Patents

Literature

33 results about "Wall slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

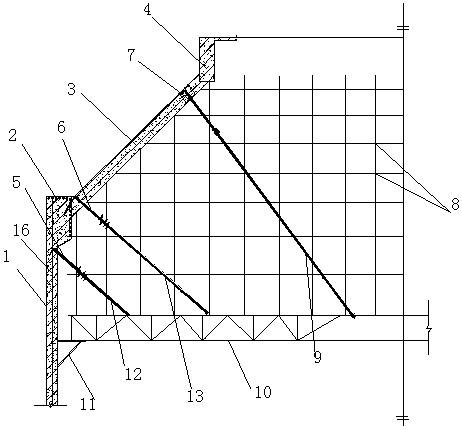

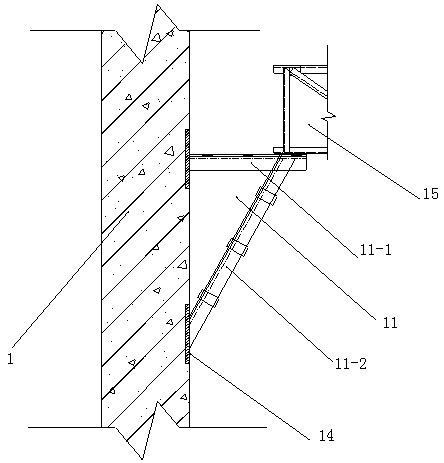

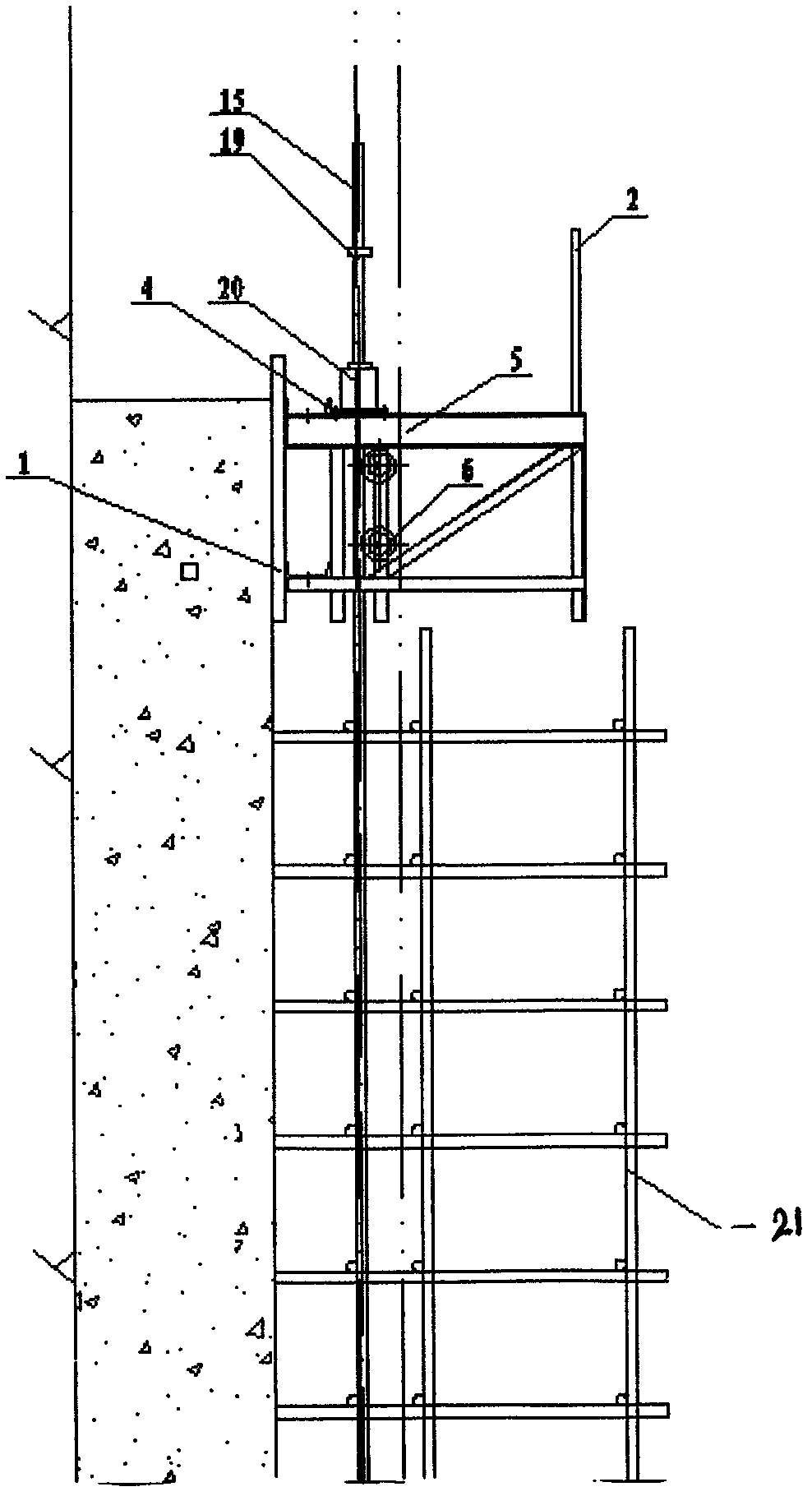

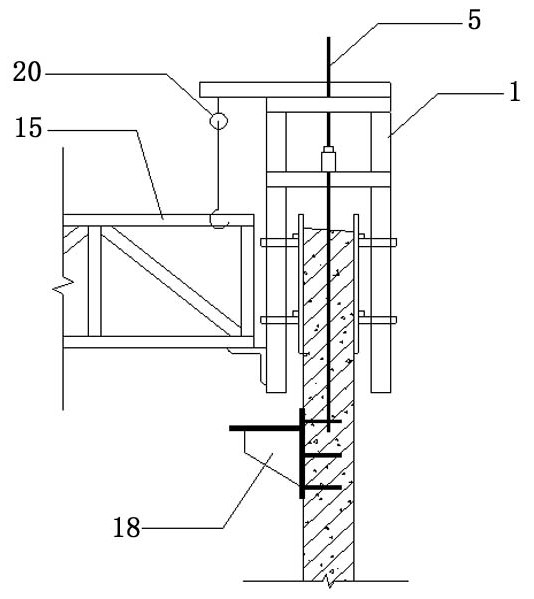

Construction platform and construction method for integrating silo roof and silo wall slip form

InactiveCN103015782AReduce labor intensitySave support materialForms/shuttering/falseworksBulk storage containerPre embeddingSilo

The invention provides a construction method for integrating a silo roof and a silo wall slip form. The method comprises the following steps of: embedding a pre-embedded part, welding a steel corbel, forming a supporting platform by a sliding module and the steel corbel, building a supporting frame and three diagonal members on the supporting platform; and then pouring concrete. The construction method is reasonable in design, convenient to operate and safe and reliable; and through the construction method, multiple shortcomings of the traditional construction method are overcome; the investment of revolving materials and labor force is reduced, the construction is safe, the construction period is shortened, and the construction cost is saved. The invention aims to provide a construction platform for realizing the construction method for integrating the silo roof and the silo wall slip form.

Owner:CHINA COAL BUILDING & INSTALLATION ENG GRP +1

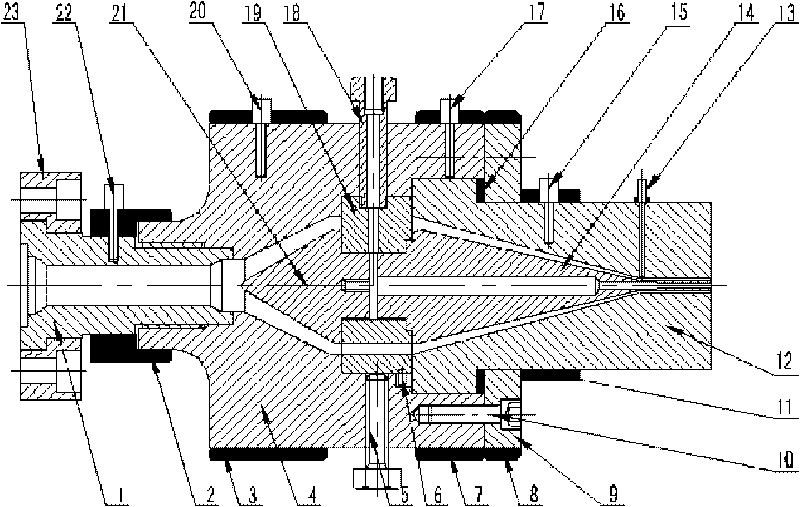

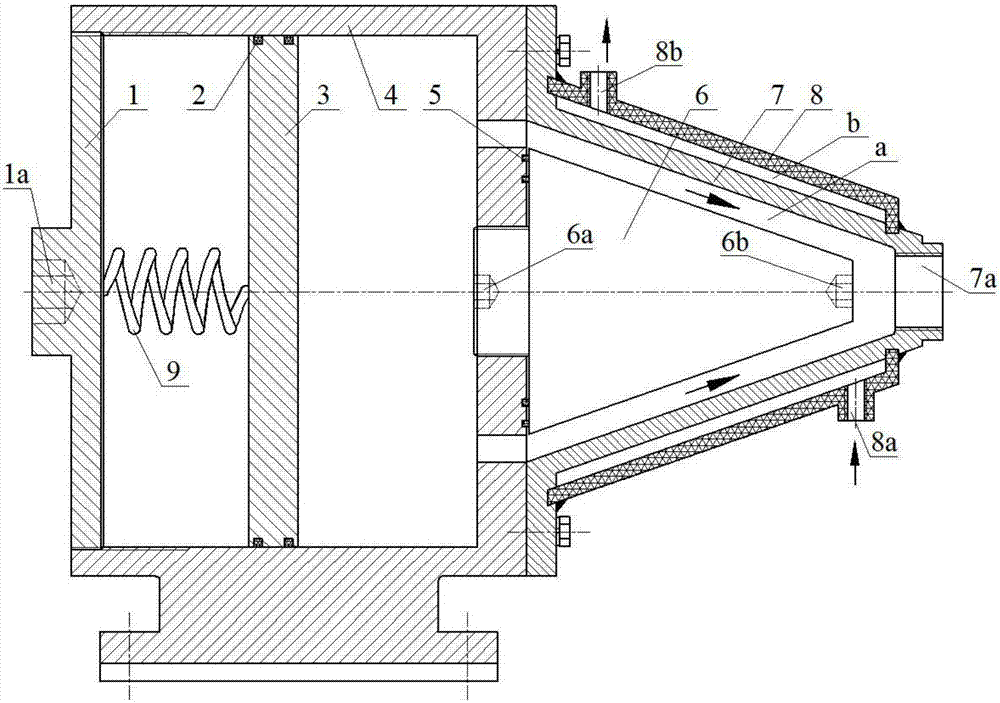

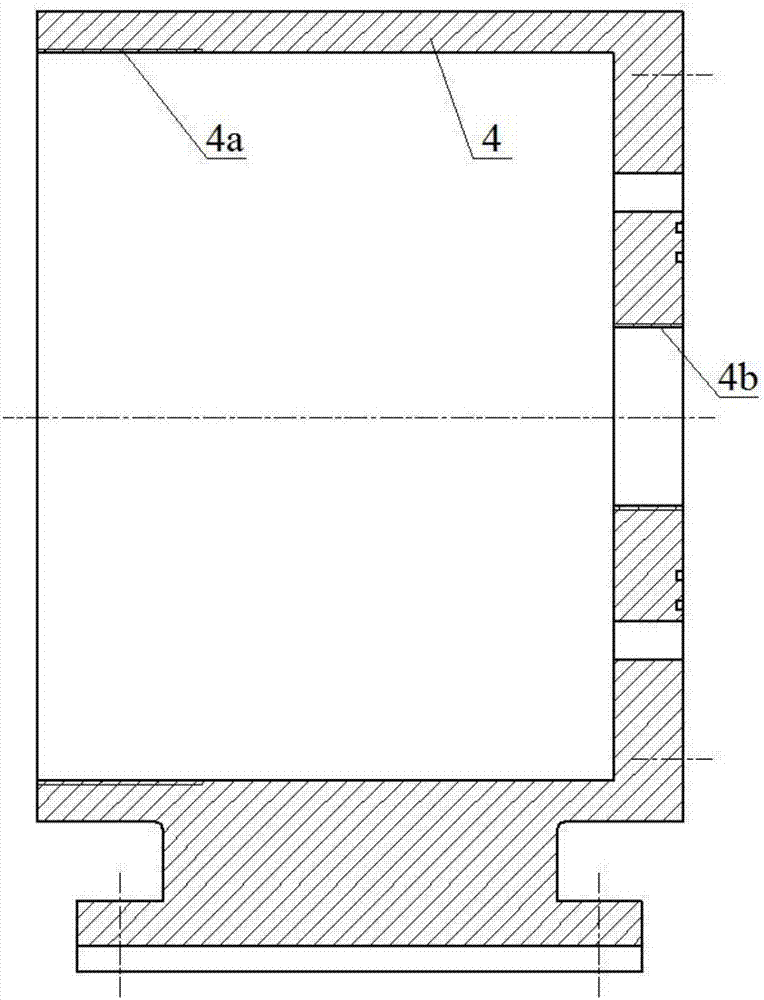

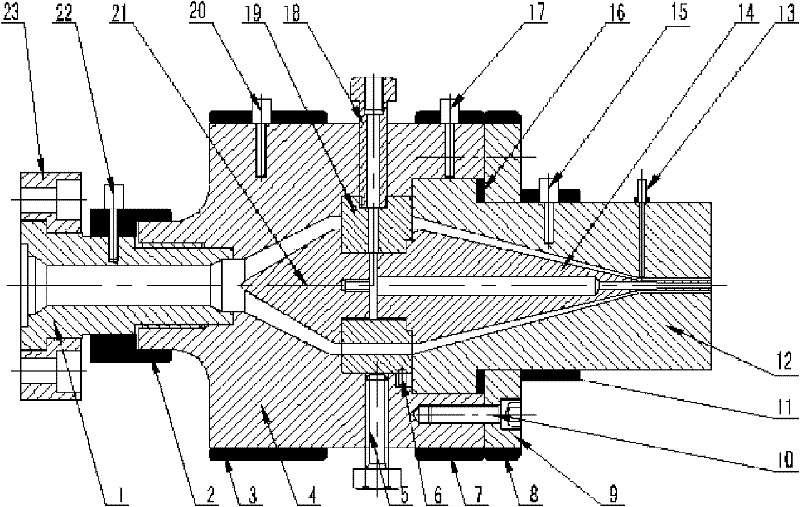

Visual polymer micro-extrusion mold

The invention discloses a visual polymer micro-extrusion mold and belongs to the technical field of polymer micro-extrusion molds. The visual polymer micro-extrusion mold is characterized in that the visual mold consists of a connecting pipe, a heating ring, a handpiece body, an adjusting bolt, a positioning pin, a baffle, a fastening bolt, a visual neck ring mold, a pressure / temperature sensor, a core rod, a gasket, a temperature sensor, a ventilating bolt, a support plate, a spure spreader and a flange. The spure spreader, the core rod and the neck ring mold with different structural parameters are respectively exchanged according to the need; coaxiality and clearance between the core rod and the visual neck ring mold are adjusted by the method of fixing the visual neck ring mold and adjusting the core rod; the visual neck ring mold is used for observing the flow state in the micro-extrusion mold of polymer melt; the pressure / temperature sensor is used for measuring pressure and temperature of straight section of the polymer melt; and the heating ring and the temperature sensor are used for controlling temperature of the micro-extrusion mold. The visual polymer micro-extrusion mold obtains flow distribution, flow characteristics and wall slip velocity of the polymer melt in the flow channel by the visual neck ring mold.

Owner:DALIAN UNIV OF TECH

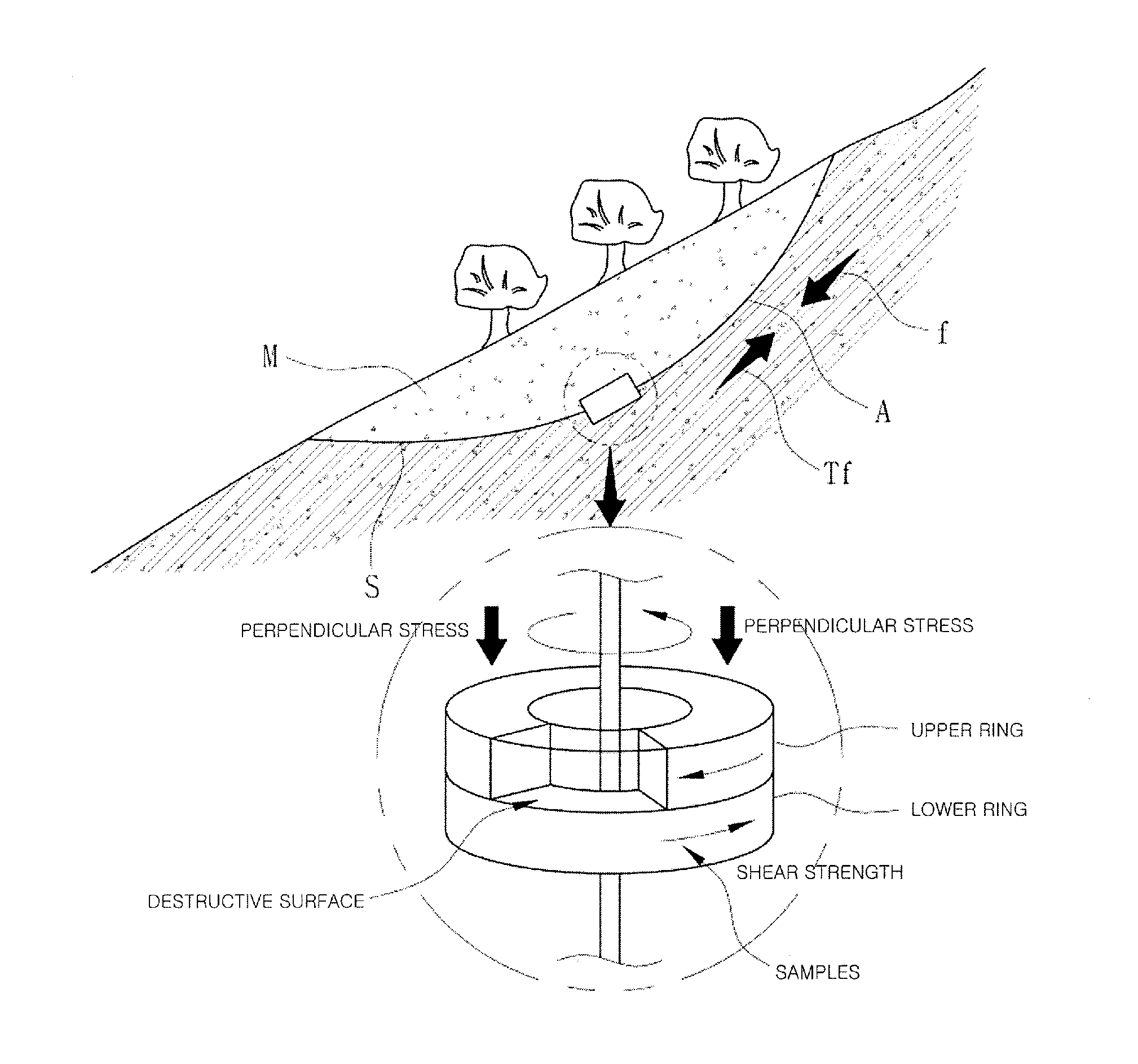

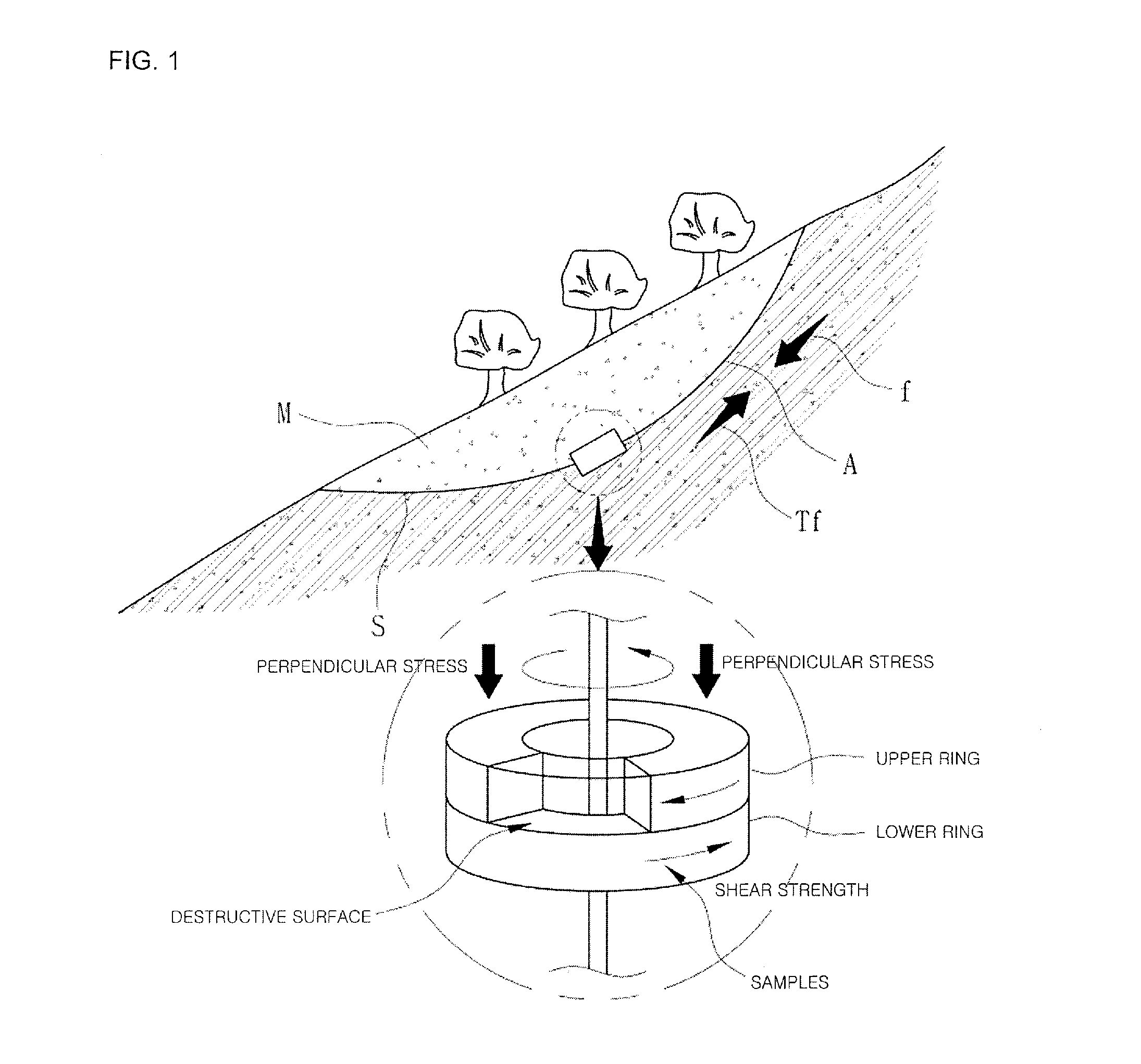

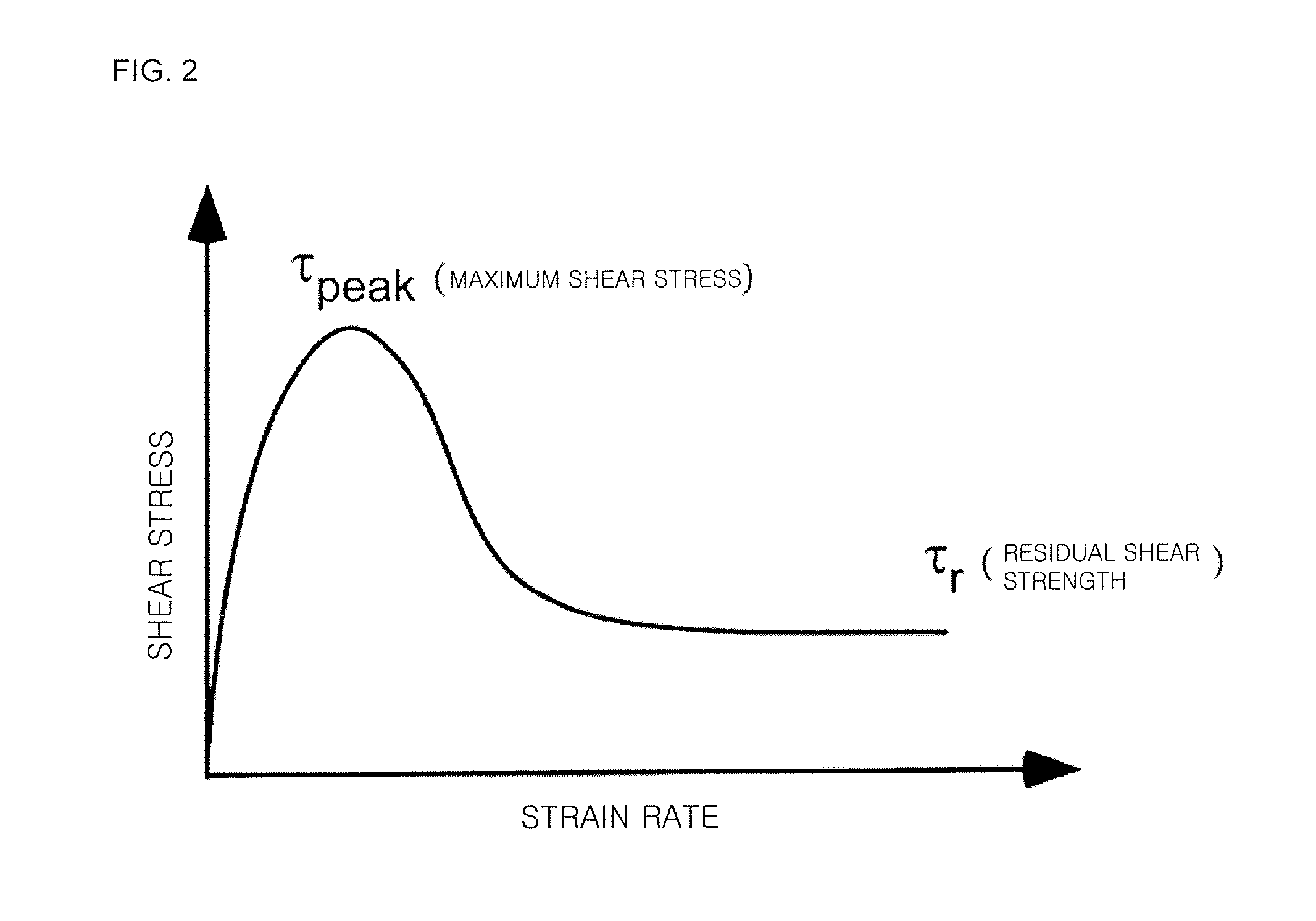

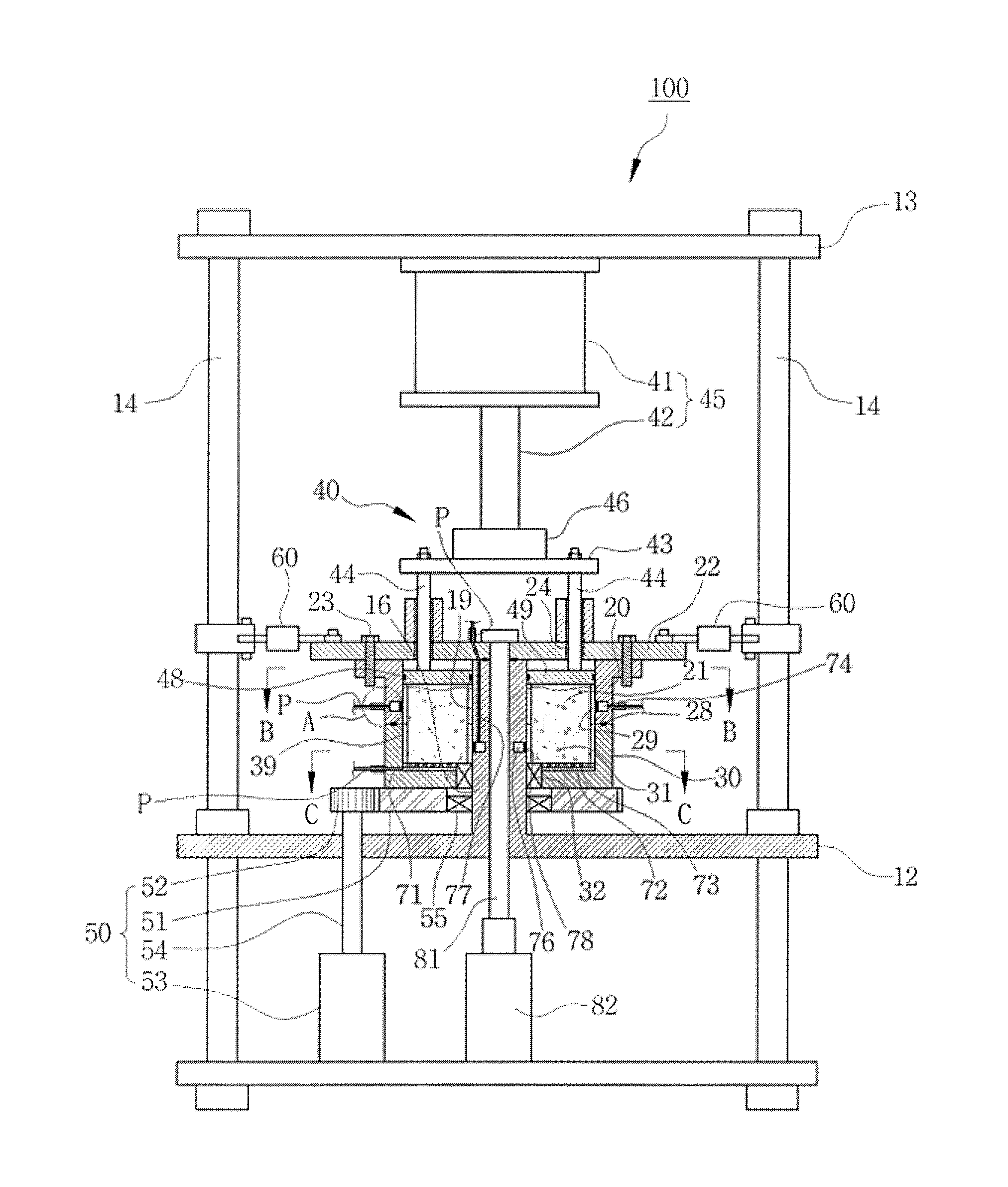

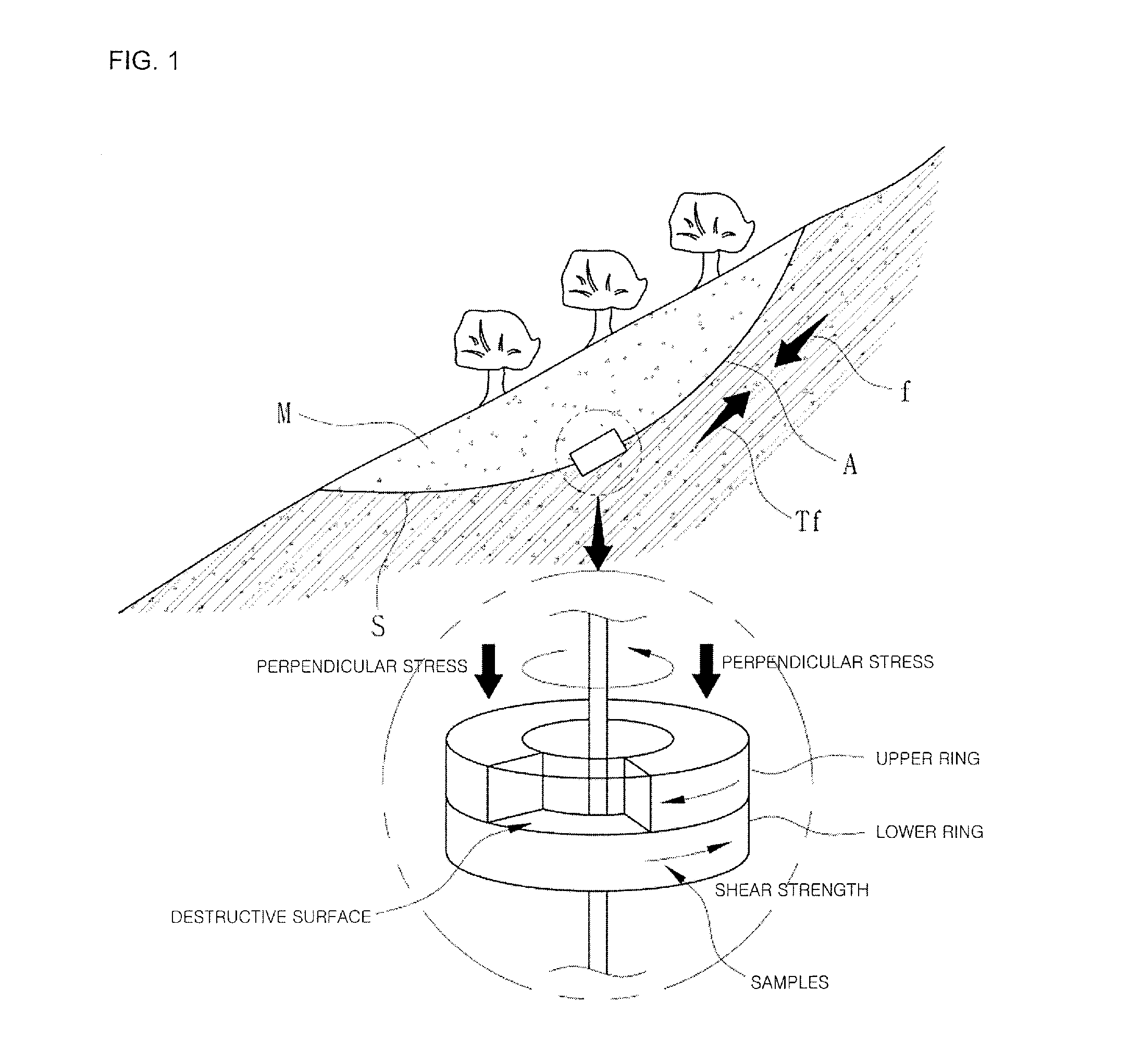

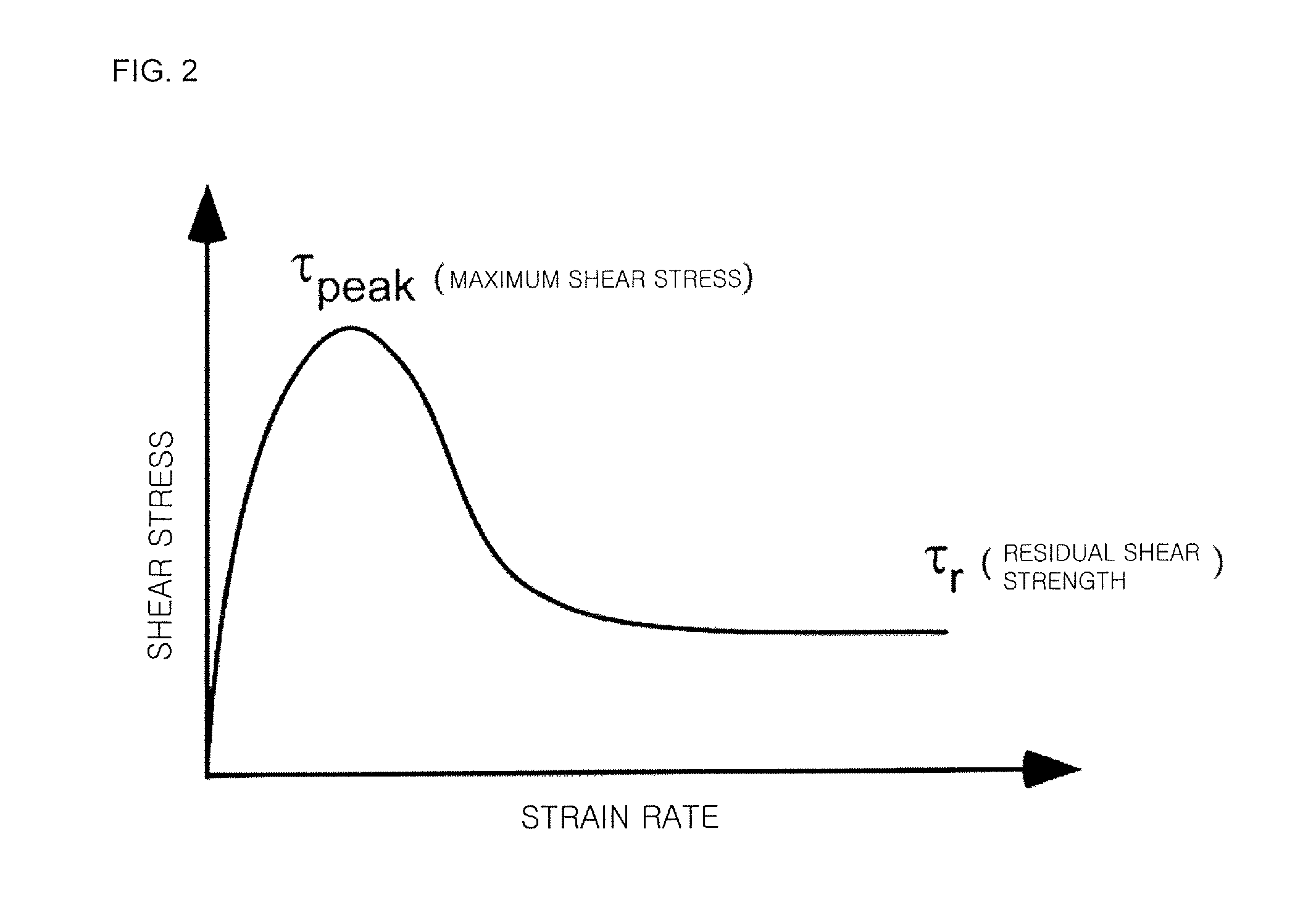

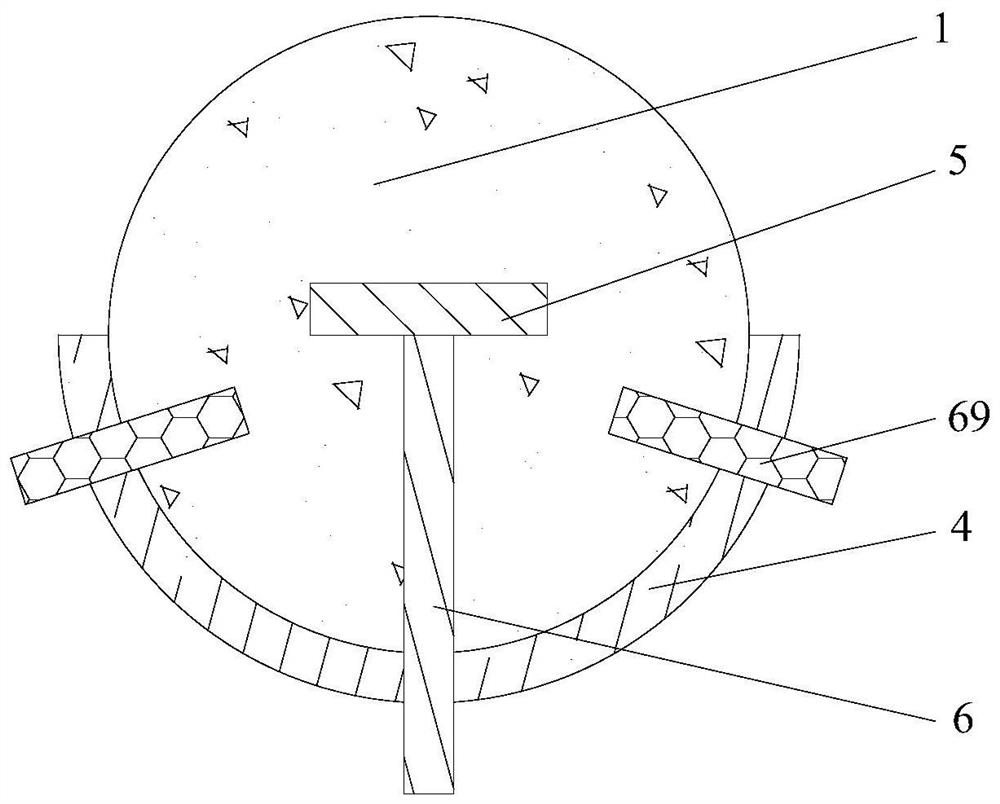

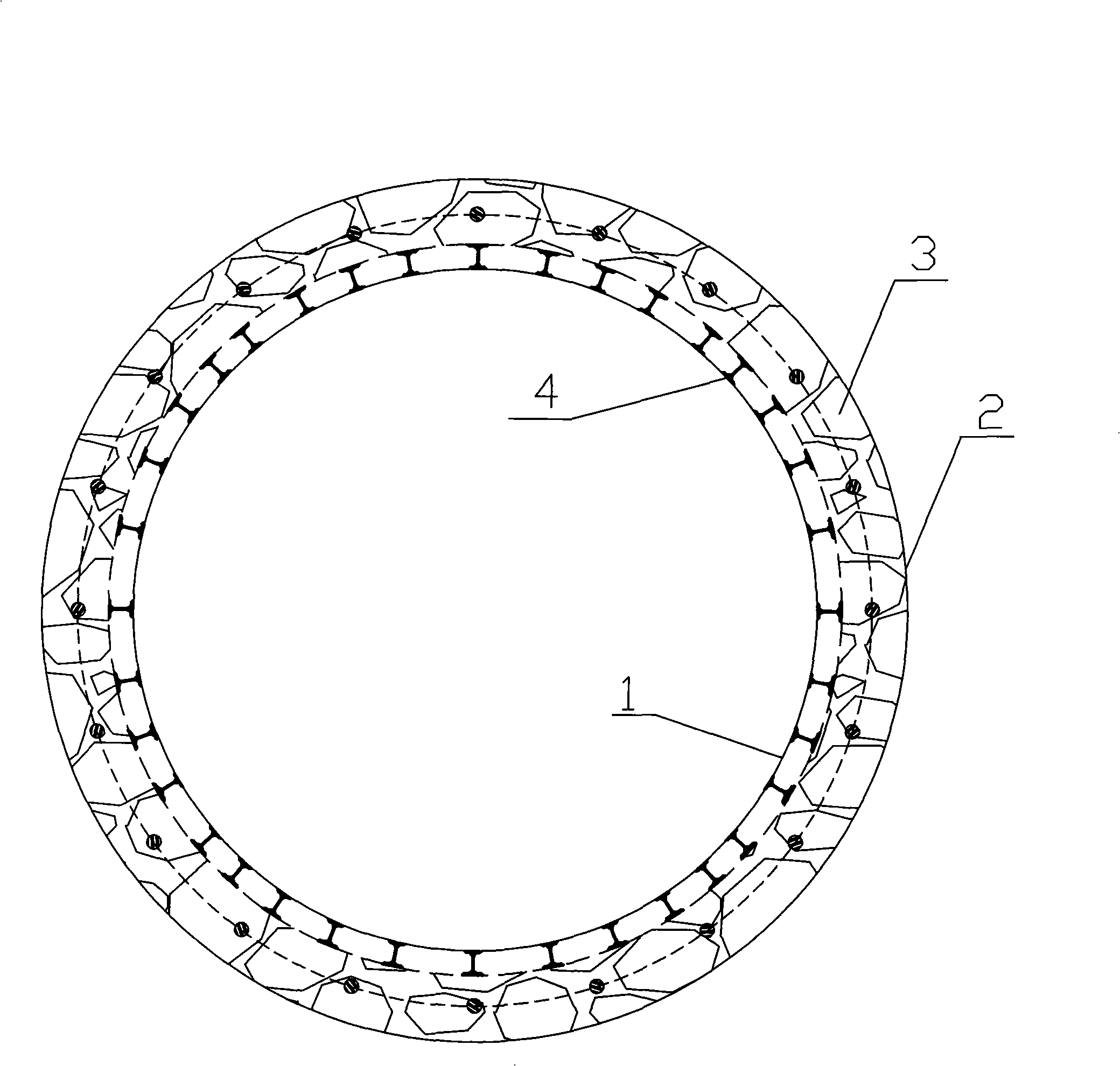

Ring shear apparatus considering wall-slip effect

ActiveUS20130112013A1High precisionHigh measurement accuracyEarth material testingFluid pressure measurement by mechanical elementsEngineeringUltimate tensile strength

A ring shear apparatus for measuring a shear strength of soil samples. The ring shear apparatus considering a wall-slip effect including: an upper ring for forming a first accommodation portion having a ring shape in which soil samples are accommodated; a lower ring for forming a second accommodation portion that corresponds to the first accommodation portion of the upper ring and has a ring shape in which soil samples are accommodated, closely attached to a lower portion of the upper ring and rotatably installed relative to the upper ring; a rotating unit for rotating the lower ring relative to the upper ring; and a shear strength measuring sensor combined with the upper ring and for measuring a shear strength of the soil samples, wherein a plurality of protrusions that protrudes from the lower ring is formed on an inner circumferential surface of the lower ring along a circumferential direction of the lower ring in order to prevent the soil samples from being slid when the lower ring is rotated.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

Ring shear apparatus considering wall-slip effect

ActiveUS8656788B2High measurement accuracyEarth material testingFluid pressure measurement by mechanical elementsEngineeringUltimate tensile strength

A ring shear apparatus for measuring a shear strength of soil samples. The ring shear apparatus considering a wall-slip effect including: an upper ring for forming a first accommodation portion having a ring shape in which soil samples are accommodated; a lower ring for forming a second accommodation portion that corresponds to the first accommodation portion of the upper ring and has a ring shape in which soil samples are accommodated, closely attached to a lower portion of the upper ring and rotatably installed relative to the upper ring; a rotating unit for rotating the lower ring relative to the upper ring; and a shear strength measuring sensor combined with the upper ring and for measuring a shear strength of the soil samples, wherein a plurality of protrusions that protrudes from the lower ring is formed on an inner circumferential surface of the lower ring along a circumferential direction of the lower ring in order to prevent the soil samples from being slid when the lower ring is rotated.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

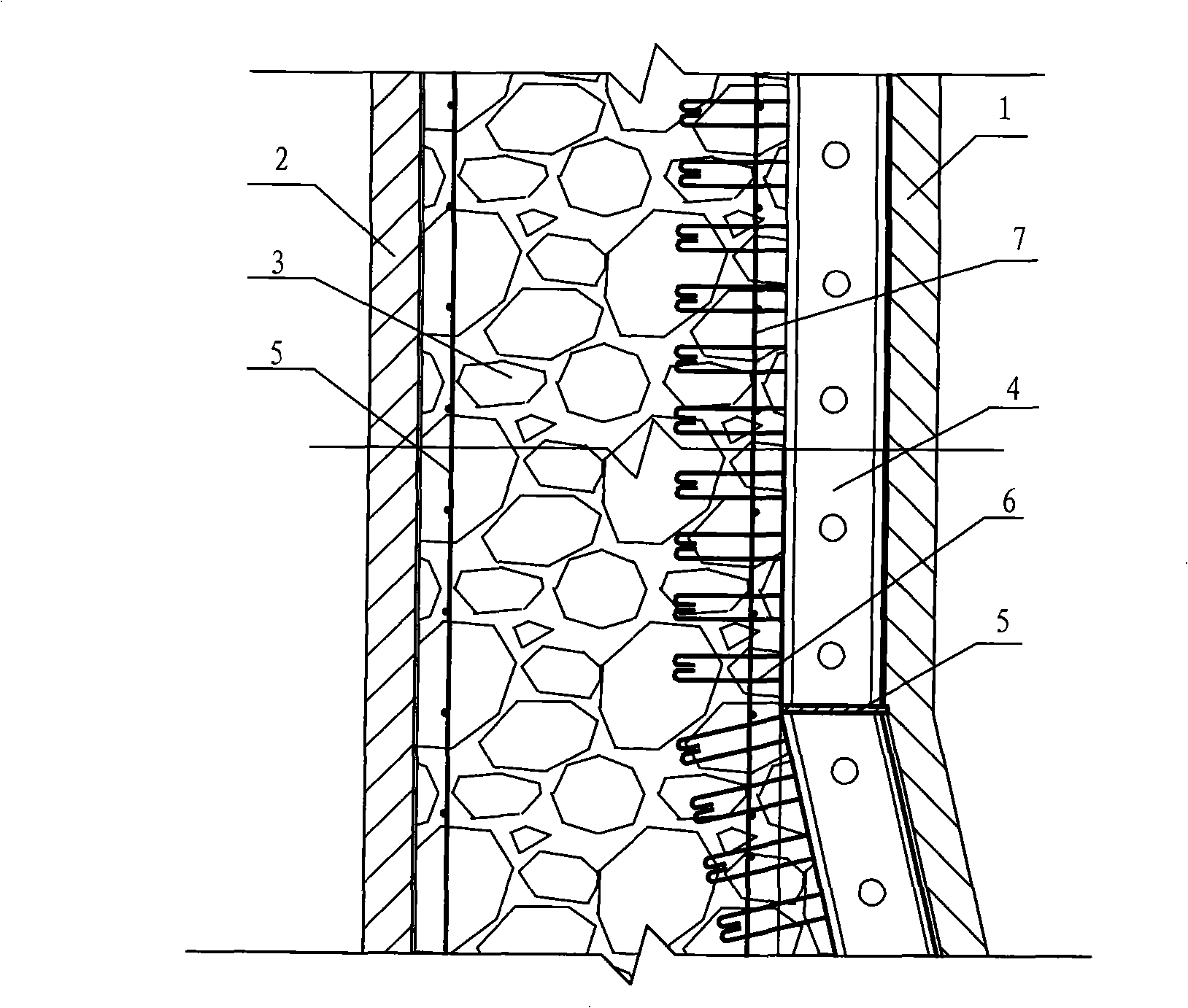

Concrete silo inner lining steel rail and warehouse wall slip form integrated construction method

ActiveCN101429826AImprove entity qualityExtended service lifeBulk storage containerMaterial consumptionEngineering

The invention discloses a construction method for integration of a concrete silo internal lining steel rail and a silo wall slip form. The method comprises the following steps: when the height of the internal lining steel rail is reached to the limestone silo construction according to design requirement, a silo wall inner formwork of the slip form is removed, and a ring steel plate is arranged at the design height of the silo inner side; effective number of steel rails are vertically arranged on the ring steel plate, and connected with one another through reinforcement steel bars, and the steel rails are welded with anchoring reinforcement steel bars connected with the silo wall reinforcement steel bars; after the position, distance and verticality of the steel rails are corrected, the joints between the reinforcement steel bars and the steel rails are welded; and the anchoring reinforcement steel bars and the silo wall reinforcement steel bars are tightly bound and arranged on the silo wall inner formwork again, and the concrete is continuously cast between the silo and the steel rails until the design height of the silo is reached, thereby improving the wearing resistance of the silo, prolonging the service life of the limestone silo by 15 to 20 years, reducing manpower consumption by 110 working days, reducing material consumption by 30,000 yuan, saving the time of welding, arrangement and secondary casting of the steel rails and shortening construction period by 30 days.

Owner:河北省第四建筑工程有限公司

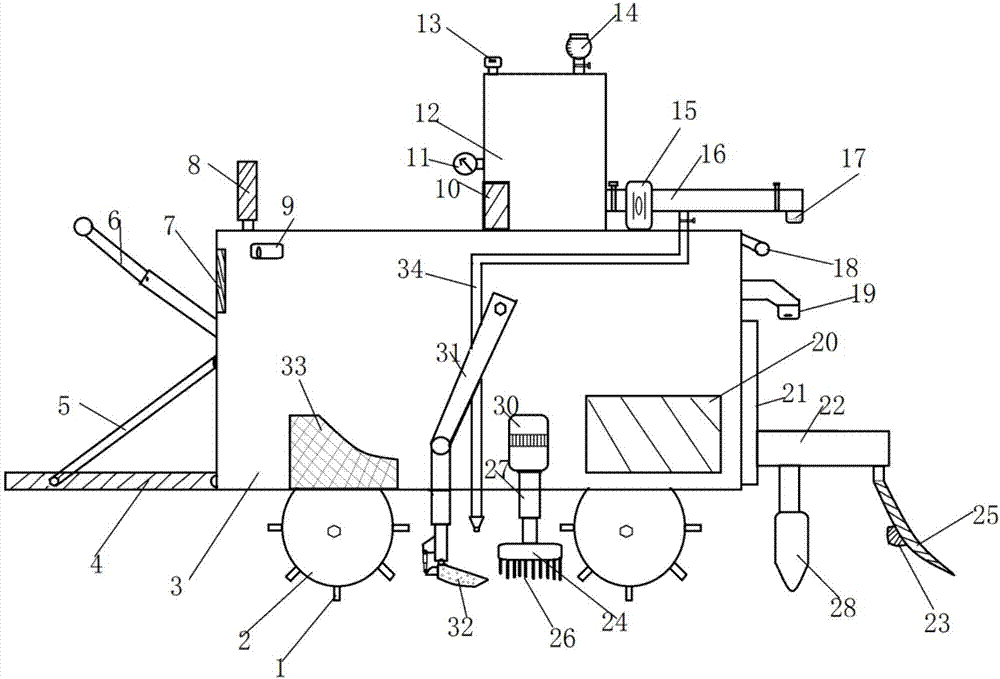

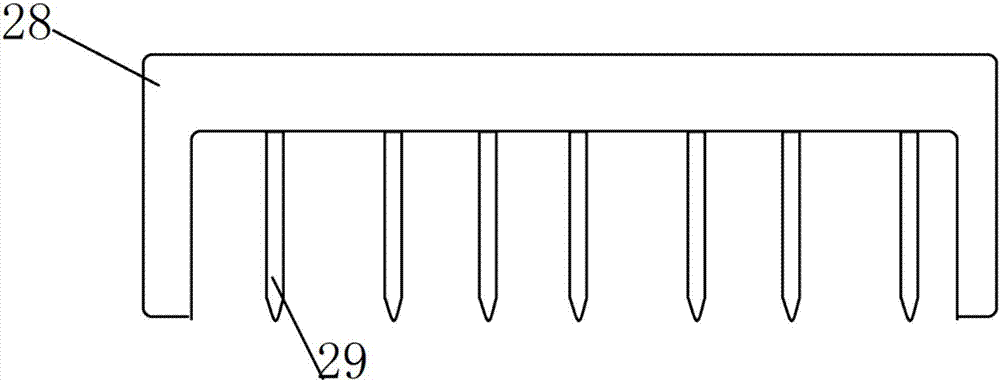

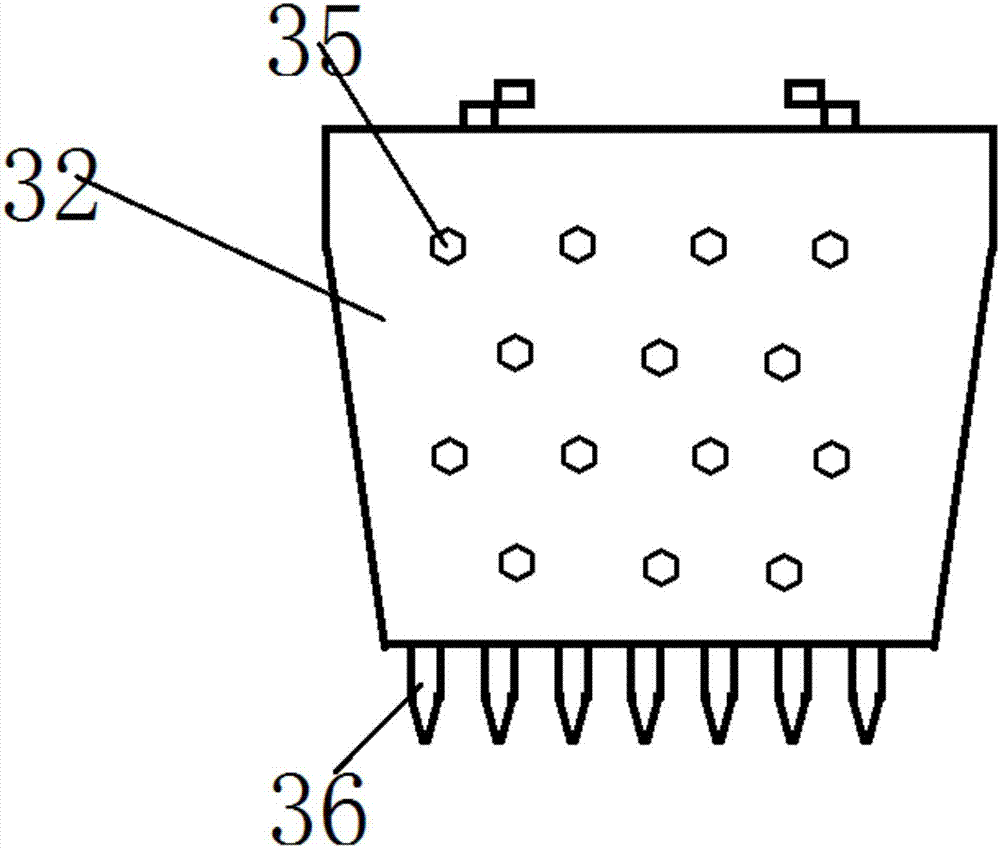

Efficient safe agriculture field ploughing arranging device

The invention discloses an efficient and safe agricultural field plowing equipment, which includes blades, wheels, mobile vehicles, pedals, magnet blocks, display devices, level meters, heaters, thermometers, water tanks, lighting lamps, cameras, slide rails, Beams, motors, coulters, runners and leveling claws, the bottom surface of the mobile car is provided with wheels, the outer edge of the wheels is provided with blades, one side of the mobile car is provided with a push handle, and the bottom of the mobile car near the push handle is provided with feet. Pedal, the side wall of the mobile car is provided with a magnet block, the mobile car is provided with a display device, the side of the mobile car away from the push handle is provided with a light and a camera, the mobile car is provided with a storage battery, and the front side wall of the mobile car is provided with a slider. rail, the slide rail is provided with a crossbeam, and the bottom surface of the crossbeam is provided with coulters and leveling claws successively from front to back; The invention is beneficial to be used in hilly areas where agriculture is not concentrated, and at the same time avoids pests affecting crops in the coming year, and has simple structure, convenient use and popularization.

Owner:苏加强

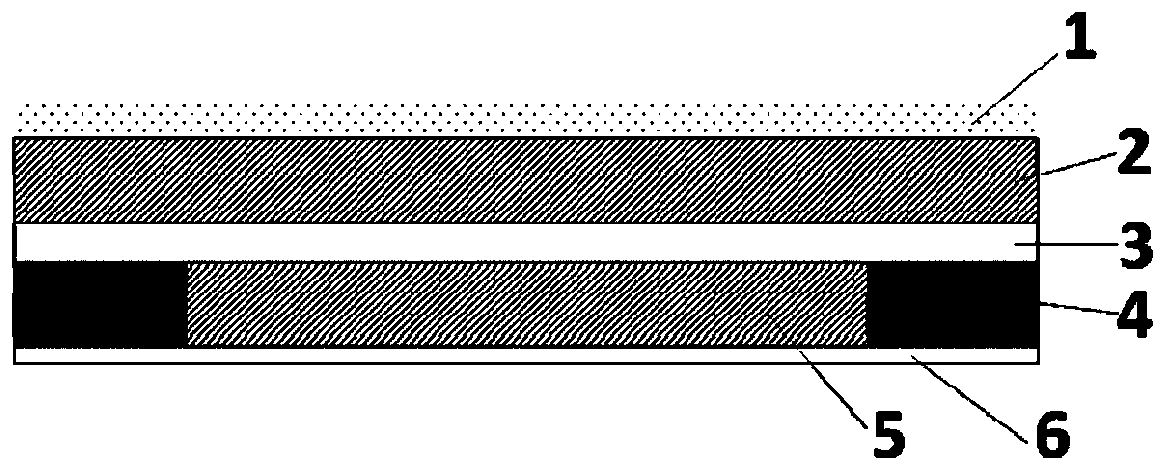

Exposed type modified asphalt waterproof coiled material and preparation method thereof

ActiveCN109747236AHigh whitenessIncrease reflectionRoof covering using flexible materialsSynthetic resin layered productsBituminous waterproofingViscosity

The invention discloses an exposed type modified asphalt waterproof coiled material and a preparation method thereof. The exposed type modified asphalt waterproof coiled material is composed of an isolating layer, a lower surface modified asphalt layer, a reinforcing layer, an upper surface high-viscosity modified asphalt layer and a ceramic particle layer which are sequentially arranged, whereinthe lower surface modified asphalt layer comprises an overlap edge outer part and overlap edge parts on both sides of the overlap edge outer part. The exposed type modified asphalt waterproof coiled material can integrate the functions of waterproofness, energy conservation, attractive appearance, ageing resistance, vertical wall slipping resistance in summer and the like.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD

Device ensuring rear side movement of double movable walls of coal chute

The invention discloses a device ensuring rear side movement of double movable walls of a coal chute, which is used in the process of coking by adopting tamping. The device comprises a baseplate and a chain, wherein the baseplate is positioned on the chain and forms a coal box with a front baffle, a left side wall, a right side wall and a rear baffle which are positioned on the baseplate; tampinghammers are arranged above the coal box; and a coking chamber of a coke oven is arranged in front of the coal box. The device is characterized in that the left side wall and the right side wall are respectively provided with cylinders; the cylinders are hinged with the middle parts of levers by cylinder rods; one end of the levers is hinged with fixed supports and the other end thereof is hinged with connecting hinge point bases; the hinge points are positioned on position stops; the position stops are respectively connected with the left side wall and the right side wall fixedly; and the movement ends of the levers are freely connected with the position stops by circular arcs and ensure the left side wall and the right side wall slip toward the rear side when being separated with coal cakes.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Heating grease supply device and method

The invention discloses a heating grease supply device and a method. The heating grease supply device is provided with a grease storage pressurizing module and a heating grease supply module, wherein the grease storage pressurizing module is used for storing not heated lubricating grease and applying certain pressure to the lubricating grease; and the heating grease supply module is provided with a grease passing gap allowing the lubricating grease in the grease storage pressurizing module to be heated, hot fluid channels uniformly distributed at the outer edge of the grease passing gap and a grease outlet for collecting the heated lubricating grease, and the grease outlet communicates with the grease passing gap. According to the heating grease supply device, a wall slip effect of the smooth wall surface of the grease passing gap and the thermorheological characteristic of the lubricating grease during heating both have a promotion effect on the flowing property of the lubricating grease; meanwhile, the higher the temperature is, the more obvious the wall slip effect is; and through the coupled promotion effect, the gap flowing performance of the lubricating grease can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

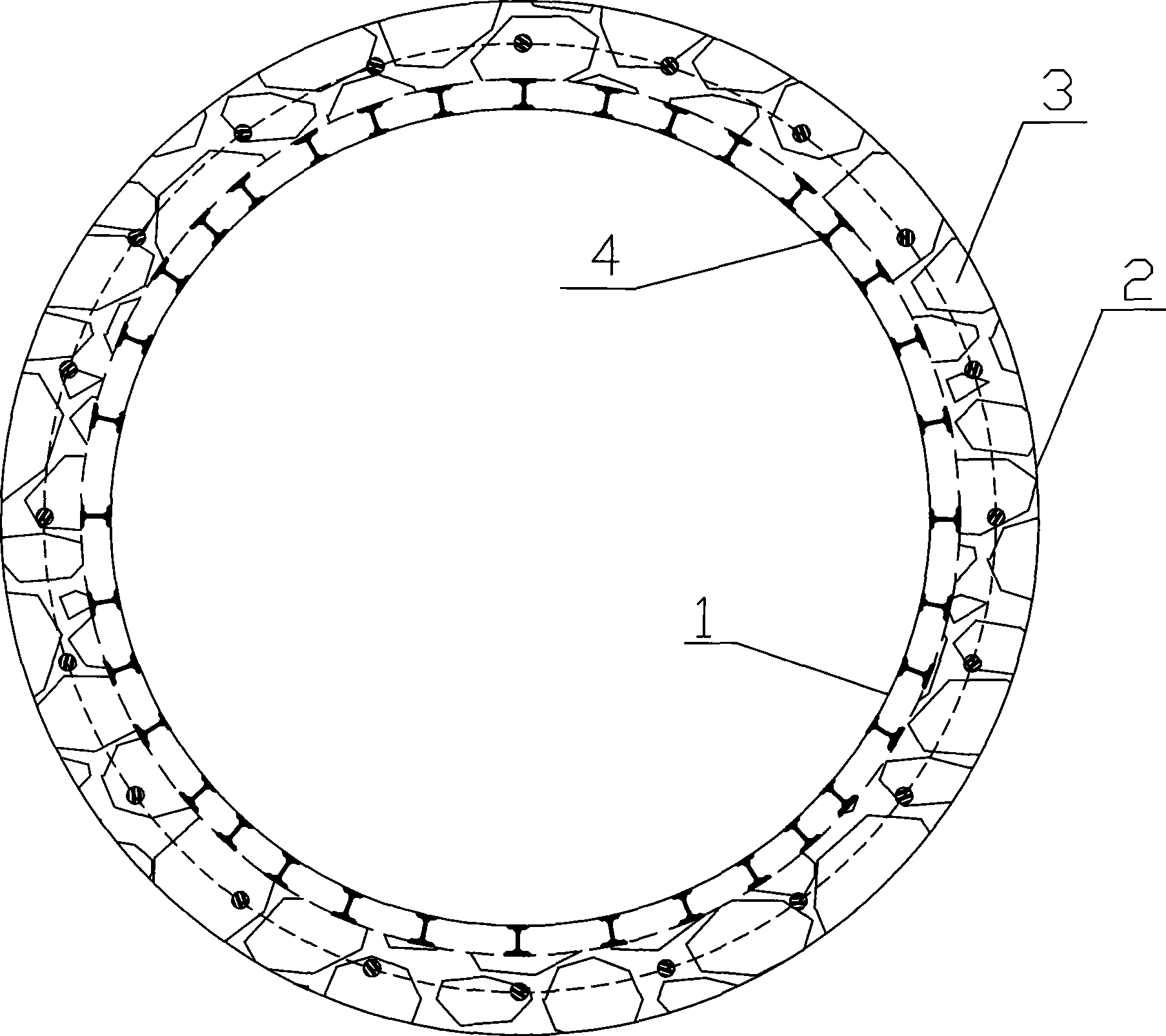

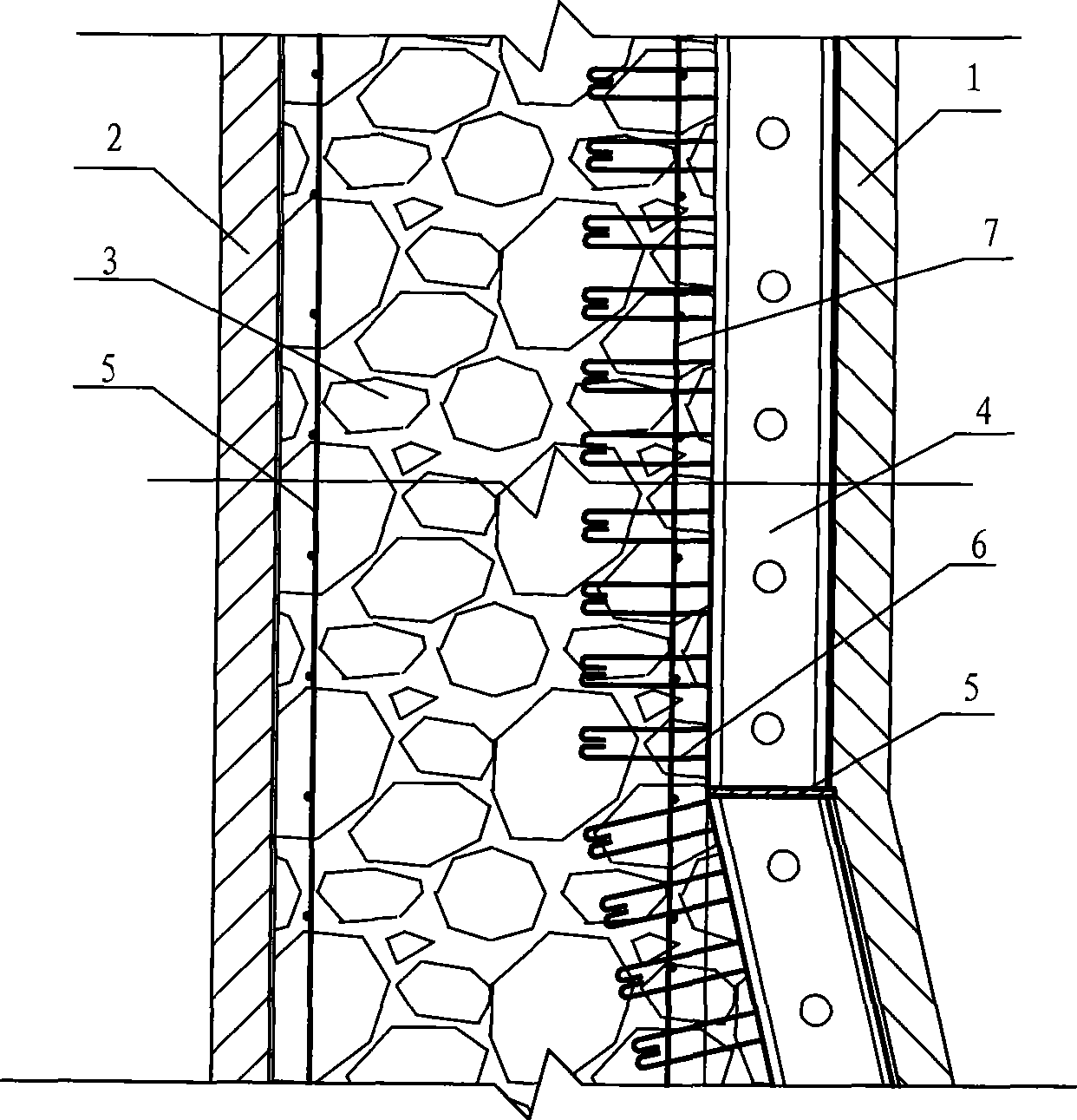

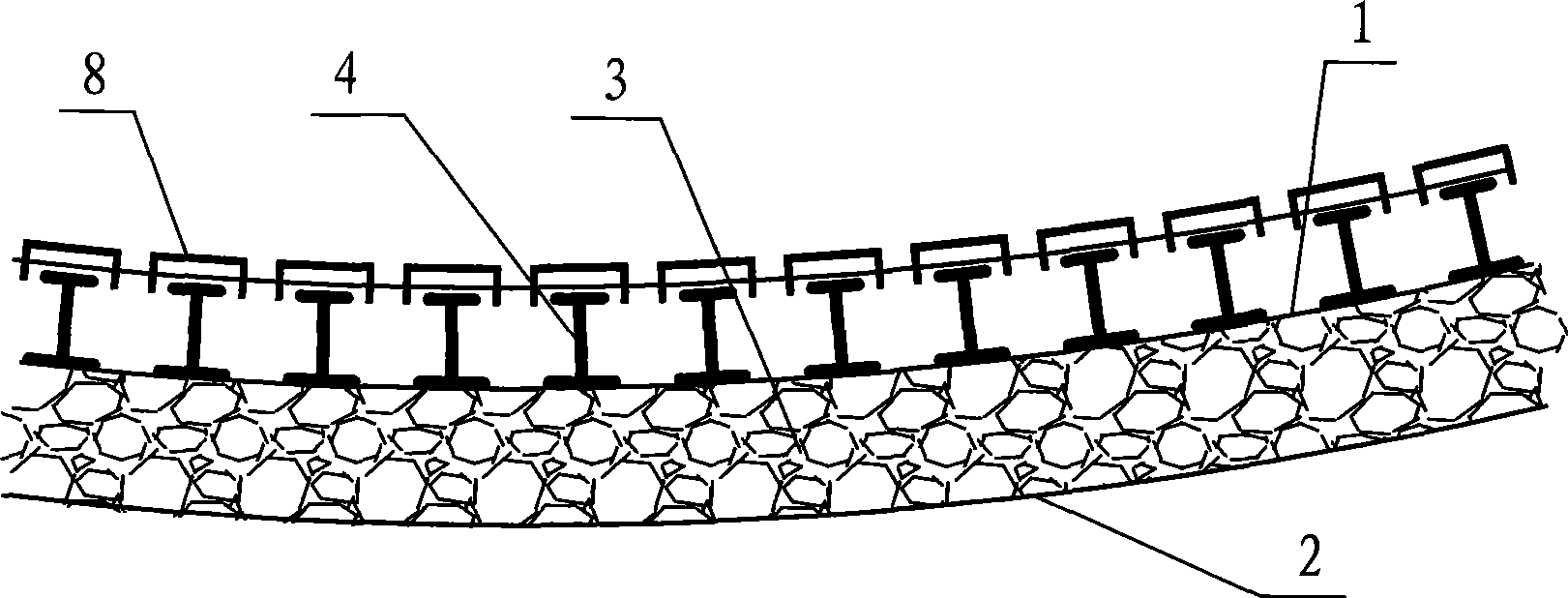

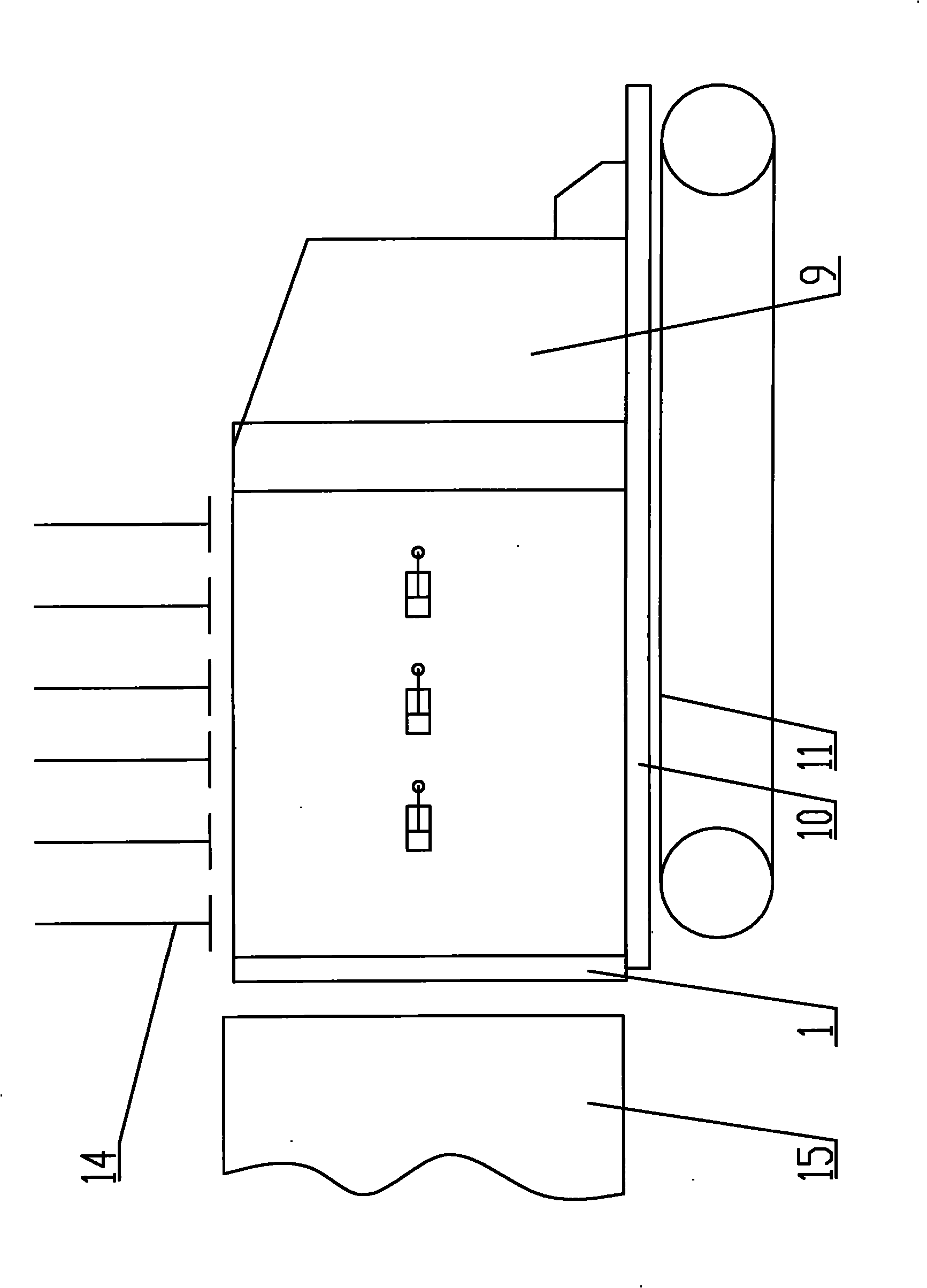

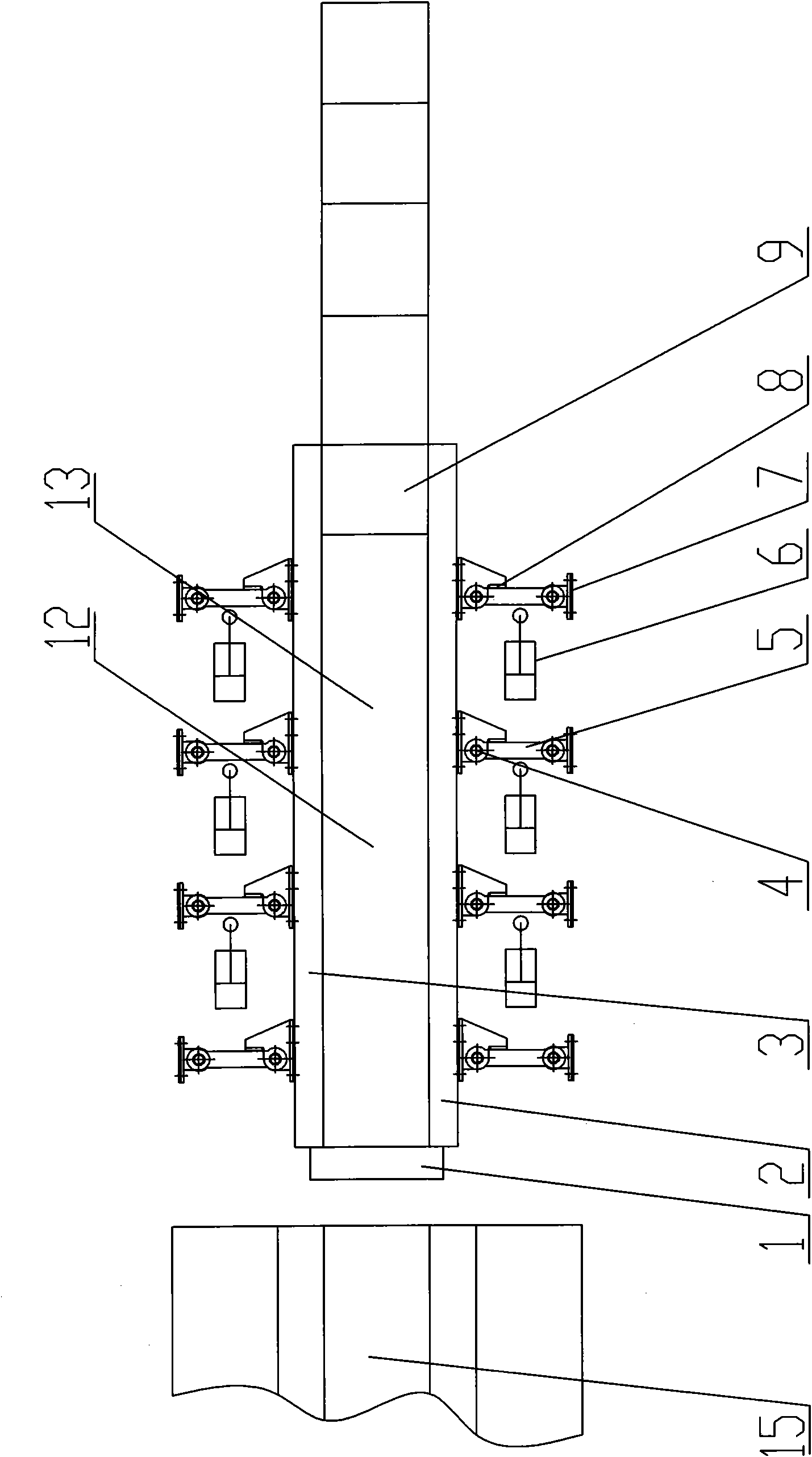

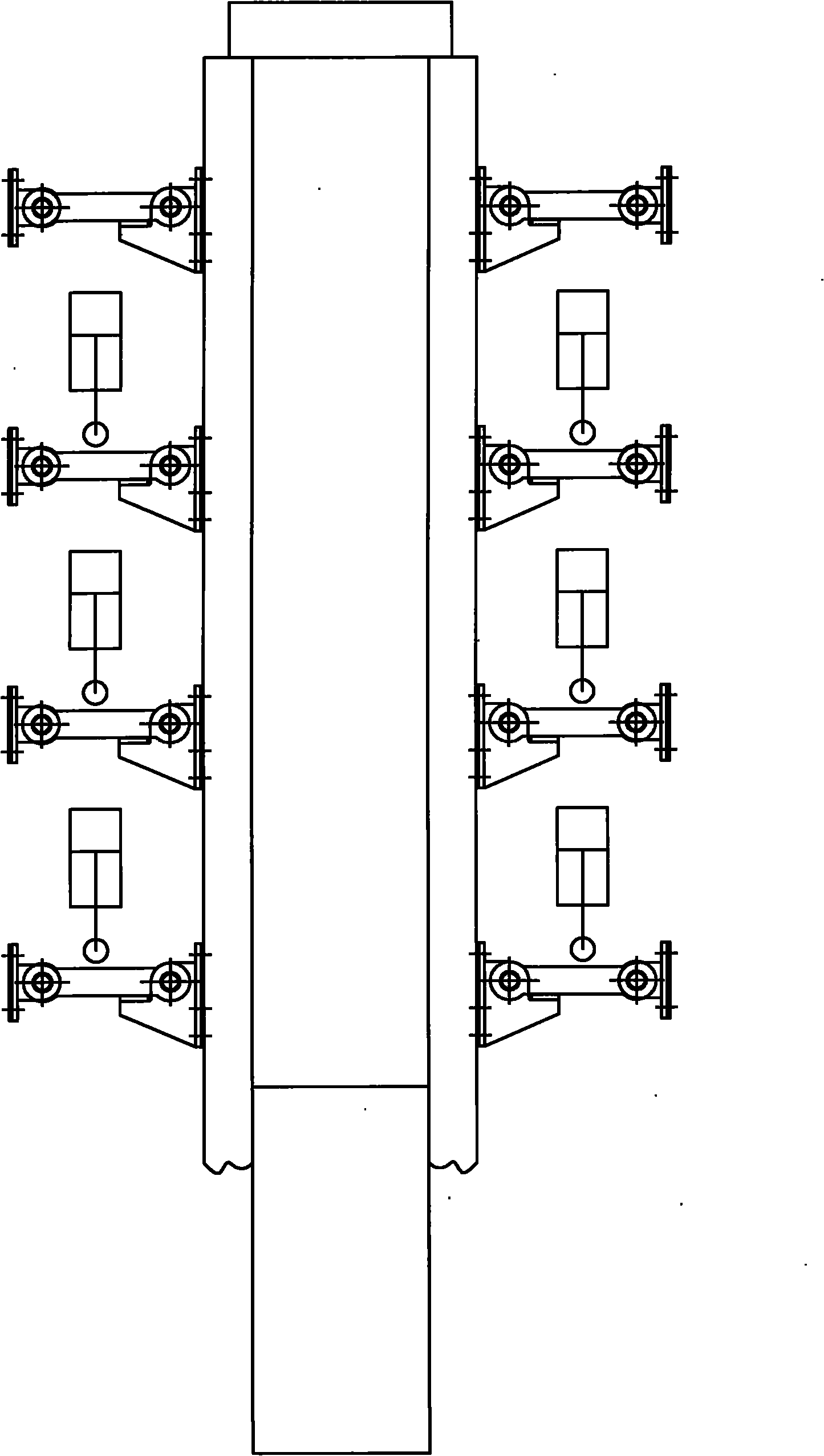

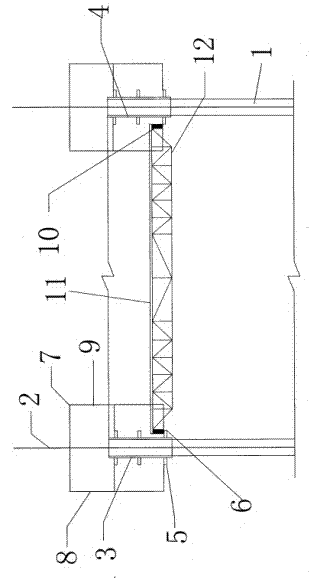

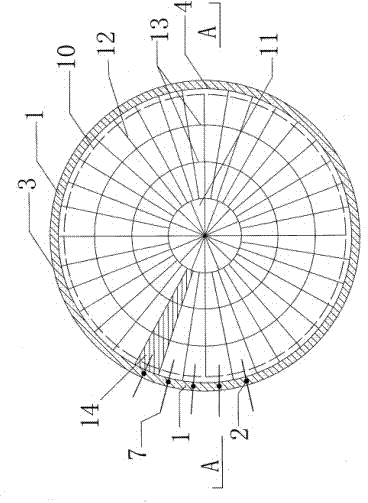

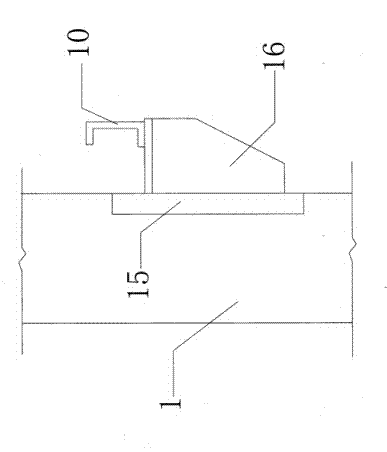

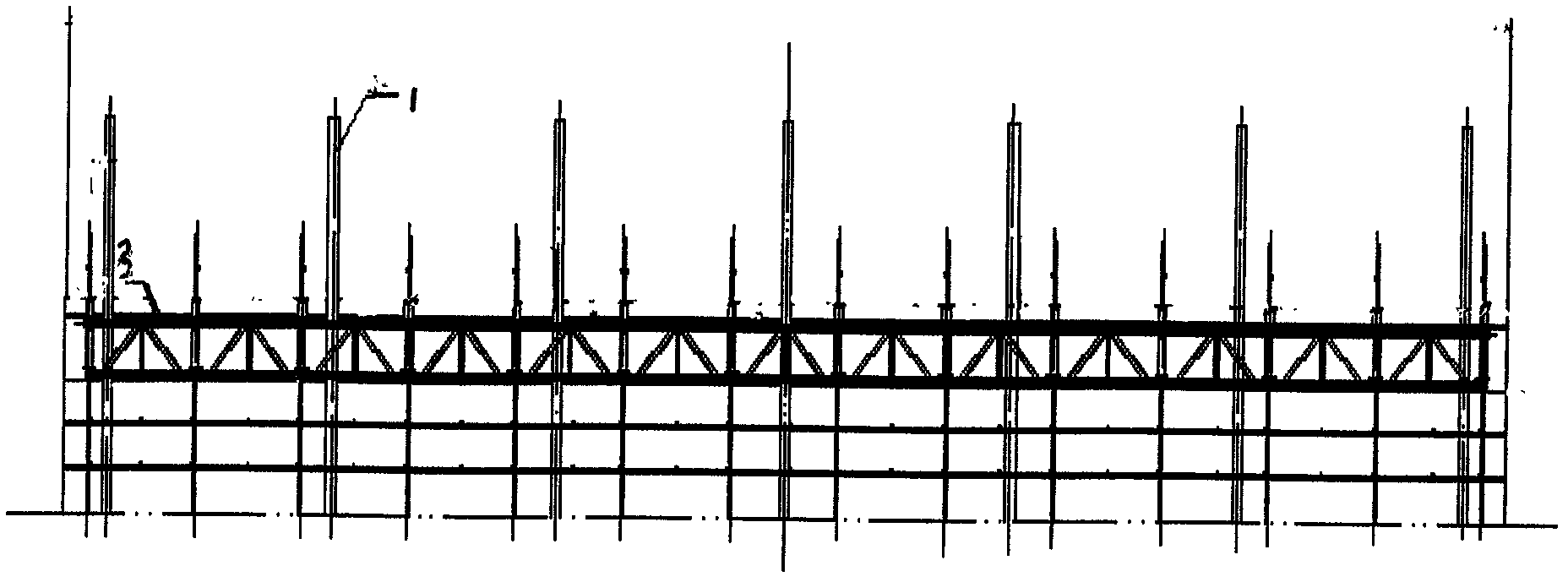

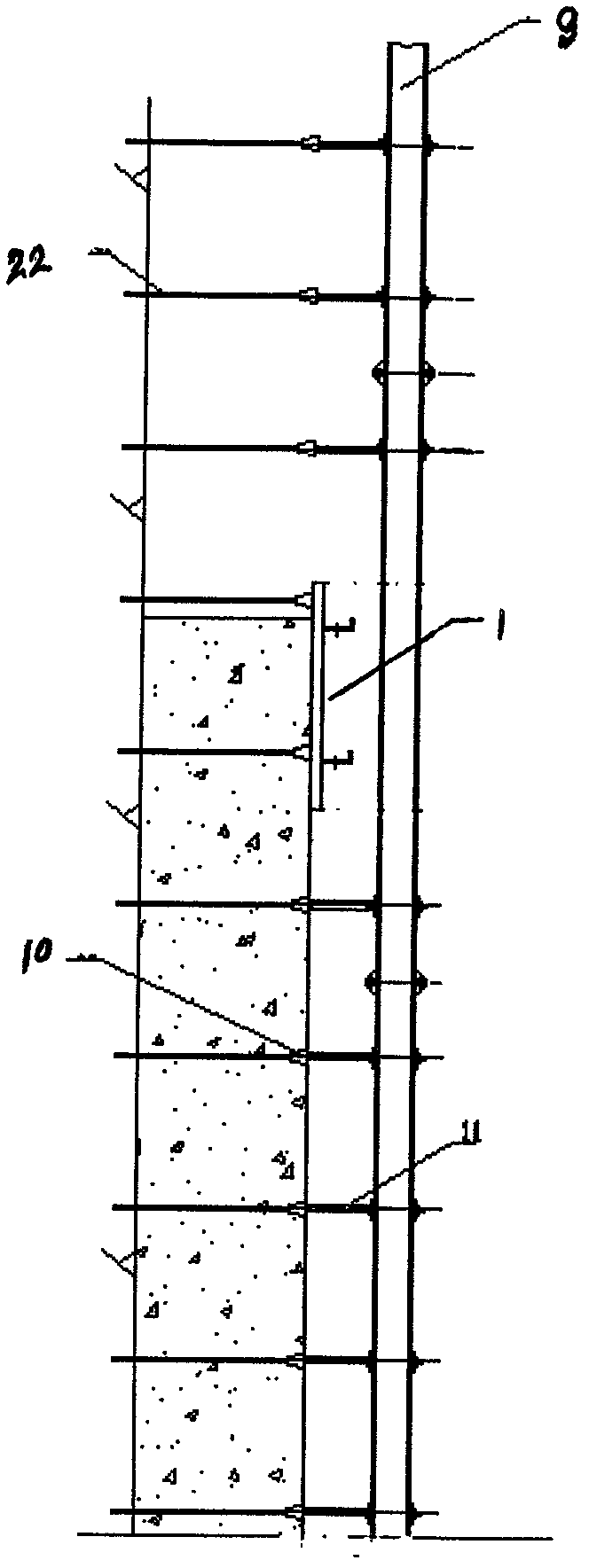

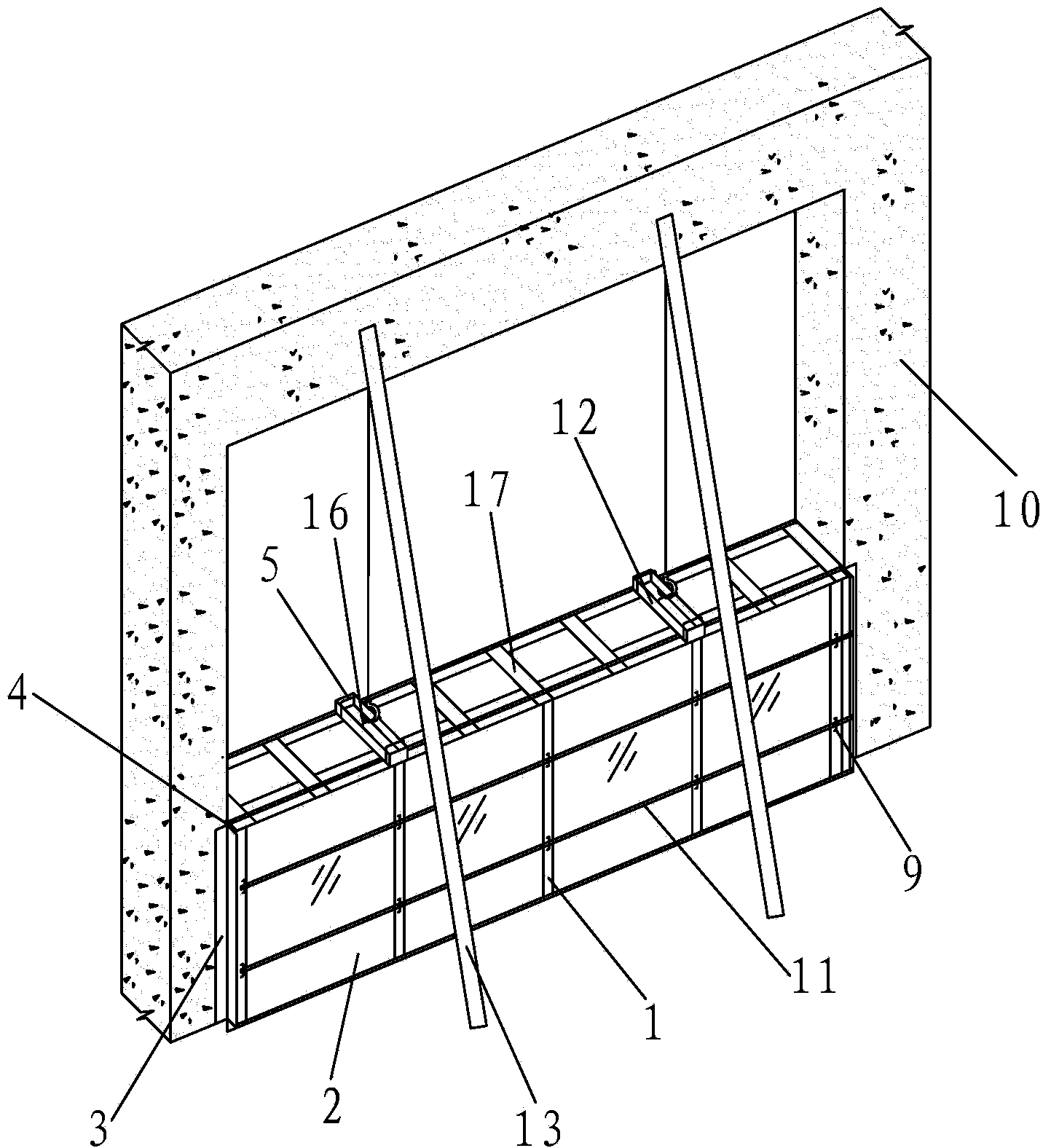

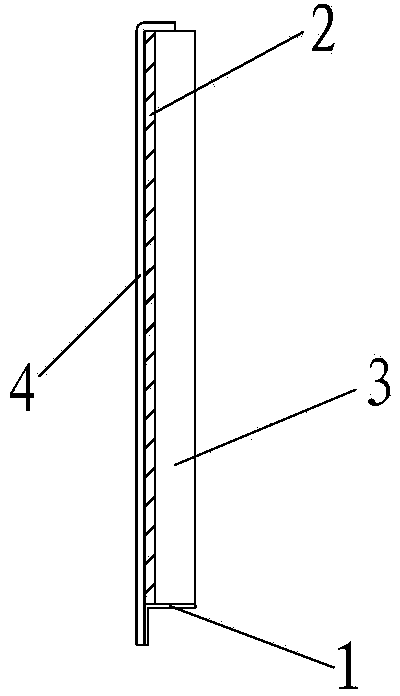

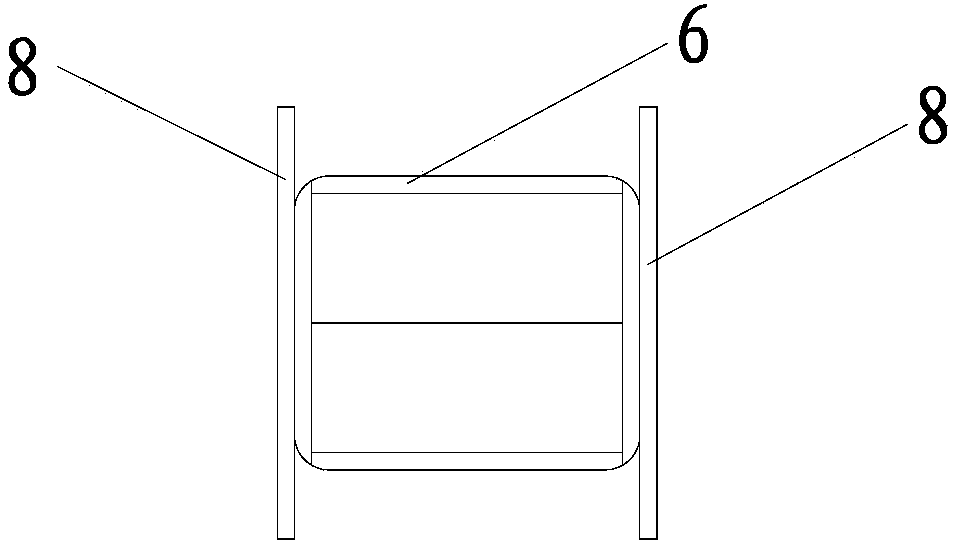

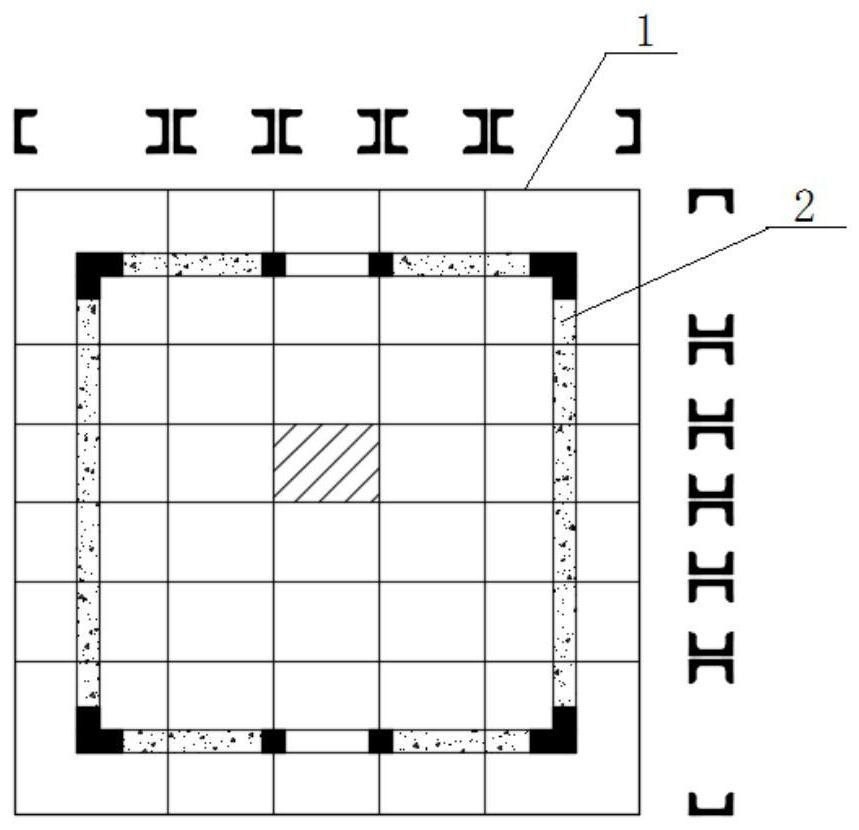

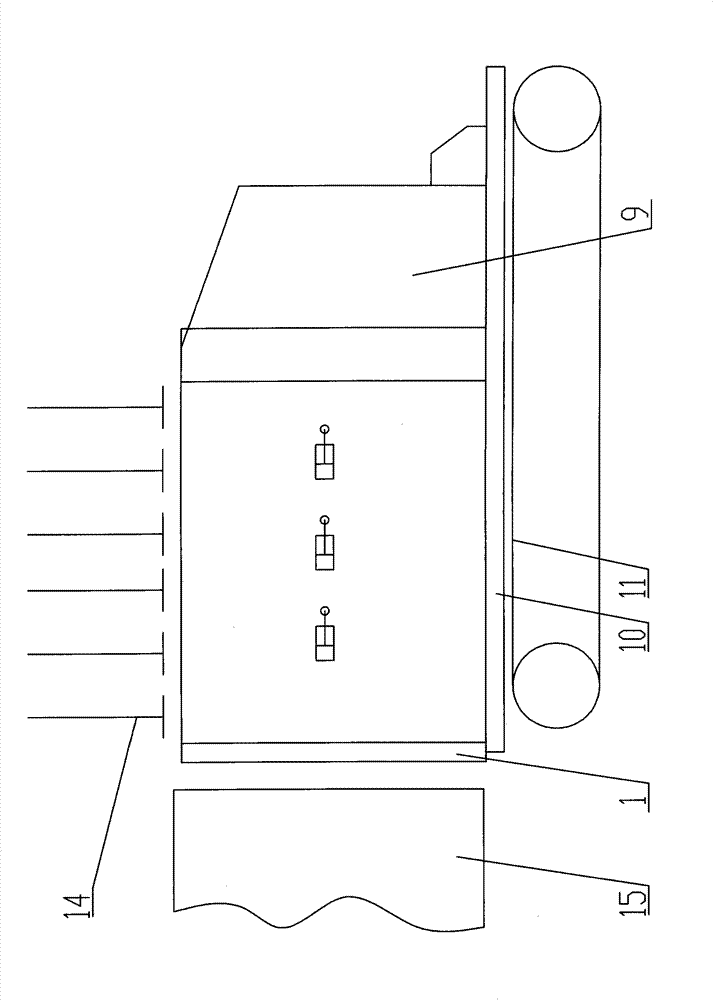

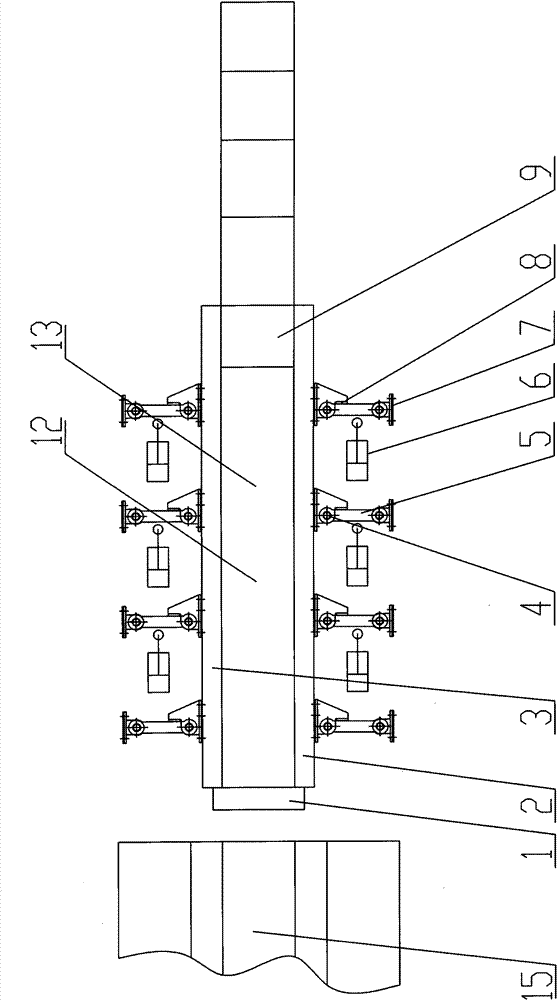

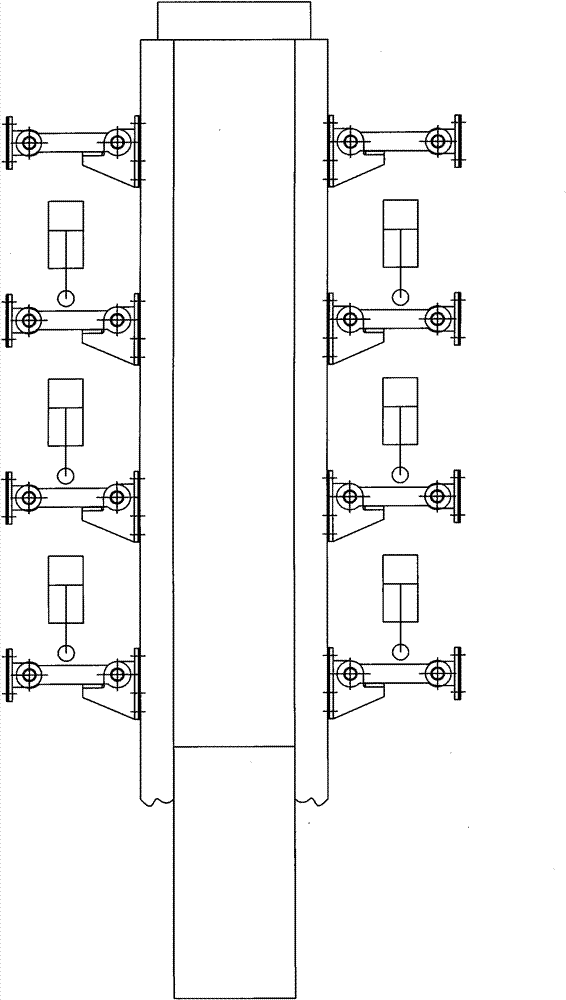

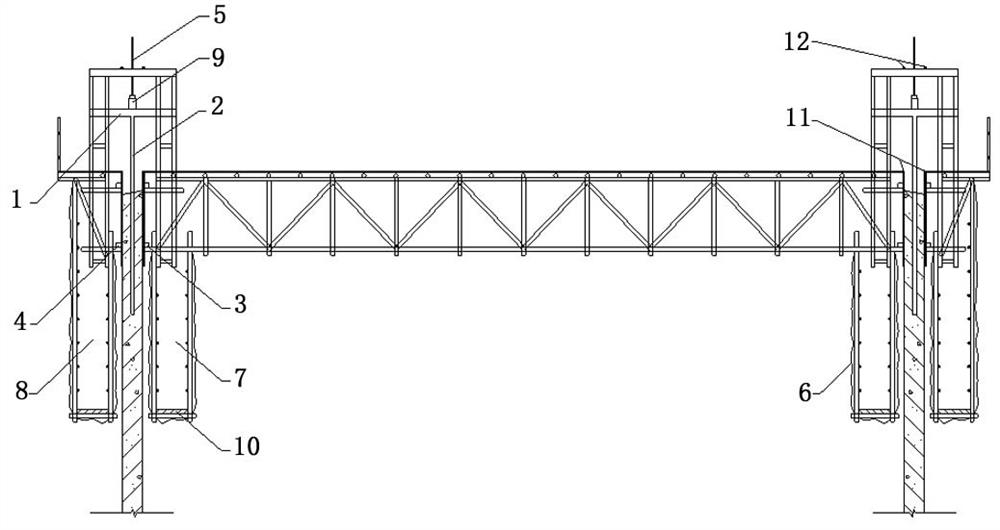

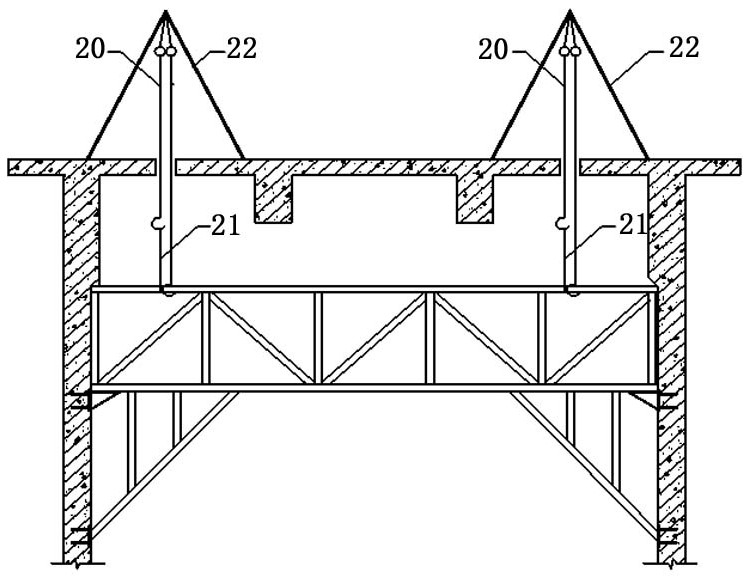

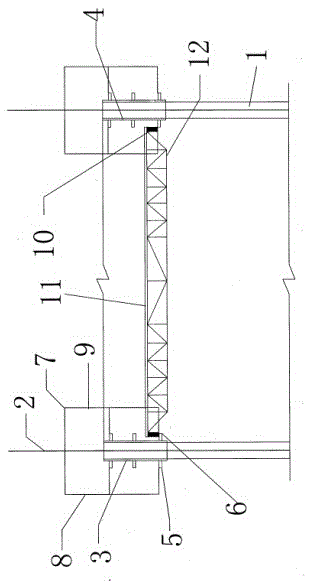

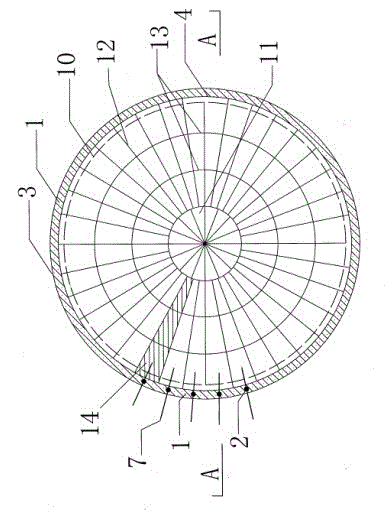

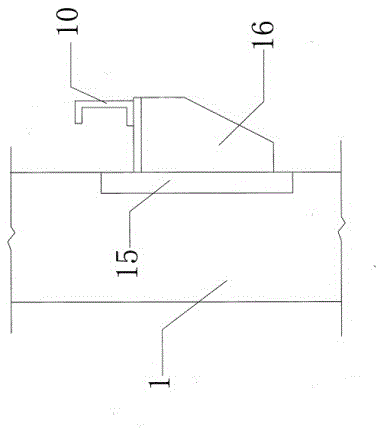

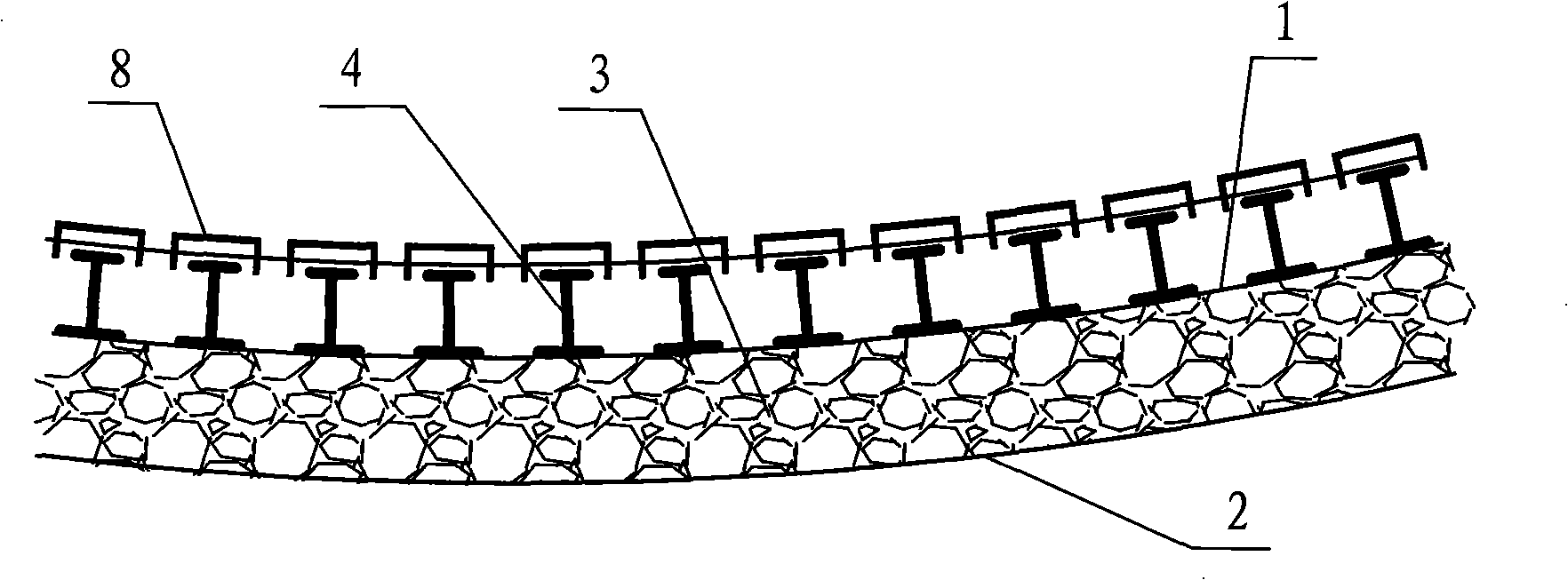

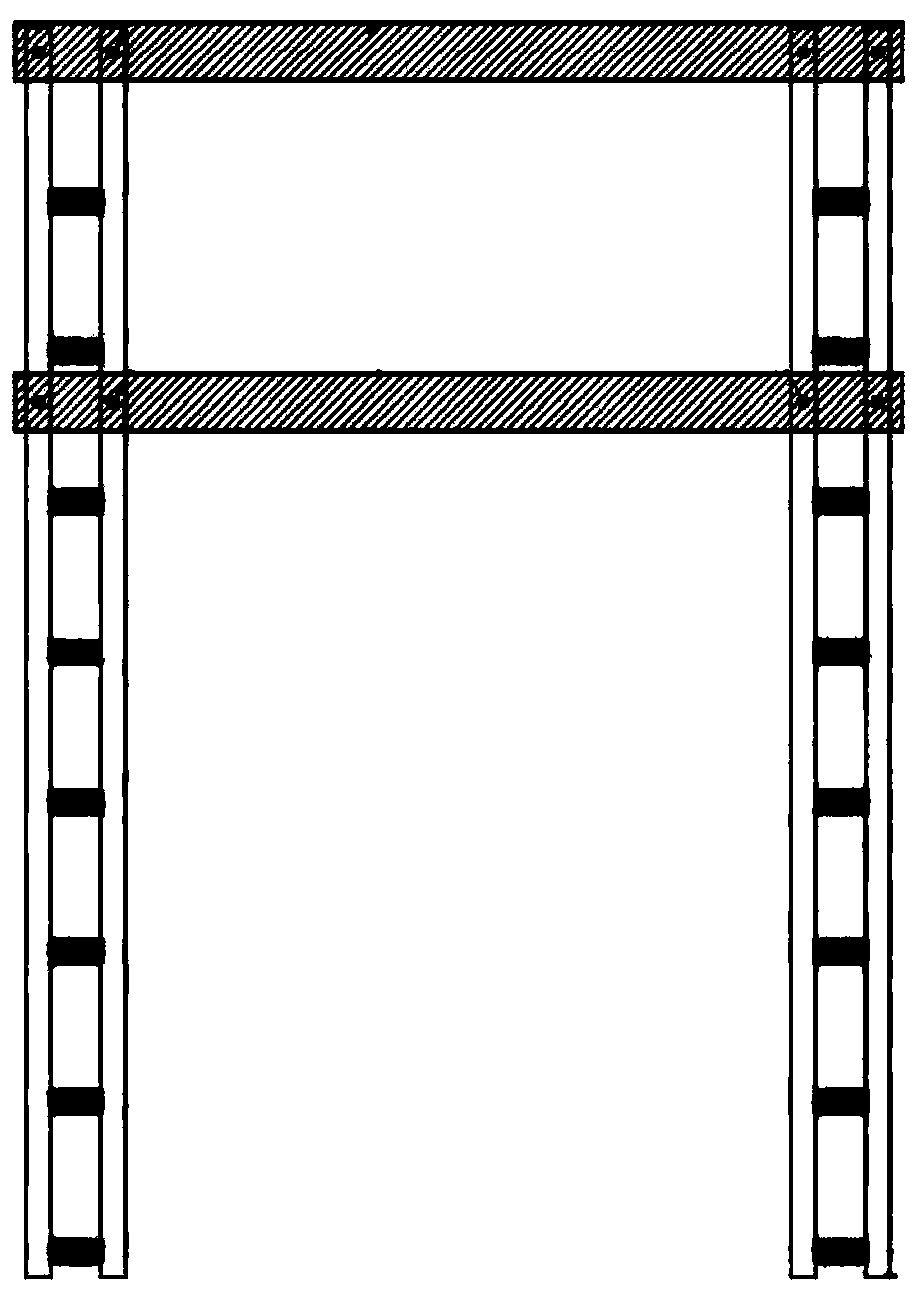

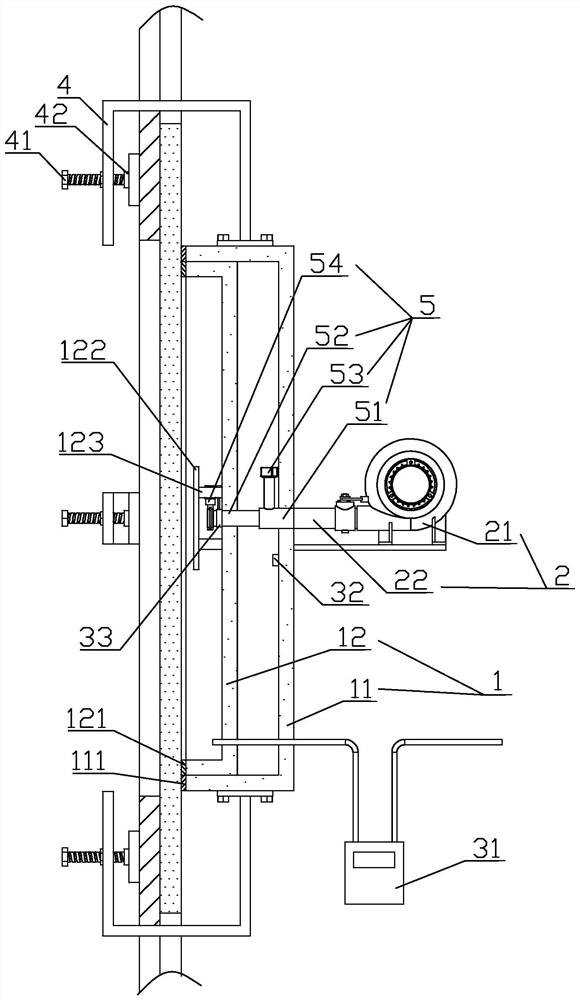

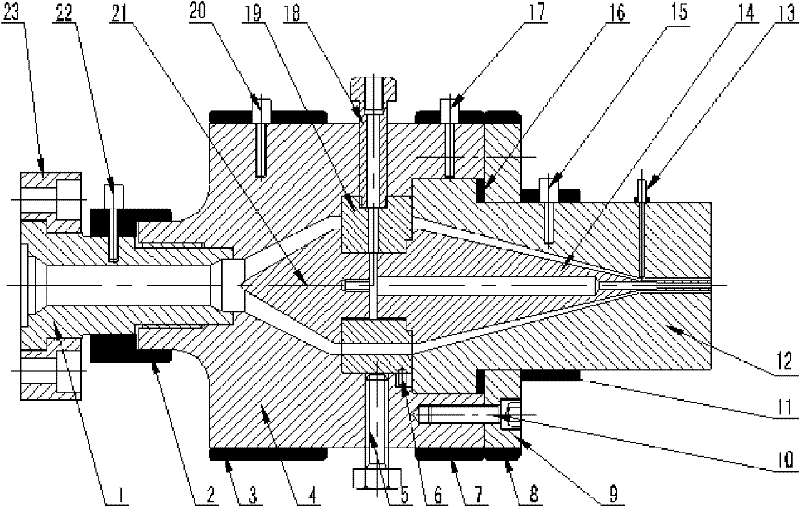

Slip form system of large-diameter cylindrical structure and construction method thereof

ActiveCN104499707AReduce investmentSimple structureForms/shuttering/falseworksSupporting systemSupport system

The invention discloses a slip form system of a large-diameter cylindrical structure and a construction method thereof and solves the problem that construction facilities in cylinder wall slip-form systems and roof slip-form support systems of the prior construction part are disconnected. The slip form system comprises support rods (2) and portal lift racks (7) embedded in a cast cylinder wall (1), inner and outer slip forms are disposed on the inner and outer sides of the cast cylinder wall, an inner slip form ring (6) and an outer slip form ring (5) are fixedly connected to the lower ends of the portal lift racks, respectively, radial lightweight steel trusses (12) are disposed on the outer periphery of a structural central cylinder (11) at equal radian intervals, the outer ends of the radial lightweight steel trusses (12) are fixedly connected to a circular steel beam (10) through bolts, the circular steel beam (10) is fixedly welded on the inner slip form ring (6), and a support (13) is disposed between every two adjacent radial lightweight steel trusses (12). The slip form system and the construction method thereof have the advantages that the structure is simple and input of manpower and tools is low.

Owner:SHANXI NO 3 CONSTR ENG

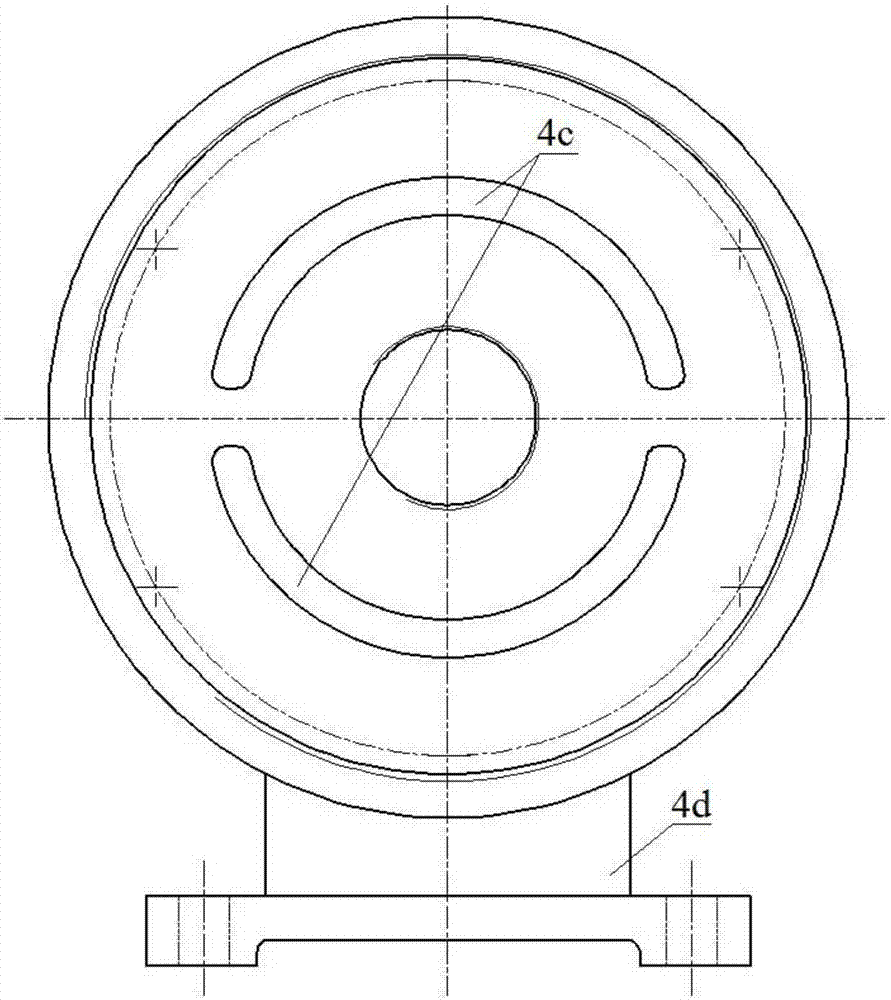

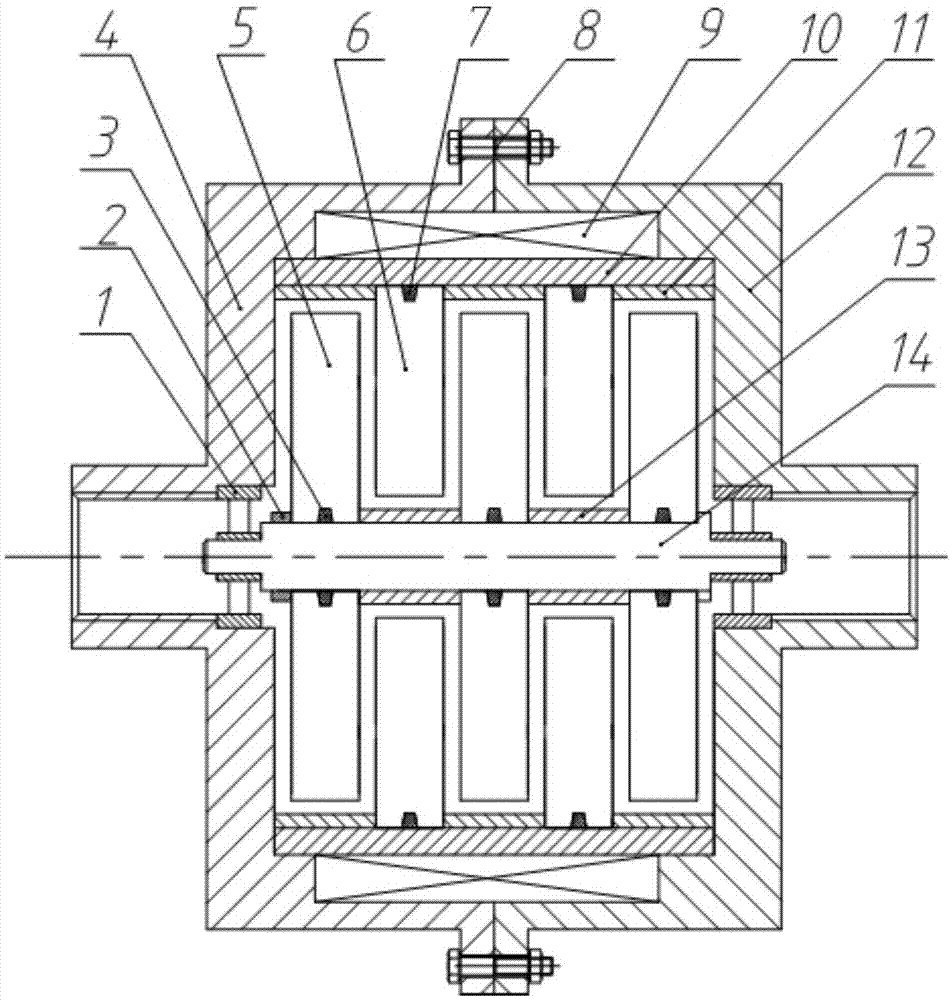

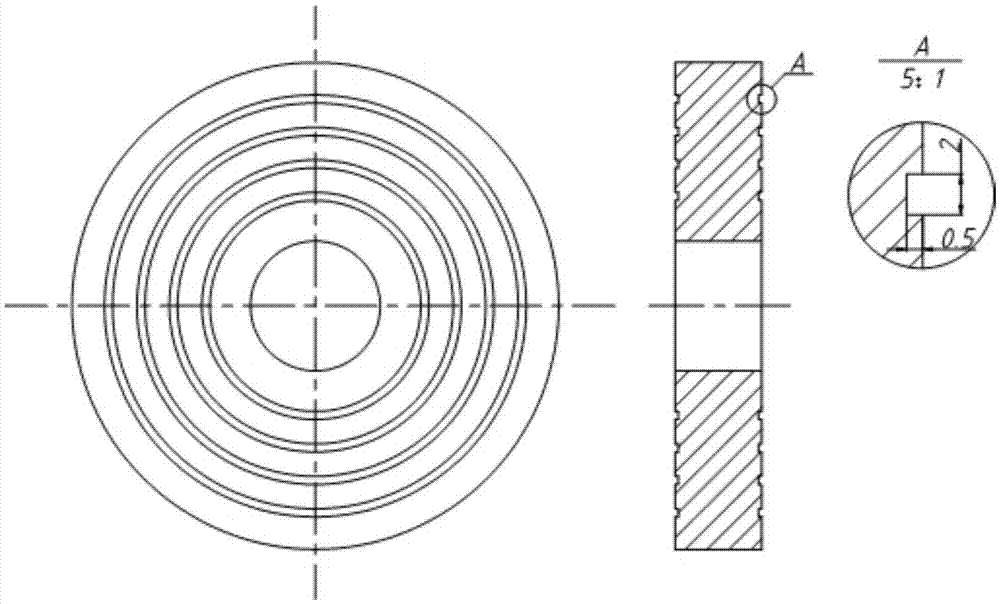

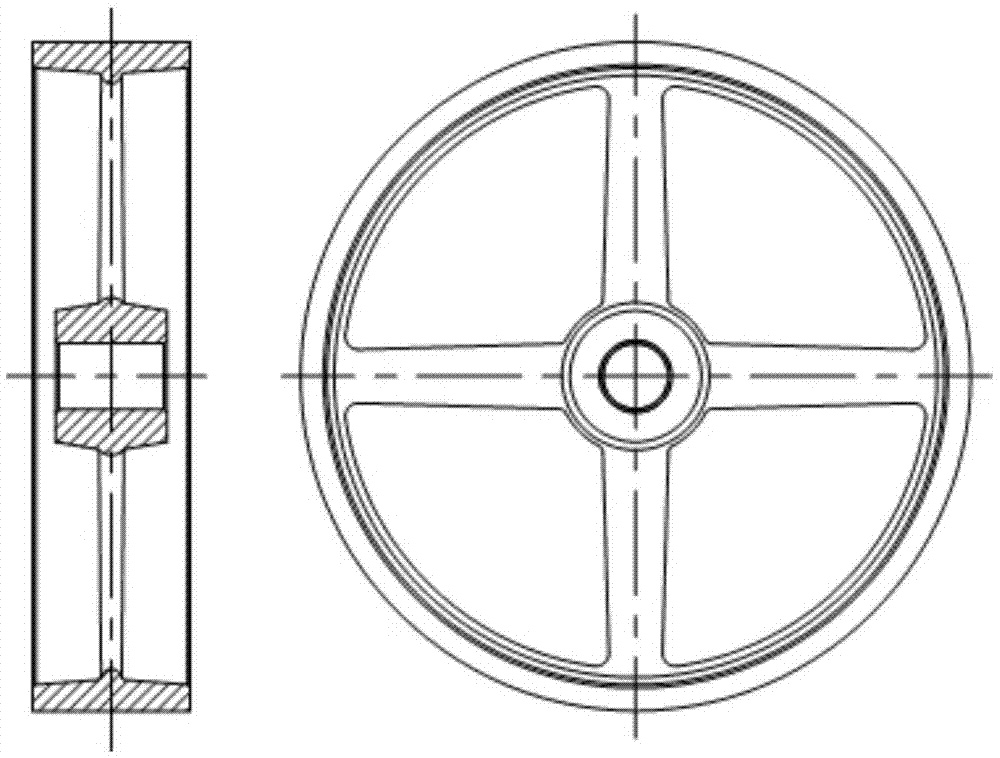

Multi-disc type radial flowing magneto-rheological valve with annular grooves

InactiveCN106968996ALarge damping forceReduced wall slipServomotor componentsCircular discControl system

The invention discloses a multi-disk radial flow magneto-rheological valve with annular grooves, which comprises a support wheel, a magnetically conductive end cover, a damping disc, a magnetic isolation ring, an exciting coil, a sealing ring and a sleeve. A plurality of damping discs are arranged at intervals to form a plurality of damping gaps, which effectively increases the length of the damping gaps. When a certain amount of current is input into the excitation coil, a gap perpendicular to the flow direction of the magnetorheological fluid is generated in the gaps between the damping discs. Magnetic field, the magnetorheological fluid in each damper changes from liquid to semi-solid instantaneously, so as to obtain a large pressure difference between the inlet and outlet. In addition, an annular groove is formed on the surface of each damping disc, thereby avoiding the wall slip of the magneto-rheological fluid and the damping disc, and enhancing the damping effect. The magneto-rheological valve makes full use of the magnetic field, and has a large adjustment range of the pressure difference between the inlet and outlet, and is suitable for a hydraulic servo control system with relatively large pressure adjustment requirements.

Owner:宿州学院

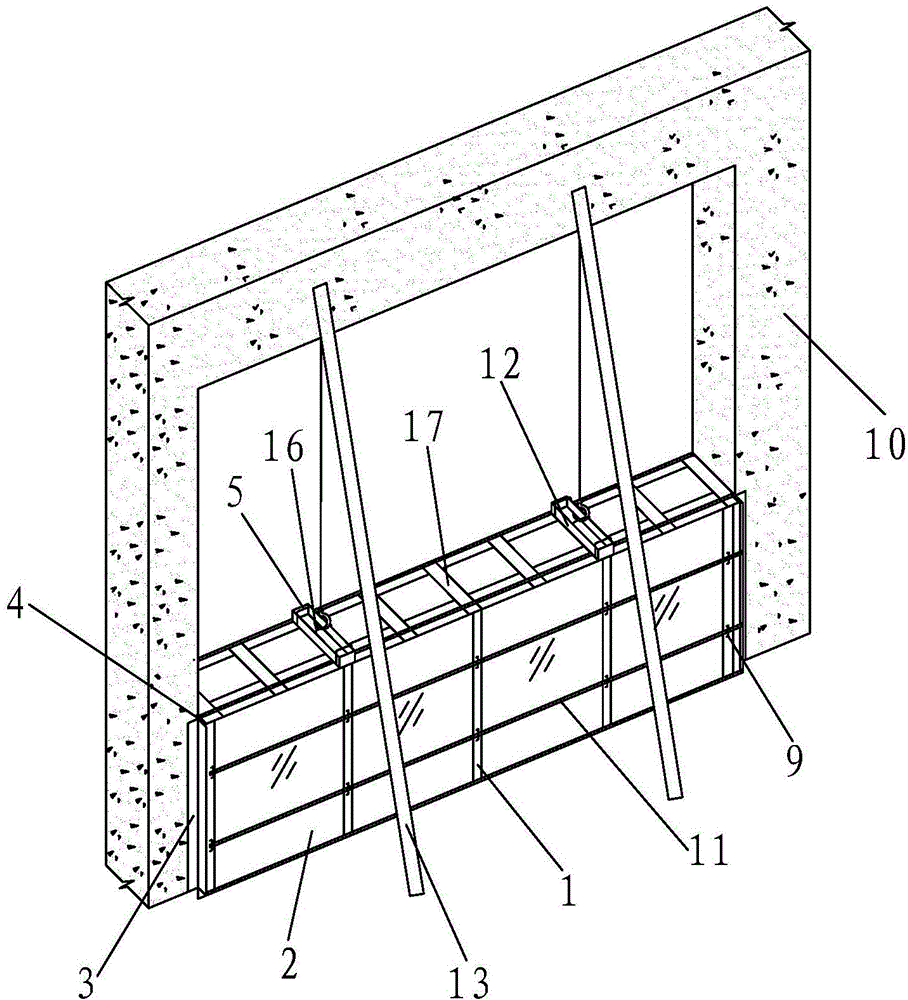

Single-side side wall slip form and construction method

ActiveCN102587644AAvoid repeated disassemblyReduce construction proceduresForms/shuttering/falseworksBuilding material handlingEngineeringSteel tube

Disclosed are a single-side slide wall slip form and a construction method thereof. The slip form is composed of form plates, lifting frames, back ridges, platforms, back connectors, a guide rail, guide wheel mechanisms, hydraulic jacks, limiting levelers, climb poles and a tube frame by bolt connection. Webs welded on a face plate of each form plate are provided with bolt holes and are suspended on the back ridges which are in channel shapes and made of steel, and thirty four form plates are connected to form a 30m high form plate set which inclines by 0.3%-0.5%. Each lifting frame is made of steel channels and steel angles by connecting. The back connectors are steel plates. The form plates, the platforms and the back connectors are integrally connected with the lifting frames, and are connected with the hydraulic jacks to drive the slip form to ascend. The lifting frames are fixedly connected with the lower back ridges through diagonal braces. The guide rail is made of steel channels and connected with rock anchor bolts by welding. Each guide wheel mechanism comprises guide wheels, a support and shafts and is mounted between the back ridges, and the support is connected with the guide rail through the shafts. The climb poles are made of steel tubes and fixed, and the jacks climb along the climb poles. The limiting levelers are used for adjusting climbing position. The tube frame is used for guaranteeing stable climbing. The construction method includes: casting when the slip form climbs, and concreting once.

Owner:SINOHYDRO BUREAU 14 CO LTD

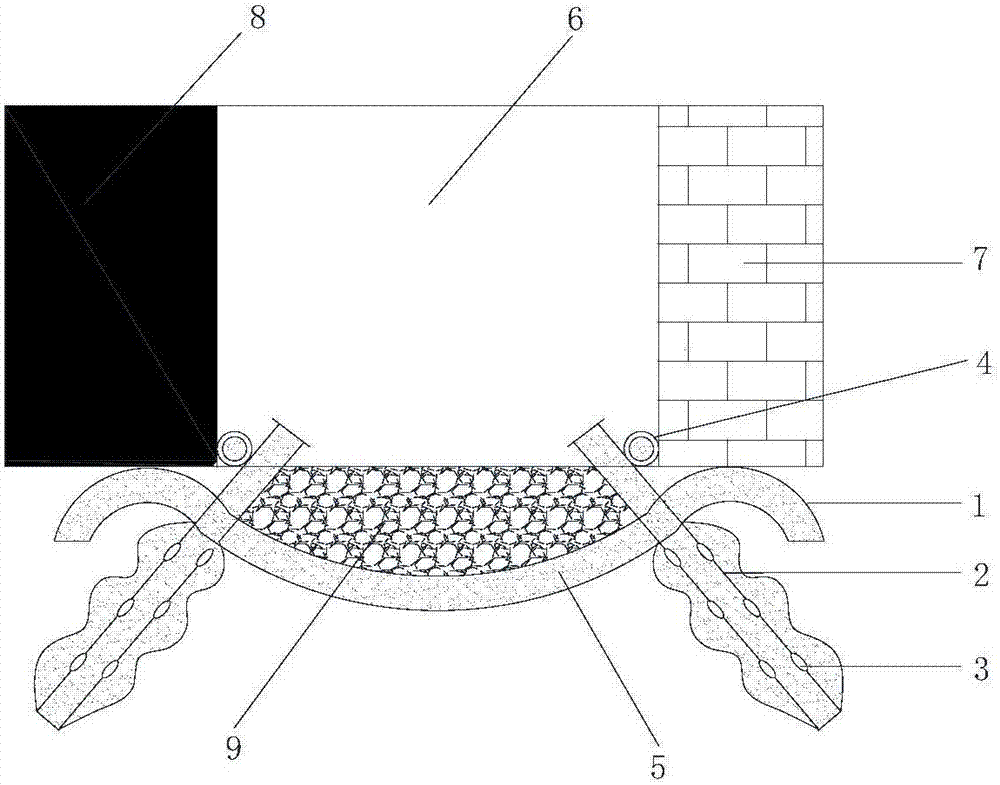

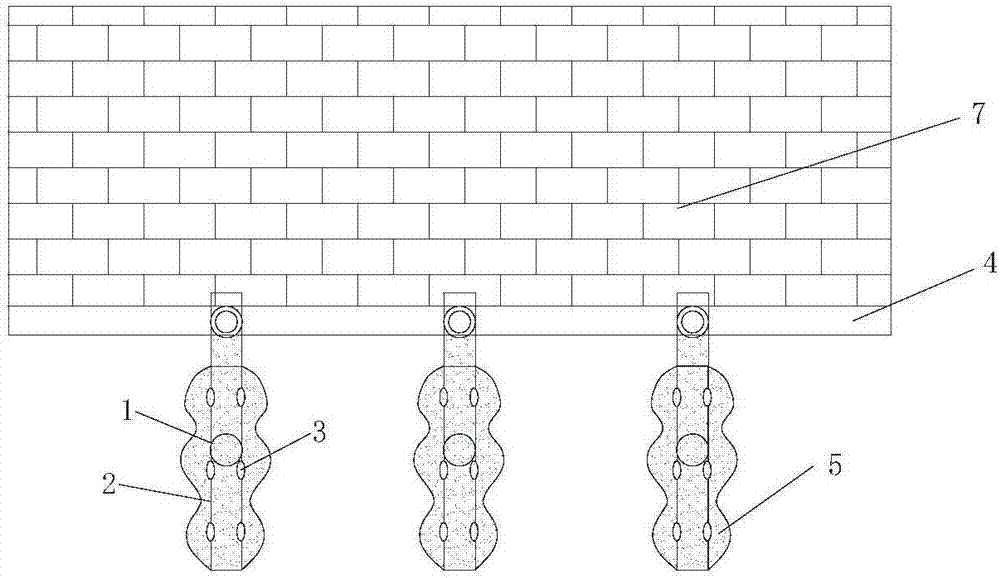

Tube structure roof panel construction method and hanger formwork system

PendingCN106223469AAvoid shakingReduce construction difficultyBuilding support scaffoldsBuilding constructionWood panel

The invention discloses a tube structure roof panel construction method. The method comprises the steps of 1, building a tube structure with a slip-form construction method, and arranging an embedded ring at the top end of a tube wall; 2, splitting a slip form inner frame and a slip form outer frame and lowering the slip form inner frame to be below the elevation of a roof panel after tube wall slip-form construction; 4, fixedly connecting the slip form inner frame with the embedded ring with a steel wire rope, and then making the slip form inner frame fixed relative to the inner wall of a tube body; 5, laying planks and steel channels on the slip form inner frame, and conducting support frame erection and roof construction. The invention further discloses a construction system. According to the roof panel construction hanger formwork system, the slip form inner frame is transformed into a hanger formwork to serve as a support platform of a roof panel support frame, so that roof panel construction is conducted; a pull-up reinforcing mode is adopted for the hanger formwork, the hanger formwork and the embedded ring at the top end of the tube wall are connected through the steel wire rope on the upper portion, the hanger formwork abuts against the tube wall through a U-shaped support, swing of a frame body is effectively prevented, the using range and using time of the hanger formwork system are widened and prolonged, construction difficulty is reduced, construction period is shortened, danger coefficient is reduced, and construction cost is saved.

Owner:MCC TIANGONG GROUP

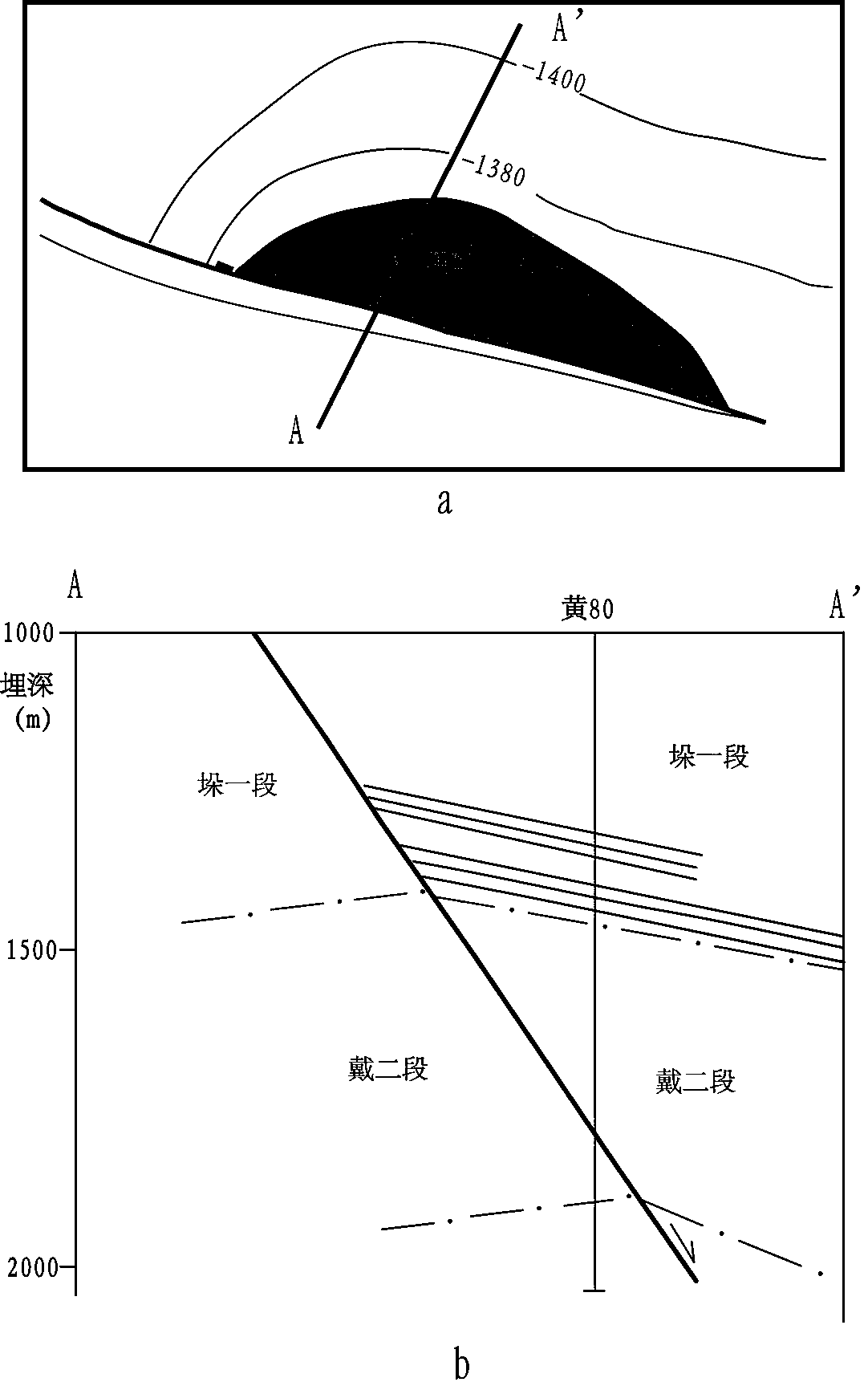

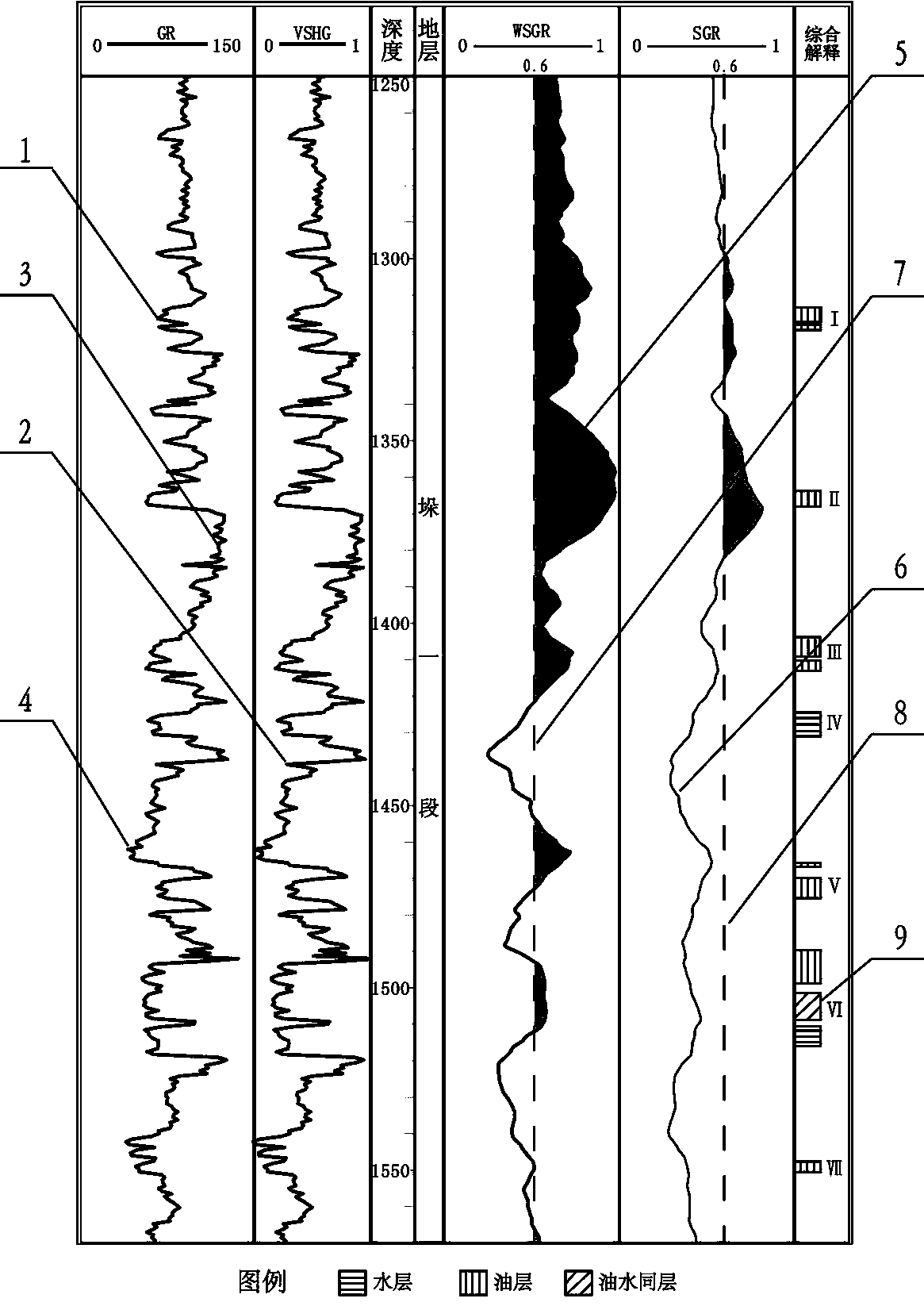

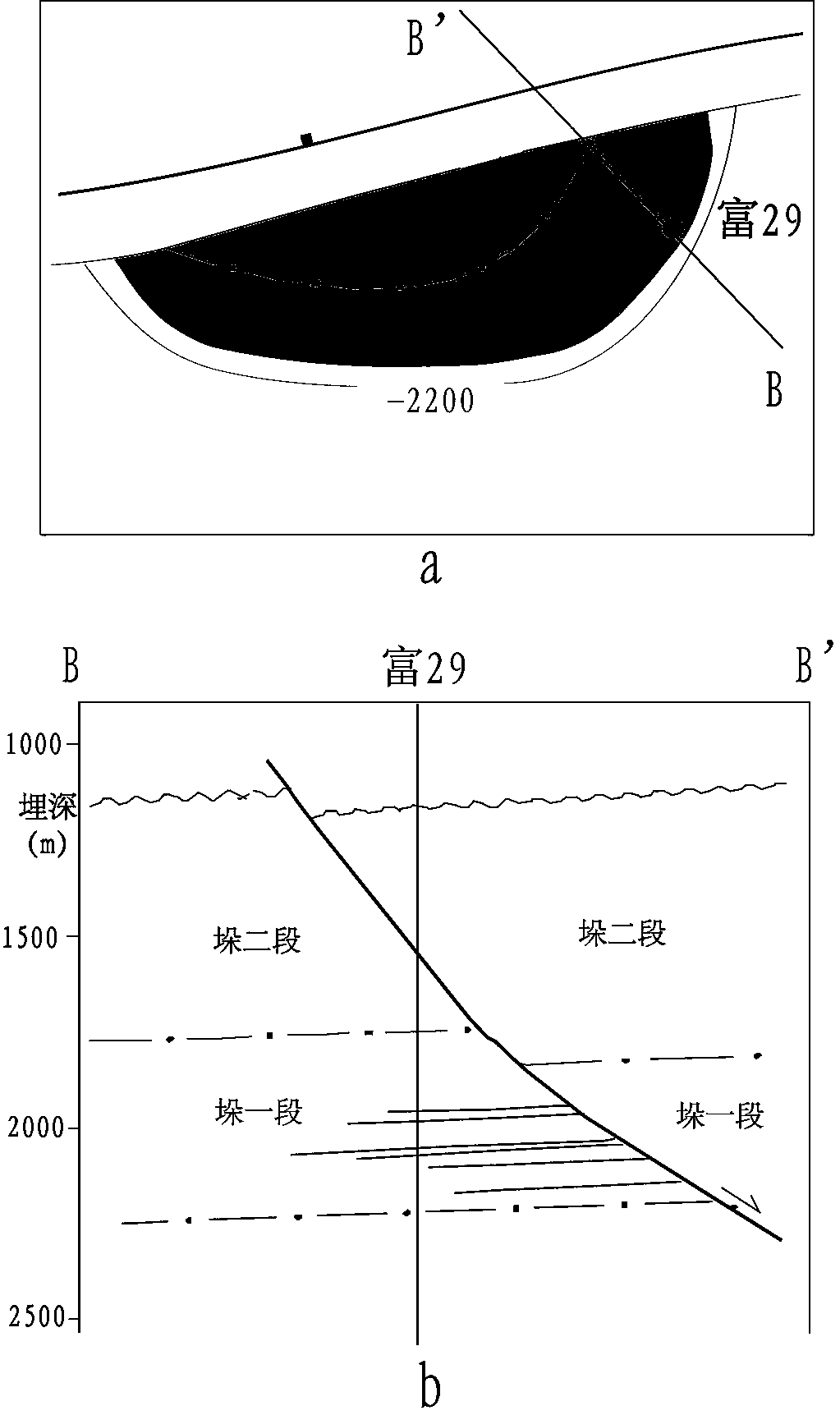

An Evaluation Method of Fault Sealing

ActiveCN108241181BImprove accuracyReduce workloadGeological measurementsGeomorphologyAccuracy and precision

The invention relates to a method for evaluating the fault sealing property in the technical field of oil and gas field exploration. The method includes the steps of (1) selecting a breakpoint in needof sealing property evaluation on a fault that is dislocated in a reservoir stratum, determining each sand-mud stratum with relative wall slip through the breakpoint, and determining the thickness [delta]Zi of each sand-mud stratum; (2) sequentially acquiring the shale content Vshi of each sand-mud stratum slipping through the breakpoint; (3) sequentially solving for a weighting coefficient Wi slipping through each sand-mud stratum; (4) calculating a weighted mudstone fault mud ratio WSGR value of the breakpoint; and (5) evaluating the sealing property of the reservoir at the breakpoint location by using the weighted mudstone fault mud ratio WSGR value, when the WSGR value is greater than or equal to 0.6, indicating that the fault sealing property of the breakpoint location is good and the oil and gas can be effectively sealed, determining the reservoir stratum as an oil stratum or an oil-bearing water stratum with a large probability, and determining the reservoir stratum as a waterstratum with a large probability otherwise. The method fully considers the docking relationship between the two walls of the fault, adds the distance coefficient to reflect the contribution degree ofeach relative wall point on the calculation point, and improves the accuracy and precision of the judgment of the fault sealing property.

Owner:CHINA PETROLEUM & CHEM CORP +1

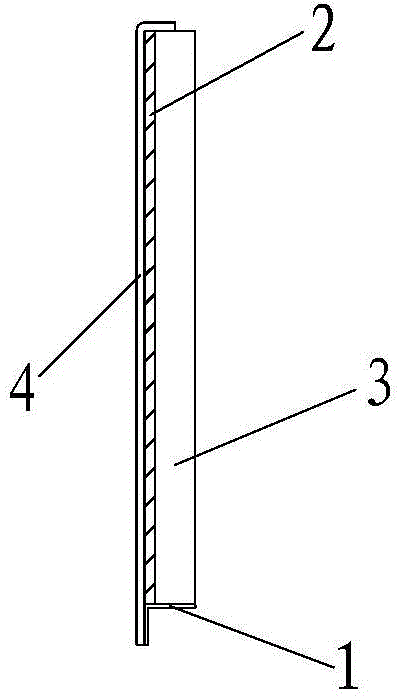

Cast-in-situ lightweight aggregate concrete filler wall slip-form construction template system and construction method

ActiveCN103726648ASimple structureEasy to processForms/shuttering/falseworksBuilding material handlingMaterials scienceConstruction waste

The invention discloses a cast-in-situ lightweight aggregate concrete filler wall slip-form construction template system and a construction method. The template system comprises an outer mold and an inner mold, wherein the outer mold comprises an outer mold frame and a first mirror multilayer board connected to the outer mold frame; reinforced angle iron is welded at the left side and the right side of the outer mold frame; inverse L-shaped round steel is arranged beside the reinforced angle iron; a first hook ring is welded at the top of the outer mold frame; the inner mold comprises a sealed inner mold body; a vibrator is arranged inside the inner mold body; two inner mold support handles are symmetrically arranged at two sides of the top of the inner mold body. The method comprises the following steps: 1, fabricating the outer mold and the inner mold; 2, mounting the outer mold; 3, installing the inner mold; 4, reinforcing and correcting the outer mold; 5, casting and vibrating lightweight aggregate concrete; 6, lifting the template system; 7, repeating the steps 5 to 6 for a plurality of times and casting until the distance from the template system to an original structure body is 150mm-250mm; and 8, stripping the mold. A constructed wall body disclosed by the invention is good in integrality, stable and reliable in strength, and free of construction waste, and the labor cost is greatly reduced.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

Hydraulic reverse formwork construction method for light aluminum alloy formwork of square chimney

PendingCN112502431AAvoid occupyingReduce in quantityForms/shuttering/falseworksTowersStructural engineeringMechanical engineering

The invention discloses a hydraulic reverse formwork construction method for a light aluminum alloy formwork of a square chimney. The light aluminum alloy formwork is adopted, and a construction trussis lifted in a hydraulic reverse formwork construction mode. The hydraulic reverse formwork construction method can effectively overcome the defects that the surface of concrete is prone to tension fracture, the surface of a cylinder wall slips, a platform drifts and twists and the like, the aluminum alloy formwork is one of new processes, the concrete constructed through the aluminum formwork can achieve the effect of fair-faced concrete, and the apparent quality is excellent; and the defects of platform drifting, torsion and the like are overcome through the hydraulic reverse formwork process, and the construction efficiency and safety of chimney engineering are greatly improved through the hydraulic reverse formwork construction method of the light aluminum alloy formwork.

Owner:CHINA THIRD METALLURGICAL GRP

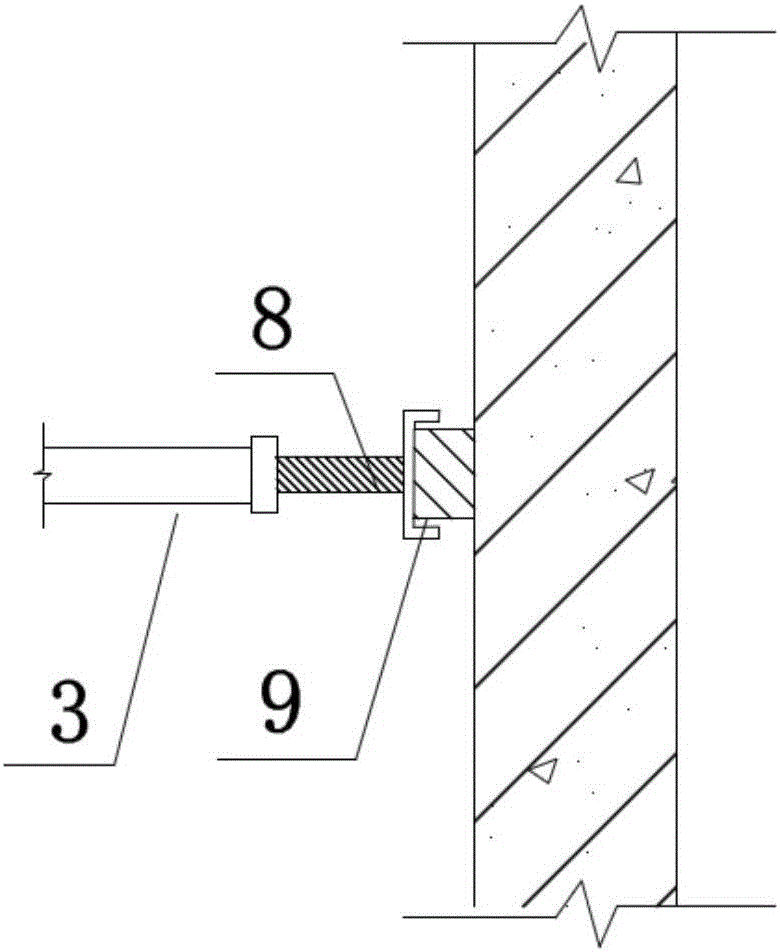

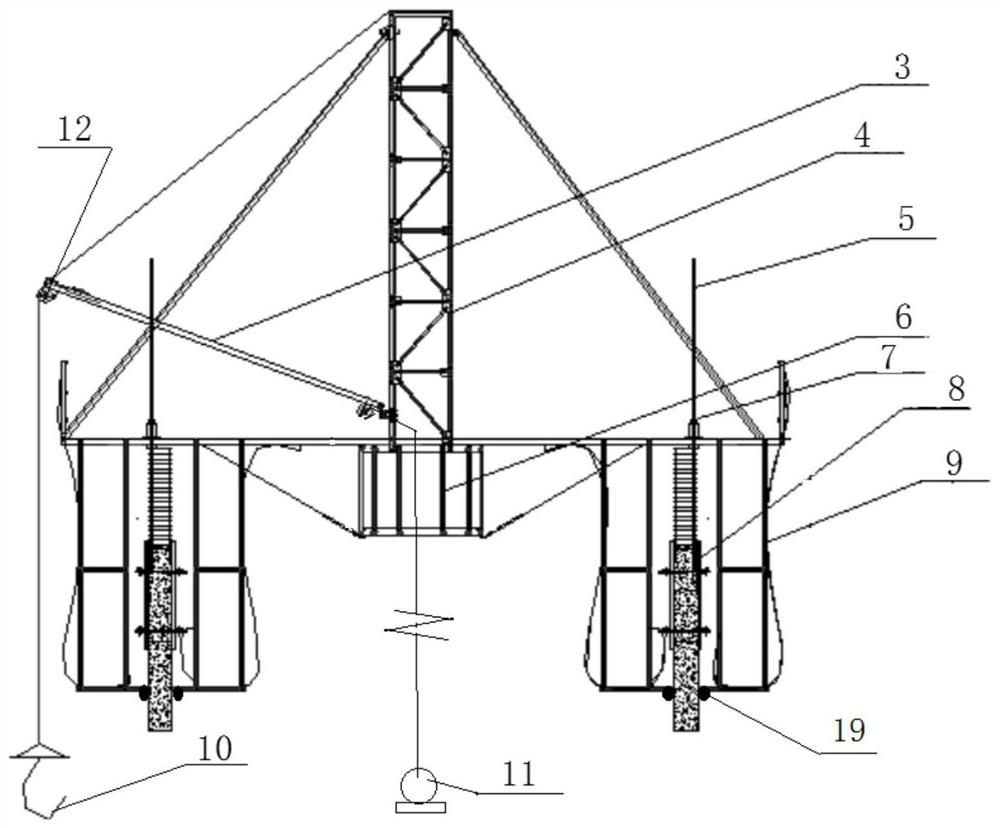

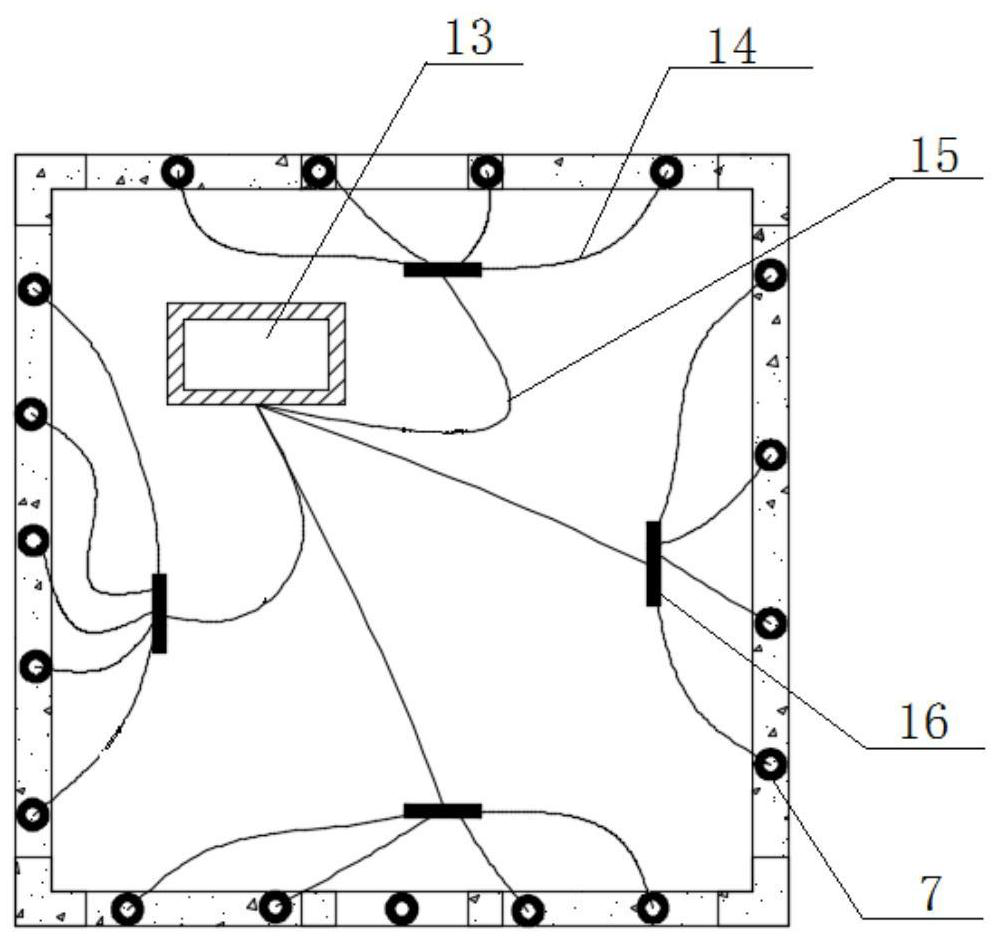

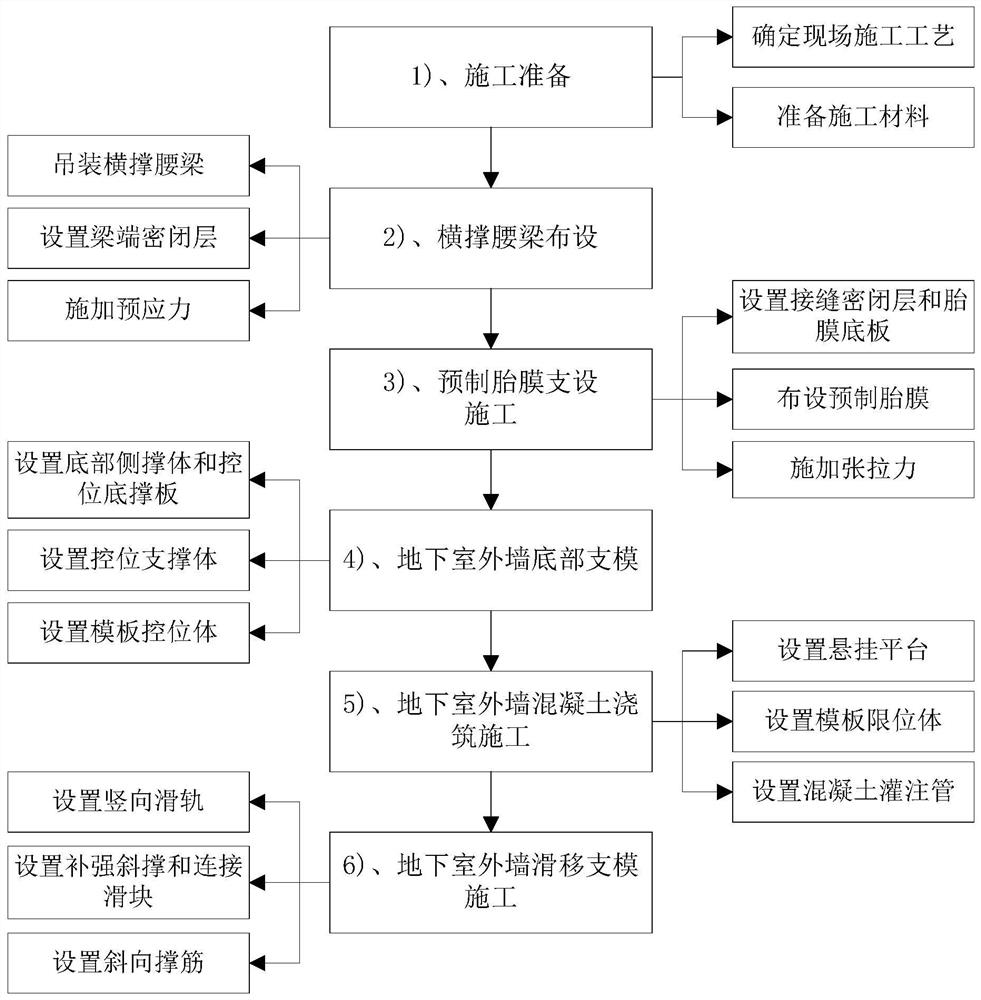

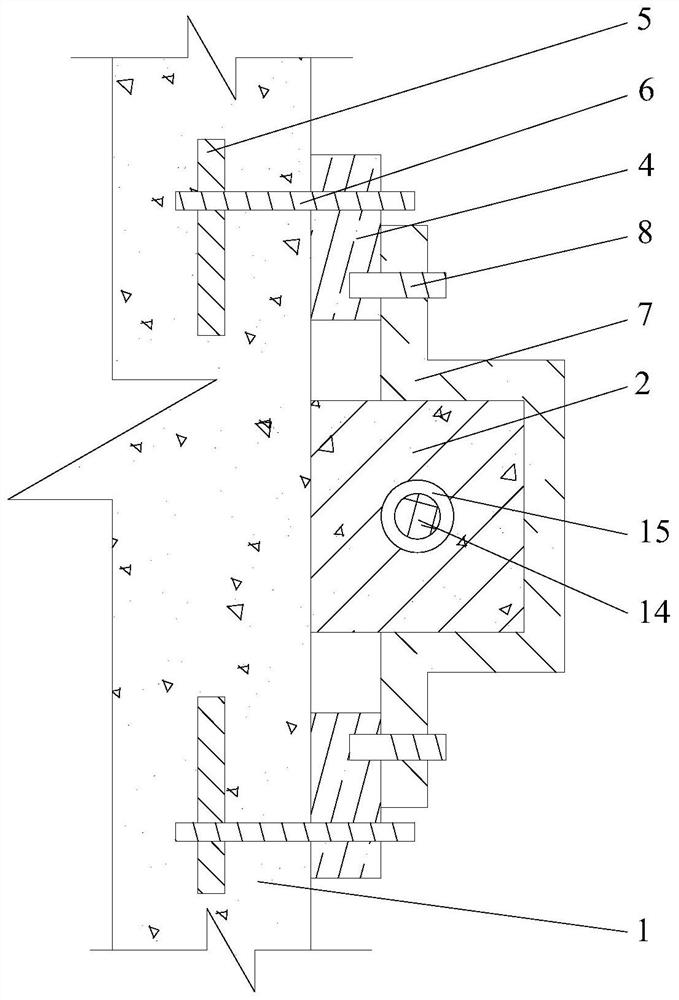

Construction method of compound single-side formwork system for basement exterior wall

ActiveCN111119237BImprove connection strengthReduce the difficulty of connection positioningArtificial islandsCellarsSupporting systemArchitectural engineering

The invention relates to a construction method of a composite single-side formwork system for an outdoor wall of a basement, comprising the steps of: 1) construction preparation; 2) layout of a transverse support waist beam; 3) construction of a prefabricated tire formwork support; 4) formwork support at the bottom of an outdoor wall of a basement; 5) Concrete pouring construction of the basement exterior wall; 6) Sliding formwork construction of the basement exterior wall. The beneficial effects of the present invention are: the pile side hoop plate and the support pile are connected through the connecting anchor bolt and the hoop plate anchor bar, and the transverse brace waist beam is connected with the pile side hoop plate through the waist beam hoop, which reduces the difficulty of component connection. The integrity of the structure is improved; at the same time, the present invention arranges the first connecting hoop and the second connecting hoop at the longitudinal junction of the cross support waist beam, and the outer wall of the first connecting hoop and the second connecting hoop Auxiliary tie bars are set between the tie support plates, which can effectively improve the connection strength of the cross brace waist beam and reduce the difficulty of connection positioning.

Owner:华中伟业建设集团有限公司

Device ensuring rear side movement of double movable walls of coal chute

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

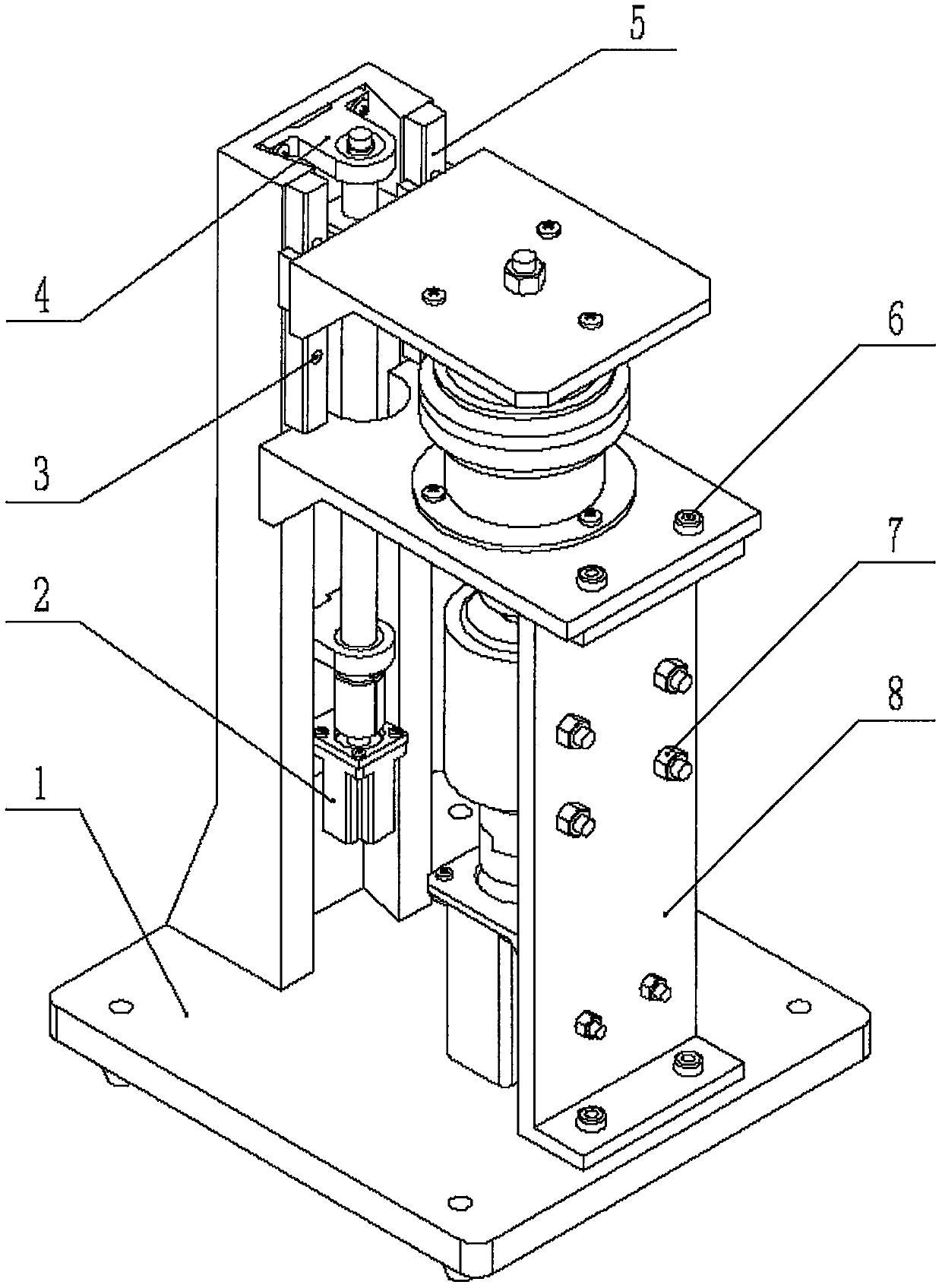

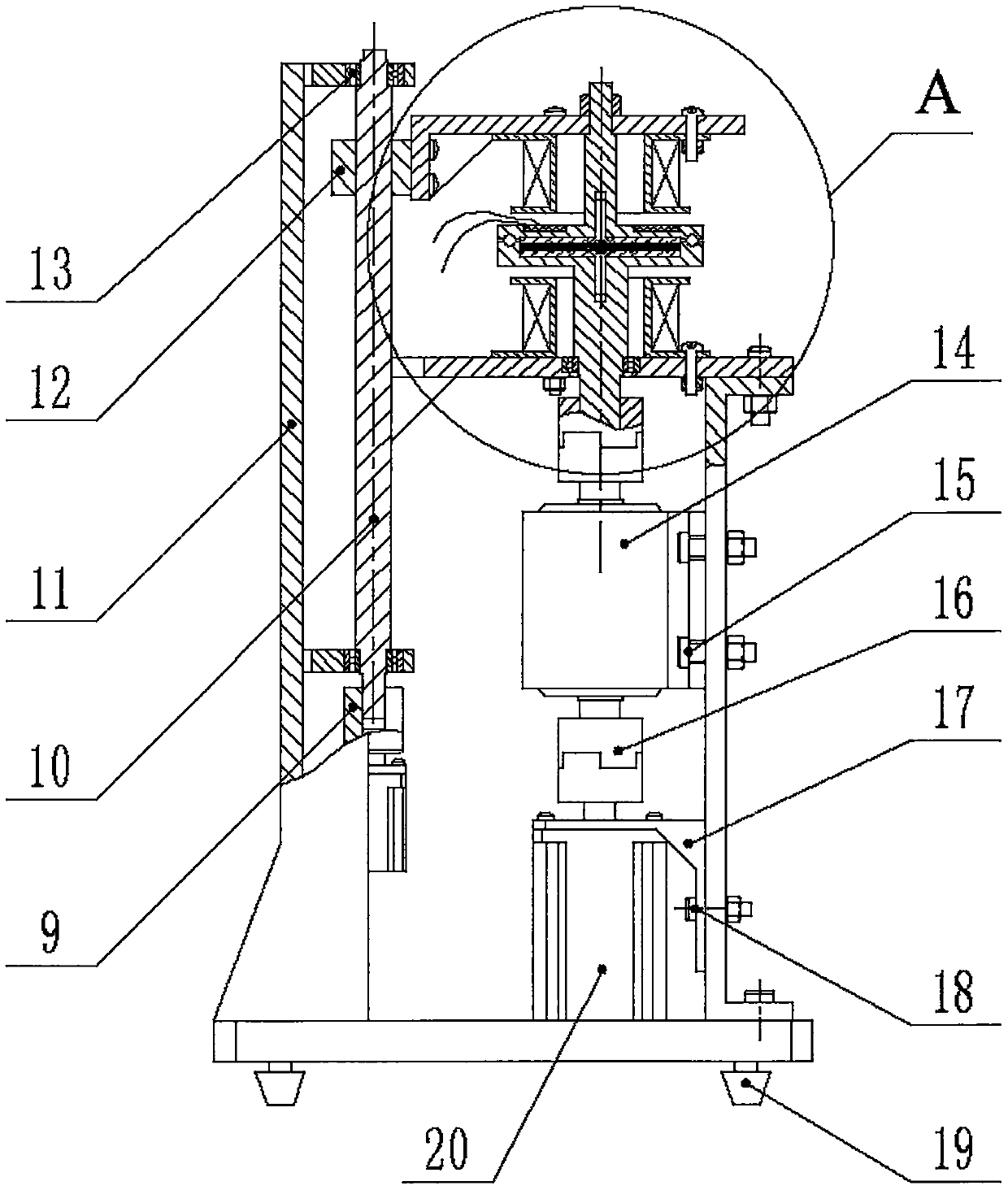

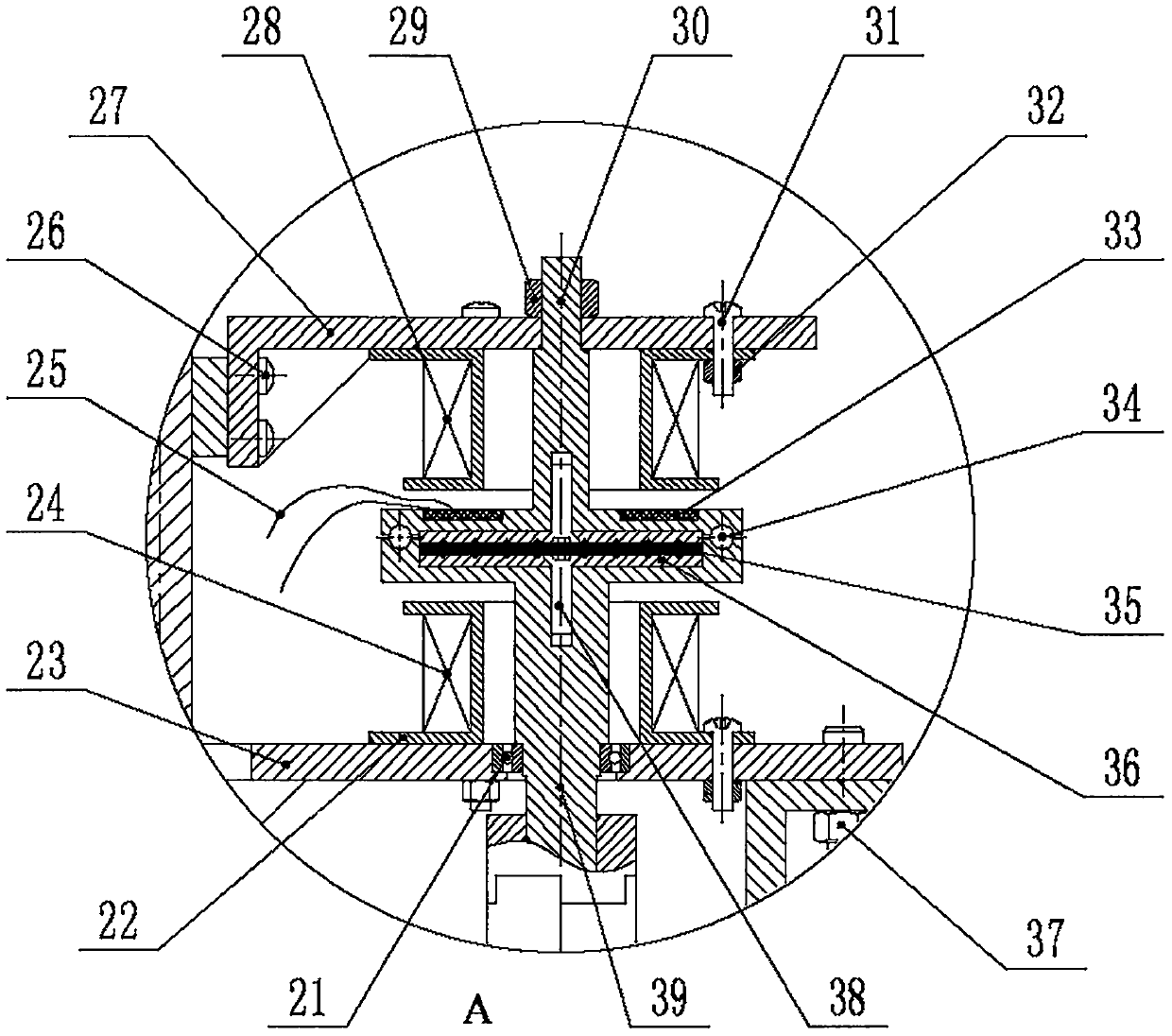

Magnetorheological fluid wall slip effect detection device

The invention discloses a magnetorheological fluid wall slip effect detection device. The magnetorheological fluid wall slip effect detection device includes a lifting plate, a fixing shearing disc, asecond coil, a coil storing barrel, a rotating shearing disc, a first coil, a fixing plate, a torque sensor, a side plate, a guide rail base, a bottom seat, and magnetorheological fluid, wherein thefixing shearing disc is fixedly connected to the lifting plate, the rotating shear disc is rotatably connected to the fixing plate, the torque sensor is fixedly connected to the side plate, the guiderail base is fixedly connected to the bottom seat, and a vertical lifting driving device is arranged on the guide rail base. According to the magnetorheological fluid wall slip effect detection device, a complex physical field with the different temperatures and magnetic fields can be generated to effectively detect the wall slip effect of the magnetorheological fluid, and the magnetorheological fluid wall slip effect detection device provides guarantee for development and application of the high-performance magnetorheological fluid.

Owner:ZHEJIANG NORMAL UNIVERSITY

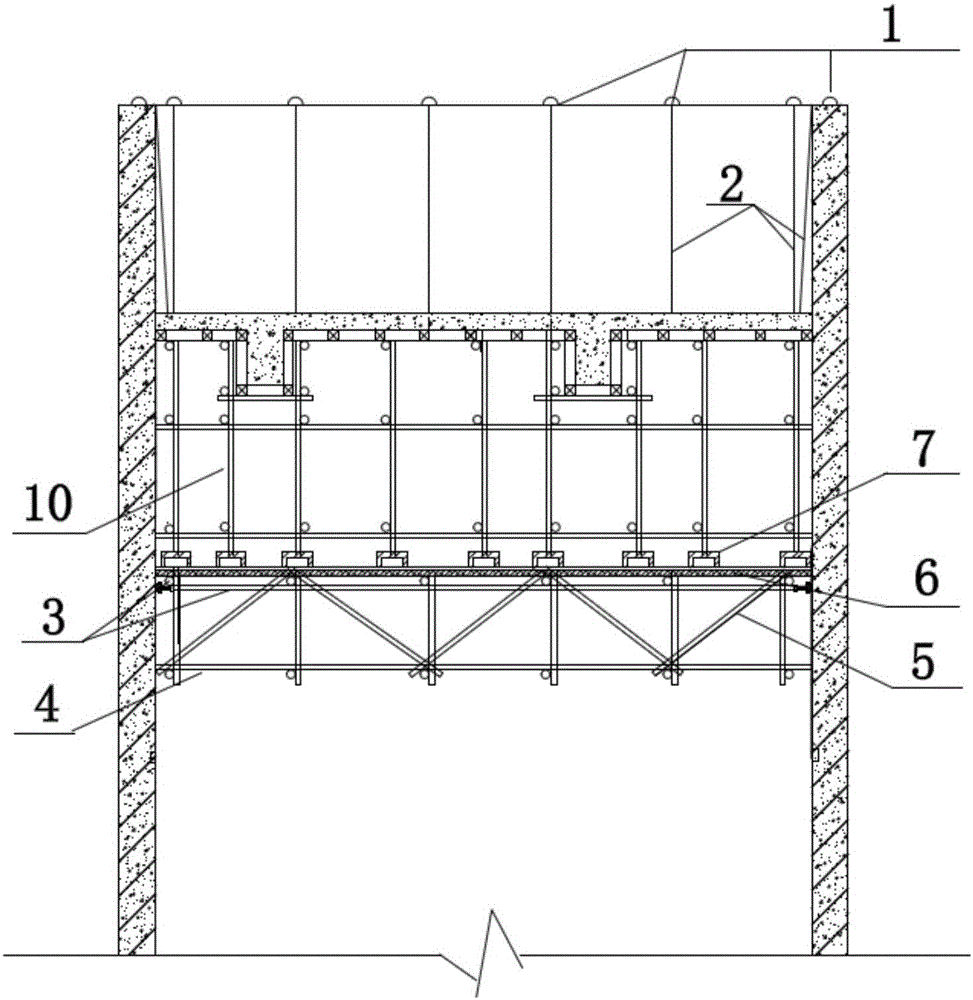

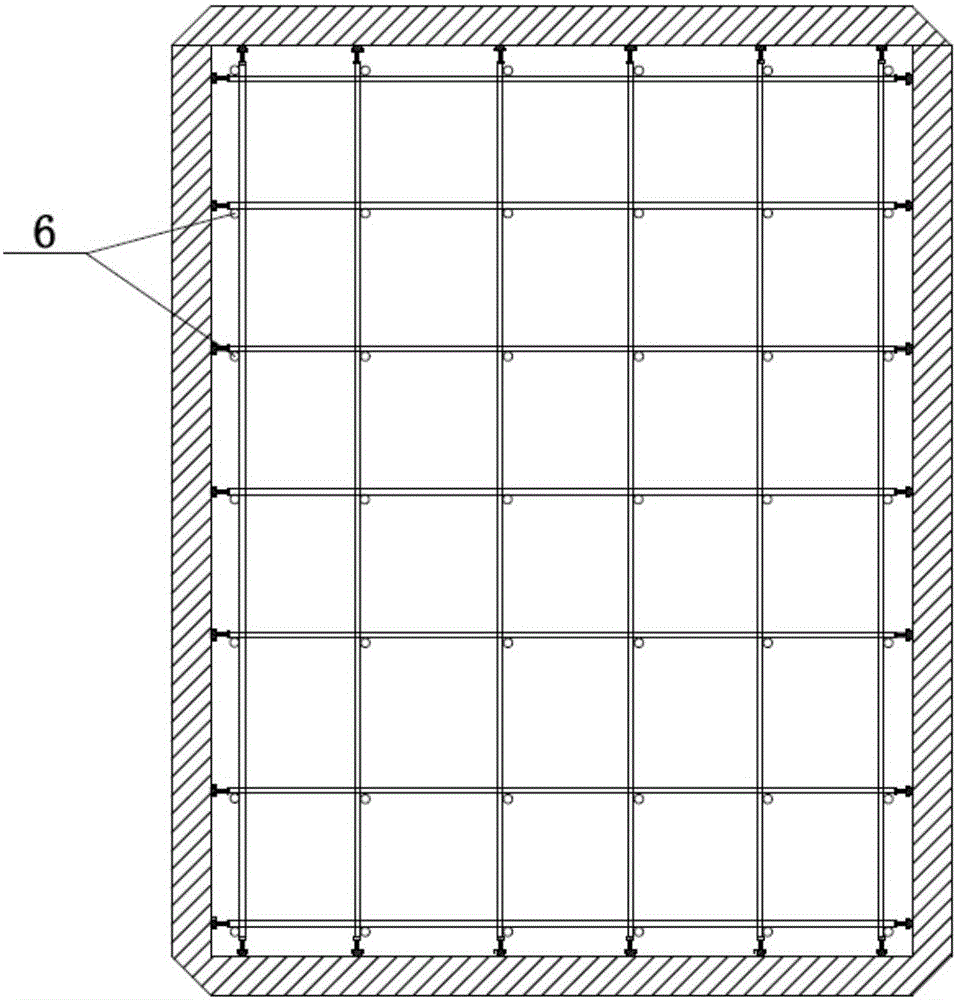

Reinforced concrete silo top plate formwork construction method

PendingCN114737750AImprove securityClimate change adaptationForms/shuttering/falseworksReinforced concreteArchitectural engineering

The invention relates to a reinforced concrete silo roof formwork construction method which comprises the following steps: after silo wall slip form construction is completed, descending a slip form platform to a preset elevation for the first time and then reinforcing the slip form platform to serve as a roof formwork supporting platform for silo roof construction; and after construction of the silo top plate is completed, the slip form platform descends to the ground for the second time, and the slip form platform is overall dismantled. And the lowered and fixed slip form platform is used as an operation platform for dismantling the slip form lifting frame and the template, so that the workload and the safety risk of hoisting on the top surface of the vertical silo are reduced. The slip form platform serves as a supporting point and a working face for supporting the silo top plate formwork, the construction process is simple, operation is convenient, cost is reduced, and the construction progress is accelerated. The slip form platform is disassembled on the ground after descending for the second time, operators do not need to work high above the ground, the risk of working high above the ground is greatly reduced, and the safety degree of construction work is improved.

Owner:CHINA CHEM ENG SECOND CONSTR

A method for preventing roadway floor heave and wall slippage in gob-side entry retention

InactiveCN106014443BPrevent slippageAdaptableUnderground chambersTunnel liningStress conditionsEngineering

Owner:SHANDONG UNIV OF SCI & TECH

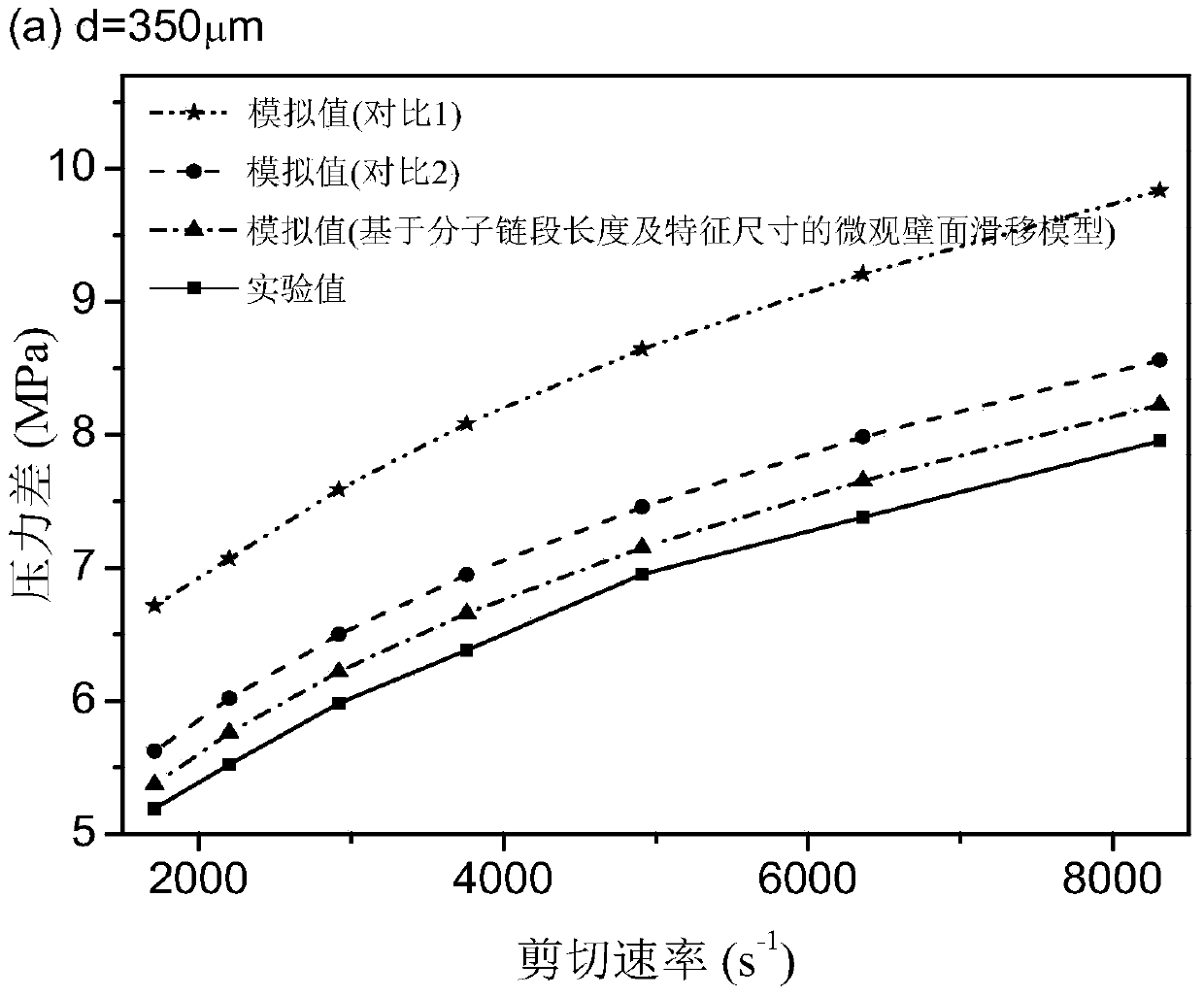

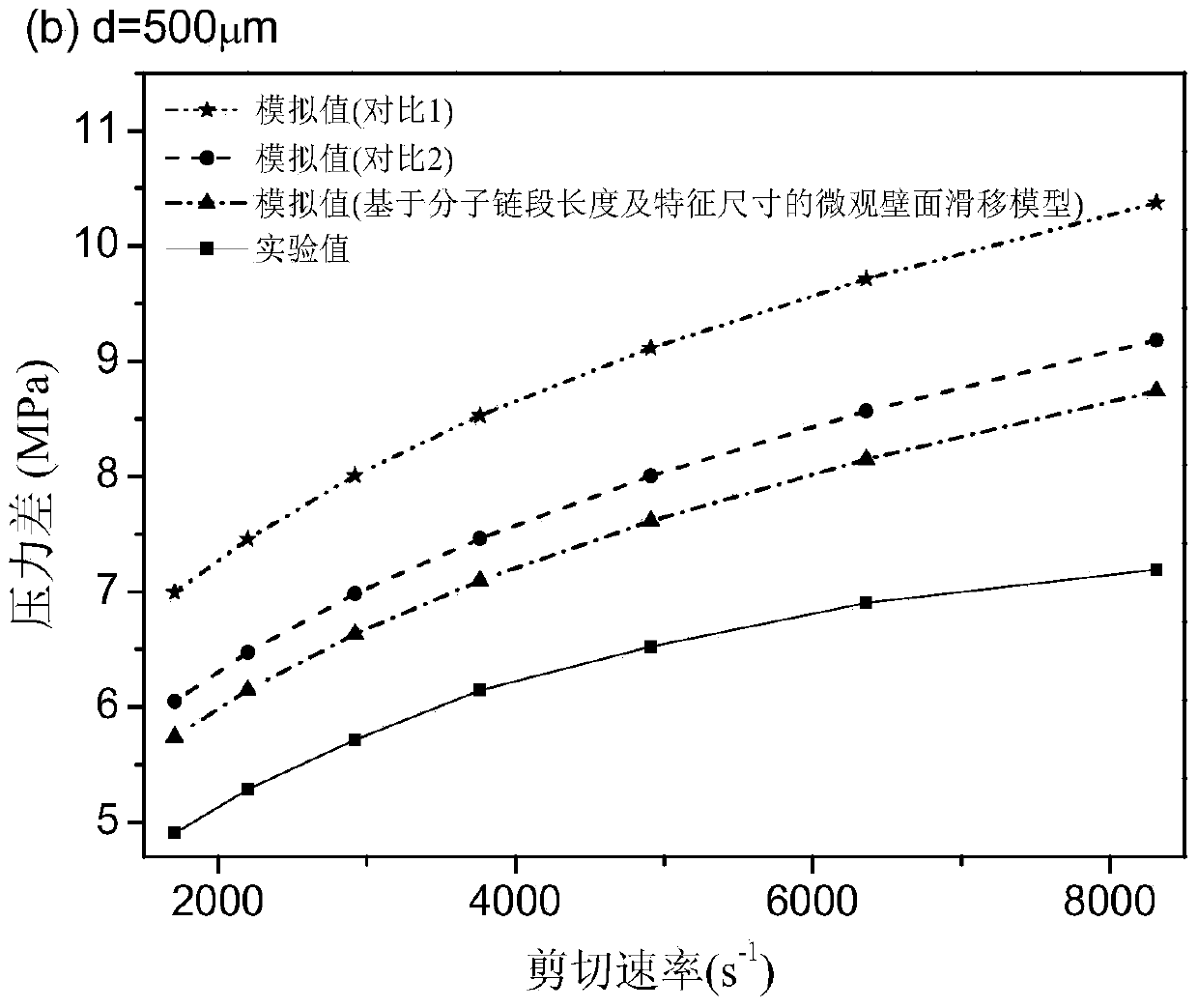

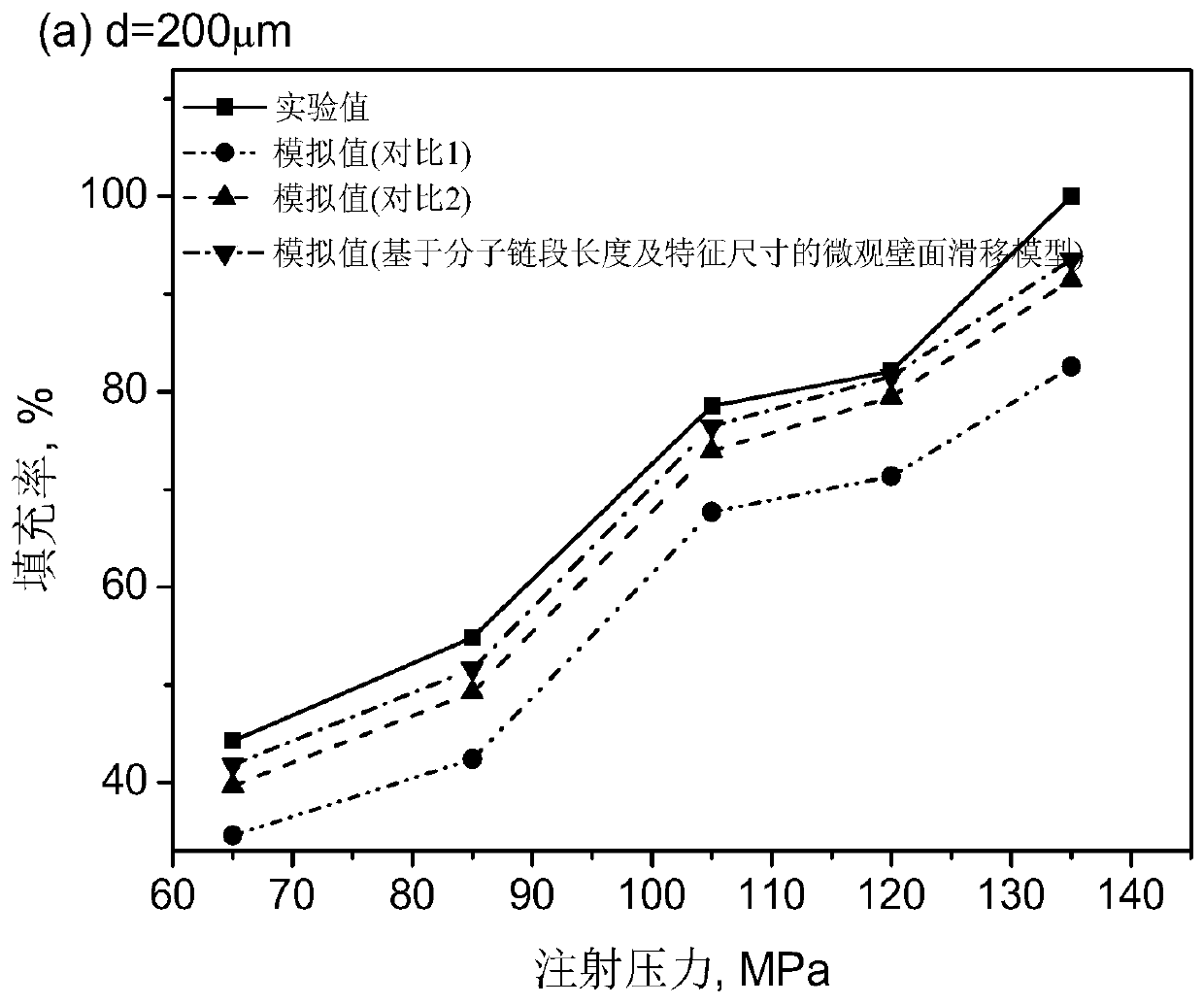

A Microscopic Wall Slip Model Establishment Method for Injection Molding

ActiveCN105302990BImprove accuracySpecial data processing applicationsMacroscopic scaleFeature Dimension

The invention discloses a method for establishing a microscopic wall slip model for injection molding. Based on the macroscopic viscosity model, the length of the molecular segment and the characteristic size of the micro-parts, the following steps are sequentially performed: 1) introducing a microscopic correction factor to the macroscopic viscosity model. Correction; 2) Set the ratio of the molecular segment length le reflecting the polymer flow characteristics to the micro-part characteristic size d as the minimum macroscopic size of the microstructure as the microcosmic influence factor; 3) establish the relationship between the microcosmic correction factor and the microcosmic influence factor , and use the least squares method to fit its parameter values; 4) Introduce the relationship between the microscopic correction factor and the microscopic influence factor into the macroscopic wall slip model relational expression, and obtain the microscopic Wall slip model relations. The establishment method of the invention considers the microscopic viscosity change and the characteristic size factors of the micro parts which affect the slippage of the wall surface, and significantly improves the accuracy of the prediction of the flow characteristics of the polymer melt.

Owner:SHENZHEN UNIV

Sliding form system and its construction method for large-diameter cylindrical structures

ActiveCN104499707BReduce investmentSimple structureForms/shuttering/falseworksSupporting systemSupport system

The invention discloses a slip form system of a large-diameter cylindrical structure and a construction method thereof and solves the problem that construction facilities in cylinder wall slip-form systems and roof slip-form support systems of the prior construction part are disconnected. The slip form system comprises support rods (2) and portal lift racks (7) embedded in a cast cylinder wall (1), inner and outer slip forms are disposed on the inner and outer sides of the cast cylinder wall, an inner slip form ring (6) and an outer slip form ring (5) are fixedly connected to the lower ends of the portal lift racks, respectively, radial lightweight steel trusses (12) are disposed on the outer periphery of a structural central cylinder (11) at equal radian intervals, the outer ends of the radial lightweight steel trusses (12) are fixedly connected to a circular steel beam (10) through bolts, the circular steel beam (10) is fixedly welded on the inner slip form ring (6), and a support (13) is disposed between every two adjacent radial lightweight steel trusses (12). The slip form system and the construction method thereof have the advantages that the structure is simple and input of manpower and tools is low.

Owner:SHANXI NO 3 CONSTR ENG

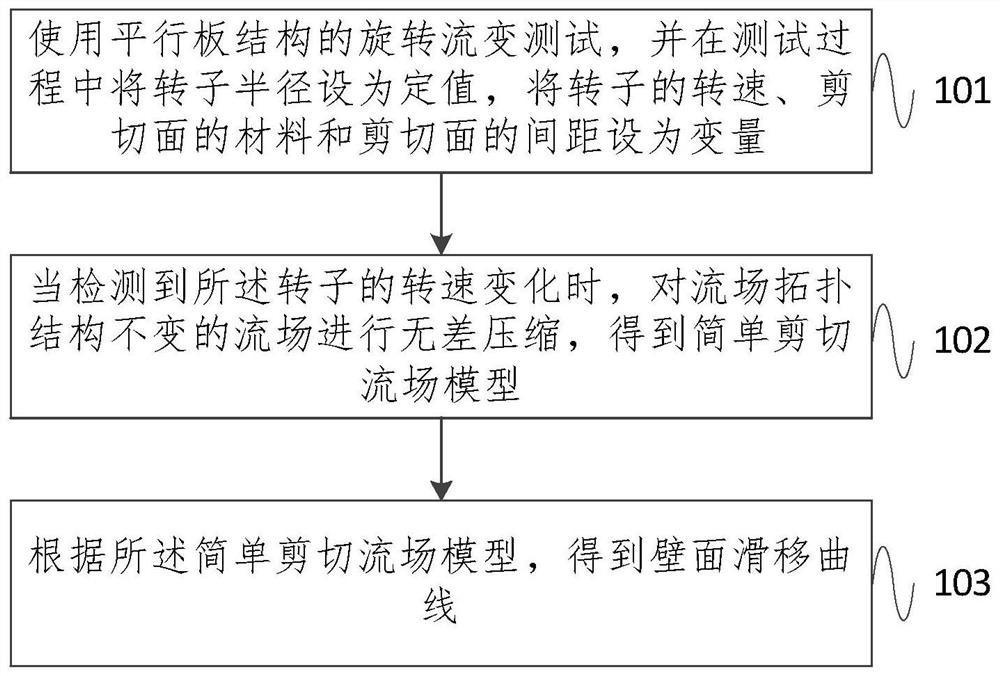

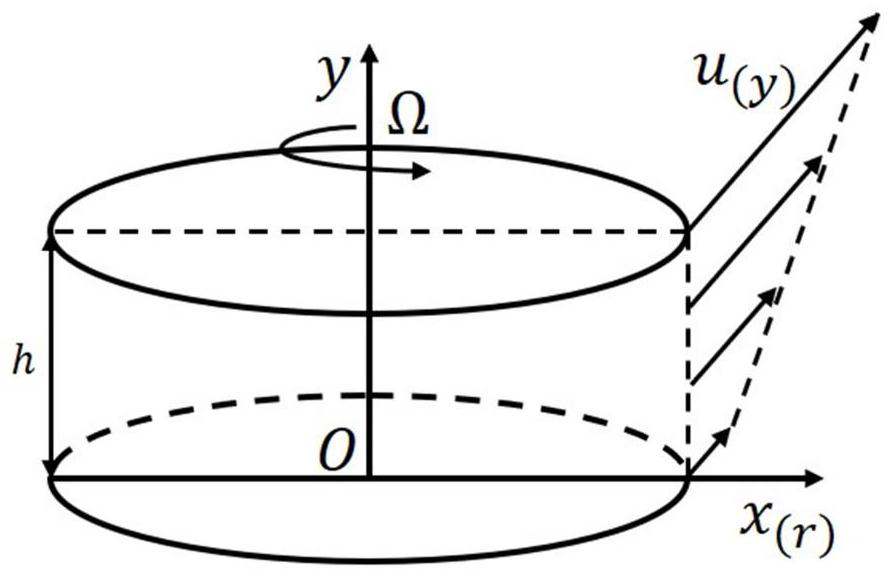

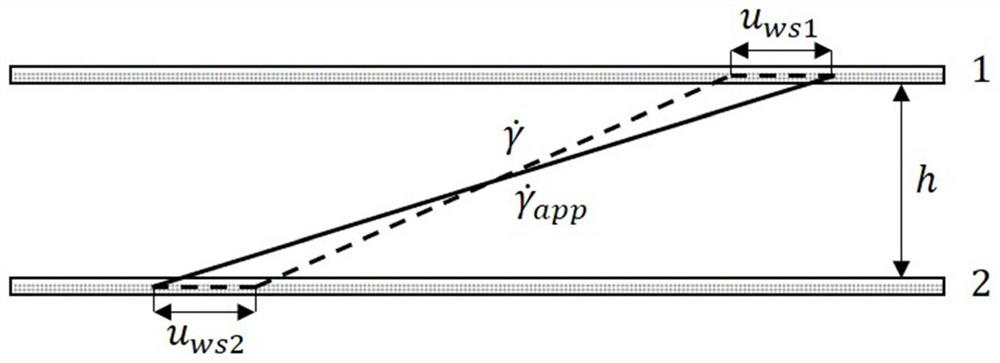

Method and system for obtaining wall slip curve based on parallel plate rheological test

An embodiment of the present invention provides a method and system for obtaining a wall slip curve based on a parallel plate rheological test. The method includes: using a parallel plate structure for a rotational rheological test, and setting the rotor radius to a constant value during the test, The rotational speed of the rotor, the material of the shear plane and the distance between the shear planes are set as variables; when the rotational speed of the rotor is detected, the flow field with the same topological structure of the flow field is differentially compressed to obtain a simple shear A flow field model; according to the simple shear flow field model, a wall slip curve is obtained. The embodiment of the present invention uses a rotational rheometer with a parallel plate structure to test, and the required data can be directly provided by the rheometer. Compared with the traditional pipeline pressure flow mode, it is simpler and requires less sample volume. Instrument cleaning and The maintenance is simpler; on the premise of not substituting the fluid and slip model, the original data is directly differentiated, and the research problem is simplified to a simple shear flow, while retaining the accurate description of the original flow field.

Owner:TSINGHUA UNIV

Concrete silo inner lining steel rail and warehouse wall slip form integrated construction method

ActiveCN101429826BImprove entity qualityExtended service lifeBulk storage containerMaterial consumptionEngineering

The invention discloses a construction method for integration of a concrete silo internal lining steel rail and a silo wall slip form. The method comprises the following steps: when the height of the internal lining steel rail is reached to the limestone silo construction according to design requirement, a silo wall inner formwork of the slip form is removed, and a ring steel plate is arranged atthe design height of the silo inner side; effective number of steel rails are vertically arranged on the ring steel plate, and connected with one another through reinforcement steel bars, and the steel rails are welded with anchoring reinforcement steel bars connected with the silo wall reinforcement steel bars; after the position, distance and verticality of the steel rails are corrected, the joints between the reinforcement steel bars and the steel rails are welded; and the anchoring reinforcement steel bars and the silo wall reinforcement steel bars are tightly bound and arranged on the silo wall inner formwork again, and the concrete is continuously cast between the silo and the steel rails until the design height of the silo is reached, thereby improving the wearing resistance of thesilo, prolonging the service life of the limestone silo by 15 to 20 years, reducing manpower consumption by 110 working days, reducing material consumption by 30,000 yuan, saving the time of welding,arrangement and secondary casting of the steel rails and shortening construction period by 30 days.

Owner:河北省第四建筑工程有限公司

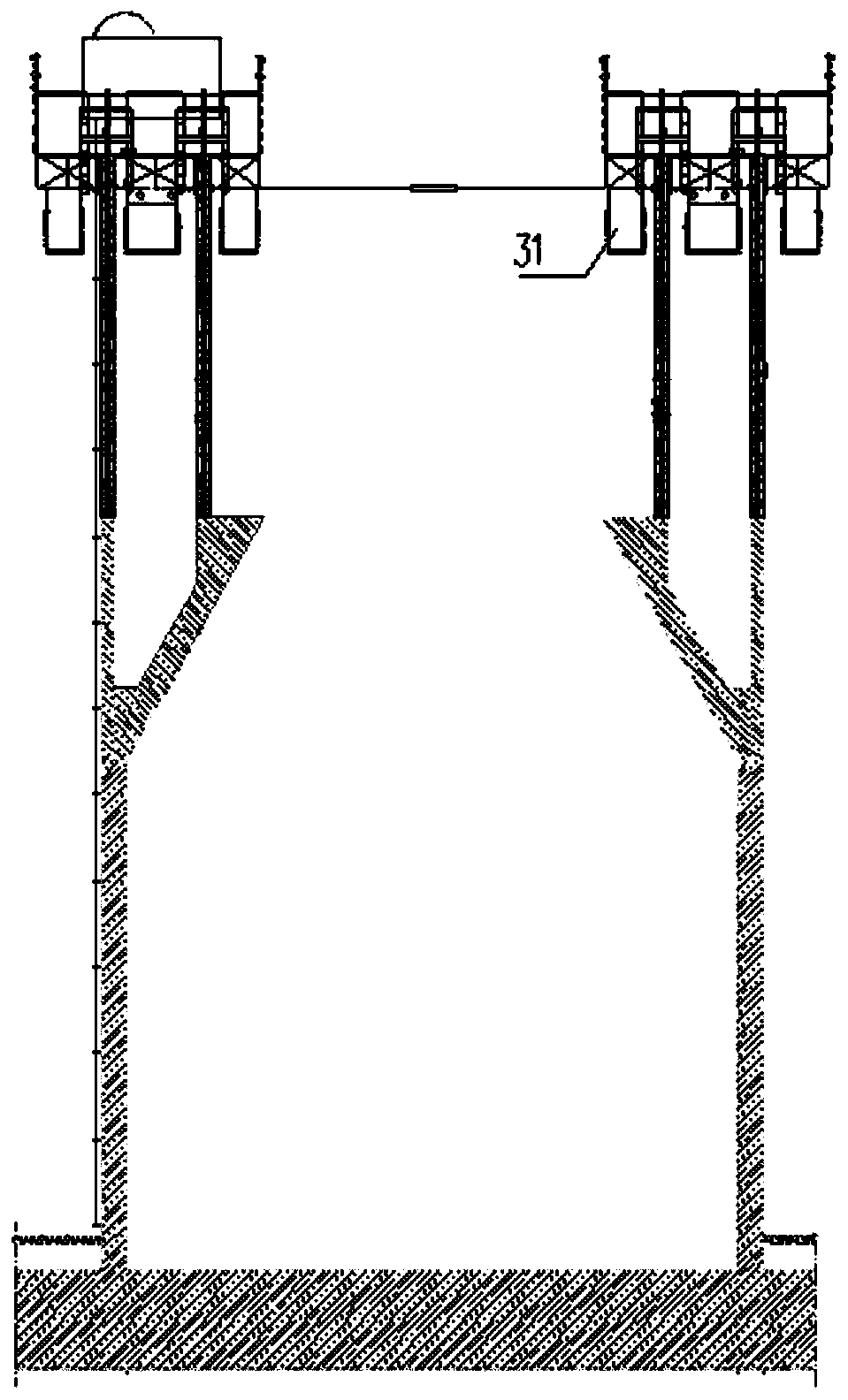

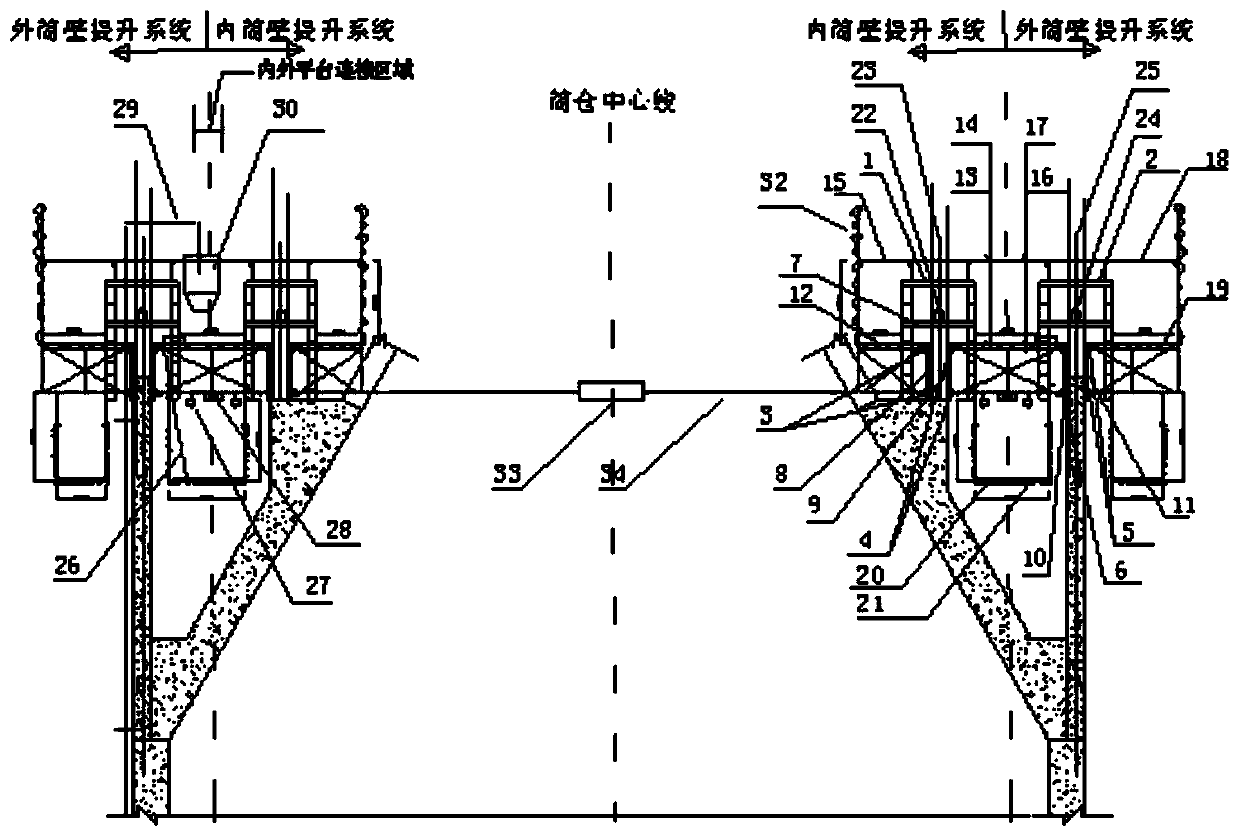

Double-cylinder-wall concrete silo slip form construction operation platform and construction method

PendingCN111424969ARelieve pressureInterspersed orderlyForms/shuttering/falseworksBuilding support scaffoldsArchitectural engineeringRebar

The invention discloses a double-cylinder-wall concrete silo slip form construction operation platform and a construction method. The double-cylinder-wall concrete silo slip form construction operation platform comprises an outer cylinder wall lifting system and an inner cylinder wall lifting system which are synchronously lifted, wherein the outer cylinder wall lifting system and the inner cylinder wall lifting system each comprise an inner side platform and an outer side platform, each of the inner side platforms and the outer side platforms comprises an upper layer, a middle layer and a lower layer, and the three layers of platform bodies on the outer side of the inner cylinder wall and the three layers of platform bodies of the inner side of the outer cylinder wall are correspondinglyconnected into a whole; and the upper-layer platform bodies are used for temporarily stacking slip form construction materials, the middle-layer platform bodies are used for steel bar binding, concrete transportation and pouring and tamping space, and the lower-layer platform bodies are used as a platform for receiving light, maintaining and checking after concrete is out of the forms. The three layers of platform bodies are reasonable in work division, and the requirement for slip form simultaneous lifting of a double-cylinder-wall silo is effectively met. By means of the double-cylinder-wallconcrete silo slip form construction operation platform and the construction method, the inner cylinder wall and the outer cylinder wall are connected into the whole on the basis of an original single-cylinder-wall slip form, so that the overall stability of a slip form system is improved, the slip form is lifted through the double cylinder walls at the same time, and the construction period is greatly shortened.

Owner:MCC5 GROUP CORP SHANGHAI

A curtain wall air tightness detection device and detection method thereof

ActiveCN111413033BImprove detection accuracyPrevent leakageMeasurement of fluid loss/gain rateAir pumpEngineering

Owner:深圳市恒义建筑技术有限公司

Visual polymer micro-extrusion mold

The invention discloses a visual polymer micro-extrusion mold and belongs to the technical field of polymer micro-extrusion molds. The visual polymer micro-extrusion mold is characterized in that the visual mold consists of a connecting pipe, a heating ring, a handpiece body, an adjusting bolt, a positioning pin, a baffle, a fastening bolt, a visual neck ring mold, a pressure / temperature sensor, a core rod, a gasket, a temperature sensor, a ventilating bolt, a support plate, a spure spreader and a flange. The spure spreader, the core rod and the neck ring mold with different structural parameters are respectively exchanged according to the need; coaxiality and clearance between the core rod and the visual neck ring mold are adjusted by the method of fixing the visual neck ring mold and adjusting the core rod; the visual neck ring mold is used for observing the flow state in the micro-extrusion mold of polymer melt; the pressure / temperature sensor is used for measuring pressure and temperature of straight section of the polymer melt; and the heating ring and the temperature sensor are used for controlling temperature of the micro-extrusion mold. The visual polymer micro-extrusion mold obtains flow distribution, flow characteristics and wall slip velocity of the polymer melt in the flow channel by the visual neck ring mold.

Owner:DALIAN UNIV OF TECH

Cast-in-place lightweight aggregate concrete filled wall slipform construction formwork system and construction method

ActiveCN103726648BSimple structureEasy to processForms/shuttering/falseworksBuilding material handlingUltimate tensile strengthMaterials science

The invention discloses a cast-in-situ lightweight aggregate concrete filler wall slip-form construction template system and a construction method. The template system comprises an outer mold and an inner mold, wherein the outer mold comprises an outer mold frame and a first mirror multilayer board connected to the outer mold frame; reinforced angle iron is welded at the left side and the right side of the outer mold frame; inverse L-shaped round steel is arranged beside the reinforced angle iron; a first hook ring is welded at the top of the outer mold frame; the inner mold comprises a sealed inner mold body; a vibrator is arranged inside the inner mold body; two inner mold support handles are symmetrically arranged at two sides of the top of the inner mold body. The method comprises the following steps: 1, fabricating the outer mold and the inner mold; 2, mounting the outer mold; 3, installing the inner mold; 4, reinforcing and correcting the outer mold; 5, casting and vibrating lightweight aggregate concrete; 6, lifting the template system; 7, repeating the steps 5 to 6 for a plurality of times and casting until the distance from the template system to an original structure body is 150mm-250mm; and 8, stripping the mold. A constructed wall body disclosed by the invention is good in integrality, stable and reliable in strength, and free of construction waste, and the labor cost is greatly reduced.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

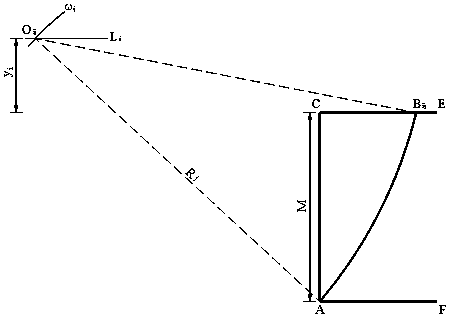

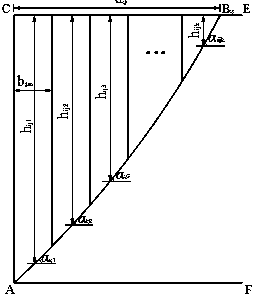

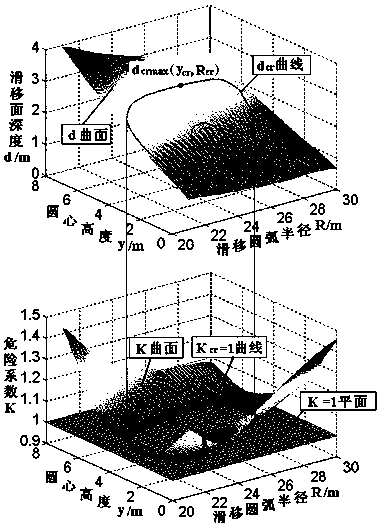

A Method of Determining the Depth of Sliding Slabs in Coal Wall and Its Slipping Risk

ActiveCN104268364BAccurate predictionPrediction is accurateSpecial data processing applicationsMaximum depthSlip sheet

The invention discloses a method for determining the depth and slip risk of a coal wall slip sheet. The method includes assuming n circle centers of heights yi (i = 1, 2, 3,..., n) far from a top plate and n slip arc radius Rj (j = 1, 2, 3,..., n), defining n*n slip surface Sij according to the yi and Rj, and figuring out a risk coefficient Kij; acquiring a slip risk coefficient curved surface K of the n*n slip surface Sij, and acquiring a curve Kcr=1 by means of the intersection of a plane K=1 and the curved surface K; defining the slip surface depth d as the distance between the intersection of the slip surface and top plate and a coal wall, acquiring a curved surface of the slip surface depth d of the n*n slip surface Sij, and acquiring a curve of a critical slip depth dcr by projecting the curve Kcr = 1 to the curved surface d; figuring out a maximum value dcrmax (ycr, Rcr) of the curve dcr, determining a slip surface as the maximum depth critical slip surface according to the ycr and Rcr, and allowing the value dcrmax to be the depth of the coal wall slip sheet. The method is used for designing and developing control implementation and parameters of the coal wall slip sheet according to the depth during the coal wall management of working face with large mining height.

Owner:TAIYUAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com