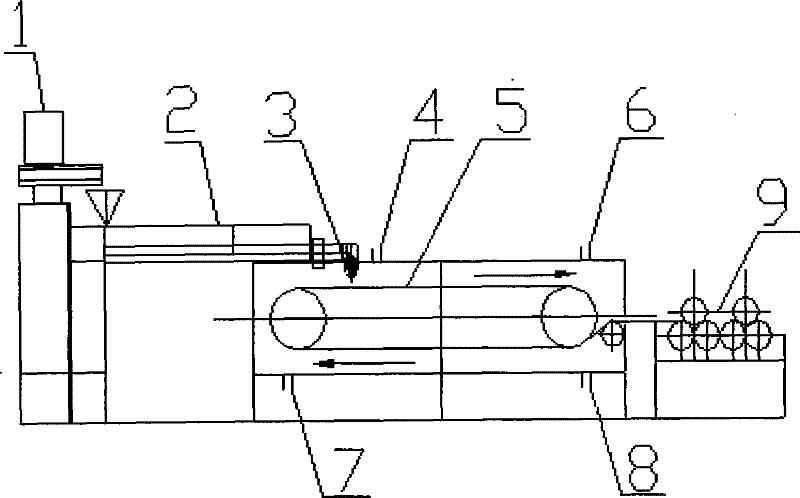

PC/PET alloy material production method

The invention relates to a method for preparing PC / PET alloy material, and belongs to plastic shaping processing technology. It comprises: mixing milled PC granulate powder, PET sheet and lubricating agent, precrystallizing, drying, mxing refining, plasticizing, neck ring mold shaping, cooling and calendering. The PC / PET alloy material is characterized by good thermal resistance, strength, tranparency, good size stability and small thickness deviation, and is ideal replacement for electrical switching membrane, car instrument board and car glass, and the production method is characterized by low cost and high efficiency.

Owner:扬州金丰新材料有限公司

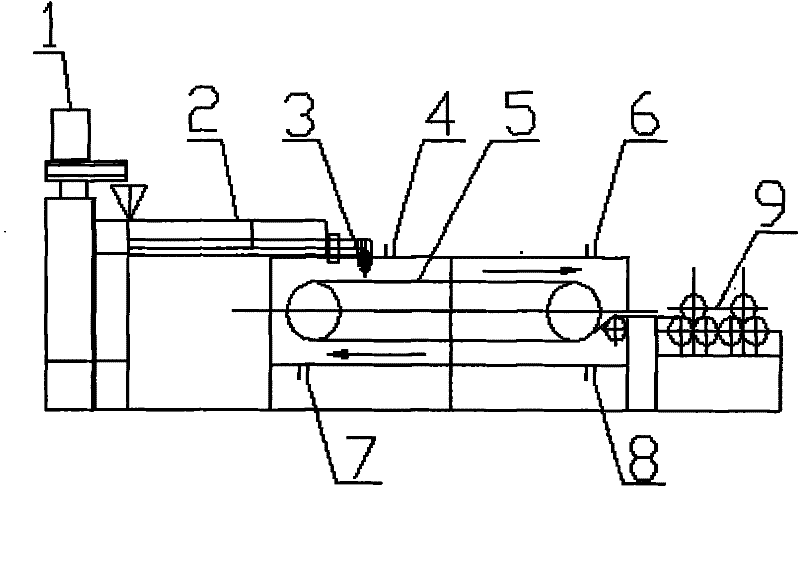

Method for preparing extruding physical foaming polypropylene bead granule

The invention discloses a preparation method of an extrusion physical foaming polypropylene bead; the method is as follows: an injector port is arranged at the middle of a machine barrel of a screw extruder, a machine head is provided with a bushing type neck ring mold and a die surface chip cutter, polypropylene foaming material and addition agents are added into the screw extruder, alkane foaming agent is injected into the machine barrel from the injector port, the proportion by weight between the polypropylene foaming material and the alkane foaming agent is 10-25%, the pressure of the neck ring mold is controlled to be 5-30MPa, and the temperature of the neck ring mold is 110-150 DEG C, thus leading the cut material to generate foams when the material enters the atmosphere, and then the product is obtained after cooling and drying. The method of the invention has the advantages of continuous extrusion of the polypropylene foaming beads, low energy consumption, little environmental pollution due to the adoption of the alkane foaming agent, low residue of foaming agent in the foaming bead and high foaming rate.

Owner:浙江华江科技股份有限公司

Mold split insert

InactiveUS20060283210A1Reduce decreaseSimple and economical to manufactureGlass drawing apparatusGlass transportation apparatusEngineeringBottle

A mold split insert for use in a molding stack assembly, and in particular a preform mold neck ring insert for use in an injection molding stack assembly for making bottle mold preforms. The split insert comprises a body with a molding surface configured thereon. The split insert also includes a coolant channel configured in the body with a partition arranged therein. The partition dividing a portion of the coolant channel into a first and a second branch. A transfer coolant channel is configured between the branches.

Owner:HUSKY INJECTION MOLDING SYST LTD

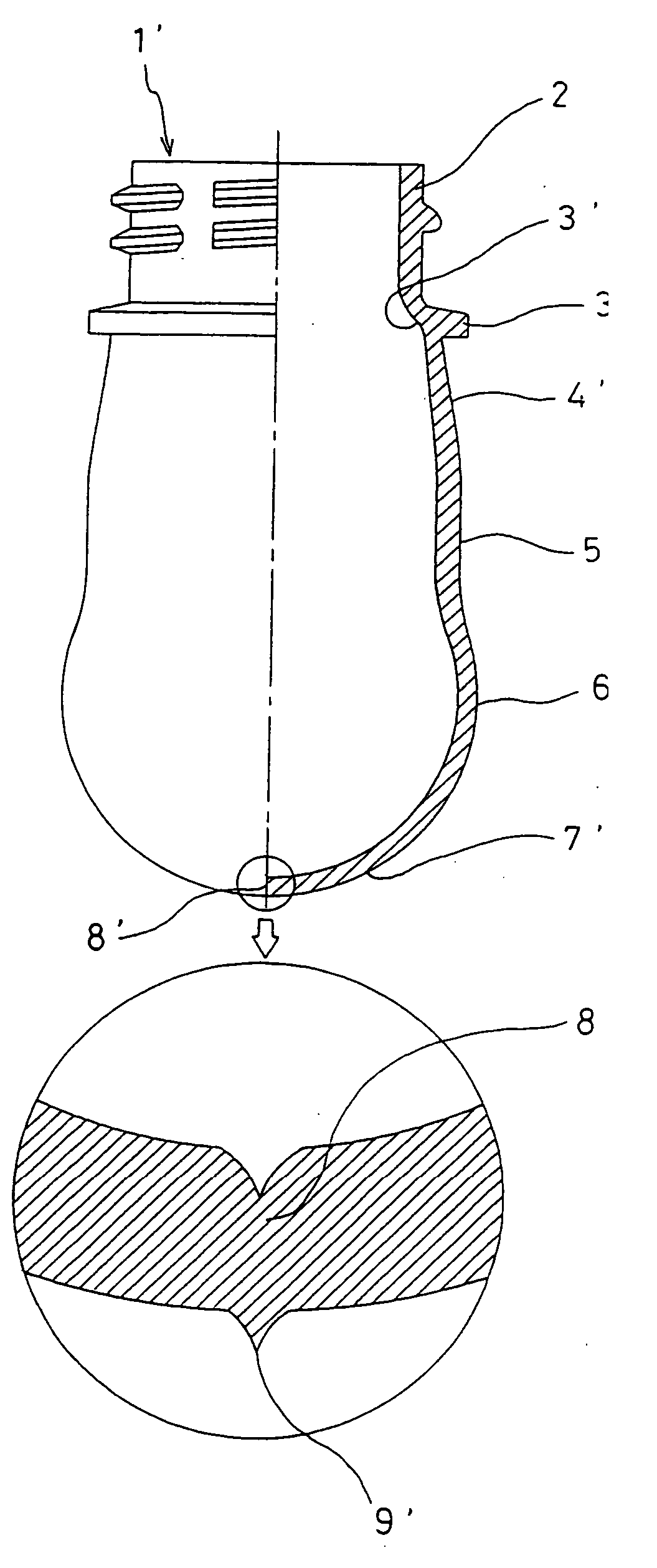

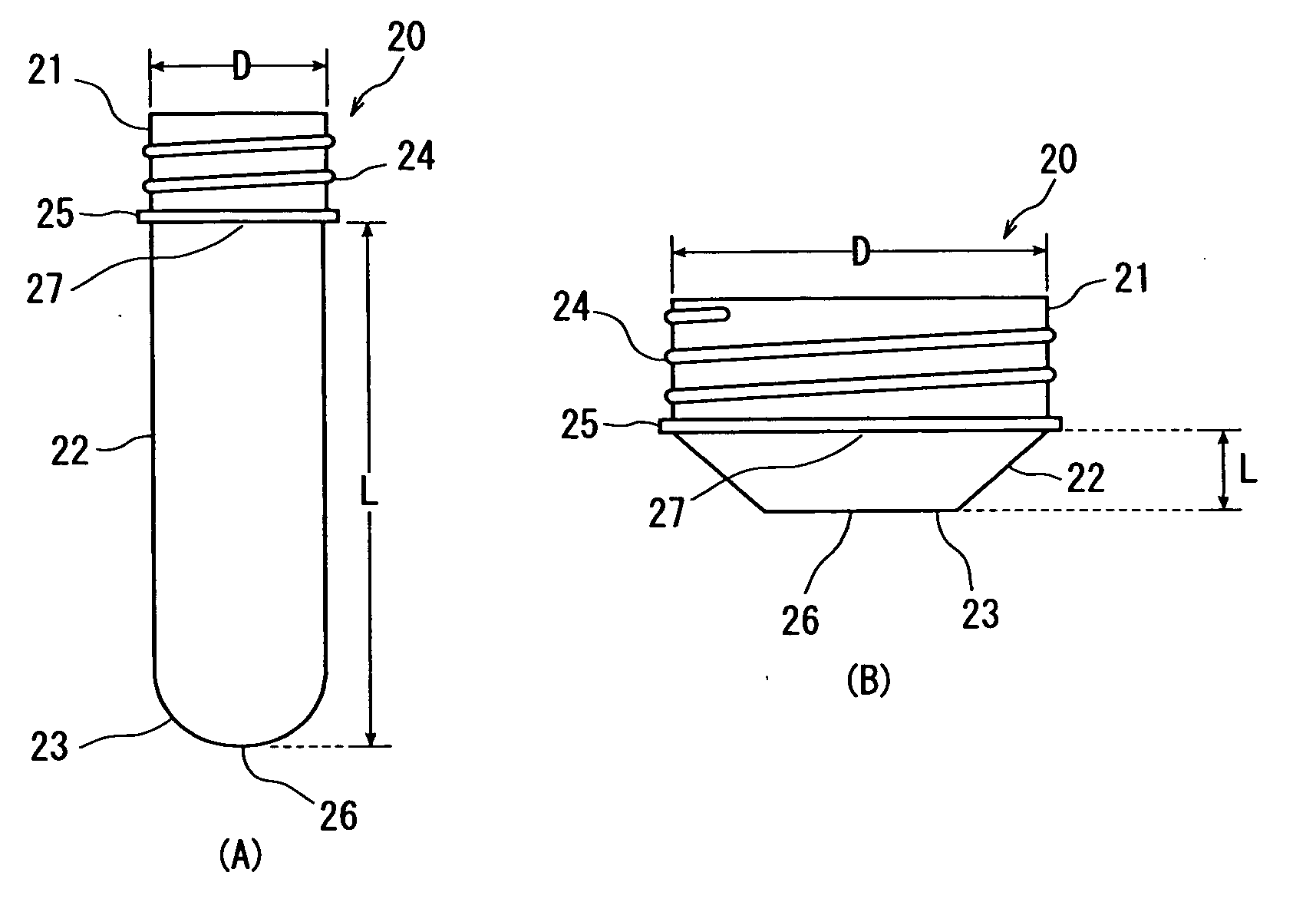

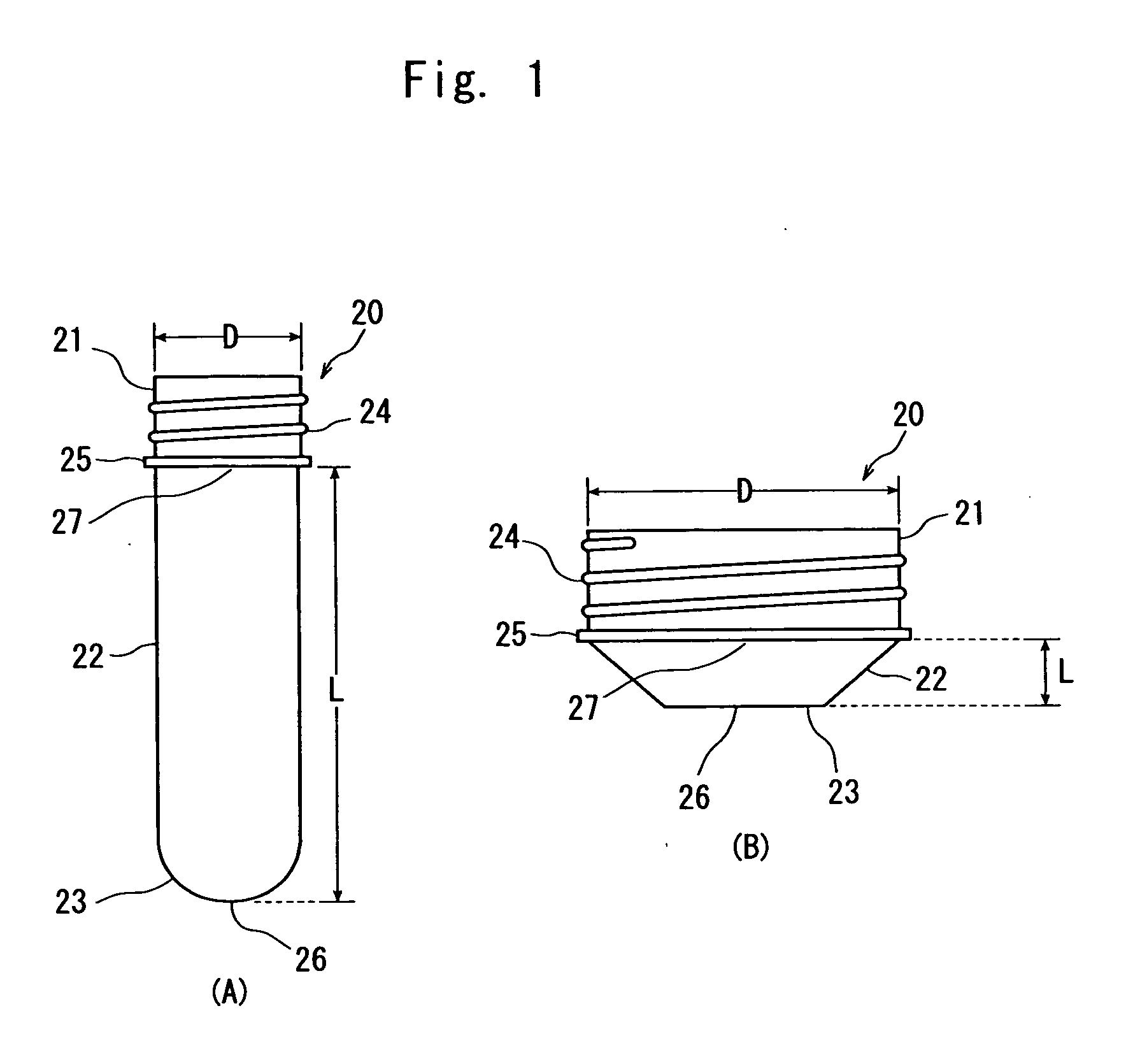

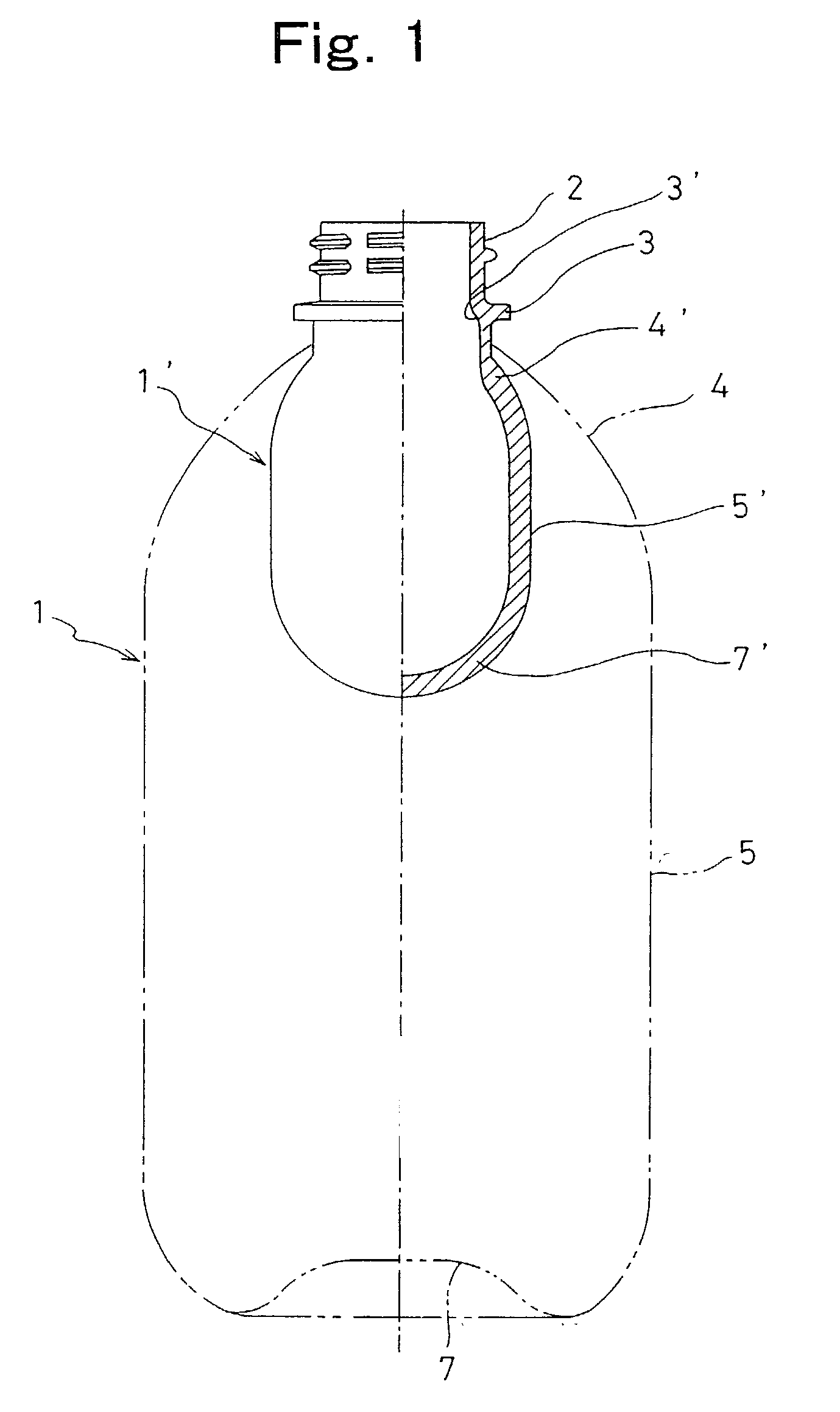

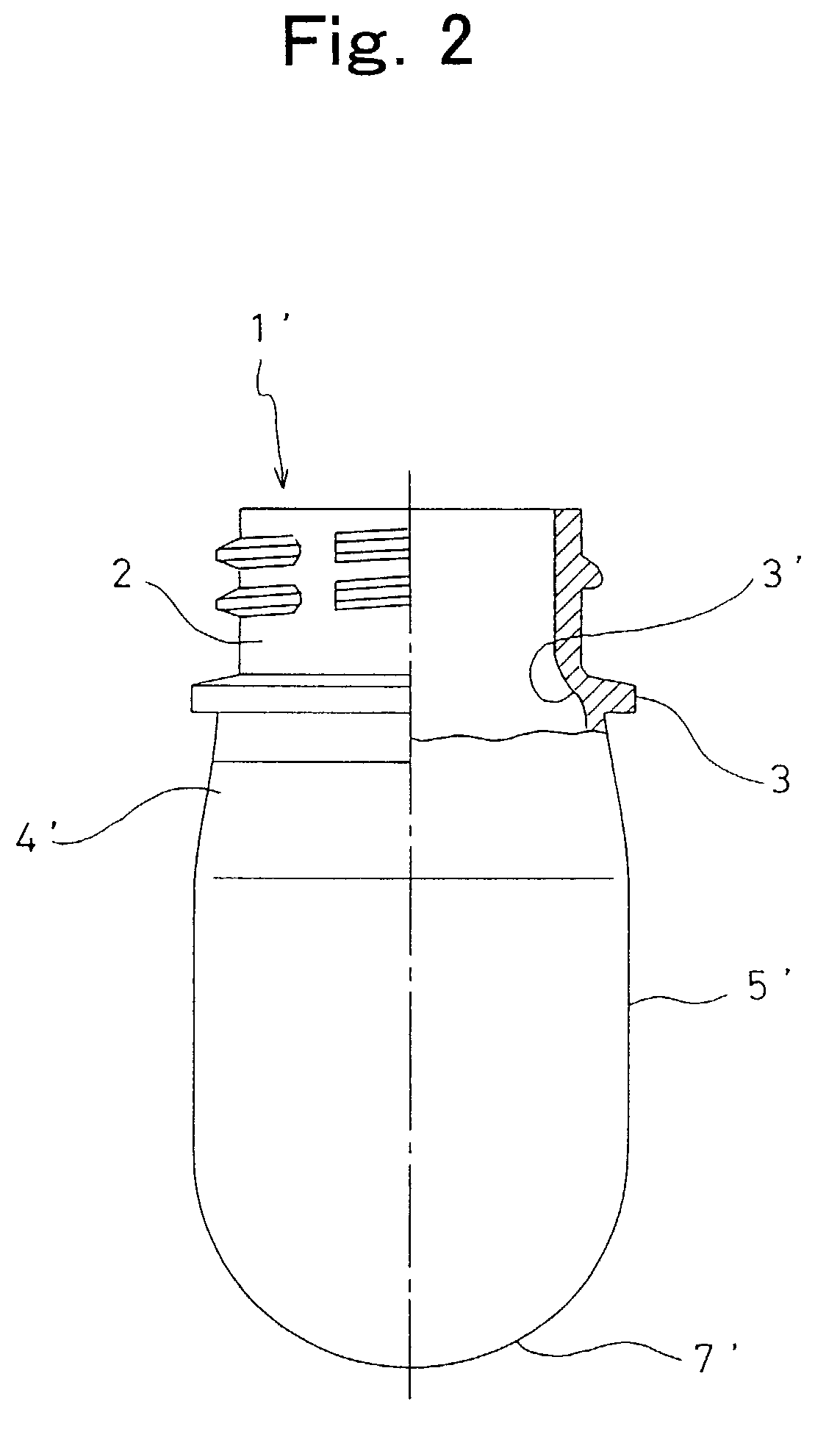

Synthetic resin preform to be biaxially stretched and blow molded into a bottle

InactiveUS20060141189A1Improve accuracyDistortion in appearanceBottlesSynthetic resin layered productsBarrel ShapedSpherical shaped

The blow molded preform of a laminated wall structure comprises a bulging shoulder portion, which has a diameter that widens slightly in the downward direction; a bottom shell portion for molding the bottom, which has been blow molded from the corresponding portion of parison P so as to have a widened and deformed shape; an inner overhang wall portion in any position starting from the opposite side of the neck ring and ending at the upper portion of the bulging shoulder portion, with the inner wall portion having a diameter that widens in the downward direction; and / or a radially widened connecting portion of an arced shape, which has a larger diameter than the barrel portion so that the entire bottom including the bottom shell portion takes a bulging spherical shape. With this configuration, no thick area is formed in the inner overhang wall portion on the opposite side of the neck ring and / or in the pinch-off portion.

Owner:YOSHINO KOGYOSHO CO LTD

Preform and Blow-Formed Container Made from the Preform

InactiveUS20080050546A1Spoil dimensional stabilityForm of distortionSynthetic resin layered productsThin material handlingCompression moldingTemperature difference

A preform having at least a layer of a polyester resin, formed by the compression forming and having a neck ring at the mouth portion, wherein a temperature difference ΔTc at the center of the bottom of the polyester layer or under the neck ring represented by the following formula (1), ΔTc=Tc2−Tc1 (1) wherein Tc1 is a temperature-elevating peak crystallization temperature of the polyester layer cut out from the preform as measured by using a differential scanning calorimeter (DSC), and Tc2 is a temperature-elevating peak crystallization temperature of the polyester layer measured by quickly cooling it after having measured Tc1 and having melted it, is not larger than 15° C. The preform has a small forming distortion and features excellent dimensional stability at the time of crystallizing the mouth portion. The article formed by draw blow-forming the preform of the invention is without irregularity in the thickness, without scars or wrinkles, and distored little, exhibits excellent appearance.

Owner:TOYO SEIKAN KAISHA LTD

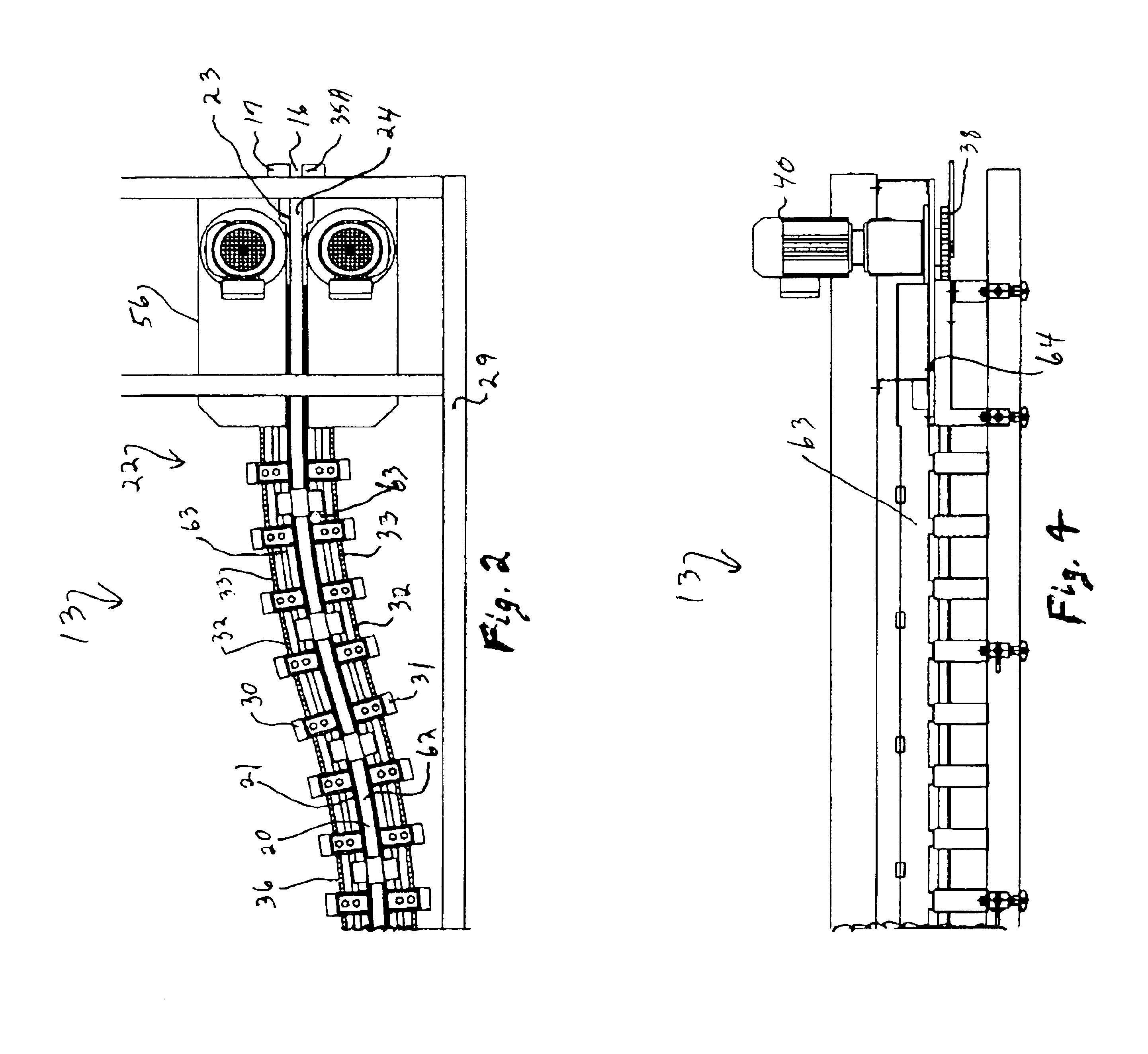

Unstable article conveying device with diverter having curved path

A conveying device with a diverter having a curved path for conveying lightweight unstable articles, such as plastic bottles having a neck portion with a neck ring thereon. The unstable articles are conveyed along a first path to different ones of plural second paths through a third path at the diverter with the third path having first and second ends alignable with the first path and different ones of the plural second paths and a middle portion maintained in a curved configuration that is varied during aligning movement of the second end. A controller controls the aligning movement of the second end, preferably along a straight path, and the unstable articles are supported by engaging members in actuating guides to urge the unstable articles along the article paths.

Owner:GOLDCO IND

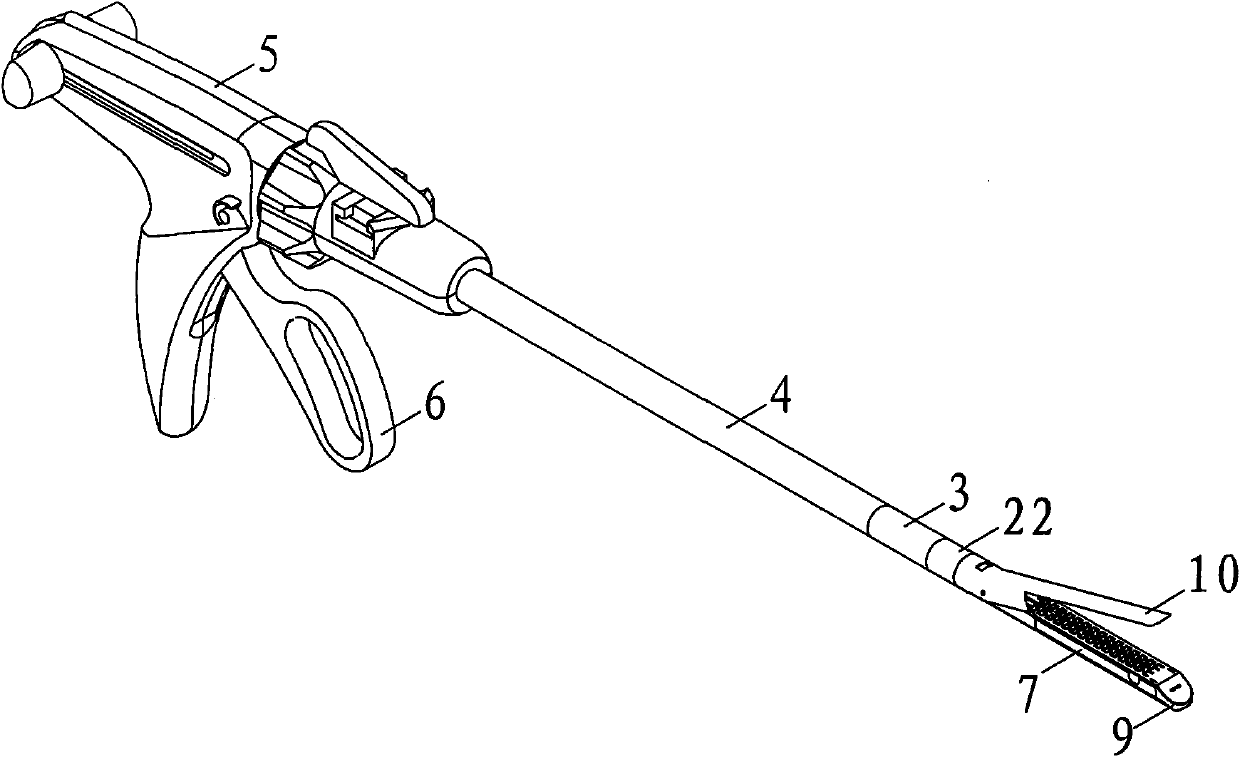

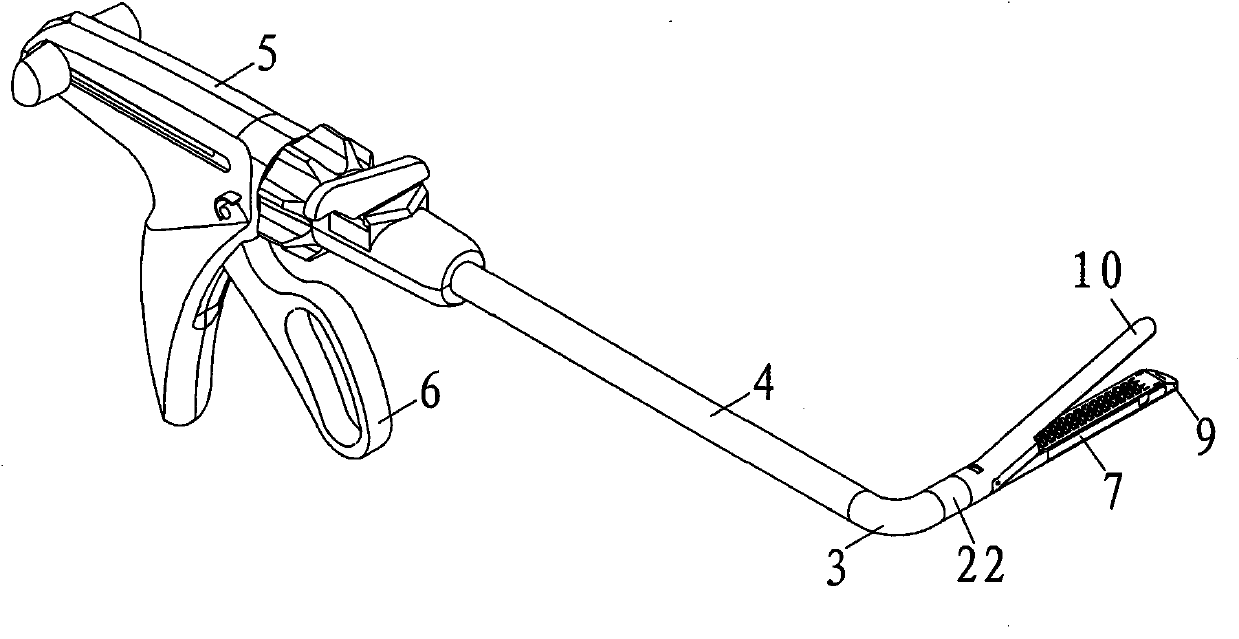

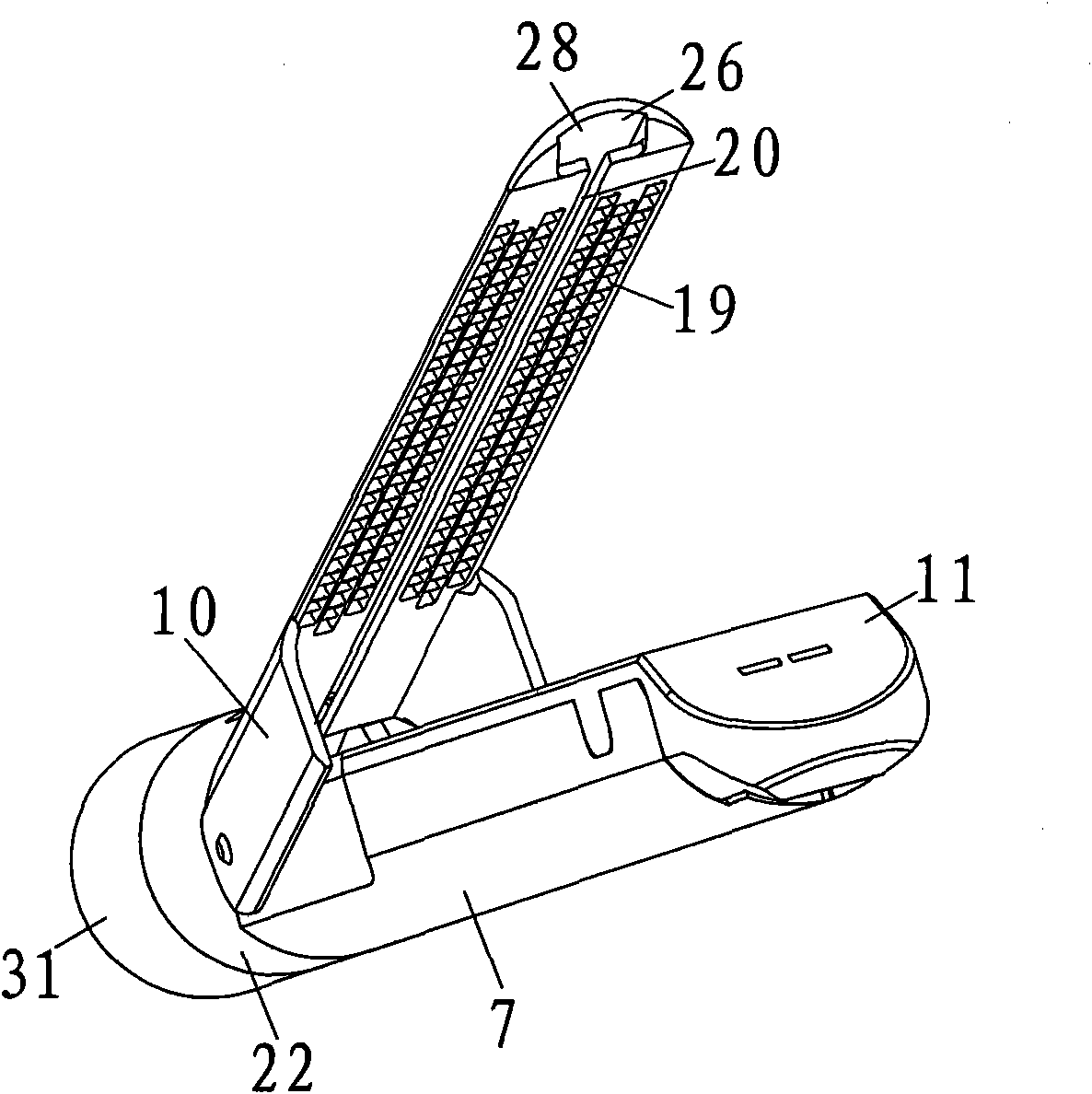

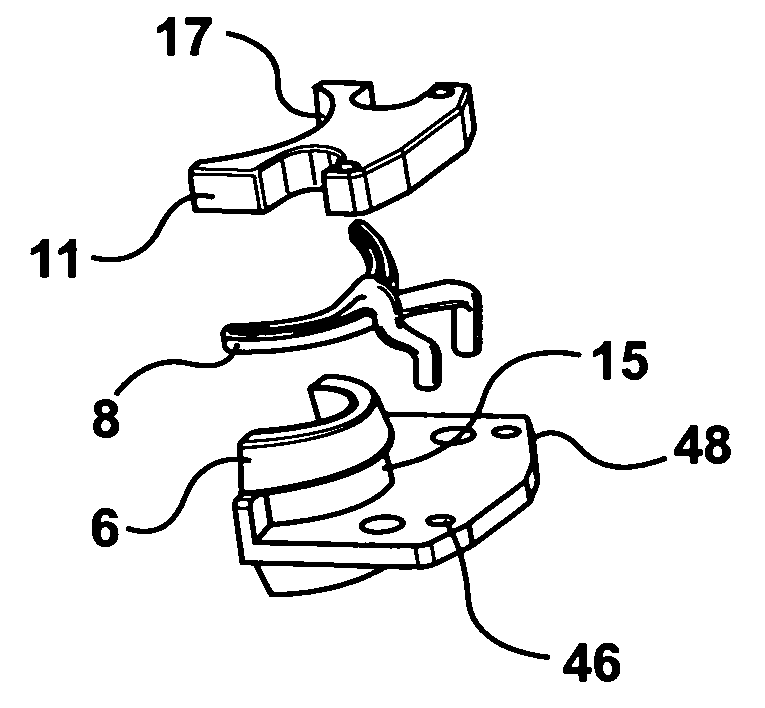

Endoscopic surgery cutting stapler with elastic neck ring

The invention relates to an endoscopic surgery cutting stapler with an elastic neck ring. The cutting stapler comprises a stapler body, an executing head, a connection stapler body, an extension pipe of the executing head and an operating mechanism for controlling the movement of the executing head, wherein the executing head consists of an executing rack, a sliding bar, a nail cartridge and a nail anvil; the sliding bar, the nail cartridge and the nail anvil are arranged on the executing rack; the nail anvil can rotate relatively to the nail cartridge; the periphery of the near end of the executing rack is covered with the elastic neck ring; the edge of the far end of the elastic neck ring closely sticks to the edge of the near end of the nail anvil; when the nail anvil rotates to be in an opening state relative to the nail cartridge, the elastic neck ring is pressed by the nail anvil to perform elastic deformation, the edge of the far end of the elastic neck ring closely sticks to the edge of near end of the nail anvil all the time; and when the nail anvil rotates to be in an closing state relative to the nail cartridge, the edge of the far end of the elastic neck ring return to closely sticks to the edge of near end of the nail anvil. By adopting the invention, the technical effects of reducing the processing and assembling difficulties of each part in the executing head and the product cost can be achieved; and the product is more convenient to use.

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

Cooling circuit for cooling neck ring of preforms

InactiveUS20050276879A1Easy to changeControlled cooling of the preform neck ringAdditive manufacturing apparatusFood shapingNeck ringsCooling channel

A cooling circuit for a neck ring of a preform is conformed to the surface of the neck ring by providing a neck ring in two parts. The first part supports the neck ring and provides strength and durability to the neck ring insert. The second part is formed of porous steel impregnated with highly thermally conductive metal and includes a cooling channel that provides substantially uniform cooling around the neck ring of the preform.

Owner:HUSKY INJECTION MOLDING SYST LTD

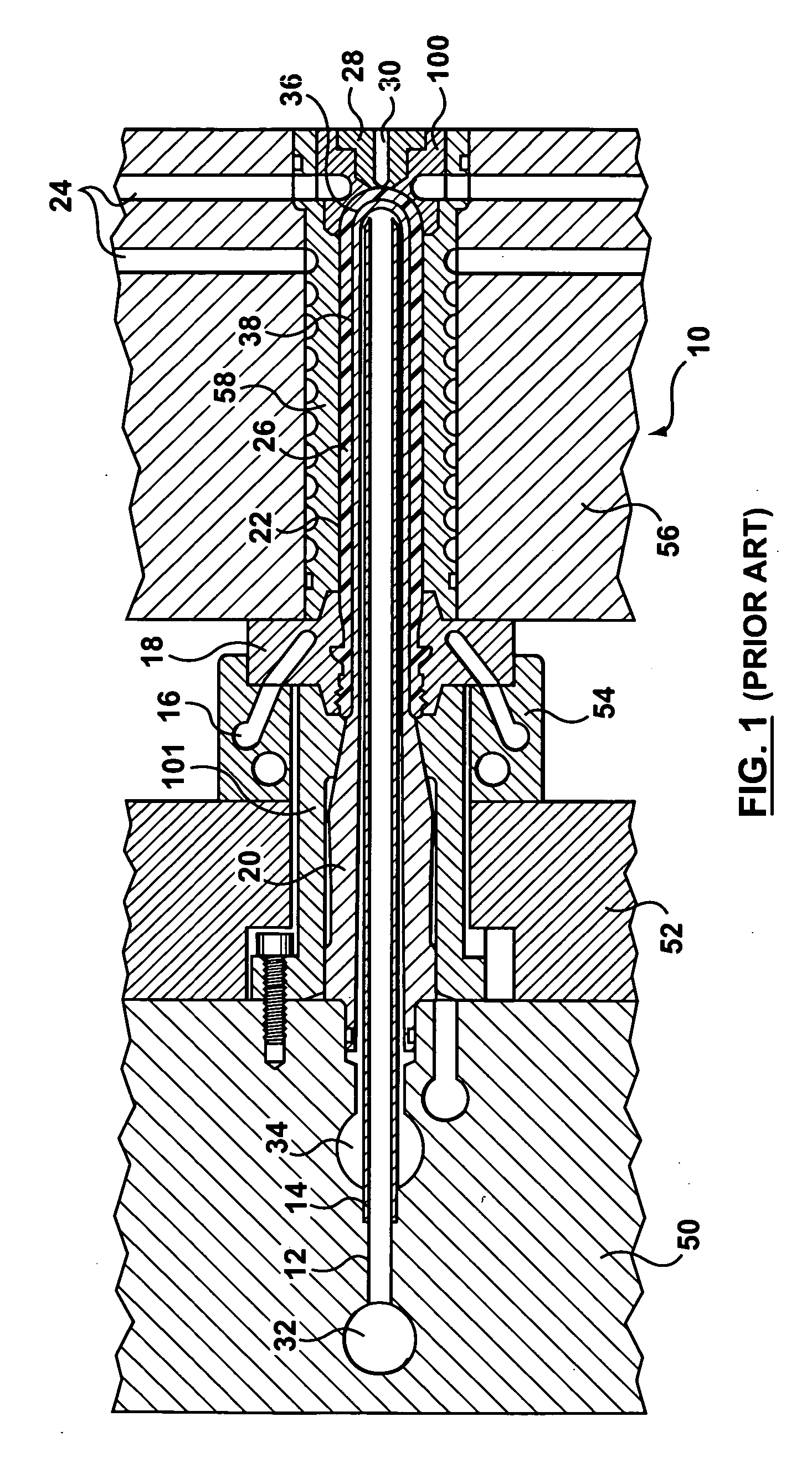

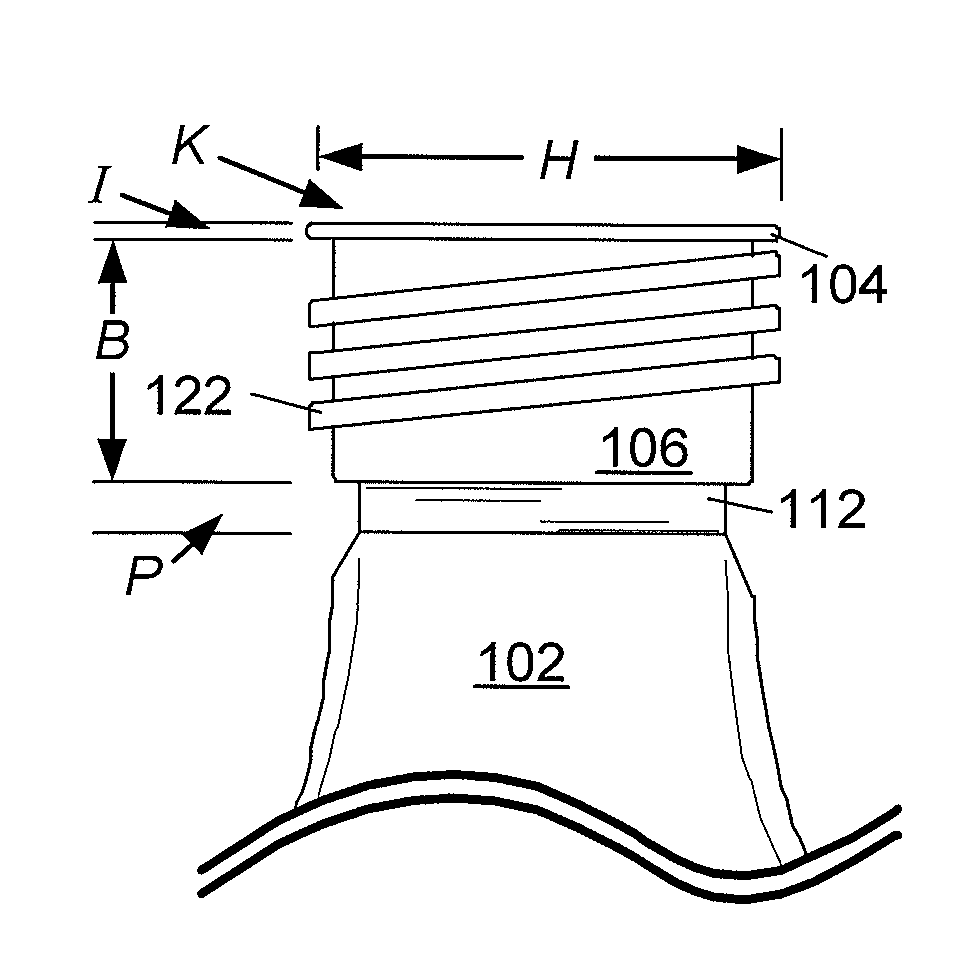

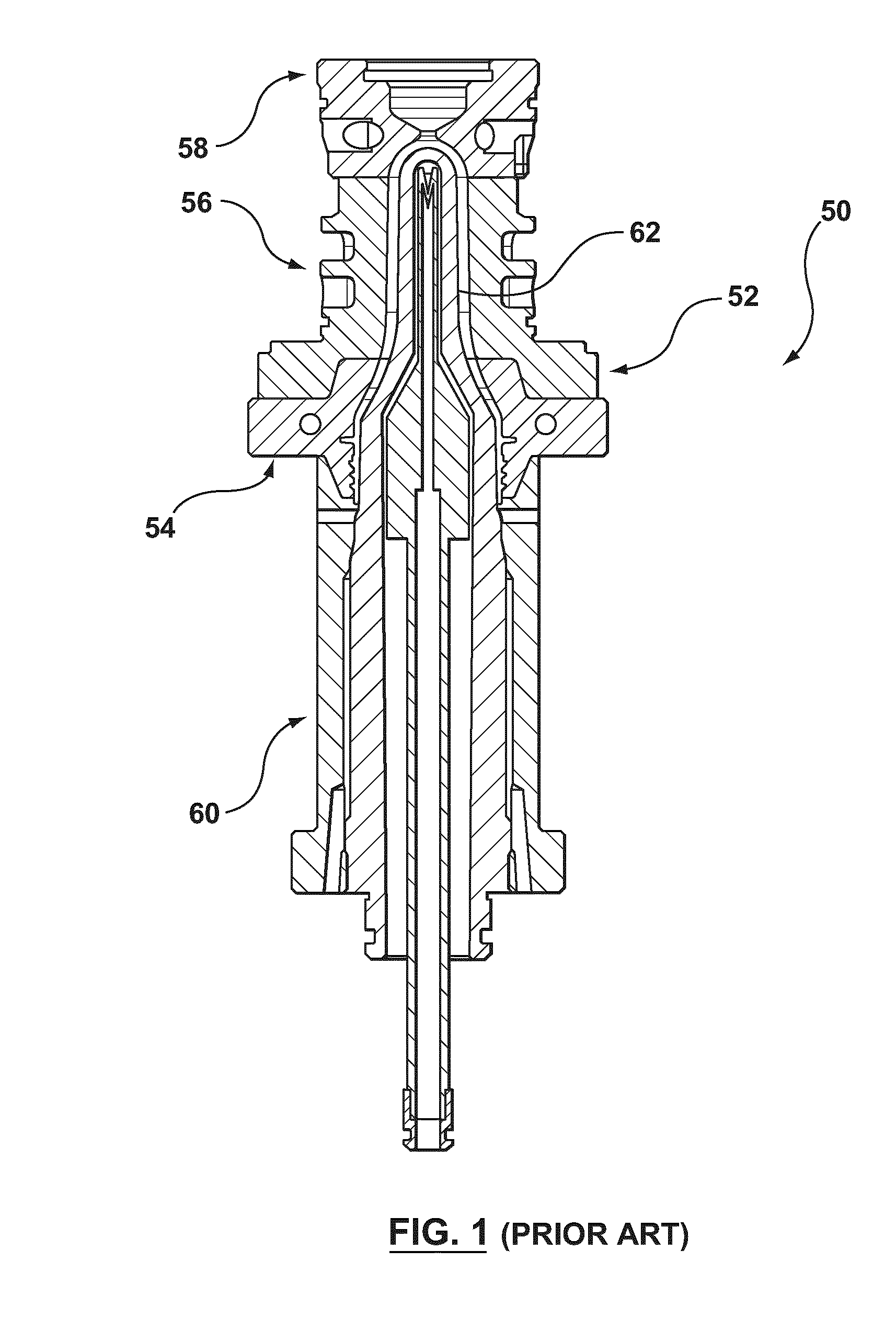

Apparatus and method for removing a molded article from a mold

Injection molding method and apparatus for ejecting a molded plastic article from a mold. A lifting structure and / or step is provided with a lifting portion which is configured to contact substantially one half of an end of the molded plastic article along a line substantially perpendicular to the lifting direction. Since the molded plastic article is lifted by its end, the article does not have to be solidified at its interior, thus allowing earlier removal of the article from the mold, reducing cycle time. A tapered surface forms an acute angle with respect to the lifting portion to form a tight seal with the mold, preventing leakage. Preferably, the neck ring engages only an outer circumferential portion of the molded plastic article during a majority of a mold opening stroke.

Owner:HUSKY INJECTION MOLDING SYST LTD

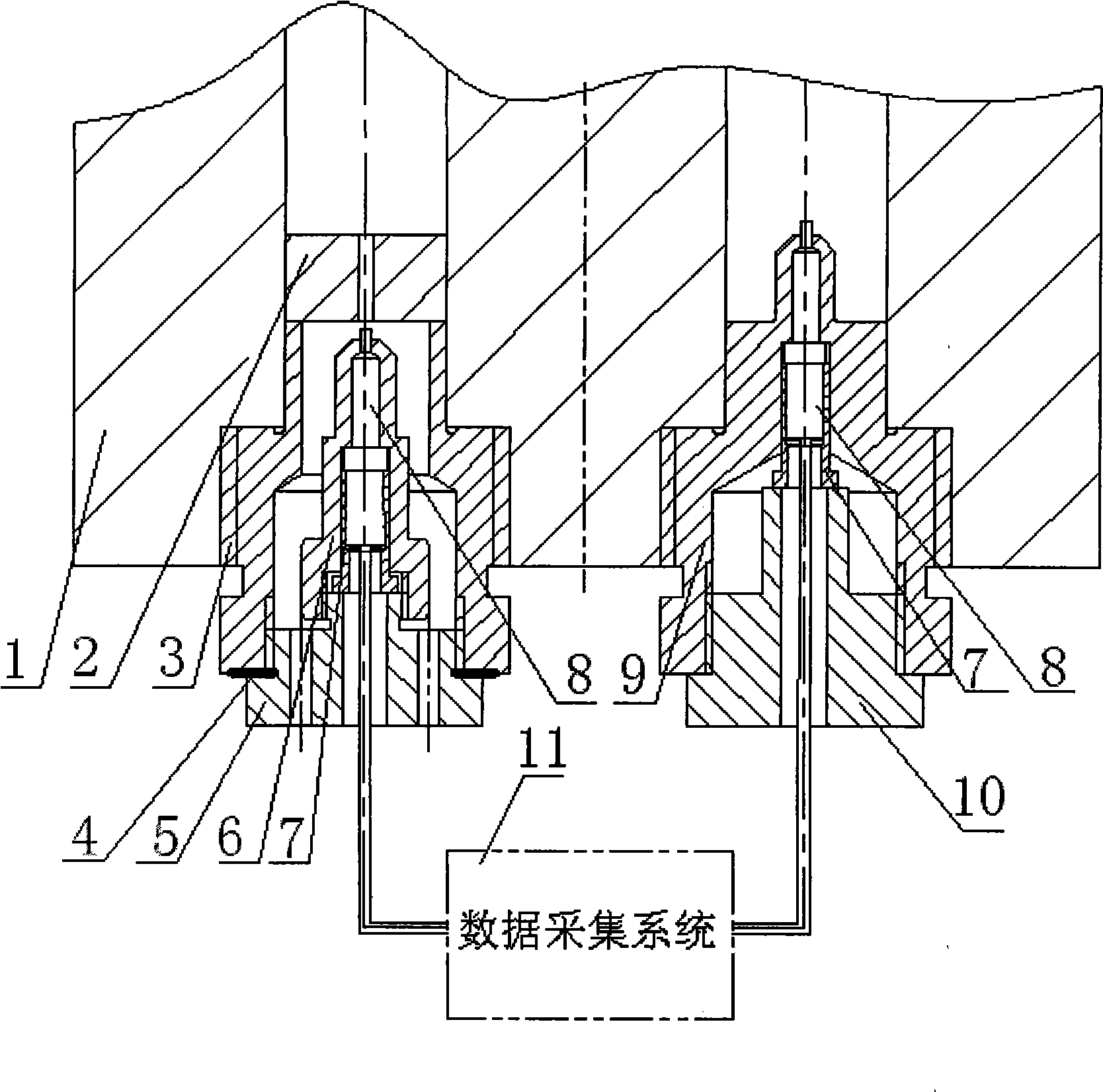

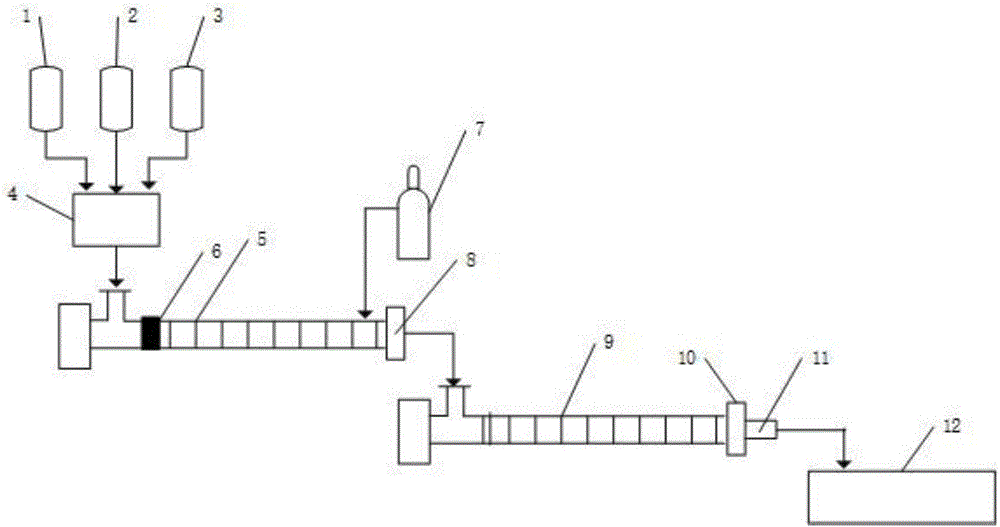

Device and method for measuring steady-state extrusion viscous dissipation of micro-scale polymer fused mass

InactiveCN101532939AAccurate temperature controlEasy loading and unloadingDirect flow property measurementTemperature controlViscous dissipation

The invention relates to a device and a method for measuring steady-state extrusion viscous dissipation of a micro-scale polymer fused mass. The device and the method are characterized in that on the basis of a capillary rheometer with two material barrels, a temperature sensor is arranged at an outlet of a neck ring mold of a capillary tube in the material barrel through a fixing device, the outlet of the neck ring mold of the capillary tube is aligned with a measuring part of the temperature sensor, and the distance between the neck ring mold of the capillary tube and the sensor is adjusted by additionally mounting a spacer; and the other temperature sensor is arranged at the outlet of the other material barrel through the fixing device for the convenience of measuring the temperature of the fused mass simultaneously by the two sensors. The flow parameters of the fused mass are set on the rheometer, the fused mass flows out of the neck ring mold at certain shearing rate through by the extrusion action of a plunger, and the sensors measure the temperature of the extruded fused mass directly. The temperature difference of the two sensors is calculated out so that the temperature rise of the fused mass caused by the viscous dissipation can be measured. The device and the method has the advantages and benefits that the temperature control of the fused mass is constant, the temperature is measured accurately and quickly, the fixing device is easy to assemble and disassemble, the neck ring mold is convenient to replace, and the range of measuring the shearing rate is higherwider.

Owner:DALIAN UNIV OF TECH

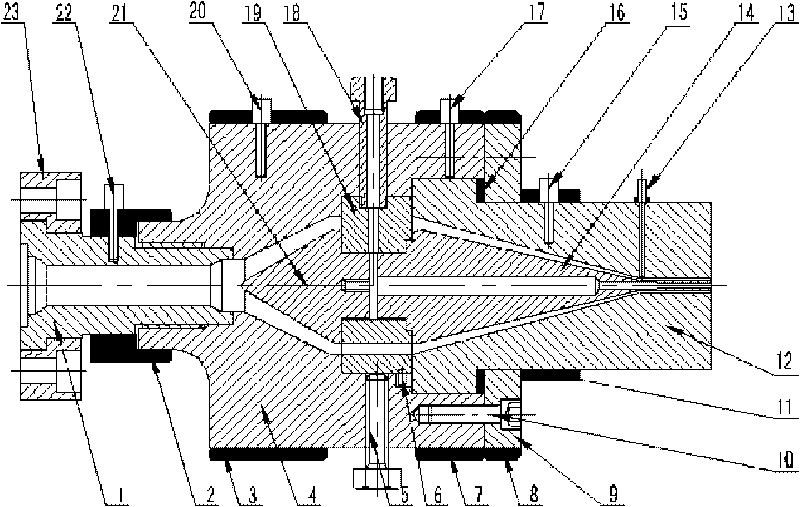

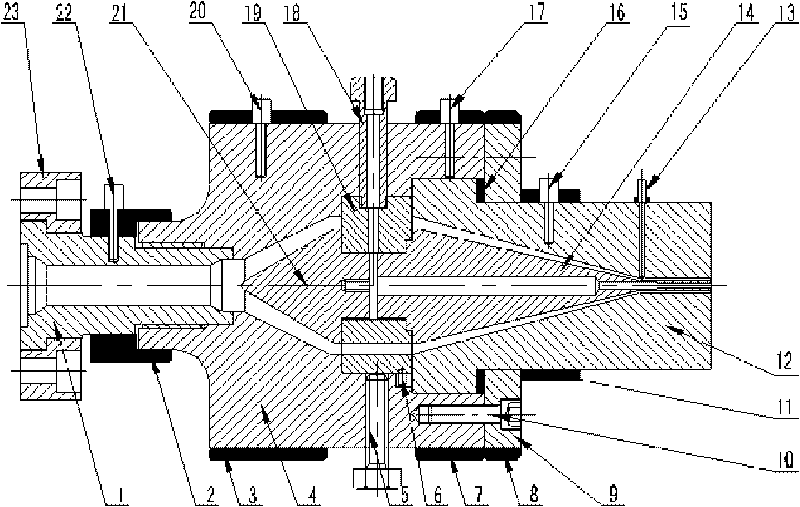

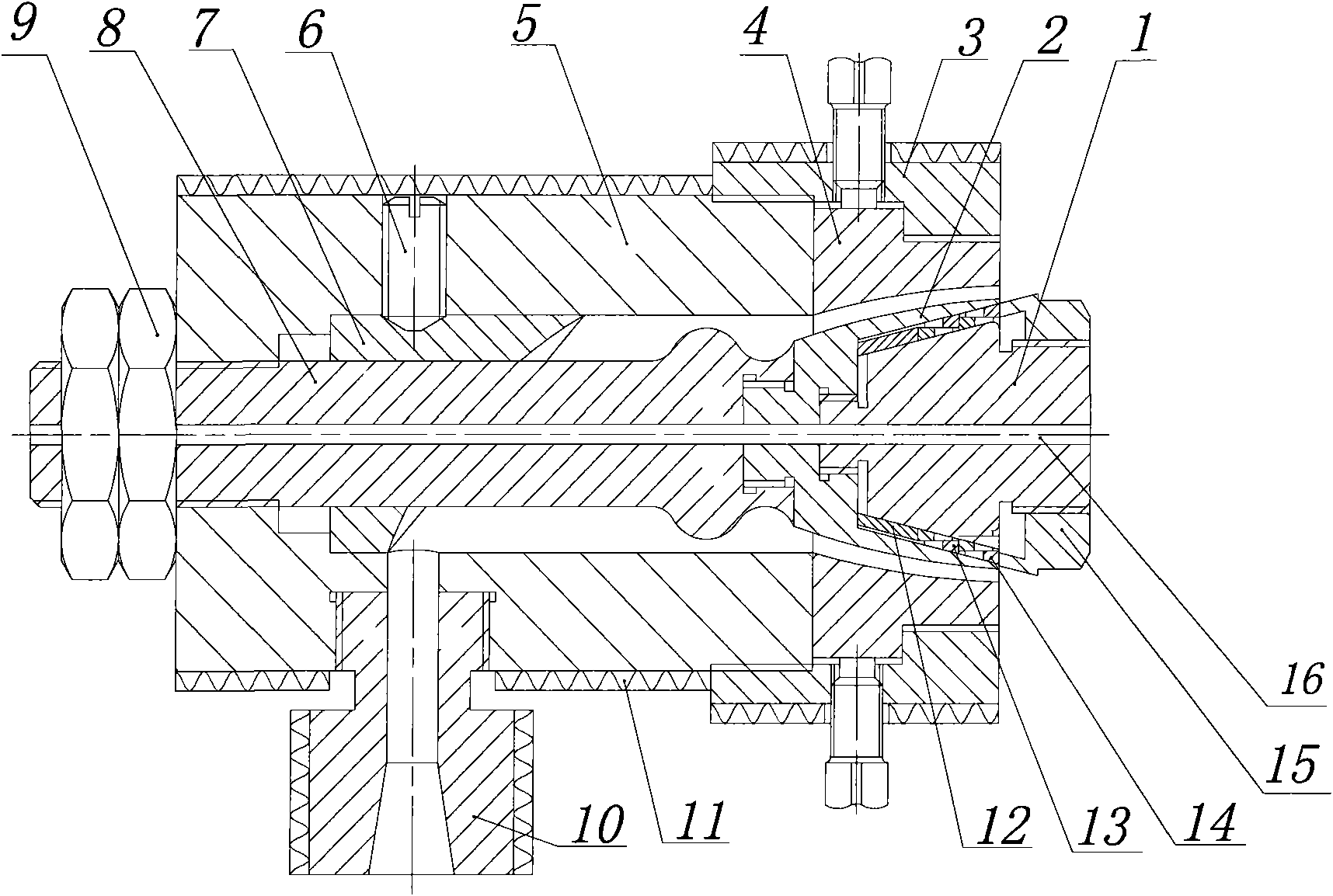

Visual polymer micro-extrusion mold

The invention discloses a visual polymer micro-extrusion mold and belongs to the technical field of polymer micro-extrusion molds. The visual polymer micro-extrusion mold is characterized in that the visual mold consists of a connecting pipe, a heating ring, a handpiece body, an adjusting bolt, a positioning pin, a baffle, a fastening bolt, a visual neck ring mold, a pressure / temperature sensor, a core rod, a gasket, a temperature sensor, a ventilating bolt, a support plate, a spure spreader and a flange. The spure spreader, the core rod and the neck ring mold with different structural parameters are respectively exchanged according to the need; coaxiality and clearance between the core rod and the visual neck ring mold are adjusted by the method of fixing the visual neck ring mold and adjusting the core rod; the visual neck ring mold is used for observing the flow state in the micro-extrusion mold of polymer melt; the pressure / temperature sensor is used for measuring pressure and temperature of straight section of the polymer melt; and the heating ring and the temperature sensor are used for controlling temperature of the micro-extrusion mold. The visual polymer micro-extrusion mold obtains flow distribution, flow characteristics and wall slip velocity of the polymer melt in the flow channel by the visual neck ring mold.

Owner:DALIAN UNIV OF TECH

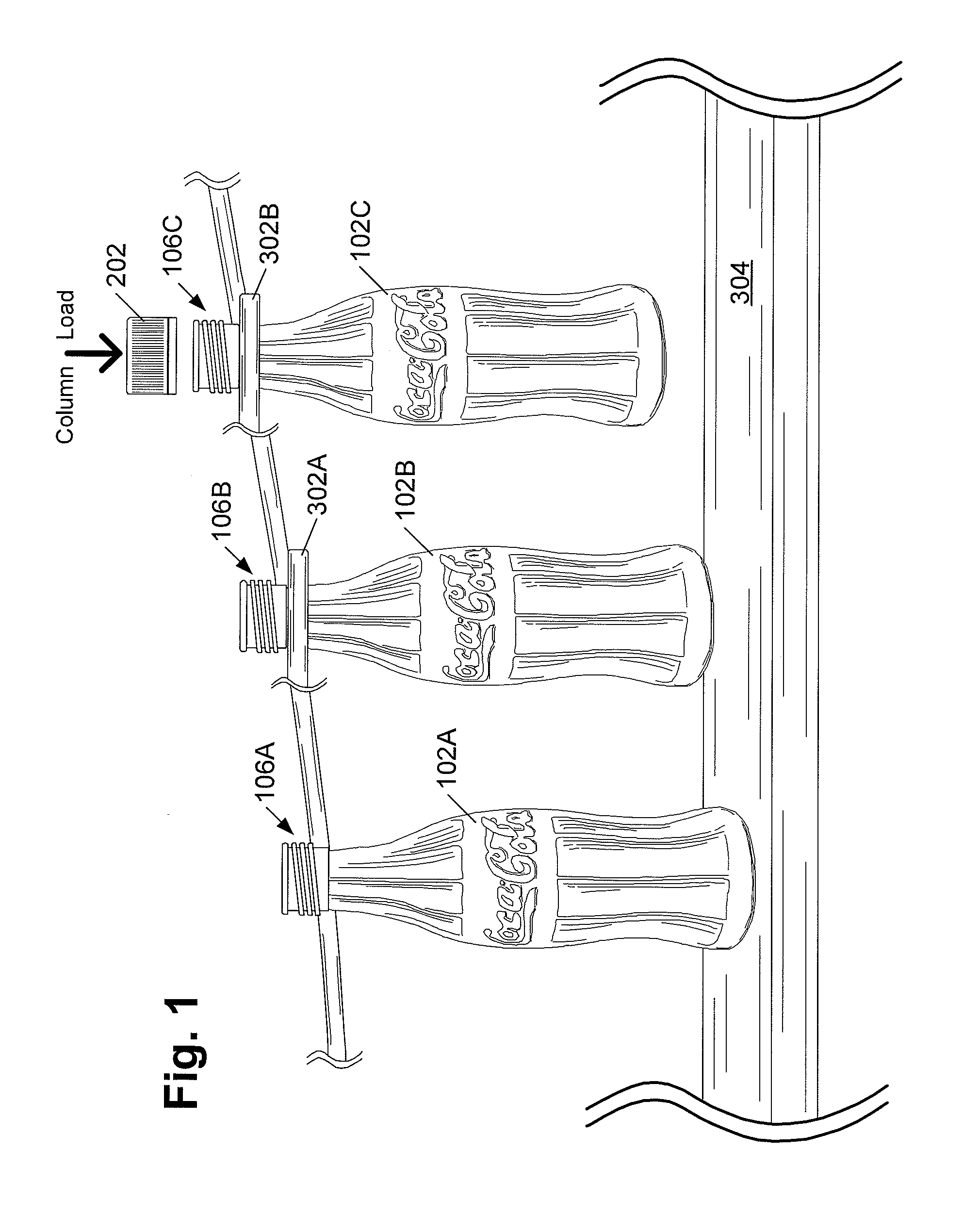

Shaped metal vessel

The present invention relates a shaped metal vessel comprising a shaped vessel body thin walled made of metal comprising a tapered body portion comprising an open end with integral rolled edge, a mid body portion, and a low body portion. A base seals one end of the low body, the low body blends with the mid body, and the mid body blends with the tapered body. Exemplary embodiments include an outsert fitted around the outside circumference of the tapered body proximate the open end, the outsert comprising a carry ring or carry ring edge formed around the circumference of the outsert, and a plurality of threads spirally affixed to the outer surface of the outsert to engage and secure a separate vessel closure to the shaped vessel body. Other exemplary embodiments integrally form a neck ring in the shaped vessel body.

Owner:THE COCA-COLA CO

Foamed type TPU (thermoplastic polyurethane elastomer) material and preparation method thereof

The invention relates to a foamed type TPU (thermoplastic polyurethane elastomer) material and a preparation method thereof. The preparation method comprises the following steps: polymer polyol, diisocyanate and a chain extender are taken and poured into a casting machine to be mixed uniformly, then a mixture I is added to a first reactive extrusion machine for a polymerization reaction, and a TPU polymer melt is obtained; a physical foaming agent is injected into the tail end of a screw of the first reactive extrusion machine, the TPU polymer melt is mixed preliminarily with the physical foaming agent, and a mixture II is obtained; the mixture II is added to a second reactive extrusion machine, and the physical foaming agent and the TPU polymer melt are mixed uniformly to form a homogeneous system; the homogeneous system passes through a neck ring mold of the second reactive extrusion machine and then is subjected to underwater palletizing, and foamed thermoplastic polyurethane particles are obtained; the foamed thermoplastic polyurethane particles are dehydrated and dried, and the foamed type TPU material is obtained. The foamed type TPU material has stable foaming density, the batch-to-batch product quality is stable, central control monitoring is performed at any time, and the yield is increased.

Owner:MIRACLL CHEM

Resistance spot welding electrode

InactiveUS20050029234A1Easy to weldLong electrode lifeOhmic-resistance electrodesWelding/cutting media/materialsElectrical resistance and conductanceEngineering

A composite resistance spot welding electrode is disclosed which comprises a co-axial annular neck ring, a co-axial insert, a co-axial annular sleeve, or combinations there of. The electrode provides improved nugget formation and longer electrode life.

Owner:BATTELLE MEMORIAL INST

Neck band for cooling or heating

InactiveUS20050177925A1Adjustable portableEasy to wearWristbandsScarvesNeck ringsBiomedical engineering

An attachable, adjustable in size neck ring made of a lightweight fabric with two plies on one side for extra comfort that includes hook and pile adjustable fasteners and a gel pack that can be heated or cooled for providing additional cooling or heating to a human being during exercising. The neck ring fabric chamber can be separated from the gel pack when not in use and for heating or cooling the gel pack.

Owner:PEEPLES LEO F

Machine head device capable of adjusting wall thickness of extrusion pipe

The invention belongs to a machine head device capable of adjusting the wall thickness of an extrusion pipe without dismantling a core mould in a neck ring mould in the technical field of polymer material processing mechanical equipment. A core mould inner shaft is sequentially provided with a lower expansion sleeve, an upper expansion sleeve and a core mould inner cushion block, a thread arranged at the right end of an adjusting nut is screwed into a nut arranged at the right end of the core mould inner shaft; a machine diameter is used for connecting the head part of an extrusion machine screw, the periphery of the machine diameter is provided with a wavy line heating ring, a transition block is arranged into a mandrel and a main mould body from a left port of the main mould body, the mandrel is connected with the main mould body into a whole; a thread arranged at the left end of a core mould body is connected with an inner thread arranged at the right end of the mandrel into a whole; the neck ring mould is arranged at the left end of a pressure sleeve, an inner thread at the left end of the neck ring mould is correspondingly assembled and connected with an outer thread at the right end of the main mould body; the neck ring mould and the main mould body form a runner inner wall of an extrusion machine head, the inner diameter of the neck ring mould is the outer diameter of the extrusion pipe, and the outer diameter of the core mould body is the inner diameter of the extrusion pipe. The machine head device capable of adjusting the wall thickness of the extrusion pipe has the advantages of simple structure, labor, financial resources and energy sources saving, and the like.

Owner:QINGDAO UNIV OF SCI & TECH

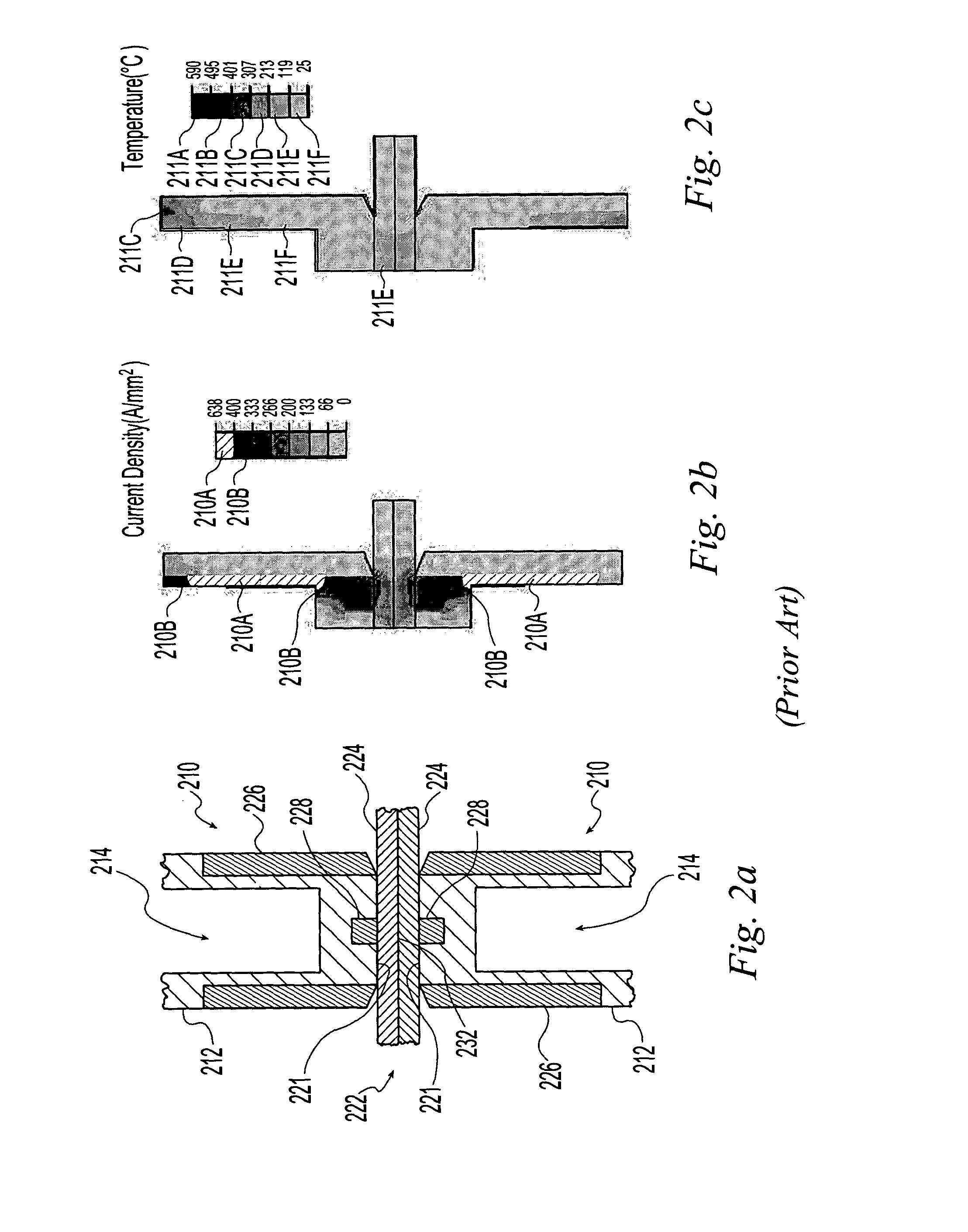

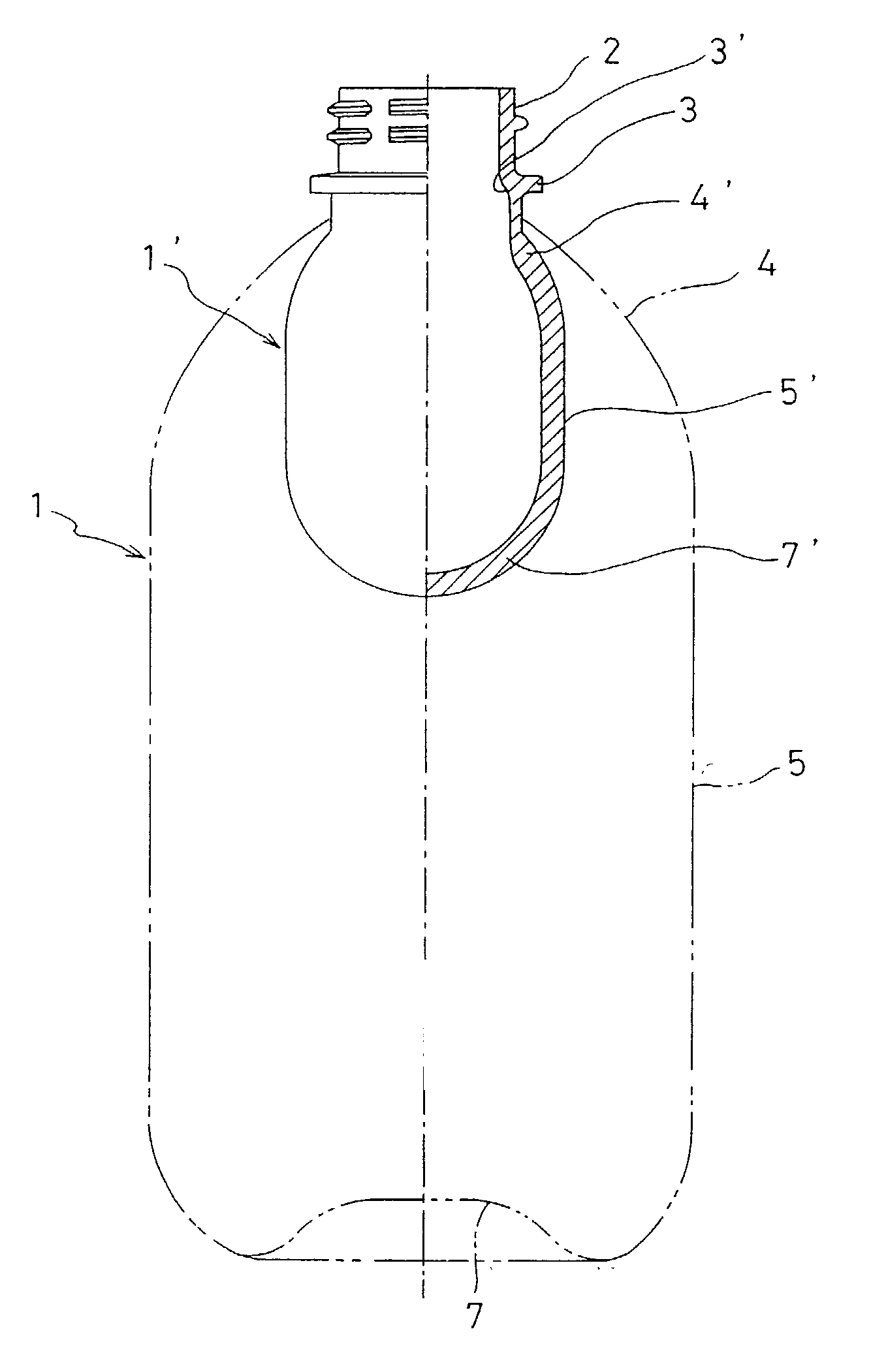

Mold stack for a preform

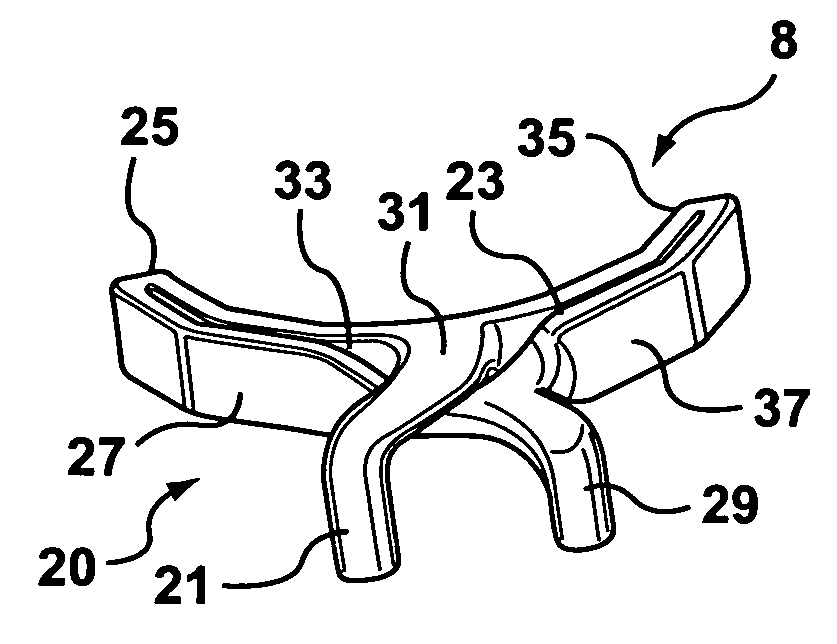

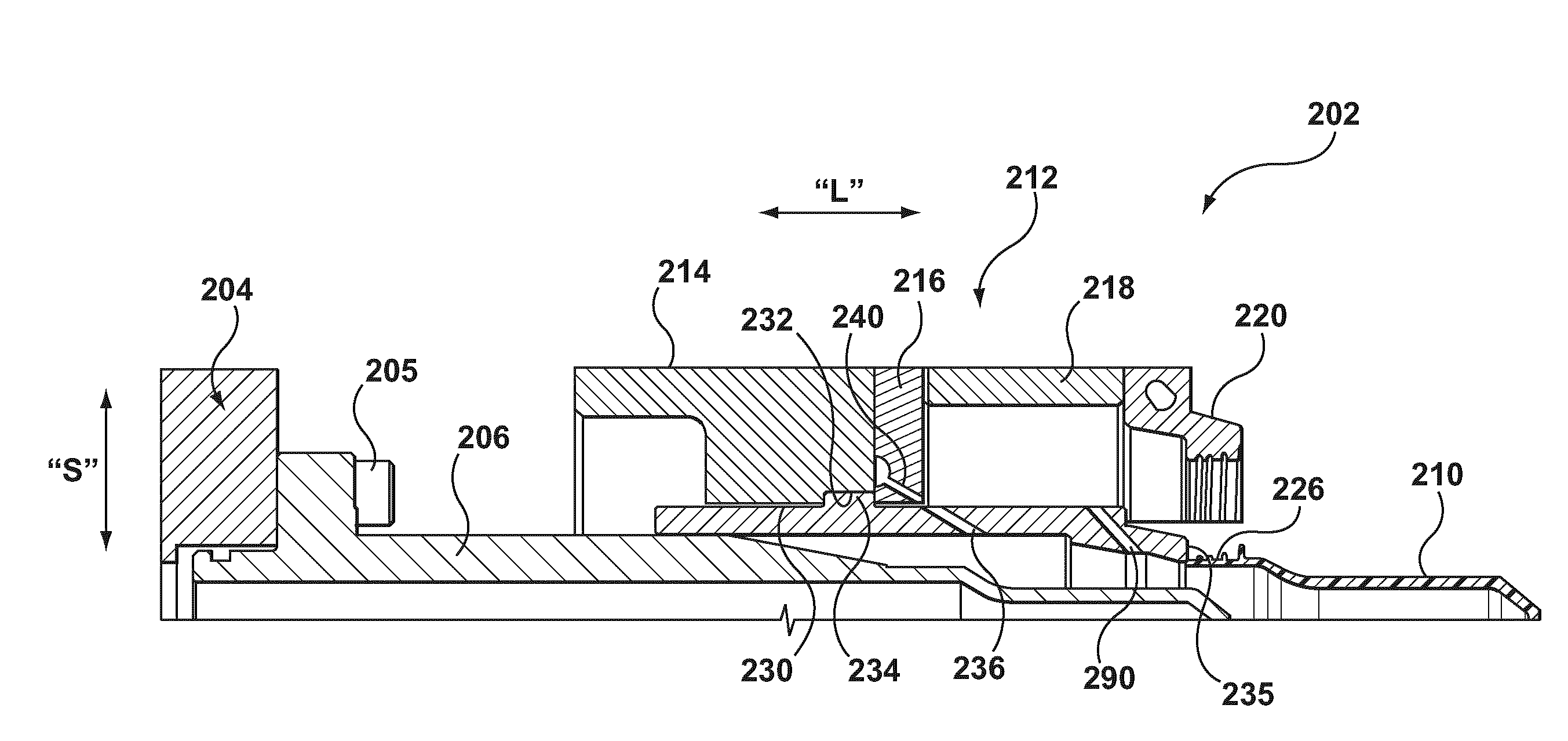

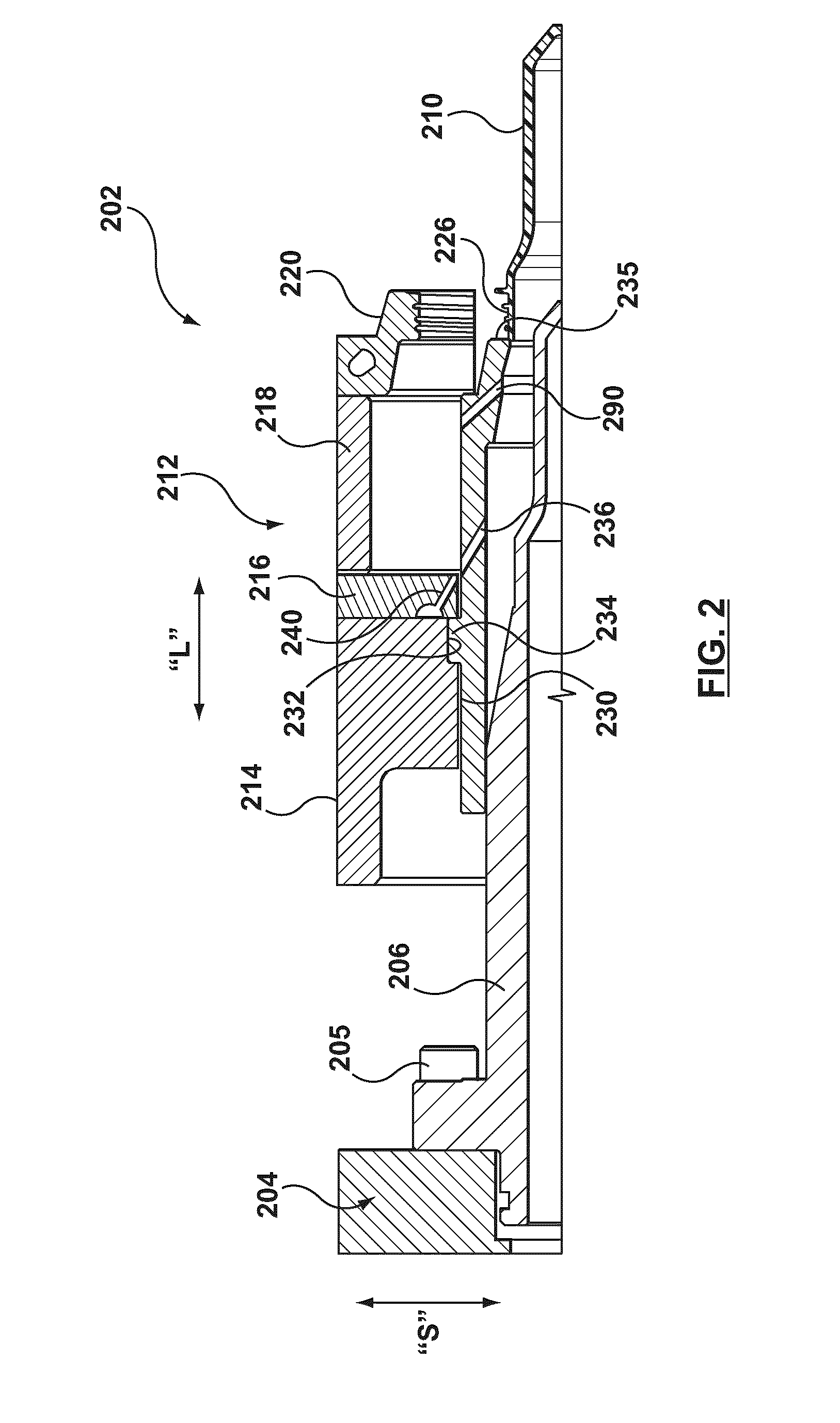

There is provided a stripper assembly (212) for use in a mold stack (202) for forming a preform (210) suitable for blow-molding into a final-shaped container. The stripper assembly (212) comprises a stripper plate (214) connectable, in use, to a stripper plate actuator; neck rings (220) configured to cooperate to define a portion a neck region (226) of the preform (210); a stripper ring (230) configured to define at least a portion of a top sealing surface of the neck region (226) of the preform (210); the stripper plate (214) being configured to actuate the neck rings (220) and the stripper ring (230), in unison, along substantially the whole length of a complete ejection path, which is substantially parallel to a longitudinal axis of the mold stack (202); and where-in the neck rings (220) are configured for movement in a direction substantially perpendicular to the longitudinal axis of the mold stack, over at a portion of the complete ejection path, the stripper ring (230) having an air channel (236) configured to directed a flow of fluid towards the preform.

Owner:HUSKY INJECTION MOLDING SYST LTD

Polyvinylidene fluoride microporous film prepared through gelatin extrusion tape casting method

InactiveCN102649315AEasy to prepareHigh film forming rateFlat articlesCoatingsSolventMechanical property

The invention relates to a process for preparing a polyvinylidene fluoride microporous film through a gelatin extrusion tape casting method. The process is as follows: polyvinylidene fluoride resin and a certain amount of solvent are mixed into gelatin and then are added into an extruder for smelting and extrusion through a feeding machine, and pass through the neck ring mold of a mold and form the film on a continuous heating and uniformly rotating roller or a steel strip, then the film is wound by a winding machine after drying, and eventually, the finished product of the microporous film is obtained. The steel strip is heated by a blaster, and air enters into an air inlet for heating and then passes through a casting machine, and then is discharged through an air outlet. The invention is characterized in that the solid content of gelinite added into the extruder is high, the volatilization quantity of the solvent is less, pollutions to air are less, besides, forming, drying and shaping can be performed at the same time during a thin film preparation process, the film forming rate is high, and the efficiency is high; the film preparing process is simple and flexible; and the film flatness is excellent, the thickness is uniform and adjustable, and the mechanical property is high.

Owner:BEIJING UNIV OF CHEM TECH

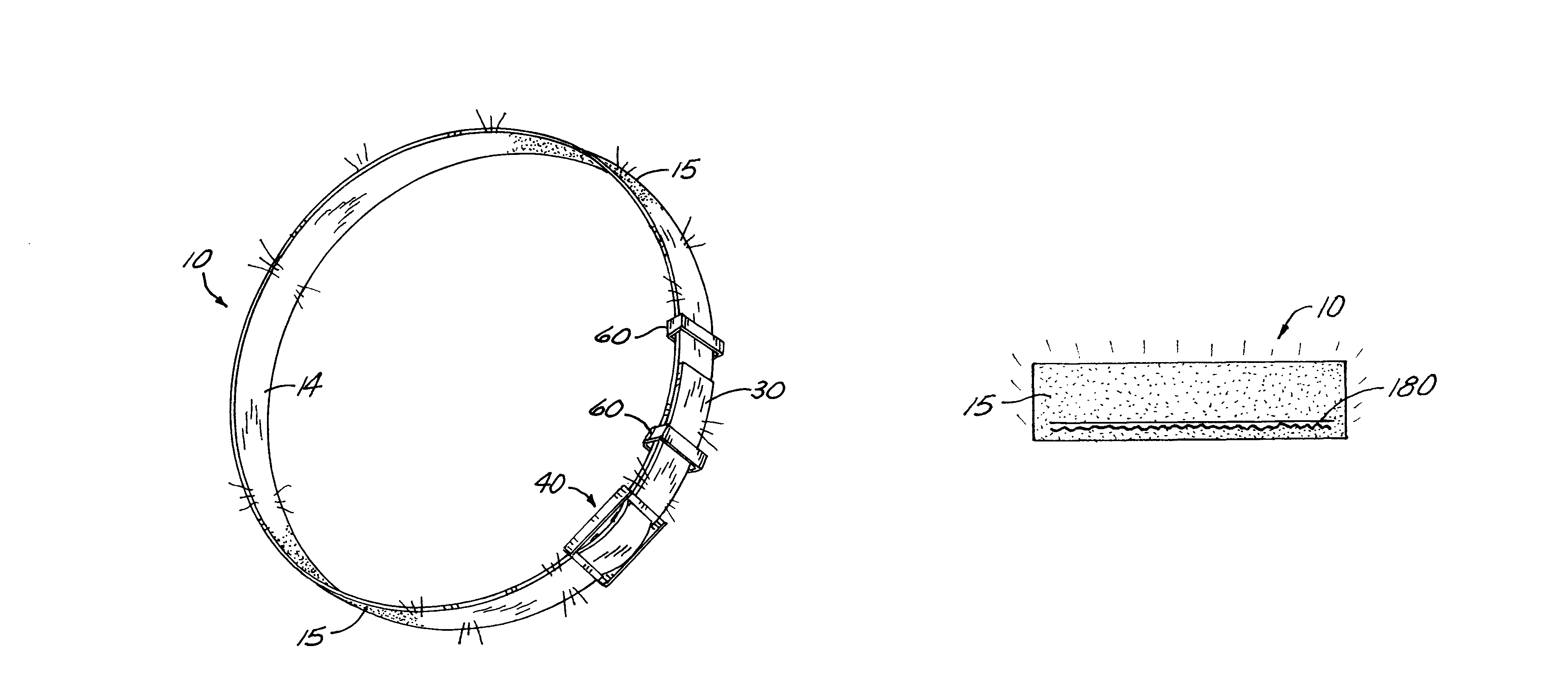

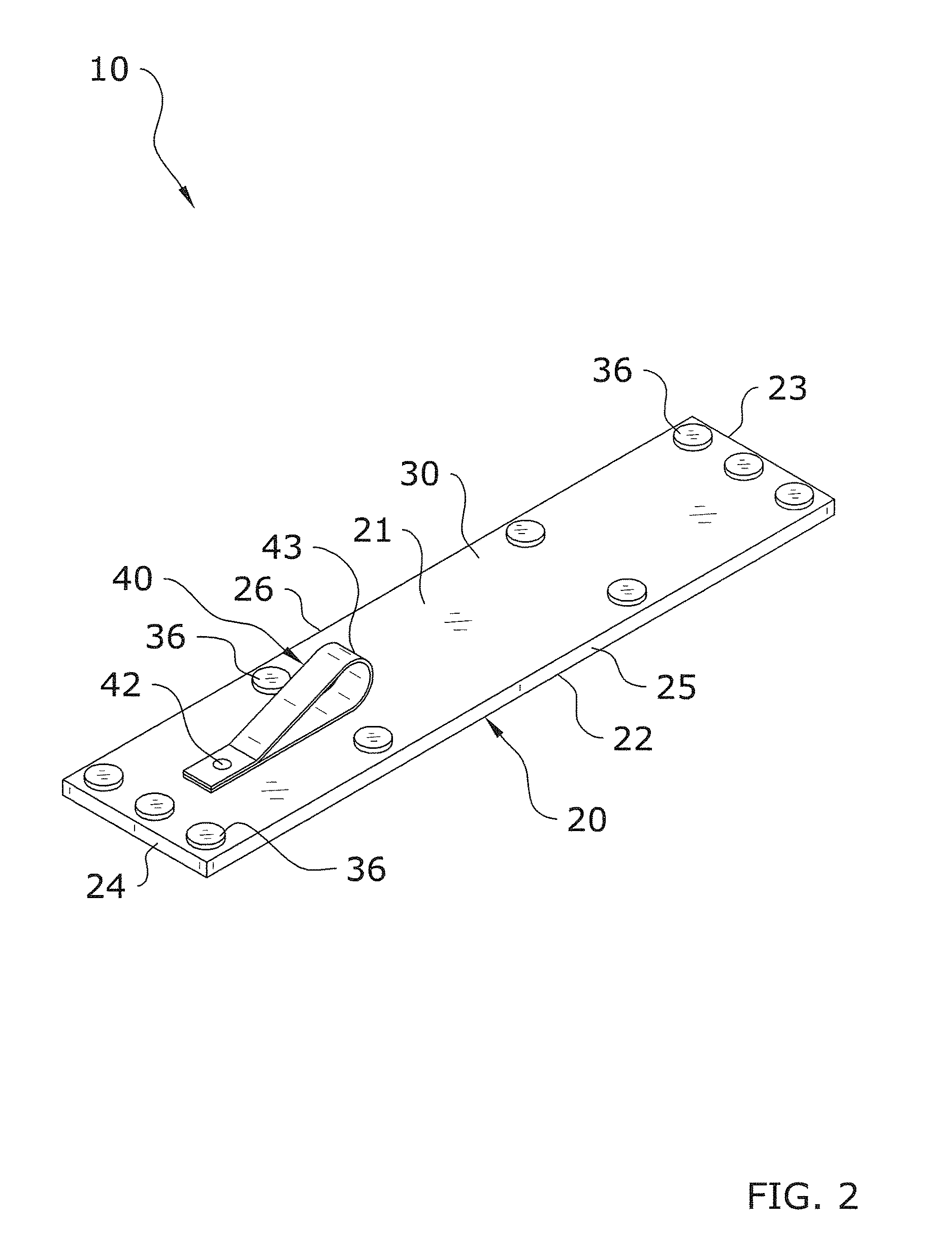

Glow in the dark pet strap

InactiveUS7980203B1Improve performanceSafety beltsTaming and training devicesElastomerPhotoluminescence

A pet strap formed of a transparent material, such as plastic or synthetic rubber, with photoluminescent or phosphorescent colored pigment homogeneously dispersed within and incorporated into the elastometric material. The preferred photoluminescent is strontium oxide aluminate or strontium barium aluminate, which emit a yellow-green light. The strap may be disposed to encircle the neck of the pet as a conventional collar with a buckle and strap end retainers. The strap may also be made in various dimensions suitable for pets of all sizes, and may be configured to be trimmed to the desired size. Another embodiment of the pet strap includes a light reversion strip and an underlying or encased fabric reinforcing strip encased within the elastomeric strap adjacent the bottom side of the strap that contacts the pet. The light reversion strip will allow available light to charge the luminescents more proficiently for better performance.

Owner:ORME DANIEL C

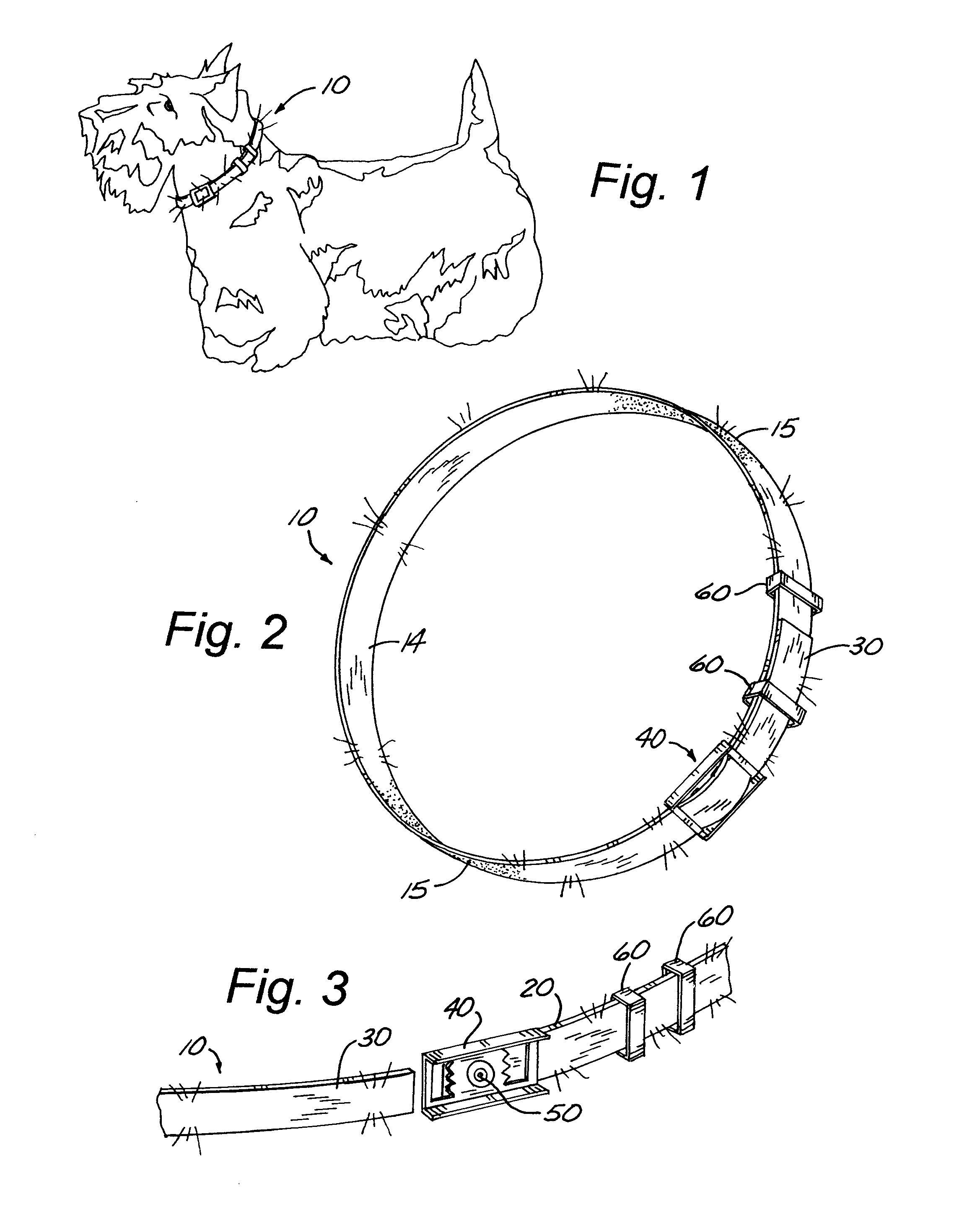

Combination collar

The Combination Collar is worn around the neck of a dog [or other animal] that one desires to control with the use of a leash attached to the collar. The collar being of a design such that the surface geometry of the inner surface of the collar, [surface of the collar facing the neck of the animal] having a plurality of posts or protruding elements that are substantially surrounded by a compressible, resilient material that, temporarily changes from a surface that is generally smooth, to a surface having protruding pressure points. This temporary change in surface geometry occurs in direct response to tension between the leash and the collar, as when the animal attempts to pull away from the attached leash. The inner surface of the collar returns to its original [generally smooth] surface geometry when the tension is absent.

Owner:DAVIES ROSS JENNIFER LYNN

Synthetic resin preform to be biaxially stretched and blow molded into a bottle

InactiveUS7115309B2Improve accuracyDistortion in appearanceEnvelopes/bags making machineryBottlesSpherical shapedEngineering

The blow molded preform of a laminated wall structure comprises a bulging shoulder portion which has a diameter that widens slightly in the downward direction; a bottom shell portion for molding a bottom, which has been blow molded from a corresponding portion of a parison so as to have a widened and deformed shape; an inner overhang wall portion in any position starting from the opposite side of a neck ring and ending at the upper portion of a bulging shoulder portion, with an inner wall portion having a diameter that widens in the downward direction; and / or a radially widened connecting portion of an arced shape, which has a larger diameter than a barrel portion so that the entire bottom including a bottom shell portion takes a bulging spherical shape.

Owner:YOSHINO KOGYOSHO CO LTD

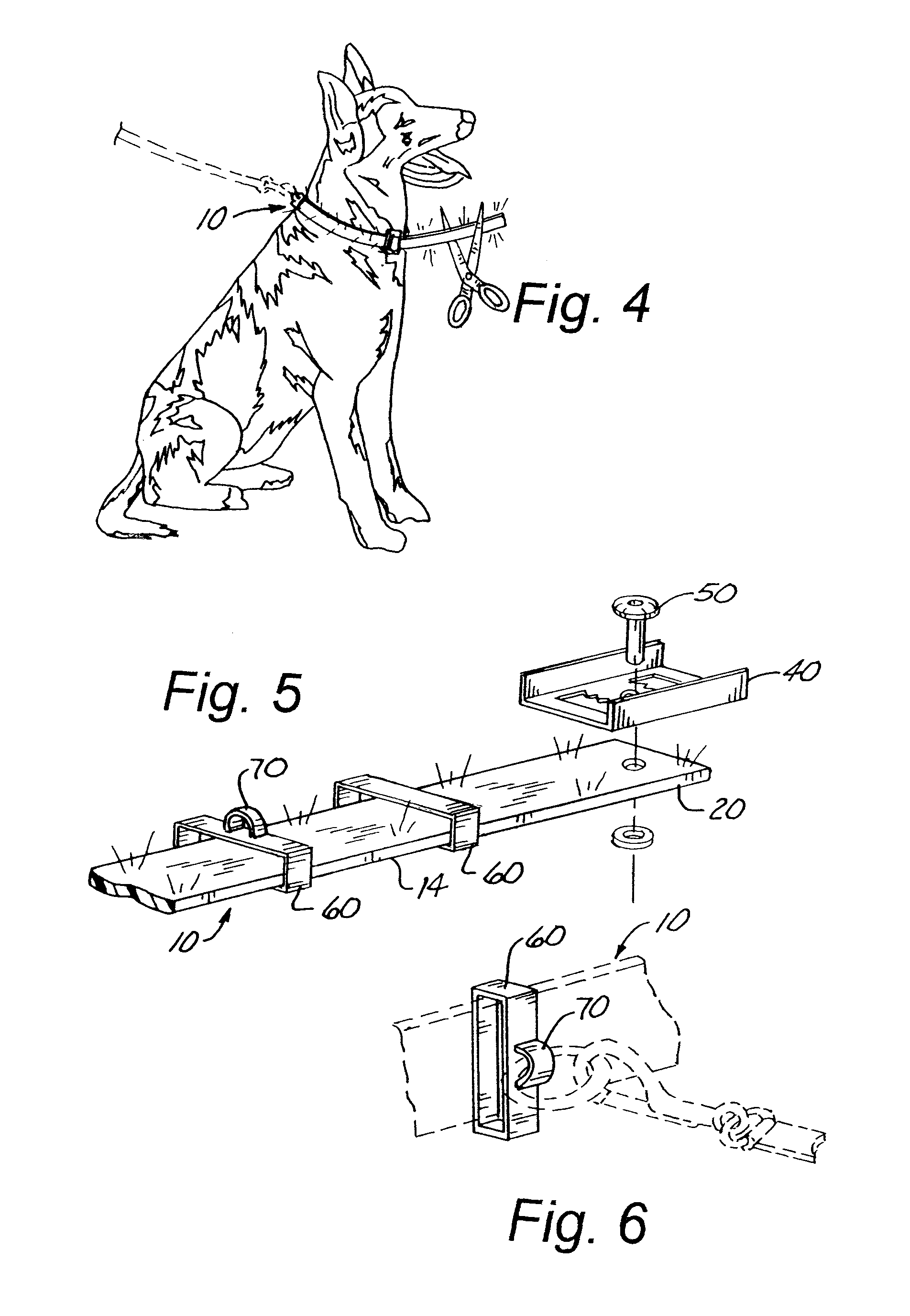

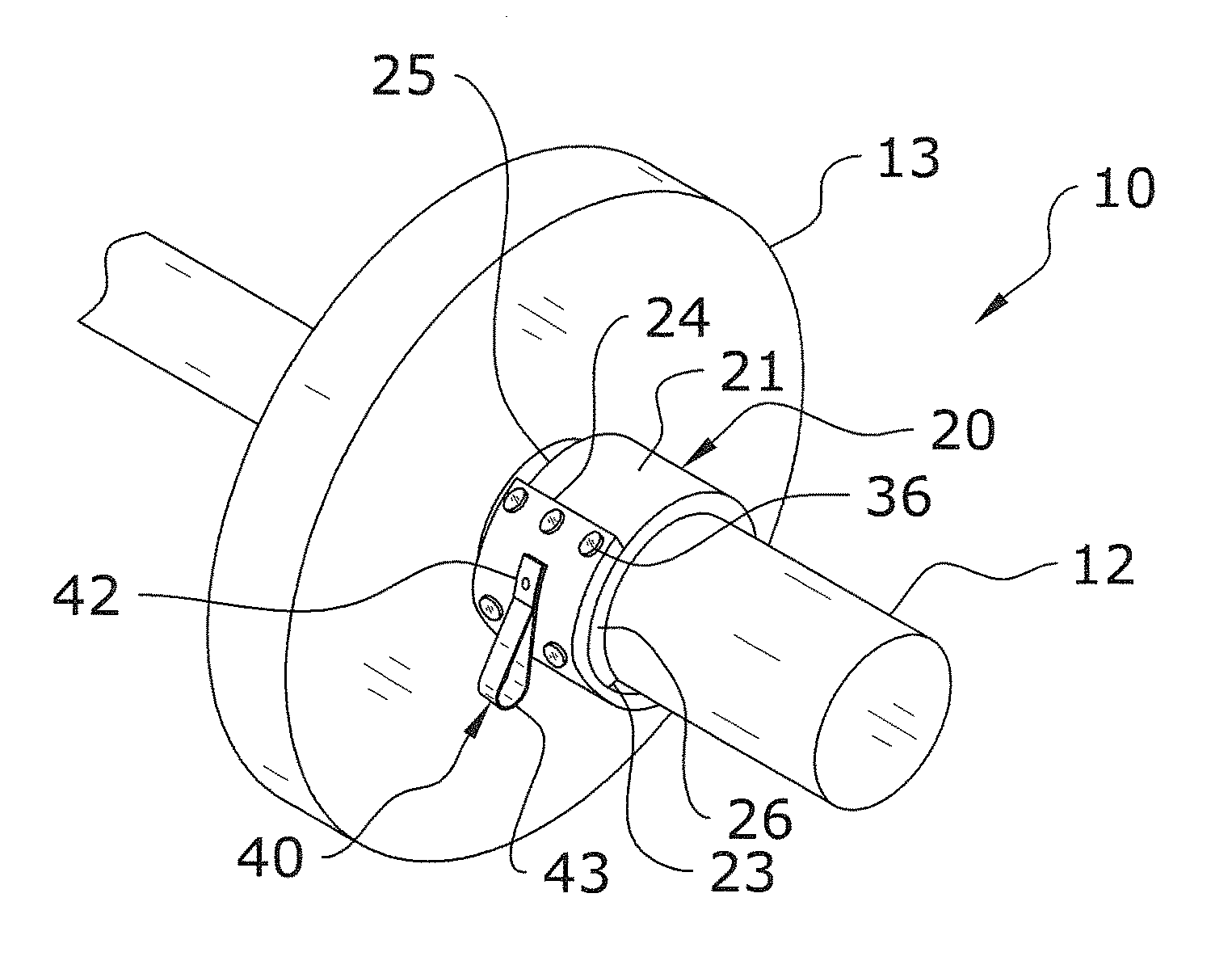

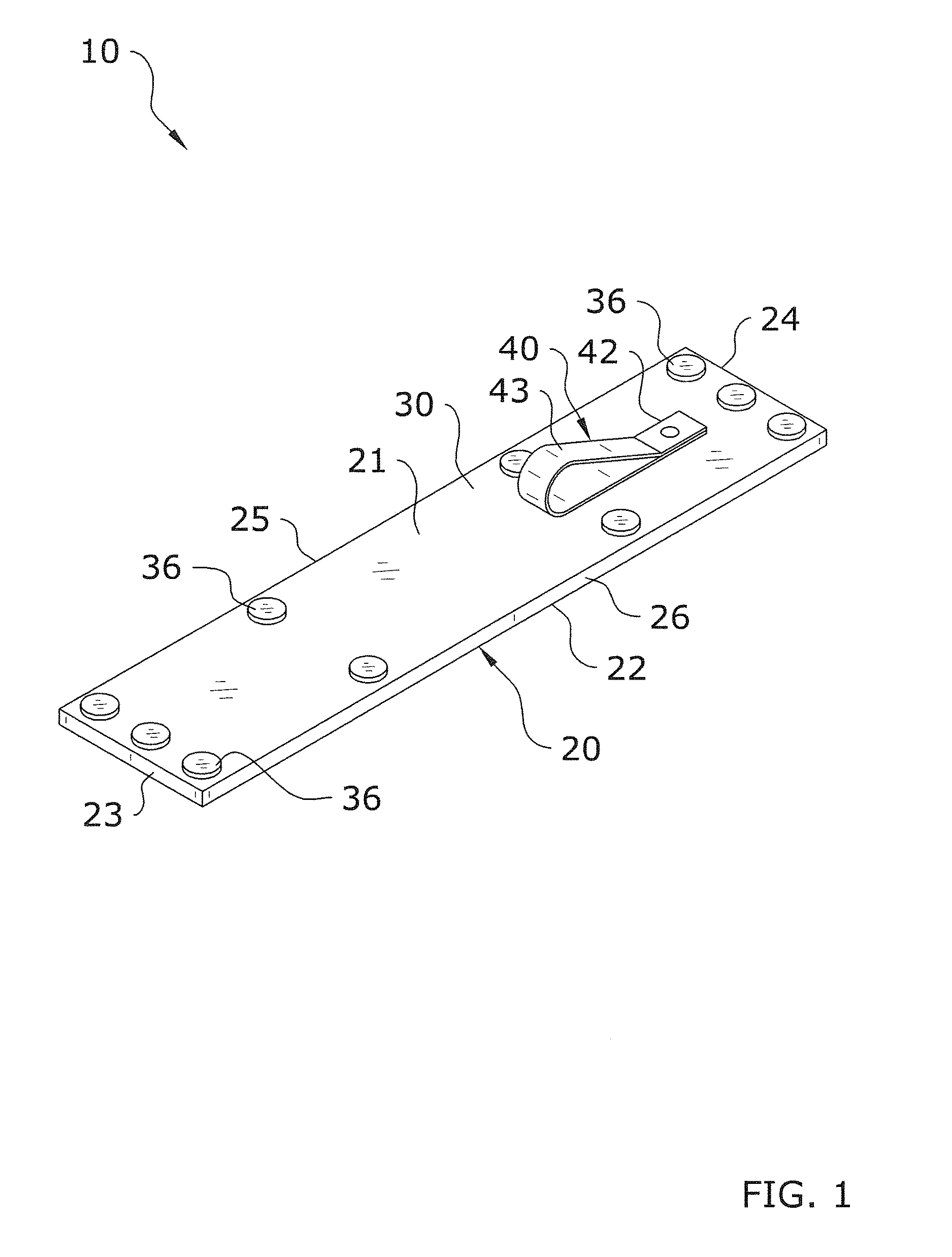

Barbell Collar System

A barbell collar system which is both easy to connect or disconnect from the barbell and secure enough to maintain weights on a barbell during extreme use. The barbell collar system generally includes a collar which is adapted to easily and quickly be connected to or removed from a barbell to retain a weight on the barbell. The collar is adapted to adjust between a first position in which the collar is curled around the barbell outside of the weight and a second position in which the collar is elongated in a linear orientation. The collar may include a ribbon spring for snapping between the two positions and an outer covering for increasing friction between the collar and the barbell. One or more magnets may be included with the collar to magnetically engage the collar with the barbell or the collar with itself.

Owner:PRX PERFORMANCE LLC

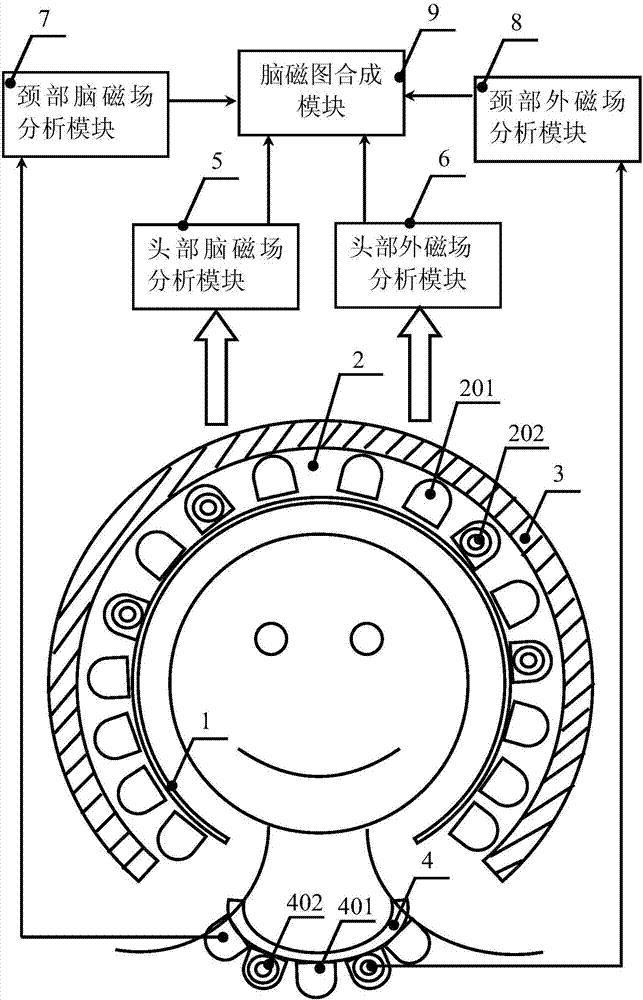

System and method for reducing background noise in magnetoencephalogram detection

InactiveCN106859629AImprove signal-to-noise ratioHigh sensitivityMedical imagingDiagnostic recording/measuringSensor arrayRight hemisphere

The invention relates to a system and a method for reducing background noise in magnetoencephalogram detection. A magnetic sensor array layer is arranged at the outer side of a head-mounted flexible substrate; a brain magnetic field sensor array and an outer magnetic field sensor array are distributed on left and right hemispheres of the brain; a magnetic shielding layer is arranged outside the magnetic sensor array layer; and a neck ring of a wearable magnetic field sensor is arranged on the neck of a human body. reduction of the background noise in magnetoencephalogram detection is achieved by collecting and analyzing a brain magnetic field of the head and an outer magnetic field of the head, analyzing the brain magnetic field of the neck and the outer magnetic field of the neck, fusing brain magnetic field information, carrying out noise analysis on the outer magnetic field information, obtaining a reference noise background signal, fusing the brain magnetic field information and subtracting the reference noise background signal, and a magnetoencephalogram with a high signal-noise ratio is obtained. The system and the method have the characteristics of being simple, convenient to implement, high in sensitivity, low in implementation cost, high in reliability, small in space and high in flexibility.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation of ferrite magnetic spliced magnet having great processability

InactiveCN101364467ALow priceImprove high temperature fluidityMagnetic materialsNitrogen gasMagnetic characteristic

The invention relates to a ferrite bonded magnet with good processing characteristics, which can retain excellent high temperature fluidity without losing magnetic characteristics and mechanical strength. The ferrite bonded magnet is prepared by the steps as follows: adding isotropic strontian ferrite magnetic powder, thermoplastic resin (nylon) monomer, a sodium salt, a processing assistant and a magnetic powder modifier into a pretreatment kettle according to a certain proportion, and vacuuming; heating the pretreatment kettle while stirring the materials for a while, introducing a certain quantity of nitrogen gas under pressure, adding a certain quantity of an activator, and stirring for a while to obtain a compound pre-polymer; and delivering the pre-polymer into a double screw extrusion machine to conduct conveying, polymerization initiation, growth, termination and residual monomers removal, extruding the obtained polymer via a neck ring mold, cooling, drying, and granulating to obtain the finished ferrite bonded magnet granules.

Owner:QINGDAO UNIV OF SCI & TECH

Neck ring guide for glassware making machine

A neck ring guide for aligning neck ring sections in a glassware forming machine has a center body and a pair of spaced parallel runners coupled to the center body for receipt in guide slots in the neck ring sections. Keepers on the outboard sides of the runners retain the runners in the guide slots. Instead of keepers, the runners may be retained in the guide slots by roll pins on the neck ring sections engaged in retainer slots in the runners.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

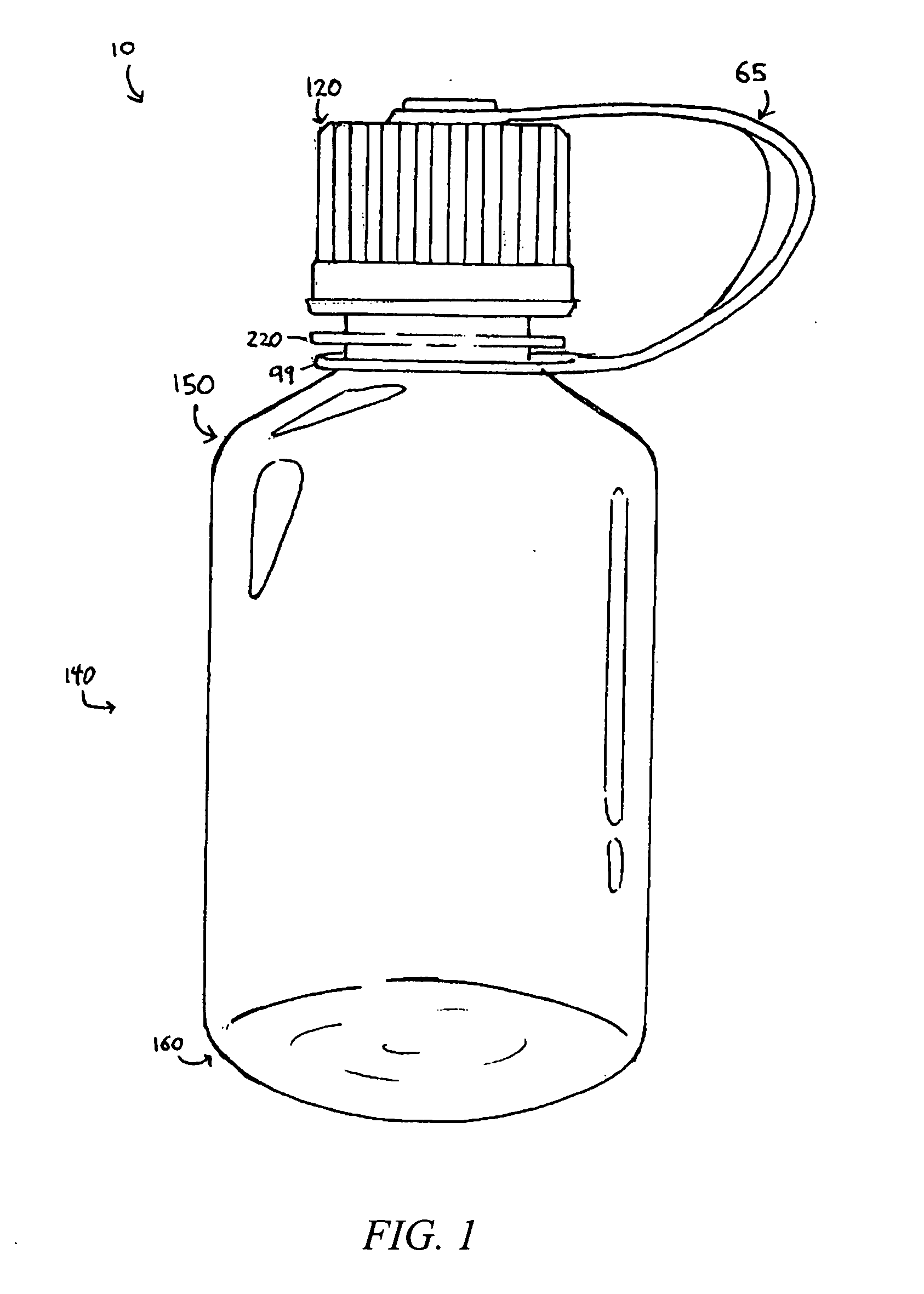

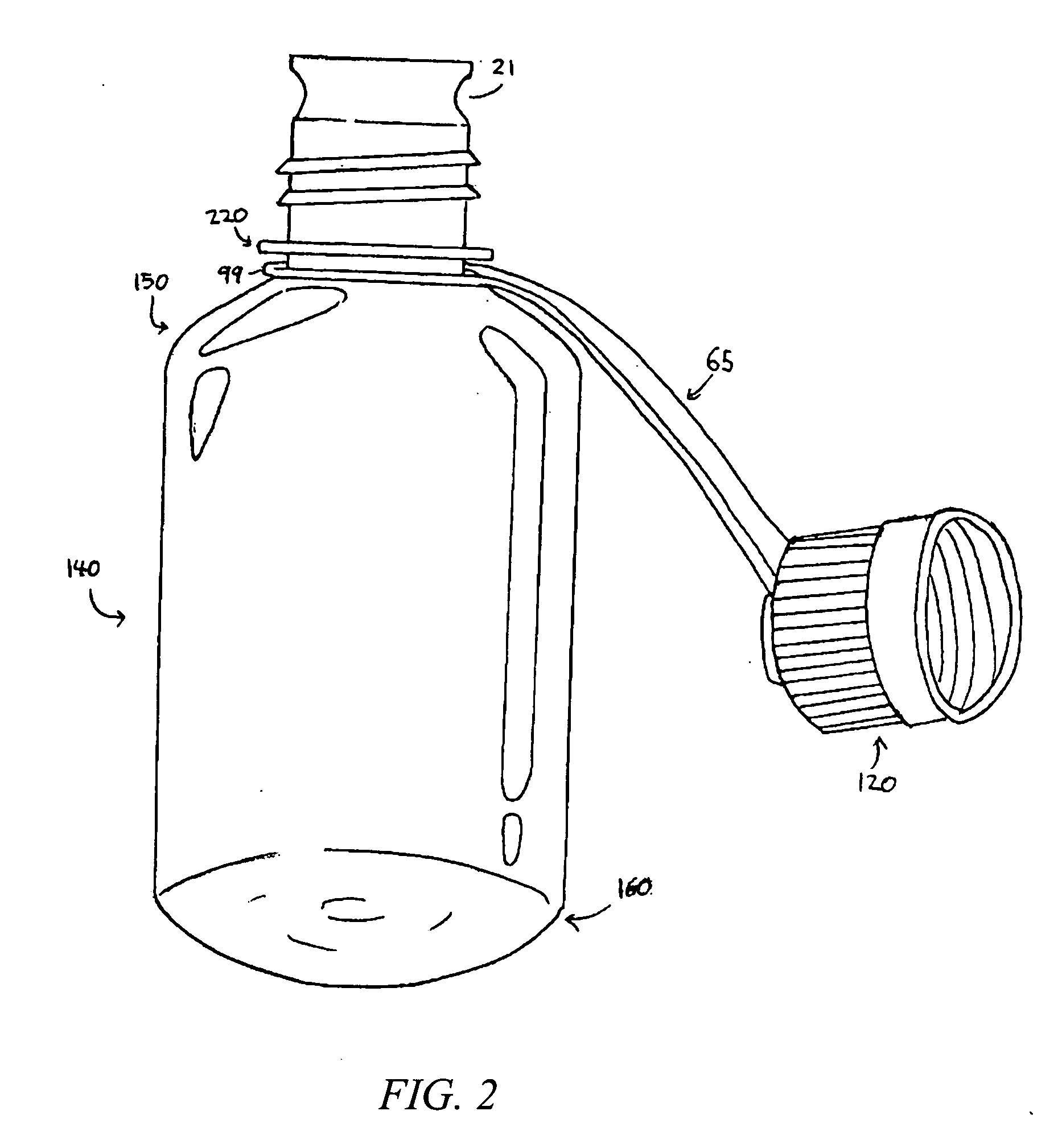

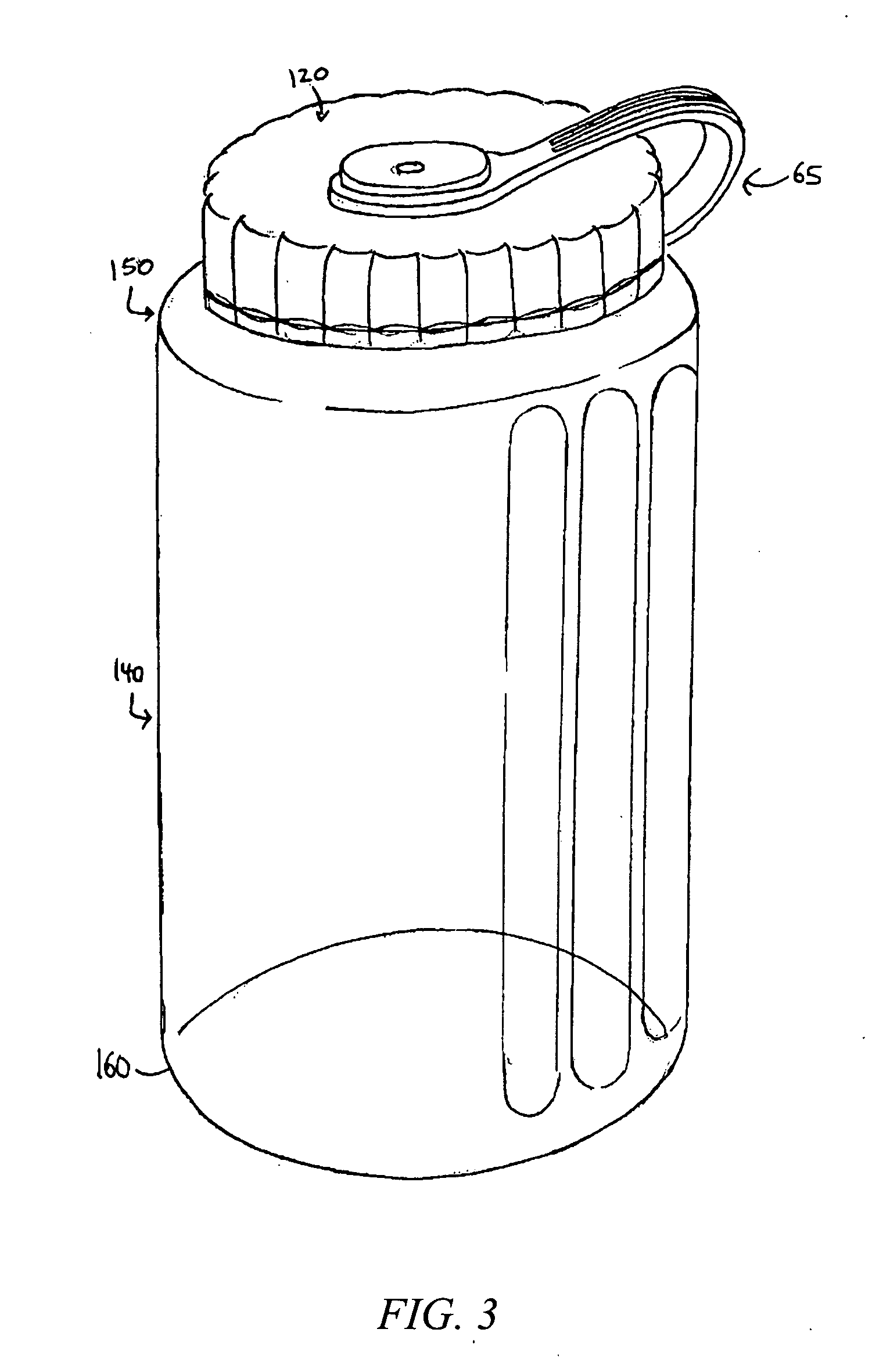

Multipurpose lab vessel and method

A plastic lab bottle created by an injection blow molding process comprises the steps of injecting plastic into a first mold from the plastic lab bottle bottom to form a preformed plastic lab bottle; blowing the preformed plastic lab bottle into a second mold by injecting air into the preformed plastic lab bottle through the mouth opening of the preformed plastic lab bottle; ejecting the finished plastic container from the second mold; providing a plastic cap for closing the bottle; and pulling the tether ring over the neck ring of the bottle.

Owner:TRIFOREST ENTERPRISES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com