Single-side side wall slip form and construction method

A sliding form and single-sided technology, which is applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., can solve the problems of long construction period and high construction cost, so as to reduce construction cost, save materials, reduce The effect of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

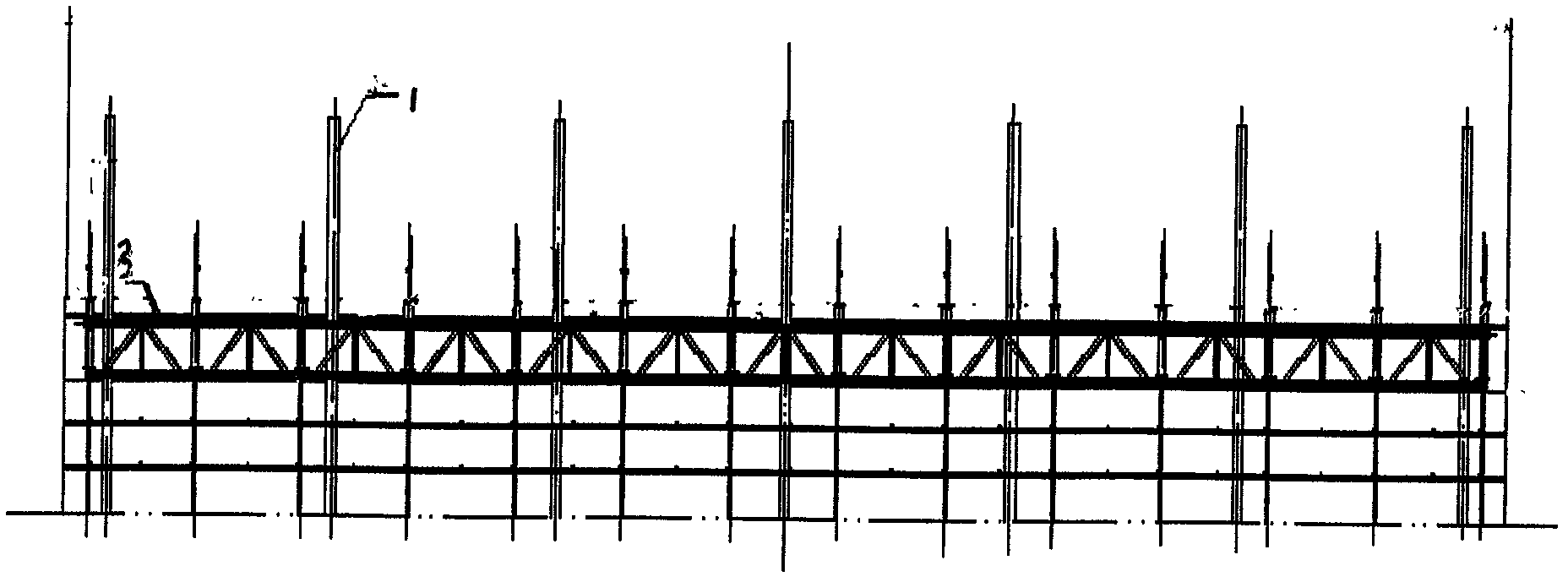

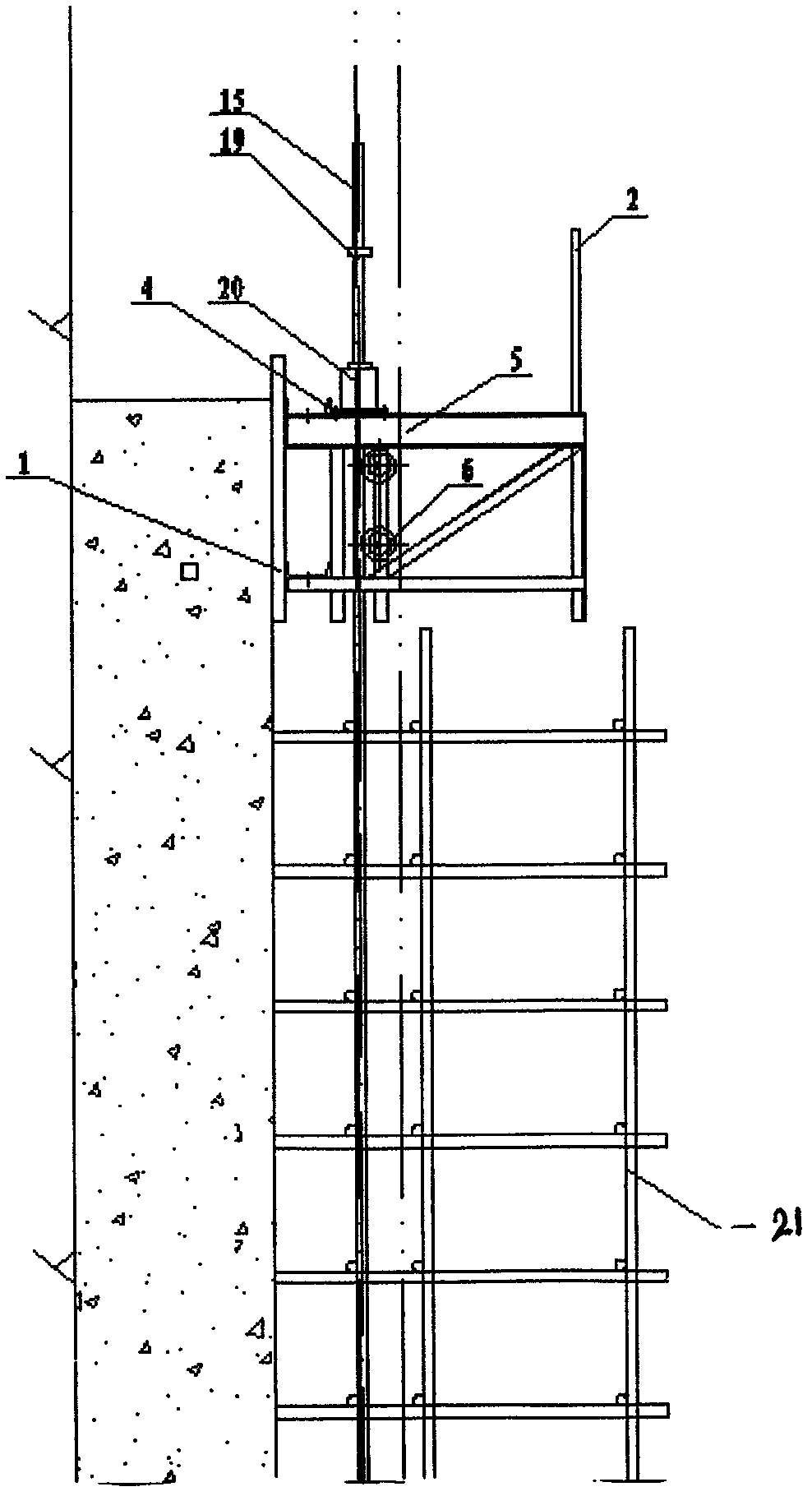

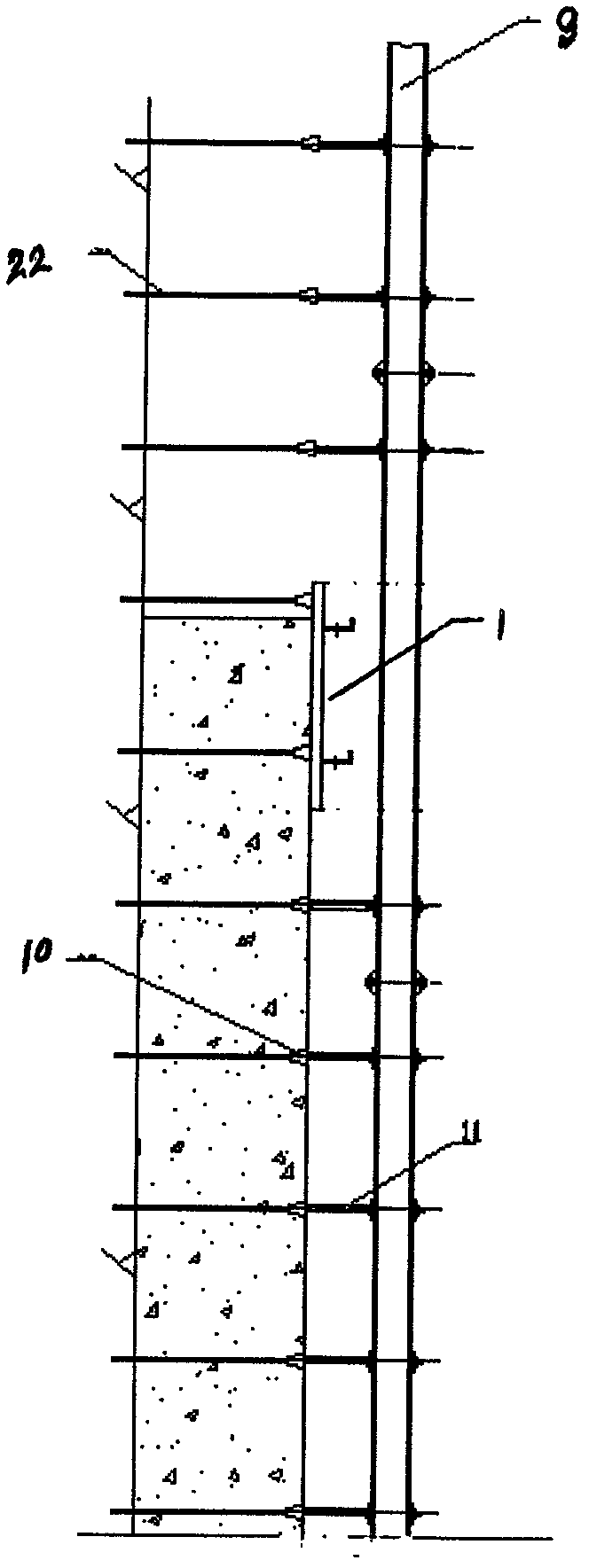

[0009] A single-sided side wall slip form suitable for underground concrete pouring in large hydropower projects is designed and manufactured. The single-sided side wall sliding form is composed of the sliding form main body, the guide rail (9), the guide wheel mechanism (6), the hydraulic climbing device and the pipe frame (21). Formwork (1), back corrugation (4), lifting frame (5), platform (3), back connection (7); hydraulic climbing device consists of hydraulic jack (20), climbing rod (15), limit leveler (19), the hydraulic pump station is composed; it is characterized in that: 1. The template (1) is made of a steel plate with a length of 1200mm, a width of 882.3mm and a thickness of 3mm as a panel, with a welded web around it, a support panel, and bolt holes are opened on the web, and two The two are connected by bolts, and 34 formwork are connected to form a formwork set. There are upper and lower backings (4) behind the formwork. The backing is grooved and made of steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com