Visual polymer micro-extrusion mold

A technology for extruding molds and polymers, which is applied in the field of visual micro-extrusion molds, can solve problems that have not been reported, and achieve the effect of avoiding easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

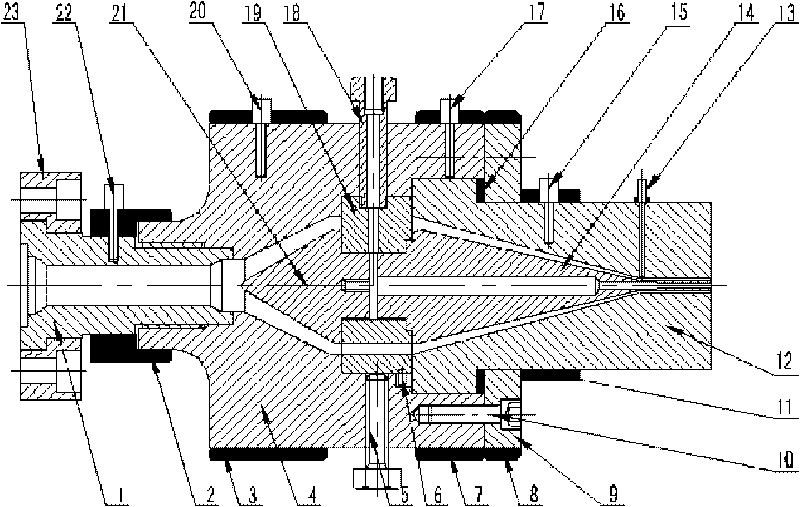

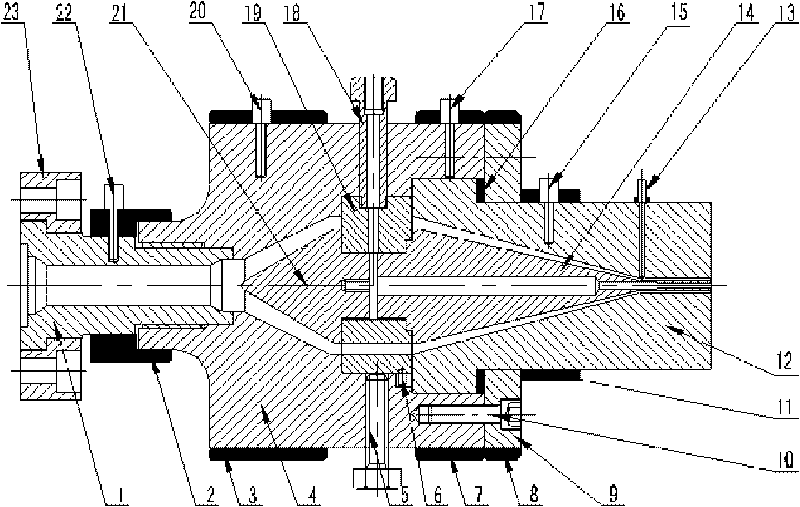

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0015] Use A heating ring 2, B heating ring 3, C heating ring 7, D heating ring 8, and E heating ring 11 to heat the mold so that the temperature of each area of the mold reaches the set value. The temperature in the extrusion process is kept constant by controlling the A temperature sensor 15, B temperature sensor 17, C temperature sensor 20, and D temperature sensor 22 installed on the connecting pipe 1, the nose body 4 and the visual die 12. Under the action of the extruder screw, the polymer melt flows into the head body 4 from the connecting pipe 1, enters the flow channel through the splitter cone 21, and then under the joint action of the mandrel 14 and the visual die 12, the melt cross section The shape is gradually compressed to meet the design requirements, and is extruded from the exit of the visible die 12 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com