Device ensuring rear side movement of double movable walls of coal chute

A technology of coal trough and briquette, which is applied in the field of coke oven charging device, can solve the problems of affecting production, destroying briquette, sticking coal, etc., and achieves the effects of simple structure, high productivity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

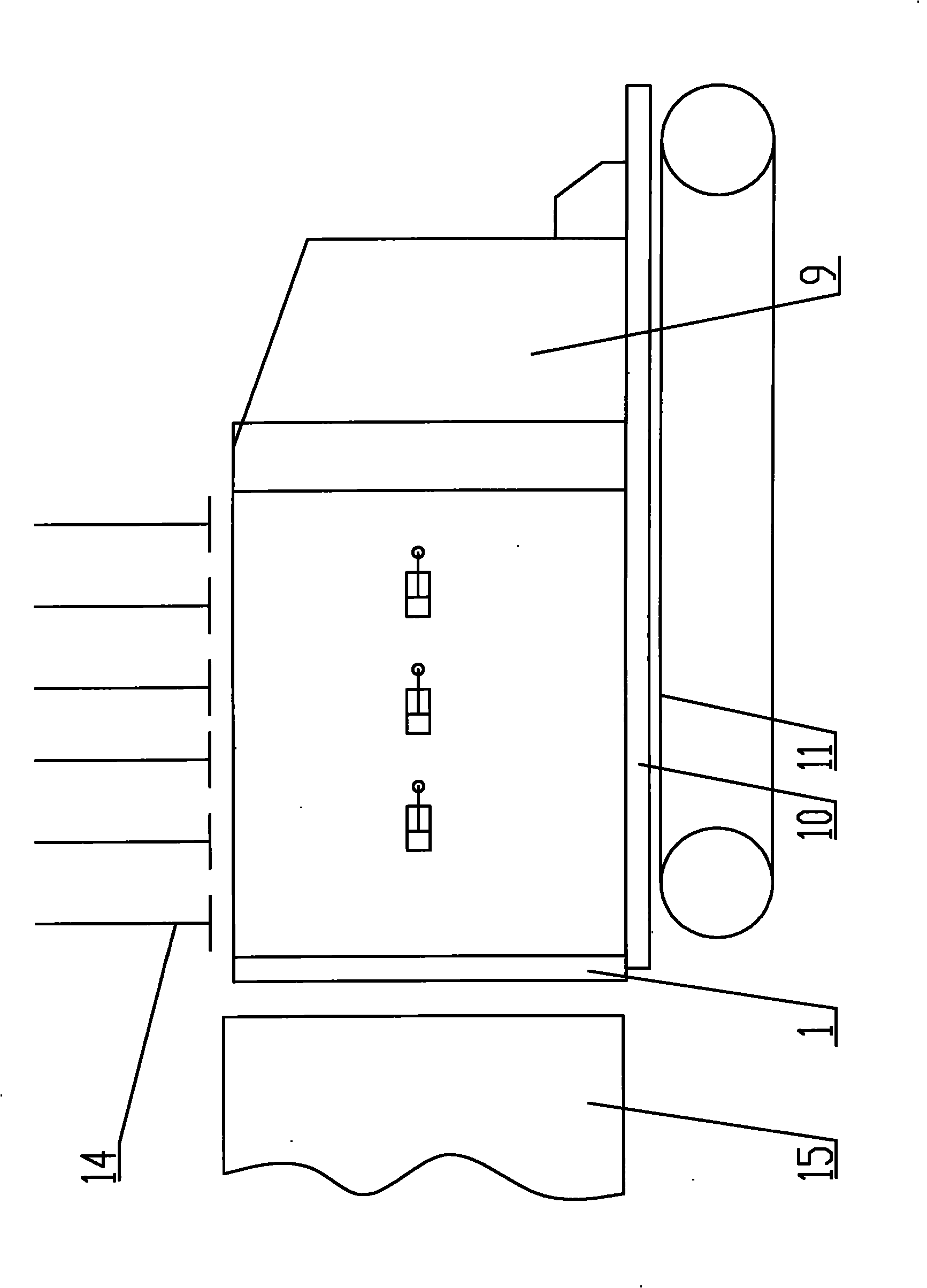

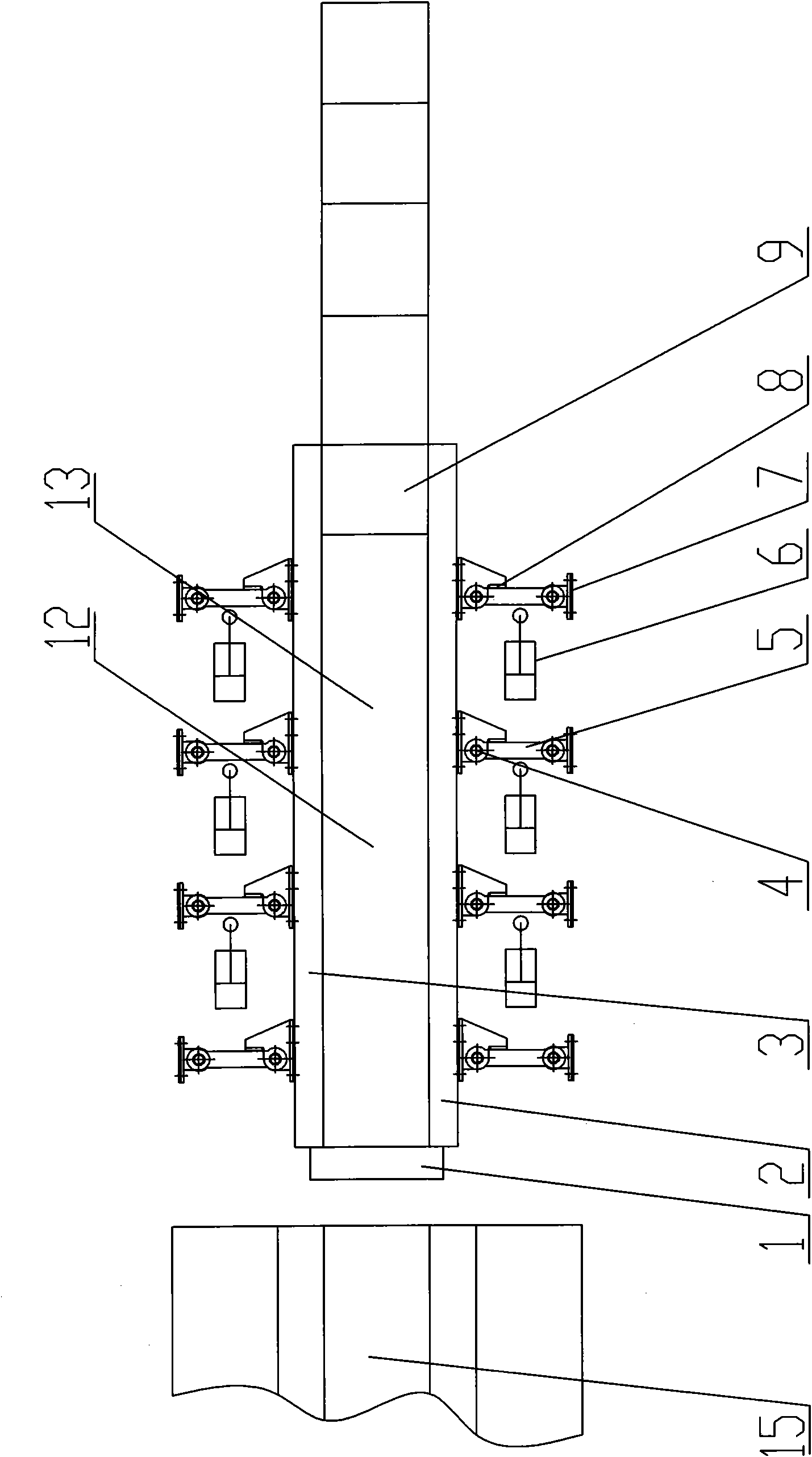

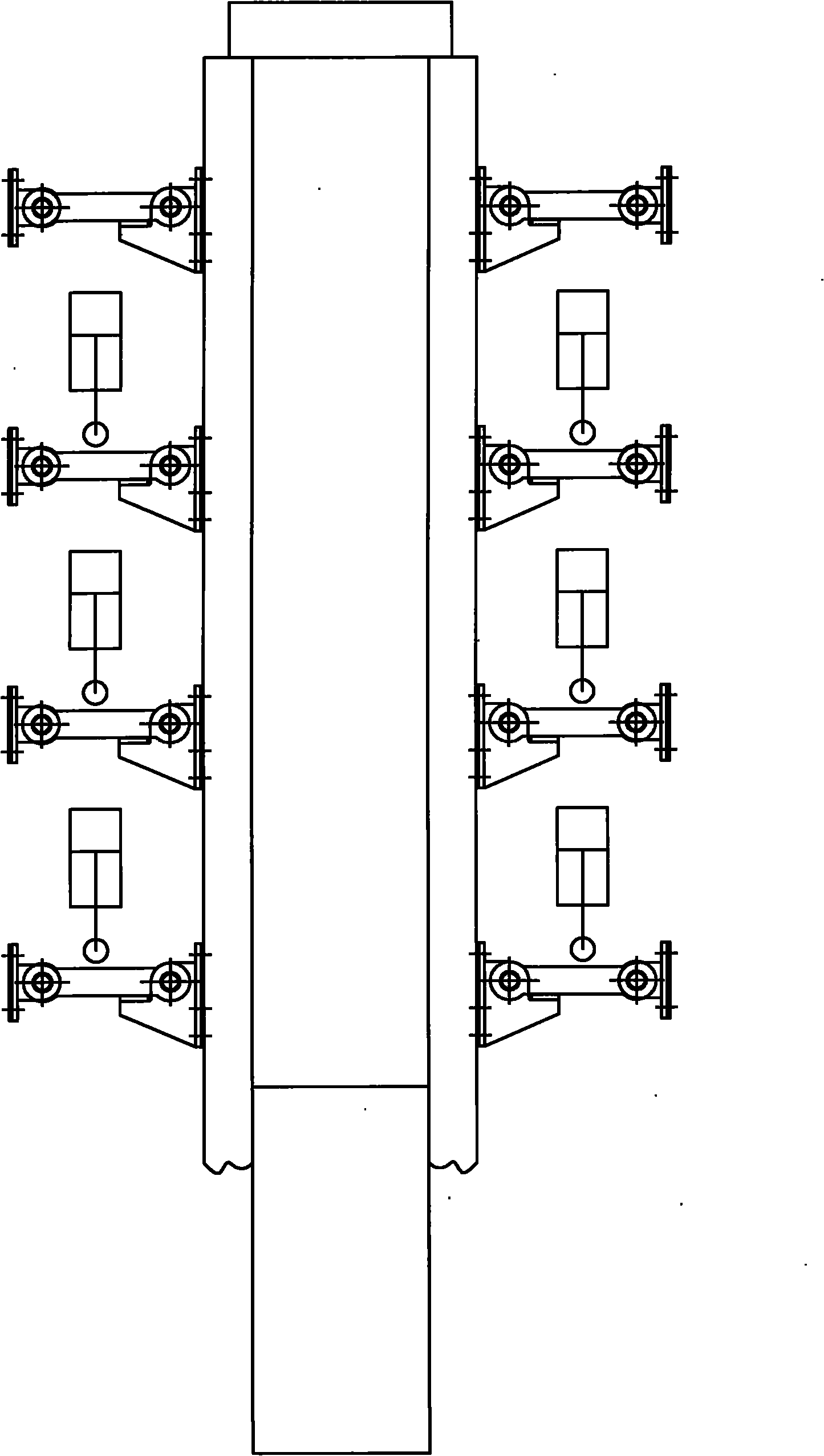

[0018] Such as Figure 1 ~ Figure 3 The rear side shifting device with double movable walls of the coal trough shown is composed of a front baffle plate 1, a left side wall 2, a right side wall 3, a connecting hinge point seat 4, a lever 5, an oil cylinder 6, a fixed support 7, and a position stopper. Iron 8, tailgate 9, coal charging floor 10 and chain 11 etc. are made up of parts.

[0019] During the working process, the loose coal is first sent to the coal box 12 composed of the front baffle 1, the left side wall 2, the right side wall 3, the back baffle 9, and the coal loading floor 10, and the tamping on the top of the coal box 12 Hammer 14, loose coal is tamped into briquette 13. Then open the front baffle plate 1, the left side wall 2, the right side wall 3 drive the lever 5 to rotate through the oil cylinder 6 respectively, one end of the lever 5 is hinged with the fixed support 7, and the other end drives the connecting hinge point seat 4 and the left side wall 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com