Cast-in-place lightweight aggregate concrete filled wall slipform construction formwork system and construction method

A formwork system and lightweight aggregate technology, applied in formwork/formwork/work frame, processing of building materials, on-site preparation of building components, etc., can solve the loss of labor costs of construction units, unfavorable energy conservation and environmental protection, and the generation of construction waste. and other problems, to achieve the effect of no construction waste, easy promotion and use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

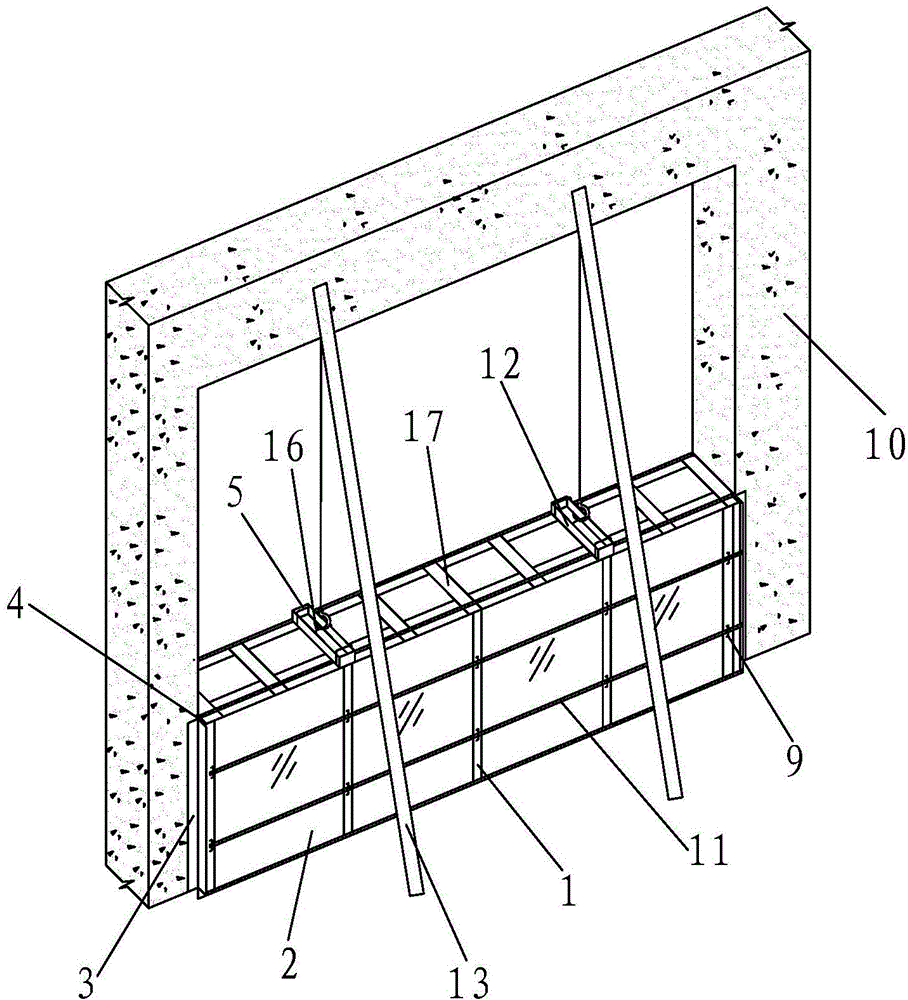

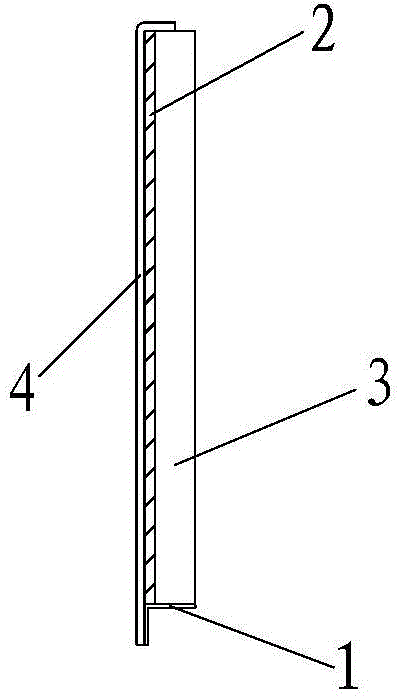

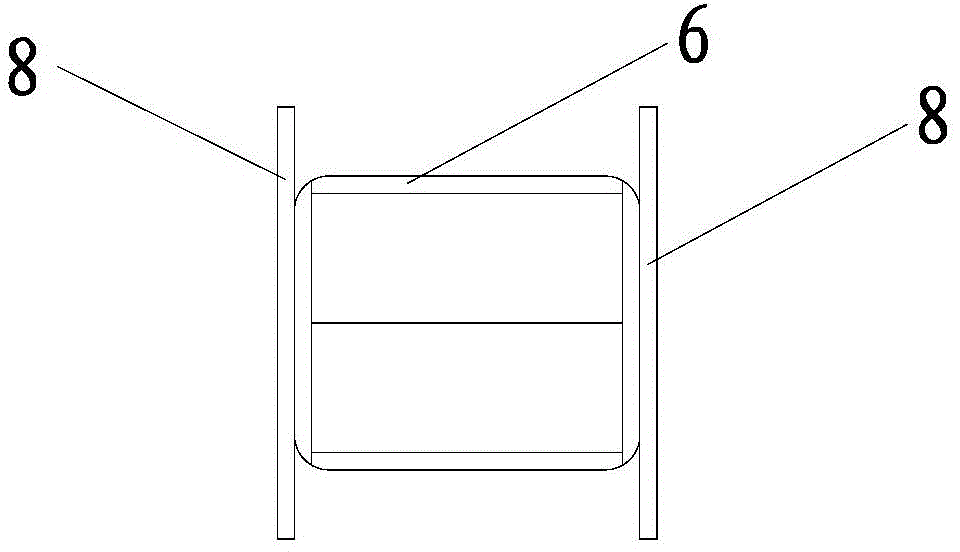

[0043] Such as Figure 1 to Figure 5As shown, the cast-in-place lightweight aggregate concrete filled wall slipform construction formwork system of the present invention includes two outer molds symmetrically arranged in the thickness direction of the original structure 10 and a plurality of inner molds arranged between the two outer molds. Die 17, described outer mold comprises the square outer mold frame 1 that is welded by angle iron and the first mirror surface multilayer board 2 that is fixedly connected on the outer mold frame 1, the left and right sides of described outer mold frame 1 width direction are all A reinforcing angle iron 3 is welded, and the side of the reinforcing angle iron 3 is provided with an inverted L-shaped round steel 4 for pressing the first mirror multilayer board 2 on the outer mold frame 1, and the round steel 4 and the outer mold frame 1 are formed. The angle iron welding of the left frame or the right frame of the mold frame 1 width direction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com