Sliding form system and its construction method for large-diameter cylindrical structures

A large-diameter, sliding form technology, which is applied in building construction, formwork/formwork/working frame, and on-site preparation of building components, can solve the problems of high manpower and equipment costs, disconnected construction facilities, and long construction period and other problems, to achieve the effect of simple structure, less labor and tool investment, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

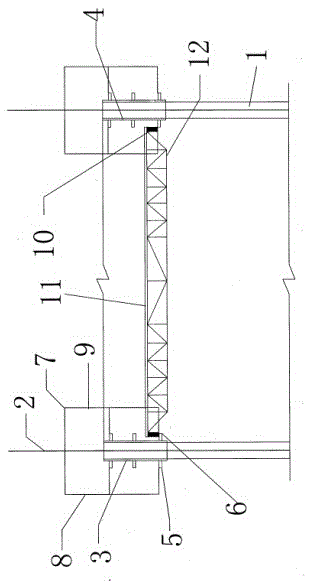

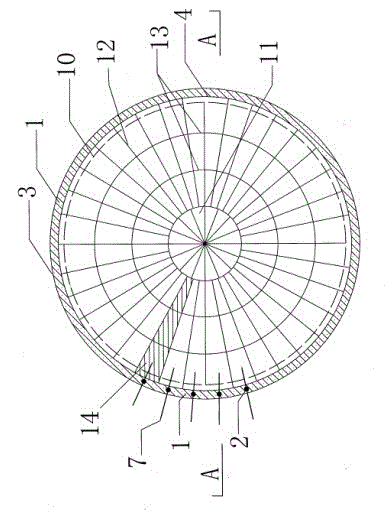

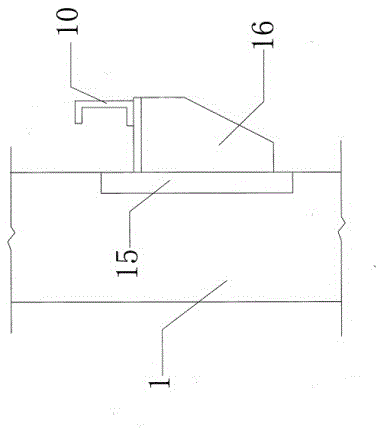

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

[0020] A sliding form system for a large-diameter cylindrical structure, including a poured cylinder wall 1, a support rod 2 is pre-embedded in the poured cylinder wall 1, and a door-shaped lifting frame 7 is arranged on the support rod 2. The inner surface of the poured cylinder wall 1 is provided with a sliding formwork inner formwork 4, the outer surface of the poured cylinder wall 1 is provided with a sliding formwork outer formwork 3, and the outer surface of the sliding formwork 3 is provided with a sliding formwork The outer mold surrounding ring 5 is provided with the sliding mold inner mold surrounding circle 6 inside the sliding mold inner mold template 4, and the sliding mold inner mold surrounding circle 6 is fixedly connected with the lower end of the inner suspender 9 of the door type lifting frame 7, and the sliding mold outer The mold enclosure 5 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com